Anaerobic Digestion of Rice Straw as Profitable Climate Solution Reduces Paddy Field Greenhousegas Emissions and Produces Climate-Smart Fertilizer Under Carbon Trading Mechanisms

Abstract

1. Introduction

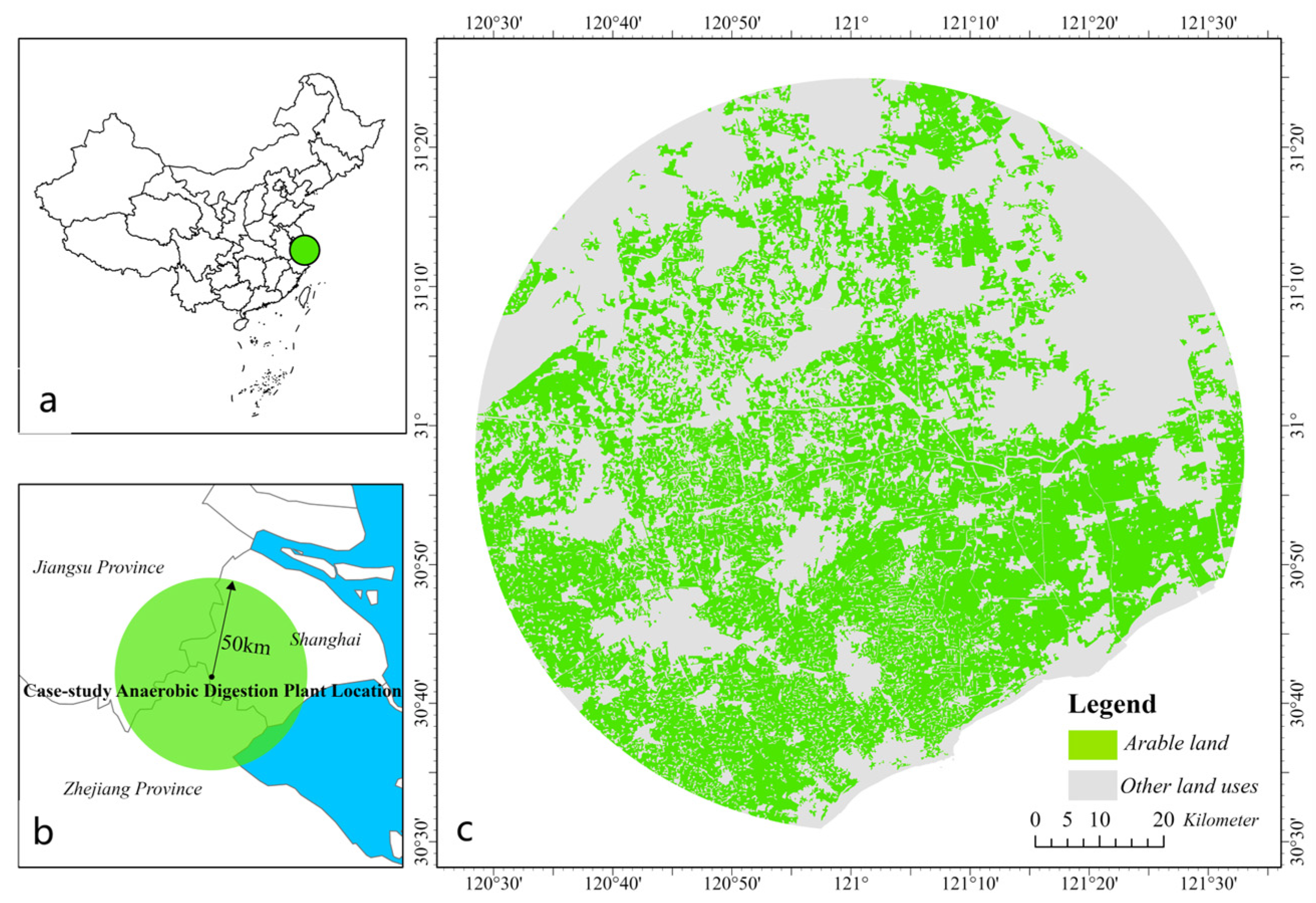

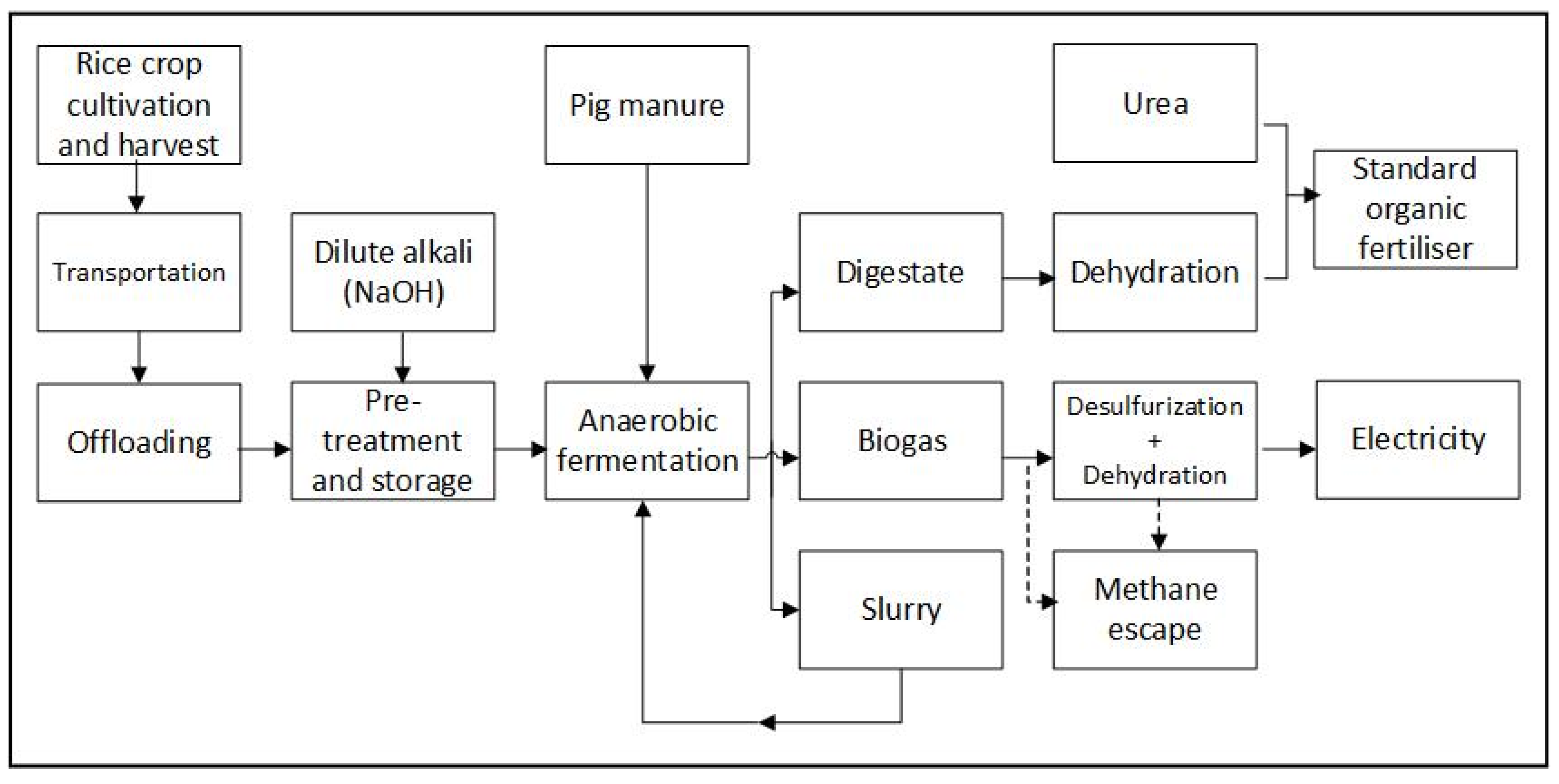

2. Materials and Methods

2.1. LCA Methodology

2.1.1. General Specification

2.1.2. Allocation Method

2.2. Economic Analysis and Marginal Carbon Reduction Cost

3. Results and Discussion

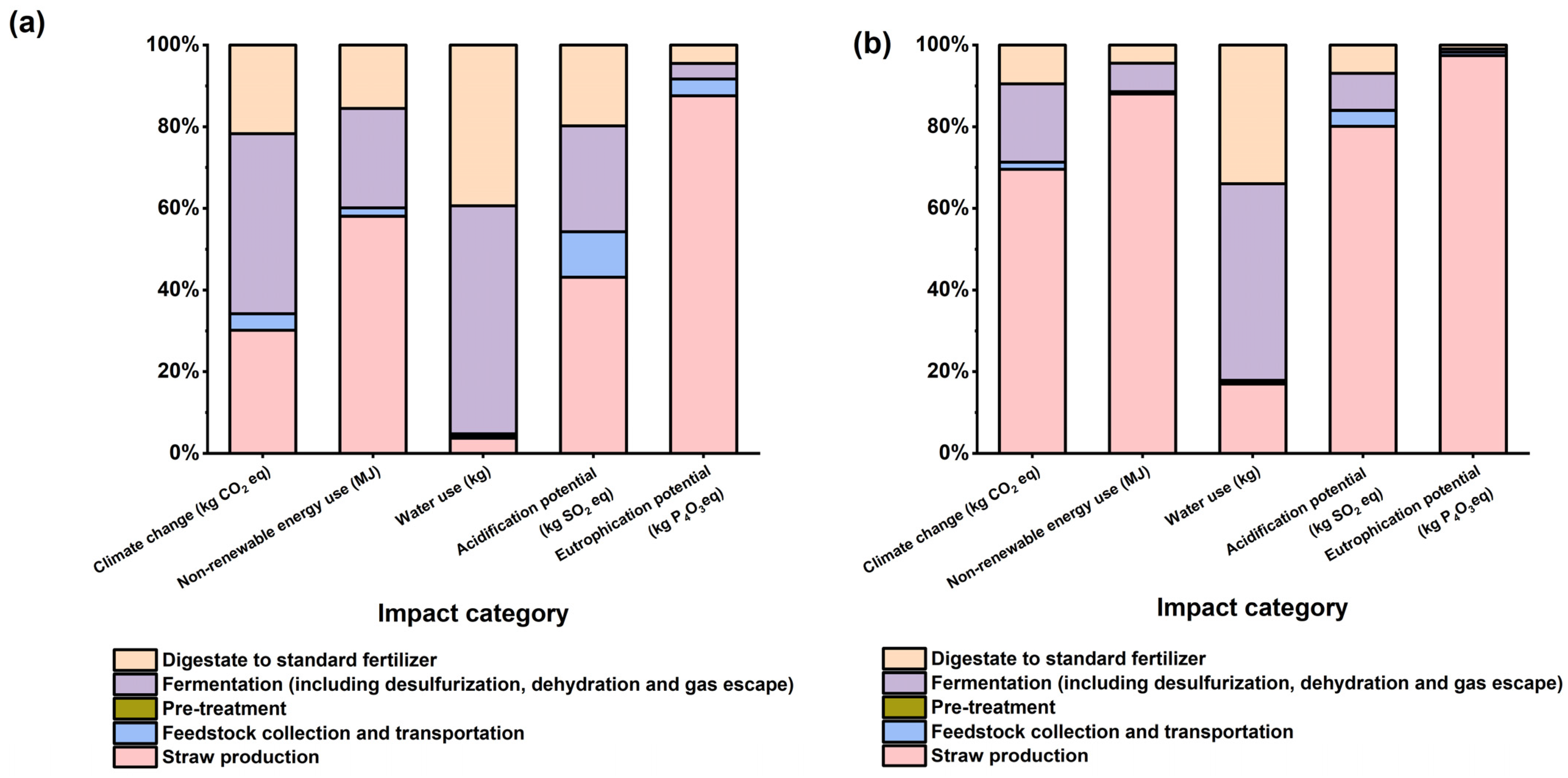

3.1. LCA Results

3.2. GHG Mitigation Potential Alongside Straw-AD Production Pathway

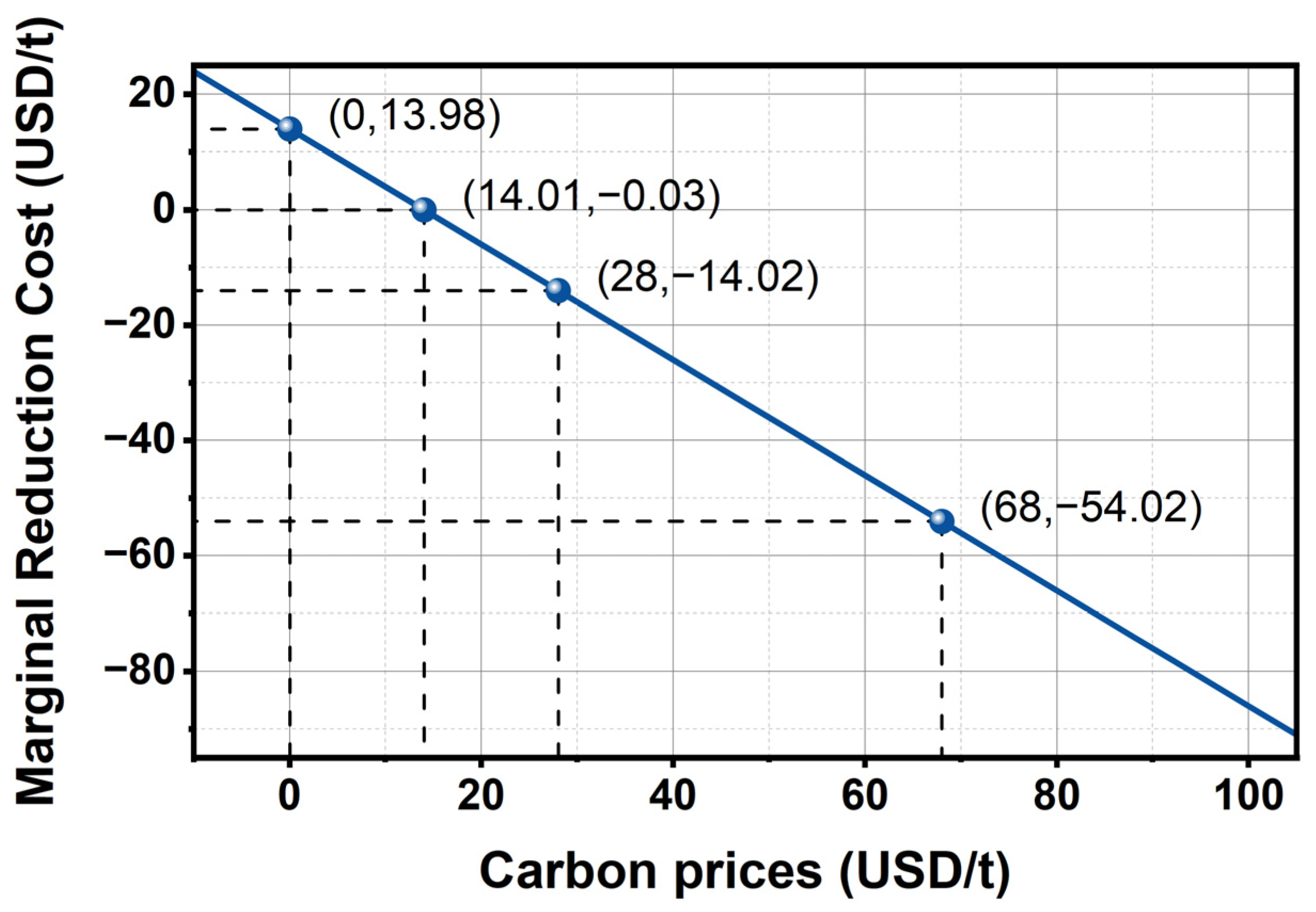

3.3. Marginal Carbon Reduction Cost

3.4. Economic Sensitivity Analysis

4. Practical Implications and Future Search Perspectives

- The high uncertainties associated with the measured or reported emission data from the agricultural sector. It is shown on the IPCC report that the uncertainty range for CO2 emissions from the land use, land use change and forestry (LULUCF) sector was ±69.70% (90% confidence level), while the corresponding figure for the fossil fuel industry was only ±7.89% [48]

