SustAI-SCM: Intelligent Supply Chain Process Automation with Agentic AI for Sustainability and Cost Efficiency

Abstract

1. Introduction

- Sustainable process automation: The SustAI-SCM automates supply chain decision making, which reduces the need for manual intervention and lowers the risk of human errors.

- Agentic AI for dynamic optimization: Going beyond the static rule-based automation and incorporation of transformer model through agentic AI framework to autonomously refine supply chain processes, ensuring optimal resource allocation.

- Carbon footprint reduction: By optimizing logistics and inventory, the model effectively reduces transportation emissions and unnecessary energy consumption, which contributes to carbon footprint reduction.

- Cost efficiency and scalability: The AI-driven approach significantly lowers operational costs while maintaining flexibility to scale across different supply chain networks.

2. Literature Review

2.1. AI in Supply Chain Management

2.2. Agentic AI and Autonomous Decision Making

2.3. Sustainability Challenges and AI Solutions

2.4. Research Gaps and Objectives

3. Methodology

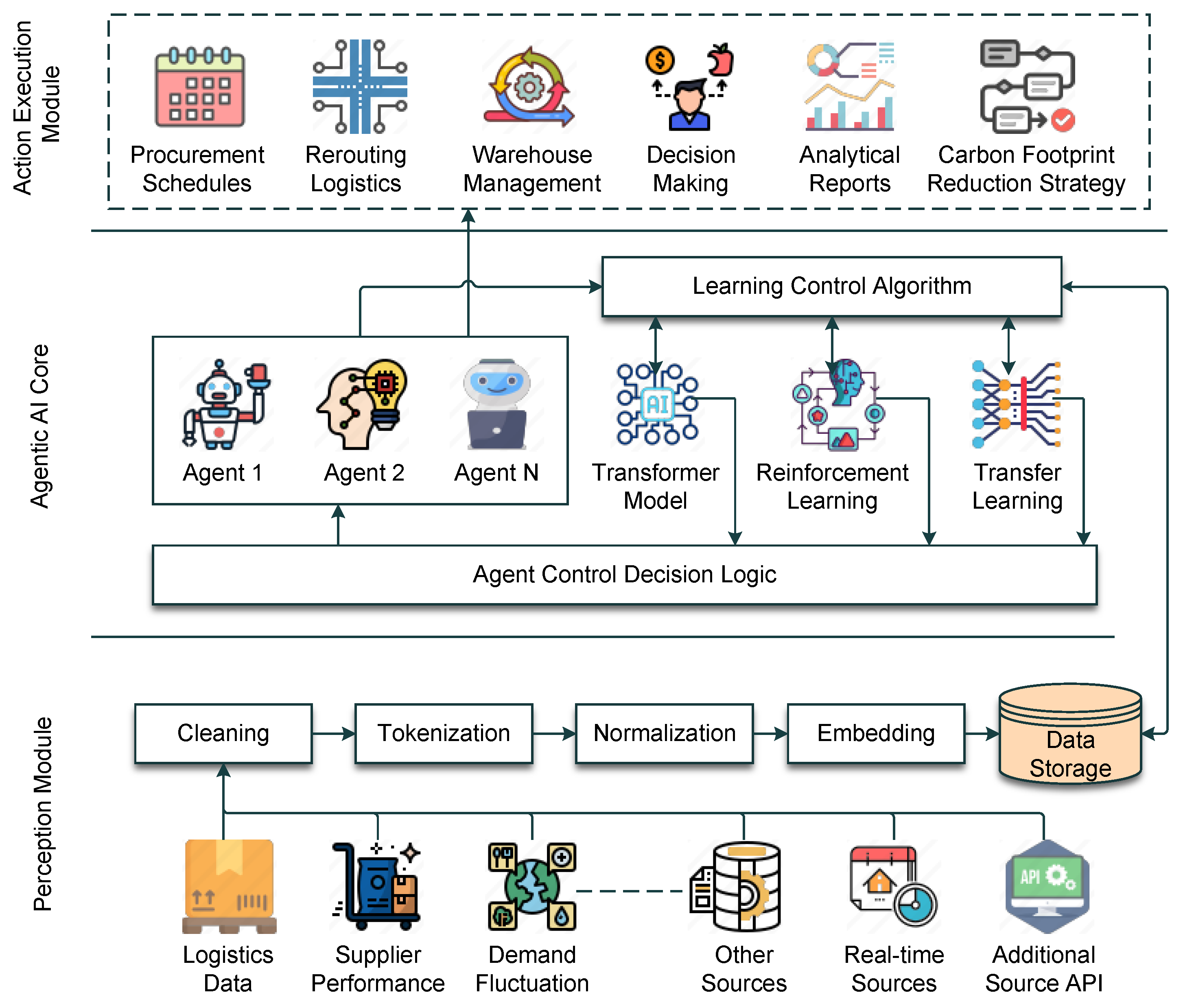

3.1. Framework Overview

- Perception module: This module has been designed to ingest both structured and unstructured data from various sources, including real-time sources. These data are related to logistics, supplier performance records, and demand fluctuation patterns. This module processes the data for the core agentic AI module.

- Agentic AI core: The agentic AI core module is the decision-making engine of the framework. It has been built using a transformer model with the facility for transfer learning and reinforcement learning for real-time adaptability. Unlike traditional static optimization, this module refines operational strategies based on evolving constraints.

- Action execution module: The third module is the action execution module. The decisions made by the agents are translated into actions in this module. That means this module translates the AI-generated insights into actionable supply chain tasks—whether it is adjusting procurement schedules, rerouting logistics for lower carbon emissions, or dynamically managing warehouse inventory.

Definition of Agentic AI in Supply Chain Management

- Design: The system is structured to autonomously adapt its decision-making logic, leveraging reinforcement learning to refine optimization strategies.

- Operation: The AI actively processes real-time supply chain data, assessing multiple competing objectives such as cost efficiency, sustainability, and operational resilience.

- Communication: The model integrates with various supply chain modules, allowing seamless information exchange between procurement, logistics, and warehouse management.

- Reasoning: Unlike static AI models, the agentic AI in SustAI-SCM evaluates multiple interdependent factors simultaneously, making context-aware adjustments without requiring explicit rule-based programming.

