Abstract

The cosmetic industry is an important economic sector with expected growth in the upcoming years and a noticeable trend towards sustainable products and product packaging options. A critical aspect of packaging sustainability is the amount of product residue left in emptied containers, as this contributes to both economic losses for consumers and environmental waste. In this study, the emptiability of different packaging systems for shampoo, hair gel, hand cream, body lotion, face cream, eye cream, and serum is assessed by developing novel testing methods. The results show a significant dependence of emptiability on the packaging system and product properties. While jars and airless pump dispensers retain less than 1% of product residues for hand cream products, pump dispensers’ values of up to 26% were found. These results underline the importance of optimal packaging choices adapted to different products to avoid economic losses for the consumer, environmental impact due to wasted products, and a negative influence on the recyclability of packaging and quality of the recyclate. Manufacturers can use these insights to design packaging that not only reduces leftover product but also aligns with circular economy principles, ultimately lowering environmental impacts and improving consumer satisfaction.

1. Introduction

Personal care products and cosmetics play an essential role in today’s society and are products used on a day-to-day basis [1,2].

Cosmetics are defined by Article 2.1 of Regulation 1223/2209 on cosmetic products by the European Commission as “any substance or mixture intended to be placed in contact with the external parts of the human body (epidermis, hair system, nails, lips and external genital organs) or with the teeth and the mucous membranes of the oral cavity with a view exclusively or mainly to cleaning them, perfuming them, changing their appearance, protecting them, keeping them in good condition or correcting body odors”, and can be categorized into perfumes, sun care, oral care, decorative cosmetics (lipstick, nail varnishes, mascara, powders), hair care (shampoo, mousses, colorants), body care (soaps, shower gels, body lotions), and skin care (facial masks, eye cream, exfoliators, sera) [3]. The cosmetic market in Germany generated over EUR 6.1 bn in 2022 [4] and, in Austria, EUR 1.8 bn [5], and is expected to grow further in the upcoming years. This puts the cosmetic industry under pressure, as brands must embrace innovative packaging designs to meet consumer demands for individualized needs [6,7].

Forecasted growth in the cosmetic market also results in challenges of environmental pressure through the product as well as the packaging [1,8]. Packaging must fulfill certain requirements, such as product protection, logistics, convenience, and communication with the consumer [9]. In addition to those main requirements, the packaging needs to perform in the filling process, be compatible with the product, and needs to fit the desired brand images [9].

The packaging in contact with the product is defined as primary packaging. Its purpose is, first and foremost, the protection of the product from factors such as air, light, and moisture [9]. Cosmetic packaging is primarily made from plastics, but glass, metals, and fiber-based packaging are also broadly used [8].

Sustainability in the context of packaging refers to the packaging circularity, the circular recycling, and the effect of food loss and waste [10], which can be equaled to the loss and waste of non-food product waste.

1.1. Residues in Packaging

The amount of product residues is dependent on several factors, from the filling good, such as the viscosity, elasticity, and surface tension, to packaging properties, such as hydrophilicity, roughness, and surface tension [11]. Moreover, consumer behavior and packaging design play an important role [11].

Existing literature on emptiability so far focusses on dairy products, which are predominantly packed in bottles, cups, and beverage cartons, while the packaging system utilized for cosmetic packaging has not, until now, been covered by the scientific literature [12,13,14]. Literature on emptiability of dairy products has, thereby, found three major influences on residue amounts within packaging [12]:

- Packaging system: the choice of packaging system can influence the amount of retained product. It has been found that bottles retain, overall, less product than beverage cartons for liquid dairy products, such as protein drinks or whey drinks.

- Packaging design: the design of beverage cartons is crucial, as shown in the case for whey drinks. Three differently shaped cartons have been found to retain 0.50%, 0.73%, and 1.04% of the same product, respectively.

- Consumer handling: information on product handling can impact the amount of food residues found in emptied packaging. In the case of buttermilk in a beverage carton, the information to shake before opening lead to a reduction of residues from 4.49% to 1.01%.

So far, one study, by Schinkel et al., (2023), has investigated product residue amounts entering recycling facilities [15]. This aspect is of great importance, as residues inside packaging can influence near-infrared (NIR) detection during the sorting process [16]. In a later stage, those impurities can negatively influence the quality of the recyclate [17]. As another factor, wastewater quality from the washing process after sorting is impacted by high residue amounts of greasy cosmetic products, causing additional costs [12,18].

As described by Schmidt, (2011), improved emptiability results in several benefits. All product can be extracted from the packaging and can be used by the consumer, limiting the need for consumption and production and, therefore, economic costs [11]. On the other hand, the packaging enters the end-of-life stage in a cleaner state, which leads to an easier cleaning process and reduces costs for energy and water and results in high-quality recyclate [11]. Schmidt, (2011) identified that complex packaging systems such as roll-on deodorant or pump dispensers, as well as packaging for a small filling volume, are prone to retaining high amounts of residues. Again, the latter aspect is highly relevant, as expensive medical or cosmetic products are primarily packaged in smaller-sized packaging [11].

Only few regulations and official documents recognize the importance and benefits of an improved emptiability behavior of packaging. One of those documents is the Code of Practice, published by INCPEN in the UK [19]. These guidelines aim to challenge the design of existing packaging, while ensuring product safety, product protection, and minimal environmental impact. Code 3 covers convenience in use, with Section 3.2

mentioning the importance of minimal residues after emptying.

The packaging and packaging waste regulation (PPWR) identifies several barriers to packaging recycling, of which one is the contamination by remaining food or product residues due to a bad emptiability behavior. The details can be found in the Impact Assessment Report accompanying the current draft of the PPWR. In anticipation of forthcoming legislation concerning the circularity and recyclability of packaging, it is vital to acknowledge that products of high viscosity in inadequately designed packaging systems present a considerable challenge, as the inability to achieve complete emptying can result in the production of low-quality recyclates [11]. At present, there is no established, standardized methodology for measuring the emptiability of packaging systems and products. Furthermore, no clear thresholds have been defined.