- The challenges in the establishment of a reliable and feasible monitoring, reporting and verification (MRV) system for agriculturally related emissions. The flexibility of agricultural activities increases the difficulty of establishing such technical standards or best practice guidelines. Agricultural emissions are a multi-variable function of regional and seasonal production inputs and climate conditions, and the impacts of different factors on the emissions may be non-linear [49]. It is financially difficult for project developers to accurately calculate and document the potential emission reductions aroused from their optimized management practices. The measurement and acquisition of project-specific emission data require strict scientific norms, and face high technical and cost constraints in practice [2].

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| CC (kg CO2 eq.) | NREU (MJ) | WU (kg) | AP (kg SO2 eq.) | ADP (kg Antimony eq.) | EP (kg PO43−eq.) | RI (kg PM2.5 eq.) | ODP (kg CFC-11 eq) | POFP (kg NMVOC eq.) | IRP (kg U235 eq.) | ET (CTUe) | HT-Cancer (CTUh) | HT-Non Cancer (CTUh) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Impacts of electricity generation (per kWh) | 2.80 × 10 −1 | 5.87 | 2.19 | 2.09 × 10−3 | 1.32 × 10−5 | 1.21 × 10−3 | 4.54 × 10−4 | 1.31 × 10−8 | 7.57 × 10−4 | 1.63 × 10−2 | 8.58 × 10−2 | 1.41 × 10−9 | 8.79 × 10−9 |

| CC (kg CO2 eq.) | NREU (MJ) | WU (kg) | AP (kg SO2 eq.) | ADP (kg Antimony eq.) | EP (kg PO43−eq.) | RI (kg PM2.5 eq.) | ODP (kg CFC-11 eq) | POFP (kg NMVOC eq.) | IRP (kg U235 eq.) | ET (CTUe) | HT-Cancer (CTUh) | HT-Non Cancer (CTUh) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Impacts of electricity generation (per kWh) | 2.10 × 10 −1 | 6.57 | 7.81 × 10−1 | 1.95 × 10−3 | 1.62 × 10−5 | 1.69 × 10−3 | 3.72 × 10−4 | 1.76 × 10−8 | 9.29 × 10−4 | 2.02 × 10−2 | 1.27 × 10−1 | 2.04 × 10−9 | 1.27 × 10 |

References

- Lee, H.-S.; Gwon, H.-S.; Lee, S.-I.; Park, H.-R.; Lee, J.-M.; Park, D.-G.; Lee, S.-R.; Eom, S.-H.; Oh, T.-K. Reducing Methane Emissions with Humic Acid–Iron Complex in Rice Cultivation: Impact on Greenhouse Gas Emissions and Rice Yield. Sustainability 2024, 16, 4059. [Google Scholar] [CrossRef]