3.2. Dataset Preparation and Processing

| Algorithm 1: Data Preprocessing Pipeline for SustAI-SCM |

Raw dataset Processed dataset Step 1: Data Collection Retrieve from Step 2: Cleaning and Normalization if then if x is duplicate or inconsistent then Step 3: Tokenization and Embedding Step 4: Sequence Standardization Step 5: Dataset Splitting return |

3.2.1. Data Cleaning and Normalization

3.2.2. Tokenization and Embedding

3.2.3. Sequence Standardization

3.2.4. Final Dataset Split

3.3. Transformer Model Design

3.3.1. Architectural Components

3.3.2. Embedding Layer

3.3.3. Multi-Head Attention Mechanism

3.3.4. Feed-Forward Network and Output Layer

3.3.5. Model Adaptability and Learning

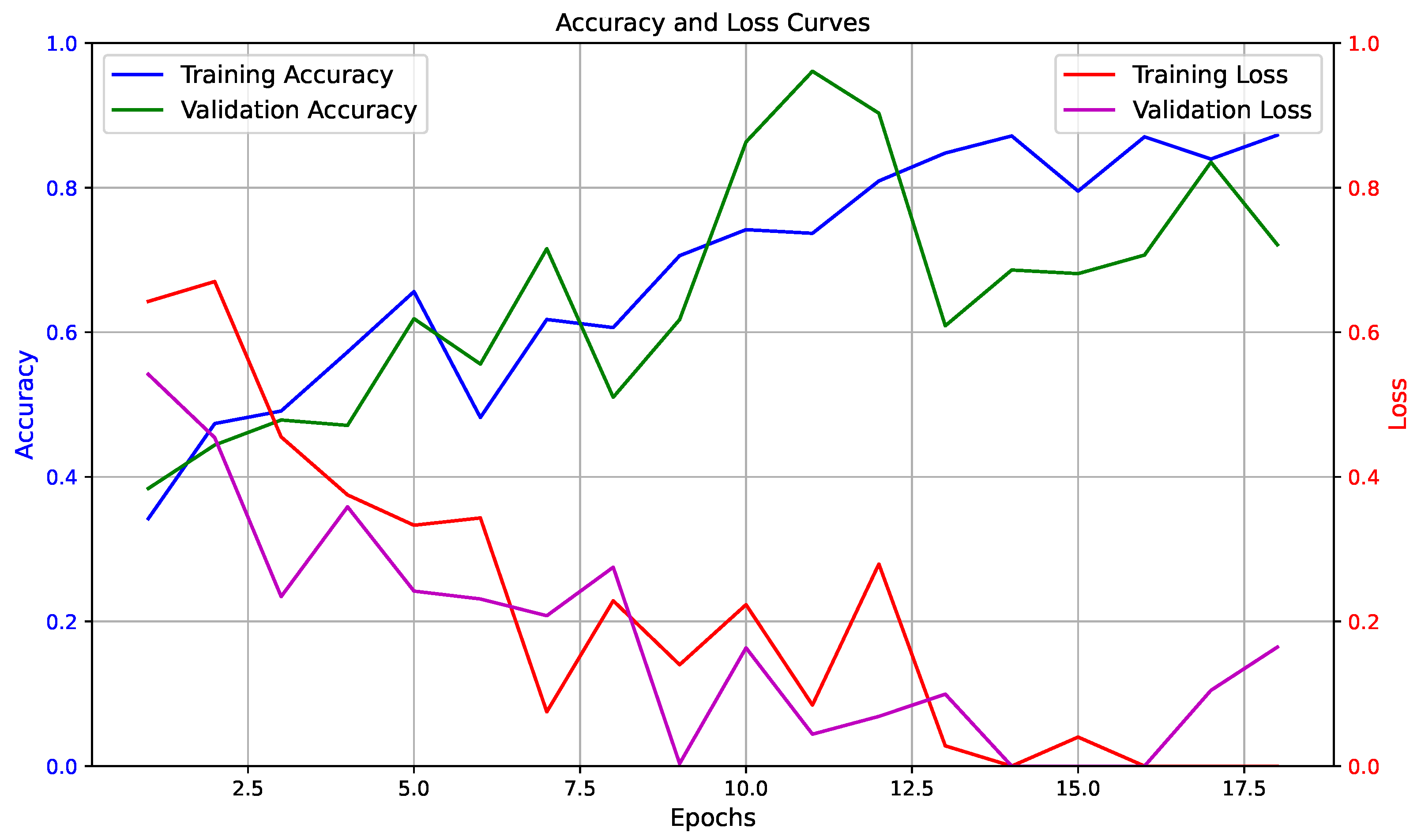

3.4. Training and Hyperparameter Optimization

3.4.1. Loss Function and Objective

3.4.2. Optimization Algorithm

3.4.3. Learning Rate Scheduling

3.4.4. Hyperparameter Tuning

3.4.5. Computational Setup

4. Implementation

4.1. Hardware Infrastructure

4.2. Software Stack

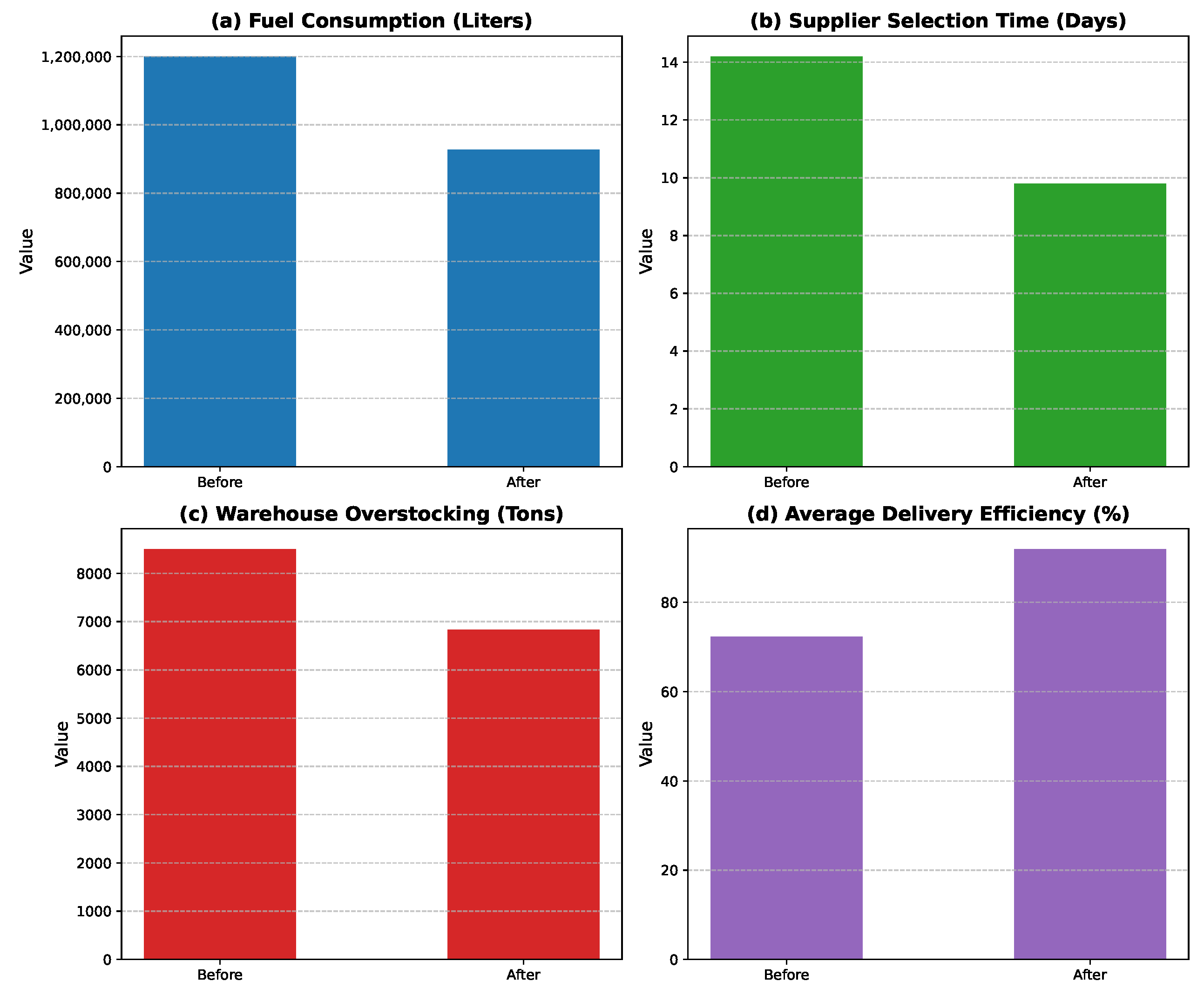

4.3. Case Study: Real-World Deployment in a Supply Chain Network

Selection of Operational Metrics

4.4. Real-Time Sustainability Integration

5. Performance Evaluation and Results

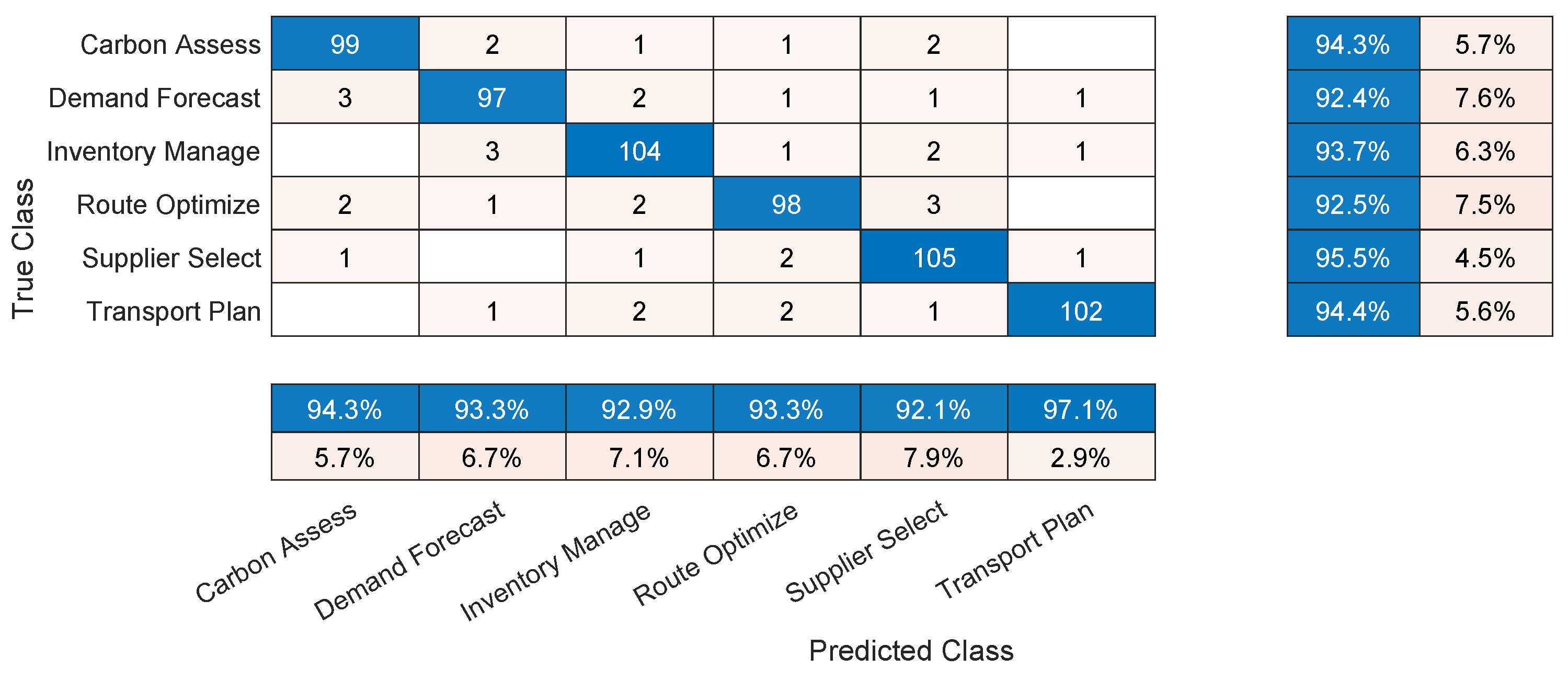

5.1. Confusion Matrix Analysis

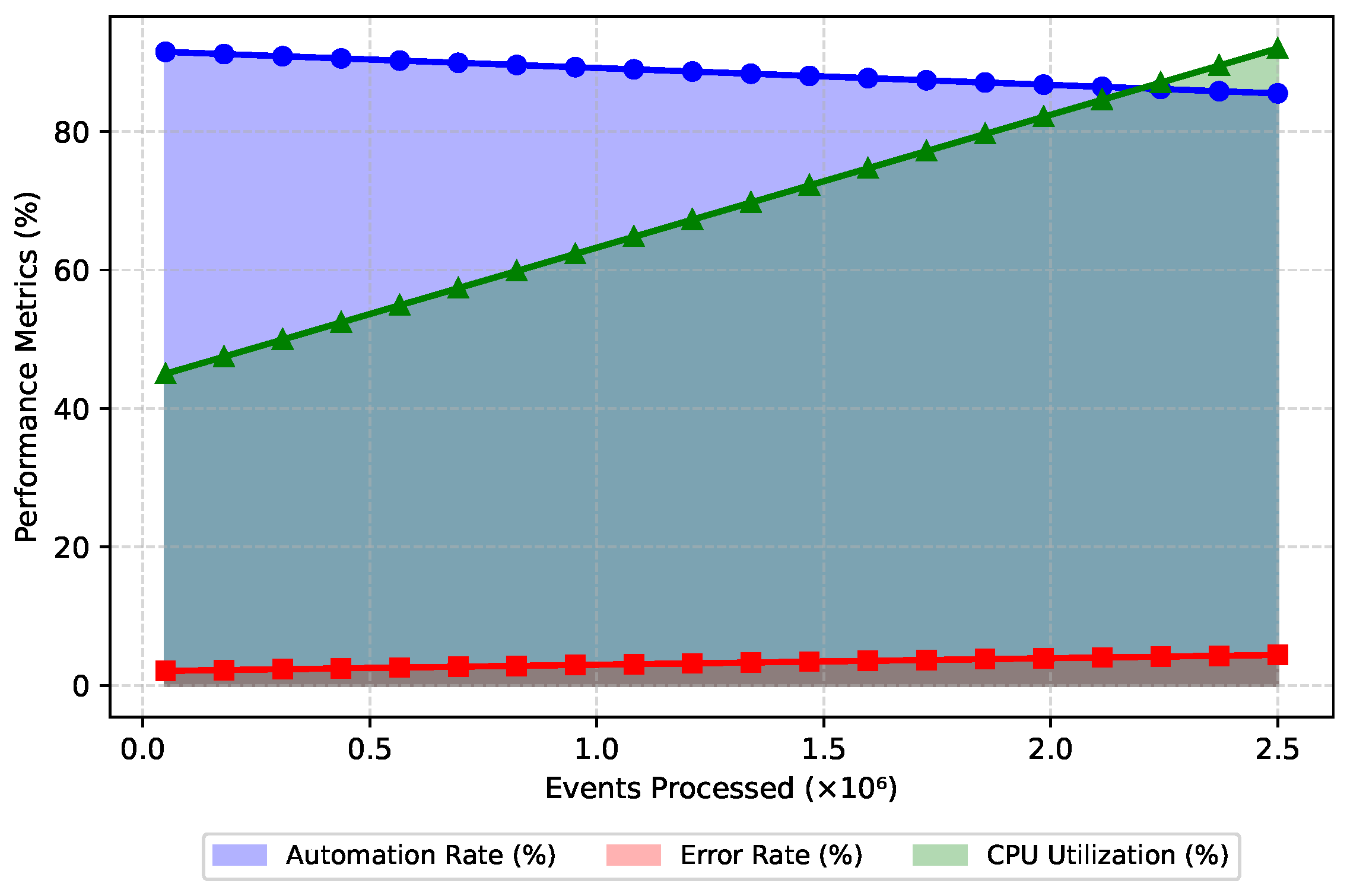

5.2. Scalability and Robustness

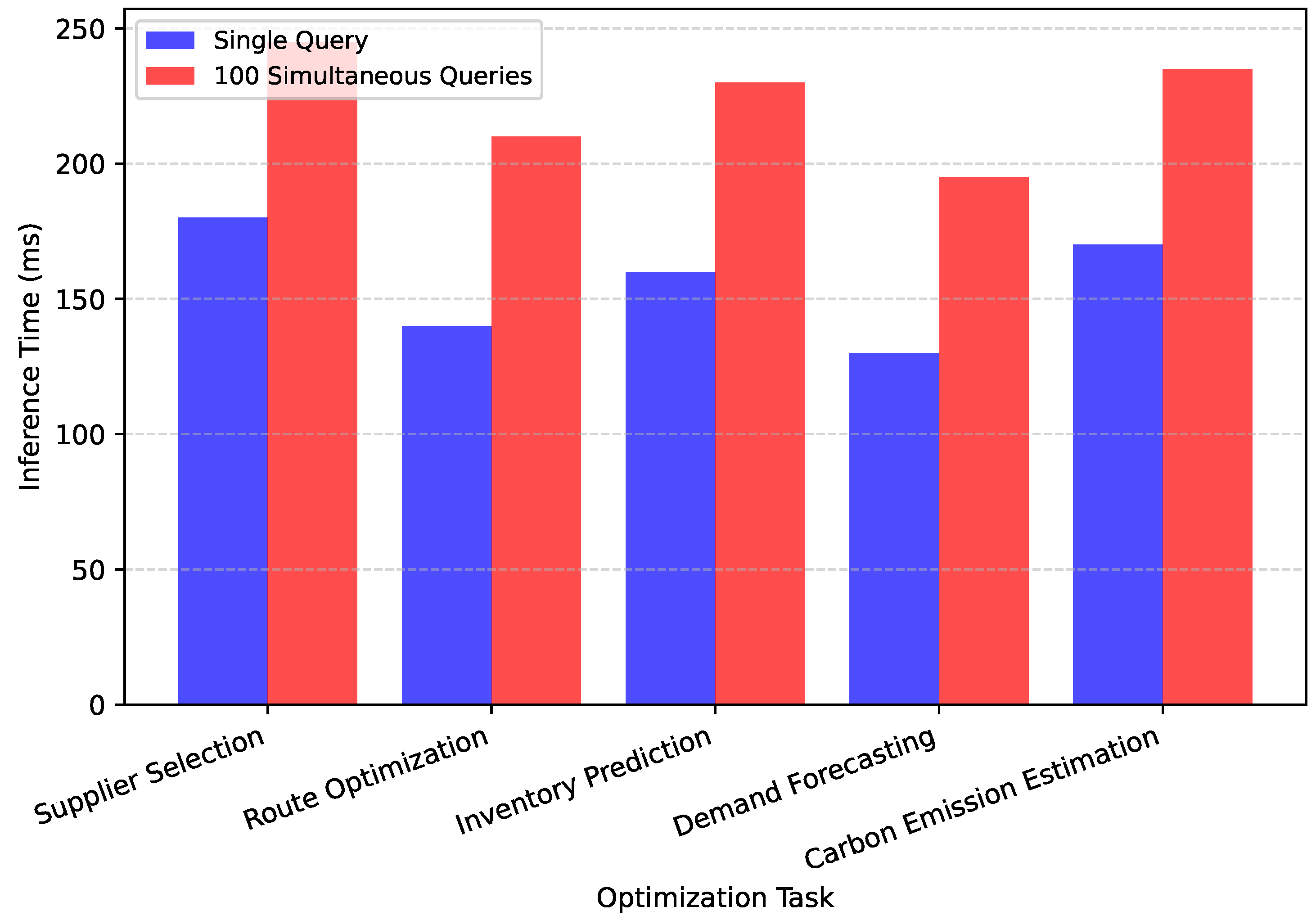