1.2. Aim of This Study

This study was conducted within the framework of a sustainability assessment of cosmetic packaging in the DACH region (Germany, Austria and Switzerland). The aspect of product residues is incorporated in the form of the parameter of emptiability. Emptiability is described as the amount of remaining product in the packaging after standardized emptying of the packaging and is found to cause environmental effects as unutilized products are discarded [12,13].

The objective is the development of novel, standardized methods for the emptying of packaging systems typically utilized in the cosmetic industry, including shampoo, hair gel, hand cream, body lotion, facial and eye cream, and serum. The hereby proposed method for standardized measurement of emptiability is, therefore, the first attempt to describe emptiability for these products and packaging types.

The development of the aforementioned methods allows for the quantification of the amount of product remaining in diverse packaging systems for different cosmetic products.

Moreover, the present study makes a direct contribution to Sustainable Development Goal 12 (Responsible Consumption and Production) by providing a scientific basis for the improvement of packaging designs that minimize product waste. By quantifying residual product levels, manufacturers can optimize packaging to ensure higher emptiability, thereby reducing the unnecessary disposal of unutilized products. This is in alignment with Target 12.5, which aims to substantially reduce waste generation through prevention, reduction, recycling, and reuse [20]. Improved emptiability has also been demonstrated to enhance packaging recyclability, thereby supporting Target 12.2 on efficient resource use [20]. Ultimately, these findings have the potential to drive more sustainable packaging solutions in the cosmetic industry, leading to lower material waste, improved consumer satisfaction, and a reduced environmental footprint.

2. Materials and Methods

The selected regional focus is the cosmetic industry in Germany, Austria, and Switzerland. Product samples were either purchased at different supermarkets or provided by retailers, producers, and packaging manufacturers from the respective area. In total, 124 articles were selected for testing and categorized into the product categories of shampoo, hair gel and wax, hand cream, body lotion, face cream, eye cream, and serum.

2.1. Market Screening

The market screening was conducted in three drug stores in Austria, namely DM, BIPA, and Müller, which hold a market share of 80% according to data from 2019 [21]. All cosmetic products from the assessed product categories that were available online were listed, and detailed information concerning product type in combination with packaging specificities was analyzed.

2.2. Product Categories

The assessed product categories were shampoo, hair gel and wax, hand cream, body lotion, face cream, eye cream, and serum. These categories were selected based on their significance within the cosmetics market, representing major product segments with high consumer demand. Additionally, these products are available in a wide variety of packaging systems, such as bottles, tubes, jars, and pump dispensers, allowing for a comprehensive evaluation of emptiability across different packaging types. The selection also ensures comparability among different product groups, as they vary in formulation and viscosity while still being commonly packaged in similar container types, enabling meaningful cross-category analysis.

2.3. Emptiability Method Development

Novel methods were developed to measure the residual emptying capacity depending on the packaging system. These methods were designed to realistically represent the behavior of an environmentally conscious consumer, characterized by common product usage practices aimed at minimizing waste. The emptying process was standardized to reflect typical consumer actions, such as shaking, squeezing, scraping, or pumping the product until no further reasonable effort would yield additional material, without damaging the packaging. Each product was obtained and tested in triplicates (n = 3) to ensure consistency and reproducibility of the results.

At the beginning of the measurements, the samples were kept upright at 23 °C for at least 24 h, and the full weight (packaging with contents) was measured. Once the emptying process was complete (as described in Section 2.3.1, Section 2.3.2, Section 2.3.3, Section 2.3.4, Section 2.3.5, Section 2.3.6, Section 2.3.7, Section 2.3.8 and Section 2.3.9 depending on the packaging system), the packaging was washed and left to dry for a minimum of 48 h to allow for the determination of the weight of the packaging (excluding its contents).

For the analysis of the results, arithmetic averages and standard deviations from the triplicates from each sample were drawn, as previously done by Wohner et al., (2019) [16].

2.3.1. Tubes

The process of emptying tubes was as follows: first, the tube was held between the thumb and the index finger on the palate and emptied with a constant pressing movement towards the tube opening. This movement was repeated three times. In the next step, the shoulder area was pressed in on both sides with the thumbs, and the cap was folded over to both sides, one after the other, until no more product could be extracted. Subsequently, the packaging was weighed for the first time, including the residual contents, and stored at 23 °C for 24 h in an upright position. On the following day, the process was repeated, and the weight was measured once more.

2.3.2. Tubes with Roll-On Applicator

The removal of the product was conducted in a manner analogous to that employed for tubes. The product was collected over the applicator using an absorbent cloth until no further product flowed out.

2.3.3. Jars

The process of emptying jars involved the manual removal of the product from its packaging and the subsequent weighing of the packaging, including the remaining contents.

2.3.4. Squeeze Bottles

The procedure for emptying bottles involved holding the bottle upside down and pressing it for five seconds. This drew air back into the bottle, after which the process was repeated until the jet stopped flowing. The bottle was then closed and knocked upside down three times, after which the process from the first step was repeated. The emptied packaging was then weighed for the first time with the remaining contents. Subsequently, the bottle was stored in an inverted position at a temperature of 23 °C for 24 h. On the following day, the bottle was subjected to a second emptying process until the jet broke off, after which a second weight measurement was conducted.

2.3.5. Pump Dispensers

The pump dispenser was operated until no more product could be removed after three pumps. Following an initial weighing, the pump dispenser was stored upright at 23 °C for 24 h. The process was repeated the following day, and the weight was determined again. In the next step, the cap was unscrewed from the bottle body, and any remaining product was wiped off the dispensing tube by hand. The bottle body was then inverted three times to remove any residual material. The packaging was then weighed a third time, including any remaining product residue.

2.3.6. Airless Pump Dispensers, Airless Jars, Bag-in-Bottle Systems

In airless packaging systems, the pump mechanism was operated until no product could be removed after three pumps. The packaging, including any residual material, was weighed and the process was repeated after 24 h of storage at 23 °C.

