Abstract

Geopolymers are a sustainable alternative to Portland cement, with the potential to significantly reduce the carbon footprint of conventional cement production. This study investigates the valorization of industrial waste iron powder (IP) as a fine filler in geopolymers synthesized from volcanic tuff (VTF). Composites were prepared with IP substitutions of 5%, 10%, and 20% by weight, using sodium hydroxide and sodium silicate as alkaline activators. Microstructural and phase analyses were conducted using scanning electron microscope coupled with energy dispersive X-ray spectroscopy (SEM-EDS), X-ray fluorescence (XRF), X-ray diffraction (XRD), and differential scanning calorimetry (DSC), while rheological properties, compressive strength, and flexural strength were assessed. The impact of curing temperatures (25 °C and 80 °C) on mechanical performance was evaluated. Results revealed that air content increased to 3.5% with 20% IP substitution, accompanied by a slight rise in flow time (0.8–2 s). Compressive and flexural strengths at 25 °C decreased by up to 22.48% and 28.39%, respectively. Elevated curing at 80 °C further reduced compressive and flexural strengths by an average of 45.30% and 64.68%, highlighting the adverse effects of higher temperatures. Although these formulations are not suitable for load-bearing applications, the findings suggest potential for non-structural uses, such as pavement base layers, aligning with sustainable construction principles by repurposing industrial waste and reducing reliance on energy-intensive cement production.

1. Introduction

In research, the use of iron powder in conventional Portland cement mortar/concrete has not proved successful, so we have turned to its use in geopolymers. The increasing use of geopolymers is driven by the significant environmental impact of the building industry, which accounts for 45% of global energy consumption and 72% of greenhouse gas emissions [1]. The cement industry is a significant contributor to global carbon emissions, accounting for 5–8% of worldwide greenhouse gas emissions. With the industry experiencing ongoing expansion, particularly in emerging economies, CO2 emissions are projected to increase by 4% by 2050 [2,3,4].

To mitigate environmental impact, reduce energy consumption, and promote the use of more sustainable building materials, a global strategy is increasingly recognized as crucial. One significant step towards this goal is replacing traditional cement with environmentally friendly alternatives [5,6,7]. One such material, “aluminosilicate geopolymers”, is synthesized at low temperatures (less than 100 °C), making it excellent for sustainability. The term ’geopolymer’ was introduced in 1972 by the French chemist Joseph Davidovits to designate green materials based on raw materials of geological origin (e.g., fly ash and slags, pozzolan) that consolidate when cold through polymerization-type reactions and that have the potential to replace cement in the construction industry [5]. Several studies [8,9,10,11,12,13,14,15,16] have demonstrated the positive impacts of using geopolymers. Geopolymer binders offer a significant environmental advantage over Ordinary Portland Cement (OPC) by reducing carbon dioxide emissions by 80–90% during production [8,9]. Research studies [10,11] demonstrated the effectiveness of porous geopolymers in water purification. These materials achieved a removal rate of 95% for both crystal violet and methylene blue, indicating their potential for practical applications in wastewater treatment. M.K. Lahoti et al. [12] have demonstrated the superior fire resistance properties of geopolymer materials. Aiken et al. [13] demonstrated that geopolymer (GP) binders exhibit superior resistance to sulfuric acid attack compared to Portland cement (PC) binders. This enhanced durability is attributed to the formation of a dense, chemically stable aluminosilicate network within the GP structure. Several studies have demonstrated that geopolymer (GP) mortars can achieve comparable or even superior resistance to traditional mortars [14] and concrete [15].

M. Yang and colleagues [16] discovered that the alkali–silica reaction (ASR) is less pronounced in fly ash geopolymer concrete than in ordinary Portland cement concrete. The more uniform and stable pore structure of fly ash geopolymer concrete over time enhances its resistance to ASR. The study by [17] demonstrates that the initial water content in geopolymer synthesis significantly influences its microstructure and mechanical properties. An increase in water content results in larger pore sizes and a decrease in compressive strength. Ailar Hajimohammadi et al. [18] found that the use of aluminum as a foaming agent in fly ash-based geopolymers significantly reduces carbonation susceptibility and superior mechanical properties under chemical attacks.

However, the lack of standards and the lack of information on the long-term behavior of geopolymer binders may be the main barriers to its widespread use [9]. Therefore, it is important to stay objective and emphasize that the widespread use of geopolymers could push sustainable development towards a new dimension where the transition from Portland cement to geopolymer will be difficult. To encourage this transition, as much research as possible needs to be performed. According to the study of Shill et al. [19], geopolymers have been used in Australia at commercial airports, in mainline railway sleepers, and in degraded concrete repair of rigid pavement. Zailani et al. [20] have proposed geopolymers as a promising material for building restoration. Geopolymers are made of various precursors, activators, and fillers. The most commonly used aluminosilicate used to make geopolymer concrete are fly ash (FA), kaolin, and metakaolin. Several studies have shown that fly ash (FA) particles function as micro-aggregates within concrete mixtures. This incorporation leads to several performance enhancements, including reduced density [21], improved thermal insulation properties [22], enhanced workability [23], decreased porosity and water absorption [24], and relatively high compressive strength and setting times [21,25]. Recently, some scholars [26] reached compressive strengths of 47.5 MPa after curing conditions of 80 °C for 24 h.

Previous studies [27,28,29] have demonstrated that kaolin and metakaolin geopolymers possess a more uniform microstructure and exhibit higher reactivity, with less incompletely reacted material. This contributes to enhanced overall performance. Sarazin et al. [30] observed that metakaolin-based geopolymer foams serve as effective thermal barriers, reducing temperatures by up to 251 °C compared to uncoated steel plates. Additionally, research has indicated that kaolin and metakaolin geopolymer binders offer superior water stability [31], thermal conductivity [32], and mechanical properties [31,32] when cured at room temperature compared to traditional binders. Mohammed DT et al. [33] found that increasing the molarity of NaOH in geopolymer formulations significantly enhanced strength. This increase in NaOH concentration promoted the formation of crystalline nepheline and resulted in a denser microstructure. Liang et al., [34] reached with metakaolin geopolymer a compressive strength of 56.6 MPa after Curing conditions of 50 °C for 24 h. Other natural raw materials or artificial raw materials can be used as precursors to geopolymers or as an addition in geopolymers, the most common of which are volcanic ash [35], slag [36], bauxite [37], pozzolan [38], tuff [39], bentonite [40], red mud [41], basalt [42], perlite [43], and zeolite [44].

Studies have shown that activator selection, mechanical activation, thermal treatment, and solution/precursor ratio are crucial parameters influencing the reactivity of natural or artificial raw materials with low amorphous content [45,46]. Furthermore, the utilization of industrial byproducts such as glass fiber, waste steel lathe scraps, and recycled steel tire wire as supplementary cementitious materials offers significant economic and environmental benefits by reducing Portland cement consumption [47,48]. Other researchers [49,50,51] have advanced sustainable construction practices by simultaneously addressing waste management challenges and reducing dependency on natural resources through the integration of recycled concrete aggregate (RCA). Their findings reveal that RCA not only aligns with principles of circular economy but also significantly enhances the mechanical properties of ductile-engineered geopolymer composites. Specifically, the incorporation of RCA improves key performance metrics such as compressive strength, flexural toughness, and durability, making it a viable alternative to conventional aggregates in advanced material applications.

Building upon the successes achieved through the utilization of diverse raw materials in geopolymer production, a promising avenue for future research lies in the exploration of Fe-based geopolymers. This is particularly relevant considering the annual global production of metal powder exceeds 700,000 tons, generating a significant amount of iron-based waste with potential for valorization in sustainable construction materials like geopolymers. Davidovits, J. [52] found that the formation of the Fe precipitation had a negative effect on geopolymerization.

Other research has investigated the effect of iron powder (IP) within the geopolymer matrix and found that IP acts as an aggregate that develops compressive strength [53]. Gulmez et al. [54] reported that the replacement of 30 to 40% by volume of slag with iron powder (IP) in geopolymer mortars increased tensile splitting strength, compressive strength, and flexural strength. Zehra Funda Akbulut et al. [55] examined the effect of 10% IP and 20% IP on the workability and strength development of Fly ash-based geopolymer mortars. They reported that IP negatively affected GP mortar’s workability and increased compressive strength and residual flexural strengths of GP mortars. Tao Ma et al. [56] reported that IP improves mechanical properties by improving the density, but an excessive amount of IP can lead to a weak interfacial transition zone between the geopolymer matrix and iron powder. Nongnuang et al. [57] showed that the replacement of 5% of IP by volume of fly ash improves compressive and flexural strength and reduces curing time to 99.70% of geopolymer. T. Nongnuang et al. [58] indicated that the addition of IP in fly ash geopolymer slightly decreased the compressive strength due to the grain shape and to the impurity in IP. The optimum content of IP was suggested as 20%. Karol Prałat et al. [59] examined the effect of the addition of IP (0.5% to 2.5%) in metakaolin geopolymer. It was reported that the addition of IP increases the thermal conductivity of metakaolin geopolymer.

This research investigates the sustainable utilization of waste iron powder (IP) as a fine filler in geopolymers synthesized from volcanic tuff (VTF). By incorporating this industrial byproduct and utilizing a naturally abundant resource like volcanic tuff, which is rich in silica, this study aims to offer an eco-friendly alternative to Portland cement while reducing reliance on non-renewable materials. Importantly, few studies have focused on the use of volcanic tuff as a precursor in alkali-activated binders. To investigate the feasibility of this approach, comprehensive material characterization was conducted using advanced techniques such as SEM-EDS, XRF, XRD, and DSC. The study evaluated critical properties of geopolymer mortars, such as flow time, compressive strength, and flexural strength, for formulations containing 5%, 10%, and 20% IP as a replacement for tuff by weight. This approach highlights the potential of geopolymers as a sustainable solution in the transition towards environmentally responsible construction practices.