5.3. Inference Time Analysis

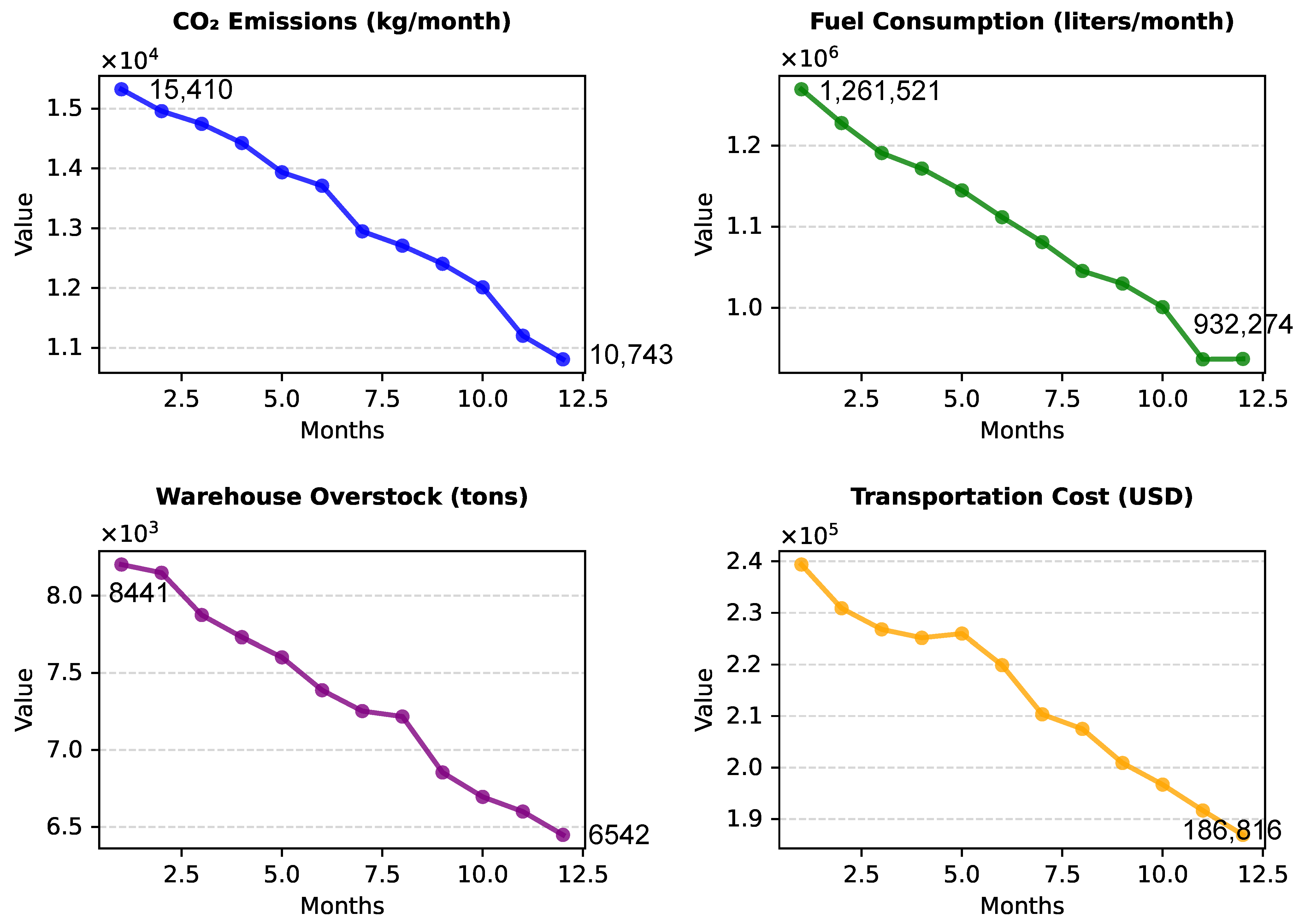

5.4. Sustainability Impact Assessment

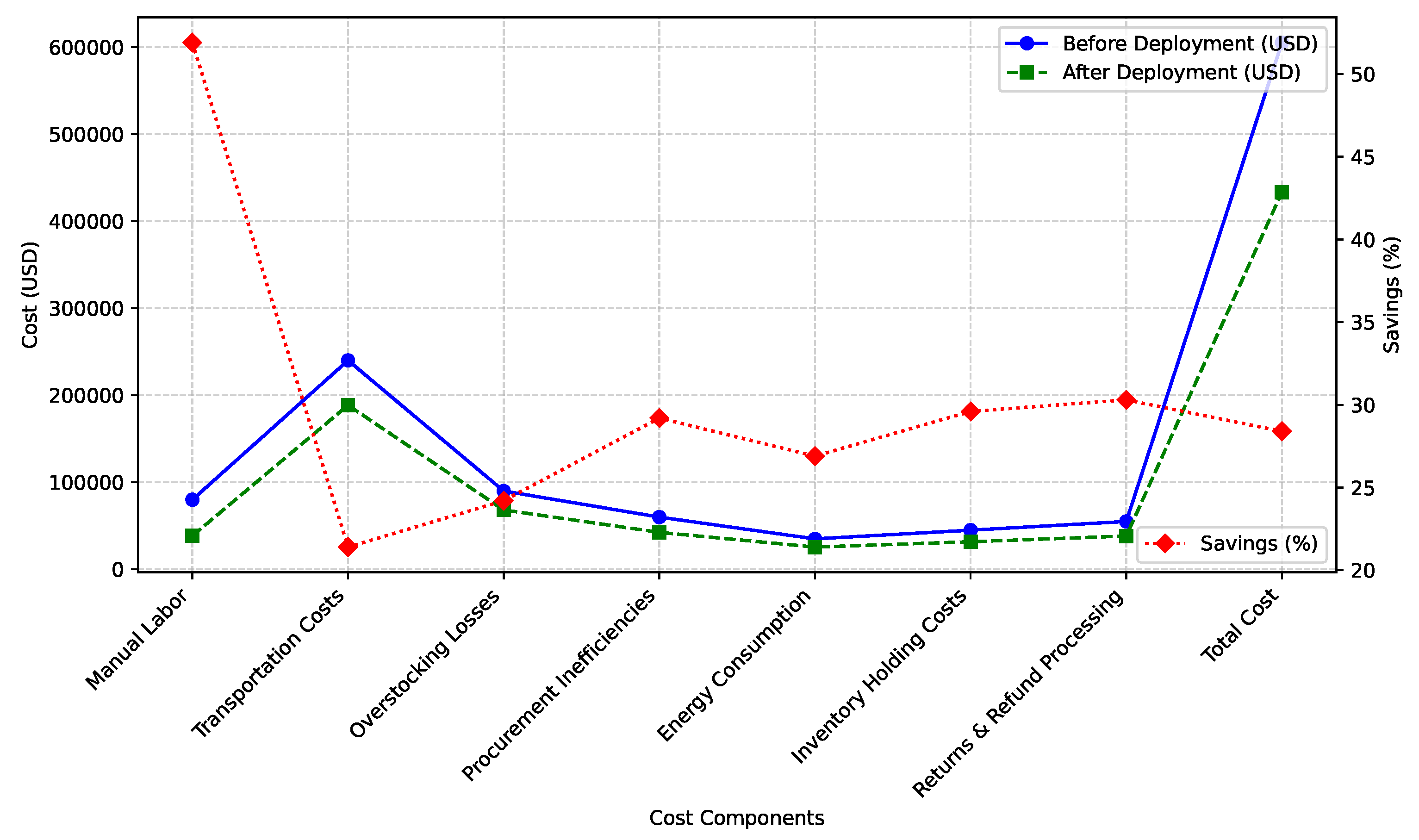

5.5. Process Optimization and Cost Savings

6. Limitations and Future Directions

6.1. Limitations

6.1.1. Limited Generalization Across Industries

6.1.2. Computational Overhead and Energy Consumption

6.1.3. High Training Time but Efficient Inference

6.2. Future Directions

6.2.1. Expanding Industry-Specific Training Datasets

6.2.2. Implementing Energy-Efficient AI Optimization

6.2.3. User-Customizable Optimization Weights

6.2.4. Reducing Training Time Through Efficient Architectures

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SCM | Supply chain management |

| SustAI-SCM | Sustainable AI-Driven Supply Chain Management Framework |

| AI | Artificial intelligence |

| LLM | Large language model |

| XAI | Explainable artificial intelligence |

| GPU | Graphics processing unit |

| CO2 | Carbon dioxide |

| API | Application programming interface |

References

- Lin, B.; Zhu, Y. Supply chain configuration and total factor productivity of renewable energy. Renew. Sustain. Energy Rev. 2025, 209, 115140. [Google Scholar] [CrossRef]

- Rashid, A.; Rasheed, R.; Amirah, N.A. Synergizing TQM, JIT, and Green Supply Chain Practices: Strategic Insights for Enhanced Environmental Performance. Logistics 2025, 9, 18. [Google Scholar] [CrossRef]