2.3.7. Pouches and Sachets

Pouches and sachets were held upside down for emptying and rolled up tightly from the end to the opening. The scale was then used to determine the packaging weight and amount of product residue. The packaging was stored upside down for 24 h at 23 °C and the process and measurement were repeated the following day.

2.3.8. Dropper/Pipette Bottles

As much product as possible was removed using a pipette, and the packaging, including residues, was then weighted. Following a 24 h storage period at 23 °C, the procedure was repeated. The bottle was then emptied upside down for ten seconds, and a final measurement was taken.

2.3.9. Canister

The canister was emptied upside down until the jet broke off. After measuring the weight of the packaging and the product residue it contained, the canister was stored upside down for 24 h at 23 °C, and the process was repeated the following day. During the emptying process, the opening of the canister was maintained in a parallel orientation to the tabletop.

3. Results

Results are described individually for the six specific product categories. Additionally, as certain products are sold in the same packaging and, in other cases, the same product is sold in different packaging options, direct comparisons are also drawn.

3.1. Market Research

The findings of the market research conducted on the product categories of shampoo, hair gel, hand cream, and body lotion are presented in Table 1. The results for face cream, eye cream, and serum are presented in the Supporting Information. In the case of shampoo, the predominant packaging format is a squeeze bottle, which accounts for 81.44% of the market share. The second, comparatively less popular packaging option for shampoo is a tube, which was used in 80 products and accounts for a market share of 11.08%. Pump dispensers and pouches are relatively uncommon packaging formats, representing only 5.82% and 1.66% of products, respectively. In the product category of hair gel, most products are available in tubes (41.44%) and jars (48.65%). A similar tendency was observed in the sampled products, with 11 out of 24 samples packed in tubes (45.83%) and nine in jars (37.50%). In the category of hand cream, 251 of the 294 products on the market are sold in tubes, which account for 85.37%. In the sampling, tubes represented 67.27% of the packaging systems. For body lotion, the shares of squeeze bottles (29.44%), tubes (29.99%), and jars (23.34%) are similarly common.

Table 1.

Exemplary presentation of the results of the market research for shampoo, hair gel, hand cream, and body lotion. The results show the number of packaging systems per product category which can be found on the Austrian market and in the sampling, as well as the respective share.

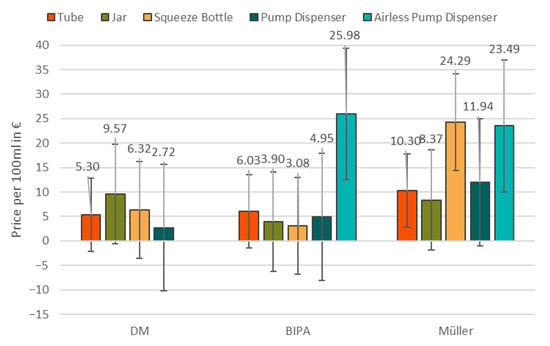

From all three stores, the average price for 100 mL hand cream was calculated based on the packaging system (Figure 1).

Figure 1.

Average prices for 100 mL of hand cream in different available packaging systems in the three assessed drug stores of DM, BIPA, and Müller in Austria.

A comparison of the hand cream offerings of the aforementioned retailers reveals that DM offers 77 hand creams in tubes for EUR 5.30 per 100 mL, BIPA offers 74 at EUR 6.03, and Müller offers 162 at EUR 10.30. It is noteworthy that both DM and Müller have six jar options, with the cost of these items being EUR 9.57 and EUR 8.37, respectively, while BIPA offers four at a cost of EUR 3.90. The presence of squeeze bottles is minimal, with only two to four per store. Pump dispensers are more prevalent, with two to four per store. Airless pump dispensers are scarce, with one at BIPA and three at Müller, all at high prices per 100 mL.

3.2. Shampoo

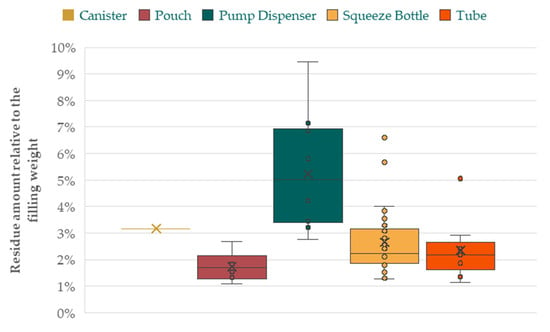

A series of specific methods, tailored to the packaging system, were developed to measure the residual emptying capacity of shampoos. The results clearly illustrate the distinctions among the various packaging systems (Figure 2). The average residue amount for pump dispensers is almost twice as high (5.23%) as that for bottles (2.65%). Pouches have the lowest average at 1.74%, and tubes at 2.35%. The highest amount of residue at 9.7% of the total filling weight was found in a pump dispenser. Different from all other shampoo products, this was not a common shampoo product, but a foaming liquid. The second highest value was measured in a pump dispenser, with a value of 7.14%, due to the feeder tube being too short, while the third highest value, at 6.85%, was due to a feeder tube being too long. A similarly high value of 6.6% of product residue was measured in a squeeze bottle. The negatively influencing packaging characteristics might lie in the small opening of the disc top, as well as in the difficult squeezability of the container, as the bottle was shaped in a round form and was made of high-density polyethylene (HDPE), which is usually stiffer than polyethylene terephthalate (PET). The lowest value was registered for a 1.5 L pouch with a spout. Due to the thin low-density polyethylene (LDPE) foil of the pouch and the large filling volume, only 1.08% of the product remained in the packaging at the end of the emptying process. The lowest residue rate in squeeze bottles with a value of 1.27% was registered for a round bottle made of PET with a screw cap. The screw cap added beneficial value to the emptiability, as the opening size is distinctively larger than that of flip-tops or disc-tops. The range of filling volumes extended from 40 mL to 1500 mL, with a median value of about 330 mL, whereby no influence of filling volume on the emptiability could be detected. Also, no influence of packaging shape and design was found.

Figure 2.

