Abstract

The main focus of this study, from a sustainable perspective, was to develop mineral circularity actions for the minimization of environmental impacts, generated over decades by the processing of run-of-mine (ROM) coal in the Catarinense coal basin–Brazil (CCB–Br), from the use of potential residual fractions (candidate residues) as raw materials for the production of organo-mineral fertilizers, or OMFs (candidate products). Therefore, the objective was to assess the potential of the residual fractions, generated in the distinct phases of ROM coal processing, as candidate waste for valorization, contributing directly to the advancement of the Sustainable Development Goals (SDGs). The samples from ROM processing resulted in 24 waste fractions identified by geological characteristics and a sustainable processing methodology. These fractions were subjected to a systematic analysis using the criteria for waste valorization CPQvA (classification (C) of hazardousness, potentiality (P), quantities/viability (Qv), and applicability (A)). Two samples were identified with significant potential for valorization in the agro-industry as sustainable raw materials for the organo-mineral fertilizers. Both samples exhibited neutral stock pH values (7.0 and 7.1), low percentage Fe2O3 content (4.2% and 3.2%), low SO3 content (0.5% and 1.2%), and low total sulfur content (1.0%). These characteristics qualified the studied ROM samples as raw materials suitable for the production of organo-mineral fertilizers (OMFs), and which comply with Brazilian legislation.

1. Introduction

Organo-mineral fertilizers (OMFs) comprise a mixture of non-mineral organic components and mineral components of natural or synthetic origin [1,2,3]. The non-mineral elements are represented by C, H, and O. Among the minerals, the most important are grouped into three categories: primary macronutrients (N, P, and K, absorbed in large quantities by plants); secondary macronutrients (Ca, Mg, Na, and S, absorbed in smaller amounts than the primary macronutrients); and micronutrients (B, Cu, Fe, Mn, Mo, Zn, and Ni, which are required in trace amounts). However, these micronutrients are toxic when present in quantities greater than those needed by the plant; on the other hand, it is known that the possible presence of nitrate ions, which can also be formed by nitrobacteria, promotes plant growth [4,5].

Until the mid-2000s, peat in various degrees of decomposition was one of the main organic components used in the formulation of organo-mineral fertilizers [2,6]. More recently, agro-industrial and urban solid waste has been increasingly used in the formulation of OMFs [1,7], seeking to improve fertilizer efficiency and reduce fertilization costs [8]. It is also known that the addition of organic matter increases the cation exchange capacity (CEC), water retention capacity, and the specific surface area of the soil. In addition, organic matter can improve the retention of complex toxic elements and increase the biotic components’ availability, solubility, and mineral stability [9,10].

Agricultural and food production are among the leading causes for the depletion of natural resources [11], and the most recent predictions indicate that the demand for food will increase by more than 60% in the next 40 years, due to the increase in the world’s population to 9.3 billion by 2050 [12]. The OMFs in their solid form should have organic carbon (minimum 8%); moisture (maximum 20%), CEC (minimum 80 mmolc kg−1), and primary macronutrients (N, P, and K) (minimum 5%). In addition, secondary macronutrients or micronutrients may be added to these products; a minimum 3% of secondary macronutrients, such as S, Ca, and Mg, can be used for exclusive mixtures [3]. Among the secondary macronutrients, sulfur plays a crucial role in the development and quality of plants, ranging from the production of amino acids and proteins to hormonal control, photosynthesis, and defense mechanisms [13].

The global consumption of N, P, and K in the agro-industry was estimated to increase annually by 1.4%, and 2.6% in 2014 and 2018, respectively. Several macronutrients originate from non-renewable sources and are expected to be exhausted in the next 50–150 years. Phosphate reserves have been predicted to last for a maximum of 300–400 years [14]. On the other hand, the necessary minimization of macronutrient losses through soil leaching can be achieved through the application of circularity actions in industrial activity, in which agro-industrial waste must be used as a viable solution for the correction and/or treatment of environmental liabilities generated by agro-industrial activities [2].

In Brazil, the recovery of sulfide from pyrite as a source of sulfur to produce sulfuric acid (H2SO4), although small, is a leading national source [15,16]. J. Weiler and I. Schneider [16] reported that between 1970 and 1990, the run-of-mine (ROM) coal waste from the Catarinense Carboniferous Basin (CCB), which was rich in pyrite compounds, was processed for H2SO4 production; however, this process was abandoned later due to economic reasons. Currently, the country consumes a large amount of S, primarily as H2SO4, for use in the chemical and steel industries and agriculture, with approximately 55% of H2SO4 used as a raw material in fertilizer production [17,18]. The residual fraction of Brazilian coal, particularly that from Santa Catarina, has potential for sulfur recovery, and could become an attractive alternative to meet the demand, as mentioned in the Official Gazette of the Union No. 115 [18] where sulfur was mentioned as the main element in the list of mineral goods imported in large quantities.

This demand, combined with environmental problems such as acid mine drainage (AMD) caused by coal mining waste owing to the high levels of sulfur, has stimulated research to look for integrated solutions wherein this type of waste can be utilized in a technically and economically feasible way [18].

Waste management from a circular economy perspective, similar to biological systems, aims to maximize the life cycle of materials [19], turn waste into sustainable raw materials and support the strategic transition from a linear to a circular economy. The circular economy is a model with an objective to close the life cycle of products for achieving a state of industrial symbiosis [20], where waste from one activity becomes a raw material for another [21,22]. It aims to reduce the use of virgin raw materials, minimize waste production, improve the circularity of raw materials and extend their useful life, and complete the economic and ecological cycles [21]. The main objective of this study was to evaluate the potential characteristics of the selected residual fractions, generated in the various stages of the ROM from coal processing, to be used in the composition of OMFs, thus contributing to increasing the sustainability of coal mining in the southern region of Santa Catarina state.

2. Materials and Methods

Sampling of the different residual fractions was performed from the waste of ROM coal processing stages employed in the six coal enterprises of the CCB, according to the Brazilian Standard of Reference NBR 10007/2004, specified by the Brazilian Association of Technical Standards (ABNT) [23]. These enterprises supply the energy fraction of interest for power generation at Jorge Lacerda Thermoelectric Power Plant, located in the municipality of Capivari de Baixo, Santa Catarina state. These residual fractions comprise materials rejected during the ROM coal processing because of the technical specifications defined by the Thermoelectric Power Plant, which requires coal that falls in a range between 42–46% ash and a calorific value greater than 4500 Kcal Kg−1 [24].

The CCB covers a polygon measuring 95 km in length and 20 km in width, located at the center of the geographic coordinates: 28°36′40.81″ S and 49°25′32.82″ W. Coal processing, adopted by the Santa Catarina companies, follows an old technology pattern that has been used for a long time. The major unit operations are performed using crushers, dense medium separators, jigs, air tables, cyclones, flotation processes, and settling basins.

The collected residual fraction samples were named using alphanumeric sequences from A1 to F6, resulting in 24 samples. The alphabets A–F represented the six enterprises and the numbers 1–6 represented the type of waste samples collected from each enterprise. All samples were obtained within the perimeter of the CCB and from the municipalities of Içara, Siderópolis, Treviso, Urussanga, and Lauro Muller. The CCB is located in an extensive coastal lowland that characterizes the entire south of Santa Catarina state; its location and proximity to the Atlantic Ocean influences the composition and quality of the coal [25].

