Recycled Materials in Construction: Trends, Status, and Future of Research

Abstract

1. Introduction

2. Data Sources and Methods

2.1. Data Source

2.2. Data Cleaning

- The research primarily focuses on fundamental physical and chemical engineering aspects, including microscopic molecular structures, nanoscale modifications, and crystallographic characterization. However, it lacks effective connections to architecture and environmental sciences and does not explore material applications or their potential for carbon emission reduction.

- Although both recycled materials and construction are discussed, the construction-related content is minimal and does not provide substantive conclusions on their practical applications.

2.3. Research Methods

3. Results

3.1. Spatial–Temporal Analysis

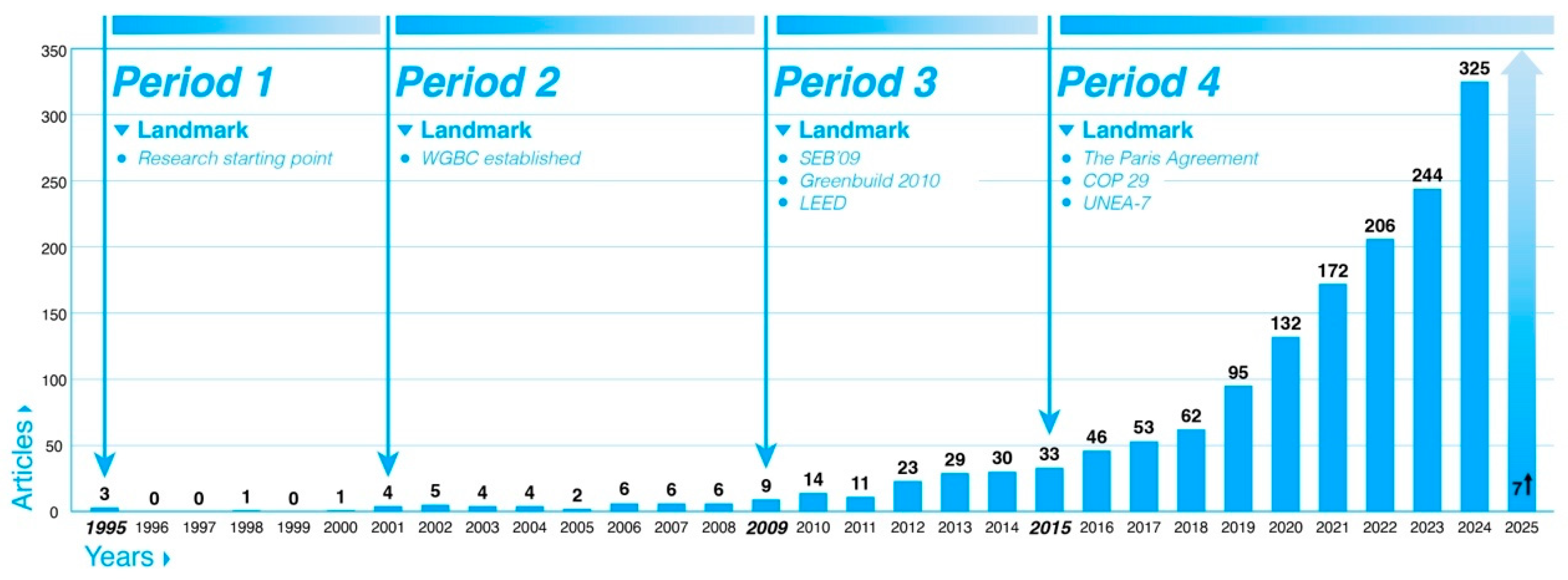

3.1.1. Spatial–Temporal Analysis of Publication Volume

3.1.2. Bibliometric Analysis of Authors

3.1.3. Bibliometric Analysis of Journals

3.1.4. Bibliometric Analysis of Countries

3.1.5. Bibliometric Analysis of Organizations

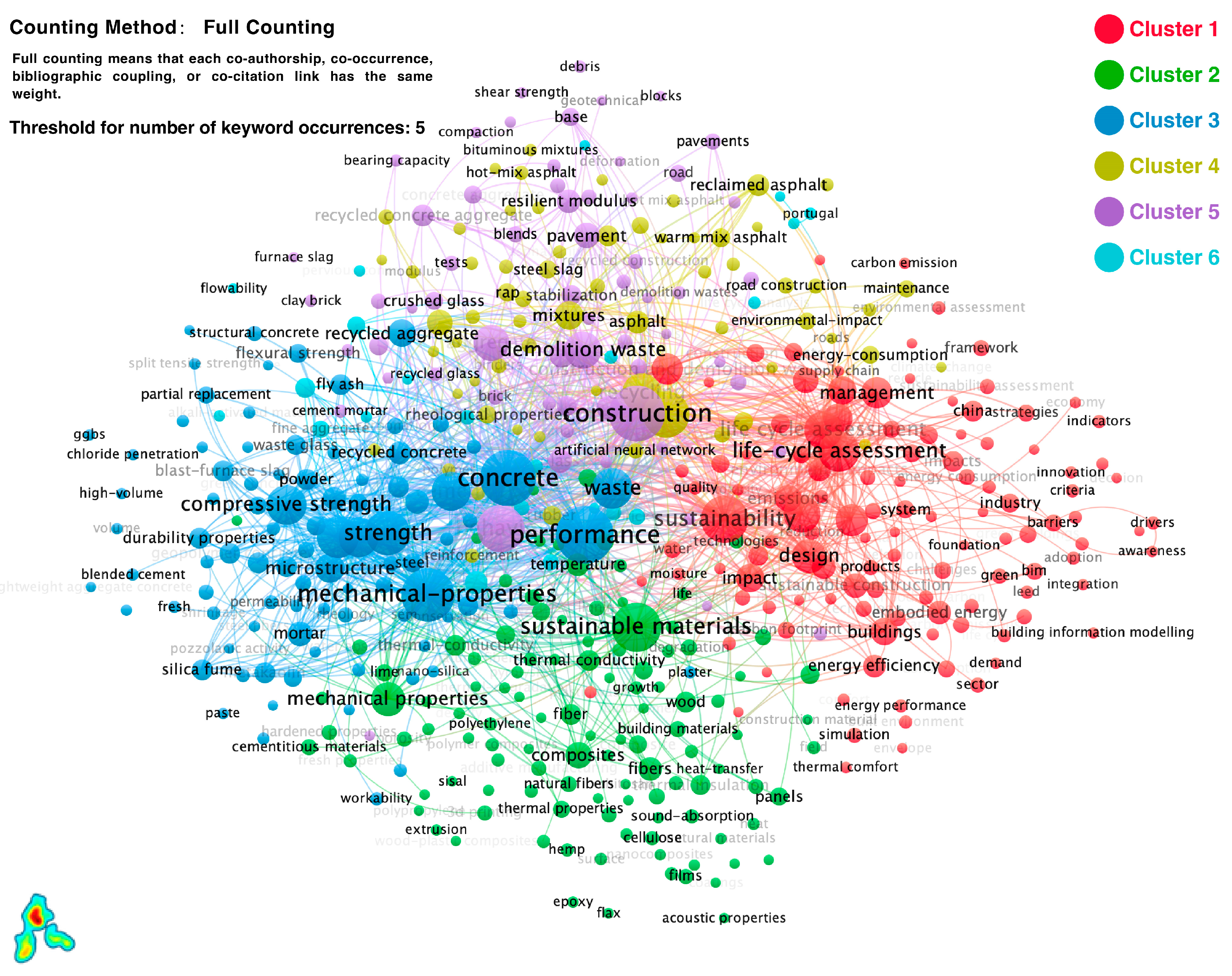

3.2. Keywords Cluster Analysis

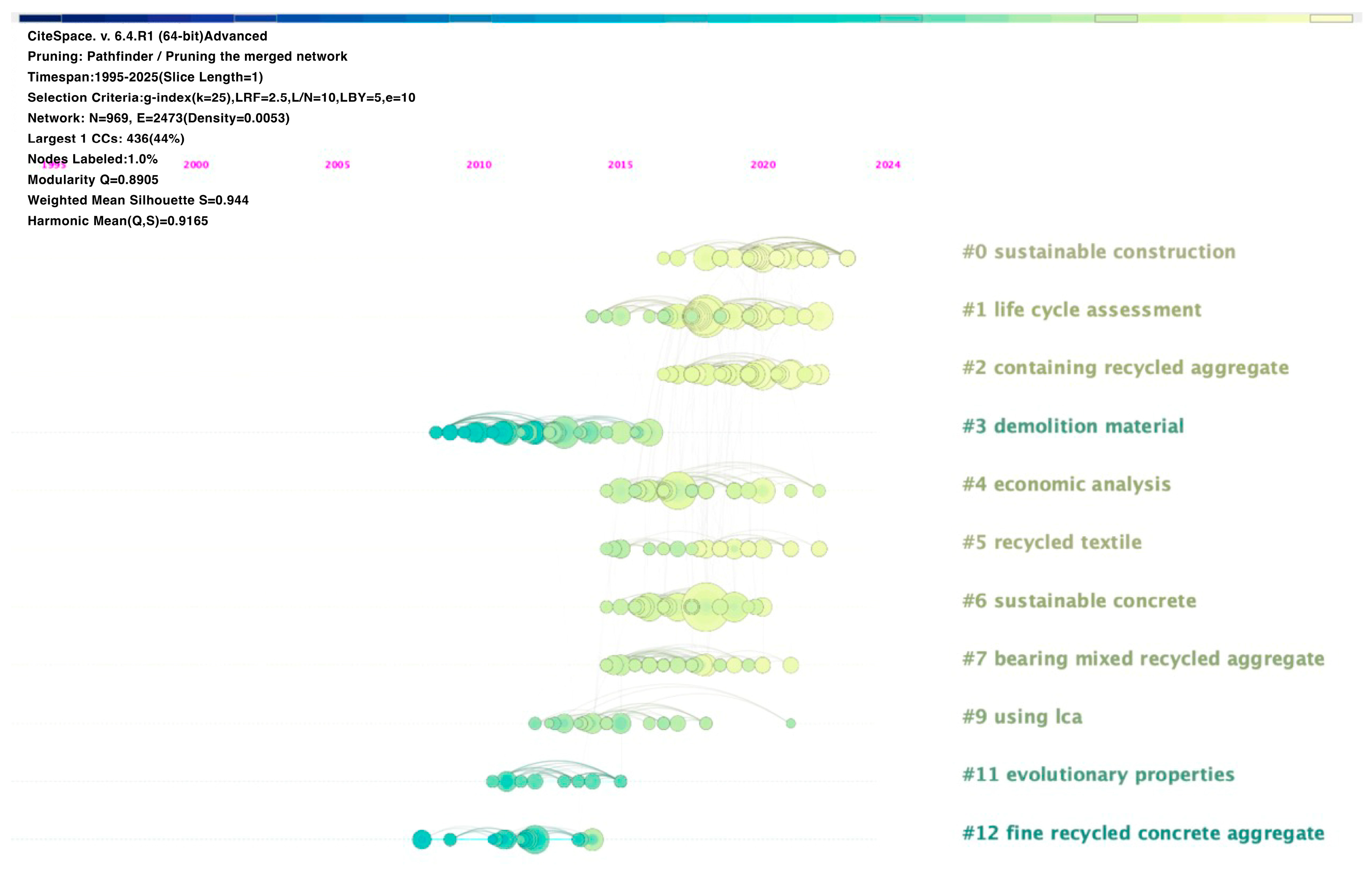

3.3. Evolution Analysis of Keywords

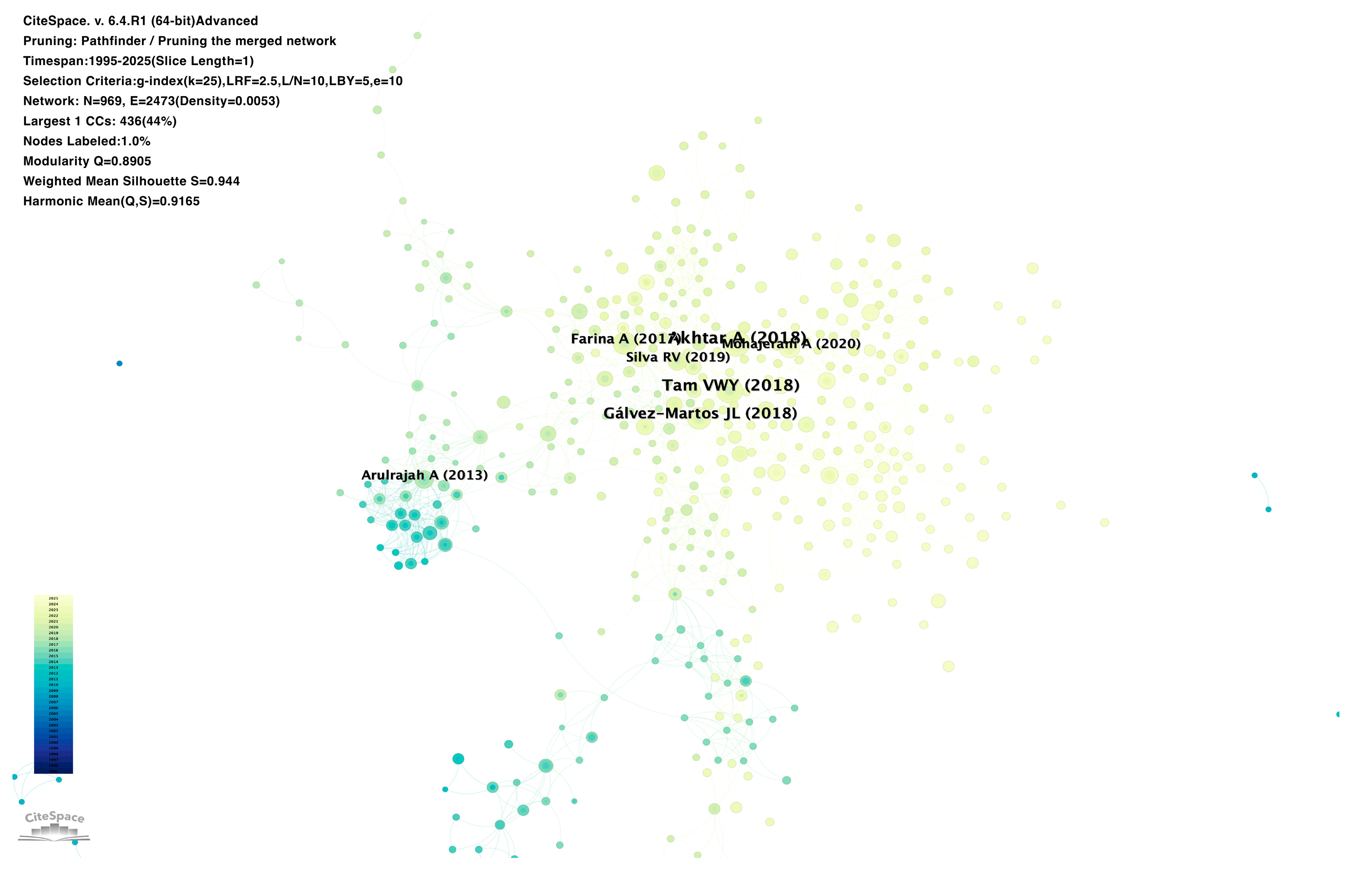

3.4. Citation Network Analysis

3.4.1. Citing Articles and Cited References

| Citing Articles in Cluster #1 | Cited References in Cluster #1 | ||

|---|---|---|---|

| Author (Year) | Coverage | Author (Year) | Freq |

| Zhang, et al. [90] (2019) | 12% | Tam, et al. [91] (2018) | 25 |

| Gherman, et al. [92] (2023) | 9% | Gálvez-Martos, Styles, Schoenberger and Zeschmar-Lahl [18] (2018) | 21 |

| Kolaventi, et al. [93] (2022) | 7% | Balaguera, et al. [94] (2018) | 11 |

| Illankoon and Vithanage [95] (2023) | 7% | Huang, et al. [96] (2018) | 11 |