2. Materials and Methods

2.1. Raw Materials

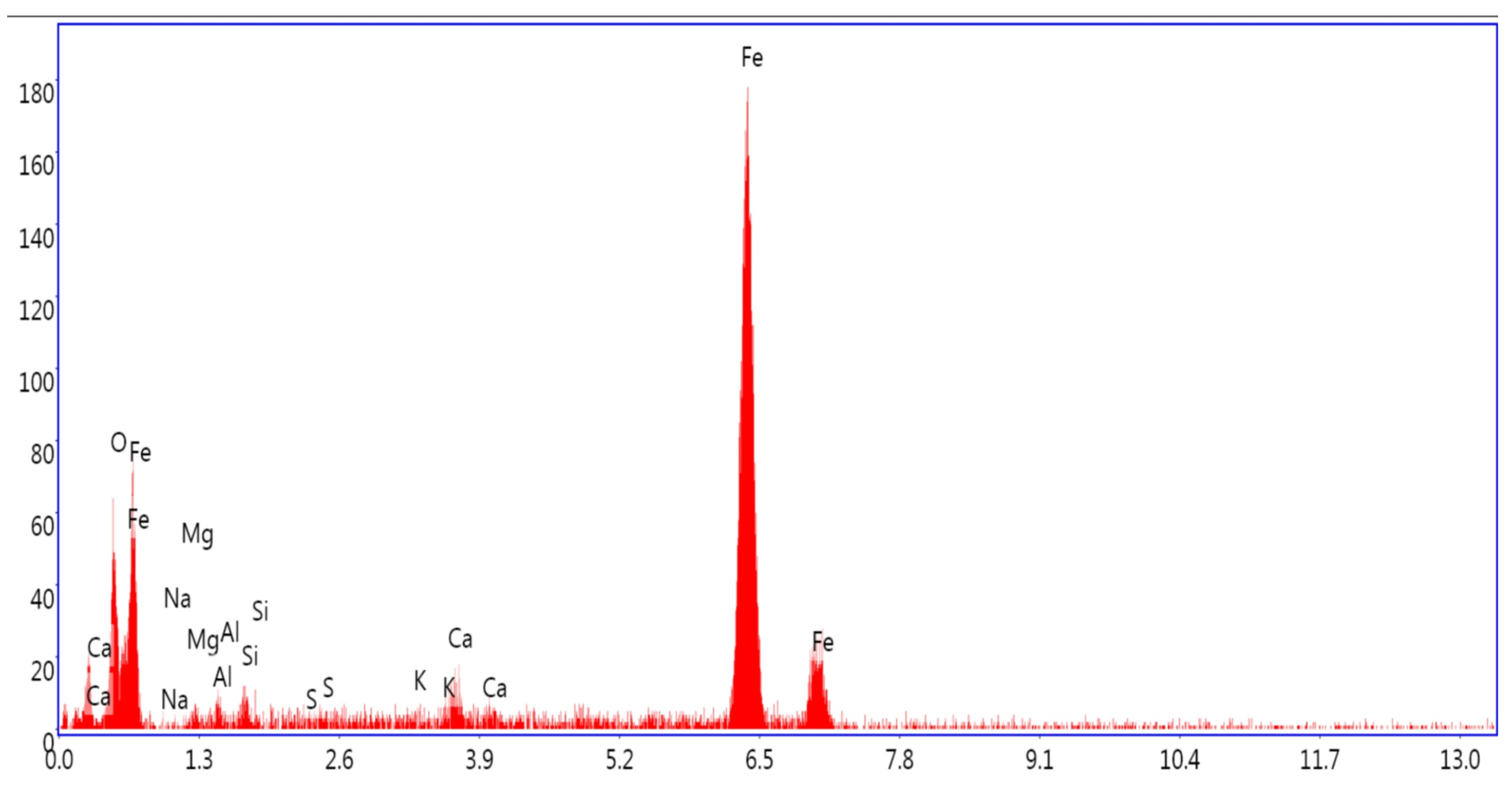

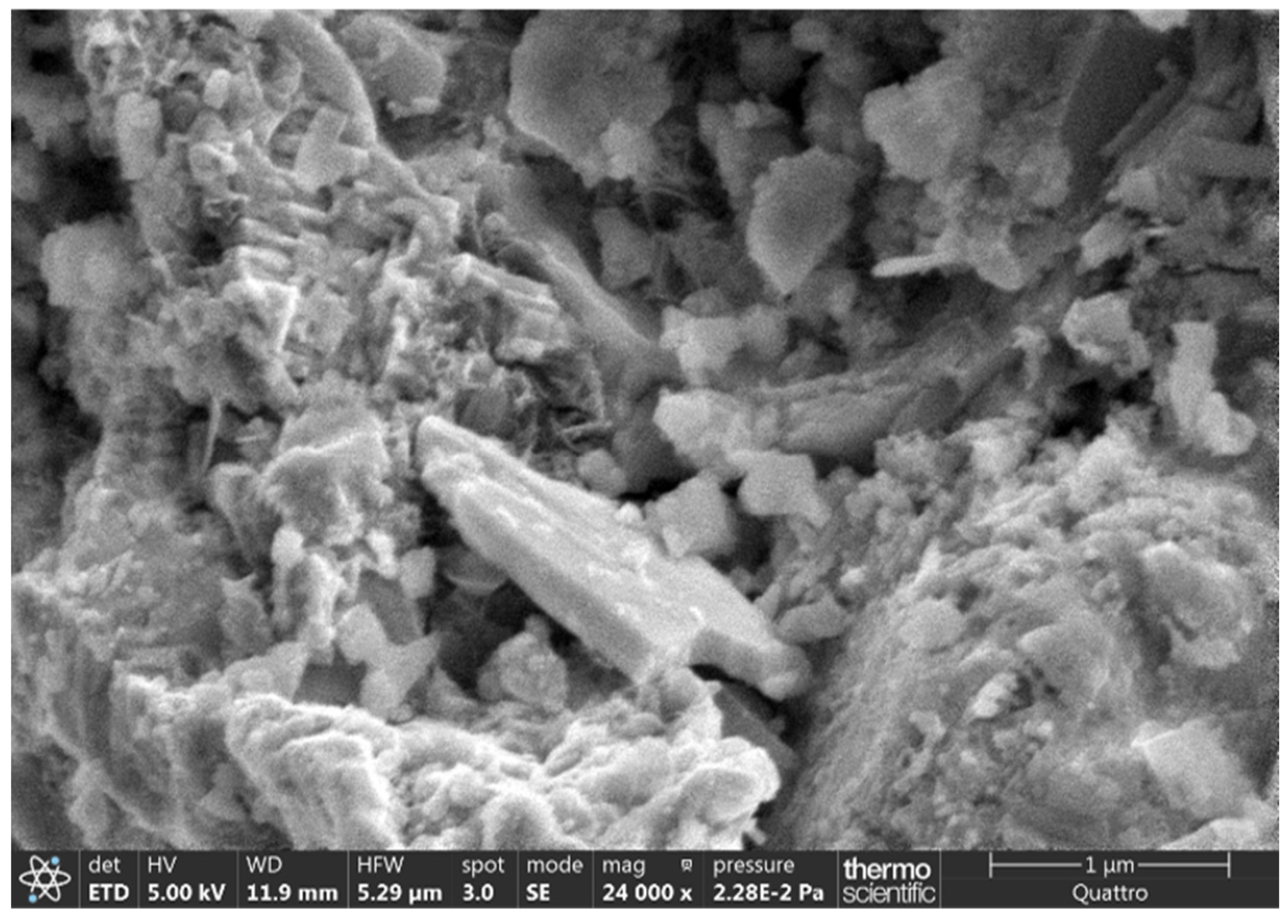

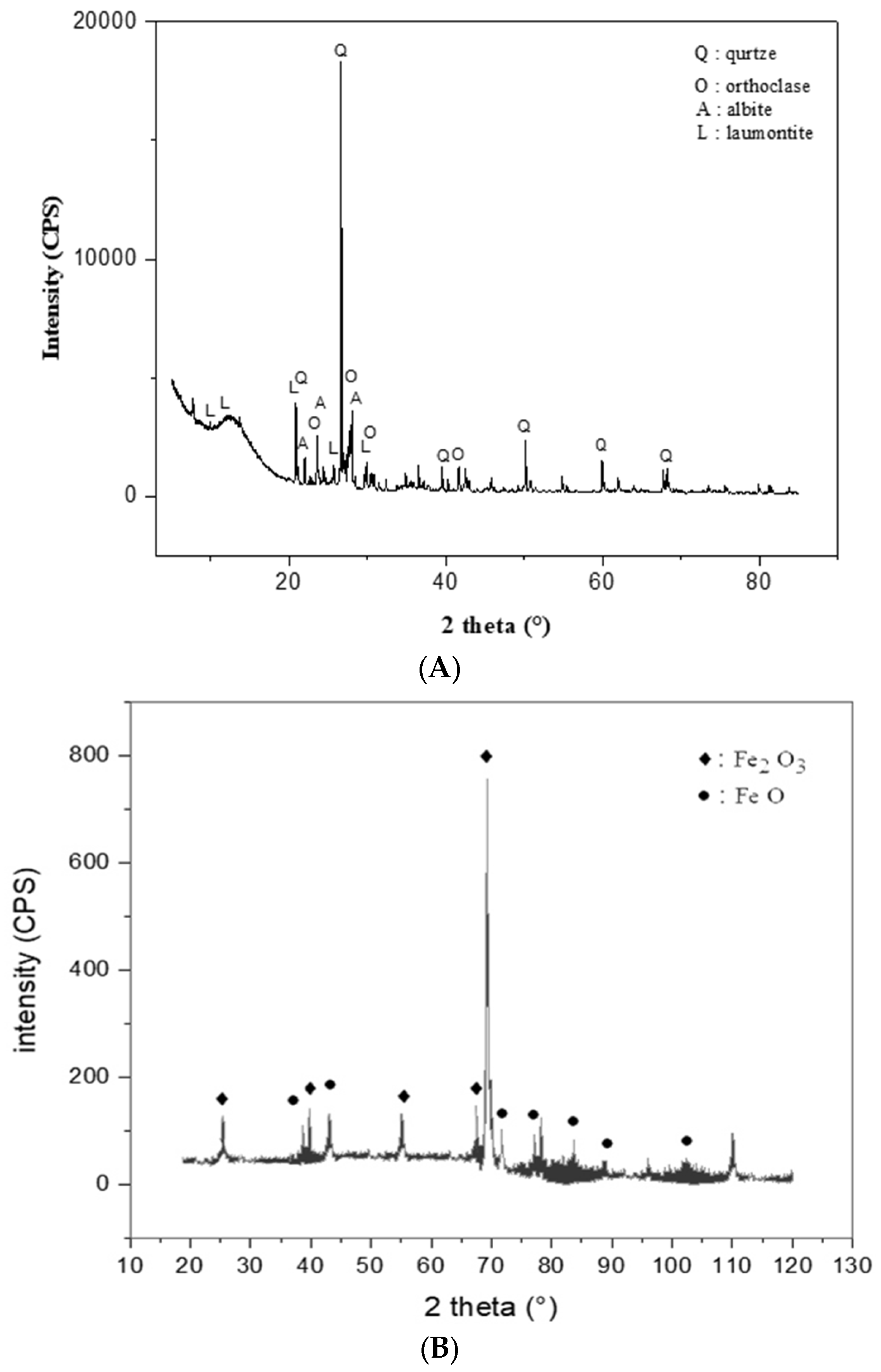

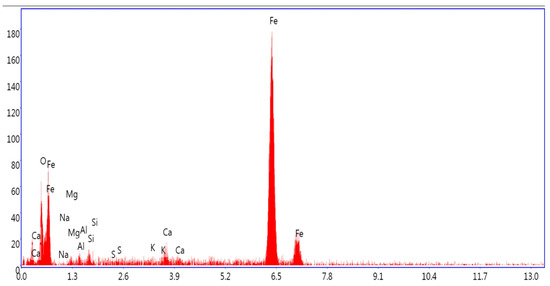

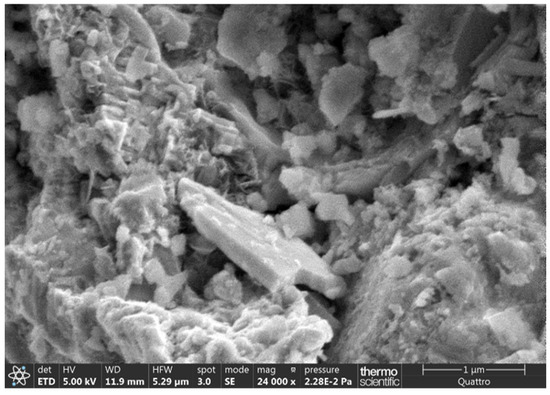

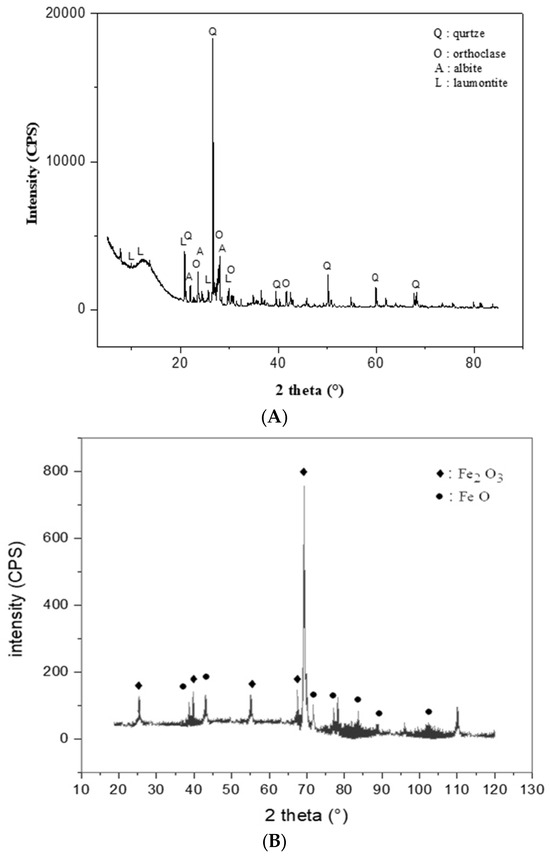

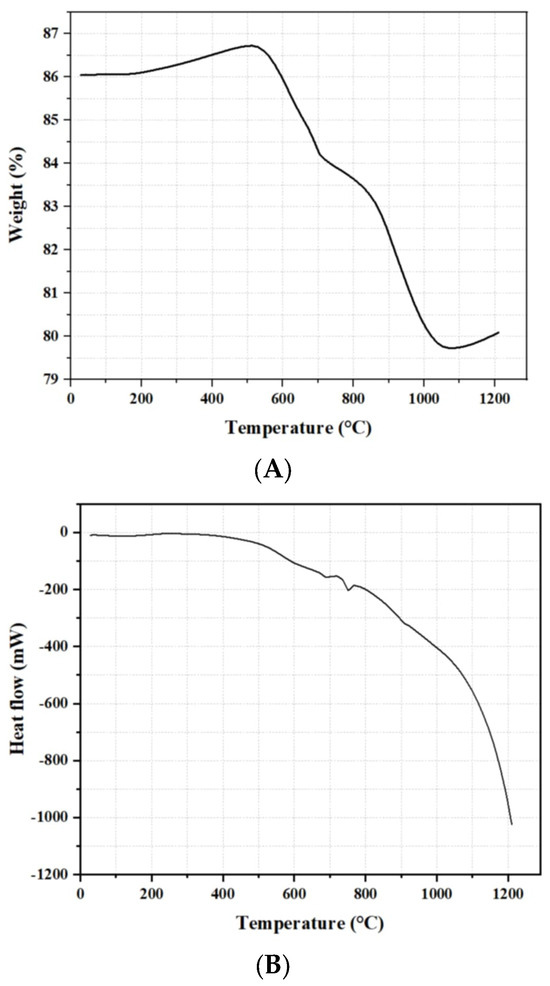

Volcanic tuff (VTF) and iron powder (IP) were used as basic materials for the formulation of geopolymer binders. Volcanic tuff (VTF) was obtained from GRANU EST (Chetaibi, Algeria), and iron powder (IP) was provided by Algerian Qatari steel–AQS (El Milia, Algeria). Using the Blaine method [60], the specific surface area of the VTF and IP was determined as 4900 cm2/g and 2250 cm2/g, respectively. The absolute density is 2.59 for VTF and 1.22 for IP. The chemical compositions of VTF and IP were determined using X-ray fluorescence (XRF) analysis, and the results are summarized in Table 1. The elemental composition of IP was determined based on energy dispersive X-ray spectroscopy (EDS) measurement (Figure 1). The EDS analysis indicates that the IP had a high Fe content and trace quantities of other elements such as O, Ca, Si, Mg, Na, Al, K, and S. Scanning electron microscopy (SEM) of IP is shown in Figure 2. The SEM image clearly reveals that iron powder particles have an angular shape. This is probably due to the way they are grounded. The results of energy-dispersive X-ray spectroscopy (EDS) quantification of iron powder are shown in Table 2. This includes the weight percent, atomic percent, and various correction parameters such as Z (atomic number) correction, A (absorption) correction, and F (fluorescence) correction. These results are significant because they indicate the purity of developed nanocrystalline structures, which affect the mechanical properties [61]. The X-ray diffraction (XRD) analysis of VTF and IP is shown in Figure 3. The most intense peaks [(18,120), 26.87°] and [(757), 69.32°] were scanned for VTF and IP, respectively. Figure 4 shows a Differential Scanning Calorimetry (DSC) analysis of iron powder.

Table 1.

Chemical composition of tuff and iron powder.

Figure 1.

EDS spectrum of iron powder.

Figure 2.

SEM image of iron powder.

Table 2.

Energy-dispersive X-ray spectroscopy (EDS) quantification of iron powder.

Figure 3.

XRD patterns of (A) volcanic tuff and (B) iron powder.

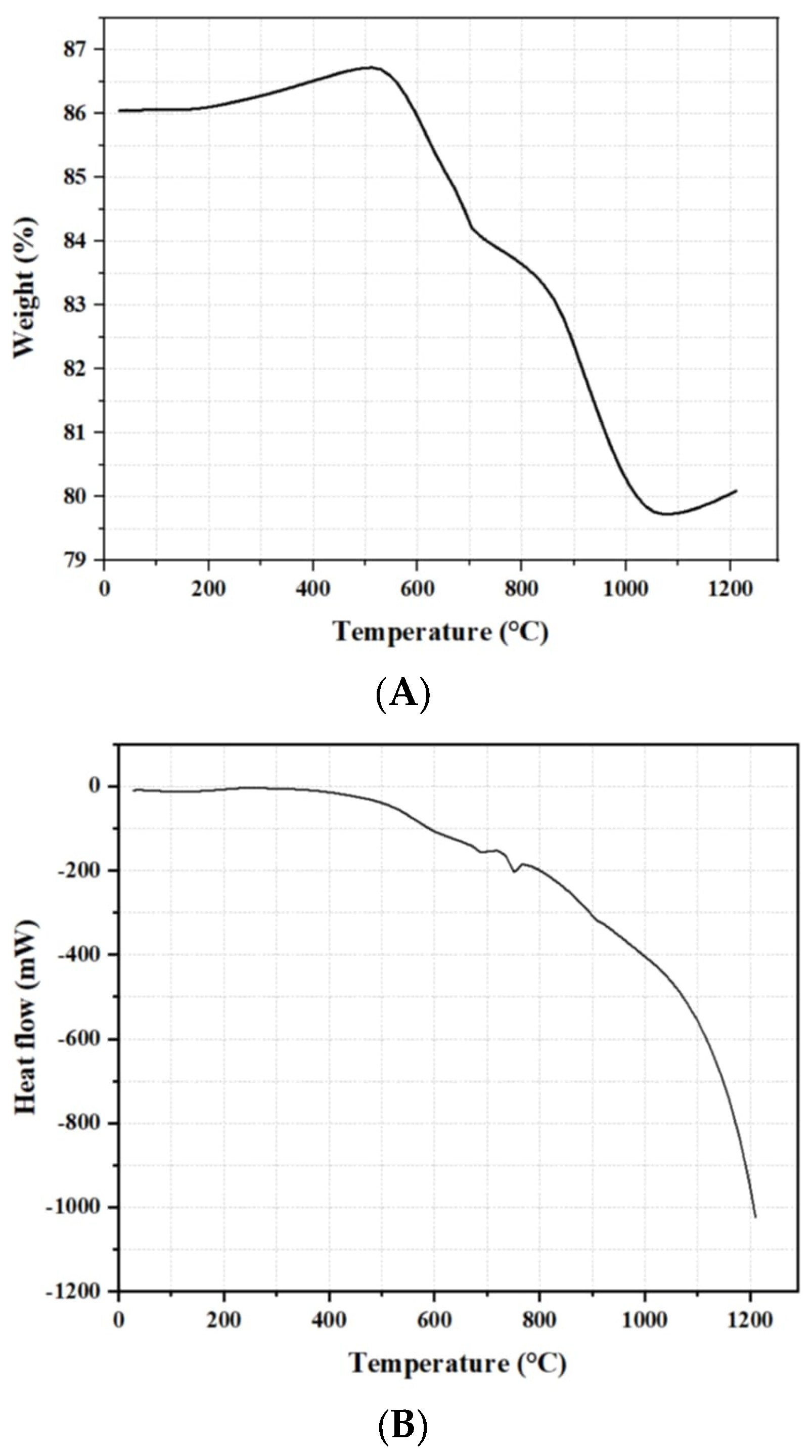

Figure 4.

Differential scanning calorimetry: (A) weight loss of iron powder as a function of temperature, and (B) heat flow of iron powder as a function of temperature.

The alkaline activators used for the production of geopolymers consisted of sodium hydroxide (SH) in micro-pearls with a purity of 99% and a molecular mass of 40 g/mol, and sodium silicate gel (SS) with SiO2 and Na2O contents of 28.8% and 14.2%, respectively, and a water content of 57%. Finally, the physical properties of the sand used in the mixture are presented in Table 3.