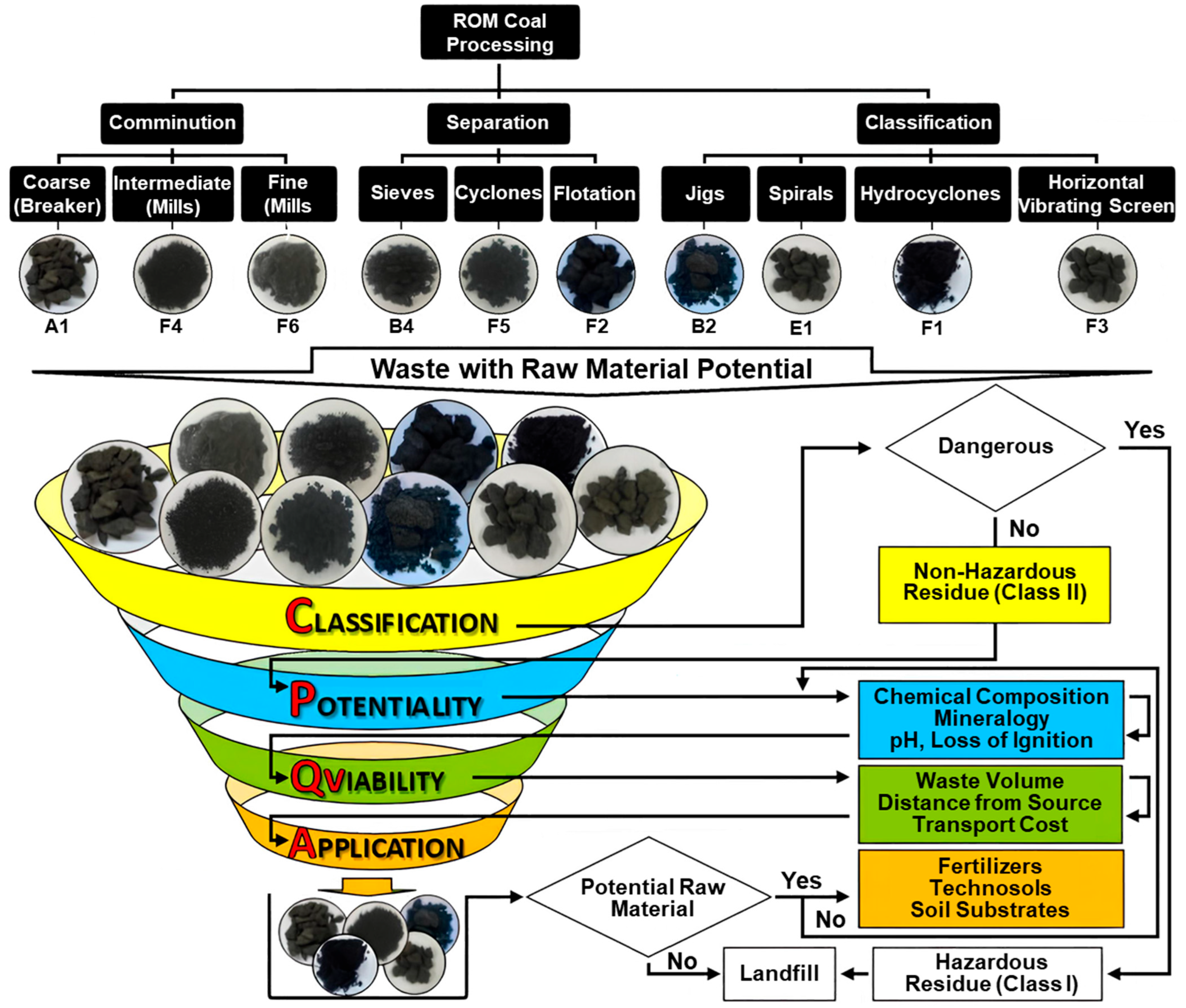

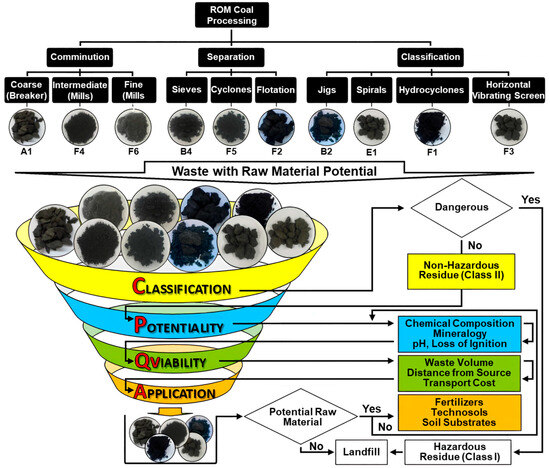

The residual fractions were selected based on the systematic CPQvA: classification (C), potentiality (P), quantity/viability (Qv), and applicability (A), proposed by Raupp-Pereira [26] as shown in Figure 1. The residual fractions were classified based on hazardousness, according to the NBR standards 10004 [27], 10005 [28], and 10006 [29]. The classification of waste, according to these standards, has been described in previous studies [30,31]. The potentiality criterion of use (P) was applied to the residual fractions, which were obtained from different ROM coal processing units used by the mining enterprises. The relevant quantity/viability (Qv) information was obtained from enterprises and the literature. For applicability (A), the integration between the potential characteristics of the different residual fractions and those required for the development of organo-mineral fertilizer was analyzed [32].

Figure 1.

The CPQvA system used to analyze the potential of the residual fractions, obtained from ROM coal processing as candidate waste, for the sustainable production of organo-mineral fertilizers (OMFs).

The selection of the specific chemical characteristics of the residual fractions, generated in the ROM coal processing used by the enterprises to produce OMFs, was based on Normative Instruction (NI) No. 61 from 8 July 2020 [3].

The samples were initially characterized based on chemical composition analysis using X-ray fluorescence spectroscopy (XRF, Shimadzu, Kyoto, Japan, EDX 7000) and mineralogical analysis using X-ray diffraction (XRD, Shimadzu LabX XRD 6100) with Cu Kα radiation, a tube voltage of 40 kV, a current of 30 mA, diffraction angle between 4° and 70° (2θ), and a speed of 0.02°/s.

The pH analysis was performed using a pH meter (pH meter AKSO-AK95, São Leopoldo, Brazil), in which the residue was mixed with deionized water (H2O) in the residue: water ratio = 4 g:1000 mL v/v. The loss on ignition (LoI) was realized at 950 °C in a muffle furnace [33], and the total sulfur content was determined by combustion of the sample (0.2 g) in a high-temperature tube furnace [34] at a temperature of 1350 ± 5 °C (Leco CHN 628 Series sulfur furnace, Chorrillos, Peru).

Finally, the pyritic sulfur was determined by titrimetric analysis, in which 2 g of the waste sample was digested in 50 mL hydrochloric acid (HCl) and 0.2–0.25 mL of ethanol (C2H5OH), and boiled for 30 min, followed by repeated washing with HCl and filtration. Sulfate (SO42−) was determined by neutralization titrimetry with HCl using the same procedure adopted for obtaining pyritic sulfur until the filtration stage, followed by the addition of 5 mL of oxygen peroxide (H2O2), boiling for 5 min, filtration, and the addition of 0.1 mL of methyl orange indicator. The amount of the sulfur forms was calculated, according to ASTM D2492 [34] as follows:

3. Results and Discussion

High ash (50–60%) and sulfur (3.3–7.7%) content [35] in the CCB coals resulted in an average recovery of approximately 36% ROM after processing [36,37]. The remaining 64% ROM comprised waste, rich in sulfide, pyrite, clay minerals [36], and environmentally relevant metals [38,39]. These wastes were classified as non-inert (Class II-A), according to NBR 10004/2004 [27], because they were not toxic and may have had properties such as biodegradability, combustibility, and water solubility.