| Bayram and Greiff [97] (2023) | 7% | Borghi, et al. [98] (2018) | 10 |

| Citing Articles in Cluster #2 | Cited References in Cluster #2 | ||

|---|---|---|---|

| Author (Year) | Coverage | Author (Year) | Freq |

| Mei, Xu, Ahmad, Khan, Amin, Aslam and Alaskar [3] (2022) | 8% | Mohajerani, Burnett, Smith, Markovski, Rodwell, Rahman, Kurmus, Mirzababaei, Arulrajah and Horpibulsuk [4] (2022) | 14 |

| Nalon, et al. [100] (2022) | 7% | Nedeljković, et al. [101] (2021) | 11 |

| Valente, et al. [102] (2022) | 7% | Amran, et al. [103] (2020) | 10 |

| Alhawat, et al. [104] (2022) | 6% | Wang, et al. [105] (2021) | 10 |

| Kim, et al. [106] (2022) | 6% | Liew and Akbar [107] (2020) | 7 |

3.4.2. High-Centrality Articles

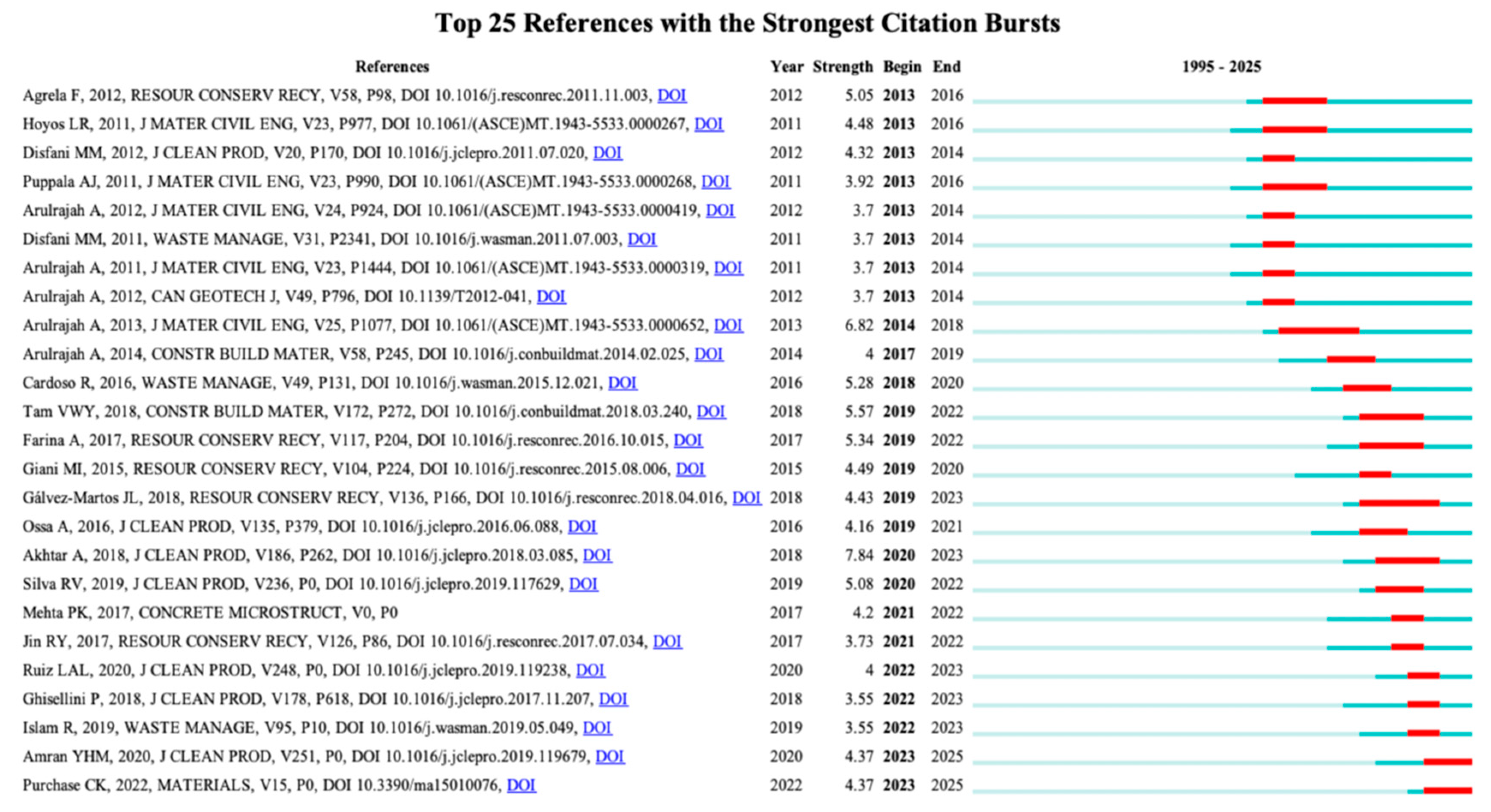

3.4.3. Strongest Citation Bursts

4. Analysis of Results

4.1. Research Developments

4.2. Co-Occurring Analysis of Keywords

4.3. Co-Citation and Cluster Analysis

4.3.1. Cluster Analysis

Value Strategies of Recycling Building Materials

- The foundation of the research

- Research response and progress

Technical Means of Recycling Building Materials

- The foundation of the research

- Research response and progress

5. Discussion

5.1. Research Patterns

5.2. Markets and Supply Chain

5.3. Future Research Trends

5.3.1. Advances and Applications of AI/ML

5.3.2. Habitat Improvement

5.3.3. Developing Countries and Poor Regions

5.3.4. Interdisciplinary Integration

5.4. Research Limitations

6. Conclusions

- The development of recycled building materials can be categorized into four distinct stages. The significant increase in publications during the last two stages indicates growing global attention to this field, the establishment of stable and representative research institutions and scholars, and a sustained high rate of literature growth in the coming years.