- IPCC. IPCC 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; The Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019. [Google Scholar]

- Zhang, B.; Tian, H.; Ren, W.; Tao, B.; Lu, C.; Yang, J.; Banger, K.; Pan, S. Methane Emissions from Global Rice Fields: Magnitude, Spatiotemporal Patterns, and Environmental Controls. Glob. Biogeochem. Cycles 2016, 30, 1246–1263. [Google Scholar] [CrossRef]

- Croce, S.; Wei, Q.; D’Imporzano, G.; Dong, R.; Adani, F. Anaerobic Digestion of Straw and Corn Stover: The Effect of Biological Process Optimization and Pre-Treatment on Total Bio-Methane Yield and Energy Performance. Biotechnol. Adv. 2016, 34, 1289–1304. [Google Scholar] [CrossRef]

- Huang, L.; Zhu, Y.; Wang, Q.; Zhu, A.; Liu, Z.; Wang, Y.; Allen, D.T.; Li, L. Assessment of the Effects of Straw Burning Bans in China: Emissions, Air Quality, and Health Impacts. Sci. Total Environ. 2021, 789, 147935. [Google Scholar] [CrossRef]

- Turmel, M.-S.; Speratti, A.; Baudron, F.; Verhulst, N.; Govaerts, B. Crop Residue Management and Soil Health: A Systems Analysis. Agric. Syst. 2015, 134, 6–16. [Google Scholar] [CrossRef]

