Analysing the Suitability of Using Different Biodegradable Fluids for Power Transformers with Thermally Upgraded Paper

Abstract

1. Introduction

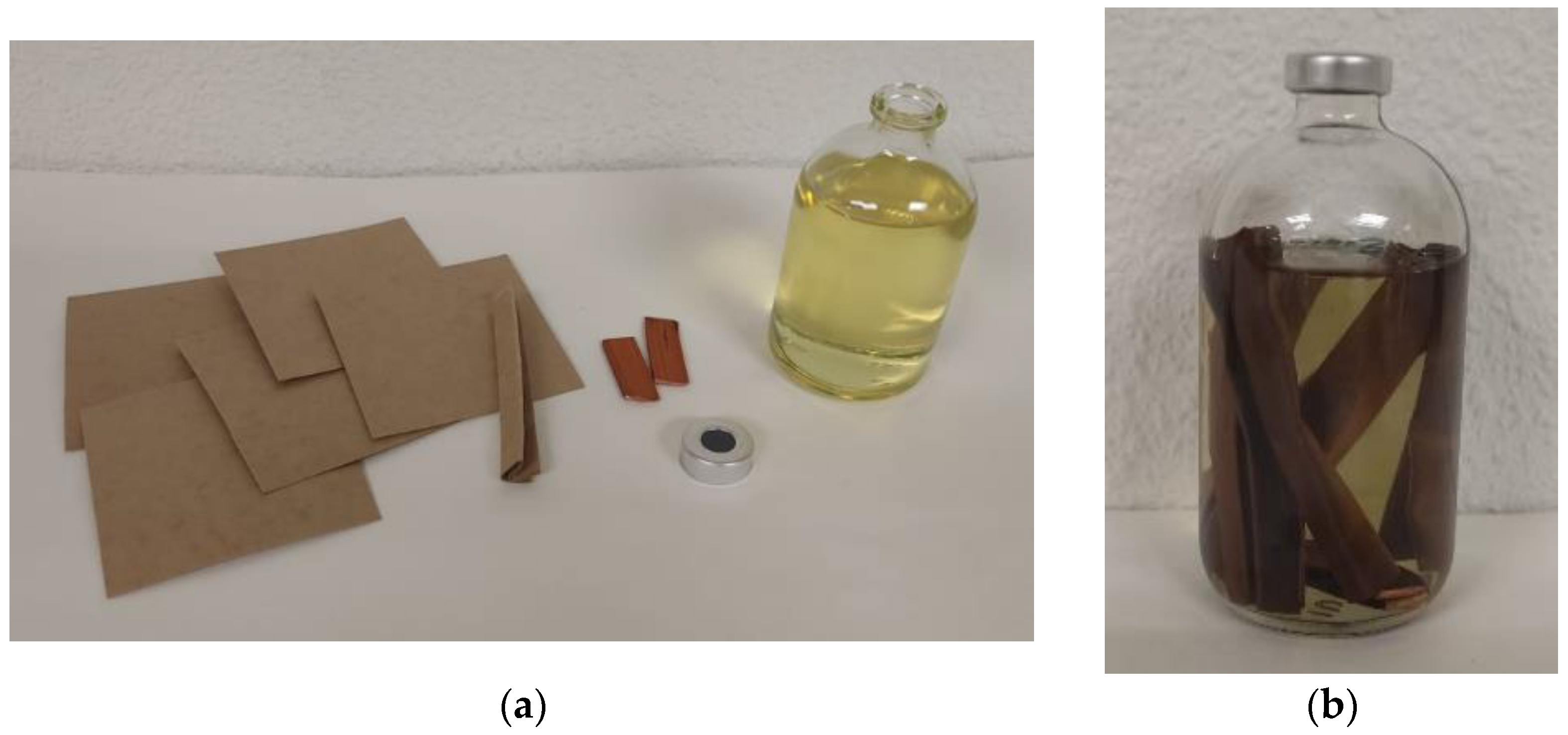

2. Materials and Methods

2.1. Materials

2.1.1. Mineral Oils

2.1.2. Natural Esters

2.1.3. Synthetic Esters

2.2. Experimental Procedure

2.2.1. Treatment

2.2.2. Characterisation

3. Results and Discussion

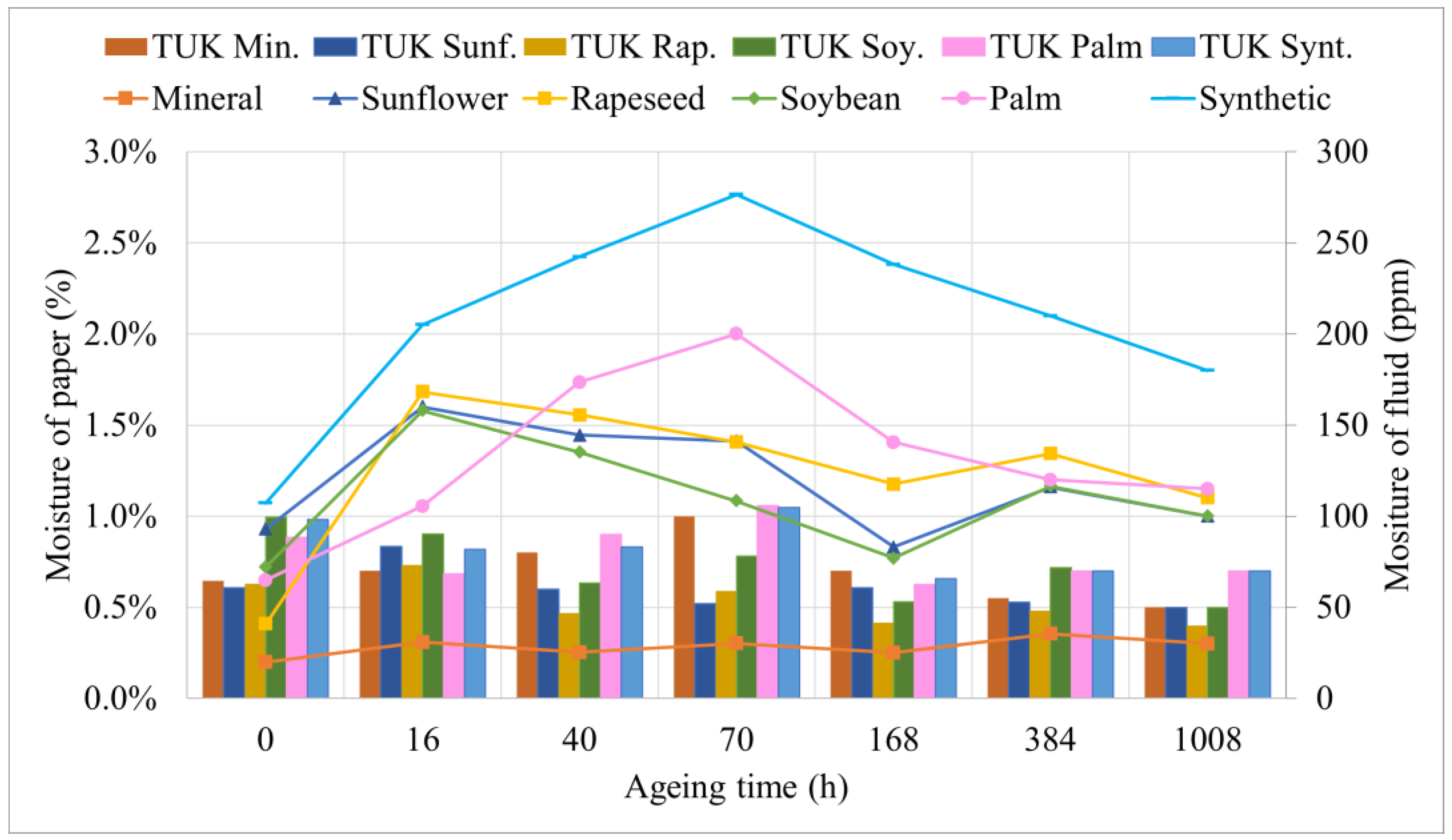

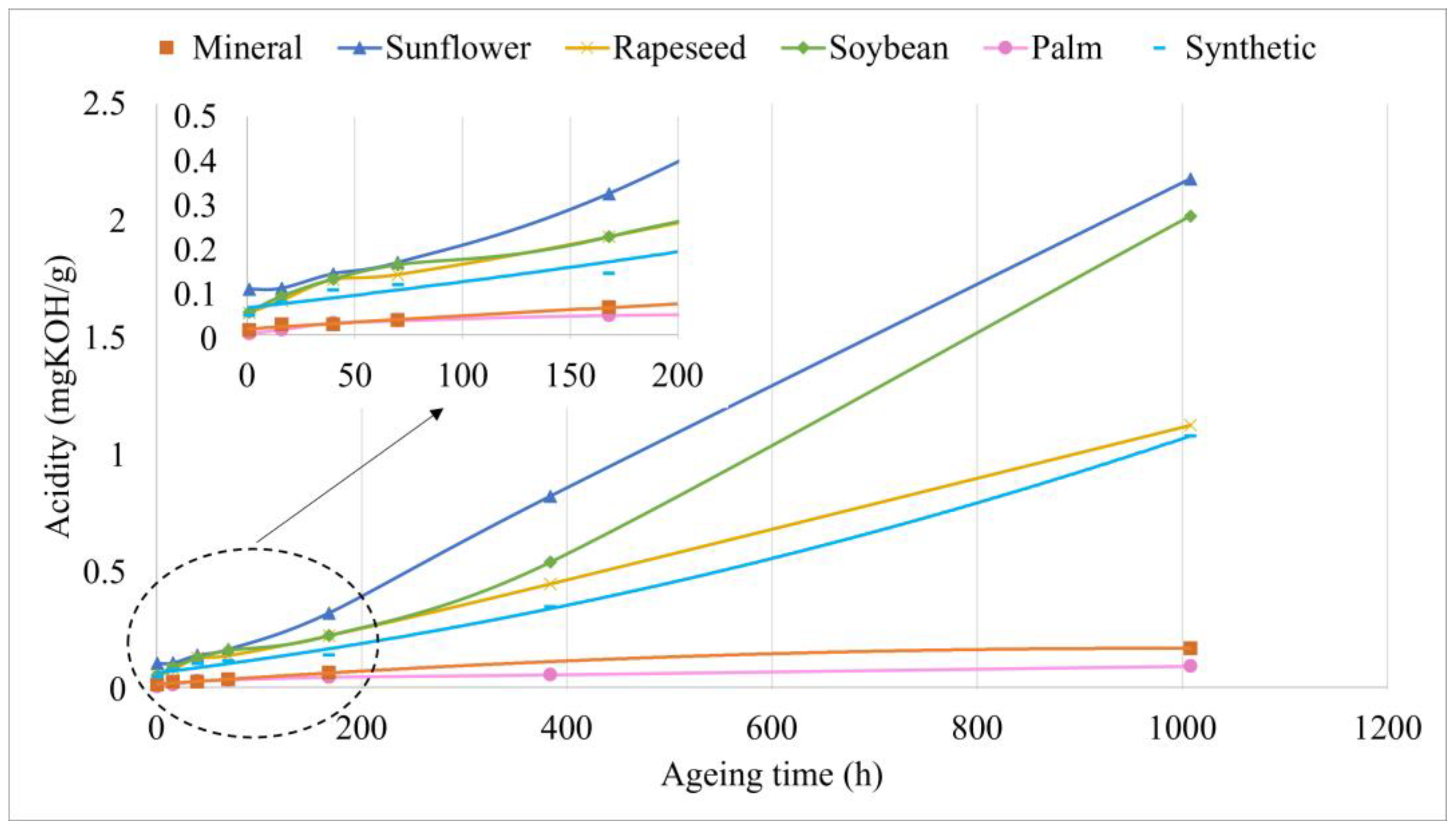

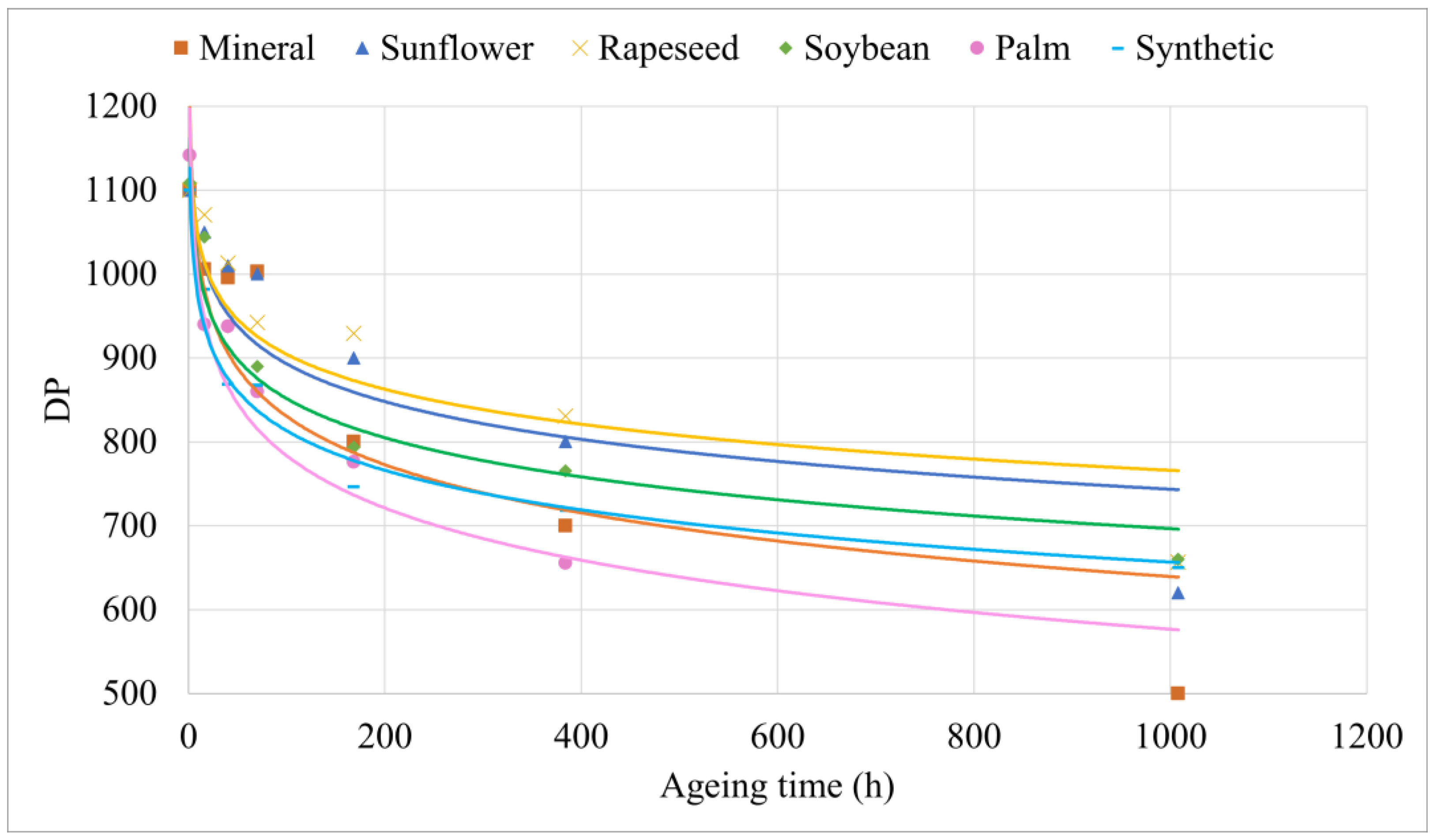

3.1. Parameters Directly Affected by the Ageing

3.1.1. Moisture Content

3.1.2. Acidity

3.1.3. Polymerisation Degree

3.2. Parameters Affected by the Ageing and by the Changes in Other Properties

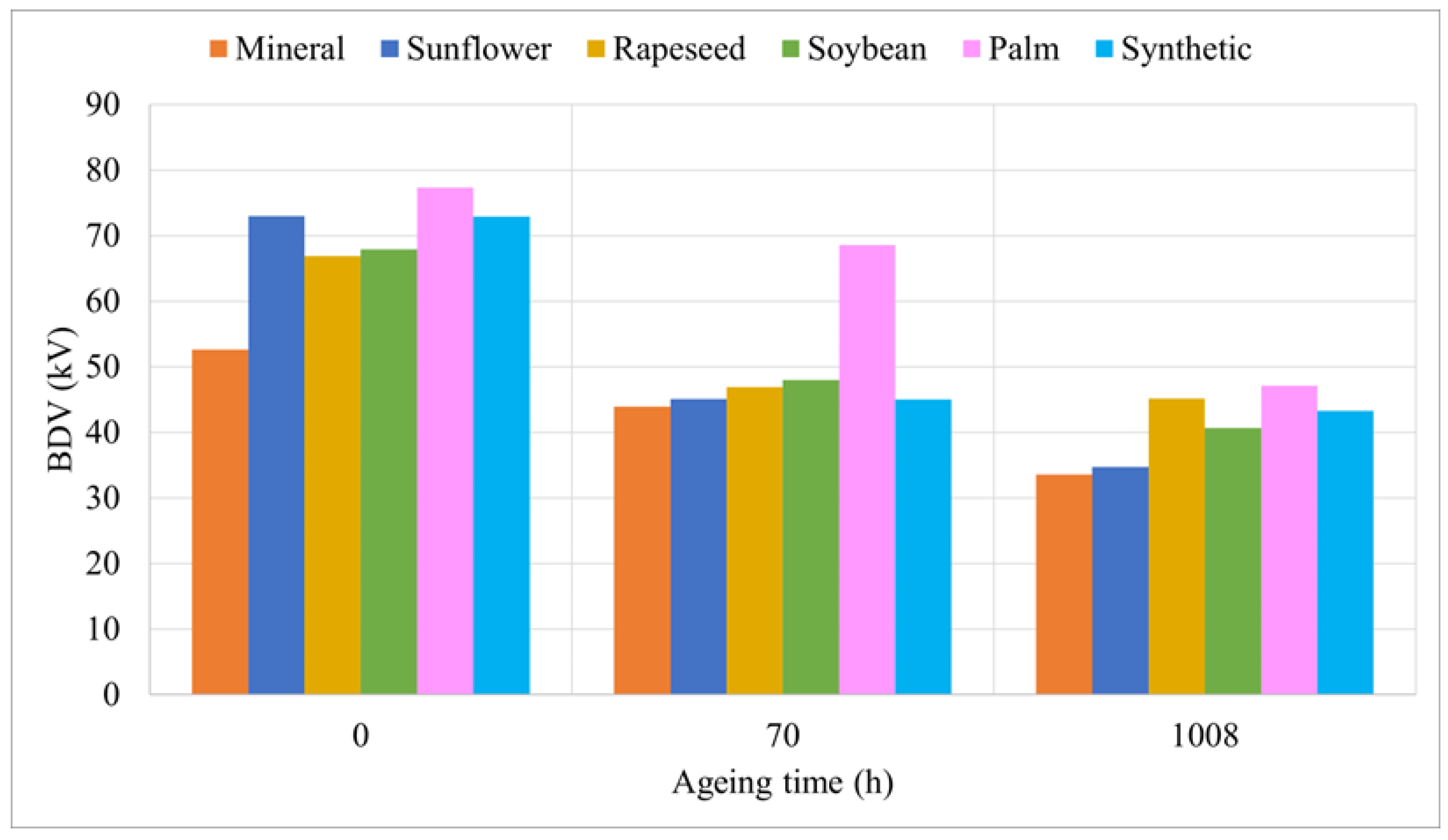

3.2.1. Breakdown Voltage