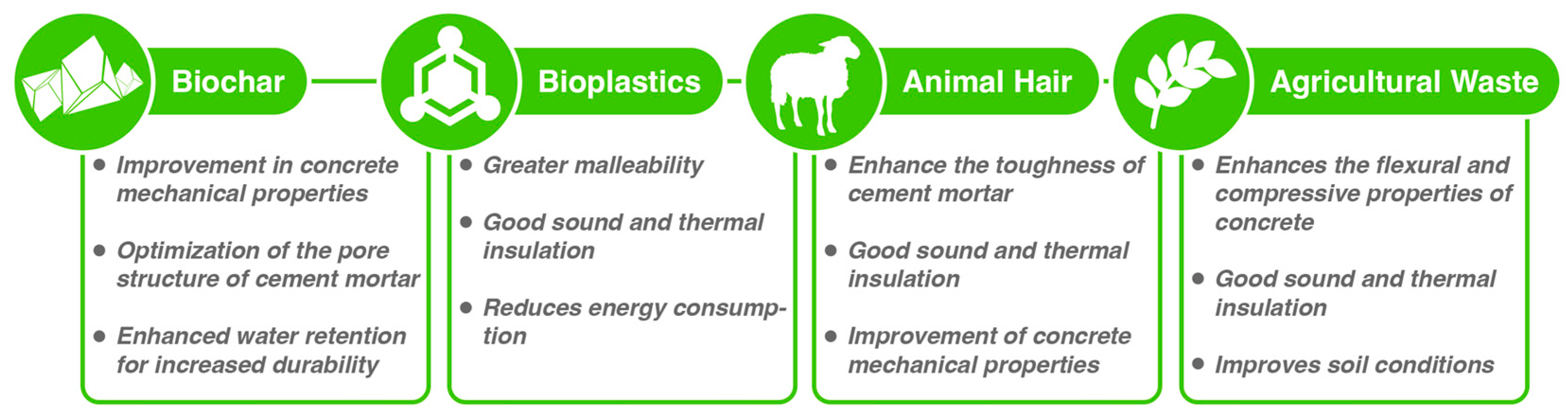

- Core research themes in recycled building materials encompass LCA and sustainability, biological and natural materials, recycled concrete, recycled asphalt and building infrastructure, C&D waste, and environmental impacts and compounding factors, with biological and natural materials emerging as the foremost area of innovation.

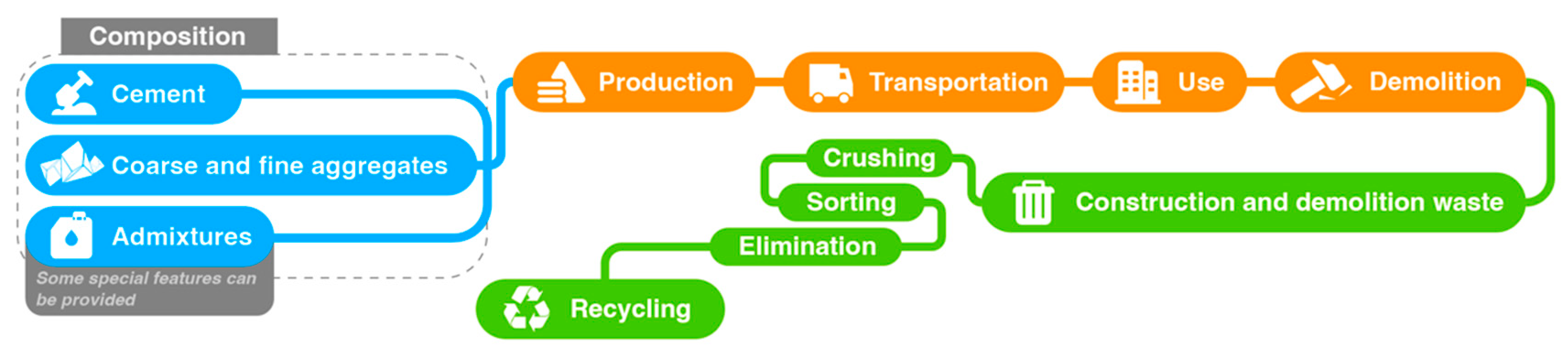

- Current research on recycled building materials is structured around two key dimensions: value strategies and technological advancements. In terms of value strategies, LCA, the CE, and C&DWM have garnered significant attention. In terms of technological advancements, recycled concrete remains the most widely utilized material, with substantial innovations focusing on optimizing the RCA production process and its integration into concrete.

- LCA and the CE have long faced challenges related to data reliability and inconsistent analytical methods, while manual analysis of material micro-images suffers from inefficiencies, high error rates, and subjectivity bias. Moving forward, the integration of AI and ML will drive transformative improvements in efficiency, analytical methods, and assessment models, positioning it as the most critical innovation direction in the field.

- The cumulative toxicity and health risks associated with traditional building materials remain a pressing concern. Beyond stricter standardization and production regulation, greater emphasis should be placed on the role of recycled materials in improving human living environments, incorporating these aspects into the core evaluation criteria for recycled building materials.

- The challenges faced by developing countries remain severe. In these regions, enhancing government efficiency and industry formalization should take precedence over complex material innovation and production processes. Additionally, interdisciplinary collaboration and knowledge sharing will be key drivers for the future development of recycled building materials.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Artificial intelligence | AI |

| Machine learning | ML |

| Construction and demolition | C&D |

| Construction and demolition management strategies | C&DWM |

| Polyethylene terephthalate | PET |

| Polyvinyl chloride | PVC |

| Fly ash | FA |

| Agricultural wastes | AWs |

| Life cycle assessment | LCA |

| Attributional LCA | ALCA |

| Consequential LCA | CLCA |

| Circular economy | CE |

| Circularity rebound | CR |

| Construction materials passport | BMP |

| Global Warming Potential | GWP |

| Recycled concrete aggregate | RCA |

| Fine recycled concrete aggregate | fRCA |

| Natural aggregate | NA |

| Hot mix asphalt | HMA |

| Rubberized asphalt | RA |

| Waste cooking oil | WCO |

| Waste engine oil | WEO |

| Geopolymer concrete | GeoPC |

| Building information modeling | BIM |

Appendix A. Other Publications in Figure 9

Appendix B. Other Publications in Figure 10

References

- Salehi, S.; Arashpour, M.; Kodikara, J.; Guppy, R. Sustainable pavement construction: A systematic literature review of environmental and economic analysis of recycled materials. J. Clean. Prod. 2021, 313, 127936. [Google Scholar] [CrossRef]

- Zhang, N.; Xi, B.; Li, J.; Liu, L.; Song, G. Utilization of CO2 into recycled construction materials: A systematic literature review. J. Mater. Cycles Waste Manag. 2022, 24, 2108–2125. [Google Scholar] [CrossRef]

- Mei, J.; Xu, G.; Ahmad, W.; Khan, K.; Amin, M.N.; Aslam, F.; Alaskar, A. Promoting sustainable materials using recycled rubber in concrete: A review. J. Clean. Prod. 2022, 373, 133927. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural waste management strategies for environmental sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef]

- Hebel, D.E.; Wisniewska, M.H.; Heisel, F. Building from Waste: Recovered Materials in Architecture and Construction; Birkhäuser: Basel, Switzerland, 2014. [Google Scholar]

- Munn, S.; Soebarto, V. The issues of using recycled materials in architecture. In Proceedings of the 38th International Conference of Architectural science Association ANZAScA “Contexts of Architecture”, Launceston, Tasmania, 10–12 November 2004. [Google Scholar]

- Vefago, L.H.M.; Avellaneda, J. Recycling concepts and the index of recyclability for building materials. Resour. Conserv. Recycl. 2013, 72, 127–135. [Google Scholar] [CrossRef]

- World Business Council for Sustainable Development. Net-Zero Buildings: Halving Construction Emissions Today; World Business Council for Sustainable Development: Geneva Switzerland, 2023. [Google Scholar]

- Pan, W.; Li, K.; Teng, Y. Rethinking system boundaries of the life cycle carbon emissions of buildings. Renew. Sustain. Energy Rev. 2018, 90, 379–390. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Global Status Report for Buildings and Construction: Beyond Foundations: Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C.; Lowrie, E.F.; Tse, P. Embodied carbon. In The Inventory of Carbon and Energy (ICE), version (2.0); BSRIA: Bracknell, UK, 2011. [Google Scholar]

- Pellegrino, C.; Faleschini, F.; Meyer, C. Recycled materials in concrete. In Developments in the Formulation and Reinforcement of Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 19–54. [Google Scholar]

- The World Green Building Council. Advancing Net Zero Status Report; The World Green Building Council: London, UK, 2022. [Google Scholar]

- Kylili, A.; Fokaides, P.A. Policy trends for the sustainability assessment of construction materials: A review. Sustain. Cities Soc. 2017, 35, 280–288. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current sustainable trends of using waste materials in concrete—A decade review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Mália, M.; De Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef]

- Wells, J.C. Science for Built Heritage; American Association for the Advancement of Science: Washington, DC, USA, 2019; Volume 364, p. 413. [Google Scholar]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Foxon, T.J. A coevolutionary framework for analysing a transition to a sustainable low carbon economy. Ecol. Econ. 2011, 70, 2258–2267. [Google Scholar] [CrossRef]

- Ahmad, N.F.A.; Ahmad, S.H.; Mokhtarruddin, M.I.E.; Sapian, S.N. The Application of Recycled Materials in Construction Building: A Brief Review. Multidiscip. Appl. Res. Innov. 2021, 2, 103–110. [Google Scholar]

- Chen, L.; Huang, L.; Hua, J.; Chen, Z.; Wei, L.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Dong, L.; Yap, P.-S. Green construction for low-carbon cities: A review. Environ. Chem. Lett. 2023, 21, 1627–1657. [Google Scholar] [CrossRef]

- Lubongo, C.; Bin Daej, M.A.; Alexandridis, P. Recent developments in technology for sorting plastic for recycling: The emergence of artificial intelligence and the rise of the robots. Recycling 2024, 9, 59. [Google Scholar] [CrossRef]