The characterization of the selected secondary raw materials was carried out to identify the materials, processes and technologies that would allow their use in OMFs, contributing to the production of sustainable solutions. The chemical characterization, pH, and LoI of the waste fractions are presented in Table 1.

Table 1.

The chemical composition (%), pH, and loss on ignition (LoI, %) of the run-of-mine (ROM) coal processing residual fractions, obtained from the Catarinense coal basin.

The acidity/alkalinity (pH values) of the materials were investigated in an aqueous medium. The pH measurements of the samples after collection ranged from 2.6 to 8.5, and after storage, it ranged from 2.3 to 7.2. A tendency towards a decrease in the pH of all samples was observed after the storage period. This was likely because the solubilities of many precipitates change as a function of the hydrogen ion potential owing to the reactions with H3O+ or OH− of the medium [40].

In the samples, silicon (SiO2), aluminum (Al2O3), and iron (Fe2O3) oxides were quantified with concentration values above 10%; sulfur (SO3), calcium (CaO), potassium (K2O), and titanium (TiO2) oxides had concentration values above 1%; and magnesium (MgO), manganese (MnO), phosphorus (P2O5), and zirconium (ZrO2) oxides had concentration values below 1%. The volatile content in the samples, according to the percentage of loss on ignition (LoI), varied from 15.2% (C1) to 41.0% (F3), indicating the presence of organic material.

Considering the pH and chemical composition of the residual fractions (Table 1), a few elements were observed in these samples that could become toxic and harmful to plant growth if they exceeded critical concentration levels, such as aluminum, iron and manganese. The major element with potential toxicity for plants being present in a free form in acidic soil conditions was Al, with concentration values ranging from 3.4% to 23.8% of Al2O3 (from 1.80% to 12.6% of Al) in samples F3 and C4, respectively. In soils with acidic conditions, free Al3+ ions can be absorbed by plants and cause damage to the radical system [41]. Under the same conditions, i.e., low pH (acidic conditions), Mn can also be toxic when present in excess. This can happen under low pH (acidic) conditions [42].

Sulfur is an important element for the structure of proteins and the activity of enzymes. It also plays a part in preserving the equilibrium of vital micronutrients, including iron (Fe), copper (Cu), zinc (Zn), and manganese (Mn). Additionally, sulfur is crucial for protecting plants from pests and stress [43].

Heavy metals can be essential to plants, playing important roles in their development by participating in metabolic reactions and acting as micronutrients (e.g., Fe, Co, Cu, Mn, Zn, and Mo), or they can be non-essential elements (e.g., Cd, Pb, Ag, Sr, Cr, As, and Sb). However, these elements, whether needed for plant development, can be potentially toxic elements (PTEs) towards plant development and can cause phytotoxic effects when their concentration exceeds a certain limit, i.e., the threshold concentration [44]. An element’s harmful effect on plants depends on the ability of its metallic ions to displace normally occurring ions that are crucial ligands or cofactors for essential enzymes involved in primary and secondary metabolism of the plant species, and the physicochemical characteristics of the soil [44].

Soil pH affects the availability of PTEs. With increasing pH values, the bioavailability of the cationic elements decreases and the bioavailability of the anionic elements increases, due to the increase in the electronegative surface charge of non-permanent-charged soil colloids, i.e., organic matter; Al and Fe oxides; 1:1 clay minerals; and some 2:1 clay minerals. As the pH increases, organometallic complexes are formed, which, being sufficiently stable and with a high molecular weight, can remove PTEs from the soil solution and make them unavailable for uptake by plant roots. The development of inorganic complexes, primarily with typically insoluble phosphates and carbonates, may reduce the bioavailability of PTEs. The absorption of cationic elements onto colloidal soil surfaces is strong in the neutral to alkaline pH range and weak in the acidic pH range [45]. Plants pose a risk of deficiency in the micronutrients of metallic elements under specific conditions, such as high pH, sandy soils, and low organic matter content [41,42].

Organo-mineral fertilizers should have a pH > 6.0, according to NI No. 61 [3], because some elements become toxic or difficult to absorb with variations in pH. The pH values determined in the residual fractions and in the stored samples (where we investigated the effect of time) (Table 1) were related to the amount of iron disulfide (pyrite, FeS2) present in these fractions. The exposure of pyrite to the soil surface accelerates its oxidation because of the aerobic process conditions [46]. This stimulates the formation of AMD (containing sulfuric acid, H2SO4) and consequently acidifies the residual fraction [16]. Therefore, when the pyrite content in the residual fraction increased, the pH tended to decrease over time.

Gangwei Fan et al. [47] indicated that the residual fractions of ROM processing with an Al2O3/SiO2 ratio > 0.7% can be used in the chemical or OMFs production. Based on the literature and the Al2O3/SiO2 ratio of the residual fractions, the samples that came closest to this value (Al2O3/SiO2 = 0.5%) were the C4 and F1 samples with values of 0.51% and 0.50%, respectively, and the A3, C3, F4, and F6 samples, all with the value of 0.46%, and so these samples were found to be the most adequate in terms of potentiality.