- Huang, T.; Wen, S.; Zhang, M.; Pan, Y.; Chen, X.; Pu, X.; Zhang, M.; Dang, P.; Meng, M.; Wang, W.; et al. Effect on Greenhouse Gas Emissions (CH4 and N2O) of Straw Mulching or Its Incorporation in Farmland Ecosystems in China. Sustain. Prod. Consum. 2024, 46, 223–232. [Google Scholar] [CrossRef]

- Wang, W.; Wu, X.; Chen, A.; Xie, X.; Wang, Y.; Yin, C. Mitigating Effects of Ex Situ Application of Rice Straw on CH4 and N2O Emissions from Paddy-Upland Coexisting System. Sci. Rep. 2016, 6, 37402. [Google Scholar] [CrossRef]

- Kumar Sakhiya, A.; Anand, A.; Aier, I.; Baghel, P.; Vijay, V.K.; Kaushal, P. Sustainable Utilization of Rice Straw to Mitigate Climate Change: A Bioenergy Approach. Mater. Today Proc. 2021, 46, 5366–5371. [Google Scholar] [CrossRef]

- Prawira, A.H.; Anugrah, R.; Bahri, S.; Firmansyah, F.H.; Roland, H.E. Utilization of Rice Straw Waste as a Source of Bioenergy: A Review. J. Clean Technol. 2024, 1, 9–18. [Google Scholar]

- Zhu, L.; Hu, N.; Yang, M.; Zhan, X.; Zhang, Z. Effects of Different Tillage and Straw Return on Soil Organic Carbon in a Rice-Wheat Rotation System. PLoS ONE 2014, 9, e88900. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, W.; Yu, H.; Ma, J.; Xu, H.; Yagi, K. Increase in CH4 Emission Due to Weeds Incorporation Prior to Rice Transplanting in a Rice-Wheat Rotation System. Atmos. Environ. 2015, 116, 83–91. [Google Scholar] [CrossRef]

- Lamnatou, C.; Nicolaï, R.; Chemisana, D.; Cristofari, C.; Cancellieri, D. Biogas Production by Means of an Anaerobic-Digestion Plant in France: LCA of Greenhouse-Gas Emissions and Other Environmental Indicators. Sci. Total Environ. 2019, 670, 1226–1239. [Google Scholar] [CrossRef]

- Traub, A.; Welsh, R.; Rogers, S.; Grimberg, S. Small Farms Using Anaerobic Digestion: A Viable Technology Education and Outreach Effort. Agroecol. Sustain. Food Syst. 2021, 45, 718–731. [Google Scholar] [CrossRef]

- Alengebawy, A.; Ran, Y.; Osman, A.I.; Jin, K.; Samer, M.; Ai, P. Anaerobic Digestion of Agricultural Waste for Biogas Production and Sustainable Bioenergy Recovery: A Review. Environ. Chem. Lett. 2024, 22, 2641–2668. [Google Scholar] [CrossRef]

- Atelge, M.R.; Krisa, D.; Kumar, G.; Eskicioglu, C.; Nguyen, D.D.; Chang, S.W.; Atabani, A.E.; Al-Muhtaseb, A.H.; Unalan, S. Biogas Production from Organic Waste: Recent Progress and Perspectives. Waste Biomass Valor. 2020, 11, 1019–1040. [Google Scholar] [CrossRef]

- Qian, X.; Shen, G.; Wang, Z.; Zhang, X.; Chen, X.; Tang, Z.; Lei, Z.; Zhang, Z. Enhancement of High Solid Anaerobic Co-Digestion of Swine Manure with Rice Straw Pretreated by Microwave and Alkaline. Bioresour. Technol. Rep. 2019, 7, 100208. [Google Scholar] [CrossRef]

- Boulamanti, A.K.; Donida Maglio, S.; Giuntoli, J.; Agostini, A. Influence of Different Practices on Biogas Sustainability. Biomass Bioenergy 2013, 53, 149–161. [Google Scholar] [CrossRef]

- O’Connor, S.; Ehimen, E.; Pillai, S.C.; Black, A.; Tormey, D.; Bartlett, J. Biogas Production from Small-Scale Anaerobic Digestion Plants on European Farms. Renew. Sustain. Energy Rev. 2021, 139, 110580. [Google Scholar] [CrossRef]

- Timonen, K.; Sinkko, T.; Luostarinen, S.; Tampio, E.; Joensuu, K. LCA of Anaerobic Digestion: Emission Allocation for Energy and Digestate. J. Clean. Prod. 2019, 235, 1567–1579. [Google Scholar] [CrossRef]

- Alengebawy, A.; Mohamed, B.A.; Ran, Y.; Yang, Y.; Pezzuolo, A.; Samer, M.; Ai, P. A Comparative Environmental Life Cycle Assessment of Rice Straw-Based Bioenergy Projects in China. Environ. Res. 2022, 212, 113404. [Google Scholar] [CrossRef]

- Bhatt, A.H.; Tao, L. Economic Perspectives of Biogas Production via Anaerobic Digestion. Bioengineering 2020, 7, 74. [Google Scholar] [CrossRef]