- Park, H.; Li, Z.; Walsh, A. Has generative artificial intelligence solved inverse materials design? Matter 2024, 7, 2355–2367. [Google Scholar] [CrossRef]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. American J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Chadegani, A.A.; Salehi, H.; Yunus, M.M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ebrahim, N.A. A comparison between two main academic literature collections: Web of Science and Scopus databases. arXiv 2013, arXiv:1305.0377. [Google Scholar] [CrossRef]

- Pranckutė, R. Web of Science (WoS) and Scopus: The titans of bibliographic information in today’s academic world. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, W. A tale of two databases: The use of Web of Science and Scopus in academic papers. Scientometrics 2020, 123, 321–335. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Passas, I. Bibliometric analysis: The main steps. Encyclopedia 2024, 4, 1014–1025. [Google Scholar] [CrossRef]

- Ellegaard, O.; Wallin, J.A. The bibliometric analysis of scholarly production: How great is the impact? Scientometrics 2015, 105, 1809–1831. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Salcedo, M.; Martínez, M.Á.; Moral-Munoz, J.A.; Herrera-Viedma, E.; Cobo, M.J. Some bibliometric procedures for analyzing and evaluating research fields. Appl. Intell. 2018, 48, 1275–1287. [Google Scholar] [CrossRef]

- Chapman, K.; Ellinger, A.E. An evaluation of Web of Science, Scopus and Google Scholar citations in operations management. Int. J. Logist. Manag. 2019, 30, 1039–1053. [Google Scholar] [CrossRef]

- Moral-Muñoz, J.A.; Herrera-Viedma, E.; Santisteban-Espejo, A.; Cobo, M.J. Software tools for conducting bibliometric analysis in science: An up-to-date review. Prof. De La Inf. 2020, 29. [Google Scholar] [CrossRef]

- Börner, K.; Chen, C.; Boyack, K.W. Visualizing knowledge domains. Annu. Rev. Inf. Sci. Technol. 2003, 37, 179–255. [Google Scholar] [CrossRef]

- Chen, C. Science mapping: A systematic review of the literature. J. Data Inf. Sci. 2017, 2, 1–40. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace: A Practical Guide for Mapping Scientific Literature; Nova Science Publishers: Hauppauge, NY, USA, 2016. [Google Scholar]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science mapping software tools: Review, analysis, and cooperative study among tools. J. Am. Soc. Inf. Sci. Technol. 2011, 62, 1382–1402. [Google Scholar] [CrossRef]

- Arruda, H.; Silva, E.R.; Lessa, M.; Proença, D., Jr.; Bartholo, R. VOSviewer and bibliometrix. J. Med. Libr. Assoc. JMLA 2022, 110, 392. [Google Scholar] [CrossRef]

- Schuler, A.; Adair, C. Demographics, the housing market, and demand for building materials. For. Prod. J. 2003, 53, 7. [Google Scholar]

- Bredenoord, J. Sustainable housing and building materials for low-income households. J. Archit. Eng. Technol. 2016, 5, 1–9. [Google Scholar]

- Ganesan, S. Housing and construction: Major constraints and development measures. Habitat Int. 1983, 7, 173–194. [Google Scholar] [CrossRef]

- Rai, A.; Rao, D. Utilisation potentials of industrial/mining rejects and tailings as building materials. Manag. Environ. Qual. Int. J. 2005, 16, 605–614. [Google Scholar] [CrossRef]

- Glass, J.; Dainty, A.R.; Gibb, A.G. New build: Materials, techniques, skills and innovation. Energy Policy 2008, 36, 4534–4538. [Google Scholar] [CrossRef]

- The World Green Building Council. Our Mission. Available online: https://worldgbc.org/about-us/our-mission/ (accessed on 28 December 2024).

- Zeiler, W.; van Houten, R.; Boxem, G. SMART Buildings: Intelligent Software Agents: Building Occupants Leading the Energy Systems. In Sustainability in Energy and Buildings: Proceedings of the International Conference in Sustainability in Energy and Buildings (SEB’09); Springer: Berlin/Heidelberg, Germany, 2009; pp. 9–17. [Google Scholar]

- Lawrence, M.; Heath, A.; Walker, P. Monitoring of the moisture content of straw bale walls. In Sustainability in Energy and Buildings: Proceedings of the International Conference in Sustainability in Energy and Buildings (SEB’09); Springer: Berlin/Heidelberg, Germany, 2009; pp. 155–164. [Google Scholar]

- Xiang, J.; Watson, S.; Liu, Y. Smart monitoring of wind turbines using neural networks. In Sustainability in Energy and Buildings: Proceedings of the International Conference in Sustainability in Energy and Buildings (SEB’09); Springer: Berlin/Heidelberg, Germany, 2009; pp. 1–8. [Google Scholar]

- Kang, H.J.; Park, J.-C.; Rhee, E.K. An evaluation of environmental and economic performance of sustainable building technologies for apartment houses in Korea. In Sustainability in Energy and Buildings: Proceedings of the International Conference in Sustainability in Energy and Buildings (SEB’09); Springer: Berlin/Heidelberg, Germany, 2009; pp. 165–174. [Google Scholar]

- Benedyk, J.C. Aluminum Rises High on a Green Foundation at Greenbuild. Light Met. Age 2010, 68, 8. [Google Scholar]

- Parekh, R. Comparison Analysis of Construction Costs According to LEED and non-LEED Certified Educational Buildings. 2024. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4924703 (accessed on 8 January 2025).

- Newsham, G.R.; Mancini, S.; Birt, B.J. Do LEED-certified buildings save energy? Yes, but…. Energy Build. 2009, 41, 897–905. [Google Scholar] [CrossRef]

- Fonta, P. The “Paris agreement” on climate change: An opportunity for cement sector to further reduce its CO2 emissions. In Proceedings of the 2017 IEEE-IAS/PCA Cement Industry Technical Conference, Calgary, AB, Canada, 21–25 May 2017; pp. 1–8. [Google Scholar]

- Moghaddasi, H.; Culp, C.; Vanegas, J.; Ehsani, M. Net zero energy buildings: Variations, clarifications, and requirements in response to the Paris Agreement. Energies 2021, 14, 3760. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Hu, X.; Ran, B.; Wu, T.; Zhou, X.; Xiong, Y. Physical performance, durability, and carbon emissions of recycled cement concrete and fully recycled concrete. Constr. Build. Mater. 2024, 447, 138128. [Google Scholar] [CrossRef]

- Pálenský, D.; Lupíšek, A. Carbon benchmark for Czech residential buildings based on climate goals set by the Paris Agreement for 2030. Sustainability 2019, 11, 6085. [Google Scholar] [CrossRef]

- Karana, E.; Blauwhoff, D.; Hultink, E.-J.; Camere, S. When the material grows: A case study on designing (with) mycelium-based materials. Int. J. Des. 2018, 12. Available online: https://www.ijdesign.org/index.php/IJDesign/article/view/2918 (accessed on 9 March 2025).

- Omole, F.O.; Olajiga, O.K.; Olatunde, T.M. Sustainable urban design: A review of eco-friendly building practices and community impact. Eng. Sci. Technol. J. 2024, 5, 1020–1030. [Google Scholar] [CrossRef]

- Iwuanyanwu, O.; Gil-Ozoudeh, I.; Okwandu, A.C.; Ike, C.S. Cultural and social dimensions of green architecture: Designing for sustainability and community well-being. Int. J. Appl. Res. Soc. Sci. 2024, 6, 1951–1968. [Google Scholar] [CrossRef]

- Agrela, F.; De Juan, M.S.; Ayuso, J.; Geraldes, V.L.; Jiménez, J. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- Kou, S.-c.; Poon, C.-s.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Celauro, C.; Bernardo, C.; Gabriele, B. Production of innovative, recycled and high-performance asphalt for road pavements. Resour. Conserv. Recycl. 2010, 54, 337–347. [Google Scholar] [CrossRef]

- Celauro, C.; Corriere, F.; Guerrieri, M.; Casto, B.L. Environmentally appraising different pavement and construction scenarios: A comparative analysis for a typical local road. Transp. Res. Part D Transp. Environ. 2015, 34, 41–51. [Google Scholar] [CrossRef]

- Luo, Y.; Shen, J.; Liang, H.; Sun, L.; Dong, L. Supporting building life cycle carbon monitoring, reporting and verification: A traceable and immutable blockchain-empowered information management system and application in Hong Kong. Resour. Conserv. Recycl. 2024, 208, 107736. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the circular economy to the UN sustainable development goals through sustainable construction. Resour. Conserv. Recycl. 2022, 178, 106023. [Google Scholar] [CrossRef]

- Dziedzic, R.; Pondicherry, P.; Dziedzic, M. Review of national policy instruments motivating circular construction. Resour. Conserv. Recycl. 2025, 215, 108053. [Google Scholar] [CrossRef]

- Hoy, M.; Tran, N.Q.; Suddeepong, A.; Horpibulsuk, S.; Buritatum, A.; Yaowarat, T.; Arulrajah, A. Wetting-drying durability performance of cement-stabilized recycled materials and lateritic soil using natural rubber latex. Constr. Build. Mater. 2023, 403, 133108. [Google Scholar] [CrossRef]

- Perera, S.; Arulrajah, A.; Wong, Y.C.; Horpibulsuk, S.; Maghool, F. Utilizing recycled PET blends with demolition wastes as construction materials. Constr. Build. Mater. 2019, 221, 200–209. [Google Scholar] [CrossRef]

- Senanayake, M.; Arulrajah, A.; Maghool, F.; Horpibulsuk, S. Evaluation of rutting resistance and geotechnical properties of cement stabilized recycled glass, brick and concrete triple blends. Transp. Geotech. 2022, 34, 100755. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Firoozi, A.A.; Oyejobi, D.; Avudaiappan, S.; Flores, E.S. Emerging trends in sustainable building materials: Technological innovations, enhanced performance, and future directions. Results Eng. 2024, 24, 103521. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Liu, Z.; Feng, T.; Zhu, X.; Gao, J.; Hu, K.; Guo, M.; Gu, F.; Li, F. Bird’s-eye view of recycled solid wastes in road engineering. J. Road Eng. 2024, 4, 93–150. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Martin, H.; Chebrolu, D.; Chadee, A.; Brooks, T. Too good to waste: Examining circular economy opportunities, barriers, and indicators for sustainable construction and demolition waste management. Sustain. Prod. Consum. 2024, 48, 460–480. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef] [PubMed]

- HaitherAli, H.; Anjali, G. Sustainable urban development: Evaluating the potential of mineral-based construction and demolition waste recycling in emerging economies. Sustain. Futures 2024, 7, 100179. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Alazaiza, M.Y.; Albahnasavi, A.; Eyvaz, M.; Al Maskari, T.; Amr, S.S.A.; Nassani, D.E.; Jazar, M.S.A.; Al-Abod, S.M. An overview of circular economy management approach for sustainable construction and demolish waste management. Glob. NEST J. 2024, 26, 1–12. [Google Scholar]

