Research Progress of Heat Damage Prevention and Control Technology in Deep Mine

Abstract

1. Introduction

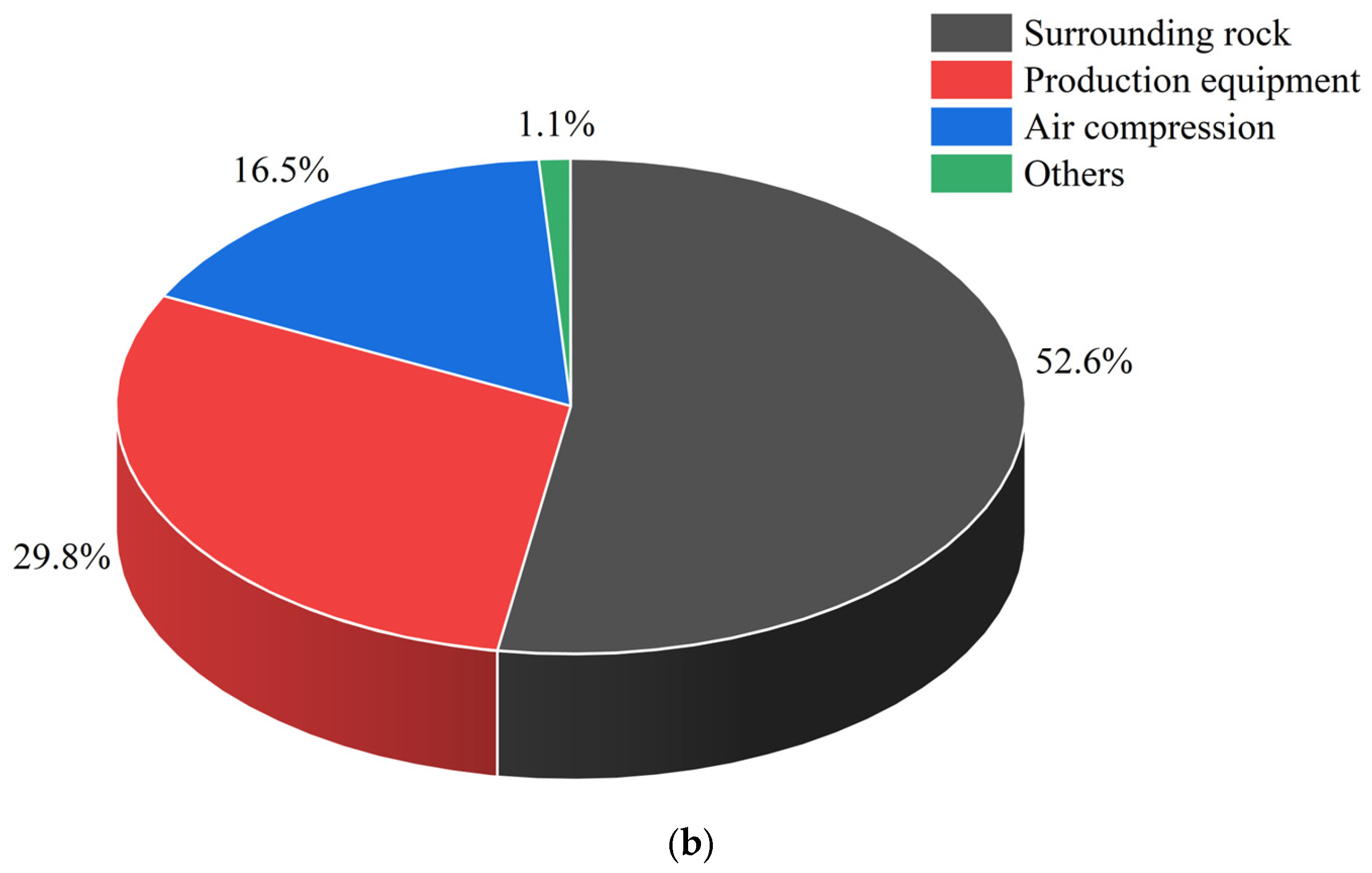

2. Causes and Hazards of Deep-Mine Heat Damage

2.1. Causes of Deep-Mine Heat Damage

- (1)