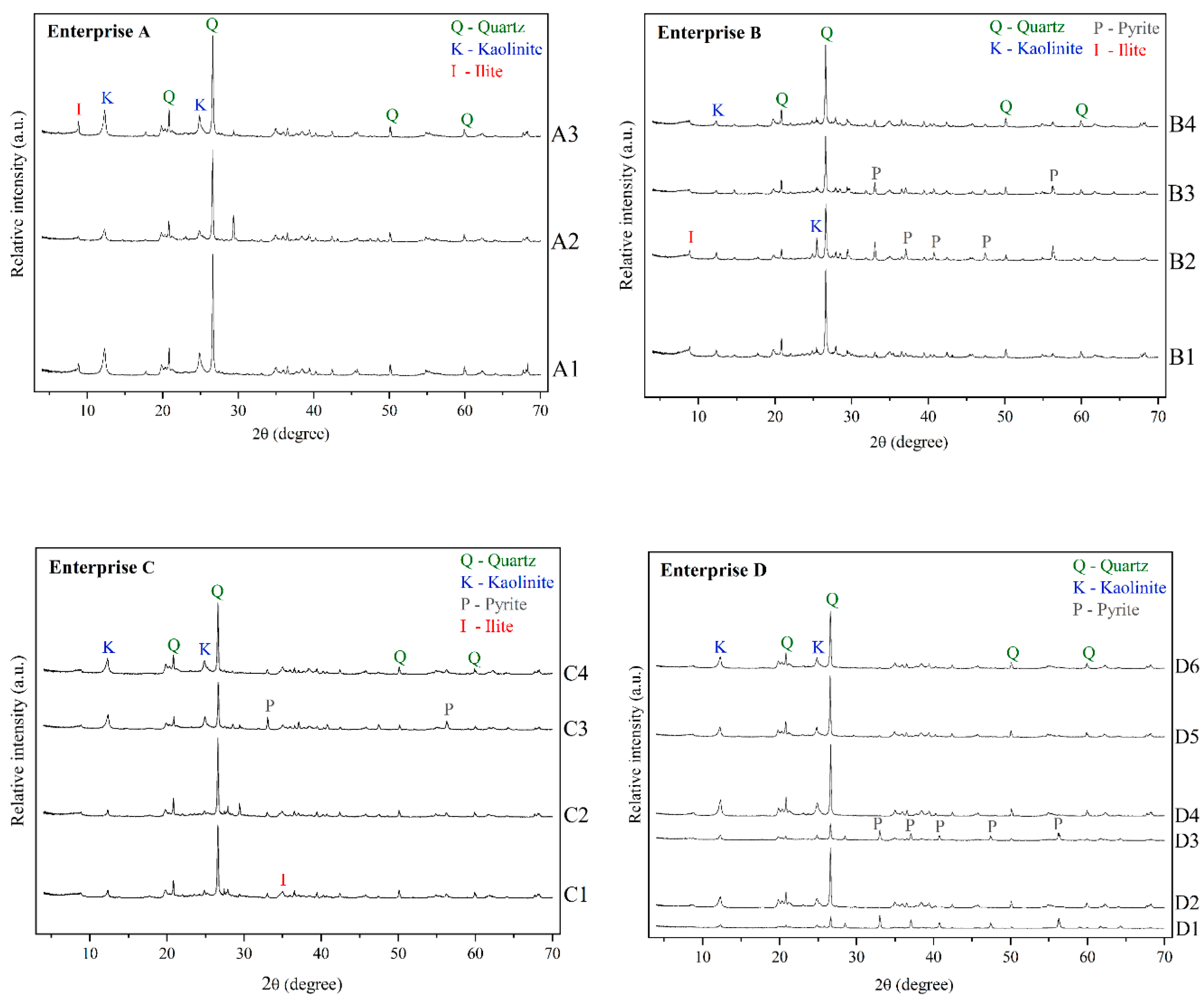

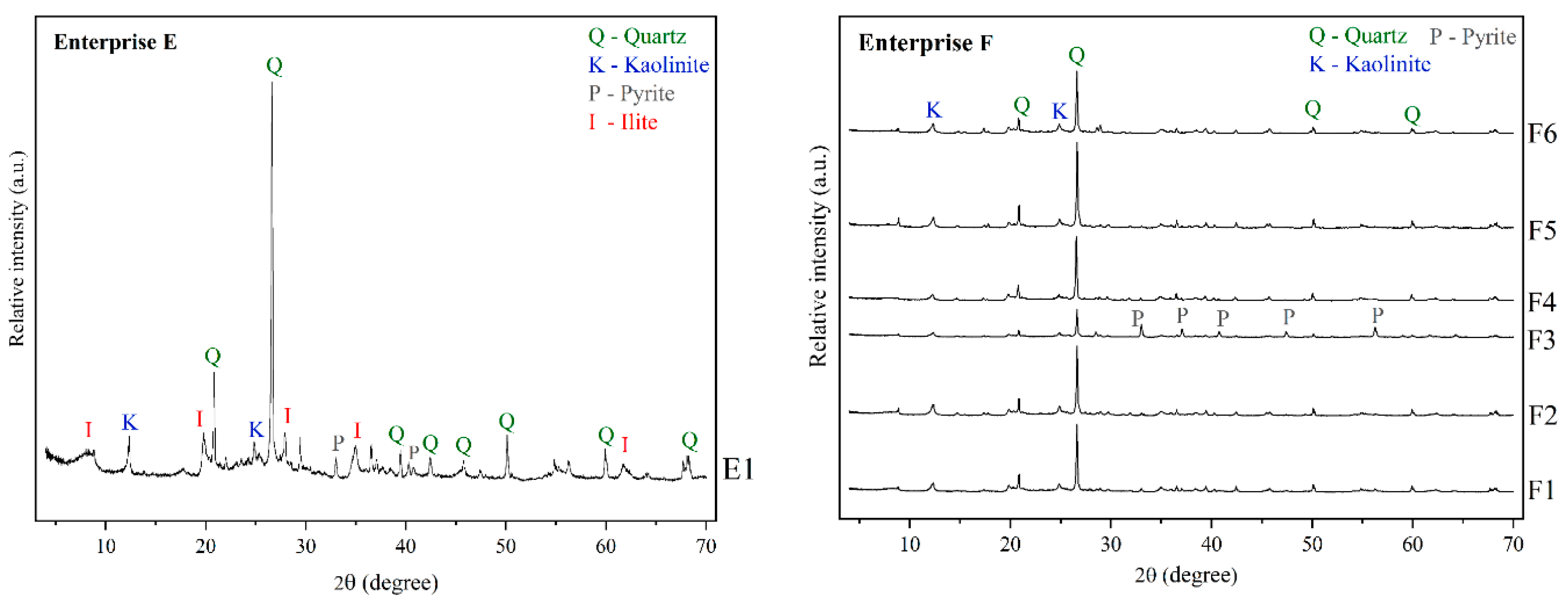

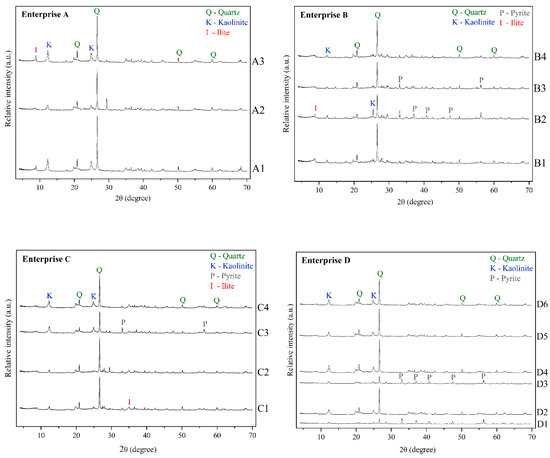

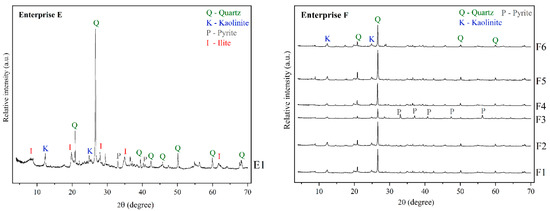

The XRD analyses (Figure 2) demonstrated the presence of four mineralogical phases: quartz (SiO2, ICDD 00-085-0457), kaolinite (Al4(OH)8(Si4O10, ICDD 01-089-6538), pyrite (FeS2, ICDD 00-042-1340), and illite (KH3O)(AlMgFe)2(SiAl)4O10[(OH)2H2O], ICDD 00-029-1496). Pyrite is a phase related to iron sulfates and sulfides, with its identification in the XRD analysis supported by the SO3 content quantified in the chemical compositions of the residual fractions. A high fraction of silicon dioxide (SiO2) corresponded to the presence of silica minerals (primarily quartz sand) and the argillomineral kaolinite [48]. Silica compounds (SiO2) can be used as substitutes for limestone in crops [49]. However, its reactivity varies depending on the particle size, dose used, type of soil, and contact time between the material and soil [50,51]. Moreover, it is a non-reactive mineral and highly resistant to weathering, resulting in high soil porosity and drainage capacity [52].

Figure 2.

The mineralogical phases identified in the residual fractions of the samples from run-of-mine (ROM) coal processing.

Kaolinites are characterized as good soils because they are stable minerals [52,53]. The kaolinite group known as argillominerals have a low CEC in the range of 1–10 cmolc kg−1 [52,54], which is below the minimum value of CEC stipulated by NI No. 61 for the formulation of organo-mineral fertilizers [3]. The organic matter addition in the soil can improve the CEC by associating with mineral sources [8,9,10].