Amount of shampoo residues in different packaging systems after the standardized emptying.

3.3. Hair Gel and Wax

The lowest product residue values in packaging for hair wax and gel were achieved by an airless pump dispenser (0.59%) and jars, with values between 0.62% and 2.98% (Figure 3). The residual content of tubes ranged from 4.23% to 8.45%, with an average value of 5.63%, and the highest values were observed in pump dispensers (8.74% and 11.17%) and one bottle (22.53%). The filling volume of the packaging samples ranged from 50 mL to 150 mL, with an average of about 100 mL, whereby the filling volume had no influence on emptiability.

Figure 3.

Amount of hair gel and wax residues in different packaging systems after the standardized emptying.

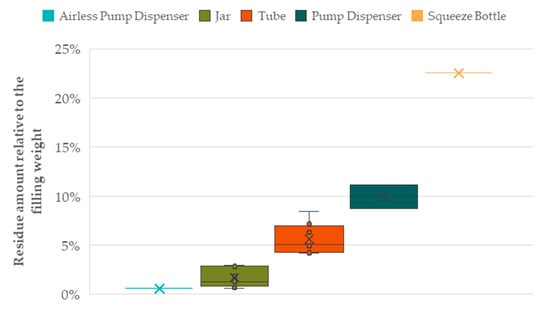

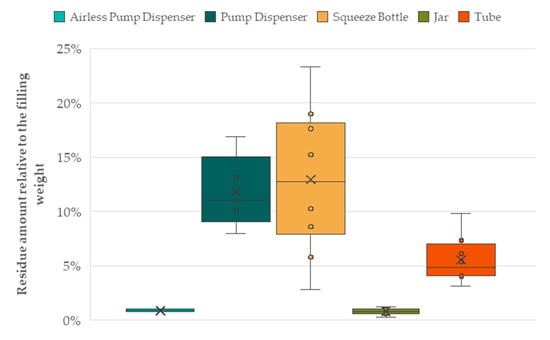

3.4. Hand Cream

In the case of hand creams, one bottle was sampled and it achieved the third-highest overall value of measured product residues at 24.51% (Figure 4). Due to the low market share of bottled hand creams, no comparative values could be obtained. Pump dispensers also proved to be an unfavorable packaging system in terms of residual emptying. The highest value for this packaging system was 26.65%, while the lowest was 12.56%. These results are based on several influencing factors, such as the length of the dip tube of the pump or the planarity of the bottom of the bottle. The mean value for tubes was 9.82%, with one outlier at 20.17%. In this case, the packaging system exhibited a particularly rigid shoulder area, which made emptying challenging. The lowest values were observed in jars and airless pump dispensers, with less than 1% of retained product. Out of 55 samples, 20 hand cream packaging samples contained 75 mL of product. Other filling volumes ranged from 20 mL to 500 mL. As most samples were packed in tubes, variations in design were not significant and had no impact on emptiability.

Figure 4.

Amount of hand cream residues in different packaging systems after the standardized emptying.

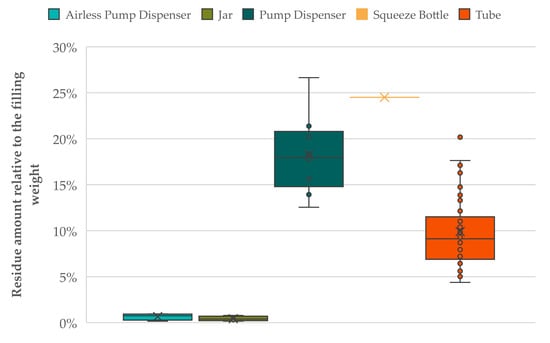

3.5. Body Lotion

Significant discrepancies were observed in the residual emptying of body lotions which can be specifically attributed to the packaging system employed (Figure 5). As with other product categories, airless pump dispensers demonstrated remarkable efficacy, with values barely exceeding 1% (0.29–1.18%). Jars also exhibited a noteworthy performance, with values ranging from 0.29% to 1.18% and a medium value of 0.80% of retained product after emptying. The average value for tubes was 5.53%. The lowest value for the analyzed pump dispensers was 7.97%, while the maximum was 16.91%. The widest range of values was observed in bottles, with a mean value of 12.94% and a range of 2.84% to 23.29%. Similarly to the results for hand cream, pump dispensers and squeeze bottles were identified as being the least favorable packaging systems for this product group. The filling volume of most packaging samples ranged from 150 mL to 500 mL, with two samples with under 100 mL of filling volume.

Figure 5.

Amount of body lotion residues in different packaging systems after the standardized emptying.

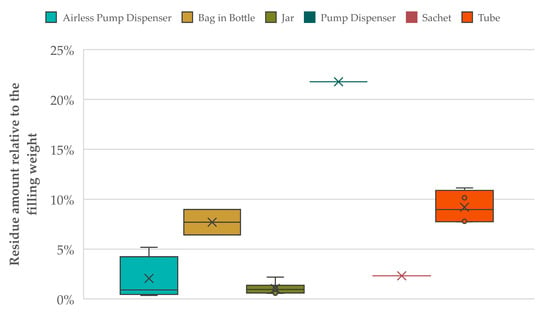

3.6. Face Cream

The differences among the various packaging systems are evident (Figure 6). The lowest values were observed in jars, with an average of 0.56–2.19%. Airless pump dispensers also exhibited low values of <1% in some cases, although a higher value of 3.3% was also measured for one product. Values between 7.73% and 11.13% were determined for tubes. Two products in the bag-in-bottle packaging system exhibited a slightly lower residue level than tubes, with an average value of 7.7%. Individual samples without comparative values were analyzed for one pump dispenser (21.77%), one airless jar (5.18%), and one sachet (2.32%). Only two samples contained 100 mL and 120 mL of product, respectively, while all other samples had sizes of 30 mL or 50 mL. Therefore, no influence of filling volume was evident.

Figure 6.

Amount of face cream residues in different packaging systems after the standardized emptying.