Table 3.

Physical properties of sand.

The DSC (differential scanning calorimetry) curve of iron powder provides valuable information about its thermal stability and oxidation behavior of iron powder. The DSC curve in Figure 4A shows a typical weight loss profile of an iron powder sample as it is heated from 0 °C to 1200 °C. Figure 4B shows the heat flow (in milliwatts) experienced by the iron powder sample during this heating process.

Analysis of Figure 4A reveals that the curve remains relatively flat from 0 to 500 °C, indicating minimal weight loss. Between 500 °C and 700 °C, a gradual decline in weight is observed, which can be attributed to the oxidation of iron, forming iron oxides (FeO, Fe2O3) and releasing oxygen. From 700 °C to 1000 °C, a steeper decline in weight is observed, suggesting accelerated oxidation. The formation of a more stable oxide layer might hinder further oxidation, leading to a slower rate of weight loss in the subsequent region (1000–1200 °C) and a near-equilibrium state.

The analysis of Figure 4B reveals an initial endothermic peak between 0 °C and 200 °C, suggesting that the sample is absorbing heat from the environment. This peak is likely attributed to the vaporization of any adsorbed moisture or volatile compounds present on the iron powder’s surface. From 200 °C to 650 °C, an exothermic peak is observed, indicating that the sample is releasing heat. This is primarily due to the oxidation of iron, as it reacts with oxygen in the atmosphere to form iron oxides. Between 650 °C and 1000 °C, several smaller endothermic peaks are observed, which might correspond to phase transformations within the iron oxide layer or the decomposition of additional compounds in the sample. A final exothermic peak is seen at higher temperatures (1000–1200 °C), potentially indicating further oxidation of the iron oxide layer or the crystallization of amorphous phases.

2.2. Geopolymer Mortar with Volcanic Tuff (VTF) and Iron Powder (IP)

Volcanic tuff (VTF) was used as a precursor and sodium silicate gel (SS) and sodium hydroxide (SH) in micro-pearls as an activator. The mixtures were made so that NaOH was kept constant at 10 M, the silica modulus was equal to 1, and the activator/precursor ratio was equal to 0.35. The alkaline activator solution was prepared and stored for 24 h before being combined with the VTF and IP. These parameters were selected on preliminary tests. A total of 4 mixtures were prepared: 1 control mixture with 100% VTF and three mixtures in which VTF is replaced by IP at percentages of 5%, 10%, and 20%. They were cast into prismatic metallic molds (40 × 40 × 160 mm3) by vibration and demolded after 24 h for the two curing time temperatures of 25 °C and 80 °C. Table 4 shows the different mixtures used in the manufacture of geopolymer mortar. Flexural and compressive strengths of geopolymer mortar were measured at 28 days.

Table 4.

Composition of different geopolymer mortars.