XRD analyses (Figure 2) indicated that the sulfur present in the residual fractions (Table 1) corresponded to pyritic sulfur. The pyritic sulfur produces iron (II) sulfate (ferrous sulfate, FeSO4) and sulfuric acid (H2SO4) when it reacts with O2 and H2O, thereby resulting in AMD formation, which is a leading environmental problem in coal mining [16]. Therefore, the residual fraction should have a low or no pyritic sulfur content to be selected as a candidate for organo-mineral fertilizer composition. The analysis of total sulfur content quantified all forms of sulfur present in the samples [34], i.e., pyritic, sulfate, and organic sulfur. Based on the results of the previous characterizations, particularly for the pH values, the Al2O3/SiO2 ratio, and the pyrite concentration, the residual fractions that were shown to be the most suitable for the OMF composition were samples A3 and F6, to which analysis of the sulfur forms and their respective content was conducted (Table 2). The chemical and mineralogical analyses of the 24 samples indicated two samples, A3 and F6, had the highest potential for the suggested application, which was supported by their low pyritic sulfur contents (0.20% and 0.48% respectively—this calculation was carried out based on the SO3 content in Table 1).

Table 2.

The S content obtained from the XRF (SO3) and sulfur forms (pyritic, sulfate, and organic) of the residual fractions selected from the waste of technological interest for use as organo-mineral fertilizer.

Most S-containing fertilizers can be divided into four groups: sulfate, elemental sulfur-containing, a combination of sulfate and elemental S-containing, and liquid S-containing fertilizers [55,56]. A significant amount of sulfur, excluding pyritic sulfur, is present in the residual fractions as the sulfate (SO4) form. This form of sulfur is readily available for plant uptake. Organic sulfur is a part of the coal structure itself; therefore, this is the most difficult type to remove from ROM coal processing products using physical operations (density separation or washing) [55]. Oxidizing systems enable the solubilization of sulphatic and pyritic sulfur [48,57,58]. Therefore, the fertilizer produced using the residual fractions of ROM coal processing is recommended for the fertility correction of soils with oxidative potential, which favors the availability of sulphatic and pyritic sulfur.

For the ROM coal processing residual fractions with low organic sulfur contents, the dissolved sulfate concentration reflected the total sulfur percentage. In contrast, the dissolved sulfate concentration indicated the sum of the pyritic and sulphatic sulfur content in the ROM coal processing residual fractions with high organic sulfur content [48]. The two residual fractions that were pre-selected as candidate residues (A3 and F6) demonstrated a low percentage content of organic sulfur, which was considered to be the total sulfur content for selecting the candidate residue. According to NI No. 61 [3], the minimum proportion of sulfur (S) in organo-mineral fertilizers is 1% (2.5% SO3) of the total fertilizer content, constituting a minority component of the overall composition.

In NPK-based fertilizers, the sulfur content usually varies between 1–10% [55]. N and S participate jointly in plant metabolism; therefore, they should be analyzed together. The N/S ratio varies from 10/1–15/1 or 0.1–0.4% of S per kg [13]. The technical specifications of the minimum percentage of the micro- and macronutrients in organo-mineral fertilizers, according to NI No. 61 [3], are listed in Table 3. These minimum acceptable content values were used to define the parameters for selecting the residual fractions as waste candidates of technological interest, which could then be valued as an OMF candidate product.

Table 3.

The minimum percentage of the micronutrients and macronutrients in the composition of organo-mineral fertilizers, according to Normative Instruction No. 61 [3].

The micronutrients and macronutrients for the composition of organo-mineral fertilizers, according to NI No. 61 [3], that appeared in the chemical composition of the formulations A3 and A6 were sulfur (S), iron (Fe), calcium (Ca), and potassium (K), as well as magnesium (Mg) for formulation A6 (Table 1). The values obtained in the chemical composition (Table 1) showed that the concentration of K2O, Fe, and Ca for formulation A3 (3.0, 2.9, and 1.0%, respectively) and K2O and Fe for formulation F6 (2.2 and 2.2%, respectively) were in agreement with the values referenced in NI No. 61 [3]. The S values for the two formulations, 0.25% and 0.80% for A3 and A6, respectively, were lower than the value presented in NI No. 61 [3], as was the calcium value for formulation A6 (0.71%); however, this value was closer to the referenced value.

The two samples selected in this study with the potentiality for the composition of OMFs exhibited low percentages of total S. The residual fraction F6 demonstrated sulfur content significantly closer to the ideal values than the residual fraction A3. According to information obtained from the mining companies, approximately 1.5 and 6 tons per month of the residual fractions A3 and F6, respectively, are produced. The proportion of each component in the OMF needs to be determined to better estimate the amount of waste required from each of the residual fractions A3 and F6. Therefore, a feasibility study related to the number of available residues should be the scope of future research.

Indeed, the residual fractions may offer several other opportunities. Therefore, these fractions should be studied thoroughly to use their potential as raw materials based on their physicochemical characteristics instead of discarding them as waste. A blend characterized by a mixture of the residual fractions of ROM coal processing with the coproducts of the agro-industry, such as poultry litter, solid urban waste, or agro-industrial waste, would be ideal for the development of organo-mineral fertilizers. Physical transformation by the removal of excess moisture, comminution, and granulation can result in an economical and environmentally sustainable product, which should be developed in future studies aligned with the principles of CE.

4. Future Perspectives for Waste Valorization

In Brazil, the national production of sulfur for primary use in the fertilizer industry comes from pyro-bituminous shale (5%), oil processing (28%), and metal sulfide roasting processes (67%) [15]. However, the national product does not meet the demand; therefore, Brazil imports a major fraction of their fertilizer supply [59,60].