- Han, Y.; Yang, Z.; Ding, T.; Xiao, J. Environmental and economic assessment on 3D printed buildings with recycled concrete. J. Clean. Prod. 2021, 278, 123884. [Google Scholar] [CrossRef]

- Deetman, S.; Marinova, S.; van der Voet, E.; van Vuuren, D.P.; Edelenbosch, O.; Heijungs, R. Modelling global material stocks and flows for residential and service sector buildings towards 2050. J. Clean. Prod. 2020, 245, 118658. [Google Scholar] [CrossRef]

- Ortlepp, R.; Gruhler, K.; Schiller, G. Material stocks in Germany’s non-domestic buildings: A new quantification method. Build. Res. Inf. 2016, 44, 840–862. [Google Scholar] [CrossRef]

- Wiedenhofer, D.; Steinberger, J.K.; Eisenmenger, N.; Haas, W. Maintenance and expansion: Modeling material stocks and flows for residential buildings and transportation networks in the EU25. J. Ind. Ecol. 2015, 19, 538–551. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Aschenbrenner, P.; Ragossnig, A. Material Passports for the end-of-life stage of buildings: Challenges and potentials. J. Clean. Prod. 2021, 319, 128702. [Google Scholar] [CrossRef]

- Göswein, V.; Carvalho, S.; Cerqueira, C.; Lorena, A. Circular material passports for buildings–Providing a robust methodology for promoting circular buildings. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Online, 23–25 November 2022; p. 012049. [Google Scholar]

- Zhang, L.; Sojobi, A.; Kodur, V.; Liew, K. Effective utilization and recycling of mixed recycled aggregates for a greener environment. J. Clean. Prod. 2019, 236, 117600. [Google Scholar] [CrossRef]

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Gherman, I.-E.; Lakatos, E.-S.; Clinci, S.D.; Lungu, F.; Constandoiu, V.V.; Cioca, L.I.; Rada, E.C. Circularity Outlines in the Construction and Demolition Waste Management: A Literature Review. Recycling 2023, 8, 69. [Google Scholar] [CrossRef]

- Kolaventi, S.S.; Momand, H.; Tezeswi, T.P.; Kumar, M.S. Implementing site waste-management plans, recycling in India: Barriers, benefits, measures. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2021; pp. 30–51. [Google Scholar]

- Balaguera, A.; Carvajal, G.I.; Albertí, J.; Fullana-i-Palmer, P. Life cycle assessment of road construction alternative materials: A literature review. Resour. Conserv. Recycl. 2018, 132, 37–48. [Google Scholar] [CrossRef]

- Illankoon, C.; Vithanage, S.C. Closing the loop in the construction industry: A systematic literature review on the development of circular economy. J. Build. Eng. 2023, 76, 107362. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Bayram, B.; Greiff, K. Life cycle assessment on construction and demolition waste recycling: A systematic review analyzing three important quality aspects. Int. J. Life Cycle Assess. 2023, 28, 967–989. [Google Scholar] [CrossRef]

- Borghi, G.; Pantini, S.; Rigamonti, L. Life cycle assessment of non-hazardous Construction and Demolition Waste (CDW) management in Lombardy Region (Italy). J. Clean. Prod. 2018, 184, 815–825. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S. Environmental and economic impact assessment of construction and demolition waste disposal using system dynamics. Resour. Conserv. Recycl. 2014, 82, 41–49. [Google Scholar] [CrossRef]

- Nalon, G.H.; Santos, R.F.; de Lima, G.E.S.; Andrade, I.K.R.; Pedroti, L.G.; Ribeiro, J.C.L.; de Carvalho, J.M.F. Recycling waste materials to produce self-sensing concretes for smart and sustainable structures: A review. Constr. Build. Mater. 2022, 325, 126658. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Chougan, M.; Ghaffar, S.H. Reducing the emission of climate-altering substances in cementitious materials: A comparison between alkali-activated materials and Portland cement-based composites incorporating recycled tire rubber. J. Clean. Prod. 2022, 333, 130013. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Kim, J.; Grabiec, A.M.; Ubysz, A. An experimental study on structural concrete containing recycled aggregates and powder from construction and demolition waste. Materials 2022, 15, 2458. [Google Scholar] [CrossRef] [PubMed]

- Liew, K.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Suksiripattanapong, C.; Prongmanee, N. Physical properties and shear strength responses of recycled construction and demolition materials in unbound pavement base/subbase applications. Constr. Build. Mater. 2014, 58, 245–257. [Google Scholar] [CrossRef]

- Ruiz, L.A.L.; Ramón, X.R.; Domingo, S.G. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Purchase, C.; Al Zulayq, D.; O’brien, B.; Kowalewski, M.; Berenjian, A.; Tarighaleslami, A.; Seifan, M. Circular economy of construction and demolition waste: A literature review on lessons, challenges, and benefits. Materials 2021, 15, 76. [Google Scholar] [CrossRef] [PubMed]

- Chu, K.F. Research on Application of Green Building Technology in Green Ecological City. Fresenius Environ. Bull. 2021, 30, 3602–3611. [Google Scholar]

- Yuan, H.P.; He, L.L.; Wu, H.Y.; Zuo, J. Differentiated subsidy mechanism for promoting construction and demolition waste recycling. J. Clean. Prod. 2023, 405, 137051. [Google Scholar] [CrossRef]

- Zhu, H.; Liou, S.R.; Chen, P.C.; He, X.Y.; Sui, M.L. Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials. Sustainability 2024, 16, 1729. [Google Scholar] [CrossRef]

- Agliata, R.; Marino, A.; Mollo, L.; Pariso, P. Historic Building Energy Audit and Retrofit Simulation with Hemp-Lime Plaster—A Case Study. Sustainability 2020, 12, 4620. [Google Scholar] [CrossRef]

- Capasso, I.; D’Angelo, G.; Fumo, M.; Merino, M.D.; Caputo, D.; Liguori, B. Valorisation of Tuff and Brick Wastes by Alkali Activation for Historical Building Remediation. Materials 2023, 16, 6619. [Google Scholar] [CrossRef]

- Pantini, S.; Rigamonti, L. Is selective demolition always a sustainable choice? Waste Manag. 2020, 103, 169–176. [Google Scholar] [CrossRef]

- Borrell, J.M.G.; Sanchis, E.J.; Alcaraz, J.S.; Belda, I.M. Sustainable sound absorbers from fruit stones waste. Appl. Acoust. 2020, 161, 107174. [Google Scholar] [CrossRef]

- Revuelta-Aramburu, M.; Verdú-Vázquez, A.; Gil-López, T.; Morales-Polo, C. Environmental analysis of the use of plant fiber blocks in building construction. Sci. Total Environ. 2020, 725, 138495. [Google Scholar] [CrossRef] [PubMed]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of construction materials: Methodologies, applications and future directions for sustainable decision-making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- Bjørn, A.; Owsianiak, M.; Molin, C.; Hauschild, M.Z. LCA history. In Life Cycle Assessment: Theory and Practice; Springer: Cham, Switzerland, 2018; pp. 17–30. [Google Scholar]

- Schaubroeck, T.; Schaubroeck, S.; Heijungs, R.; Zamagni, A.; Brandão, M.; Benetto, E. Attributional & consequential life cycle assessment: Definitions, conceptual characteristics and modelling restrictions. Sustainability 2021, 13, 7386. [Google Scholar] [CrossRef]

- Weidema, B.P.; Pizzol, M.; Schmidt, J.; Thoma, G. Attributional or consequential life cycle assessment: A matter of social responsibility. J. Clean. Prod. 2018, 174, 305–314. [Google Scholar] [CrossRef]

- Trappey, A.J.; Trappey, C.V.; Liu, P.H.; Hsiao, C.-T.; Ou, J.J.; Chen, K.W. Location quotient EIO-LCA method for carbon emission analysis. In Concurrent Engineering Approaches for Sustainable Product Development in a Multi-Disciplinary Environment: Proceedings of the 19th ISPE International Conference on Concurrent Engineering; Springer: London, UK, 2013; pp. 367–377. [Google Scholar]

- Singh, S.; Bakshi, B.R. Eco-LCA: A tool for quantifying the role of ecological resources in LCA. In Proceedings of the 2009 IEEE International Symposium on Sustainable Systems and Technology, Tempe, AZ, USA, 18–20 May 2009; pp. 1–6. [Google Scholar]

- Hauschild, M.Z. Introduction to LCA methodology. In Life Cycle Assessment: Theory and Practice; Springer: Cham, Switzerland, 2018; pp. 59–66. [Google Scholar]

- Hoxha, E.; Habert, G.; Lasvaux, S.; Chevalier, J.; Le Roy, R. Influence of construction material uncertainties on residential building LCA reliability. J. Clean. Prod. 2017, 144, 33–47. [Google Scholar] [CrossRef]

- Guo, M.; Murphy, R. LCA data quality: Sensitivity and uncertainty analysis. Sci. Total Environ. 2012, 435, 230–243. [Google Scholar] [CrossRef]

- Hauschild, M. Spatial differentiation in life cycle impact assessment: A decade of method development to increase the environmental realism of LCIA. Int. J. Life Cycle Assess. 2006, 11, 11–13. [Google Scholar] [CrossRef]

- Van Zelm, R.; Preiss, P.; van Goethem, T.; Van Dingenen, R.; Huijbregts, M. Regionalized life cycle impact assessment of air pollution on the global scale: Damage to human health and vegetation. Atmos. Environ. 2016, 134, 129–137. [Google Scholar] [CrossRef]

- Mutel, C.; Liao, X.; Patouillard, L.; Bare, J.; Fantke, P.; Frischknecht, R.; Hauschild, M.; Jolliet, O.; Maia de Souza, D.; Laurent, A. Overview and recommendations for regionalized life cycle impact assessment. Int. J. Life Cycle Assess. 2019, 24, 856–865. [Google Scholar] [CrossRef]

- Legan, M.; Gotvajn, A.Ž.; Zupan, K. Potential of biochar use in building materials. J. Environ. Manag. 2022, 309, 114704. [Google Scholar] [CrossRef] [PubMed]

- Patel, R.; Babaei-Ghazvini, A.; Dunlop, M.J.; Acharya, B. Biomaterials-based concrete composites: A review on biochar, cellulose and lignin. Carbon Capture Sci. Technol. 2024, 12, 100232. [Google Scholar] [CrossRef]

- Restuccia, L.; Ferro, G.A.; Suarez-Riera, D.; Sirico, A.; Bernardi, P.; Belletti, B.; Malcevschi, A. Mechanical characterization of different biochar-based cement composites. Procedia Struct. Integr. 2020, 25, 226–233. [Google Scholar] [CrossRef]