3. Result and Discussion

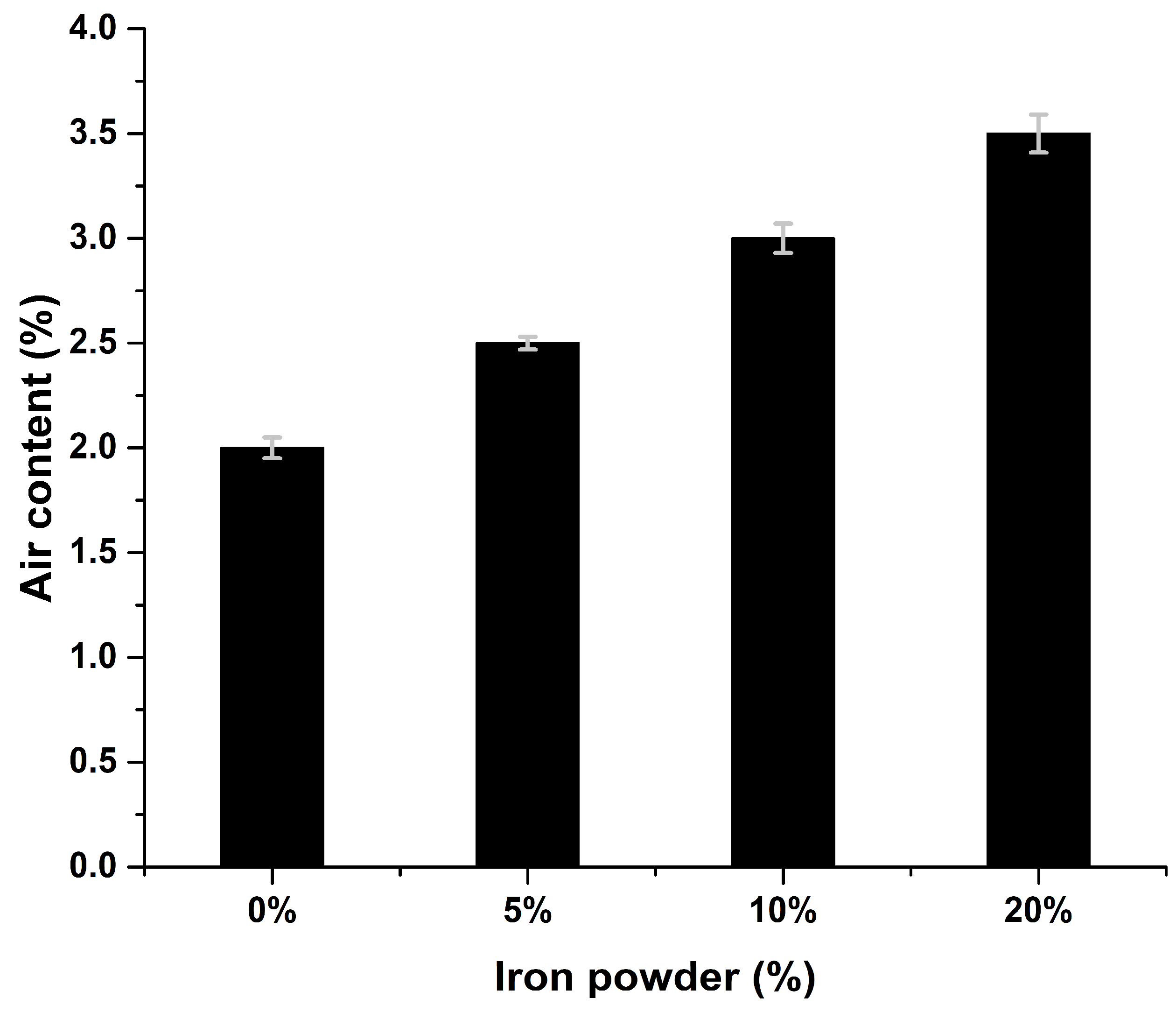

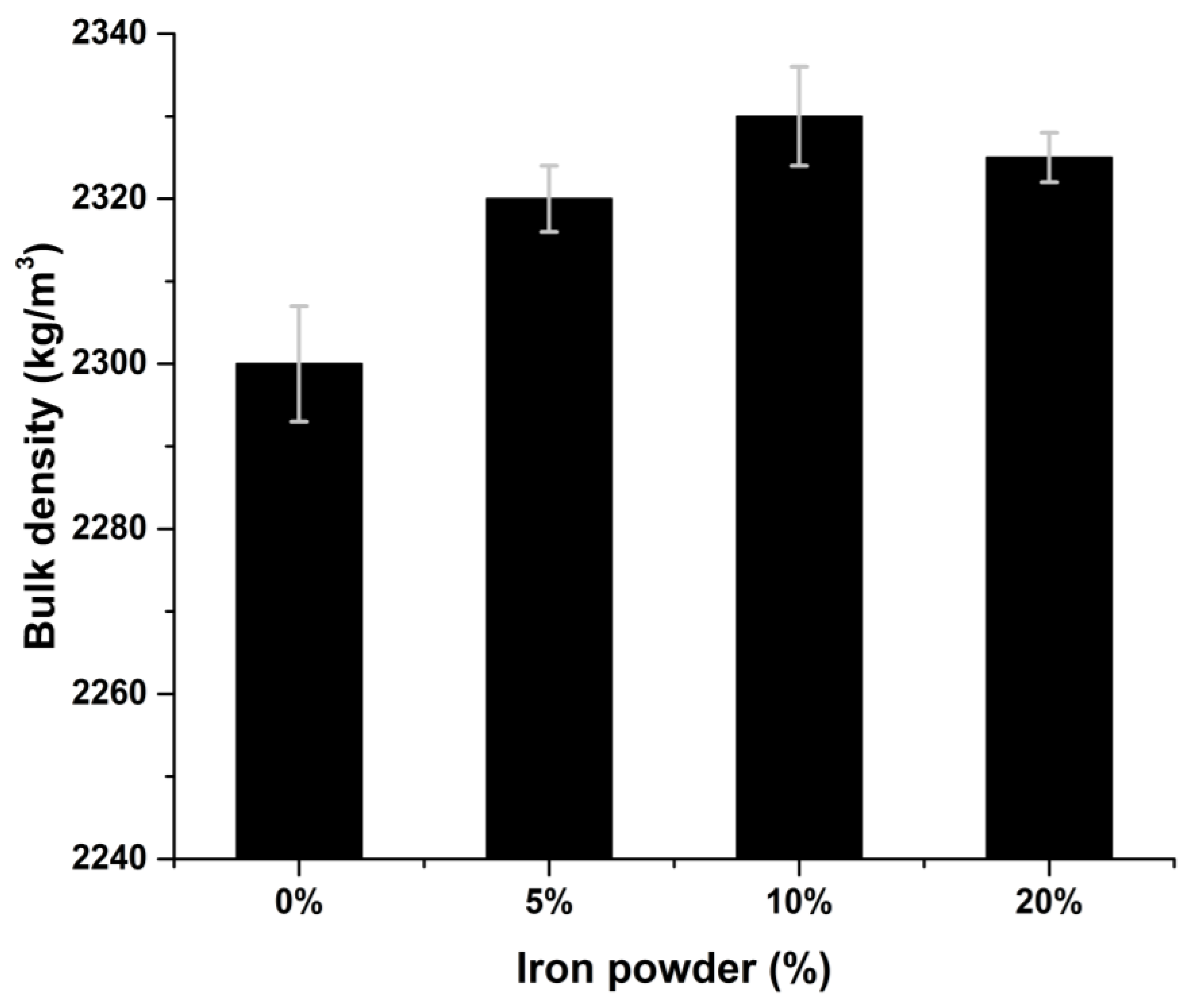

3.1. Air Content and Bulk Density

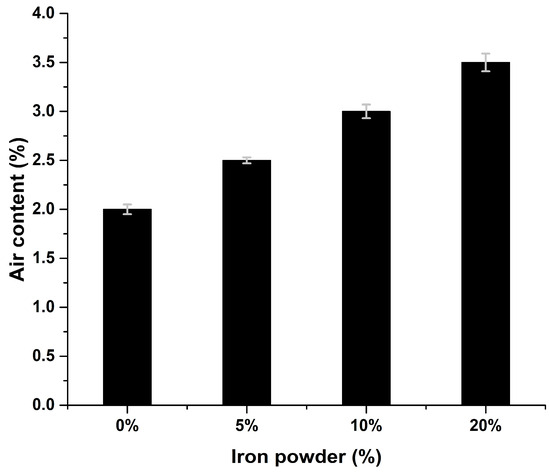

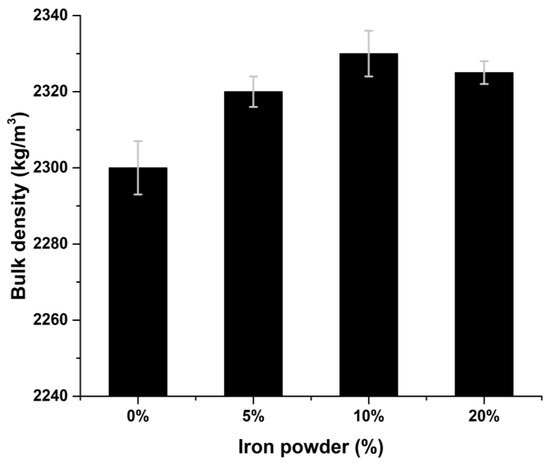

The air content was measured using a mortar aerometer following standard NF EN 1015-7 [62]. The bulk density of the mortar was determined according to standard NF EN 1015-6 [63]. The results of air content and bulk density of the different geopolymers mortars are shown in Figure 5 and Figure 6.

Figure 5.

Evolution of air content according to substitution rate of tuff with iron powder.

Figure 6.

Evolution of bulk density according to substitution rate of tuff with iron powder.

The results shown in Figure 5 indicate that the air content in all geopolymer mortars increases according to the IP substitution rate, reaching 3.5% for mixtures with 80% tuff and 20% IP. This result can be explained by two facts. Angular iron powder particles (Figure 2) typically exhibit a larger surface area compared to their rounded counterparts. This increased surface area provides more nucleation sites for air bubbles, hindering their coalescence and subsequent escape. Furthermore, the interlocking of these angular particles, facilitated by their sharp edges, creates voids within the powder bed, further trapping air bubbles and impeding their release.

On the other hand, the mixing process of geopolymer mortars (adding solutions of SS, SH and IP over several times) generates more air bubbles, leading to higher air content compared to control geopolymer without IP.

As can be seen from Figure 6, the bulk density of the geopolymers mortars is slightly affected (up to 1.3%) according to the IP substitution rate. These results are in agreement with previous investigations [64,65,66].

By correlating these results with the SEM images, we can better understand why the bulk density is higher for the 10% iron powder despite its higher air content. The 10% iron powder may have a more favorable particle size distribution or shape that allows for more efficient packing compared to the 20% iron powder. While the air content is higher at 10%, the air voids might be smaller or more irregularly shaped, facilitating a denser packing of the solid particles.