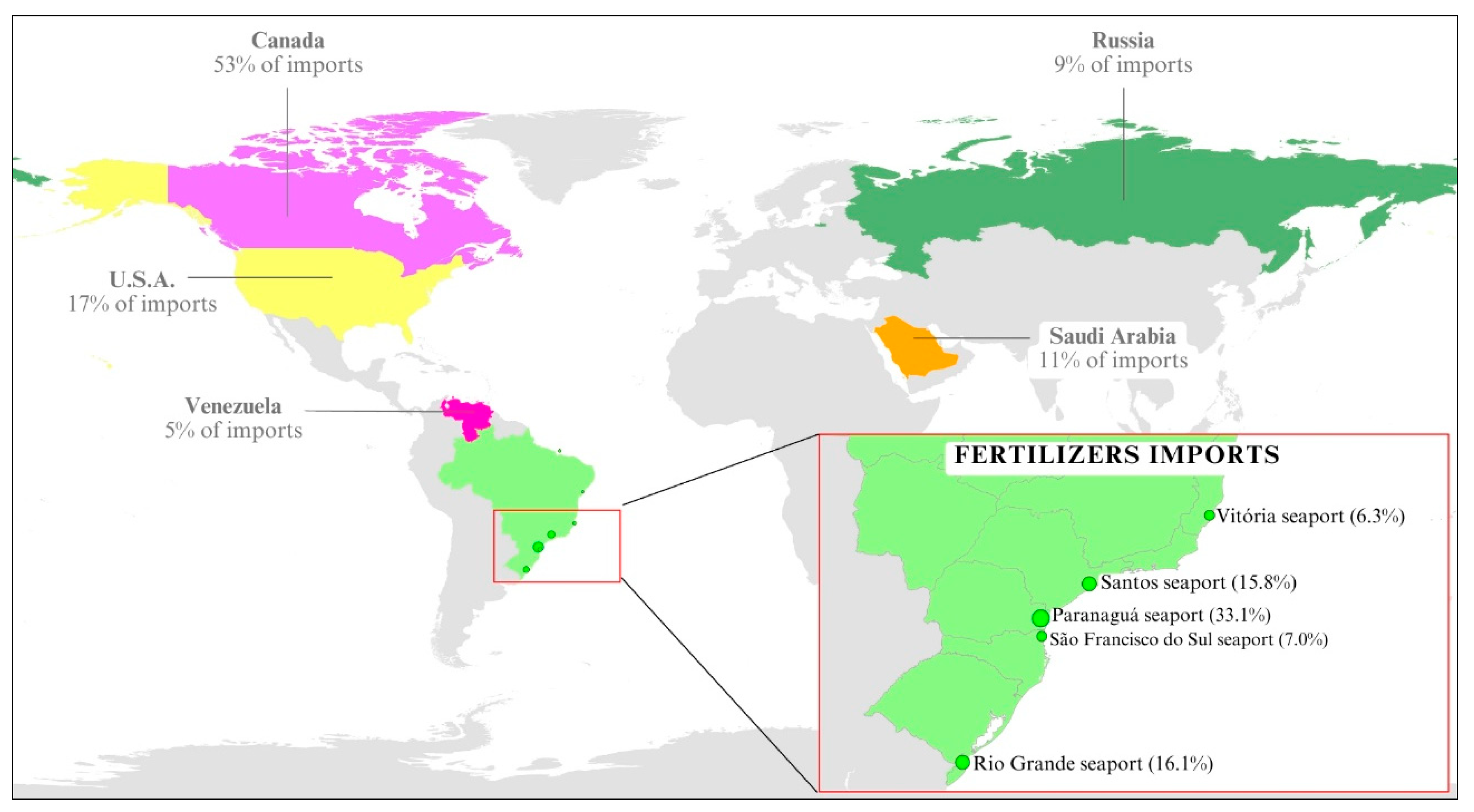

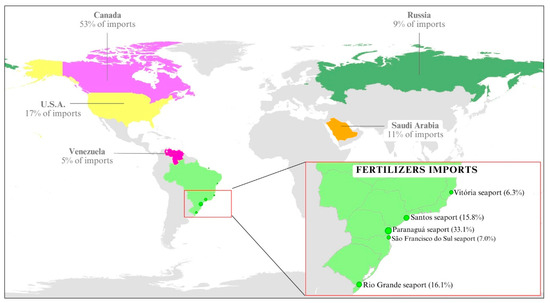

In 2021, 41.6 million tons of fertilizer was imported into Brazil [61]. Until 2017 (Figure 3), the Brazilian seaports with the highest percentages of fertilizer imports were Paranaguá/Paraná (33.1%) and Santos/São Paulo (15.8%) [62,63]. With the growing agricultural expansion in the southern region of Brazil, particularly in the Rio Grande do Sul state [60], the Rio Grande ranked second (16.1%) in 2018 based on the reports on the import scenario [62]. Many factors negatively influence the distribution of fertilizer, such as climate adversities, commercial disagreements, or the increase in sea freight, which eventually affects the country’s economy, thereby representing a bottleneck for the commercialization of these imports [60,64].

Figure 3.

The percentage of fertilizers imports received by the major Brazilian seaports in 2018 and the countries of origin of these materials (Source: Adapted from [60]).

The pyrite fraction in the CCB coal originates from marine and estuarine sedimentation, which is rich in sulfates (SO42−) [35]. CCB deposits follow a pattern of chemical content linked to the site of origin, where sulfur content mostly ranges from 3.4% to 7.7% by mass, of which a major fraction is in the form of pyritic sulfur [35]. Residual fractions from ROM coal processing with SO3 content > 6% can have the sulfur content recovered through the gravity separation process [46]. In this case, the ROM coal residual fractions B1 (SO3 = 10.8%) and B3 (SO3 = 10.2%) exhibited potential for sulfur recovery.

This is an interesting aspect of the present study, which allowed for the selection of samples for both fertilizer and sulfur production, because sulfur is a strategic chemical compound for the country, according to Resolution No. 2 of 18 June 2021 [18]. These potential indications are of paramount importance for the transition of the coal industry to a circular economy, particularly to minimize waste disposal in controlled landfills and from the perspective of waste valorization as a source of sustainable raw materials [57,65].

5. Conclusions

Based on analyses of the pH; chemical content, with an emphasis on sulfur; and mineralogy, two samples of the ROM coal residual fractions were selected for fertilizer production: samples F6 and A3 (from a total of 24 generated/sampled), according to the recommendations of the Brazilian legislation. However, the ROM coal processing waste should be recollected at distinct stages and residual fractions should be selectively obtained from local coal mining companies in order to be evaluated as sustainable sources for the production of OMFs.

Considering that sulfur is the primary strategic chemical compound of the country, the potential utilization of these residual fractions is even more relevant in combating dependence on imports, in addition to reducing the environmental impacts of the coal industry. Moreover, the selective and sustainable exploitation of these fractions contributes directly to the Sustainable Development Goals (SDGs), fostering practices that minimize environmental impacts and promoting the optimized use of natural resources. These indications of potential are of utmost importance in the transition to a circular economy. On the other hand, different residual fractions may offer other alternative opportunities, and for this reason, future valorization studies should be carried out, which will allow for their subsequent use as the sustainable sources of secondary minerals.

Author Contributions

Methodology, J.A. and É.M.R.F.; Validation, L.S.; Formal analysis, E.F.O. and M.N.S.F.; Investigation, E.F.O. and M.N.S.F.; Writing—review & editing, M.J.R. and É.M.R.F.; Supervision, L.S., M.J.R., J.J.Z. and F.R.-P.; Project administration, F.R.-P.; Funding acquisition, F.R.-P. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the financial support provided by the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and the Coordenação de Aperfeiçoamento de Pessoal de Ensino Superior (CAPES). We thank the Fundação de Amparo à Pesquisa e Inovação do Estado de Santa Catarina (FAPESC) for funding this research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

We further extend our thanks to the Technical Ceramics Laboratory (CERTEC), where this research was conducted, and the University of the Extreme South of Santa Catarina (UNESC).

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AMD | Acid mine drainage |

| ROM | Run-of-mine |

| CCB | Catarinense Carboniferous Basin |

| CEC | Cation exchange capacity |

| LoI | Loss on ignition |

| OMFs | Organo-mineral fertilizers |

| NPK | Nitrogen, phosphorus, and potassium |

References

- Antille, D.L.; Sakrabani, R.; Godwin, R.J. Field-Scale Evaluation of Biosolids-Derived Organomineral Fertilisers Applied to Ryegrass (Lolium perenne L.) in England. Appl. Environ. Soil Sci. 2013, 2013, 960629. [Google Scholar] [CrossRef]

- Cruz, A.C.; Pereira, F.d.S.; Figueiredo, V.S. Fertilizantes Organominerais de Resíduos do Agronegócio: Avaliação do Potencial Económico Brasileiro. Indústria Química|BNDES Setorial 2017, 45, 137–187. [Google Scholar]

- Serviço Público Federal. Instrução Normativa Nº61, de 8 de Julho de 2020; DOU Imprensa Nacional: Brasília, Brazil, 2020. [Google Scholar]

- Weil, R.R.; Brady, N.C. Soil Phosphorus and Potassium. In The Nature and Properties of Soils; Pearson Education: Upper Saddle River, NJ, USA, 2017; pp. 643–695. [Google Scholar]

- Sun, E.; Liao, G.; Zhang, Q.; Qu, P.; Wu, G.; Huang, H. Biodegradable copolymer-based composites made from straw fiber for biocomposite flowerpots application. Compos. Part B 2019, 165, 193–198. [Google Scholar] [CrossRef]