- Ni, Y.; Richter, G.M.; Mwabonje, O.N.; Qi, A.; Patel, M.K.; Woods, J. Novel Integrated Agricultural Land Management Approach Provides Sustainable Biomass Feedstocks for Bioplastics and Supports the UK’s ‘Net-Zero’ Target. Environ. Res. Lett. 2021, 16, 014023. [Google Scholar] [CrossRef]

- Ren, J.; Yu, P.; Xu, X. Straw Utilization in China—Status and Recommendations. Sustainability 2019, 11, 1762. [Google Scholar] [CrossRef]

- Ni, Y.; Mwabonje, O.N.; Richter, G.M.; Qi, A.; Yeung, K.; Patel, M.; Woods, J. Assessing Availability and Greenhouse Gas Emissions of Lignocellulosic Biomass Feedstock Supply—Case Study for a Catchment in England. Biofuels Bioprod. Bioref. 2019, 13, 568–581. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO International Organization for Standardization: Geneva, Switzerland, 2006.

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- PAS 2050:2008; Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services. BSI British Standards Institution: London, UK, 2008.

- Zhang, Y.C.; Luo, M.; Fang, X.Y.; Zhang, F.Q.; Cao, M.H. Energy Value of Rice, Broken Rice, and Rice Bran for Broiler Chickens by the Regression Method. Poult. Sci. 2021, 100, 100972. [Google Scholar] [CrossRef]

- Gummert, M.; Hung, N.V.; Chivenge, P.; Douthwaite, B. (Eds.) Sustainable Rice Straw Management; Springer International Publishing: Cham, Switzerland, 2020; ISBN 978-3-030-32372-1. [Google Scholar]

- Kratzeisen, M.; Starcevic, N.; Martinov, M.; Maurer, C.; Müller, J. Applicability of Biogas Digestate as Solid Fuel. Fuel 2010, 89, 2544–2548. [Google Scholar] [CrossRef]

- Walling, E.; Vaneeckhaute, C. Greenhouse Gas Emissions from Inorganic and Organic Fertilizer Production and Use: A Review of Emission Factors and Their Variability. J. Environ. Manag. 2020, 276, 111211. [Google Scholar] [CrossRef]

- Zhang, L.; Li, S.; Hu, Y.; Nie, Q. Economic Optimization of a Bioenergy-Based Hybrid Renewable Energy System under Carbon Policies—From the Life-Cycle Perspective. Appl. Energy 2022, 310, 118599. [Google Scholar] [CrossRef]

- Ji, L.; Liang, S.; Qu, S.; Zhang, Y.; Xu, M.; Jia, X.; Jia, Y.; Niu, D.; Yuan, J.; Hou, Y.; et al. Greenhouse Gas Emission Factors of Purchased Electricity from Interconnected Grids. Appl. Energy 2016, 184, 751–758. [Google Scholar] [CrossRef]

- Wrzesińska-Jędrusiak, E.; Muradin, M.; Herkowiak, M.; Łaska-Zieja, B.; Myczko, A. Environmental Performance of the Innovative, Patented Mixing System in an Agricultural Biogas Plant Based on LCA Approach. J. Clean. Prod. 2022, 349, 131420. [Google Scholar] [CrossRef]

- Bacenetti, J.; Sala, C.; Fusi, A.; Fiala, M. Agricultural Anaerobic Digestion Plants: What LCA Studies Pointed out and What Can Be Done to Make Them More Environmentally Sustainable. Appl. Energy 2016, 179, 669–686. [Google Scholar] [CrossRef]

- Siegl, S.; Laaber, M.; Holubar, P. Green Electricity from Biomass, Part I: Environmental Impacts of Direct Life Cycle Emissions. Waste Biomass Valor. 2011, 2, 267–284. [Google Scholar] [CrossRef]

- Brentrup, F.; Küsters, J.; Lammel, J.; Barraclough, P.; Kuhlmann, H. Environmental Impact Assessment of Agricultural Production Systems Using the Life Cycle Assessment (LCA) Methodology II. The Application to N Fertilizer Use in Winter Wheat Production Systems. Eur. J. Agron. 2004, 20, 265–279. [Google Scholar] [CrossRef]

- Menegat, S.; Ledo, A.; Tirado, R. Greenhouse Gas Emissions from Global Production and Use of Nitrogen Synthetic Fertilisers in Agriculture. Sci. Rep. 2022, 12, 14490. [Google Scholar] [CrossRef]

- Duan, N.; Khoshnevisan, B.; Lin, C.; Liu, Z.; Liu, H. Life Cycle Assessment of Anaerobic Digestion of Pig Manure Coupled with Different Digestate Treatment Technologies. Environ. Int. 2020, 137, 105522. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Manandhar, A.; Li, G.; Shah, A. Life Cycle Assessment of Integrated Solid State Anaerobic Digestion and Composting for On-Farm Organic Residues Treatment. Waste Manag. 2018, 76, 294–305. [Google Scholar] [CrossRef]

- Williams, A.G.; Audsley, E.; Sandars, D.L. Environmental Burdens of Producing Bread Wheat, Oilseed Rape and Potatoes in England and Wales Using Simulation and System Modelling. Int. J. Life Cycle Assess. 2010, 15, 855–868. [Google Scholar] [CrossRef]