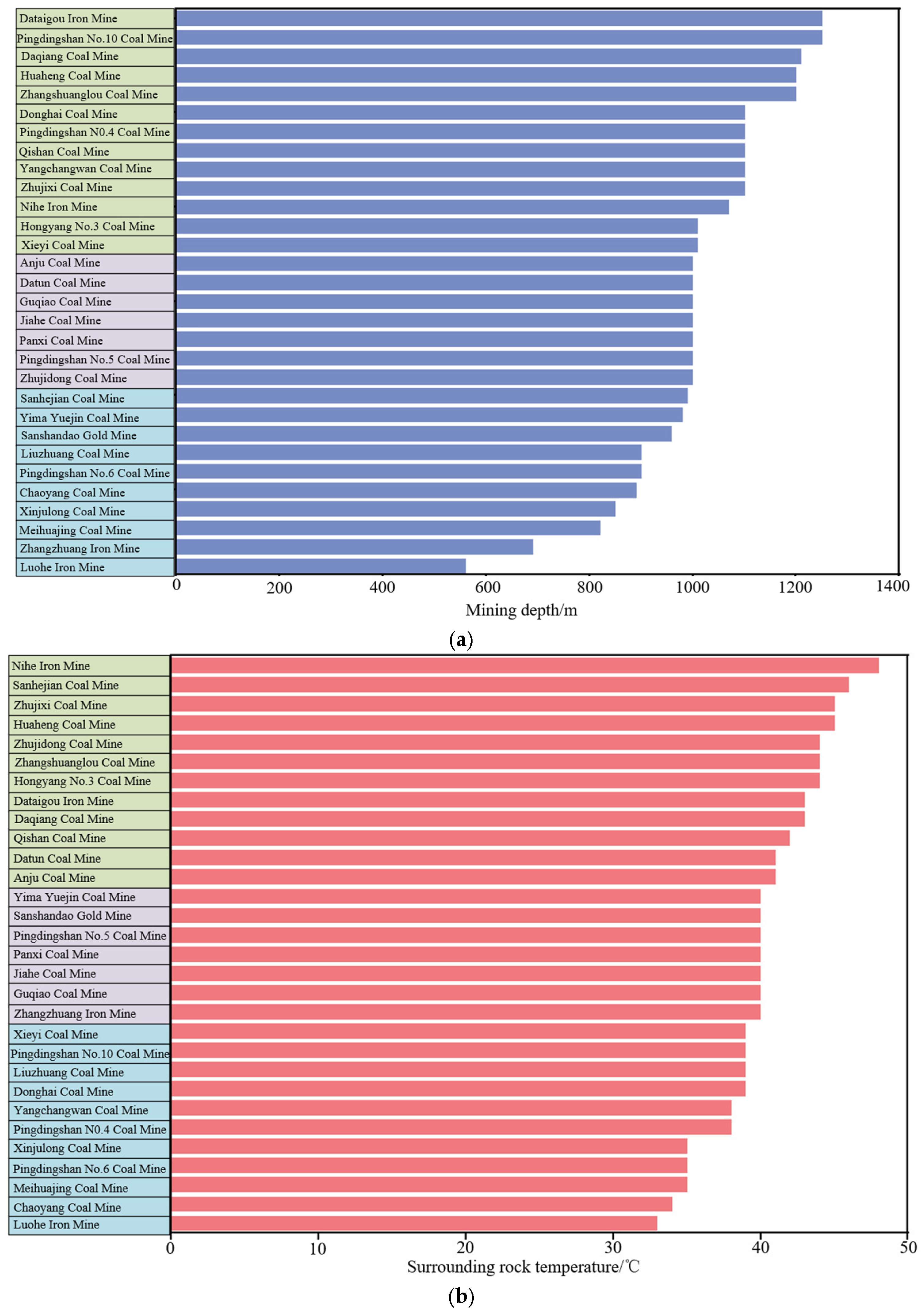

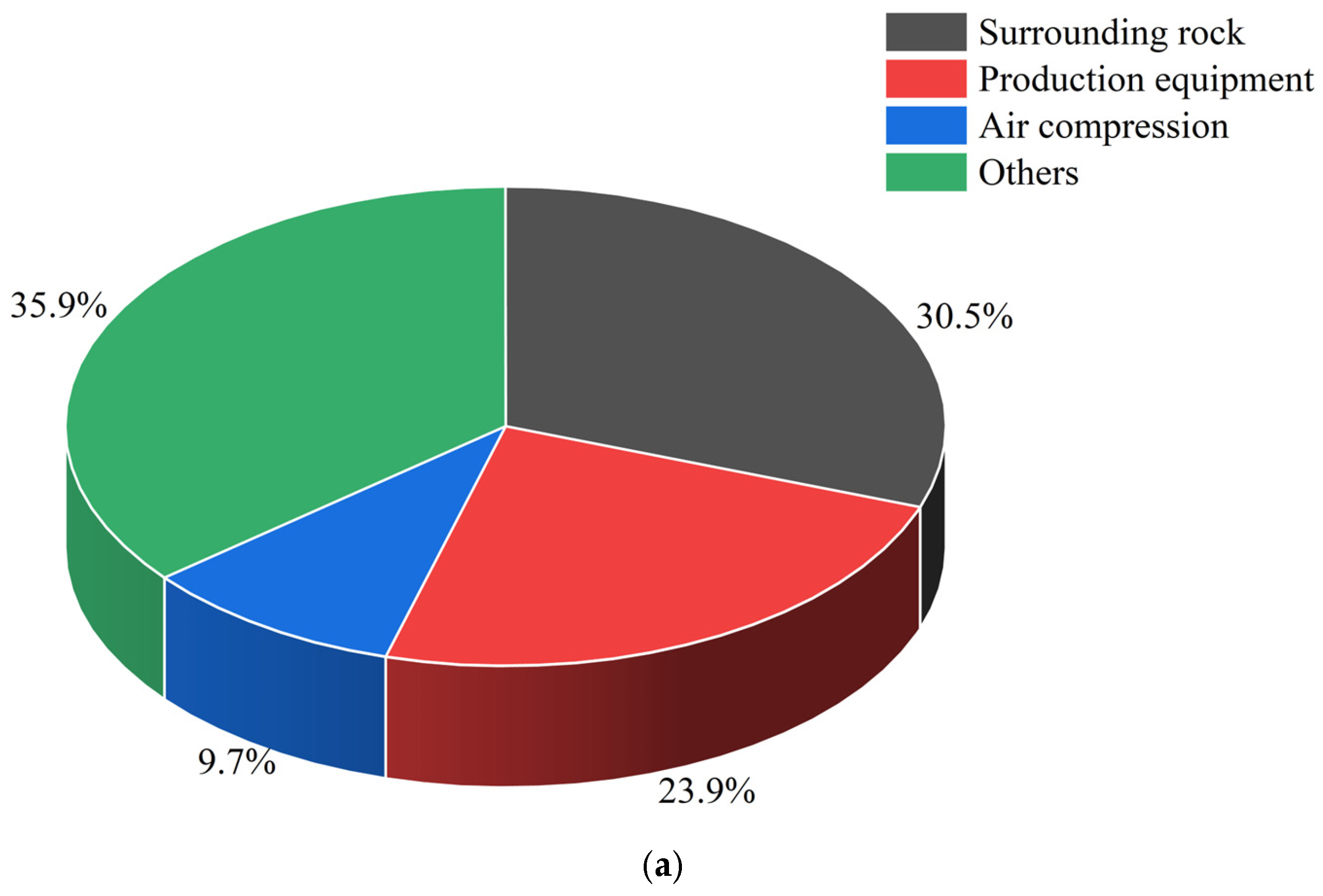

- Surrounding-rock heat dissipation: Surrounding-rock heat dissipation is a significant contributor to mine heat damage. The geothermal gradient is a key factor that influences the surrounding rock temperature. As the mining depth increases, the surrounding rock temperature also increases, leading to an increase in thermal discharge into roadways [12]. The heat within the surrounding rock is transferred to the roadway wall via conduction. When the airflow enters the roadway, convective heat transfer occurs along the wall. Owing to the temperature difference between the airflow and the surrounding rock, the mine airflow temperature increases [13]. In deep mines, surrounding-rock heat dissipation is the primary cause of elevated temperatures.

- (2)

- Production equipment heat dissipation: Electromechanical equipment heat dissipation refers to the release of energy as thermal energy during the conversion of electrical energy to mechanical energy during mechanical operations, thereby increasing the temperature of the mine environment.

- (3)

- Air compression heat dissipation: Air compression heat dissipation is attributed to pressure changes as air flows through the mine owing to varying depths. Pressure causes air compression, converting potential energy into heat and increasing the enthalpy [14]. As the mining depth increases, the air compression intensifies, leading to a substantial increase in temperature. In a 1000 m deep mine, potential energy changes can increase the air temperature by 10 °C when the air is delivered to the working face.

- (4)

- Other factors: Other factors such as mineral oxidation and mine water heat dissipation also contribute to mine heat damage. Mineral oxidation involves exothermic chemical reactions between ores and oxygen during mining, producing oxides and releasing heat [15]. This process not only elevates the working face temperature but may also induce spontaneous ore combustion, posing significant safety hazards. Mine water heat dissipation occurs as mine water transfers heat to the working face air via heat exchange, thereby increasing the ambient temperature [16]. In deep mines, which are affected by geothermal gradients, the mine water temperatures are typically higher. Additional heat sources in mines include blasting, filling material heat release, and human body heat dissipation, all of which further increase air temperatures.