- Luz, A.B.; Lapido-Loureiro, F.E.; Sampaio, J.A.; Castilhos, Z.C.; Bezerra, M.S. Rochas, Minerais e Rotas Tecnológicas Para a Produção de Fertilizantes Alternativos. In Agrominerais para o Brasil; CETEM: Rio de Janeiro, Brazil, 2010; pp. 61–88. [Google Scholar]

- Larney, F.J.; Angers, D.A. The Role of Organic Amendments in Soil Reclamation: A Review. Can. J. Soil Sci. 2012, 92, 19–38. [Google Scholar] [CrossRef]

- Ulsenheimer, A.; Sordi, A.; Cericato, A.; Lajús, C. Formulação de Fertilizantes Organominerais e Ensaio de Produtividade. Unoesc Ciência-ACET 2016, 7, 195–202. [Google Scholar]

- Kiehl, E.J. Fertilizantes Organominerais; CERES: Piracicaba, Brazil, 1993; Volume 7. [Google Scholar]

- Kiehl, E.J. Fertilizantes Orgânicos; CERES: São Paulo, Brazil, 1985; Volume 7. [Google Scholar]

- Kominko, H.; Gorazda, K.; Wzorek, Z. The Possibility of Organo-Mineral Fertilizer Production from Sewage Sludge. Waste Biomass Valorization 2017, 8, 1781–1791. [Google Scholar] [CrossRef]

- Lee, R. The Outlook for Population Growth. Science 2011, 333, 569–573. [Google Scholar] [CrossRef] [PubMed]

- Vitti, G.C.; Otto, R.; Savietto, J. Manejo Do Enxofre Na Agricultura. J. Informações Agronômicas 2015, 152, 1–14. [Google Scholar]

- Dawson, C.J.; Hilton, J. Fertiliser Availability in a Resource-Limited World: Production and Recycling of Nitrogen and Phosphorus. Food Policy 2011, 36, S14–S22. [Google Scholar] [CrossRef]

- Fonseca, D.S.; Bacic, I.R. Enxofre. In Economia Mineral Do Brasil; DNPM: Brasília, Brazil, 2009; pp. 577–590. [Google Scholar]

- Weiler, J.; Schneider, I.A.H. Pyrite Utilization in the Carboniferous Region of Santa Catarina, Brazil-Potentials, Challenges, and Environmental Advantages. REM—Int. Eng. J. 2019, 72, 515–522. [Google Scholar] [CrossRef]

- Departamento Nacional de Produção Mineral—DNPM. Sumário Mineral 2016; DNPM: Brasília, Brazil, 2016. [Google Scholar]

- Brasil Decreto 10657 24 Marco 2021|Decreto No 10.657, de 24 de Março de 2021, Presidência Da Republica. Available online: https://presrepublica.jusbrasil.com.br/legislacao/1184546522/decreto-10657-24-marco-2021 (accessed on 8 February 2023).

- MacArthur, E. Towards the Circular Economy: Opportunities for the Consumer Goods Sector; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2003, 25, 313–337. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring Circular Economy Strategies through Index Methods: A Critical Analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H. Circular Economy: Lessons from China. Nature 2016, 531, 440–442. [Google Scholar] [CrossRef] [PubMed]

- ABNT. NBR 10007—Amostragem de Resíduos Sólidos; ABNT: Rio de Janeiro, Brazil, 2004; p. 21. [Google Scholar]

- UTE ENGIE Unidade Termelétrica Engie—Engie Brasil Energia S/A. Relatório de Monitoramento Ambiental: Complexo Termelétrico Jorge Lacerda; Engie Brasil Energia: Florianópolis, Brazil, 2018. [Google Scholar]

- CPRM. Relatório Anual de Atividades 2005; CPRM: Rio de Janeiro, Brazil, 2006. [Google Scholar]

- Raupp-Pereira, F. Valorizaçao de Resíduos Industriais Como Fonte Alternativa Mineral: Composiçoes Cerâmicas e Cimentíceas; Universidade de Aveiro: Aveiro, Portugal, 2006. [Google Scholar]

- ABNT NBR 10004:2004; Resíduos Sólidos—Classificação. ABNT: Rio de Janeiro, Brazil, 2004; p. 71.

- ABNT NBR 10005:2004; Procedimento Para Obtenção de Extrato Lixiviado de Resíduos Sólidos. ABNT: Rio de Janeiro, Brazil, 2004.

- ABNT NBR 10006:2004; Procedimento Para Obtenção de Extrato Solubilizado de Resíduos Sólidos. ABNT: Rio de Janeiro, Brazil, 2004.

- Simão, L.; Souza, M.T.; Ribeiro, M.J.; Klegues Montedo, O.R.; Hotza, D.; Novais, R.M.; Raupp-Pereira, F. Assessment of the Recycling Potential of Stone Processing Plant Wastes Based on Physicochemical Features and Market Opportunities. J. Clean. Prod. 2021, 319, 128678. [Google Scholar] [CrossRef]

- Souza, M.T.; Simão, L.; Montedo, O.R.K.; Raupp Pereira, F.; de Oliveira, A.P.N. Aluminum Anodizing Waste and Its Uses: An Overview of Potential Applications and Market Opportunities. Waste Manag. 2019, 84, 286–301. [Google Scholar] [CrossRef]

- de Oliveira, K.A.; Raupp-Pereira, F. Sistemática CPQvA Para a Valorização de Resíduos Sólidos Industriais: Um Guia Para Tomada de Decisão; Universidade Federal Santa Catarina: Florianópolis, Brazil, 2017. [Google Scholar]

- ASTM D7348:2007; Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues. ASTM: West Conshohocken, PA, USA, 2007; p. 6.

- ASTM D2492:2002; Standard Test Methods for Forms of Sulfur in Coal. ASTM: West Conshohocken, PA, USA, 2012; p. 251.

- Kalkreuth, W.; Holz, M.; Mexias, A.; Balbinot, M.; Levandowski, J.; Willett, J.; Finkelman, R.; Burger, H. Depositional Setting, Petrology and Chemistry of Permian Coals from the Paraná Basin: 2. South Santa Catarina Coalfield, Brazil. Int. J. Coal. Geol. 2010, 84, 213–236. [Google Scholar] [CrossRef]

- Amaral Filho, J.R.; Schneider, I.A.H.; de Brum, I.A.S.; Sampaio, C.H.; Miltzarek, G.; Schneider, C. Caracterização de Um Depósito de Rejeitos Para o Gerenciamento Integrado Dos Resíduos de Mineração Na Região Carbonífera de Santa Catarina, Brasil. REM Rev. Esc. Minas 2013, 66, 347–353. [Google Scholar] [CrossRef]

- Oliveira, M.L.S.; Ward, C.R.; Sampaio, C.H.; Querol, X.; Cutruneo, C.M.N.L.; Taffarel, S.R.; Silva, L.F.O. Partitioning of Mineralogical and Inorganic Geochemical Components of Coals from Santa Catarina, Brazil, by Industrial Beneficiation Processes. Int. J. Coal. Geol. 2013, 116–117, 75–92. [Google Scholar] [CrossRef]

- Costa, S.; Zocche, J.J. Fertilidade de Solos Construídos Em Áreas de Mineração de Carvão Na Região Sul de Santa Catarina. Rev. Árvore 2009, 33, 665–674. [Google Scholar] [CrossRef]