- Whittaker, C.; McManus, M.C.; Hammond, G.P. Greenhouse Gas Reporting for Biofuels: A Comparison between the RED, RTFO and PAS2050 Methodologies. Energy Policy 2011, 39, 5950–5960. [Google Scholar] [CrossRef]

- Griscom, B.W.; Adams, J.; Ellis, P.W.; Houghton, R.A.; Lomax, G.; Miteva, D.A.; Schlesinger, W.H.; Shoch, D.; Siikamäki, J.V.; Smith, P.; et al. Natural Climate Solutions. Proc. Natl. Acad. Sci. USA 2017, 114, 11645–11650. [Google Scholar] [CrossRef]

- Luo, C.-J.; Chen, M.-P. Theoretical and Pathway Analysis of Utilizing Carbon Trading to Promote Agricultural Emission Reductions: International Experience and Its Implications for China. Adv. Clim. Change Res. 2023, 19, 761. [Google Scholar] [CrossRef]

- Li, G.; Hou, C.; Zhou, X. Carbon Neutrality, International Trade, and Agricultural Carbon Emission Performance in China. Front. Environ. Sci. 2022, 10, 931937. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2022—Mitigation of Climate Change: Working Group III Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2023; ISBN 978-1-009-15792-6. [Google Scholar]

- Garnache, C.; Mérel, P.R.; Lee, J.; Six, J. The Social Costs of Second-Best Policies: Evidence from Agricultural GHG Mitigation. J. Environ. Econ. Manag. 2017, 82, 39–73. [Google Scholar] [CrossRef]

| Input | Quantity | Unit | |

|---|---|---|---|

| Input | Rice straw (dry matter) | 2125.00 | t/year |

| Swine manure (moisture content 78%) | 142.00 | t/year | |

| Feedstock transportation | 50.00 | km | |

| NaOH | 3.65 | kg/year | |

| Water pre-treatment | 36.50 | t/year | |

| Water operation | 2187.00 | t/year | |

| Desulfurizer-FaO | 5.00 | t/year | |

| Diesel consumption—straw harvest and loading | 5.00 | t/year | |

| Diesel consumption—straw site offloading | 2.86 | t/year | |

| Electricity—AD | 199,405.00 | kwh/year | |

| Electricity—fertilizer production | 87,447.00 | kwh/year | |

| Urea | 9474.00 | kg/year | |

| Intermediate product | Biogas | 442,015.00 | m3/year |

| Digestate | 3285.00 | t/year | |

| Output | Electricity | 662,475 | kWh/year |

| Organic fertilizer | 1095.00 | t/year |

| Input/Product Item | Economic Value | Data Source | Energy Content | Data Source |

|---|---|---|---|---|

| Rice | 3000 CNY/t | Chinese National food and Strategic Reserves Administration | 15.31 MJ/kg | [30] |

| Rice straw | 375 CNY/t | Survey questionnaire | 14.2 MJ/kg | [31] |

| Digestate-based fertilizer | 500 CNY/t | Survey questionnaire | 14 MJ/kg | [32] |

| Bio-mass electricity | 0.75 CNY/kWh | Chinese National Development and Reform Commission | 1 kWh = 3.6 MJ |

| Category | Quantity | Cost per Unit * | Total Cost (103 USD/Year) | |

|---|---|---|---|---|

| Variable cost (VCAD) | Rice straw (CRS) | 2125.00 t/year (dry matter) | 52.52 USD/t (converted from 375 CNY/t) | 111.61 |

| Manure (Cmanure) | 142.0 t/year (moisture content of 80%) | 23.11 USD/t (converted from 165 CNY/t) | 3.28 | |

| NaOH (CNaOH) | 3.65 kg/year | 5.04 USD/kg (converted from 36.00 CNY/kg) | 0.02 | |

| Water (Cwater) | 2226.5 m3/year | 0.56 USD/m3 (converted from 4.00 CNY/m3) | 1.23 | |

| Desulfurizer (Cdesulfurizer) | 5.00 t/year | 940.08 USD/t (converted from 6712.17 CNY/t) | 4.70 | |

| Diesel (Cdisel) (for straw harvest and on-site loading/offloading) | 7.86 t/year | 1251 USD/t (converted from 8932.14 CNY/t) | 6.26 | |

| Electricity consumed (Celectricity) | 286,852 kWh/year | 0.092 USD/kWh (converted from 0.60 CNY/kWh) | 24.10 | |

| Urea (Curea) | 9.47 t/year | 280.11 USD/t (converted from 2000.00 CNY/t) | 2.65 | |

| Fixed cost (FCAD) | Equipment (Cequipment) | Converted from 433,333.00 CNY/year (initial investment on equipment was 13.00 million CNY, assuming service time of 30 years) | 60.69 | |

| Employee (Cemployee) | Converted from 300,000.00 CNY/year | 40.02 | ||

| Venue rental (Crental) | Converted from 240,000.00 CNY/year | 33.61 | ||

| Impact Category | CC (kg CO2 eq) | NREU (MJ) | WU (kg) | AP (kg SO2 eq) | EP (kg PO43−eq) | |