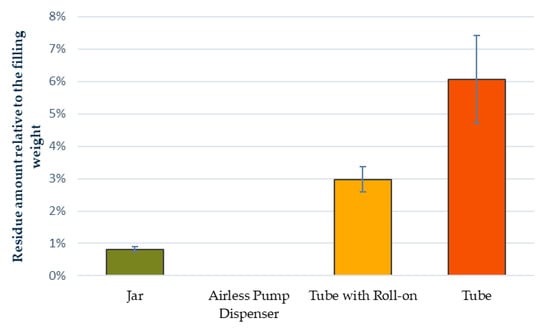

3.7. Eye Cream

There are significant discrepancies in the residual emptying of eye creams (Figure 7). The airless pump dispenser could be emptied completely, whereas 0.82% remained in the jar, a result which is consistent with the findings on jars from other product groups. The tubes exhibited residue levels of 6.06%, with the tube with a roll-on applicator demonstrating 3% less residue than the tube without an applicator cap.

Figure 7.

Amount of eye cream residues in different packaging systems after the standardized emptying.

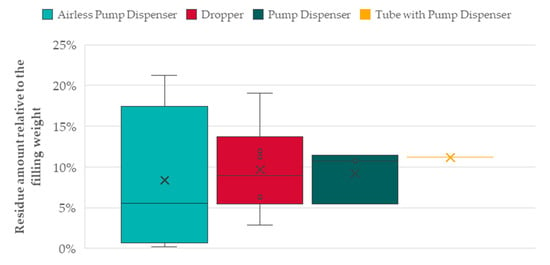

3.8. Serum

It is challenging to make general statements about the emptiability of serum packaging. This is largely due to the diverse range of serum consistencies, some of which were highly liquid, viscous, or creamy, thereby significantly compromising comparability. This contrasts with samples from other product categories, where consistencies were found to be similar among different product samples. A sample with a comparable consistency was available in the same bottle, one with a pipette and one with a pump dispenser. The values were comparable, with an average of 6.54% and 5.47%, respectively. The results for airless pump dispensers show considerable differences, as results varied between 0.20% and 21.28% due to the mentioned diverse product properties in addition to the varying functionality and construction of the packaging (Figure 8). For the dropper, the emptiability depends on the amount of space between the range of the dropper and the bottom of the glass. Of the 15 samples analyzed, 10 had a filling volume of 30 mL.

Figure 8.

Amount of serum residues in different packaging systems after the standardized emptying.

3.9. Comparison of Different Products in the Same Packaging

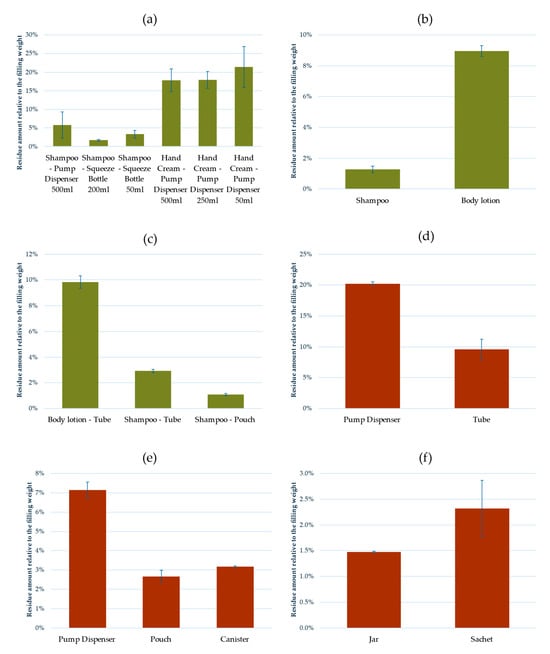

Brand owners frequently utilize the same packaging for different products or offer the same product in various packaging options and sizes (see Figure 9 for illustration). For instance, in case (a), shampoo and hand cream were analyzed in three different packaging systems and volumes. The results demonstrated that hand cream left up to three times more residue than shampoo in the same 500 mL pump dispenser. Furthermore, it was observed that smaller filling volumes resulted in higher residue percentages, as evidenced by the cases of shampoo (50 mL and 200 mL squeeze bottles) and hand cream (50 mL, 250 mL, and 500 mL pump dispensers). In the second case, a squeeze bottle was examined with respect to both shampoo and body lotion. While the shampoo left only 1.29% of residue, body lotion retained 8.96%. In a similar manner, in case (c), the same tube containing body lotion and shampoo exhibited a higher residue for the body lotion (9.84%) compared to the shampoo (2.92%). The delivery of the same shampoo in a pouch with a spout resulted in an optimal emptiability result of 1.08%.

Figure 9.

(a) Emptiability results of hand cream and shampoo in divers packaging options; (b) residue amounts of shampoo and body lotion sold in the same squeeze bottle; (c) emptiability results of shampoo and body lotion; (d) residues of hand cream in a pump dispenser and a tube; (e) comparative results of shampoo offered in three different packaging options; (f) residue amounts of face cream in a jar and a sachet. For each sample, n = 3 applies.

In case (d), the hand cream in the tube (9.57%) left approximately half the residue of the pump dispenser (20.21%). In case (e), the shampoo was tested in different packaging systems: a 200 mL pump dispenser (7.14%), a 500 mL pouch (2.67%), and a 2000 mL canister (3.17%). Finally, in case (f), face cream in a jar (1.47%) left less residue compared to the same product in a sachet (2.32%). These findings highlight how both product properties and packaging design impact emptiability, with larger filling volumes and flexible packaging generally resulting in less waste.

4. Discussion

The results of the study show large differences in emptiability, depending on the product type and the packaging system. The assessment was performed for the product categories of shampoo, hair gel, hand cream, body lotion, face cream, eye cream, and sera and included a vast variety of packaging systems. Most of the tested packaging options included tubes, jars, squeeze bottles, and pump dispensers, as well as airless pump dispensers. In some product categories, other packaging types were also assessed, such as pouches and sachets, canisters, droppers, and tubes with a pump dispenser closure or a roll-on applicator.