- Silva, L.F.O.; Izquierdo, M.; Querol, X.; Finkelman, R.B.; Oliveira, M.L.S.; Wollenschlager, M.; Towler, M.; Pérez-López, R.; MacIas, F. Leaching of Potential Hazardous Elements of Coal Cleaning Rejects. Environ. Monit. Assess. 2011, 175, 109–126. [Google Scholar] [CrossRef]

- Oliveira, C.M.; Müller, T.G.; André, R.A.; de Oliveira, E.M.; de Oliveira, E.M.; Peterson, M.; Raupp-Pereira, F. Pyrite from Coal Mining: High-Energy Milling and Analysis of the Electrical and Optical Properties. Mater. Lett. 2019, 253, 339–342. [Google Scholar] [CrossRef]

- Pes, L.Z.; Arenhardt, M.H. Fisiologia Vegetal; Politécnico, C., Ed.; UFSM: Santa Maria, Brazil, 2015; ISBN 9788563573902. [Google Scholar]

- Kabata-Pendias, A. Trace Elements in Soils and Plants: Fourth Edition; CRC Press: Boca Raton, FL, USA, 2010; ISBN 9781420093704. [Google Scholar]

- Narayan, O.P.; Kumar, P.; Yadav, B.; Dua, M.; Johri, A.K. Sulfur Nutrition and Its Role in Plant Growth and Development. Plant Signal. Behav. 2023, 18, 2030082. [Google Scholar] [CrossRef]

- Angulo-Bejarano, P.I.; Puente-Rivera, J.; Cruz-Ortega, R. Metal and Metalloid Toxicity in Plants: An Overview on Molecular Aspects. Plants 2021, 10, 635. [Google Scholar] [CrossRef] [PubMed]

- Thalassinos, G.; Petropoulos, S.A.; Grammenou, A.; Antoniadis, V. Potentially Toxic Elements: A Review on Their Soil Behavior and Plant Attenuation Mechanisms against Their Toxicity. Agriculture 2023, 13, 1684. [Google Scholar] [CrossRef]

- Moses, C.O.; Kirk Nordstrom, D.; Herman, J.S.; Mills, A.L. Aqueous Pyrite Oxidation by Dissolved Oxygen and by Ferric Iron. Geochim. Cosmochim. Acta 1987, 51, 1561–1571. [Google Scholar] [CrossRef]

- Fan, G.; Zhang, D.; Wang, X. Reduction and Utilization of Coal Mine Waste Rock in China: A Case Study in Tiefa Coalfield. Resour. Conserv. Recycl. 2014, 83, 24–33. [Google Scholar] [CrossRef]

- Fallavena, V.L.V.; De Abreu, C.S.; Inácio, T.D.; Pires, M.; Azevedo, C.M.N.; Fernandes, I.D.; Ferret, L.S.; Tarazona, M.R.M. Caracterização Detalhada de Material de Referência Certificado de Carvão Brasileiro. Quim. Nova 2013, 36, 859–864. [Google Scholar] [CrossRef]

- Korndorfer, G.H. Elementos Benéficos. In Nutrição Mineral de Plantas; UFC: Viçosa, Brazil, 2006; pp. 355–374. [Google Scholar]

- Piau, W.C. Viabilidade Do Uso Das Escorias Como Corretivo e Fertilizante, Uniwersytet Śląski; Wydział Matematyki, Fizyki i Chemii: Piracicaba, Brazil, 1991; Volume 7. [Google Scholar]

- Amaral Sobrinho, N.M.B.; Costa, L.M.; Dias, L.E.; Barros, N.F. Aplicação de Resíduo Siderúrgico Em Um Latossolo: Efeitos Na Correção Do Solo e Na Disponibilidade de Nutrientes e Metais Pesados. Rev. Bras. Cienc. Solo 1993, 17, 299–304. [Google Scholar]

- Pejon, O.J.; Rodrigues, V.G.S.; Zuquette, L.V. Impactos Ambientais Sobre o Solo. Engenharia Ambiental: Conceitos, Tecnologia e Gestão; Elsevier Editora Ltd.: Amsterdam, The Netherlands, 2013; pp. 741–765. [Google Scholar]

- Carvalho, J.B.Q. de Fundamentos Da Mecânica Dos Solos; Marcone; Campina Grande: Paraíba, Brazil, 1997. [Google Scholar]

- Gillott, J.E. Clay in Engineering Geology; The University of Calgary: Calgary, AB, Canada, 1987; Volume 41, pp. 1–484. [Google Scholar]

- TSI Sulphur—The Fourth Major Plant Nutrient. Available online: https://www.sulphurinstitute.org/sulphur-in-agriculture/sulphur-the-fourth-major-crop-nutrient/ (accessed on 9 February 2023).

- Calkins, W.H. The Chemical Forms of Sulfur in Coal: A Review. Fuel 1994, 73, 475–484. [Google Scholar] [CrossRef]

- Ward, C.R.; Bocking, M.; Ruan, C. De Mineralogical Analysis of Coals as an Aid to Seam Correlation in the Gloucester Basin, New South Wales, Australia. Int. J. Coal. Geol. 2001, 47, 31–49. [Google Scholar] [CrossRef]

- Pinetown, K.L.; Ward, C.R.; van der Westhuizen, W.A. Quantitative Evaluation of Minerals in Coal Deposits in the Witbank and Highveld Coalfields, and the Potential Impact on Acid Mine Drainage. Int. J. Coal. Geol. 2007, 70, 166–183. [Google Scholar] [CrossRef]

- Czycza, R.V.; Fontaniva, S.; Lana, M.C.; Frandoloso, J.F.; Vale, F. Eficiência Agronômica de Diferentes Fertilizantes Contendo Enxofre Para a Cultura Do Milho. Agronomic Efficiency of Different Fertilizers Containing Sulphur for the Corn Culture. 2008. Available online: http://www.diadecampo.com.br/arquivos/materias/%7BC203E713-5A5B-4D35-8759-DE6A16475A69%7D_68_1.pdf (accessed on 26 December 2024).

- Daminato, B.; Benitiz, L. Caracterização Das Movimentações de Fertilizantes No Brasil; Grupo de Extensão e Pesquisa em Logística Agroindustrial—ESALQ-LOG: Piracicaba, Brazil, 2015. [Google Scholar]

- CONAB Série Histórica de Produção. Available online: https://portaldeinformacoes.conab.gov.br/precos-agropecuarios-serie-historica.html (accessed on 26 December 2024).

- Ministério do Desenvolvimento, Indústria e Comércio Exterior. Secretaria de Comércio Exterior, M. Sistema de Análise Das Informações de Comércio Exterior. Available online: http://comexstat.mdic.gov.br/pt/comex-vis (accessed on 26 December 2024).

- SPA/MAPA. Projeções Do Agronegócio: Brasil 2017/18 a 2027/28 Projeções de Longo Prazo: Ministério Da Agricultura, Pecuária e Abastecimento; Secretaria de Política Agrícola: Brasília, Brazil, 2018; ISBN 9788579911163. [Google Scholar]

- Fernandes, E.; Guimarães, B.d.A.; Matheus, R.R. Principais Empresas e Grupos Brasileiros Do Setor de Fertilizantes; BNDES Setorial: Piracicaba, Brazil, 2009. [Google Scholar]

- Wang, T.; Zhang, H.; Liu, Q.; Yang, H. Experimental Studies on Phase Transformation during Pyrite Concentrate Oxidation under Circulating Fluidized Bed (CFB) Roasting Conditions. Ind. Eng. Chem. Res. 2011, 50, 14168–14174. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).