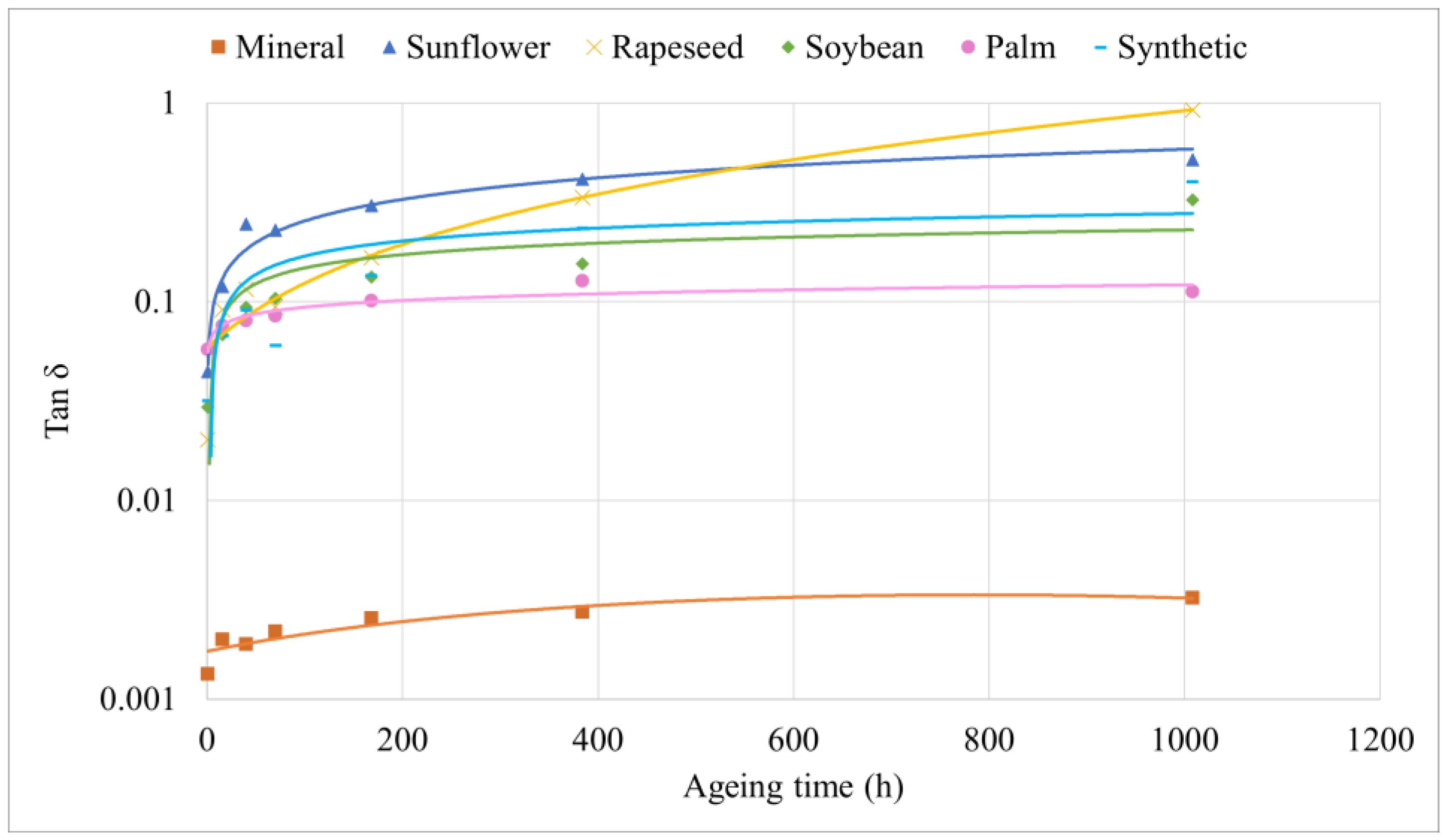

3.2.2. Dielectric Dissipation Factor

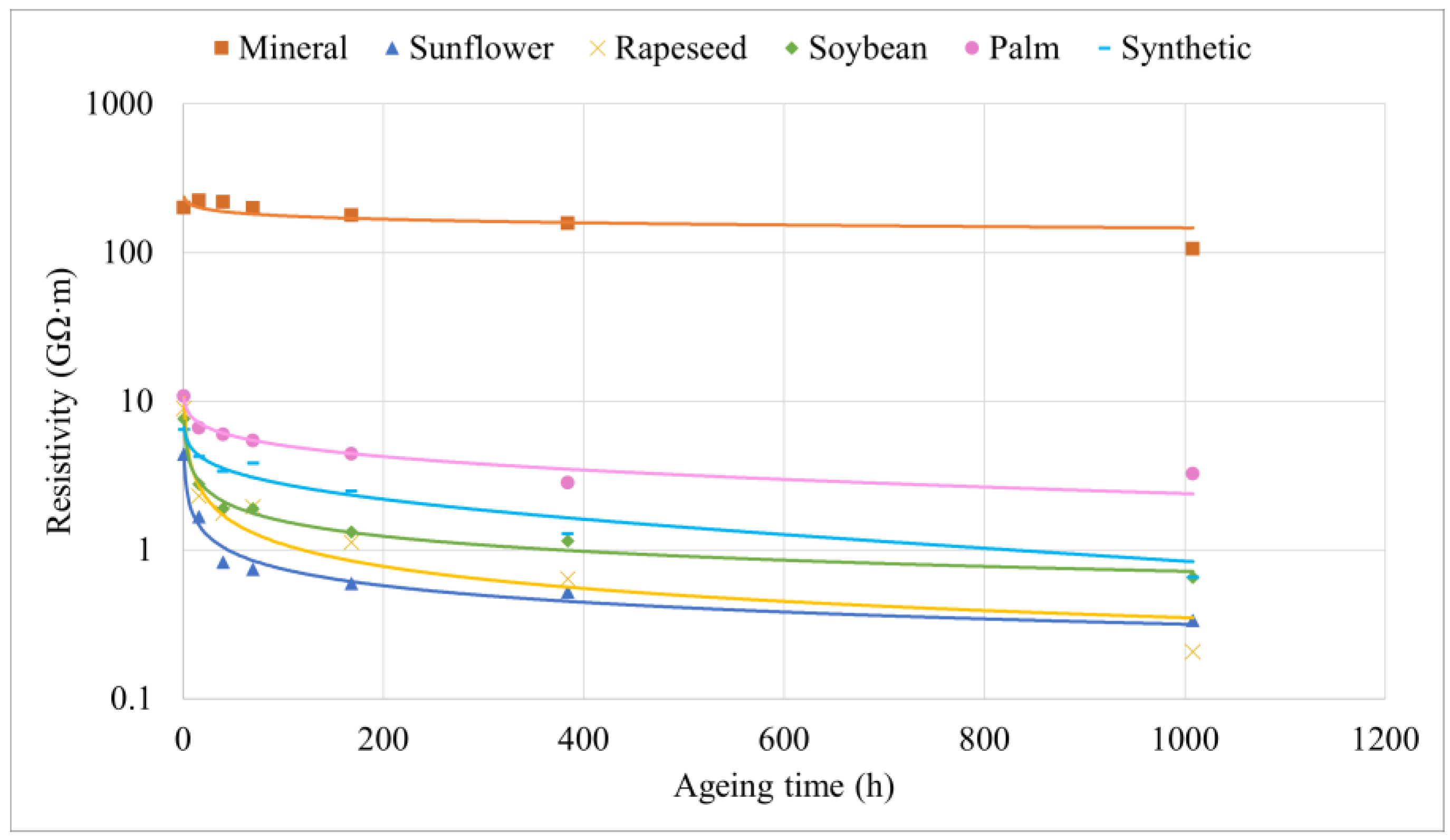

3.2.3. Resistivity

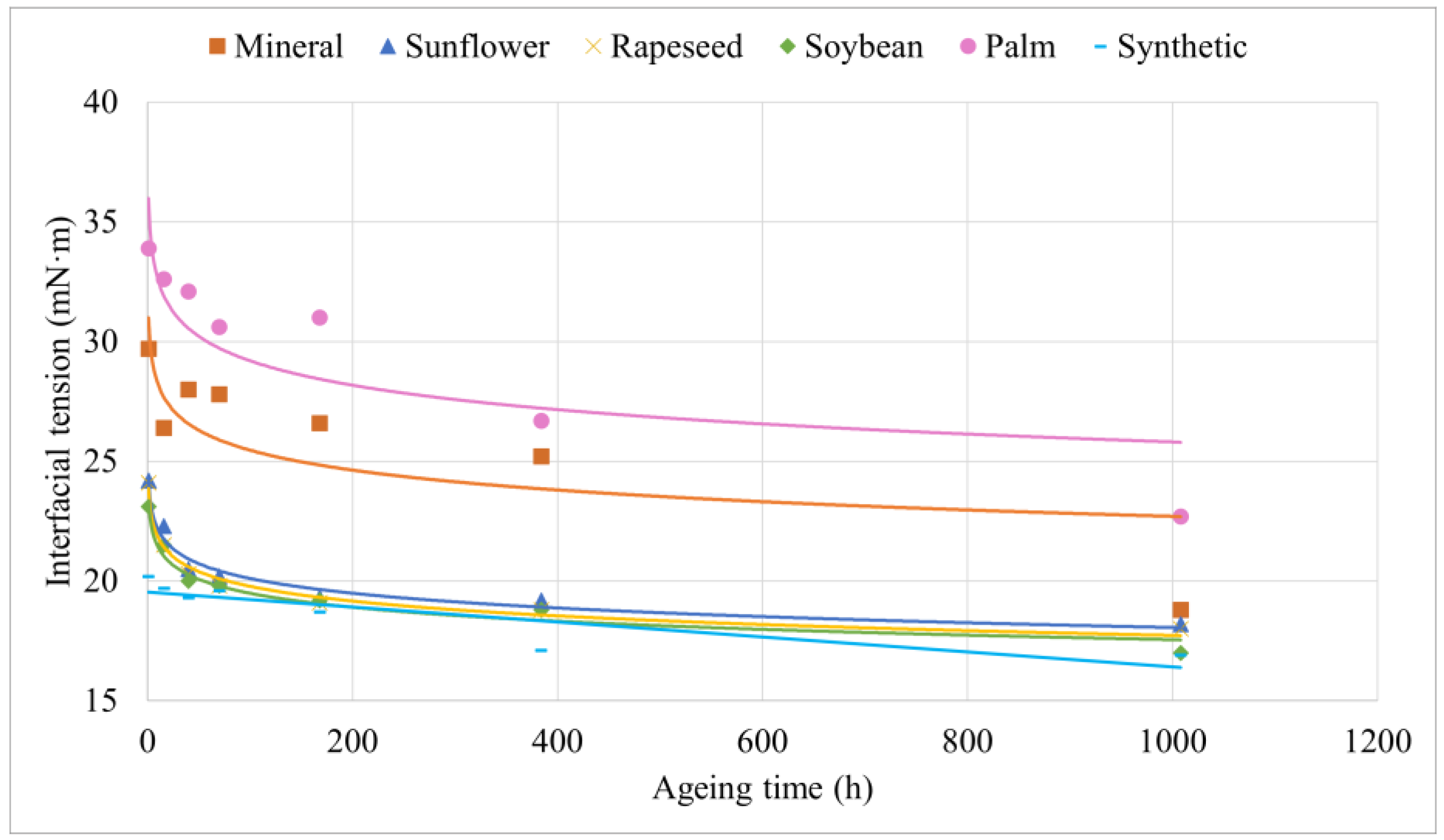

3.2.4. Interfacial Tension

3.3. Parameters Not Affected by the Ageing

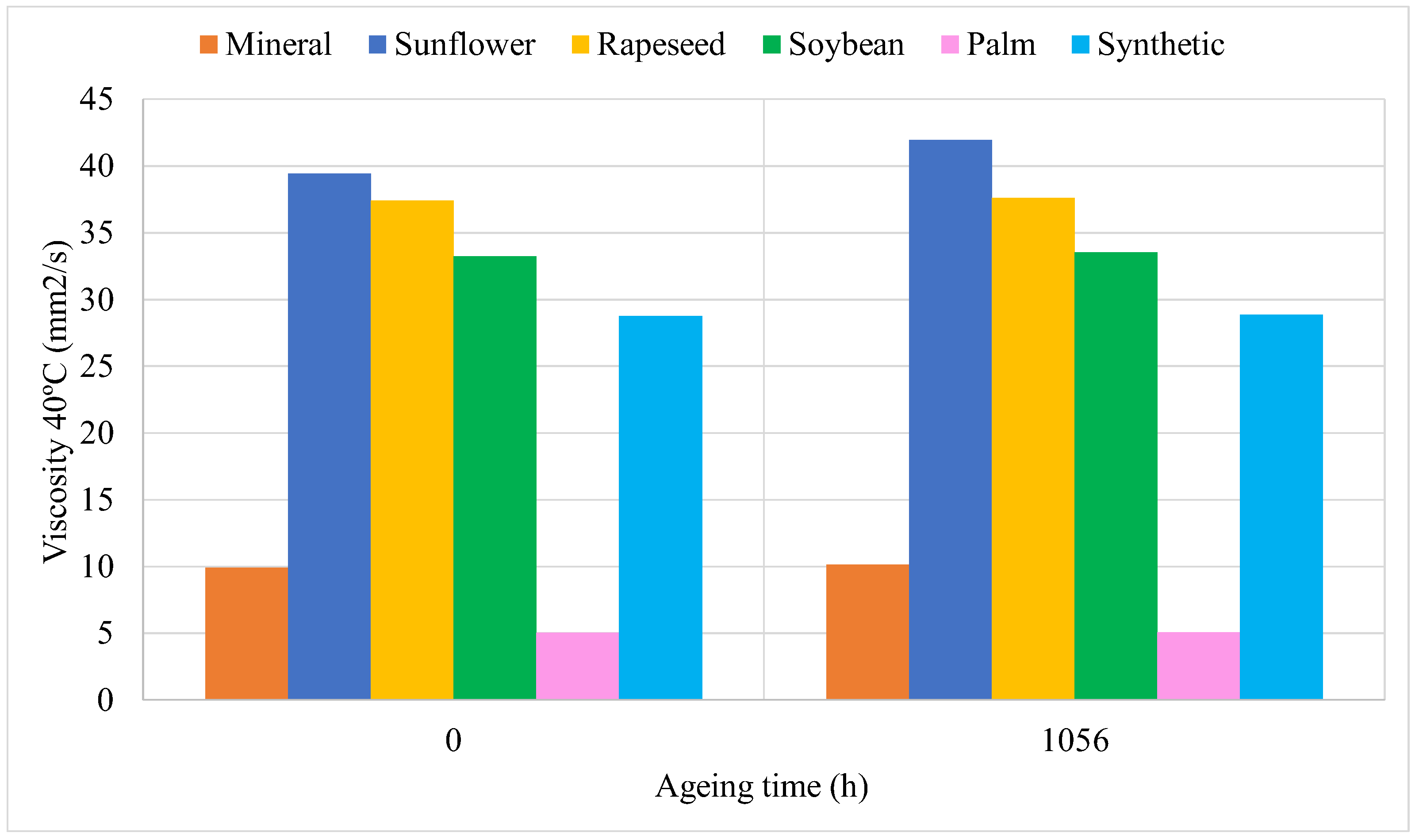

3.3.1. Density and Viscosity

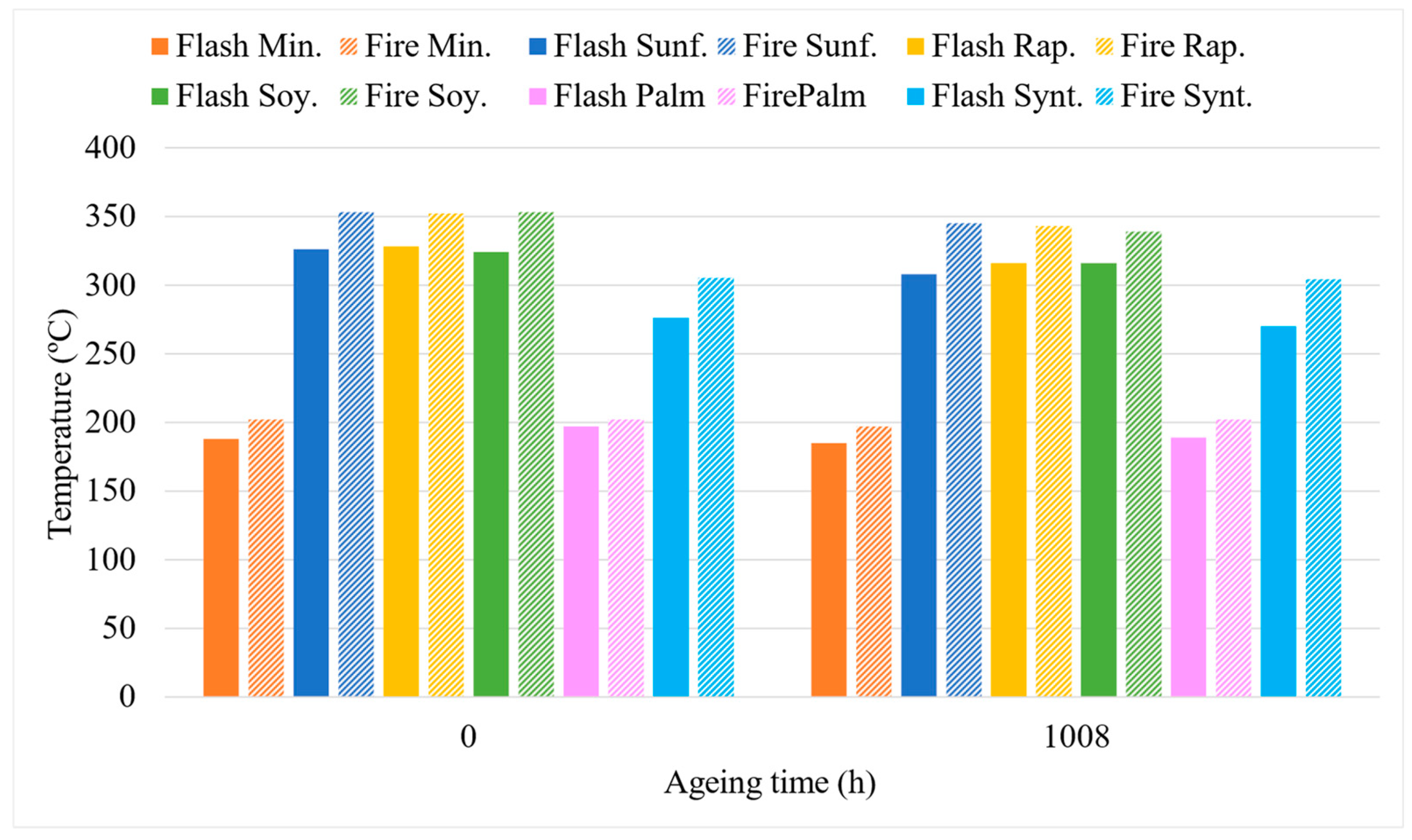

3.3.2. Flash and Fire Points

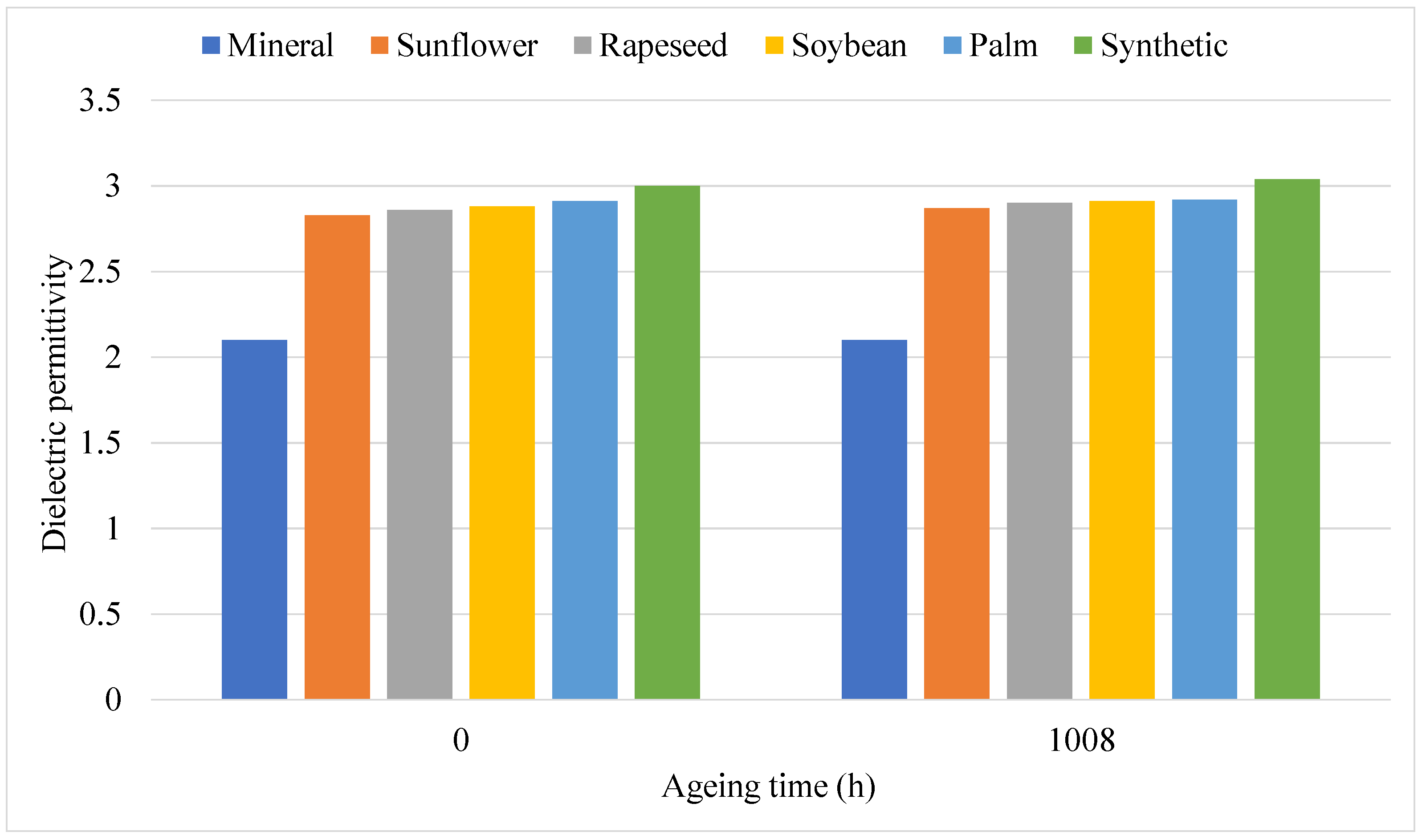

3.3.3. Dielectric Permittivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sandu, S.; Yang, M.; Mahlia, T.M.I.; Wongsapai, W.; Ong, H.C.; Putra, N.; Rahman, S.M. Energy-Related CO2 Emissions Growth in ASEAN Countries: Trends, Drivers and Policy Implications. Energies 2019, 12, 4650. [Google Scholar] [CrossRef]