- Cosentino, I.; Restuccia, L.; Ferro, G.A.; Tulliani, J.-M. Type of materials, pyrolysis conditions, carbon content and size dimensions: The parameters that influence the mechanical properties of biochar cement-based composites. Theor. Appl. Fract. Mech. 2019, 103, 102261. [Google Scholar] [CrossRef]

- Gan, L.; Garg, A.; Wang, H.; Mei, G.; Liu, J. Influence of biochar amendment on stormwater management in green roofs: Experiment with numerical investigation. Acta Geophys. 2021, 69, 2417–2426. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural waste: Review of the evolution, approaches and perspectives on alternative uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Lim, J.L.G.; Raman, S.N.; Lai, F.-C.; Zain, M.F.M.; Hamid, R. Synthesis of nano cementitious additives from agricultural wastes for the production of sustainable concrete. J. Clean. Prod. 2018, 171, 1150–1160. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; García-Cobos, F.J.; Sánchez-Delgado, F.J.; Mota-López, M.I.; Meneses-Rodríguez, J.M.; Romero-Casado, A.; Acedo-Fuentes, P.; López-Ramos, L. Mechanical, thermal and acoustical evaluation of biocomposites made of agricultural waste for ceiling tiles. Appl. Acoust. 2022, 191, 108689. [Google Scholar] [CrossRef]

- Taylor, P.C.; Voigt, G.F. Integrated Materials and Construction Practices for Concrete Pavement: A State-of-the-Practice Manual; United States, Federal Highway Administration, Office of Pavement Technology: Washington, DC, USA, 2007. Available online: https://rosap.ntl.bts.gov/view/dot/42865 (accessed on 9 March 2025).

- Thomas, B.S.; Gupta, R.C. Long term behaviour of cement concrete containing discarded tire rubber. J. Clean. Prod. 2015, 102, 78–87. [Google Scholar] [CrossRef]

- Gómez-Soberón, J.M. Porosity of recycled concrete with substitution of recycled concrete aggregate: An experimental study. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef]

- Neupane, R.P.; Devi, N.R.; Imjai, T.; Rajput, A.; Noguchi, T. Cutting-edge techniques and environmental insights in recycled concrete aggregate production: A comprehensive review. Resour. Conserv. Recycl. Adv. 2024, 25, 200241. [Google Scholar] [CrossRef]

- Lopatin, N.A.; Motornaja, A.I.; Neguliaeva, E.Y. The most effective crushing equipment and testing of recycled concrete aggregates. Stroit. Unikal’nyh Zdanij I Sooruz. 2015, 10, 34–45. [Google Scholar]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Influence of different treatment methods on the mechanical behavior of recycled aggregate concrete: A comparative study. Cem. Concr. Compos. 2019, 104, 103398. [Google Scholar] [CrossRef]

- Jin, D.; Boateng, K.A.; Chen, S.; Xin, K.; You, Z. Comparison of rubber asphalt with polymer asphalt under long-term aging conditions in Michigan. Sustainability 2022, 14, 10987. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hasan, M.R.M.; Lee, M.T. Comparative study on engineering properties and energy efficiency of asphalt mixes incorporating fly ash and cement. Constr. Build. Mater. 2018, 168, 295–304. [Google Scholar] [CrossRef]

- Li, H.; Zhang, M.; Temitope, A.A.; Guo, X.; Sun, J.; Yombah, M.; Zou, X. Compound reutilization of waste cooking oil and waste engine oil as asphalt rejuvenator: Performance evaluation and application. Environ. Sci. Pollut. Res. 2022, 29, 90463–90478. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Steenbakkers, P.; Verheggen, B.; Vola, M.; Vermeulen, D.J. Reaching New Heights in Timber-Hybrid Design: Designing the Netherlands’ Tallest Timber-Hybrid Residential Building. Int. J. High-Rise Build. 2024, 13, 195–204. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Yudhistira, B.; Punthi, F.; Gavahian, M.; Chang, C.-K.; Hazeena, S.H.; Hou, C.-Y.; Hsieh, C.-W. Nonthermal technologies to maintain food quality and carbon footprint minimization in food processing: A review. Trends Food Sci. Technol. 2023, 141, 104205. [Google Scholar] [CrossRef]

- Corvellec, H.; Stowell, A.F.; Johansson, N. Critiques of the circular economy. J. Ind. Ecol. 2022, 26, 421–432. [Google Scholar] [CrossRef]

- Lowe, B.H.; Bimpizas-Pinis, M.; Zerbino, P.; Genovese, A. Methods to estimate the circular economy rebound effect: A review. J. Clean. Prod. 2024, 443, 141063. [Google Scholar] [CrossRef]

- Castro, C.G.; Trevisan, A.H.; Pigosso, D.C.; Mascarenhas, J. The rebound effect of circular economy: Definitions, mechanisms and a research agenda. J. Clean. Prod. 2022, 345, 131136. [Google Scholar] [CrossRef]

- Zink, T.; Geyer, R. Circular economy rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Chen, C.-W. Clarifying rebound effects of the circular economy in the context of sustainable cities. Sustain. Cities Soc. 2021, 66, 102622. [Google Scholar] [CrossRef]

- Kennedy, M.; Dela, P.; Sibeko, Z.; Lötter, B.; Ishmael, J.; Serongoane, T. The green, the bad and the ugly: The risks of greenwashing. J. S. Afr. Inst. Min. Metall. 2022, 122, vi–vii. [Google Scholar]

- de Freitas Netto, S.V.; Sobral, M.F.F.; Ribeiro, A.R.B.; Soares, G.R.d.L. Concepts and forms of greenwashing: A systematic review. Environ. Sci. Eur. 2020, 32, 19. [Google Scholar] [CrossRef]

- Sanchez, B.; Haas, C. Capital project planning for a circular economy. Constr. Manag. Econ. 2018, 36, 303–312. [Google Scholar] [CrossRef]

- Akanbi, L.; Oyedele, L.; Davila Delgado, J.M.; Bilal, M.; Akinade, O.; Ajayi, A.; Mohammed-Yakub, N. Reusability analytics tool for end-of-life assessment of building materials in a circular economy. World J. Sci. Technol. Sustain. Dev. 2019, 16, 40–55. [Google Scholar] [CrossRef]

- Rasmussen, F.N.; Birkved, M.; Birgisdóttir, H. Upcycling and Design for Disassembly–LCA of buildings employing circular design strategies. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Brussels, Belgium, 5–7 February 2019; p. 012040. [Google Scholar]

- Hossain, M.U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar] [CrossRef]

- Abidnejad, R.; Baniasadi, H.; Fazeli, M.; Lipponen, S.; Kontturi, E.; Rojas, O.J.; Mattos, B.D. High-fiber content composites produced from mixed textile waste: Balancing cotton and polyester fibers for improved composite performance. Int. J. Biol. Macromol. 2025, 292, 139227. [Google Scholar] [CrossRef] [PubMed]

- Mashiri, M.; Vinod, J.; Sheikh, M.N.; Tsang, H.-H. Shear strength and dilatancy behaviour of sand–tyre chip mixtures. Soils Found. 2015, 55, 517–528. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. Properties of high strength concrete containing scrap tire rubber. J. Clean. Prod. 2016, 113, 86–92. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Evans, A.; Evans, R. The Composition of a Tyre: Typical Components; The Waste & Resources Action Programme: Banbury, UK, 2006; Volume 5. [Google Scholar]

- Askar, M.K.; Al-Kamaki, Y.S.; Hassan, A. Utilizing polyethylene terephthalate PET in concrete: A review. Polymers 2023, 15, 3320. [Google Scholar] [CrossRef]

- Pereira, E.L.; de Oliveira Junior, A.L.; Fineza, A.G. Optimization of mechanical properties in concrete reinforced with fibers from solid urban wastes (PET bottles) for the production of ecological concrete. Constr. Build. Mater. 2017, 149, 837–848. [Google Scholar] [CrossRef]

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Pekmezci, B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Davidovits, J. False Values on CO2 Emission for Geopolymer Cement/Concrete Published in Scientific Papers; Technical paper; Geopolymer Institute: Saint-Quentin, France, 2015; Volume 24, pp. 1–9. [Google Scholar]

- Anuradha, R.; Thirumala, R.; John, P.N. Optimization of molarity on workable self-compacting geopolymer concrete and strength study on SCGC by replacing fly ash with silica fume and GGBFS. Int. J. Adv. Struct. Geotech. Eng 2014, 3, 11–18. [Google Scholar]

- Frazao, C.; Barros, J.; Bogas, J.A.; Garcia-Cortes, V.; Valente, T. Technical and environmental potentialities of recycled steel fiber reinforced concrete for structural applications. J. Build. Eng. 2022, 45, 103579. [Google Scholar] [CrossRef]

- EPA. Resource Conservation and Recovery Act (RCRA) Laws and Regulations. Available online: https://www.epa.gov/rcra (accessed on 9 March 2025).

- Fang, D.L. System-Level Design of Low-Carbon Structures. Doctoral Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 2024. [Google Scholar]

- Anderson, A.M. Fabrication and Construction Methods for Low-Cost, Low-Carbon Structural Components for Housing in India. Doctoral Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 2019. [Google Scholar]

- Shooshtarian, S.; Maqsood, T.; Khalfan, M.; Yang, R.J.; Wong, P. Landfill levy imposition on construction and demolition waste: Australian stakeholders’ perceptions. Sustainability 2020, 12, 4496. [Google Scholar] [CrossRef]

- Domani, I. Strategia Nazionale per l’Economia Circolare. Available online: https://www.italiadomani.gov.it/it/Interventi/riforme/riforme-settoriali/strategia-nazionale-per-l-economia-circolare.html (accessed on 9 March 2025).

- MINISTERIO DE AGRICULTURA, A.Y.A. Plan Estatal Marco de Gestión de Residuos (PEMAR). Available online: https://www.miteco.gob.es/es/calidad-y-evaluacion-ambiental/planes-y-estrategias/planes-y-programas.html (accessed on 9 March 2025).