2.2. Hazards of Deep-Mine Heat Damage

2.2.1. Surrounding Rock

2.2.2. Working Environment

2.2.3. Supporting Structure

2.2.4. Other Hazards

3. Deep Mine Cooling Technology

3.1. Evaluation Index

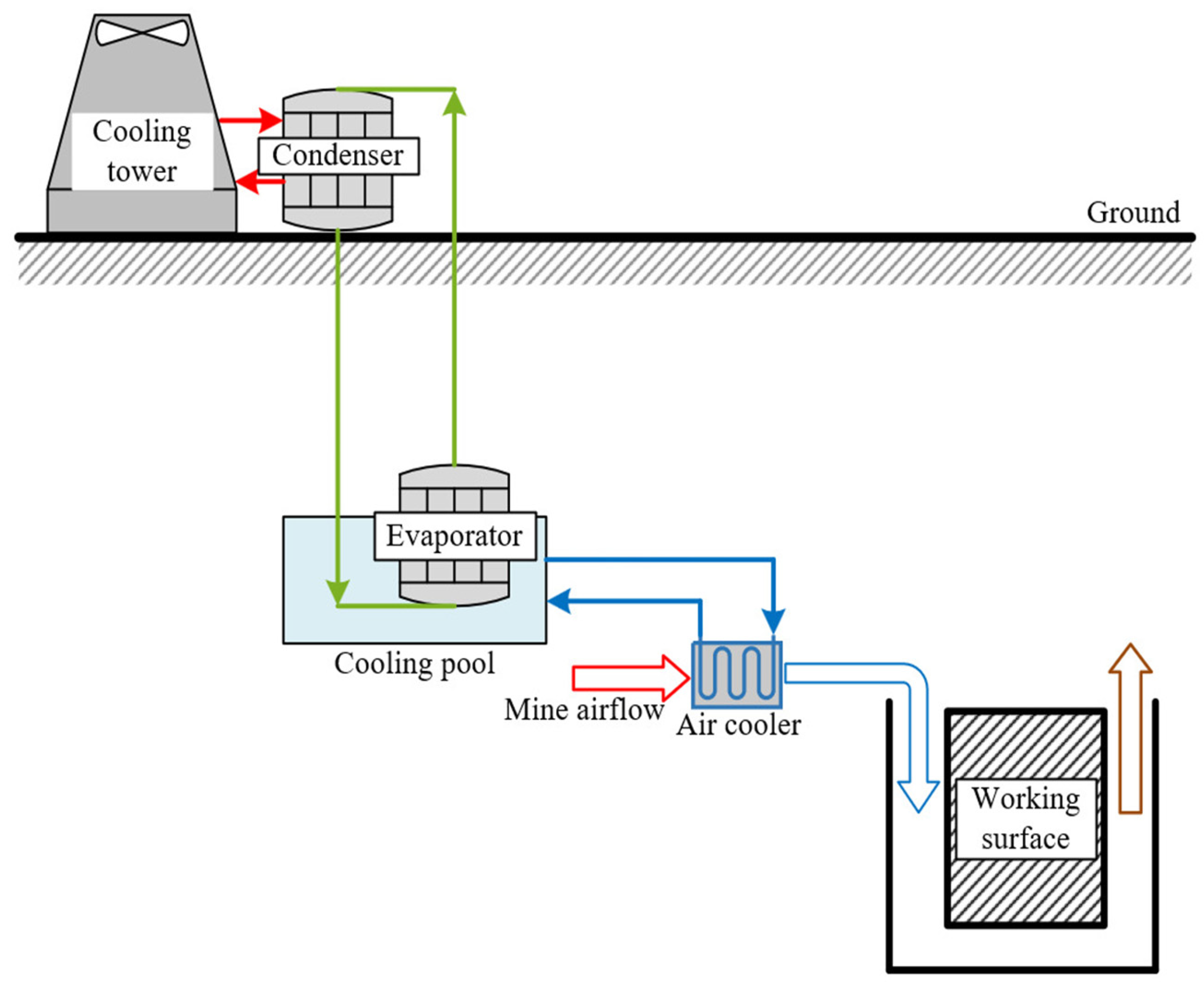

3.2. Traditional Refrigeration Cooling Technology

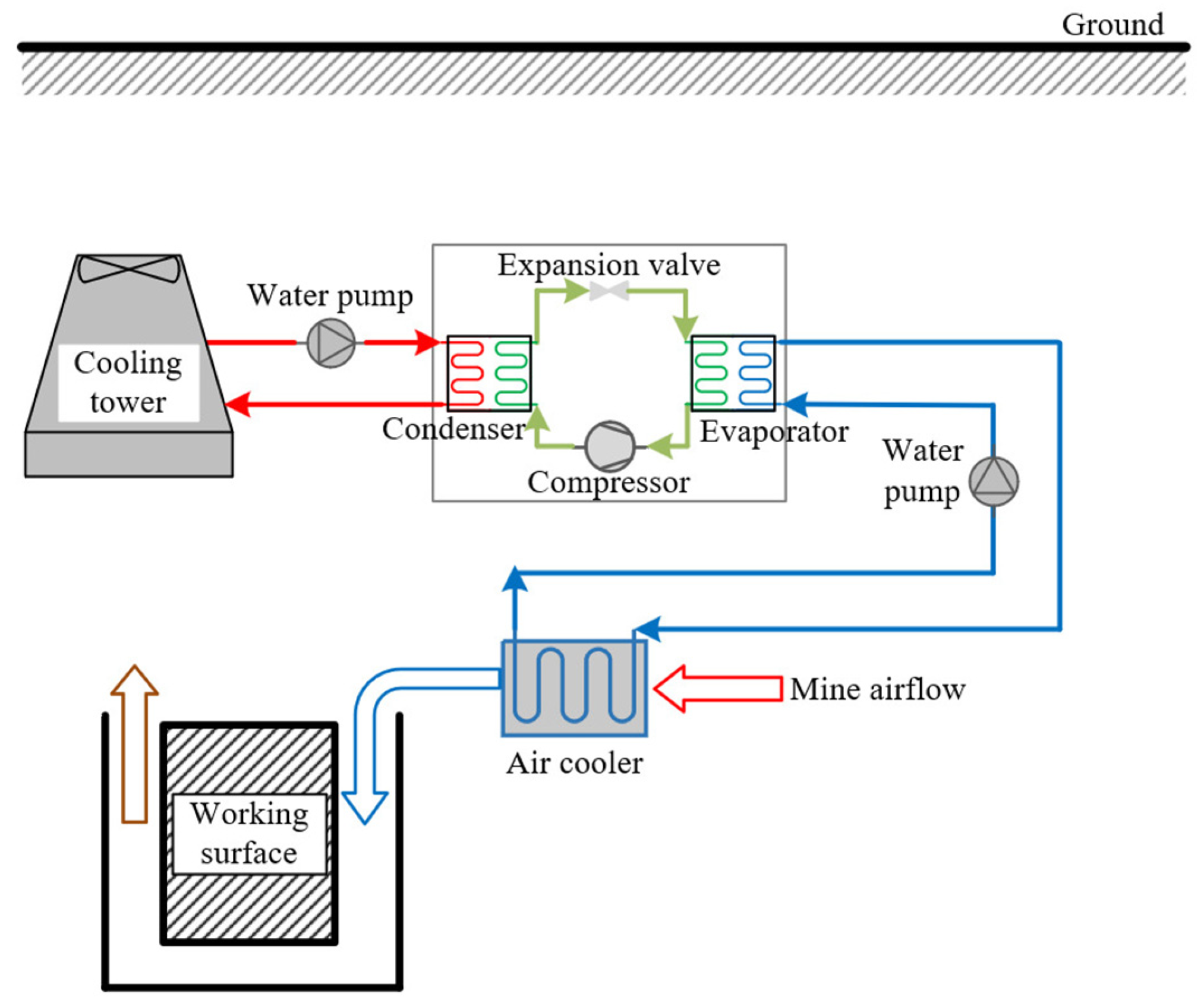

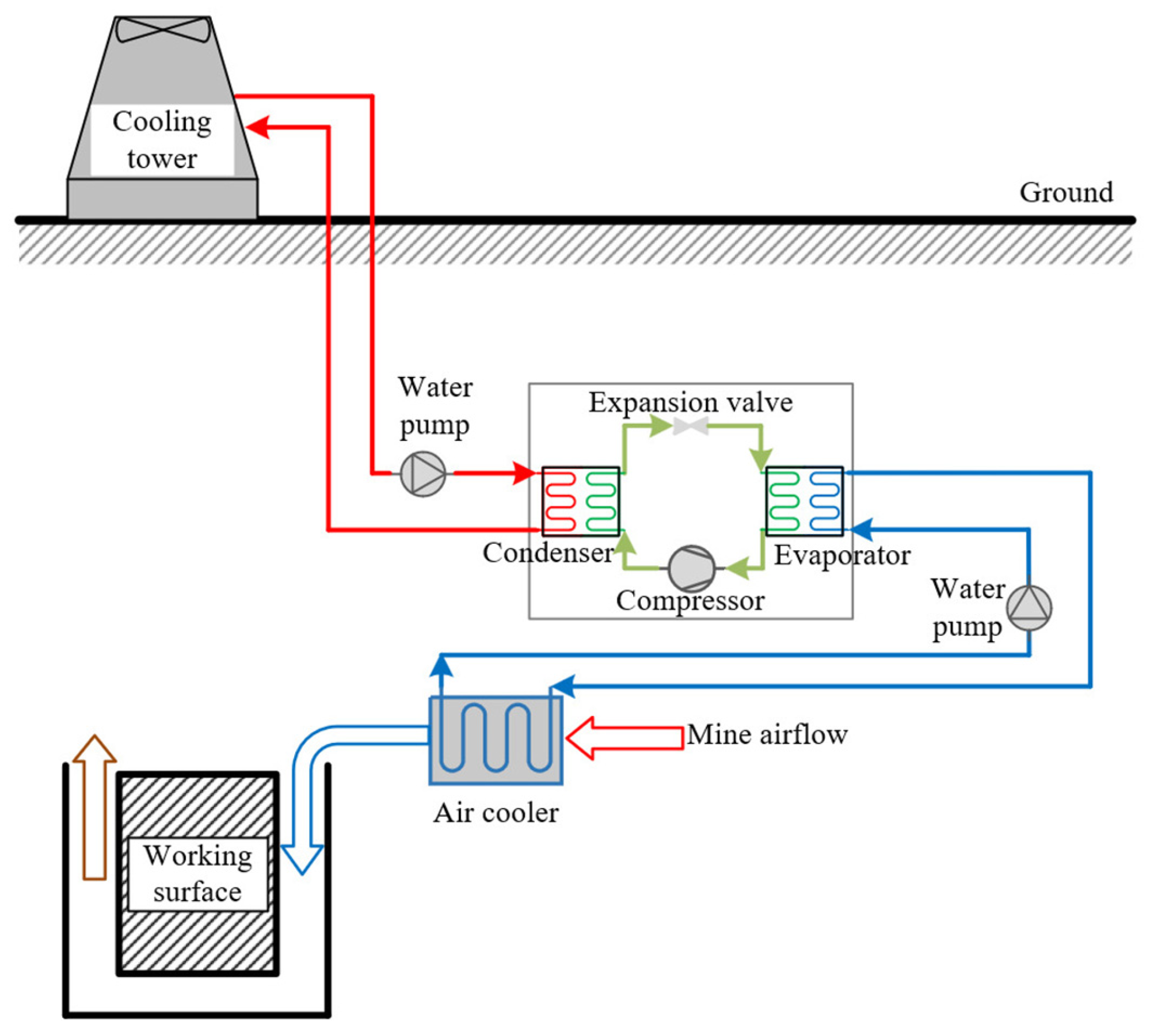

3.2.1. Water-Cooled Refrigeration Cooling Technology

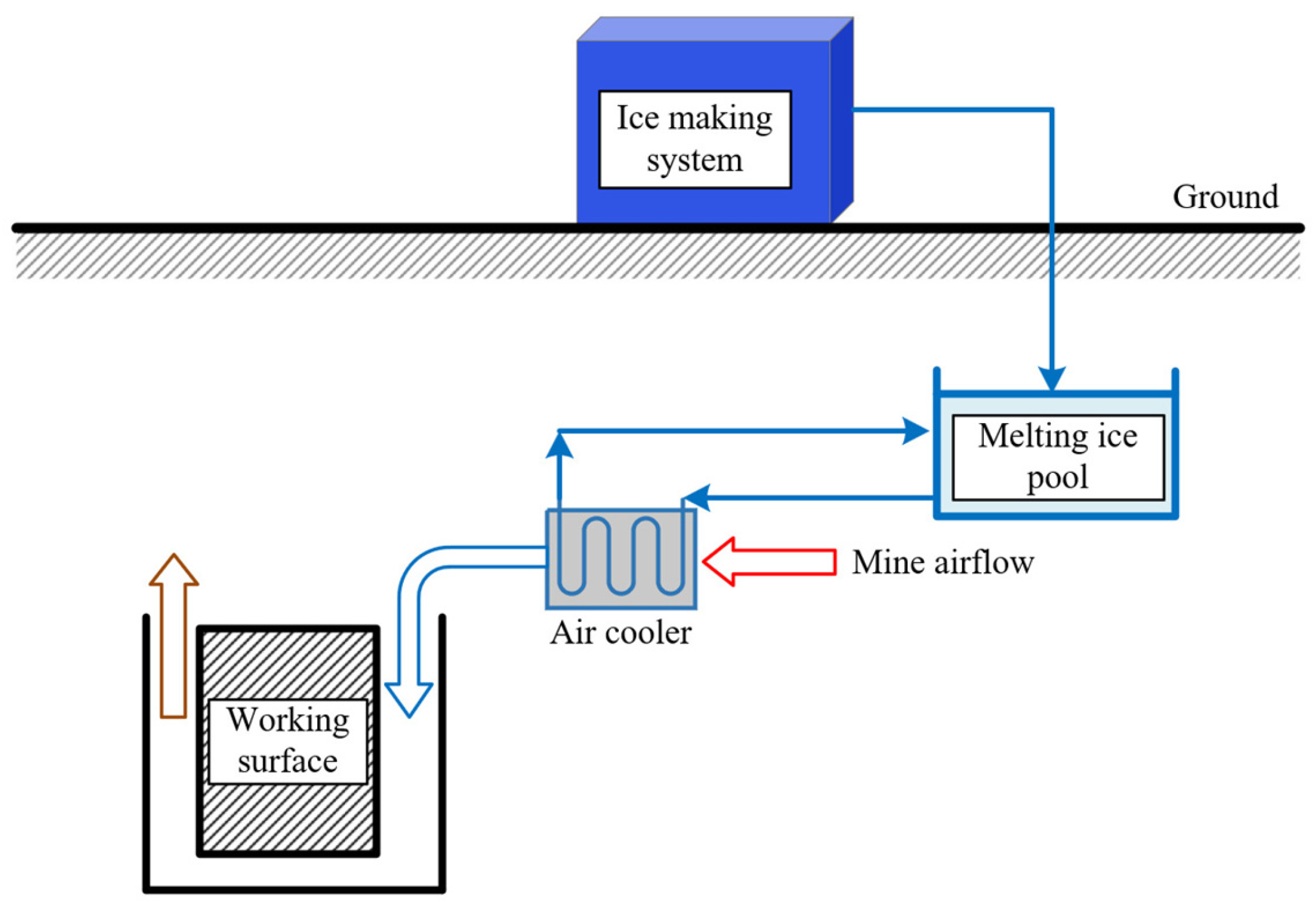

3.2.2. Ice-Cooled Refrigeration Cooling Technology

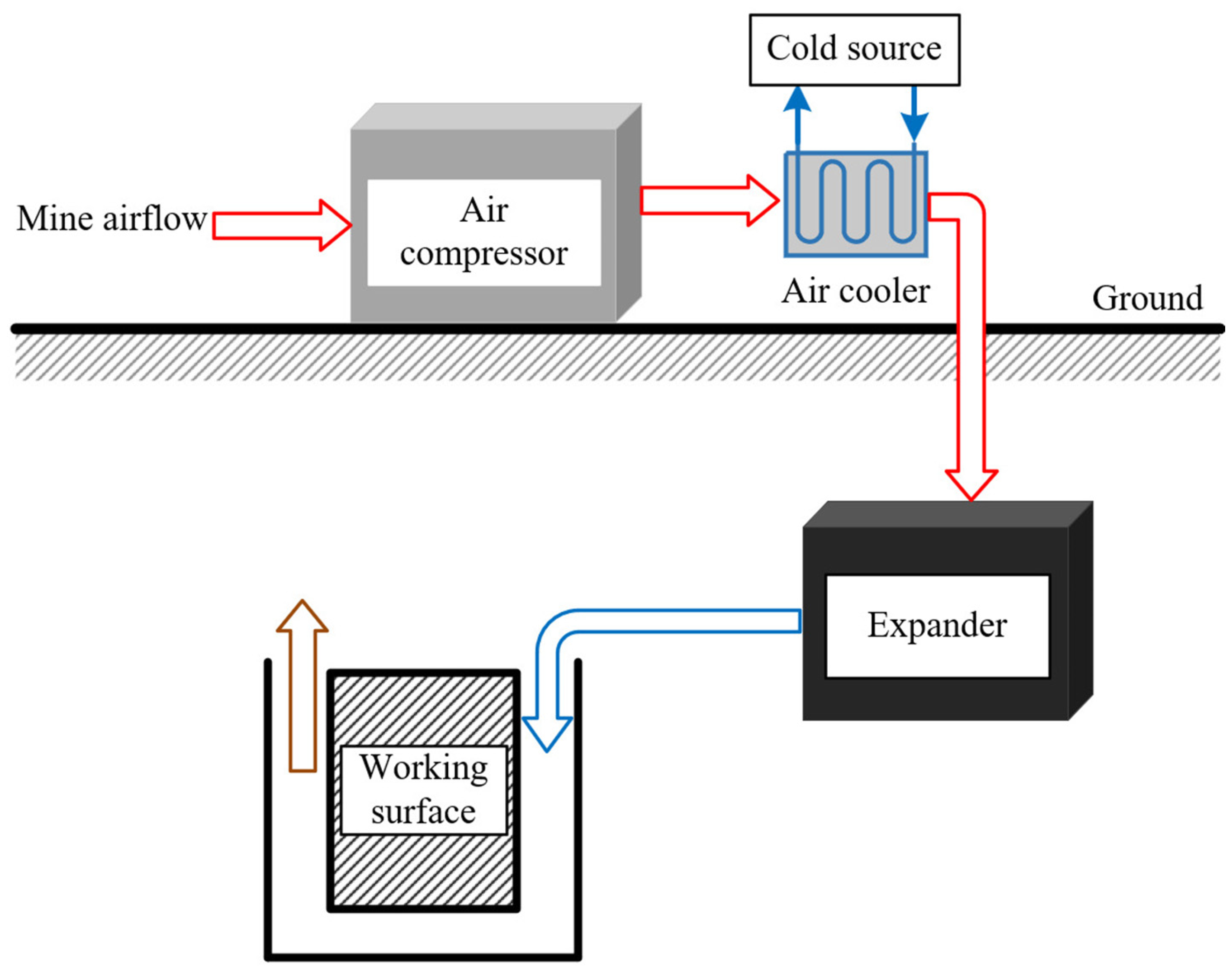

3.2.3. Air-Cooled Refrigeration Cooling Technology

3.3. Green Mine Cooling Technology

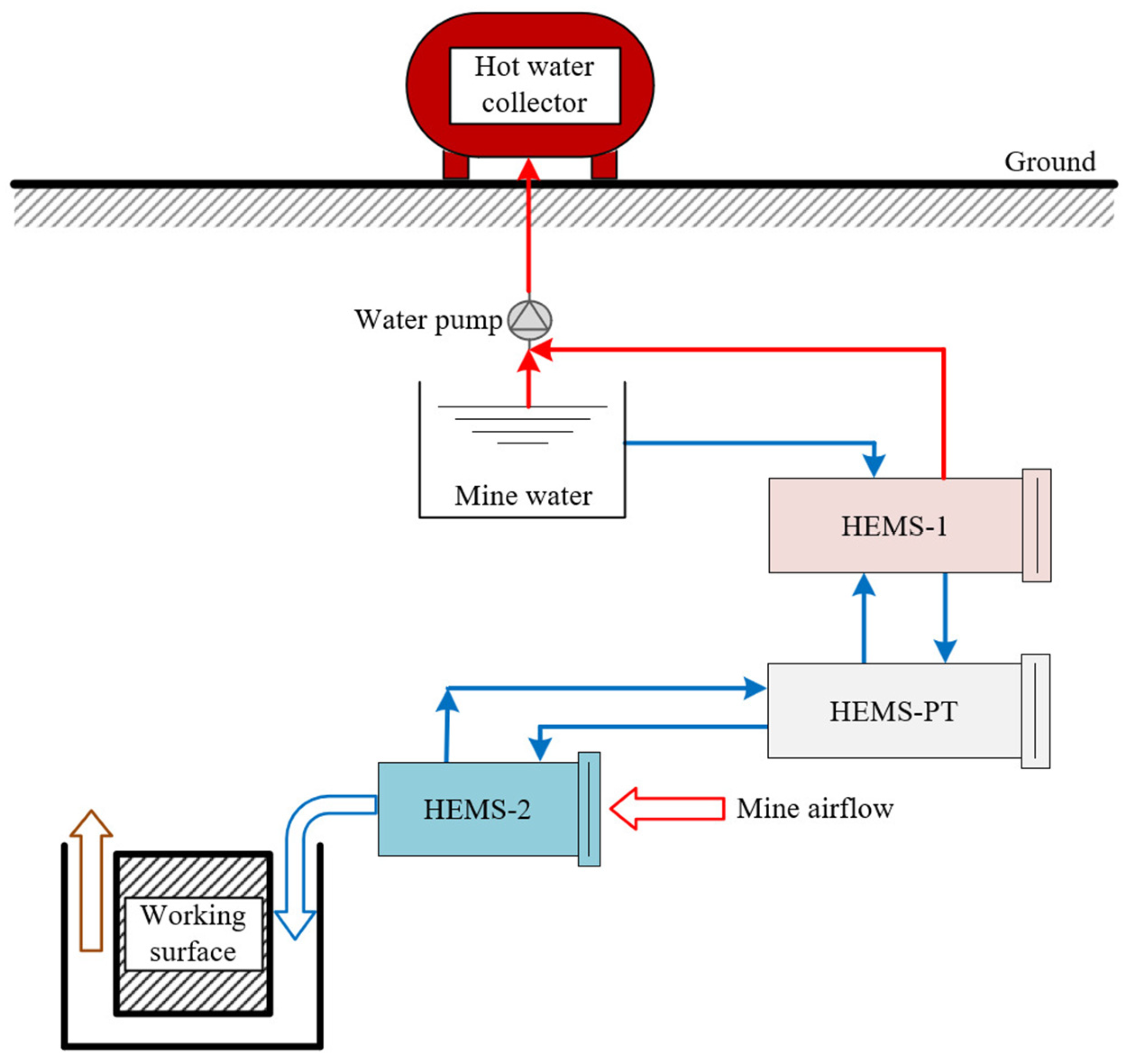

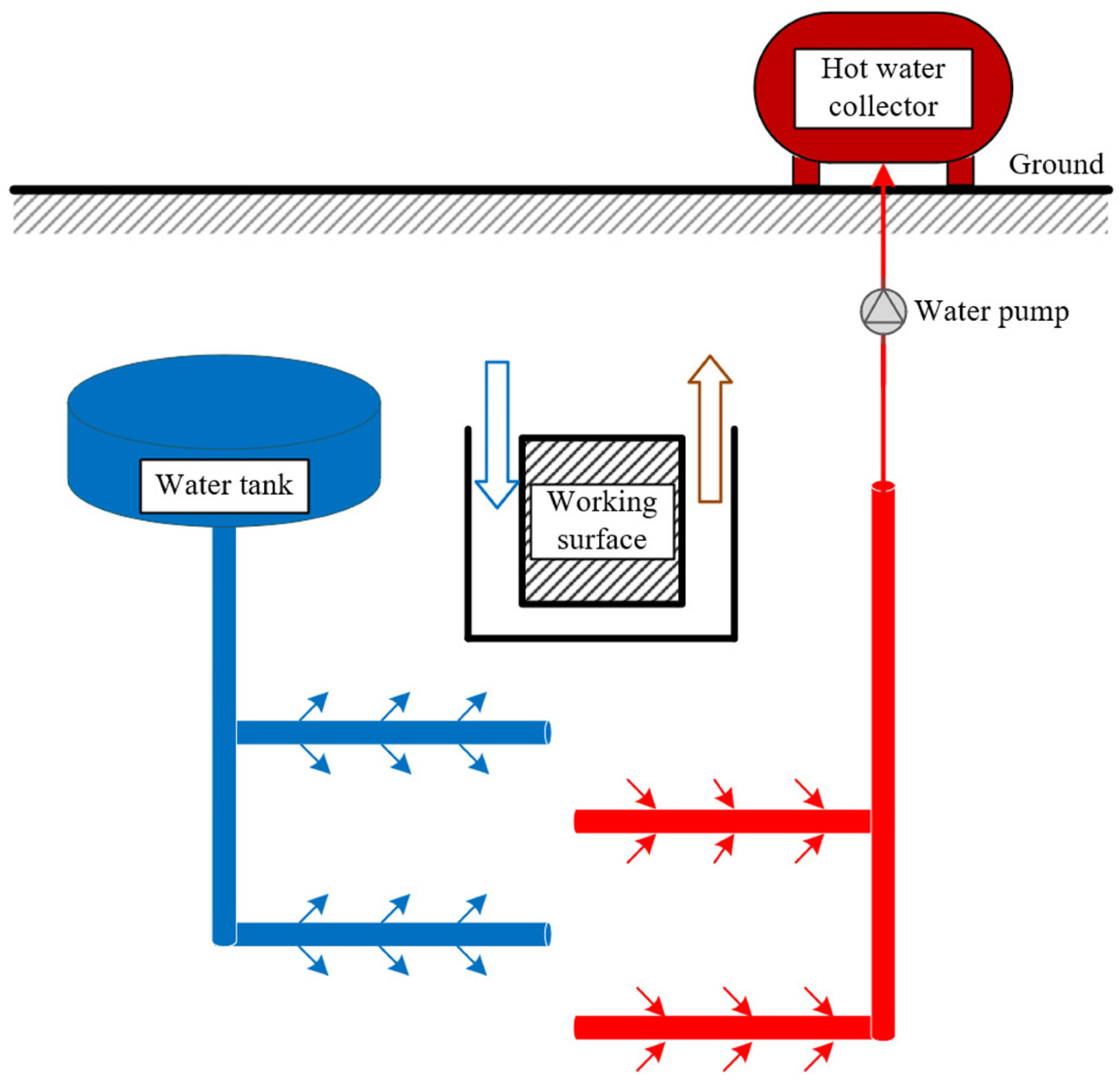

3.3.1. Deep-Mine Heat Damage Resource Utilization Systems

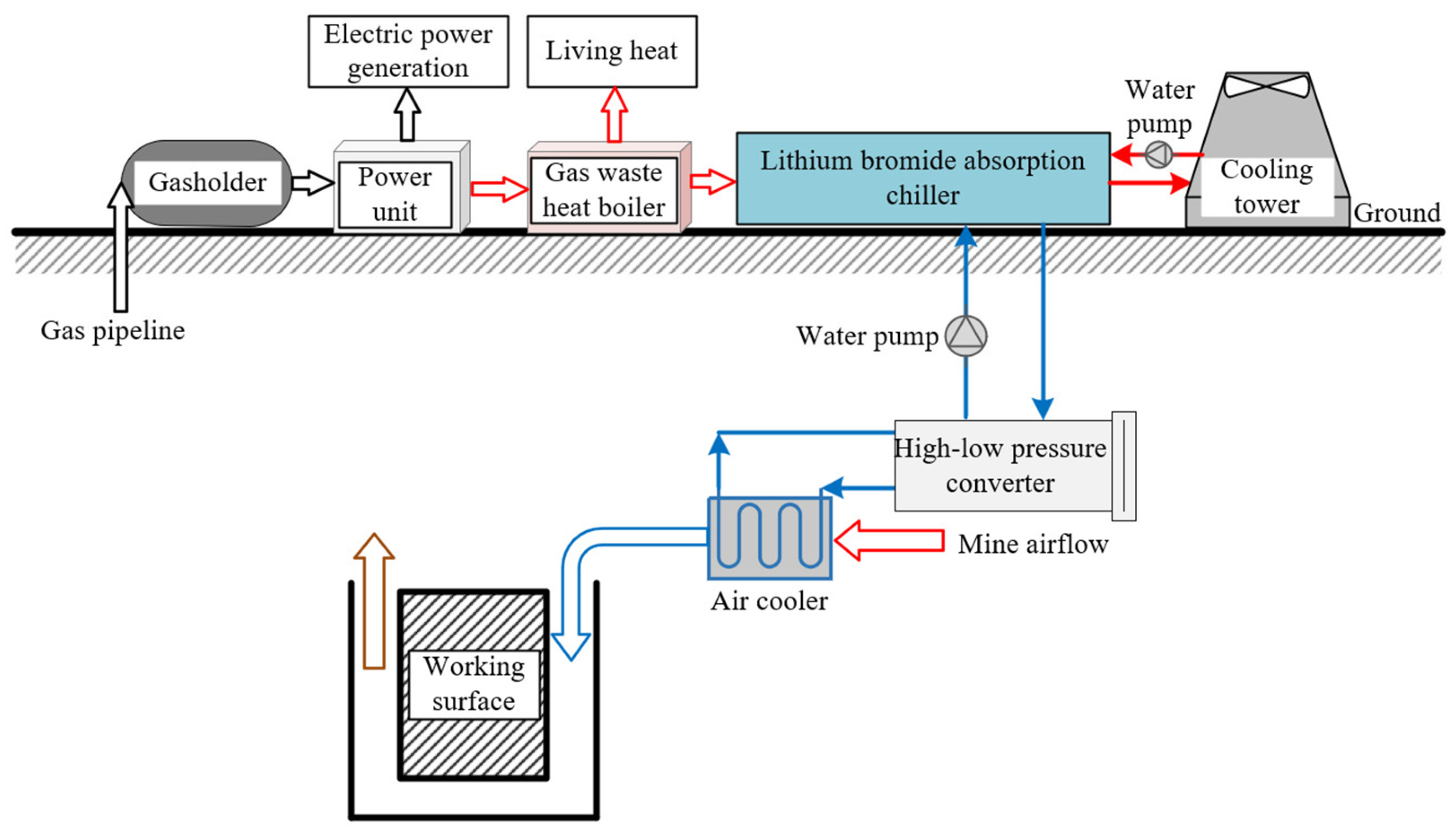

3.3.2. Combined Cooling, Heating, and Power Technology

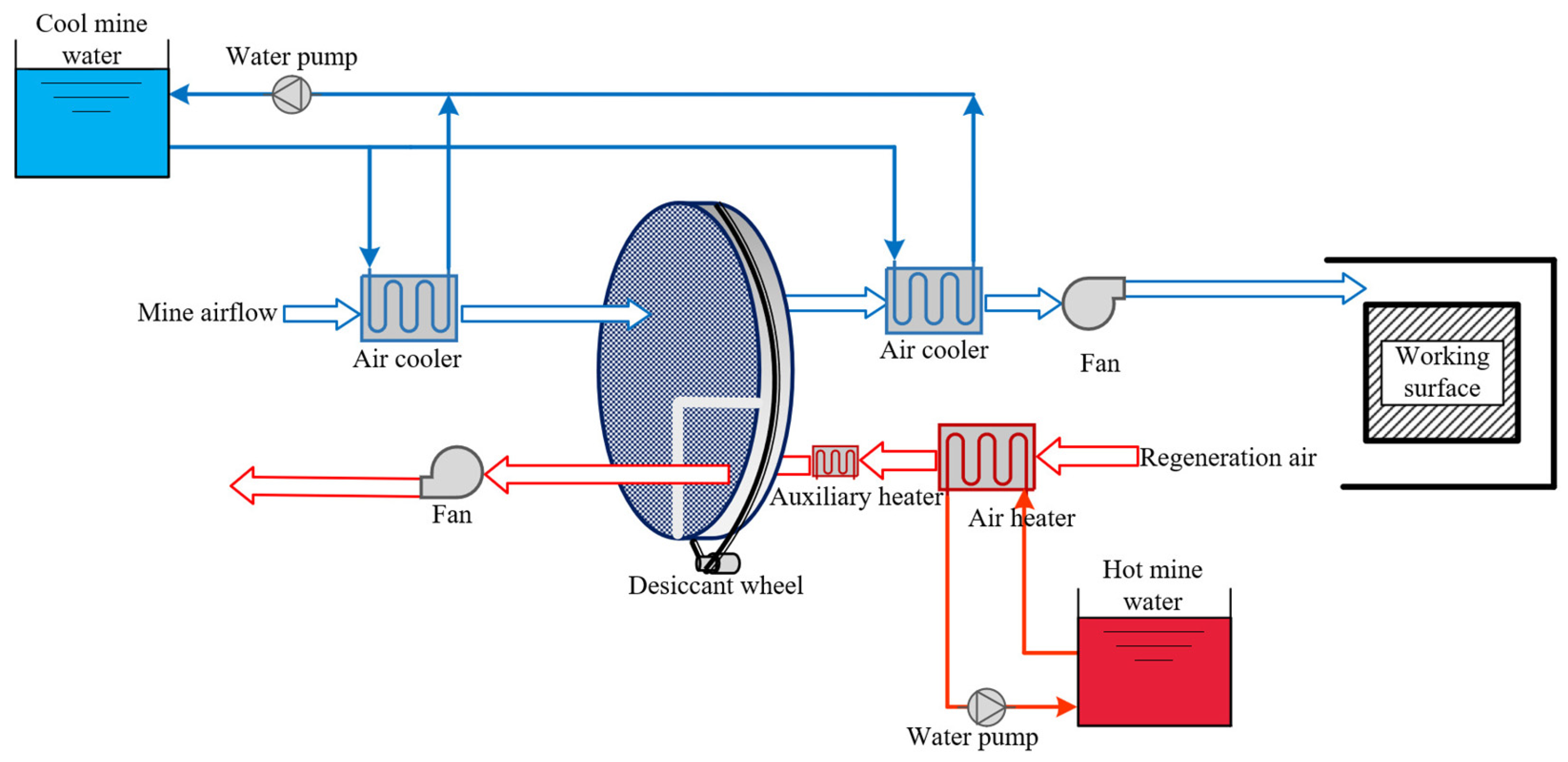

3.3.3. Deep Dehumidification and Cooling Technology

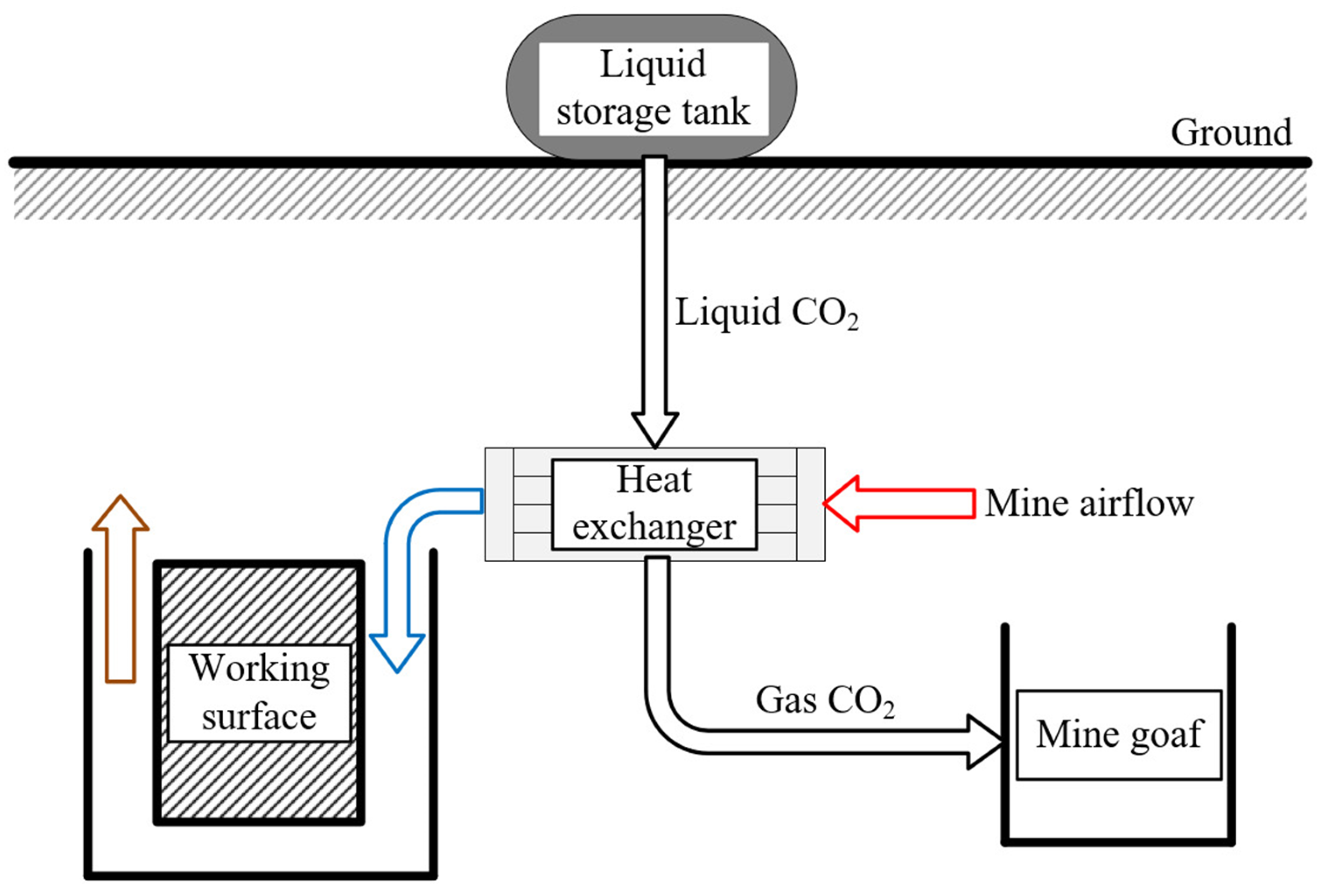

3.3.4. Liquid-Phase-Change Refrigeration Technology

3.3.5. Heat Pipe Cooling Technology

4. Prospect of Deep Mine Cooling Technology

4.1. Integration of Diverse Technologies

4.2. Collaboration Cooling and Geothermal Mining

4.3. Deep Dehumidification and Cooling

4.4. Intelligent Control

5. Conclusions

- (1)