- United Nations 2030 Agenda for Sustainable Development. Available online: https://www.un.org/sustainabledevelopment/es/objetivos-de-desarrollo-sostenible/ (accessed on 12 February 2024).

- Atılgan Türkmen, B.; Deveci, E.Ü.; Sağlam, Ç.Ş. Environmental Sustainability of Electricity Generation: Case Study of Lignite Combustion. Environ. Prog. Sustain. Energy 2021, 40, e13521. [Google Scholar] [CrossRef]

- Li, C.; Wang, N.; Zhang, H.; Liu, Q.; Chai, Y.; Shen, X.; Yang, Z.; Yang, Y. Environmental Impact Evaluation of Distributed Assessment and Fuzzy Rough Sets. Energies 2019, 12, 4214. [Google Scholar] [CrossRef]

- Zsembinszki, G.; Llantoy, N.; Palomba, V.; Frazzica, A.; Dallapiccola, M.; Trentin, F.; Cabeza, L.F. Life Cycle Assessment (Lca) of an Innovative Compact Hybrid Electrical-Thermal Storage System for Residential Buildings in Mediterranean Climate. Sustainability 2021, 13, 5322. [Google Scholar] [CrossRef]

- Wang, H.; Abdollahi, E.; Lahdelma, R.; Jiao, W.; Zhou, Z. Modelling and Optimization of the Smart Hybrid Renewable Energy for Communities (SHREC). Renew. Energy 2015, 84, 114–123. [Google Scholar] [CrossRef]

- De Vito, S.; Del Giudice, A.; Di Francia, G. Electric Transmission and Distribution Network Air Pollution. Sensors 2024, 24, 587. [Google Scholar] [CrossRef] [PubMed]

- Martin, T. Transformers Magazine. 2021, pp. 132–135. Available online: https://www.midel.com/app/uploads/2021/03/Ester-transformer-fluids-and-their-potential-role_Midel.pdf (accessed on 12 February 2024).