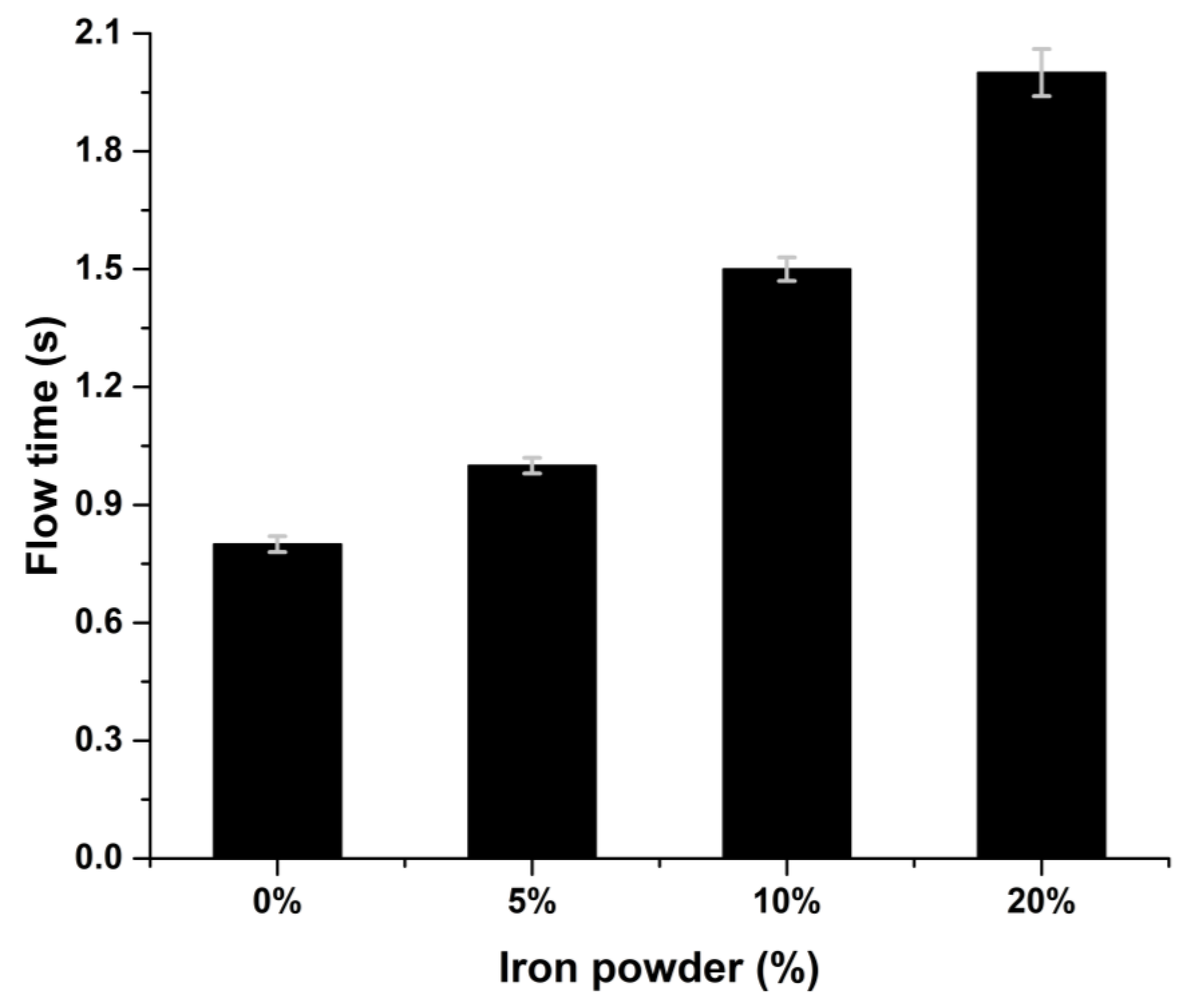

3.2. Workability (Flow Time)

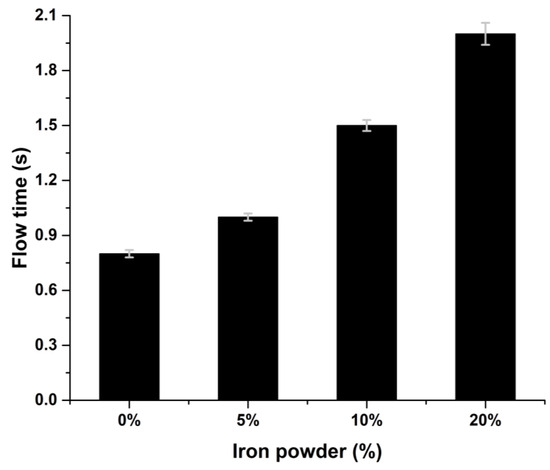

To characterize the workability and flow time of all the mortars tested, the workability meter LCPC (French test) was used. It is composed of a rectangular form with a movable wall and vibrator. The principle of the test is to determine the time taken for the mortar to reach a mark on the inner surface of the mold after removal of the movable wall and vibration. The results of the flow time test are shown in Figure 7.

Figure 7.

Evolution of flow time according to substitution rate of tuff with iron powder.

The results shown in Figure 7 indicate that the best flow time was obtained with control geopolymer mortar with 100% tuff. It has been observed that the use of iron powder slightly increases the flow time of geopolymer mortars (from 0.8 to 2 s). This increase is more pronounced with increasing the percentage of iron powder.

Indeed, it can be seen that the variation in air content is in good accordance with the variation in workability (flow time). A mixture with a high flow time will contain more air than the other geopolymer mortar mixtures. There can be two explanations for this development. Firstly, a less workable mixture contains more entrapped air. Secondly, the higher viscosity of the mixture makes it more difficult to achieve a homogenous mix and effectively release entrapped air [55,67,68].

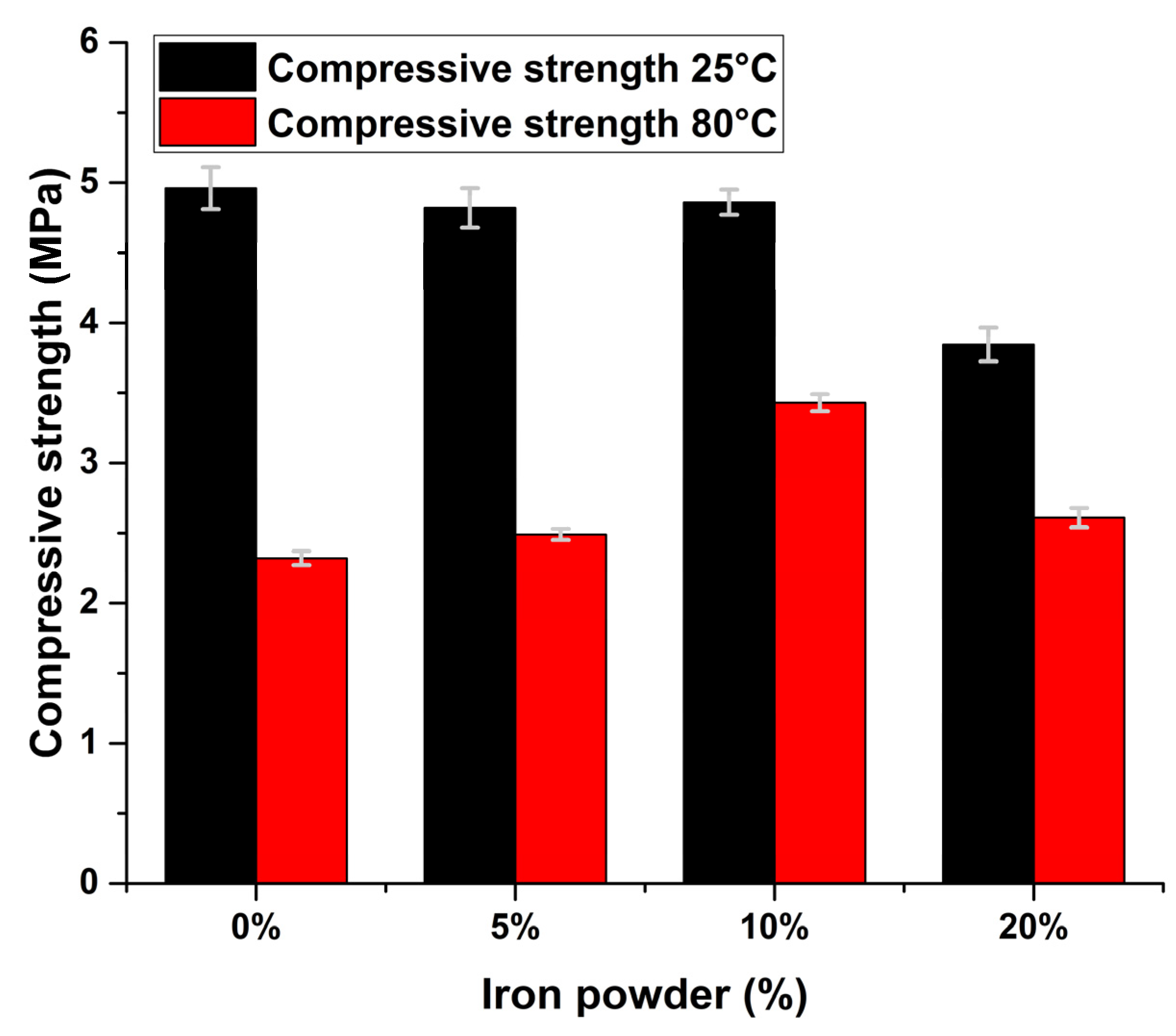

3.3. Compressive Strength

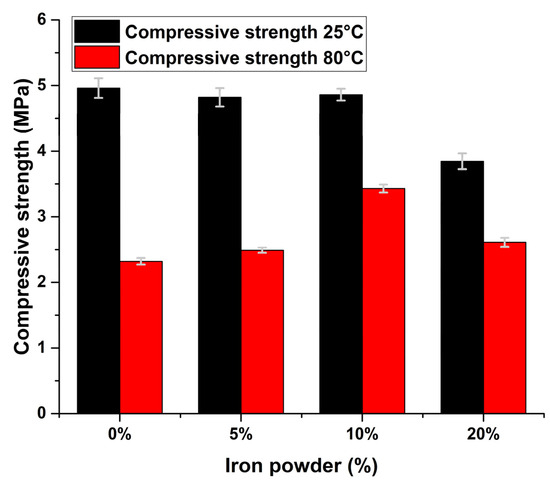

The results of the compressive strength test after 28 days are shown in Figure 8, each value being the average of three measurements. The NF EN 1015-11/A1 standard [69] was used for the compressive strength test.

Figure 8.

Evolution of compressive strength according to substitution rate of tuff with iron powder and according to cure temperature.

According to Figure 8, the use of iron powder reduces the compressive strength by a percentage of 2.82% for GPM5, 2.01% for GPM10, and 22.479% for GPM20 in comparison to control concrete for geopolymers mortars cured at 25 °C. Furthermore, the cure at 80 °C shows that the compressive strength reduces by a percentage of 53.22% for GPM0, 49.79% for GPM5, 30.84% for GPM10, and 47.37% for GPM20 in comparison to geopolymers mortars cured at 25 °C. The decrease in compressive strength was less pronounced when incorporating iron powder, particularly with a 10% addition, at both curing temperatures of 25 °C and 80 °C.

These findings align with previous observations regarding air content. Specifically, an increase in air voids within the geopolymer mortar (GPM) leads to higher porosity and consequently a decrease in compressive strength. On the other hand, the decrease in compressive strength after curing at 80 °C was attributed to the reduction in the quantity of water after curing, which is defined by the H2O/NaOH ratio. Although water is not a geopolymerization reagent. This ratio is determined by the intended application and could be related to another ratio, water/solid, which can be related to the W/C ratio in cementitious materials.

The use of iron powder reduces the sudden evaporation of water in the mixture, thereby cushioning the drop in resistance of 23.62% for GPM10 compared to the GPM0 without IP. Considering that 10% of the iron powder is the optimum dosage for compressive strength. By comparing these results with XRF, EDS, and DSC data, we can better understand how the presence of iron powder affects the compressive strength of geopolymer mortars. When iron powder is added to geopolymer mortars, it can undergo oxidation to form iron oxide. The presence of iron oxide particles might have interfered with the formation of the three-dimensional aluminosilicate network, hindering the development of a strong and cohesive matrix.

Moreover, this oxidation process is often exothermic, meaning it releases heat. The heat released during iron oxide formation can also inhibit the polymerization of the geopolymer matrix, leading to a less well-connected structure with more air content. In addition, iron has a different coefficient of thermal expansion than the geopolymer matrix. This mismatch can lead to internal stresses and microcracks when the material is subjected to temperature fluctuations (curing at 80 °C). These microcracks can weaken the structure and reduce compressive strength.