- Chen, W.; Yang, S.; Zhang, X.; Jordan, N.D.; Huang, J. Embodied energy and carbon emissions of building materials in China. Build. Environ. 2022, 207, 108434. [Google Scholar] [CrossRef]

- Ma, M.; Tam, V.W.; Le, K.N.; Li, W. Challenges in current construction and demolition waste recycling: A China study. Waste Manag. 2020, 118, 610–625. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Wang, X.; Zou, P.X. Barriers and countermeasures of construction and demolition waste recycling enterprises under circular economy. J. Clean. Prod. 2023, 420, 138235. [Google Scholar] [CrossRef]

- El-Shaboury, N.; Abdelhamid, M.; Marzouk, M. Framework for economic assessment of concrete waste management strategies. Waste Manag. Res. 2019, 37, 268–277. [Google Scholar] [CrossRef]

- Tennakoon, G.; Rameezdeen, R.; Chileshe, N. Diverting demolition waste toward secondary markets through integrated reverse logistics supply chains: A systematic literature review. Waste Manag. Res. 2022, 40, 274–293. [Google Scholar] [CrossRef]

- Liu, J.; Wu, P.; Jiang, Y.; Wang, X. Explore potential barriers of applying circular economy in construction and demolition waste recycling. J. Clean. Prod. 2021, 326, 129400. [Google Scholar] [CrossRef]

- Tan, R.; Qing, X.; Yang, J.; Zhang, J.; Li, D. Analysis on recycling channel selection of construction and demolition waste in China from the perspective of supply chain. Int. J. Environ. Res. Public Health 2022, 19, 4975. [Google Scholar] [CrossRef]

- Schenck, C.J.; Blaauw, P.F.; Swart, E.C.; Viljoen, J.M.; Mudavanhu, N. The management of South Africa’s landfills and waste pickers on them: Impacting lives and livelihoods. Dev. S. Afr. 2019, 36, 80–98. [Google Scholar] [CrossRef]

- Navarrete-Hernández, P.; Navarrete-Hernández, N. Unleashing waste-pickers’ potential: Supporting recycling cooperatives in Santiago de Chile. World Dev. 2018, 101, 293–310. [Google Scholar] [CrossRef]

- Cano, N.S.d.S.L.; Iacovidou, E.; Rutkowski, E.W. Typology of municipal solid waste recycling value chains: A global perspective. J. Clean. Prod. 2022, 336, 130386. [Google Scholar] [CrossRef]

- Prado, V.; Seager, T.P.; Guglielmi, G. Challenges and risks when communicating comparative LCA results to management. Int. J. Life Cycle Assess. 2022, 27, 1164–1169. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Li, W.; Field, K.G.; Morgan, D. Automated defect analysis in electron microscopic images. npj Comput. Mater. 2018, 4, 36. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, L.; Zhou, X.; Huang, L.; Sandanayake, M.; Yap, P.-S. Recent technological advancements in BIM and LCA integration for sustainable construction: A review. Sustainability 2024, 16, 1340. [Google Scholar] [CrossRef]

- Hollberg, A.; Genova, G.; Habert, G. Evaluation of BIM-based LCA results for building design. Autom. Constr. 2020, 109, 102972. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Integrating BIM and AI for smart construction management: Current status and future directions. Arch. Comput. Methods Eng. 2023, 30, 1081–1110. [Google Scholar] [CrossRef]

- Gachkar, D.; Gachkar, S.; García Martínez, A.; Angulo, C.; Aghlmand, S.; Ahmadi, J. Artificial intelligence in building life cycle assessment. Archit. Sci. Rev. 2024, 67, 484–502. [Google Scholar] [CrossRef]

- Al-Shargabi, A.A.; Almhafdy, A.; Ibrahim, D.M.; Alghieth, M.; Chiclana, F. Buildings’ energy consumption prediction models based on buildings’ characteristics: Research trends, taxonomy, and performance measures. J. Build. Eng. 2022, 54, 104577. [Google Scholar] [CrossRef]

- Algren, M.; Fisher, W.; Landis, A.E. Machine learning in life cycle assessment. In Data Science Applied to Sustainability Analysis; Elsevier: Amsterdam, The Netherlands, 2021; pp. 167–190. [Google Scholar]

- Faisal, H.M.; Javaid, N.; Sarfraz, B.; Baqi, A.; Bilal, M.; Haider, I.; Shuja, S.M. Prediction of building energy consumption using enhance convolutional neural network. In Web, Artificial Intelligence and Network Applications: Proceedings of the Workshops of the 33rd International Conference on Advanced Information Networking and Applications (WAINA-2019) 33, Matsue, Japan, 27–29 March 2019; Springer: Cham, Switzerland, 2019; pp. 1157–1168. [Google Scholar]

- Płoszaj-Mazurek, M.; Ryńska, E. Artificial intelligence and digital tools for assisting low-carbon architectural design: Merging the use of machine learning, large language models, and building information modeling for life cycle assessment tool development. Energies 2024, 17, 2997. [Google Scholar] [CrossRef]

- Statsenko, L.; Samaraweera, A.; Bakhshi, J.; Chileshe, N. Construction 4.0 technologies and applications: A systematic literature review of trends and potential areas for development. Constr. Innov. 2023, 23, 961–993. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- de Jesus, J.O.; Oliveira-Esquerre, K.; Medeiros, D.L. Integration of artificial intelligence and life cycle assessment methods. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Dublin, Ireland, 19–23 July 2021; p. 012028. [Google Scholar]

- Golafshani, E.M.; Kim, T.; Behnood, A.; Ngo, T.; Kashani, A. Sustainable mix design of recycled aggregate concrete using artificial intelligence. J. Clean. Prod. 2024, 442, 140994. [Google Scholar] [CrossRef]

- Pan, X.; Xiao, Y.; Suhail, S.A.; Ahmad, W.; Murali, G.; Salmi, A.; Mohamed, A. Use of artificial intelligence methods for predicting the strength of recycled aggregate concrete and the influence of raw ingredients. Materials 2022, 15, 4194. [Google Scholar] [CrossRef]

- Nguyen, T.-D.; Cherif, R.; Mahieux, P.-Y.; Lux, J.; Aït-Mokhtar, A.; Bastidas-Arteaga, E. Artificial intelligence algorithms for prediction and sensitivity analysis of mechanical properties of recycled aggregate concrete: A review. J. Build. Eng. 2023, 66, 105929. [Google Scholar] [CrossRef]

- Pande, P.B.; Dhengare, S.W.; Raut, J.M.; Bhagat, R.M.; Bahoria, B.V.; Shelke, N.; Upadhye, S.D.; Vairagade, V.S. Optimizing sustainability and resilience of composite construction materials using life cycle assessment and advanced artificial intelligence techniques. Asian J. Civ. Eng. 2024, 26, 471–489. [Google Scholar] [CrossRef]

- Luu, R.K.; Arevalo, S.; Lu, W.; Ni, B.; Yang, Z.; Shen, S.C.; Berkovich, J.; Hsu, Y.-C.; Zan, S.; Buehler, M.J. Learning from Nature to Achieve Material Sustainability: Generative AI for Rigorous Bio-inspired Materials Design. MIT Explor. Gener. AI 2024. [Google Scholar] [CrossRef]

- Badini, S.; Regondi, S.; Pugliese, R. Enhancing mechanical and bioinspired materials through generative AI approaches. Next Mater. 2025, 6, 100275. [Google Scholar] [CrossRef]

- Fu, N.; Wei, L.; Song, Y.; Li, Q.; Xin, R.; Omee, S.S.; Dong, R.; Siriwardane, E.M.D.; Hu, J. Material transformers: Deep learning language models for generative materials design. Mach. Learn. Sci. Technol. 2023, 4, 015001. [Google Scholar] [CrossRef]

- Hsu, Y.-C.; Yang, Z.; Buehler, M.J. Generative design, manufacturing, and molecular modeling of 3D architected materials based on natural language input. APL Mater. 2022, 10, 041107. [Google Scholar] [CrossRef]

- Reza, M. AI-Driven solutions for enhanced waste management and recycling in urban areas. Int. J. Sustain. Infrastruct. Cities Soc. 2023, 8, 1–13. [Google Scholar]

- Pacheco-Torgal, F.; Jalali, S. Toxicity of building materials: A key issue in sustainable construction. Int. J. Sustain. Eng. 2011, 4, 281–287. [Google Scholar] [CrossRef]

- Wagoner, J.K. Toxicity of vinyl chloride and poly (vinyl chloride): A critical review. Environ. Health Perspect. 1983, 52, 61–66. [Google Scholar] [CrossRef]

- Lahtela, V.; Hämäläinen, K.; Kärki, T. The effects of preservatives on the properties of wood after modification. Balt. For. 2013, 20, 189–203. [Google Scholar]

- Järvinen, J.; Ilgın, H.E.; Karjalainen, M. Wood preservation practices and future outlook: Perspectives of experts from Finland. Forests 2022, 13, 1044. [Google Scholar] [CrossRef]

- Gualtieri, A.F.; Lassinantti Gualtieri, M.; Scognamiglio, V.; Di Giuseppe, D. Human health hazards associated with asbestos in building materials. In Ecological and Health Effects of Building Materials; Springer: Cham, Switzerland, 2022; pp. 297–325. [Google Scholar]

- Alsulaili, A.D.; Al-Matrouk, M.F.; Al-Baghli, R.A.; Al-Enezi, A.F. Environmental and economic benefits of applying green building concepts in Kuwait. Environ. Dev. Sustain. 2020, 22, 3371–3387. [Google Scholar] [CrossRef]

- Sheth, K. Sustainable building materials used in green buildings. In Proceedings of the 9th International Conference on Engineering and Business Education (ICEBE) & 6th International Conference on Innovation and Entrepreneurship (ICIE), Gujarat, India, 24–26 February 2016; pp. 23–26. [Google Scholar]

- Majumder, A.; Canale, L.; Mastino, C.C.; Pacitto, A.; Frattolillo, A.; Dell’Isola, M. Thermal characterization of recycled materials for building insulation. Energies 2021, 14, 3564. [Google Scholar] [CrossRef]

- Buluklu, H.M.; Kocyigit, F.B.; Kose, E. Organic Waste as a Soundproofing Material: An Experimental Study. J. Vib. Eng. Technol. 2024, 12, 8043–8065. [Google Scholar] [CrossRef]

- Bianchini, F.; Hewage, K. How “green” are the green roofs? Lifecycle analysis of green roof materials. Build. Environ. 2012, 48, 57–65. [Google Scholar] [CrossRef]

- Tams, L.; Nehls, T.; Calheiros, C.S.C. Rethinking green roofs-natural and recycled materials improve their carbon footprint. Build. Environ. 2022, 219, 109122. [Google Scholar] [CrossRef]

- Mickovski, S.B.; Buss, K.; McKenzie, B.M.; Sökmener, B. Laboratory study on the potential use of recycled inert construction waste material in the substrate mix for extensive green roofs. Ecol. Eng. 2013, 61, 706–714. [Google Scholar] [CrossRef]

- Liebenberg, C. Waste recycling in developing countries in Africa: Barriers to improving reclamation rates. In Proceedings of the Eleventh International Waste Management and Landfill Symposium, Cagliari, Italy, 1–5 October 2007; pp. 1–5. [Google Scholar]

- Van Wyk, L.V. Towards Net-Zero Construction and Demolition Waste. Alive2green: 2014. Available online: https://researchspace.csir.co.za/server/api/core/bitstreams/437be571-6ff5-40ca-9b40-06aed60f8cbc/content (accessed on 9 March 2025).