- Naegler, T.; Becker, L.; Buchgeister, J.; Hauser, W.; Hottenroth, H.; Junne, T.; Lehr, U.; Scheel, O.; Schmidt-Scheele, R.; Simon, S.; et al. Integrated Multidimensional Sustainability Assessment of Energy System Transformation Pathways. Sustainability 2021, 13, 5217. [Google Scholar] [CrossRef]

- Rouse, T.O. Mineral Oil in Transformers. IEEE Electr. Insul. Mag. 1998, 14, 6–16. [Google Scholar] [CrossRef]

- Bertagnolli, G. Power Transformers & Short Circuits Evaluation of the Short-Circuit Performance of Power Transformers; ABB Limited Transformers: Moorebank, Australia, 2014. [Google Scholar]

- Rafiq, M.; Lv, Y.Z.; Zhou, Y.; Ma, K.B.; Wang, W.; Li, C.R.; Wang, Q. Use of Vegetable Oils as Transformer Oils—A Review. Renew. Sustain. Energy Rev. 2015, 52, 308–324. [Google Scholar] [CrossRef]

- IEC 61099:2010; Insulating Liquids—Specifications for Unused Synthetic Organic Esters for Electrical Purposes. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- Ahmad, M.; Daris, I.; Rahmat, H.; Suprijadi, S. Aging Behavior of Mineral Oil, Gas-to-Liquid ( GTL ), and Natural Ester Liquids in Presence of Cellulosic Materials. In Proceedings of the 2021 3rd International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Bandung, Indonesia, 5–6 October 2021; pp. 501–506. [Google Scholar]

- Krause, C. Power Transformer Insulation—History, Technology and Design. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1941–1947. [Google Scholar] [CrossRef]

- IEEE C57.12.00; Standard for General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers. IEEE Standards Association: Piscataway, NJ, USA, 2015.