While previous studies on other precursors (e.g., fly ash, kaolin, and metakaolin) [17,58] have also shown a negative impact of iron powder on compressive strength, our findings with volcanic tuff as a precursor corroborate these observations.

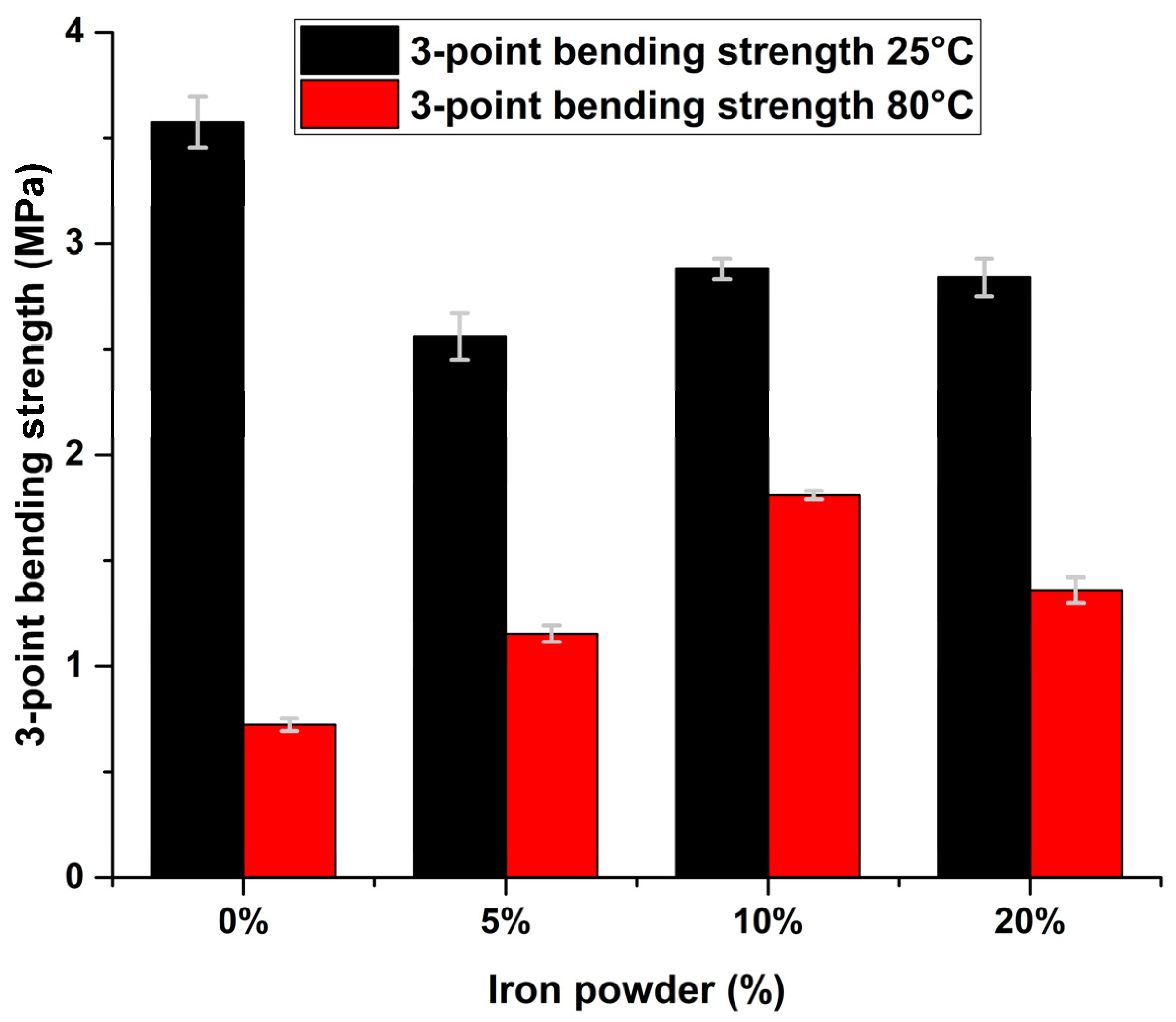

3.4. Three-Point Bending Strength

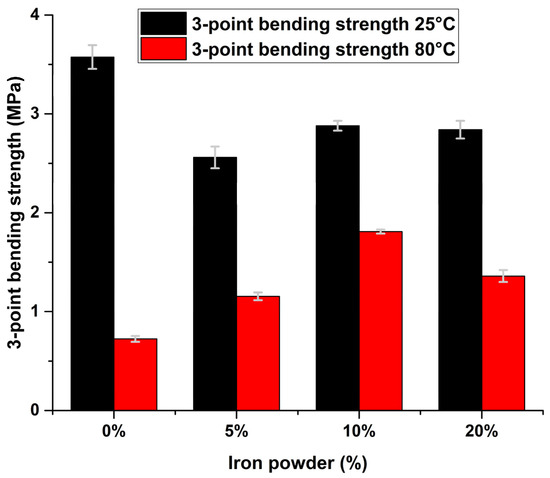

The 3-point flexural strength test has been carried out following NF EN 1015-11/A1 [69]. Figure 9 shows the test results.

Figure 9.

Evolution of 3-point bending strength according to substitution rate of tuff with iron powder and according to cure temperature.

The experimental results of 3-point bending strength of mortar cured at 25 °C in Figure 9 show that the 3-point flexural strength decreases with increasing iron powder content by 28.39% for GPM5, 19.44% for GPM10 and 20.56 for GPM20. Curing at 80 °C does not give better results than curing at 25 °C because the drop in resistance was 79.72% for GPM0, 67.69% for GPM5, 49.37% for GPM10 and 61.95% for GPM 20. This decrease was less pronounced for GPM10 at both temperatures, which confirms the results of the compressive strength and air content.

Indeed, the GPM with higher air content (Figure 5) causes an increase of air bubbles and pore space within the GPM and thus a decrease of the 3-point flexural strength. The significant decrease in flexural strength observed after curing at 80 °C aligns with the observed reduction in compressive strength. This decline can be attributed to several factors. Firstly, the elevated curing temperature accelerates water evaporation, leading to a decrease in the H2O/NaOH ratio, which is crucial for the geopolymerization reaction. Secondly, the presence of iron powder exacerbates this issue. The oxidation of iron powder at 80 °C is an exothermic process, generating heat that can inhibit the geopolymerization reaction, resulting in a less well-connected microstructure with increased porosity. Finally, the mismatch in thermal expansion coefficients between iron and the geopolymer matrix can induce internal stresses and microcracks during the curing process, further weakening the material.

Nevertheless, iron powder helps prevent rapid water evaporation from the mixture, consequently attenuating the drop in resistance of 30.35% for GPM10 compared to GPM0 without IP. These results align with the findings for compressive strength, suggesting a shared underlying mechanism. We consider that the optimal dosage for 3-point flexural strength is 10% iron powder.

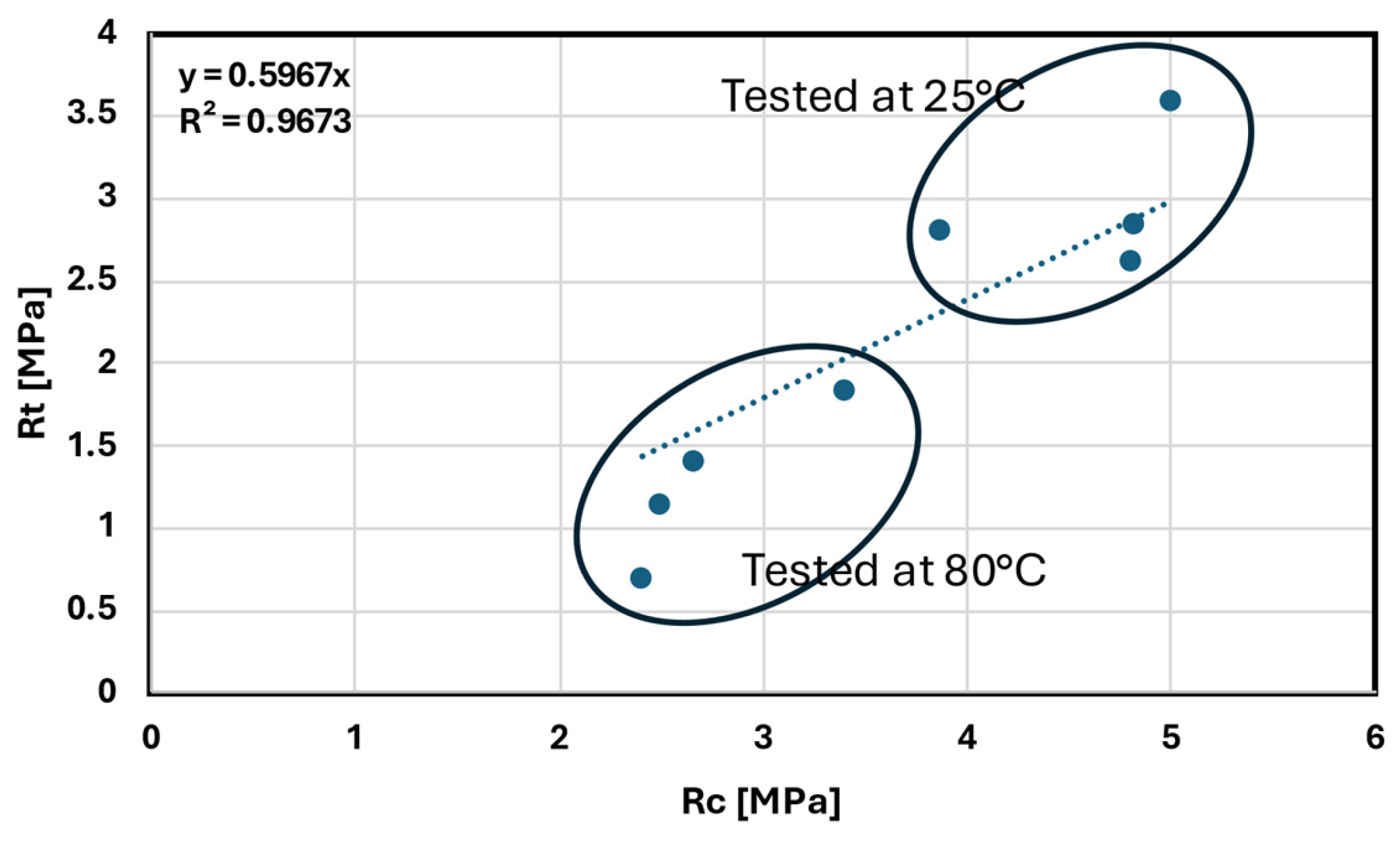

3.5. Correlation Between Flexural and Compressive Strength

Several studies have reported the relationship between flexural strength (Rt) and compressive strength (Rc) of concrete [70,71] and geopolymer mortars [72,73]. The relationships cited in the references are shown in Table 5.

Table 5.

Relationships cited in the references.

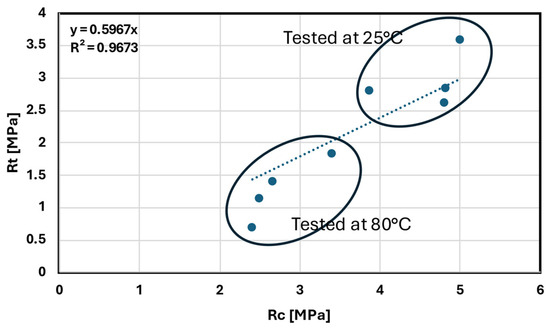

According to Figure 10, Equation (1) shows the empirical relationship between the 3-point flexural strength and compressive strength of geopolymer mortars. Equation (1) can be adapted in this situation so that we obtain the following:

Rt = 0.5967 Rc

Figure 10.