- Nair, K.; Bhardwaj, S.; Chopra, R.; Balasubramanian, S.; Mishra, M. Integrating policy, technology, and knowledge: A roadmap to circular manufacturing adoption. Int. J. Sustain. Eng. 2025, 18, 1–11. [Google Scholar] [CrossRef]

- Scheve, K.; Serlin, T. Trains, trade, and transformation: A spatial Rogowski theory of America’s 19th-century protectionism. Am. J. Political Sci. 2024, in press. [Google Scholar] [CrossRef]

- Khedr, A.M. Enhancing supply chain management with deep learning and machine learning techniques: A review. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100379. [Google Scholar] [CrossRef]

- Chandratreya, A. Synergizing Success the Dynamics of Collaborative Business Ecosystems. In Navigating Collective Intelligence for Sustainable Futures; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 85–118. [Google Scholar]

- Okogwu, C.; Agho, M.O.; Adeyinka, M.A.; Odulaja, B.A.; Eyo-Udo, N.L.; Daraojimba, C.; Banso, A.A. Exploring the Integration of Sustainable Materials in Supply Chain Management for Environmental Impact. Eng. Sci. Technol. J. 2023, 4, 49–65. [Google Scholar] [CrossRef]

- Haiqi, J.; Liu, L. The impact of supply chain sustainability management on firm performance and its coordination mechanism. Acad. J. Bus. Manag. 2024, 6, 231–237. [Google Scholar] [CrossRef]

- Daraojimba, A.I.; Atadoga, A.; Obi, O.C.; Osasona, F.; Onwusinkwue, S.; Dawodu, S.O. AI in supply chain optimization: A comparative review of USA and African Trends. Int. J. Sci. Res. Arch. 2024, 11, 896–903. [Google Scholar] [CrossRef]

- Jackson, I.; Ivanov, D.A.; Dolgui, A.; Namdar, J. Generative artificial intelligence in supply chain and operations management: A capability-based framework for analysis and implementation. Int. J. Prod. Res. 2024, 62, 6120–6145. [Google Scholar] [CrossRef]

- Xue, X. Analysis of the Impact and Application of Artificial Intelligence on the Development of Supply Chain Technology in Large Enterprises. Mod. Econ. Manag. Forum 2023, 4, 142–146. [Google Scholar] [CrossRef]

- Naveena, M.; Ellaturu, N.; Kumari, T.L.; Bambuwala, S.; Rajalakshmi, M. Ai-Driven Solutions for Supply Chain Management. J. Inform. Educ. Res. 2024, 4, 861–868. [Google Scholar] [CrossRef]

- Hasan, M.R.; Rabbi, R.E.; Rahman, A.; Mukaddim, A.A.; Khan, M.A.; Hider, M.A.; Zeeshan, M.A.F. Optimizing Sustainable Supply Chains: Integrating Environmental Concerns and Carbon Footprint Reduction through AI-Enhanced Decision-Making in the USA. J. Econ. Financ. Account. Stud. 2024, 6, 57–71. [Google Scholar] [CrossRef]

- Alkhaldi, F.; Raymond, M.I.; Abu-AlSondos, I.A.; Almazaydeh, L. Artificial Intelligence Applications and Roles in Supply Chain Sustainability. In Proceedings of the 2023 Asia Conference on Cognitive Engineering and Intelligent Interaction (CEII), Hong Kong, China, 15–16 December 2023; pp. 120–124. [Google Scholar] [CrossRef]

- Alsheyadi, A.; Baawain, A.; Shaukat, M.R. E-supply chain coordination and performance impacts: An empirical investigation. Prod. Manuf. Res. 2024, 12, 2379942. [Google Scholar] [CrossRef]

- Nimmy, S.F. Explainable Artificial Intelligence in Supply Chain Operational Risk Management (XAI-SCORM): A Comprehensive Approach Towards Interpretability, Transparency, and Trustworthiness. Ph.D. Thesis, UNSW Sydney, Sydney, Australia, 2024. [Google Scholar]

- Matos, S.V.; Schleper, M.C.; Hall, J.K.; Baum, C.M.; Low, S.; Sovacool, B.K. Beyond the new normal for sustainability: Transformative operations and supply chain management for negative emissions. Int. J. Oper. Prod. Manag. 2024, 44, 263–295. [Google Scholar] [CrossRef]

- Pasupuleti, V.; Thuraka, B.; Kodete, C.S.; Malisetty, S. Enhancing supply chain agility and sustainability through machine learning: Optimization techniques for logistics and inventory management. Logistics 2024, 8, 73. [Google Scholar] [CrossRef]

- Shahzadi, G.; Jia, F.; Chen, L.; John, A. AI adoption in supply chain management: A systematic literature review. J. Manuf. Technol. Manag. 2024, 35, 1125–1150. [Google Scholar] [CrossRef]

- Andrei, N.; Scarlat, C.; Ioanid, A. Transforming E-commerce logistics: Sustainable practices through autonomous maritime and last-mile transportation solutions. Logistics 2024, 8, 71. [Google Scholar] [CrossRef]

- Alherimi, N.; Saihi, A.; Ben-Daya, M. A Systematic Review of Optimization Approaches Employed in Digital Warehousing Transformation. IEEE Access 2024, 12, 145809–145831. [Google Scholar] [CrossRef]

- Rapp, A.; Boldi, A.; Curti, L.; Perrucci, A.; Simeoni, R. How do people ascribe humanness to chatbots? An analysis of real-world human-agent interactions and a theoretical model of humanness. Int. J. Hum.-Interact. 2024, 40, 6027–6050. [Google Scholar] [CrossRef]

- Wang, D.; Wang, L.; Zhang, Z.; Wang, D.; Zhu, H.; Gao, Y.; Fan, X.; Tian, F. “Brilliant AI doctor” in rural clinics: Challenges in AI-powered clinical decision support system deployment. In Proceedings of the 2021 CHI Conference on Human Factors in Computing Systems, Online, 8–13 May 2021; pp. 1–18. [Google Scholar]

- Joel, O.S.; Oyewole, A.T.; Odunaiya, O.G.; Soyombo, O.T. Leveraging Artificial Intelligence for Enhanced Supply Chain Optimization: A Comprehensive Review Of Current Practices and Future Potentials. Int. J. Manag. Entrep. Res. 2024, 6, 707–721. [Google Scholar] [CrossRef]

- Xiang, X.; Xue, J.; Zhao, L.; Lei, Y.; Yue, C.; Lu, K. Real-time Integration of Fine-tuned Large Language Model for Improved Decision-Making in Reinforcement Learning. In Proceedings of the 2024 International Joint Conference on Neural Networks (IJCNN), Yokohama, Japan, 30 June–5 July 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Rane, N.; Choudhary, S.; Rane, J. Artificial Intelligence-Driven Corporate Finance: Enhancing Efficiency and Decision-Making Through Machine Learning, Natural Language Processing, and Robotic Process Automation in Corporate Governance and Sustainability. SSRN Electron. J. 2024. [Google Scholar] [CrossRef]