- Gasser, H.P.; Krause, C.; Lashbrook, M.; Martin, R. Aging of Pressboard in Different Insulating Liquids. In Proceedings of the 2011 IEEE International Conference on Dielectric Liquids, Trondheim, Norway, 26–30 June 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1–5. [Google Scholar]

- Münster, T.; Werle, P.; Hämel, K.; Preusel, J. Thermally Accelerated Aging of Insulation Paper for Transformers with Different Insulating Liquids. Energies 2021, 14, 3036. [Google Scholar] [CrossRef]

- Hemmer, M.; Badent, R.; Leibfried, T. Electrical Properties of Vegetable Oil-Impregnated Paper Insulation. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Annual Report, Albuquerque, NM, USA, 19–22 October 2003; pp. 60–63. [Google Scholar]

- Tenbohlen, S.; Koch, M. Aging Performance and Moisture Solubility of Vegetable Oils for Power Transformers. IEEE Trans. Power Deliv. 2010, 25, 825–830. [Google Scholar] [CrossRef]

- Liao, R.; Liang, S.; Sun, C.; Yang, L.; Sun, H. A Comparative Study of Thermal Aging of Transformer Insulation Paper Impregnated in Natural Ester and in Mineral Oil. Eur. Trans. Electr. Power 2009, 20, 518–533. [Google Scholar] [CrossRef]

- Fernández-diego, C.; Ortiz, A.; Fernández, I.; Renedo, C.J.; Delgado, F. Ageing of Crepe Paper in Mineral Oil and Natural Ester. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Tokyo, Japan, 13–17 September 2020; pp. 217–220. [Google Scholar]

- Matharage, S.Y.; Liu, Q.; Wang, Z.D.; Wilson, G.; Krause, C. Aging Assessment of Synthetic Ester Impregnated Thermally Non-Upgraded Kraft Paper through Chemical Markers in Oil. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 507–515. [Google Scholar] [CrossRef]

- Prevost, T.A.; Oommen, T. V Cellulose Insulation in Oil-Filled Power Transformers: Part I—History and Development. IEEE Electr. Insul. Mag. 2006, 22, 28–35. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Allan, D.; Höhlein, I.A.; Clavreul, R.; Dahlund, M.O.; Gasser, H.P.; Heywood, R.; Krause, C.; Lessard, M.C.; Saha, T.K.; et al. Ageing of Cellulose in Mineral-Oil Insulated Transformers; CIGRE: Johannesburg, South Africa, 2007. [Google Scholar]

- Fofana, I.; Fofana, F. 50 Years in the Development of Insulating Liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25. [Google Scholar] [CrossRef]

- Mohan Rao, U.; Fofana, I.; Sarathi, R. (Eds.) Alternative Liquid Dielectrics for High Voltage Transformer Insulation Systems; Wiley-IEEE Press: Hoboken, NJ, USA, 2022; ISBN 978-1-119-80018-7. [Google Scholar]

- Tokunaga, J.; Nikaido, M.; Koide, H.; Hikosaka, T. Palm Fatty Acid Ester as Biodegradable Dielectric Fluid in Transformers: A Review. IEEE Electr. Insul. Mag. 2019, 35, 34–46. [Google Scholar] [CrossRef]

- Harlow, J.H. Electric Power Transformer Engineering; CRC Press: Boca Raton, FL, USA, 2003; ISBN 0-8493-9186-5. [Google Scholar]

- Oparanti, S.O.; Rao, U.M.; Fofana, I. Natural Esters for Green Transformers: Challenges and Keys for Improved Serviceability. Energies 2023, 16, 61. [Google Scholar] [CrossRef]

- IEC 60814; Insulating Liquids—Oil-Impregnated Paper and Pressboard—Determination of Water by Automatic Coulometric Karl Fischer Titration. International Electrotechnical Commission: Geneva, Switzerland, 1997.

- IEEE Std C57.152; Guide for Diagnostic Field Testing of Fluid-Filled Power Transformers, Regulators, and Reactors. IEEE Standards Association: Piscataway, NJ, USA, 2013.

- IEEE Standard C57.100; Test Procedure for Thermal Evaluation of Insulation Systems for Liquid-Immersed Distribution and Power Transformers. IEEE Standards Association: Piscataway, NJ, USA, 2012.

- IEC 60156:2018; Insulating Liquids—Determination of the Breakdown Voltage at Power Frequency—Test Method. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- IEC 60247:2004; Insulating Liquids—Measurement of Relative Permittivity, Dielectric Dissipation Factor (Tan d) and d.c. Resistivity. International Electrotechnical Commission: Geneva, Switzerland, 2004.

- ASTM D92; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- IEC 62961:2018; Insulating Liquids—Test Methods for the Determination of Interfacial Tension of Insulating Liquids—Determination with the Ring Method. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- IEC 62021:2003; Insulating Liquids—Determination of Acidity—Part 1: Automatic Potentiometric Titration. International Electrotechnical Commission: Geneva, Switzerland, 2003.

- IEC 62021:2014; Insulating Liquids—Determination of Acidity—Part 3: Test Methods for Non-Mineral Insulating Oils. International Electrotechnical Commission: Geneva, Switzerland, 2014.

- ASTM D4243; Standard Test Method for Measurement of Average Viscometric Degree of Polymerization of New and Aged Electrical Papers and Boards. ASTM International: West Conshohocken, PA, USA, 2016.

- Oommen, T.V.; Prevost, T.A. Cellulose Insulation in Oil-Filled Power Transformers: Part II–Maintaining. IEEE Electr. Insul. Mag. 2006, 22, 5–14. [Google Scholar] [CrossRef]

- Bandara, K.; Ekanayake, C.; Saha, T.K.; Annamalai, P.K. Understanding the Ageing Aspects of Natural Ester Based Insulation Liquid in Power Transformer. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 246–257. [Google Scholar] [CrossRef]

- Ariffin, M.M.; Ishak, M.T.; Hamid, M.H.A.; Katim, N.I.A.; Ishak, A.; Azis, N. Ageing Effect of Vegetable Oils Impregnated Paper in Transformer Application. In Proceedings of the International Conference on High Voltage Engineering and Power Systems, ICHVEPS 2017, Denpasar, Indonesia, 2–5 October 2017; pp. 183–187. [Google Scholar]

- Lelekakis, N.; Martin, D.; Wijaya, J. Ageing Rate of Paper Insulation Used in Power Transformers Part 2: Oil/Paper System with Medium and High Oxygen Concentration. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 2009–2018. [Google Scholar] [CrossRef]

- Liao, R.; Hao, J.; Chen, G.; Ma, Z.; Yang, L. A Comparative Study of Physicochemical, Dielectric and Thermal Properties of Pressboard Insulation Impregnated with Natural Ester and Mineral Oil. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1626–1637. [Google Scholar] [CrossRef]

- Villarroel, R.; García, D.F.; García, B.; Burgos, J.C. Moisture Diffusion Coefficients of Transformer Pressboard Insulation Impregnated with Natural Esters. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 581–589. [Google Scholar] [CrossRef]

- Villarroel, R.; de Burgos, B.G.; García, D.F. Systems Moisture Dynamics in Natural-Ester Fi Lled Transformers. Electr. Power Energy Syst. 2021, 124, 106172. [Google Scholar] [CrossRef]

- Lelekakis, N.; Martin, D.; Wijaya, J. Ageing Rate of Paper Insulation Used in Power Transformers Part 1: Oil/Paper System with Low Oxygen Concentration. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1999–2008. [Google Scholar] [CrossRef]

- Frimpong, G.; Oommen, T.V.; Asano, R. A Survey of Aging Characteristics of Cellulose Insulation in Natural Ester and Mineral Oil. IEEE Electr. Insul. Mag. 2011, 27, 36–48. [Google Scholar] [CrossRef]

- Tokunaga, J.; Koide, H.; Mogami, K.; Hikosaka, T. Comparative Studies on the Aging of Thermally Upgraded Paper Insulation in Palm Fatty Acid Ester, Mineral Oil, and Natural Ester. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 258–265. [Google Scholar] [CrossRef]

- Mendez, C.; Ortiz, A.; Renedo, C.J.; Olmo, C.; Maina, R. Understanding the Ageing Performance of Alternative Dielectric Fluids. IEEE Access 2023, 11, 9656–9671. [Google Scholar] [CrossRef]

- Condition Assessment of Power Transformers; WG A2.49; CIGRE: Johannesburg, South Africa, 2019.