- Deep-mine heat damage poses a significant challenge for mining with complex causes, including heat dissipation from the surrounding rock, production equipment, and air compression. High-temperature and high-humidity conditions exacerbate heat damage, adversely affecting the surrounding rocks, working environments, and supporting structures.

- (2)

- Conventional refrigeration cooling technologies, categorized by the refrigerant types as water-cooled, ice-cooled, and air-cooled, can reduce the air temperature at mine working faces. However, these methods are associated with high energy consumption, inadequate dehumidification capacity, and a significant loss of refrigeration capacity.

- (3)

- The deep-mine heat-damage resource utilization system and CCHP technology enable the simultaneous utilization of geothermal resource and mine cooling. These systems optimize energy efficiency by harnessing waste heat from deep-mine water and exhaust air, thereby enhancing overall energy utilization rates. Employing DWS and solution dehumidification technology addresses mine high-humidity-ratio issues and achieves effective cooling and dehumidification at mine working faces. Liquid-phase-change refrigeration technology and heat pipe cooling technology leverage phase transition principles to cool the working face air and enhance the system refrigeration capacity.

- (4)

- Regarding the future development of deep mine cooling technology, this paper proposes four key directions: the integration of diverse technologies, collaboration cooling and geothermal mining, deep dehumidification and cooling, and intelligent control. By evaluating the