The results show large differences in the emptiability of different packaging systems in the specific product categories. The best overall emptiability was measured for shampoos, ranging between 1.08% and 2.97%, with a median value of 2.97% of remaining product. For body lotion, despite low residue amounts due to the easy product accessibility in jars, the results ranged from 0.29% to 23.29%, with a median value of 7.30%. Overall, the highest values from emptiability quantification were measured in pump dispensers, due to a combination of unfavorable product properties (high viscosity) and design aspects (dispenser tube length). The lowest results overall were achieved by jars and airless pump dispensers. For squeeze bottles and tubes, the results were highly dependent on the material and design properties of the packaging system. For tubes, in particular, the stiffness of the material around the shoulder was identified as a limiting factor in the emptying process. The filling volume seemed to make no impact on the emptiability, and no specific design features were identified to influence the emptiability.

4.1. Comparison to Existing Data and Methods

To date, no studies with a similar methodology have been published. Nevertheless, a careful comparison can be drawn with a study that evaluated the residue amounts found in packaging at the stage of entering a recycling facility [15]. The authors stated average values of residues in tubes, with shampoo residues at 3 wt.%, a figure that is similarly reflected by the emptiability results concluded in this study, as the median value for shampoo in tubes was 2.35%. A further comparable result can be derived for the product category of hair gel, with 7 wt.%, as reported by Schinkel et al., (2023) [15], in comparison to 5.63% following the standardized emptying. The results of 11 wt.% for skin creams [15] are not replicated in the present study, as residue amounts for body lotion in tubes comprised a median value of 5.53% and, for face cream, of 9.20%. It should be noted that the calculation methodology differs between the two sets of results. In contrast to the aforementioned procedure, Schinkel et al., (2023) compare the residue weight to the filling volume, assuming a general product density of 1 g/cm3 [15]. Furthermore, a non-destructive method was selected for the standardized emptiability measurement to facilitate the analysis of residue amounts based on the intended usage of the packaging. The authors indicate that, in several instances, the closures were removed from the tubes [15]. However, it is unclear whether tube bodies were cut up by consumers or whether other non-product impurities could have influenced the results due to the removal of the closures.

Direct comparisons with previous studies focusing on the emptiability of dairy products cannot be drawn, as different packaging systems were investigated which are not applied to cosmetic products [12,13,14].

Although no studies with identical methodologies have been published, the findings of this study are consistent with those of prior research, particularly with regard to the residue levels of shampoo and hair gel. However, discrepancies emerged with regard to products such as skin cream, where the results of the present study diverge from previously reported values. These discrepancies are likely attributable to variations in calculation methodologies, product densities, and measurement techniques. The utilization of a non-destructive method in the present study offers an analysis that is more reflective of real-world consumer behavior, whereas prior studies may have been influenced by additional factors such as the removal of closures and potential non-product impurities. A comparison with studies on dairy products is not feasible due to differences in packaging systems.

4.2. Economic Losses of the Consumer Due to Limited Emptiability

In a study conducted by Gomez-Berrada et al., (2017), the impact of packaging on the consumption of cosmetic products, including shampoo and cream, was examined. In particular, two types of packaging were examined, which were tubes and pump dispensers [22]. The published data indicate that French men use 7.4 g/use from tubes and 6.1 g/use of shampoo, while women use, on average, 11.9 g/use from shampoo tubes and 10.3 g/use from pump dispensers. The data for cream products demonstrate less differentiation between the sexes. The mean quantities of cosmetic products consumed from tubes were 7.4 g/use for men and 6.6 g/use for women, while the corresponding figures for cream were 6.0 g/use and 6.2 g/use, respectively [22].

The sample of hand cream in a dispenser with a filling volume of 500 mL retained, on average, 17.78%, equating to 80.98 g. This quantity of residue would suffice for an additional 13 applications, based on the measured amounts by Gomez-Berrada et al., (2017) [22]. A pump dispenser containing shampoo retained 33.52 g of product after emptying, which could serve another five and a half uses for men or three uses for women.

It can be observed that the values for residues from tubes containing hand cream and shampoo are more favorable. The maximum amount of product was found to be 10.79 g, which would serve approximately one additional use for both men and women. The maximum amount of hand cream retained in a tube was measured to be 17.16 g in a tube with a total filling weight of 85 g. In this case, two to three additional uses of the product would be possible in the event of complete emptying.

In light of the prices identified through market research, it is possible to ascertain the economic losses sustained by the consumer based on the quantity of remaining product residue. The measured amount of residue in hand cream tubes ranged from 1.71 g to 17.16 g, with an average value of 7.26 g. Based on the prices in Figure 1, this would result in economic losses for hand cream in tubes of a value of EUR 0.38 (DM), EUR 0.40 (BIPA), and EUR 0.75 (Müller), calculating an average product loss of 7.26 g. In the case of the squeeze bottle, 20.21 g was left in the packaging, resulting in monetary losses of EUR 1.28 (DM), EUR 0.62 (BIPA), and EUR 4.91 (Müller). Pump dispensers exhibited residue levels of 11.82 g to 80.98 g, with an average of 31.92 g. Based on the average value and the average prices from the three drug stores, the economic losses are EUR 0.86 (DM), EUR 1.58 (BIPA), and EUR 3.81 (Müller).

4.3. Carbon Emissions of Wasted Product

A review of the literature reveals a notable scarcity of research on the carbon footprint of cosmetic products. One study on the product environmental footprint (PEF) of shampoo was published by Kröhnert and Stucki, (2021). The authors identified a significant degree of uncertainty in the comparability of their data, primarily due to the limited availability of datasets on shampoo ingredients and the energy consumption of retail stores. A further consideration in calculating the PEF of cosmetic products is the impact of emissions during the use phase, given that consumer behavior can influence the results. In this case, shower time, shower temperature, and amount of product used per wash must be taken into account. The latter aspect is influenced by various factors, including gender, age, hair length, and hair wash frequency, all of which affect the dosage [23]. While Golsteijn et al., (2018) developed a method and guidelines for the assessment of PEF for shampoos, no definitive data from the application of this method are publicly accessible to date [24].