|---|---|---|---|---|---|---|

| Economic allocation | ||||||

| Production stages | Straw production | 2.27 × 10−1 | 8.49 | 2.82 × 10−1 | 2.36 × 10−3 | 2.33 × 10−3 |

| Feedstock collection and transportation | 3.01 × 10−2 | 2.90 × 10−1 | 2.51 × 10−2 | 6.09 × 10−4 | 1.09 × 10−4 | |

| Pre-treatment | 1.75 × 10−5 | 2.45 × 10−4 | 5.61 × 10−2 | 1.03 × 10−7 | 1.95 × 10−8 | |

| Fermentation (including desulfurization, dehydration and gas escape) | 3.31 × 10−1 | 3.56 | 4.23 | 1.42 × 10−3 | 1.02 × 10−4 | |

| Digestate to standard fertilizer | 1.63 × 10−1 | 2.28 | 2.98 | 1.08 × 10−3 | 1.20 × 10−4 | |

| Total | 7.51 × 10−1 | 1.46 × 10 | 7.58 | 5.47 × 10−3 | 2.66 × 10−3 | |

| Bio-electricity (impacts after alloaction) | 2.80 × 10−1 | 5.87 | 2.19 | 2.09 × 10−3 | 1.21 × 10−3 | |

| Digestate-based fertilizer (impacts after alloaction) | 4.72 × 10−1 | 8.74 | 5.39 | 3.38 × 10−3 | 1.45 × 10−3 | |

| Energy allocation | ||||||

| Production stages | Straw production | 1.20 | 4.49 × 10 | 1.49 | 1.25 × 10−2 | 1.23 × 10−2 |

| Feedstock collection and transportation | 3.01 × 10−2 | 2.90 × 10−1 | 2.51 × 10−2 | 6.09 × 10−4 | 1.09 × 10−4 | |

| Pre-treatment | 1.75 × 10−5 | 2.45 × 10−4 | 5.61 × 10−2 | 1.03 × 10−7 | 1.95 × 10−8 | |

| Fermentation (including desulfurization, dehydration and gas escape) | 3.31 × 10−1 | 3.56 | 4.23 | 1.42 × 10−3 | 1.02 × 10−4 | |

| Digestate to standard fertilizer | 1.63 × 10−1 | 2.28 | 2.98 | 1.08 × 10−3 | 1.20 × 10−4 | |

| Total | 1.72 | 5.11 × 10 | 8.79 | 1.56 × 10−2 | 1.27 × 10−2 | |

| Bio-electricity (impacts after alloaction) | 2.10 × 10−1 | 6.57 | 7.81 × 10−1 | 1.95 × 10−3 | 1.69 × 10−3 | |

| Digestate-based fertilizer (impacts after alloaction) | 1.51 | 4.45 × 10 | 8.01 | 1.36 × 10−2 | 1.10 × 10−2 | |

| Product | EF | Unit | Reference | |

|---|---|---|---|---|

| AD system (this study) | Standard organic fertilizer | 6.88 (economic allocation) 22.09 (energy Allocation) | kg CO2eq./kg N | |

| Electricity | 0.28 (economic allocation) 0.21 (energy Allocation) | kgCO2eq./kwh | ||

| Alternatives | Urea (China) | 5.5 | kg CO2eq./kg N | [39] |

| Ammonium nitrite (China) | 10.3 | kg CO2eq./kg N | [39] | |

| Compost | 170–850 | kg CO2eq./kg N | [33] | |

| Electricity—national grid | 0.759 | kgCO2eq./kWh | [35] | |

| Electricity from AD of pig manure | 1.09–1.26 | kgCO2eq./kWh | [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Y.; Zhang, M.; Qian, X.; Shen, G.; Mwabonje, O. Anaerobic Digestion of Rice Straw as Profitable Climate Solution Reduces Paddy Field Greenhousegas Emissions and Produces Climate-Smart Fertilizer Under Carbon Trading Mechanisms. Sustainability 2025, 17, 2439. https://doi.org/10.3390/su17062439

Ni Y, Zhang M, Qian X, Shen G, Mwabonje O. Anaerobic Digestion of Rice Straw as Profitable Climate Solution Reduces Paddy Field Greenhousegas Emissions and Produces Climate-Smart Fertilizer Under Carbon Trading Mechanisms. Sustainability. 2025; 17(6):2439. https://doi.org/10.3390/su17062439

Chicago/Turabian StyleNi, Yuanzhi, Min Zhang, Xiaoyong Qian, Genxiang Shen, and Onesmus Mwabonje. 2025. "Anaerobic Digestion of Rice Straw as Profitable Climate Solution Reduces Paddy Field Greenhousegas Emissions and Produces Climate-Smart Fertilizer Under Carbon Trading Mechanisms" Sustainability 17, no. 6: 2439. https://doi.org/10.3390/su17062439

APA StyleNi, Y., Zhang, M., Qian, X., Shen, G., & Mwabonje, O. (2025). Anaerobic Digestion of Rice Straw as Profitable Climate Solution Reduces Paddy Field Greenhousegas Emissions and Produces Climate-Smart Fertilizer Under Carbon Trading Mechanisms. Sustainability, 17(6), 2439. https://doi.org/10.3390/su17062439