strengths and limitations of various cooling technologies, a coupled system can be employed to achieve comprehensive cooling and dehumidification at mine working faces. The integration of green and energy-efficient deep mine cooling technologies is crucial for achieving safe, efficient, and environmentally sustainable deep mining.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| COP | Coefficient of performance |

| d | Humidity ratio, g m−3 |

| E | Total investment, CNY |

| h | Enthalpy, kJ kg−1 |

| K | Cooling capacity value |

| K1 | Unit cooling investment value, CNY |

| L | Mine roadway length, m |

| ma | Airflow rate, m3 min−1 |

| M | Dehumidification capacity value |

| M1 | Unit dehumidification investment value, CNY/(g m−3) |

| qw | Waterflow rate, m3 h−1 |

| QC | Refrigeration capacity, kW |

| T | Temperature, °C |

| W | Total energy consumption, kW |

| Subscript | |

| in | Inlet |

| out | Outlet |

| d | Design |

| Abbreviations | |

| CCHP | Combined cooling, heating, and power |

| DWS | Desiccant wheel system |

| GCRCS | Ground centralized refrigeration cooling system |

| GHR&URCS | Ground heat removal underground refrigeration cooling system |

| HEMS | High temperature exchange machinery system |

| THM | Thermo-hydro-mechanical |

| UCRCS | Underground centralized refrigeration cooling system |

| WSHP | Water-source heat pump |

References