One study focused on the differences in energy consumption in water-in-oil emulsions for products with standard and natural ingredients and different production standards [25]. For emulsions, such as hand cream, made of standard ingredients, the carbon footprint ranges between 136.99 and 204.53 equivalents for 500 kg of product, considering the ingredients and manufacturing process. The packaging is not included in this value but is considered to contribute an additional standardized 29.58 equivalents. For natural products, the carbon equivalents are estimated to be within a range of 137.89 to 206.53 equivalents. For a tube, containing 75 mL of product and leaving 9.90% of residue on average, this would sum up to 0.0025 equivalents for standard and 0.0026 equivalents for natural products. In the case of a pump dispenser with a filling volume of 500 mL and an emptiability value of 26.65%, this would lead to carbon emissions of 0.0455 equivalents for standard products and 0.0459 equivalents for natural products.

4.4. Limitations

It should be noted that the results of the study are subject to a number of limitations. The methodology employed was specifically selected for use with cosmetic products, which limits the comparability of the results with those obtained from studies of food products in similar packaging systems. A further limitation is the methodology applied to the emptying process, which involved making assumptions about how an eco-conscious consumer would handle different packaging systems. It should be noted that other assumptions about consumer behavior and the handling of packaging would yield different results. Further work is needed to standardize the methodology for measuring packaging emptiability.

Additionally, further research should be conducted to examine the influence of packaging material composition, as well as product viscosity and texture, in greater depth. The surface properties, rigidity, and interaction of packaging materials, including plastics, glass, and metals, with diverse products can significantly influence the residual product left behind. To illustrate, non-stick or hydrophobic coatings may result in a reduction of waste in specific packaging materials, whereas, in others, they may retain a greater quantity of product due to their surface texture or porosity.

Similarly, product viscosity and texture are of critical importance in determining the ease with which a product can be dispensed. The viscosity of a product may influence the degree to which it adheres to the packaging material. Highly viscous products, such as creams or gels, may adhere more strongly to packaging walls, resulting in greater residual waste compared to less viscous liquids. Furthermore, the texture of a product, whether smooth, granular, or fibrous, can interact with the packaging material in distinctive ways, influencing both the consumer’s ability to extract the product and the overall efficiency of the packaging system.

The aim of this study was to conduct a comprehensive analysis of a variety of products and packaging systems with a specific focus on identifying optimal packaging solutions for a range of products.

5. Conclusions

This study quantifies residues of various cosmetic products in different packaging systems after a standardized emptying procedure, and, therefore, it is the first study investigating emptiability of non-food products. As different packaging systems compared to food packaging were applied, novel methods had to be developed and are proposed for future comparability.

With the introduction of international regulations such as the PPWR, optimizing emptiability is critical for ensuring packaging recyclability, reducing the carbon footprint, and minimizing economic losses from wasted products. The findings of this study provide practical recommendations for stakeholders in the cosmetic industry:

- For creamy products (hand cream, body lotion, face cream, hair gel, and wax): jars and airless pump dispensers demonstrate the highest emptiability and should be prioritized for formulations where these packaging types are suitable.

- For liquid products such as shampoo: flexible pouches show superior emptiability compared to rigid bottles, making them a more sustainable choice.

- For all product categories: packaging designs should incorporate material efficiency, ease of product retrieval, and compatibility with existing recycling streams to align with upcoming sustainability regulations.

By considering these insights, manufacturers, packaging designers, and policymakers can make informed decisions that support a circular economy, reduce material waste, and enhance the overall sustainability of cosmetic packaging.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su17031056/s1, “Supporting Data” will be provided with the manuscript.

Author Contributions

Conceptualization, M.K.; methodology, M.K.; validation, M.K., S.A. and M.T.; formal analysis, M.K.; investigation, M.K.; resources, M.K.; data curation, M.K.; writing—original draft preparation, M.K.; writing—review and editing, M.K., S.A. and M.T.; visualization, M.K.; supervision, S.A. and M.T.; project administration, M.K.; funding acquisition, S.A. and M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work was created within a research project of the Austrian Competence Centre for Feed and Food Quality, Safety and Innovation (FFoQSI). The COMET-K1 competence center FFoQSI is funded by the Austrian federal ministries BMK, BMDW, and the Austrian provinces of Lower Austria, Upper Austria, and Vienna within the scope of COMET—Competence Centers for Excellent Technologies. The program COMET is handled by the Austrian Research Promotion Agency FFG, Funding Number 36184885.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the Supplementary Materials.

Acknowledgments

The authors would like to express their gratitude to all project participants who provided product samples. Special thanks are directed to all students and interns who were involved in the data collection, as well as to the team members of the Institute of Packaging and Resource Management at FH Campus Wien and Circular Analytics. In particular, the authors would like to thank Mary Grace Wallis for her invaluable contribution in reviewing and providing comments on the manuscript.

Conflicts of Interest

Author Manfred Tacker was employed by the company Circular Analytics TK GmbH. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Bom, S.; Jorge, J.; Ribeiro, H.; Marto, J. A step forward on sustainability in the cosmetics industry: A review. J. Clean. Prod. 2019, 225, 270–290. [Google Scholar] [CrossRef]

- Chandra Pal, K. Environmental Pain with Human Beauty. Cognitive Data Models for Sustainable Environment; Elsevier: Amsterdam, The Netherlands, 2022; pp. 231–252. ISBN 9780128240380. [Google Scholar]

- Barton, S.; Eastham, A.; Isom, A.; Mclaverty, D.; Soong, Y.L. Discovering Cosmetic Science; The Royal Society of Chemistry: London, UK, 2020; ISBN 978-1-78262-472-1. [Google Scholar]

- Statista Consumer Market Insights. Kosmetikmarkt in Deutschland und Weltweit. Available online: https://de.statista.com/themen/25/kosmetik/#topicOverview (accessed on 18 September 2024).