Correlation between 3-point bending strength and compressive strength.

On the other hand, in the context of geopolymer mortars with volcanic tuff (VTF) and iron powder (IP) as precursors and sodium silicate gel (SS) and sodium hydroxide (SH) as activators, a very high value of R2 = 0.9673 was obtained, indicating an excellent fit of the model to the data. The empirical relationship established between bending and compressive strengths provides valuable insights into the mechanical behavior of geopolymer mortars produced with volcanic tuff (VTF) and iron powder (IP). Analysis reveals a balanced resistance in both compression and bending, with an approximate 60% ratio of bending to compressive strength. This balanced performance likely stems from a homogeneous and well-consolidated microstructure within the geopolymer matrix, facilitated by the unique chemical composition of VTF and the incorporation of IP. This strong correlation suggests that compressive strength can effectively predict the bending strength of these materials, indicating a consistent and predictable stress-strain response.

4. Conclusions

The results obtained from the experimental program, combined with the silica-rich composition and natural abundance of volcanic tuff, establish it as a highly promising and eco-friendly precursor for sustainable geopolymer applications. The incorporation of waste iron powder, particularly at dosages below 10%, has demonstrated its viability for use in applications such as earth block construction and plastering. Indeed, according to the Algerian standard NA 5020, dirt blocks should ideally possess a minimum compressive strength of 5 MPa and a minimum flexural strength of 2 MPa. These values are generally considered sufficient for most residential and commercial applications. This innovative approach aligns with the principles of sustainable development by reducing industrial waste, promoting the circular economy, and minimizing the environmental footprint of construction materials. Furthermore, by decreasing reliance on Portland cement, which is associated with high carbon emissions, this research advances environmentally responsible and resource-efficient construction practices. These findings underscore the potential of volcanic tuff and iron powder-based geopolymers to contribute to the development of greener and more sustainable infrastructure. More detailed findings can be summarized in points as follows:

Incorporating iron powder (IP) into volcanic tuff (VTF) geopolymer mortars significantly increases the air content. This is due to the angular shape of the IP particles, which trap air bubbles, and the multi-stage mixing process, which generates additional air, which affects workability, compressive strength, and 3-point flexural strength.

The addition of iron powder (IP) has a minimal impact on the bulk density of geopolymer mortars.

The incorporation of iron powder into geopolymer mortars reduces compressive strength and 3-point bending strength, whatever the cure temperature.

Increasing the curing temperature (80 °C) led to a more pronounced decrease in compressive strength and 3-point bending strength due to water loss, which adversely affected the geopolymerization process.

10% of iron powder (IP) helps retain water in geopolymer mortars, reducing the negative impact of high-temperature curing on compressive strength and 3-point bending strength.

Linear regression will help us to predict the relationship between 3-point bending strength (Rt) and compressive strength (Rc).

However, further research and comprehensive testing are crucial to fully assess the material’s suitability for these applications and to optimize the recovery process. Specifically, investigations should focus on durability, environmental impact under various conditions, influence of surface area, and long-term performance. While the current study demonstrates the feasibility of fabricating geopolymers using volcanic tuff and iron powder under varying fabrication temperatures and iron powder percentages, the conclusions could benefit from a more robust statistical validation. Future work will incorporate statistical analysis, such as ANOVA [7,51], to assess the significance of observed differences between compositions and identify the primary factors influencing mechanical performance. Additionally, multi-criteria decision analysis (MCDA) will be explored to comprehensively evaluate the trade-offs between various properties of the geopolymers. These approaches will ensure a more rigorous assessment of the material modifications and further support the development of optimized geopolymer formulations.

Author Contributions

Conceptualization, M.L.K.K. and C.B.; methodology, M.L.K.K., C.B. and S.C.; software, all authors.; validation, M.L.K.K., C.B. and S.C.; formal analysis, all authors; investigation, M.L.K.K., S.B., C.B., A.B. and S.H.; resources, all authors; data curation, all authors; writing—original draft preparation, all authors; writing—review and editing, all authors; visualization, M.L.K.K., S.B., C.B. and S.C.; supervision, C.B. and S.C.; project administration, C.B.; funding acquisition, C.B. and S.C. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the Wroclaw University of Science and Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are presented in the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ürünveren, H.; Beycíoğlu, A.; Resuloğulları, E.Ç.; Diíşken, N.B. A comparative investigation of eco-friendly fly ash-based geopolymer mortar produced by using electrical and heat curing: Mechanical properties, energy consumption and cost. Constr. Build. Mater. 2024, 439, 137200. [Google Scholar] [CrossRef]

- El Moustapha, B. Formulation et Étude d’un Géopolymère Accumulateur d’Énergie Thermique dans le Cadre de l’Éco-Construction des Bâtiments. Doctoral Dissertation, HESAM Université, Université de Nouakchott, Nouakchott, Mauritania, 2023. [Google Scholar]

- U.S. Geological Survey. Mineral Commodity Summaries; U.S. Geological Survey: Reston, VA, USA, 2015; p. 196. [CrossRef]

- Khaiyum, M.Z.; Sarker, S.; Kabir, G. Evaluation of carbon emission factors in the cement industry: An emerging economy context. Sustainability 2023, 15, 15407. [Google Scholar] [CrossRef]

- Rossignol, S.; Gharzouni, A. Géopolymères—Précurseurs et Propriétés. Tech. L’ingénieur 2022, 3303, 1–18. [Google Scholar] [CrossRef]

- Shen, W.G.; Cao, L.; Li, Q.; Zhang, W.S.; Wang, G.M.; Li, C.C. Quantifying CO2 Emissions from China’s Cement Industry. Renew. Sustain. Energy Rev. 2015, 50, 1004–1012. [Google Scholar] [CrossRef]

- Kępniak, M.; Recha, F.; Prochoń, P. Application of a Generalized Utility Function to Determine the Optimal Composition of Geopolymer Mortar. Materials 2024, 17, 6237. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications; Institut Géopolymère: Saint-Quentin, France, 2011. [Google Scholar]

- Jwaida, Z.; Dulaimi, A.; Mashaan, N.; Othuman Mydin, M.A. Geopolymers: The green alternative to traditional materials for engineering applications. Infrastructures 2023, 8, 98. [Google Scholar] [CrossRef]

- Zhang, J.; Ge, Y.; Li, Z.; Wang, Y. Facile Fabrication of a Low-Cost and Environmentally Friendly Inorganic–Organic Composite Membrane for Aquatic Dye Removal. J. Environ. Manag. 2020, 256, 109969. [Google Scholar] [CrossRef]

- Aouan, B.; Alehyen, S.; Fadil, M.; El Alouani, M.; Saufi, H.; El Makhoukhi, F.; Taibi, M.H. Development and Optimization of Geopolymer Adsorbent for Water Treatment: Application of Mixture Design Approach. J. Environ. Manag. 2023, 338, 117853. [Google Scholar] [CrossRef]

- Lahoti, M.; Tan, K.H.; Yang, E.H. A Critical Review of Geopolymer Properties for Structural Fire-Resistance Applications. Constr. Build. Mater. 2019, 221, 514–526. [Google Scholar] [CrossRef]

- Aiken, T.A.; Kwasny, J.; Sha, W.; Soutsos, M.N. Effect of Slag Content and Activator Dosage on the Resistance of Fly Ash Geopolymer Binders to Sulfuric Acid Attack. Cem. Concr. Res. 2018, 111, 23–40. [Google Scholar] [CrossRef]

- Samantasinghar, S.; Singh, S.P. Effect of Synthesis Parameters on Compressive Strength of Fly Ash-Slag Blended Geopolymer. Constr. Build. Mater. 2018, 170, 225–234. [Google Scholar] [CrossRef]

- Çelik, A.I.; Özkılıç, Y.O.; Bahrami, A.; Hakeem, I.Y. Mechanical performance of geopolymer concrete with micro silica fume and waste steel lathe scraps. Case Stud. Constr. Mater. 2023, 19, e02548. [Google Scholar] [CrossRef]

- Yang, M.J.; Paudel, S.R.; Asa, E. Comparison of Pore Structure in Alkali-Activated Fly Ash Geopolymer and Ordinary Concrete due to Alkali-Silica Reaction Using Micro-Computed Tomography. Constr. Build. Mater. 2020, 236, 117524. [Google Scholar] [CrossRef]

- Wan, Q.; Zhang, Y.; Zhang, R. The Effect of Pore Behavior and Gel Structure on the Mechanical Property at Different Initial Water Content. Constr. Build. Mater. 2021, 309, 125146. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Mendis, P. How Does Aluminium Foaming Agent Impact the Geopolymer Formation Mechanism? Cem. Concr. Compos. 2017, 80, 277–286. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M.; Hutchison, W. Resistance of Fly Ash-Based Geopolymer Mortar to Both Chemicals and High Thermal Cycles Simultaneously. Constr. Build. Mater. 2020, 239, 117886. [Google Scholar] [CrossRef]

- Zailani, W.W.A.; Norain, M.N.; Apandi, N.M.; Tahir, M.F.M.; Faris, M.A.; Abdullah, M.M.A.B.; Razak, R.A.; Sinarta, I.N.; Agustini, N.K.A. Properties and performance of fly ash–based geopolymer as concrete repair material. In Recent Developments of Geopolymer Materials; Woodhead Publishing: Cambridge, UK, 2025; pp. 163–179. [Google Scholar]

- Faris, M.A.; Abdullah, M.M.A.B.; Tahir, M.F.M.; Hashim, M.F.A.; Zailani, W.W.A. Properties of fly ash–metakaolin-based geopolymer concrete by inclusion steel fibers. In Recent Developments of Geopolymer Materials; Woodhead Publishing: Cambridge, UK, 2025; pp. 181–199. [Google Scholar]

- Łach, M.; Pławecka, K.; Bąk, A.; Lichocka, K.; Korniejenko, K.; Cheng, A.; Lin, W.T. Determination of the influence of hydraulic additives on the foaming process and stability of the produced geopolymer foams. Materials 2021, 14, 5090. [Google Scholar] [CrossRef]

- Bhutta, A.; Farooq, M.; Banthia, N. Performance characteristics of micro fiber-reinforced geopolymer mortars for repair. Constr. Build. Mater. 2019, 215, 605–612. [Google Scholar] [CrossRef]

- Tammam, Y.; Uysal, M.; Canpolat, O. Effects of alternative ecological fillers on the mechanical, durability, and microstructure of fly ash-based geopolymer mortar. Eur. J. Environ. Civ. Eng. 2022, 26, 5877–5900. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, W.H.; Liu, M.H. Setting time and mechanical properties of chemical admixtures modified FA/GGBS-based engineered geopolymer composites. Constr. Build. Mater. 2024, 431, 136473. [Google Scholar] [CrossRef]

- Liu, X.H.; Hu, C.F.; Chu, L.S. Microstructure, compressive strength, and sound insulation property of fly ash-based geopolymeric foams with silica fume as a foaming agent. Materials 2020, 13, 3215. [Google Scholar] [CrossRef] [PubMed]

- Sindhunata, A. Conceptual Model of Geopolymerisation. Ph.D. Thesis, University of Melbourne, Melbourne, Australia, 2006. [Google Scholar]

- Bai, C.Y.; Zheng, J.; Rizzi, G.A.; Colombo, P. Low-temperature fabrication of SiC/geopolymer cellular composites. Compos. B Eng. 2018, 137, 23–30. [Google Scholar] [CrossRef]

- Kabirova, A.; Uysal, M.; Hüsem, M.; Aygörmez, Y.; Dehghanpour, H.; Pul, S.; Canpolat, O. Physical and mechanical properties of metakaolin-based geopolymer mortars containing various waste powders. Eur. J. Environ. Civ. Eng. 2023, 27, 437–456. [Google Scholar] [CrossRef]