- Liu, X.; Song, G. Development status of coal industries in the worlds major coal-producing countries. J. S. Afr. Inst. Min. Metall. 2024, 124, 383–386. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Peng, S.; Guo, Y.; Liu, P. Development status and prospect of geological guarantee technology for intelligent coal mining in China. Green. Smart Min. Eng. 2024, 1, 433–446. [Google Scholar] [CrossRef]

- Cai, M.; Brown, E.T. Challenges in the mining and utilization of deep mineral resources. Engineering 2017, 3, 432–433. [Google Scholar] [CrossRef]

- Xie, H.; Konietzky, H.; Zhou, H.W. Special issue “deep mining” Rock. Mech. Rock. Eng. 2019, 52, 1415–1416. [Google Scholar] [CrossRef]

- Bian, M.; Dong, X. Numerical simulation of fluid-solid coupling heat transfer in excavation roadway. Mining. Metall. Explor. 2022, 39, 1475–1485. [Google Scholar] [CrossRef]

- Tong, X.; Guo, W.; Kang, K.; Qin, Y. Experimental evaluation of heat and moisture transmission characteristics of the working ensemble of hot coal mines using the thermal manikin. Int. J. Heat. Technol. 2017, 35, 836–842. [Google Scholar] [CrossRef]

- Friedman, L.; Almberg, K.; Cohen, R. Injuries associated with long working hours among employees in the US mining industry: Risk factors and adverse outcomes. Occup. Environ. Med. 2019, 76, 389–395. [Google Scholar] [CrossRef]

- National Mine Safety Administration. Coal Mine Safety Regulations; Coal Industry Publishing House: Beijing, China, 2022.

- GB 16423-2020; Safety Regulation for Metal and Nonmetal Mines. Coal Industry Publishing House: Beijing, China, 2020.