- Statista Consumer Market Insights. Umsatz im Markt für Beauty & Personal Care in Österreich in den Jahren 2015 bis 2028. Available online: https://de.statista.com/prognosen/1219879/umsatz-mit-kosmetik-und-koerperpflegeprodukten-in-oesterreich (accessed on 18 September 2024).

- Rundh, B. The role of packaging within marketing and value creation. Br. Food J. 2016, 118, 2491–2511. [Google Scholar] [CrossRef]

- Yeo, S.-F.; Tan, C.-L.; Lim, K.-B.; Khoo, Y.-H. Product Packaging: Impact on Customers’ Purchase Intention. Int. J. Bus. Soc. 2021, 21, 857–864. [Google Scholar] [CrossRef]

- Cubas, A.L.V.; Bianchet, R.T.; Reis, I.M.A.S.D.; Gouveia, I.C. Plastics and Microplastic in the Cosmetic Industry: Aggregating Sustainable Actions Aimed at Alignment and Interaction with UN Sustainable Development Goals. Polymers 2022, 14, 4576. [Google Scholar] [CrossRef] [PubMed]

- Morel, S.; Mura, G.; Gallarate, M.; Sapino, S. Cosmetic Packaging: European Regulatory Aspects and Sustainability. Cosmetics 2024, 11, 110. [Google Scholar] [CrossRef]

- Brouwer, M.; van Velzen, U.T. Multi-Dimensional Sustainability Assessment of Product-Packaging Combinations: MuDiSa: A Calculation Tool to Assess the Sustainability of Product-Packaging Combinations in Multiple Dimensions of Sustainability; Wageningen: Wageningen, The Netherlands, 2023. [Google Scholar]

- Schmidt, M.C. Untersuchung und Verbesserung des Entleerungsverhaltens von Füllgut-Verpackungssystemen. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2011. [Google Scholar]

- Klein, M.; Werner, C.; Tacker, M.; Apprich, S. Influence of Packaging Design on Technical Emptiability of Dairy Products and Implications on Sustainability through Food Waste Reduction. Sustainability 2024, 16, 6335. [Google Scholar] [CrossRef]

- Wohner, B.; Schwarzinger, N.; Gürlich, U.; Heinrich, V.; Tacker, M. Technical emptiability of dairy product packaging and its environmental implications in Austria. PeerJ 2019, 7, e7578. [Google Scholar] [CrossRef] [PubMed]

- Meurer, I.R.; Lange, C.C.; Hungaro, H.M.; Bell, M.J.V.; dos Anjos, V.D.C.; de Sá Silva, C.A.; de Oliveira Pinto, M.A. Quantification of whole ultra high temperature UHT milk waste as a function of packages type and design. J. Clean. Prod. 2017, 153, 483–490. [Google Scholar] [CrossRef]

- Schinkel, K.; Küppers, B.; Reichenbach, S.; Rohrmeier, T.; Müller, K.; Fell, T.; Sängerlaub, S. Amount of Fill Product Residues in Plastic Packagings for Recycling. Waste 2023, 1, 901–918. [Google Scholar] [CrossRef]

- Strangl, M.; Schlummer, M.; Maeurer, A.; Buettner, A. Comparison of the odorant composition of post-consumer high-density polyethylene waste with corresponding recycled and virgin pellets by combined instrumental and sensory analysis. J. Clean. Prod. 2018, 181, 599–607. [Google Scholar] [CrossRef]

- Cinelli, P.; Coltelli, M.B.; Signori, F.; Morganti, P.; Lazzeri, A. Cosmetic Packaging to Save the Environment: Future Perspectives. Cosmetics 2019, 6, 26. [Google Scholar] [CrossRef]

- Feil, A.; Pretz, T. Mechanical Recycling of Packaging Waste. In Plastic Waste and Recycling; Elsevier: Amsterdam, The Netherlands, 2020; pp. 283–319. ISBN 9780128178805. [Google Scholar]

- INCPEN. Responsible Packaging—Code of Practice for Optimising Packaging and Minimising Waste; Incpen: Reading, UK, 2003. [Google Scholar]

- United Nations. Goal 12: Ensure Sustainable Consumption and Production Patterns. 2024. Available online: https://unric.org/en/sdg-12/ (accessed on 1 October 2024).

- Statista Consumer Market Insights. Marktanteile der Führenden Unternehmen im Drogerie- und Parfümeriefachhandel in Österreich im Jahr 2019. Available online: https://de.statista.com/statistik/daten/studie/936406/umfrage/marktanteile-der-fuehrenden-drogeriefachhaendler-in-oesterreich/ (accessed on 1 October 2024).

- Gomez-Berrada, M.P.; Ficheux, A.S.; Galonnier, M.; Rolfo, J.E.; Rielland, A.; Guillou, S.; De Javel, D.; Roudot, A.C.; Ferret, P.J. Influence of the container on the consumption of cosmetic products. Food Chem. Toxicol. 2017, 109, 230–236. [Google Scholar] [CrossRef] [PubMed]

- Kröhnert, H.; Stucki, M. Life Cycle Assessment of a Plant-Based, Regionally Marketed Shampoo and Analysis of Refill Options. Sustainability 2021, 13, 8478. [Google Scholar] [CrossRef]

- Golsteijn, L.; Lessard, L.; Campion, J.-F.; Capelli, A.; D’Enfert, V.; King, H.; Kremer, J.; Krugman, M.; Orliac, H.; Furnemont, S.R.; et al. Developing Product Environmental Footprint Category Rules (PEFCR) for shampoos: The basis for comparable life cycle assessment. Integr. Environ. Assess. Manag. 2018, 14, 649–659. [Google Scholar] [CrossRef] [PubMed]

- Tamburic, S.; Fröhlich, J.; Mistry, S.; Fischer, L.J.; Barbary, T.; Bunyan, S.; Dufton, E. Sustainability by Reduced Energy Consumption during Manufacturing: The Case of Cosmetic Emulsions. Cosmetics 2023, 10, 132. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).