- Ageing of Liquid Impregnated Cellulose for Power Transformers; Working Group D1.53 Materials and Emerging Test Techniques; CIGRE: Kaalfontein, South Africa, 2018.

- Trnka, P.; Hornak, J.; Prosr, P.; Michal, O.; Wang, F. Various Aging Processes in a Paper-Natural Ester Insulation System in the Presence of Copper and Moisture. IEEE Access 2020, 8, 61989–61998. [Google Scholar] [CrossRef]

- Mo, W.; Huang, Q.; Song, H.; Yao, W. Influence of Acids on the Electrical Lifetime of Vegetable Oil Impregnated Paper Insulation. In Proceedings of the ICHVE 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016. [Google Scholar]

- Yang, L.; Liao, R.; Sun, C.; Yin, J.; Zhu, M. Influence of Vegetable Oil on the Thermal Aging Rate of Kraft Paper and Its Mechanism. In Proceedings of the 2010 International Conference on High Voltage Engineering and Application, New Orleans, LA, USA, 11–14 October 2010; IEEE: Piscataway, NJ, USA, 2010. [Google Scholar]

- García, B.; García, T.; Burgos, J.C.; Urquiza, D. Studying the Loss of Life of Natural- Ester-Filled Transformer Insulation: Impact of Moisture on the Aging Rate of Paper. IEEE Electr. Insul. Mag. 2017, 33, 15–23. [Google Scholar] [CrossRef]

- IEC 62975:2021; Natural Esters—Guidelines for Maintenance and Use in Electrical Equipment. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- Guo, C.; Liao, R.; Yang, L.; Wang, K.; Qi, C. Thermal Aging Properties of BIOTEMP Oil with Controlled Air. In Proceedings of the 2012 International Conference on High Voltage Engineering and Application, Shanghai, China, 17–20 September 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 13–17. [Google Scholar]

- Prevost, T.A. Dielectric Properties of Natural Esters and Their Influence on Transformer Insulation System Design and Performance—An Update. In Proceedings of the 2009 IEEE Power & Energy Society General Meeting, Calgary, AB, Canada, 26–30 July 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–7. [Google Scholar]

- Gielniak, J.; Graczkowski, A.; Moscicka-Grzesiak, H. Does the Degree of Cellulose Polymerization Affect the Dielectric Response? IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1647–1650. [Google Scholar] [CrossRef]

- Jadav, R.B.; Ekanayake, C.; Saha, T.K. Understanding the Impact of Moisture and Ageing of Transformer Insulation on Frequency Domain Spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 369–379. [Google Scholar] [CrossRef]

- IEC 60422:2013; Mineral Insulating Oils in Electrical Equipment—Supervision and Maintenance Guidance. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Tokunaga, J.; Koide, H.; Mogami, K.; Kawanishi, K.; Hikosaka, T. Lifetime Estimation of Cellulosic Insulation Material in Palm Fatty Acid Ester for Power Transformers. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1010–1017. [Google Scholar] [CrossRef]

- Asano, R.; Page, S.A. Reducing Environmental Impact and Improving Safety and Performance of Power Transformers With Natural Ester Dielectric Insulating Fluids. IEEE Trans. Ind. Appl. 2014, 50, 134–141. [Google Scholar] [CrossRef]

- Forouhari, S.; Abu-Siada, A. Remnant Life Estimation of Power Transformer Based on IFT and Acidity Number of Transformer Oil. In Proceedings of the IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 552–555. [Google Scholar]

- Xu, Y.; Qian, S.; Liu, Q.; Wang, Z. Oxidation Stability Assessment of a Vegetable Transformer Oil under Thermal Aging. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 683–692. [Google Scholar] [CrossRef]

- Montero, A.; García, B.; Burgos, J.C.; González-garcía, C. Dielectric Design of Ester-Filled Power Transformers: AC Stress Analysis. IEEE Trans. Power Deliv. 2022, 37, 2403–2412. [Google Scholar] [CrossRef]

- Wang, S.Q.; Zhang, G.J.; Wei, J.L.; Yang, S.S.; Dong, M.; Huang, X.B. Investigation on Dielectric Response Characteristics of Thermally Aged Insulating Pressboard in Vacuum and Oil-Impregnated Ambient. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1853–1862. [Google Scholar] [CrossRef]

- Ciuriuc, A.; Dumitran, L.M.; Notingher, P.V.; Badicu, L.V.; Setnescu, R.; Setnescu, T. Lifetime Estimation of Vegetable and Mineral Oil Impregnated Paper for Power Transformers. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; pp. 720–723. [Google Scholar]

| Property | Test Method | TUK |

|---|---|---|

| Density [g/cm3] | IEC 60641 | 1 |

| Tensile strength (machine direction) [MPa] | IEC 60641 | 115 |

| Elongation (machine direction) [%] | IEC 60641 | 2 |

| Moisture content [%] | ISO 287 | <8 |

| Electric strength in air [kV/mm] | IEC 60243 | 10 |

| Electric strength in oil [kV/mm] | IEC 60243 | 70 |

| Property | Mineral | Sunflower | Rapeseed | Soybean | Palm | Synthetic |

|---|---|---|---|---|---|---|

| Density 20 °C [g/cm3] | 0.839 | 0.91 | 0.92 | 0.92 | 0.97 | 0.839 |

| Kinematic viscosity 40 °C [mm2/s] | 9.98 | 39.2 | 37 | 34 | 5.062 | 29 |

| Flash point [°C] | 176 | 330 | >315 | 320 | 188 | 260 |

| Fire point [°C] | - | 362 | >350 | 350 | 206 | 316 |

| Pour point [°C] | −48 | −25 | -31 | −18 | −37.5 | −56 |

| Acidity [mg KOH/g] | <0.01 | 0.05 | ≤0.04 | <0.05 | <0.01 | <0.03 |

| Moisture [mg/kg] | 15 | 150 | 50 | 4-50 | 52 | 50 |

| Dielectric dissipation factor 90 °C | 0.002 | 0.03 | <0.03 | <0.03 | <0.003 | <0.008 |

| Breakdown voltage [kV] | 46 | 65 | >75 | ≥55 | 85 | >75 |

| Biodegradability | - | 85 | 98 | > 99 | 77 | 89 |

| Moisture | Mineral | Sunflower | Rapeseed | Soybean | Palm | Synthetic |

|---|---|---|---|---|---|---|

| Fluid [ppm] | 25.3 | 92.8 | 40.8 | 72.1 | 64.9 | 107.2 |

| TUK [%] | 0.5 | 0.9 | 0.6 | 1 | 0.9 | 1 |

| Mineral | Sunflower | Rapeseed | Soybean | Palm | Synthetic |

|---|---|---|---|---|---|

| 0.861 | 0.917 | 0.922 | 0.924 | 0.863 | 0.971 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Méndez, C.; Olmo, C.; Antolín, I.; Ortiz, A.; Renedo, C.J. Analysing the Suitability of Using Different Biodegradable Fluids for Power Transformers with Thermally Upgraded Paper. Sustainability 2024, 16, 3259. https://doi.org/10.3390/su16083259

Méndez C, Olmo C, Antolín I, Ortiz A, Renedo CJ. Analysing the Suitability of Using Different Biodegradable Fluids for Power Transformers with Thermally Upgraded Paper. Sustainability. 2024; 16(8):3259. https://doi.org/10.3390/su16083259

Chicago/Turabian StyleMéndez, Cristina, Cristian Olmo, Ismael Antolín, Alfredo Ortiz, and Carlos J. Renedo. 2024. "Analysing the Suitability of Using Different Biodegradable Fluids for Power Transformers with Thermally Upgraded Paper" Sustainability 16, no. 8: 3259. https://doi.org/10.3390/su16083259

APA StyleMéndez, C., Olmo, C., Antolín, I., Ortiz, A., & Renedo, C. J. (2024). Analysing the Suitability of Using Different Biodegradable Fluids for Power Transformers with Thermally Upgraded Paper. Sustainability, 16(8), 3259. https://doi.org/10.3390/su16083259