- Agrawal, S.; Gangu, K.; Kirupa, P.; Gopalakrishna; Agarwal, R.; Jain, D.A. Sustainability in Supply Chain Planning. Mod. Dyn. Math. Progress. 2024, 1, 248–269. [Google Scholar] [CrossRef]

- Plambeck, E.L. Reducing greenhouse gas emissions through operations and supply chain management. Energy Econ. 2012, 34, S64–S74. [Google Scholar] [CrossRef]

- Chen, W.; Men, Y.; Fuster, N.; Osorio, C.; Juan, A.A. Artificial intelligence in logistics optimization with sustainable criteria: A review. Sustainability 2024, 16, 9145. [Google Scholar] [CrossRef]

- Brintrup, A.; Kosasih, E.; Schaffer, P.; Zheng, G.; Demirel, G.; MacCarthy, B.L. Digital supply chain surveillance using artificial intelligence: Definitions, opportunities and risks. Int. J. Prod. Res. 2024, 62, 4674–4695. [Google Scholar] [CrossRef]

- Danach, K.; El Dirani, A.; Rkein, H. Revolutionizing Supply Chain Management with AI: A Path to Efficiency and Sustainability. IEEE Access 2024, 12, 188245–188255. [Google Scholar] [CrossRef]

- Shekhar, A.; Prabhat, P.; Yandrapalli, V.; Umar, S.; Abdul, F.; Wakjira, W.D. Generative AI in Supply Chain Management. Int. J. Recent Innov. Trends Comput. Commun. 2023, 11, 4179–4185. [Google Scholar] [CrossRef]

- Kim, T.; Kim, J.; Oh, H.; Kang, J. Deep transformer based video inpainting using fast fourier tokenization. IEEE Access 2024, 12, 21723–21736. [Google Scholar] [CrossRef]

- Tay, Y.; Tran, V.Q.; Ruder, S.; Gupta, J.; Chung, H.W.; Bahri, D.; Qin, Z.; Baumgartner, S.; Yu, C.; Metzler, D. Charformer: Fast character transformers via gradient-based subword tokenization. arXiv 2021, arXiv:2106.12672. [Google Scholar]

- Stankevičius, L.; Lukoševičius, M. Extracting sentence embeddings from pretrained transformer models. Appl. Sci. 2024, 14, 8887. [Google Scholar] [CrossRef]

- Zhou, Z.; Ostrow, K.S. Transformer-based automated content-standards alignment: A pilot study. In Proceedings of the International Conference on Human-Computer Interaction, Virtual, 26 June–1 July 2022; Springer: Cham, Switzerland, 2022; pp. 525–542. [Google Scholar]

- Jayaraman, A.K.; Murugappan, A.; Trueman, T.E.; Ananthakrishnan, G.; Ghosh, A. Imbalanced aspect categorization using bidirectional encoder representation from transformers. Procedia Comput. Sci. 2023, 218, 757–765. [Google Scholar] [CrossRef]

- Zhao, T.; Faruqui, N. EconoFormer: A Novel Macroeconomic Policy Analysis and Implementation Planner using Generative Transformer Model. IEEE Access 2024, 12, 184714–184725. [Google Scholar] [CrossRef]

- Faruqui, N.; Thatoi, P.; Choudhary, R.; Roncevic, I.; Alqahtani, H.; Sarker, I.H.; Khanam, S. AI-Analyst: An AI-Assisted SDLC Analysis Framework for Business Cost Optimization. IEEE Access 2024, 12, 195188–195203. [Google Scholar] [CrossRef]

- Sathupadi, K.; Achar, S.; Bhaskaran, S.V.; Faruqui, N.; Abdullah-Al-Wadud, M.; Uddin, J. Edge-cloud synergy for AI-enhanced sensor network data: A real-time predictive maintenance framework. Sensors 2024, 24, 7918. [Google Scholar] [CrossRef]

- Shahiwala, A.F.; Qawoogha, S.S.; Faruqui, N. Designing optimum drug delivery systems using machine learning approaches: A prototype study of niosomes. AAPS PharmSciTech 2023, 24, 94. [Google Scholar] [CrossRef]

- Barron, J.T. A general and adaptive robust loss function. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Long Beach, CA, USA, 15–20 June 2019; pp. 4331–4339. [Google Scholar]

- Tay, Y.; Dehghani, M.; Rao, J.; Fedus, W.; Abnar, S.; Chung, H.W.; Narang, S.; Yogatama, D.; Vaswani, A.; Metzler, D. Scale efficiently: Insights from pre-training and fine-tuning transformers. arXiv 2021, arXiv:2109.10686. [Google Scholar]

- Chen, T.; Li, S. An Improved Adaptive Moment Estimation Algorithm for the Industrial Robot Calibration. In Proceedings of the 2024 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Kuching, Sarawak, Malaysia, 6–10 October 2024; IEEE: New York, NY, USA, 2024; pp. 1–6. [Google Scholar]

- Konar, J.; Khandelwal, P.; Tripathi, R. Comparison of various learning rate scheduling techniques on convolutional neural network. In Proceedings of the 2020 IEEE International Students’ Conference on Electrical, Electronics and Computer Science (SCEECS), Bhopal, India, 22–23 February 2020; IEEE: New York, NY, USA, 2020; pp. 1–5. [Google Scholar]

- Chen, D.Q.; Preston, D.S.; Swink, M. How the use of big data analytics affects value creation in supply chain management. J. Manag. Inf. Syst. 2015, 32, 4–39. [Google Scholar] [CrossRef]

| Research Gap | Proposed Solution |

|---|---|

| Lack of real-time adaptability in AI-driven supply chain models. | Implement an agentic AI framework capable of autonomous decision-making. |

| Isolated task automation leads to inefficiencies in sustainability. | Develop an integrated AI system that connects procurement, inventory, and logistics processes dynamically. |

| Inability to align AI-driven decision making with carbon footprint reduction strategies. | Introduce AI-driven sustainability tracking that actively adjusts supply chain operations to minimize environmental impact. |

| Category | Description | Records | Attributes |

|---|---|---|---|

| Procurement transactions | 350,000 | 12 | |

| Logistics and transportation | 1,200,000 | 15 | |

| Carbon footprint and sustainability | 900,000 | 10 | |

| Total | - | 2,450,000 | - |

| Subset | Percentage (%) | Total Records |

|---|---|---|

| Training set | 70 | 1,715,000 |

| Validation set | 15 | 367,500 |

| Testing set | 15 | 367,500 |

| Layer | Type | Heads | Dimensions | Description |

|---|---|---|---|---|

| 1 | Input Embedding | - | 60,000 | Maps tokenized supply chain data into dense vectors |

| 2 | Positional Encoding | - | Encodes word order information for sequence modeling | |

| 3–10 | Encoder Blocks | - | - | Consists of multi-head attention and feed-forward layers |

| Details of Transformer Encoder Block (3–10) | ||||

| 3a–10a | Multi-Head Attention | 12 | Computes attention across sequence positions | |

| 3b–10b | Layer Normalization | - | 512 | Stabilizes activations and accelerates convergence |

| 3c–10c | Feed-Forward Network | - | Applies non-linear transformations for feature extraction | |