- Sarazin, J.; Davy, C.A.; Bourbigot, S.; Tricot, G.; Hosdez, J.; Lambertin, D.; Fontaine, G. Flame resistance of geopolymer foam coatings for the fire protection of steel. Compos. B Eng. 2021, 222, 109045. [Google Scholar] [CrossRef]

- Matalkah, F.; Aqel, R.; Ababneh, A. Enhancement of the mechanical properties of kaolin geopolymer using sodium hydroxide and calcium oxide. Procedia Manuf. 2020, 44, 164–171. [Google Scholar] [CrossRef]

- Qiao, Y.; Li, X.; Bai, C.; Li, H.; Yan, J.; Wang, Y.; Wang, X.; Zhang, X.; Zheng, T.; Colombo, P. Effects of surfactants/stabilizing agents on the microstructure and properties of porous geopolymers by direct foaming. J. Asian Ceram. Soc. 2021, 9, 412–423. [Google Scholar] [CrossRef]

- Mohammed, D.T.; Yaltay, N. Strength and elevated temperature resistance properties of the geopolymer paste produced with ground granulated blast furnace slag and pumice powder. Ain Shams Eng. J. 2024, 15, 102483. [Google Scholar] [CrossRef]

- Liang, G.; Zhu, H.; Zhang, Z.; Wu, Q.; Du, J. Investigation of the waterproof property of alkali-activated metakaolin geopolymer added with rice husk ash. J. Clean. Prod. 2019, 230, 603–612. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Elimbi, A.; Tchakouté, H.K.; Kumar, S. Mechanical properties and durability of volcanic ash-based geopolymer mortars. Constr. Build. Mater. 2016, 124, 606–614. [Google Scholar] [CrossRef]

- Buchwald, A.; Vanooteghem, M.; Gruyaert, E.; Hilbig, H.; de Belie, N. Purdocement: Application of alkali-activated slag cement in Belgium in the 1950s. Mater. Struct. 2015, 48, 501–511. [Google Scholar] [CrossRef]

- Ye, J.; Zhang, W.; Shi, D. Properties of an aged geopolymer synthesized from calcined ore-dressing tailing of bauxite and slag. Cem. Concr. Res. 2017, 100, 23–31. [Google Scholar] [CrossRef]

- González-García, D.M.; Téllez-Jurado, L.; Jiménez-Álvarez, F.J.; Balmori-Ramírez, H. Structural Study of Geopolymers Obtained from Alkali-Activated Natural Pozzolan Feldspars. Ceram. Int. 2017, 43, 2606–2613. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, T.; Deng, Y.; Han, Y.; Zhang, T.; Hou, P.; Zhang, G. Microstructure and Mechanical Performance of Alkali-Activated Tuff-Based Binders. Cem. Concr. Compos. 2023, 139, 105030. [Google Scholar] [CrossRef]

- Waqas, R.M.; Zaman, S.; Alkharisi, M.K.; Butt, F.; Alsuhaibani, E. Influence of Bentonite and Polypropylene Fibers on Geopolymer Concrete. Sustainability 2024, 16, 789. [Google Scholar] [CrossRef]

- Raza, A.; Selmi, A.; Elhadi, K.M.; Ghazouani, N.; Chen, W. Strength analysis and microstructural characterization of calcined red mud based-geopolymer concrete modified with slag and phosphogypsum. J. Mater. Res. Technol. 2024, 33, 6168–6181. [Google Scholar] [CrossRef]

- Özdemir, M.H.S.; Bayrak, B.; Aydın, A.C. Bond performance of geopolymer concrete with bazalt/glass fiber under elevated temperature. Eng. Struct. 2025, 324, 119368. [Google Scholar] [CrossRef]

- Korniejenko, K.; Pławecka, K.; Bulut, A.; Şahin, B.; Azizağaoğlu, G.; Figiela, B. Development of Lightweight Geopolymer Composites Containing Perlite and Vermiculite. J. Achiev. Mater. Manuf. Eng. 2023, 117, 49–56. [Google Scholar] [CrossRef]

- Ören, O.H.; Mandev, E.; Kaya, M.; Sarı, A.; Hekimoğlu, G.; Çıkman, İ.Ü.; Subaşı, S.; Maraşlı, M.; Gencel, O. Effects of microencapsulated phase change material on physico-mechanical and thermoregulation performance of lightweight geopolymer concrete with zeolite and perlite. J. Energy Storage 2025, 109, 115225. [Google Scholar] [CrossRef]

- Ghafoori, N.; Najimi, M.; Radke, B. Natural Pozzolan-Based Geopolymers for Sustainable Construction. Environ. Earth Sci. 2016, 75, 55. [Google Scholar] [CrossRef]

- Acar, M.C.; Celik, A.I.; Kayabaşı, R.; Şener, A.; Özdöner, N.; Özkılıç, Y.O. Production of perlite-based-aerated geopolymer using hydrogen peroxide as eco-friendly material for energy-efficient buildings. J. Mater. Res. Technol. 2023, 24, 81–99. [Google Scholar] [CrossRef]

- Çelik, A.I.; Karalar, M.; Aksoylu, C.; Mydin, A.O.; Althaqafi, E.; Yılmaz, F.; Umiye, O.A.; Özkılıç, Y.O. Effect of GBFS ratio and recycled steel tire wire on the mechanical and microstructural properties of geopolymer concrete under ambient and oven curing conditions. Case Stud. Constr. Mater. 2024, 21, e03890. [Google Scholar] [CrossRef]

- Çelik, A.I. Lightweight geopolymer concrete using pumice and glass fiber. Comput. Concr. 2024, 34, 577–589. [Google Scholar]

- Wang, C.; Zhang, Z.; Liu, X.; Zhang, Y.; Ma, Z. Elucidating the role of recycled concrete aggregate in ductile engineered geopolymer composites: Effects of recycled concrete aggregate content and size. J. Build. Eng. 2024, 95, 110150. [Google Scholar] [CrossRef]

- Wu, H.; Liu, X.; Wang, C.; Zhang, Y.; Ma, Z. Micro-properties and mechanical behavior of high-ductility engineered geopolymer composites (EGC) with recycled concrete and paste powder as green precursor. Cem. Concr. Compos. 2024, 152, 105672. [Google Scholar] [CrossRef]

- Kępniak, M.; Chyliński, F.; Łukowski, P.; Woyciechowski, P. Recycled Aggregate Integration for Enhanced Performance of Polymer Concrete. Materials 2024, 17, 4007. [Google Scholar] [CrossRef]

- Davidovits, J. Ferro-Sialate Geopolymers; Technical Papers #27; Geopolymer Institute Library: Saint-Quentin, France, 2020. [Google Scholar]

- Wu, X.; Zhou, X.; Guo, C.; Kang, D.; Zhang, W.; Lan, J.; Fang, Z. Behavior of Hematite, Magnetite, and Reduced Iron Powder in Geopolymers: Effects on Mechanical Properties and Reaction Mechanism. J. Clean. Prod. 2024, 444, 141178. [Google Scholar] [CrossRef]

- Gulmez, N.; Kockal, N.U. Effects of Iron Powder on Properties of Geopolymers Subjected to Different Curing Regimes. J. Clean. Prod. 2021, 296, 126667. [Google Scholar]

- Akbulut, Z.F.; Guler, S.; Khan, M. The Effects of Waste Iron Powder and Steel Fiber on the Physical and Mechanical Properties of Geopolymer Mortars Exposed to High Temperatures. Structures 2023, 58, 105398. [Google Scholar] [CrossRef]

- Ma, T.; Gu, G.; Chen, F.; Wang, N. Influence of Iron Powder Content on the Electromagnetic and Mechanical Performance of Soft Magnetic Geopolymer Composite. J. Road Eng. 2023, 3, 288–299. [Google Scholar] [CrossRef]

- Nongnuang, T.; Jitsangiam, P.; Rattanasak, U.; Chindaprasirt, P. Novel Electromagnetic Induction Heat Curing Process of Fly Ash Geopolymer Using Waste Iron Powder as a Conductive Material. Sci. Rep. 2022, 12, 9530. [Google Scholar] [CrossRef]

- Nongnuang, T.; Jitsangiam, P.; Rattanasak, U.; Tangchirapat, W.; Suwan, T.; Thongmunee, S. Characteristics of Waste Iron Powder as a Fine Filler in a High-Calcium Fly Ash Geopolymer. Materials 2021, 14, 2515. [Google Scholar] [CrossRef] [PubMed]

- Prałat, K.; Ciemnicka, J.; Koper, A.; Szczypiński, M.M.; Łoś, P.; Nguyen, V.V.; Buczkowska, K.E. Determination of the Thermal Parameters of Geopolymers Modified with Iron Powder. Polymers 2022, 14, 2009. [Google Scholar] [CrossRef] [PubMed]

- NF EN 196-6; Méthodes D’essai des Ciments—Détermination de la Finesse. Afnor EDITIONS: Paris, France, 2018.

- Gupta, R.K.; Birbilis, N. The Influence of Nanocrystalline Structure and Processing Route on Corrosion of Stainless Steel: A Review. Corros. Sci. 2015, 92, 1–15. [Google Scholar] [CrossRef]

- NF EN 1015-7; Methods of Test for Mortar for Masonry. Part 7: Determination of Air Content of Fresh Mortar. Afnor EDITIONS: Paris, France, 1999.

- NF EN 1015-6; Methods of Test for Mortar for Masonry. Part 6: Determination of Bulk Density of Fresh Mortar. Afnor EDITIONS: Paris, France, 1999.

- Mohammed, A.S.S.K.; Géber, R. Effect of liquid-solid ratio on metakaolin-based geopolymer binder properties. Pollack Period. 2024. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, Z.; Huang, F.; Ni, C.; Wu, J.; Zheng, B. Utilizing municipal solid waste incineration bottom ash and volcanic tuff to produce geopolymer materials. Constr. Build. Mater. 2024, 425, 136015. [Google Scholar] [CrossRef]

- Largeau, M.A.; Mutuku, R.; Thuo, J. Effect of Iron Powder (Fe2O3) on Strength, Workability, and Porosity of the Binary Blended Concrete. Open J. Civ. Eng. 2018, 8, 411. [Google Scholar] [CrossRef]

- Chen, S.; Ruan, S.; Zeng, Q.; Liu, Y.; Zhang, M.; Tian, Y.; Yan, D. Pore structure of geopolymer materials and its correlations to engineering properties: A review. Constr. Build. Mater. 2022, 328, 127064. [Google Scholar] [CrossRef]

- Wallevik, O.H. Introduction to Rheology of Fresh Concrete; Innovation Center Iceland: Reykjavik, Iceland, 2009. [Google Scholar]

- NF EN 1015-11/A1; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Afnor EDITIONS: Paris, France, 2007.

- ACI Committee. Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- IS-456: 2000; Plain and Reinforced Concrete—Code of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- Celik, A.; Yilmaz, K.; Canpolat, O.; Al-Mashhadani, M.M.; Aygörmez, Y.; Uysal, M. High-Temperature Behavior and Mechanical Characteristics of Boron Waste Additive Metakaolin-Based Geopolymer Composites Reinforced with Synthetic Fibers. Constr. Build. Mater. 2018, 187, 1190–1203. [Google Scholar] [CrossRef]

- Arslan, A.A.; Uysal, M.; Yılmaz, A.; Al-Mashhadani, M.M.; Canpolat, O.; Şahin, F.; Aygörmez, Y. Influence of Wetting-Drying Curing System on the Performance of Fiber Reinforced Metakaolin-Based Geopolymer Composites. Constr. Build. Mater. 2019, 225, 909–926. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).