- You, B.; Chen, Y.; Yang, M.; Gao, K.; Cui, D.; Lu, M. Management of thermal hazards in deep mines in China: Applications and prospects of mine cooling technology. Water 2024, 16, 2347. [Google Scholar] [CrossRef]

- Qu, M.; Zhang, Y.; Zhang, X.; Mu, H.; Yin, S.; Liu, Y.; Meng, L. A review of the research progress of cooling technology in deep mining. J. Therm. Anal. Calorim. 2024, 149, 14535–14557. [Google Scholar] [CrossRef]

- Gao, J.; Li, S.; Wu, F.; Ma, L. Heat transfer model and thermal insulation characteristics of surrounding rock of thermal insulation roadway in a high-temperature mine. Sustainability 2023, 15, 12555. [Google Scholar] [CrossRef]

- Xie, Z. Distribution law of high temperature mine’s thermal environment parameters and study of heat damage’s causes. Procedia Eng. 2012, 43, 588–593. [Google Scholar] [CrossRef]

- Wagner, H. The management of heat flow in deep mines. Min. Rep. 2013, 149, 88–100. [Google Scholar] [CrossRef]

- Rabelo, N.; Lima, D.; Pinheiro, T.; Almeida, R.; Dantas, T.; Dantas, M.; Araujo, M.; Cavalcante, C.; Azevedo, D. Thermo-oxidative stability of mineral naphthenic insulating oils: Combined effect of antioxidants and metal passivator. Ind. Eng. Chem. Res. 2004, 43, 7428–7434. [Google Scholar] [CrossRef]

- Fan, B.; Shi, P.; Wan, Z.; Zhang, Y.; Xiong, L.; Hu, S.; Gou, H. Simulation study on the disaster-causing mechanism of geothermal water in deep high-temperature heat-damaged mines. Minerals 2022, 12, 1355. [Google Scholar] [CrossRef]

- Guo, D. Research on the effect of deep heat hazard on man-machine system efficiency in Sanshandao gold mine. Univ. Sci. Technol. Beijing 2022. [Google Scholar] [CrossRef]

- Wei, D.; Du, C.; Lin, Y.; Chang, B.; Wang, Y. Thermal environment assessment of deep mine based on analytic hierarchy process and fuzzy comprehensive evaluation. Case Stud. Therm. Eng. 2020, 19, 100618. [Google Scholar] [CrossRef]

- He, M.; Wu, Y.; Gao, Y.; Tao, Z. Research progress of rock mechanics in deep mining. J. Chin. Coal Soc. 2024, 49, 75–99. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, J.; Hou, T.; Wei, Y. Influence of high temperature on surrounding rock damage of underground coal gasification. J. Chin. Coal Soc. 2022, 47, 2270–2278. [Google Scholar] [CrossRef]

- Li, M.; Liu, X. Effect of thermal treatment on the physical and mechanical properties of sandstone: Insights from experiments and simulations. Rock. Mech. Rock. Eng. 2022, 55, 3171–3194. [Google Scholar] [CrossRef]

- Maurya, T.; Karena, K.; Vardhan, H.; Aruna, M.; Raj, M. Effect of heat on underground mine workers. Procedia Earth. Planet. Sci. 2015, 11, 491–498. [Google Scholar] [CrossRef]

- Setyawan, H.; Qodrijati, I.; Widjanarti, M.; Rinawati, S.; Atmojo, T.; Fajariani, R.; Wardhani, T.; Utomo, E. The impact of hot work climate on textile industry productivity. IOP Conf. Ser. Earth. Environ. Sci. IOP Publ. 2018, 200, 012053. [Google Scholar] [CrossRef]

- Shu, H.; Li, N.; Dong, L.; Luo, Q.; Sabao, A. Thermal humidity risk assessment in high-temperature environment of mines based on uncertainty measurement theory. Case Stud. Therm. Eng. 2023, 50, 103401. [Google Scholar] [CrossRef]

- Ismail, A.; Jusoh, N.; Makhtar, N.; Zein, R.; Rahman, I.; Wahab, S.; Othman, R. Experimental study on human physiology during repetitive workload simulated under high temperature and high relative humidity. J. Phys. Conf. Ser. IOP Publ. 2021, 1793, 012077. [Google Scholar] [CrossRef]

- Li, J.; Yang, L.; Song, T.; Qi, R. Research on the effects of the high temperature and humidity environment on human comfort in coal mine emergency refuge system. Safety 2019, 5, 28. [Google Scholar] [CrossRef]

- Cramer, M.; Gagnon, D.; Laitano, O.; Crandall, C. Human temperature regulation under heat stress in health, disease, and injury. Physiol. Rev. 2022, 102, 1907–1989. [Google Scholar] [CrossRef]

- Liu, X.; Yao, Z.; Xue, W.; Wang, X.; Huang, X. Experimental study of the failure mechanism of the anchorage interface under different surrounding rock strengths and ambient temperatures. Adv. Civ. Eng. 2021, 1, 6622418. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, S.; Li, S.; Li, D.; Jiang, F.; Zhang, X.; Chen, Y.; Meng, X. Mechanism and prediction of anchor rod strength degradation with deep mine high-stress corrosion environment. J. Chin. Coal Soc. 2024, 49, 4295–4310. [Google Scholar] [CrossRef]

- Kang, H. Sixty years development and prospects of rock bolting technology for underground coal mine roadways in China. J. China Univ. Min. Technol. 2016, 45, 1071–1081. [Google Scholar] [CrossRef]

- Mctyer, K. The effect of elevated temperature on resin-anchored rock bolts. Res. Online 2020, 163, 163–174. [Google Scholar]

- Qin, J.; Li, X.; Zhou, Z.; Yu, X.; Shang, X.; Ren, W.; Jia, H. Experimental study on the influence of ground temperature on coal spontaneous combustion characteristics with different metamorphic degree. China Min. Mag. 2024, 33, 186–192. [Google Scholar] [CrossRef]

- Zhang, Y. Influence of temperature and pressure on desorption law of coalbed methane. Contemp. Chem. Ind. 2025, 54, 513–516. [Google Scholar] [CrossRef]

- Chen, C.; Chen, L.; Zhao, Y. Study on solar and mine water complementary desiccant wheel air conditioning. Renew. Energy Resour. 2023, 41, 1587–1595. [Google Scholar] [CrossRef]

- He, M.; Guo, P. Thermodynamics and Thermal Control Technology of Deep Rocks; Science Press: Beijing, China, 2017. [Google Scholar]

- He, M.; Guo, P. Deep rock mass thermodynamic effect and temperature control measures. Chin. J. Rock Mech. Eng. 2013, 32, 2377–2393. [Google Scholar]

- Yan, M. Research and application of cooling technology in Weijiagou colliery. Min. Proc. Equip. 2018, 46, 56–58. [Google Scholar] [CrossRef]

- Chen, W.; Liang, S.; Liu, J. Proposed split-type vapor compression refrigerator for heat hazard control in deep mines. Appl. Thermal. Eng. 2016, 105, 425–435. [Google Scholar] [CrossRef]

- Sithole, S.; Gous, A.; Schutte, C. A dynamic simulation model for optimal deep-level mine cooling management and operational decision-making for eskom’s load curtailment. S. Afr. J. Ind. Eng. 2023, 34, 68–83. [Google Scholar] [CrossRef]

- Crawford, J.; Joubert, H.; Mathews, M.; Kleingeld, M. Optimised dynamic control philosophy for improved performance of mine cooling systems. Appl. Thermal. Eng. 2019, 150, 50–60. [Google Scholar] [CrossRef]

- Zhao, X. Design of mine cooling system for WBM coal mine in Indonesia. Inner Mongolia Coal Econ. 2022, 17, 14–17. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, F.; Liu, Q.; Xu, Y.; Li, D. Engineering practice of ground centralized cooling for Shoushan No. 1 Mine. Coal Eng. 2020, 52, 94–97. Available online: http://www.coale.com.cn/CN/10.11799/ce202011019 (accessed on 3 July 2025).

- Guo, P.; Wang, Y.; Duan, M.; Peng, D.; Li, N. Research and application of methods for effectiveness evaluation of mine cooling system. Int. J. Min. Sci. Technol. 2015, 25, 649–654. [Google Scholar] [CrossRef]

- Wang, K.; Li, Q.; Wang, J.; Yang, S. Thermodynamic characteristics of deep space: Hot hazard control case study in 1010-m-deep mine. Case Stud. Therm. Eng. 2021, 28, 101656. [Google Scholar] [CrossRef]

- Yan, M. Research and application of underground centralized cooling technology in Yangcheng coal mine. Coal Mine Mach. 2018, 39, 120–122. [Google Scholar] [CrossRef]

- Zhang, X. Application of ZLS-3300 refrigeration device in centralized cooling system in underground mine. Min. Process. Eq. 2020, 48, 62–65. [Google Scholar] [CrossRef]

- Zhou, T.; Xiang, D.; Chen, Y.; Wang, G. Engineering practice and discussion on condensing heat emission during local cooling engineering. Chin. Coal 2012, 38, 90–94. [Google Scholar] [CrossRef]

- Wang, L. Study on the application of medium refrigeration and cooling technology in the treatment of thermal damage in Yangcheng coal mine. Mod. Ind. Econ. Inform. 2018, 8, 85–86+93. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, M. EER test and analysis of surface ice cooling system for coal mine. Int. J. Low-Carbon Tec. 2020, 15, 382–388. [Google Scholar] [CrossRef]

- Bu, F.; Zhang, M.; Meng, X.; Liu, Q. Application of natural ice cold storage in mine cooling. Coal Technol. 2015, 34, 158–160. [Google Scholar] [CrossRef]

- Yuan, S. Application of ice making and cooling technology in high temperature min. Inner Mong. Coal Econ. 2018, 14, 135–143. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, S. The present situation and existing problems of artificial refrigeration cooling technology of coal mine in China. J. Zhongyuan Univ. Technol. 2016, 27, 66–69. [Google Scholar] [CrossRef]