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Srour, I.M.; Chehab, G.R.; Gharib, N. Recycling construction materials in a developing country: Four case studies. Int. J. Eng. Manag. Econ. 2012, 3, 135–151. [Google Scholar] [CrossRef]

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. Waste Manag. 2013, 33, 220–232. [Google Scholar] [CrossRef]

- Gunarathne, A.; Tennakoon, T.; Weragoda, J. Challenges and opportunities for the recycling industry in developing countries: The case of Sri Lanka. J. Mater. Cycles Waste Manag. 2019, 21, 181–190. [Google Scholar] [CrossRef]

- Duan, H.; Zhao, Q.; Song, J.; Duan, Z. Identifying opportunities for initiating waste recycling: Experiences of typical developed countries. J. Clean. Prod. 2021, 324, 129190. [Google Scholar] [CrossRef]

- Graham, P. Building Ecology: First Principles for a Sustainable Built Environment; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Kibert, C.J. Sustainable Construction: Green Building Design and Delivery; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Schaefer, C.E.; Kupwade-Patil, K.; Ortega, M.; Soriano, C.; Büyüköztürk, O.; White, A.E.; Short, M.P. Irradiated recycled plastic as a concrete additive for improved chemo-mechanical properties and lower carbon footprint. Waste Manag. 2018, 71, 426–439. [Google Scholar] [CrossRef] [PubMed]

- Herrmann, A.; Nickel, J.; Riedel, U. Construction materials based upon biologically renewable resources—From components to finished parts. Polym. Degrad. Stab. 1998, 59, 251–261. [Google Scholar] [CrossRef]

- Ivanov, V.; Stabnikov, V. Construction Biotechnology: Biogeochemistry, Microbiology and Biotechnology of Construction Materials and Processes; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Buswell, R.A.; Soar, R.C.; Gibb, A.G.; Thorpe, A. Freeform construction: Mega-scale rapid manufacturing for construction. Autom. Constr. 2007, 16, 224–231. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Corker, J.; Fan, M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom. Constr. 2018, 93, 1–11. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Farina, A.; Zanetti, M.C.; Santagata, E.; Blengini, G.A. Life cycle assessment applied to bituminous mixtures containing recycled materials: Crumb rubber and reclaimed asphalt pavement. Resour. Conserv. Recycl. 2017, 117, 204–212. [Google Scholar] [CrossRef]

- Silva, R.; De Brito, J.; Dhir, R. Use of recycled aggregates arising from construction and demolition waste in new construction applications. J. Clean. Prod. 2019, 236, 117629. [Google Scholar] [CrossRef]

- Hoyos, L.R.; Puppala, A.J.; Ordonez, C.A. Characterization of cement-fiber-treated reclaimed asphalt pavement aggregates: Preliminary investigation. J. Mater. Civ. Eng. 2011, 23, 977–989. [Google Scholar] [CrossRef]

- Disfani, M.; Arulrajah, A.; Bo, M.; Sivakugan, N. Environmental risks of using recycled crushed glass in road applications. J. Clean. Prod. 2012, 20, 170–179. [Google Scholar] [CrossRef]

- Puppala, A.J.; Hoyos, L.R.; Potturi, A.K. Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J. Mater. Civ. Eng. 2011, 23, 990–998. [Google Scholar] [CrossRef]

- Arulrajah, A.; Ali, M.; Piratheepan, J.; Bo, M. Geotechnical properties of waste excavation rock in pavement subbase applications. J. Mater. Civ. Eng. 2012, 24, 924–932. [Google Scholar] [CrossRef]

- Disfani, M.; Arulrajah, A.; Bo, M.; Hankour, R. Recycled crushed glass in road work applications. Waste Manag. 2011, 31, 2341–2351. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Aatheesan, T.; Bo, M. Geotechnical properties of recycled crushed brick in pavement applications. J. Mater. Civ. Eng. 2011, 23, 1444–1452. [Google Scholar] [CrossRef]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef]

- Giani, M.I.; Dotelli, G.; Brandini, N.; Zampori, L. Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour. Conserv. Recycl. 2015, 104, 224–238. [Google Scholar] [CrossRef]

- Ossa, A.; García, J.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An empirical study of perceptions towards construction and demolition waste recycling and reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

| Category | Specific Standard Requirements |

|---|---|

| Research database | Web of Science Core Collection |

| Citation indexes | All |

| Language | English |

| Query preview | (((TS = (“recycled materials” OR “sustainable materials”) And TS = (“construction” OR “architecture” OR “building”) And LA = (“English”))) AND DT = (“Article” OR “Review”)) |

| Document types | Article, Review Article |

| Data extraction | Full Record and Cited References |

| Sample size | 1791 |

| Category | Data |

|---|---|

| Total | 1533 |

| Article | 1326 |

| Review Article | 207 |

| Journals | 439 |

| Authors | 5601 |

| Organizations | 1850 |

| Countries/Regions | 104 |

| References | 76,772 |

| Cited Journal | 25,541 |

| Rank | Author | Documents | Citations | Average Citation/Publication |

|---|---|---|---|---|

| 1 | José Ramón Jiménez | 7 | 360 | 51.43 |

| 2 | Jesus Ayuso | 9 | 438 | 48.67 |

| 3 | Francisco Agrela | 16 | 609 | 38.06 |

| 4 | Clara Celauro | 7 | 239 | 34.14 |

| 5 | Cesare Sangiorgi | 7 | 225 | 32.14 |

| 6 | Suksun Horpibulsuk | 20 | 515 | 25.75 |

| 7 | Arul Arulrajah | 25 | 624 | 24.96 |

| Rank | Source | Publications | Citations | Average Citation/Publication |

|---|---|---|---|---|

| 1 | Construction and Building Materials | 144 | 5133 | 35.65 |

| 2 | Sustainability | 127 | 1379 | 10.86 |

| 3 | Journal of Cleaner Production | 75 | 3598 | 47.97 |

| 4 | Materials | 72 | 1077 | 14.96 |

| 5 | Journal of Building Engineering | 53 | 1368 | 25.81 |

| 6 | Transportation Research Record | 36 | 523 | 14.53 |

| 7 | Buildings | 34 | 253 | 7.44 |

| 8 | Resources Conservation and Recycling | 26 | 2373 | 91.27 |

| 9 | Journal of Materials in Civil Engineering | 26 | 1333 | 51.27 |

| 10 | Case Studies in Construction Materials | 26 | 355 | 13.65 |

| Rank | Source | Documents | Citations | Average Citation/Publication |

|---|---|---|---|---|

| 1 | USA | 216 | 8364 | 38.72 |

| 2 | China | 176 | 4711 | 26.77 |

| 3 | Italy | 158 | 4251 | 26.90 |

| 4 | Spain | 134 | 2711 | 20.23 |

| 5 | Australia | 121 | 3901 | 32.24 |

| Rank | Organization | Documents | Citations | Average Citation/Publication |

|---|---|---|---|---|

| 1 | Swinburne University of Technology | 33 | 1354 | 41.03 |

| 2 | Royal Melbourne Institute of Technology University | 24 | 1109 | 46.20 |

| 3 | University of Córdoba | 22 | 777 | 35.32 |

| 4 | Suranaree University of Technology | 21 | 562 | 26.76 |

| 5 | University of Lisbon | 17 | 538 | 31.65 |

| Cluster ID | Size | Silhouette | Mean (Year) | Label |

|---|---|---|---|---|

| 0 | 74 | 0.97 | 2020 | Sustainable construction |

| 1 | 60 | 0.841 | 2018 | Life cycle assessment |

| 2 | 53 | 0.933 | 2019 | Containing recycled aggregate |

| 3 | 45 | 0.998 | 2012 | Demolition material |

| 4 | 37 | 0.925 | 2017 | Economic analysis |

| 5 | 34 | 0.959 | 2018 | Recycled textile |

| 6 | 33 | 0.929 | 2017 | Sustainable concrete |

| 7 | 29 | 0.961 | 2017 | Bearing mixed recycled aggregate |

| 9 | 27 | 0.997 | 2015 | Using lca |

| 11 | 22 | 0.994 | 2011 | Evolutionary properties |

| 12 | 22 | 0.946 | 2013 | Fine recycled concrete |

| Citing Articles in Cluster #0 | Cited References in Cluster #0 | ||

|---|---|---|---|

| Author (Year) | Coverage | Author (Year) | Freq |

| Firoozi, et al. [74] (2024) | 22% | Benachio, et al. [75] (2020) | 9 |

| Liu, et al. [76] (2024) | 8% | Ghisellini, et al. [77] (2018) | 8 |

| Martin, et al. [78] (2024) | 8% | Aslam, et al. [79] (2020) | 7 |

| HaitherAli and Anjali [80] (2024) | 7% | Kabirifar, et al. [81] (2020) | 6 |

| Alazaiza, et al. [82] (2024) | 7% | Han, et al. [83] (2021) | 6 |

| Year | Centrality | Articles | Contributions |

|---|---|---|---|

| 2020 | 0.07 | Benachio, Freitas and Tavares [75] |

|

| 2015 | 0.07 | Bravo, et al. [108] |

|

| 2014 | 0.05 | Arulrajah, et al. [109] |

|

| 2018 | 0.05 | Balaguera, Carvajal, Albertí and Fullana-i-Palmer [94] |

|

| 2018 | 0.05 | Huang, Wang, Kua, Geng, Bleischwitz and Ren [96] |

|

| Begin | End | Articles | Contributions |

|---|---|---|---|

| 2022 | 2023 | Ruiz, et al. [110] |

|

| 2022 | 2023 | Ghisellini, Ripa and Ulgiati [77] |

|

| 2022 | 2023 | Islam, et al. [111] |

|

| 2023 | 2025 | Amran, Alyousef, Alabduljabbar and El-Zeadani [103] |

|

| 2023 | 2025 | Purchase, et al. [112] |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Ye, X.; Cui, H. Recycled Materials in Construction: Trends, Status, and Future of Research. Sustainability 2025, 17, 2636. https://doi.org/10.3390/su17062636

Wu J, Ye X, Cui H. Recycled Materials in Construction: Trends, Status, and Future of Research. Sustainability. 2025; 17(6):2636. https://doi.org/10.3390/su17062636

Chicago/Turabian StyleWu, Jiawei, Xunrong Ye, and Huachun Cui. 2025. "Recycled Materials in Construction: Trends, Status, and Future of Research" Sustainability 17, no. 6: 2636. https://doi.org/10.3390/su17062636

APA StyleWu, J., Ye, X., & Cui, H. (2025). Recycled Materials in Construction: Trends, Status, and Future of Research. Sustainability, 17(6), 2636. https://doi.org/10.3390/su17062636