| 3d–10d | Dropout | - | - | Prevents overfitting by randomly deactivating neurons |

| 11 | Output Projection | - | 60,000 | Converts encoder output to vocabulary logits |

| 12 | Softmax Layer | - | 60,000 | Outputs probability distribution over tokens |

| Hyperparameter | Optimized Value |

|---|---|

| Batch Size | 32 |

| Learning Rate (Peak) | |

| Warm-up Steps | 500 |

| Epochs | 15 |

| Weight Decay | |

| Gradient Clipping Threshold | |

| Dropout Rate | |

| Attention Heads | 8 |

| Optimizer | AdamW |

| Scheduler | Linear Warm-up with Exponential Decay |

| Component | Specification | Manufacturer | Model/Version | Location (City, Country) |

|---|---|---|---|---|

| Processor | Intel Xeon Gold 6238R (28 cores, 2.2 GHz) | Intel Corporation | Xeon Gold 6238R | Santa Clara, CA, USA |

| GPU | NVIDIA A100 Tensor Core (40 GB memory) | NVIDIA Corporation | A100 | Santa Clara, CA, USA |

| RAM | 256 GB DDR4 | Samsung Electronics | DDR4 | Suwon, South Korea |

| Storage | 2 TB NVMe SSD | Western Digital | NVMe SSD | San Jose, CA, USA |

| Operating System | Ubuntu 22.04 LTS | Canonical Ltd. | 22.04 LTS | London, UK |

| Frameworks | PyTorch 2.0, CUDA 11.7, Transformers 4.31.0 | – | – | – |

| Component | Specifications | Manufacturer | Model/Version | Location (City, Country) |

|---|---|---|---|---|

| Processor | Intel Xeon Gold 6248R (24 cores, 3.0 GHz) | Intel Corporation | Xeon Gold 6248R | Santa Clara, CA, USA |

| GPU | NVIDIA A100 Tensor Core (40 GB HBM2) | NVIDIA Corporation | A100 | Santa Clara, CA, USA |

| RAM | 512 GB DDR4 | Samsung Electronics | DDR4 | Suwon, South Korea |

| Storage | 4 TB NVMe SSD | Western Digital | NVMe SSD | San Jose, CA, USA |

| Network Interface | 10 Gbps Ethernet | Broadcom Inc. | NetXtreme 10G | San Jose, CA, USA |

| Operating System | Ubuntu 22.04 LTS | Canonical Ltd. | 22.04 LTS | London, UK |

| Component | Technology Used (Version) | Developer/Vendor | Location (City, Country) |

|---|---|---|---|

| Programming Language | Python 3.9.13 | Python Software Foundation | Wilmington, NC, USA |

| Machine Learning Framework | PyTorch 2.0.1, Transformers 4.31.0 | Meta AI, Hugging Face | Menlo Park, CA, USA; Paris, France |

| Data Processing | Pandas 1.5.3, NumPy 1.23.5, Spark 3.3.2 | NumFOCUS, Apache Foundation | Austin, TX, USA; Forest Hill, IN, USA |

| Database | PostgreSQL 15.1, MongoDB 6.0 | PostgreSQL Dev Group, MongoDB Inc. | Berkeley, CA, USA; New York, NY, USA |

| API Deployment | Flask 2.2.5, FastAPI 0.95.2 | Pallets, FastAPI Community | San Francisco, CA, USA |

| Cloud Integration | AWS Lambda, Google Cloud Functions | Amazon AWS, Google Cloud | Seattle, DC, USA; Mountain View, CA, USA |

| Containerization | Docker 24.0.2, Kubernetes 1.26.3 | Docker Inc., CNCF | Palo Alto, CA, USA; San Francisco, CA, USA |

| Monitoring | Prometheus 2.45.0, Grafana 9.5.2 | CNCF, Grafana Labs | San Francisco, CA, USA |

| Metric | Before Deployment | After Deployment | Improvement (%) |

|---|---|---|---|

| Fuel consumption (liters) | 1,200,000 | 927,600 | 22.8 |

| Supplier selection time (days) | 14.2 | 9.8 | 31.4 |

| Warehouse overstocking (tons) | 8500 | 6837 | 19.6 |

| Average delivery efficiency (%) | 72.3 | 91.9 | 27.2 |

| Events Processed | Automation Rate (%) | Error Rate (%) | CPU Utilization (%) | Processing Time (s) |

|---|---|---|---|---|

| 50,000 | 91.5 | 2.1 | 45 | 1.2 |

| 200,000 | 90.2 | 2.5 | 57 | 4.8 |

| 500,000 | 88.7 | 3.1 | 71 | 12.3 |

| 1,000,000 | 87.2 | 3.8 | 85 | 24.7 |

| 2,500,000 | 85.5 | 4.4 | 92 | 62.5 |

| Task | Single Query (ms) | 100 Simultaneous Queries (ms) |

|---|---|---|

| Supplier selection | 180 | 245 |

| Route optimization | 140 | 210 |

| Inventory prediction | 160 | 230 |

| Demand forecasting | 130 | 195 |

| Carbon emission estimation | 170 | 235 |

| Metric | Before Deployment | After Deployment | Reduction |

|---|---|---|---|

| CO2 emissions (kg/month) | 15,600 | 10,870 | 30.3% |

| Fuel consumption (liters/month) | 1,250,000 | 925,000 | 26.0% |

| Warehouse overstock (tons) | 8300 | 6490 | 21.8% |

| Transportation costs (USD) | 240,000 | 188,500 | 21.4% |

| Cost Component | Before (USD) | After (USD) | Savings (%) |

|---|---|---|---|

| Manual labor | 80,000 | 38,500 | 51.9 |

| Transportation costs | 240,000 | 188,500 | 21.4 |

| Overstocking losses | 90,000 | 68,200 | 24.2 |

| Procurement inefficiencies | 60,000 | 42,500 | 29.2 |

| Energy consumption | 35,000 | 25,600 | 26.9 |

| Inventory holding costs | 45,000 | 31,700 | 29.6 |

| Returns and refund processing | 55,000 | 38,300 | 30.3 |

| Total Cost | 605,000 | 433,300 | 28.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aylak, B.L. SustAI-SCM: Intelligent Supply Chain Process Automation with Agentic AI for Sustainability and Cost Efficiency. Sustainability 2025, 17, 2453. https://doi.org/10.3390/su17062453

Aylak BL. SustAI-SCM: Intelligent Supply Chain Process Automation with Agentic AI for Sustainability and Cost Efficiency. Sustainability. 2025; 17(6):2453. https://doi.org/10.3390/su17062453

Chicago/Turabian StyleAylak, Batin Latif. 2025. "SustAI-SCM: Intelligent Supply Chain Process Automation with Agentic AI for Sustainability and Cost Efficiency" Sustainability 17, no. 6: 2453. https://doi.org/10.3390/su17062453

APA StyleAylak, B. L. (2025). SustAI-SCM: Intelligent Supply Chain Process Automation with Agentic AI for Sustainability and Cost Efficiency. Sustainability, 17(6), 2453. https://doi.org/10.3390/su17062453