- Hu, C.; Zhou, X. Compressed air refrigeration technology applied to Barapukuria Mine in Bangladesh. Coal Eng. 2005, 11, 37–39. [Google Scholar] [CrossRef]

- Guo, P.; Qin, F. Preventive measures against heat hazard and its utilization in Zhangshuanglou coal mine. Chin. Coal Soc. 2013, 38, 393–398. [Google Scholar] [CrossRef]

- He, M.; Xu, M. Research and development of HEMS cooling system and heat-harm control in deep mine. Chin. J. Rock Mech. Eng. 2008, 7, 1353–1361. [Google Scholar]

- He, M. Application of HEMS cooling technology in deep mine heat hazard control. Min. Sci. Technol. 2009, 19, 269–275. [Google Scholar] [CrossRef]

- He, M. Research and development on hems cooling system and heat-harm control in deep mine. Chin. Basic Sci. 2008, 10, 11–16. [Google Scholar] [CrossRef]

- Han, Q.; Zhang, Y.; Li, K.; Zou, S. Computational evaluation of cooling system under deep hot and humid coal mine in China: A thermal comfort study. Tunn. Undergr. Space Tech. 2019, 90, 394–403. [Google Scholar] [CrossRef]

- Gao, T.; Yue, F.; Wei, J.; Wu, X. Study of the heat pump integrated system combined mine cooling and heat storage with variable working condition. Coal Eng. 2017, 49, 118–121. [Google Scholar] [CrossRef]

- Feng, X.; Jia, Z.; Liang, H.; Wang, Z.; Wang, B.; Jiang, X.; Cao, H.; Sun, X. A full air cooling and heating system based on mine water source. Appl. Thermal. Eng. 2018, 145, 610–617. [Google Scholar] [CrossRef]

- Niu, Y. Integration technology research on mine cooling and heat energy utilization. Saf. Coal Min. 2017, 48, 84–87. [Google Scholar] [CrossRef]

- Guo, P.; Chen, C. Field experimental study on the cooling effect of mine cooling system acquiring cold source from return air. Int. J. Min. Sci. Technol. 2013, 23, 453–456. [Google Scholar] [CrossRef]

- Liu, J. Application of heat pump technology in coal mine. Adv. Mater. Res. 2012, 562, 1083–1086. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Chen, Y.; Jia, M.; Zhang, M.; Li, R. Synergetic mining of geothermal energy in deep mines: An innovative method for heat hazard control. Appl. Thermal. Eng. 2022, 210, 118398. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Tao, M.; Jalilinasrababy, S.; Wang, J.; Li, G.; Zhong, K. An investigation into the effect of water injection parameters on synergetic mining of geothermal energy in mines. J. Clean. Prod. 2023, 382, 135256. [Google Scholar] [CrossRef]

- Zhang, L.; Dieudonné, A.C.; Daniilidis, A.; Dong, L.; Cao, W.; Thibaut, R.; Tas, L.; Hermans, T. Thermo-hydro-mechanical modeling of geothermal energy systems in deep mines: Uncertainty quantification and design optimization. Appl. Energy 2025, 377, 124531. [Google Scholar] [CrossRef]

- Liu, M.; Shi, Y.; Fang, F. Combined cooling, heating and power systems: A survey. Renew. Sustain. Energy Rev. 2014, 35, 1–22. [Google Scholar] [CrossRef]

- Chen, L.; Han, G. The implementation of power plant waste heat for mine cooling engineering equipment installation. Sci. Technol. Innov. 2014, 17, 21. [Google Scholar] [CrossRef]

- Yang, D.; Wang, B.; Zhou, S.; Qin, R. Application of CCHP in deep mine thermal hazard control. Coal Eng. 2012, 36, 443–451. [Google Scholar] [CrossRef]

- Yang, Q.; Du, X. Application of absorption refrigeration in the coal mine & fluent simulation. Mod. Manuf. Technol. Eq. 2015, 57–59. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Lai, X.; Wang, G.; Sang, C. Investigation of heat stress and thermal response in deep hot-humid underground environments: A field and experimental study. Build. Environ. 2025, 270, 112506. [Google Scholar] [CrossRef]

- Tu, Y.; Wang, R.; Ge, T. New concept of desiccant-enhanced heat pump. Enery. Convers. Manag. 2018, 156, 568–574. [Google Scholar] [CrossRef]

- Abd-Elhady, M.; El-Sharkawy, I.; Hamed, A.; Salem, M. Performance evaluation of a novel multi-tray packed bed solid desiccant dehumidification system. Int. J. Refrig. 2023, 146, 403–415. [Google Scholar] [CrossRef]

- Yadav, L.; Verma, A. Evolution of purge with multi-sector, novel designs, and configurations of desiccant wheels: A technical review. Int. J. Refrig. 2024, 167, 102–117. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, L. A comprehensive review of low dew-point desiccant wheel system: Mechanisms, configuration, and optimization. Int. J. Refrig. 2024, 168, 345–363. [Google Scholar] [CrossRef]

- Lin, F.; Jin, L.; Huang, Z.; Huang, F. Experimental study on dehumidification performance of mine desiccant applied in refuge chamber. J. Saf. Sci. Technol. 2015, 11, 51–56. [Google Scholar] [CrossRef]

- Chen, L.; Liu, L.; Zhang, B.; Zhang, X.; Wang, M. Mechanism of backfill thermal utilization adsorption cooling system in deep mine. J. Chin. Coal Soc. 2018, 43, 483–489. [Google Scholar] [CrossRef]

- Ji, H.; Zhang, J.; Fan, H.; Chen, L. Development of mine cooling system with mine influx water cold-heat method. J. Xi’an Univ. Sci. Technol. 2022, 42, 83–90. [Google Scholar] [CrossRef]

- Fahad, F.; Al-Humairi, S.; Al-Ezzi, A.; Majdi, H.; Sultan, A.; Alhuzaymi, T.; Aljuwaya, T. Advancements in liquid desiccant technologies: A comprehensive review of materials, systems, and applications. Sustainability 2023, 15, 14021. [Google Scholar] [CrossRef]

- Cao, Y.; Gao, W.; Lou, Z.; Song, D. Research and application of centralized local cooling and dehumidification device in working face. Inner Mong. Coal Econ. 2015, 191–198. [Google Scholar] [CrossRef]

- Guo, Z.; Miao, D.; Kong, L. Research on performance of mine dehumidification and cooling system based on heat pump. IOP Conf. Ser. Earth. Environ. Sci. IOP Publ. 2021, 647, 012083. [Google Scholar] [CrossRef]

- Song, D.; Zhou, X.; Li, J.; Bai, G. Liquid carbon dioxide phase-change refrigeration and cooling technology of high temperature mine. Coal Sci. Technol. 2017, 45, 82–87. [Google Scholar] [CrossRef]

- Zhai, X.; Xu, Y.; Yu, Z. Design and performance simulation of a novel liquid CO2 cycle refrigeration system for heat hazard control in coal mines. J. Therm. Sci. 2019, 28, 585–595. [Google Scholar] [CrossRef]

- Xi, S.; Zhang, Q.; Zhang, L. Feasibility analysis of mixed cooling with liquid nitrogen and liquid oxygen. Coal Eng. 2018, 50, 13–15. Available online: http://www.coale.com.cn/CN/10.11799/ce201804004 (accessed on 3 July 2025).

- Su, M. Application of gravity heat pipe in mine air-conditioning system. Coal Mine Mach. 2008, 11, 161–162. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, Q.; Yu, X. Exploration of separated heat pipe in mine cooling. Coal Eng. 2007, 50–51. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, J.; Chang, D.; Chu, Y.; Cao, X.; Li, Y. Experimental study on deep mine geothermal hazard control based on heat pump and power heat pipe. Met. Mine 2020, 01, 101–107. [Google Scholar] [CrossRef]

| Performance | Index | Equation | Meaning | Reference | |

|---|---|---|---|---|---|

| Cooling performance | System temperature difference | (1) | Air temperature difference between inlet and outlet. | [34] | |

| Cooling capacity value | (2) | Cooling capacity of the system. | [35,36] | ||

| Unit cooling investment value | (3) | The investment required to reduce the air temperature by 1 °C. | [35,36] | ||

| Dehumidification performance | System humidity ratio difference | (4) | Air humidity difference between inlet and outlet. | [34] | |

| Dehumidification capacity value | (5) | Dehumidification capacity of the system. | [35,36] | ||

| Unit dehumidification investment value | (6) | The investment required to reduce the air humidity ratio by 1 g/kg. | [35,36] | ||

| Overall system performance | Refrigeration capacity | (7) | The system refrigeration capacity. | [37] | |

| Coefficient of performance (COP) | (8) | The ratio of refrigeration capacity to total energy consumption. | [34] | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Chen, L.; Zhang, J.; Ji, H. Research Progress of Heat Damage Prevention and Control Technology in Deep Mine. Sustainability 2025, 17, 6200. https://doi.org/10.3390/su17136200

Xu Y, Chen L, Zhang J, Ji H. Research Progress of Heat Damage Prevention and Control Technology in Deep Mine. Sustainability. 2025; 17(13):6200. https://doi.org/10.3390/su17136200

Chicago/Turabian StyleXu, Yujie, Liu Chen, Jin Zhang, and Haiwei Ji. 2025. "Research Progress of Heat Damage Prevention and Control Technology in Deep Mine" Sustainability 17, no. 13: 6200. https://doi.org/10.3390/su17136200

APA StyleXu, Y., Chen, L., Zhang, J., & Ji, H. (2025). Research Progress of Heat Damage Prevention and Control Technology in Deep Mine. Sustainability, 17(13), 6200. https://doi.org/10.3390/su17136200