Research on the Fissure Development and Seepage Evolution Patterns of Overburden Rock in Weakly Cemented Strata Under Repeated Mining

Abstract

:1. Introduction

2. Strength Degradation Patterns of Weakly Cemented Mudstone

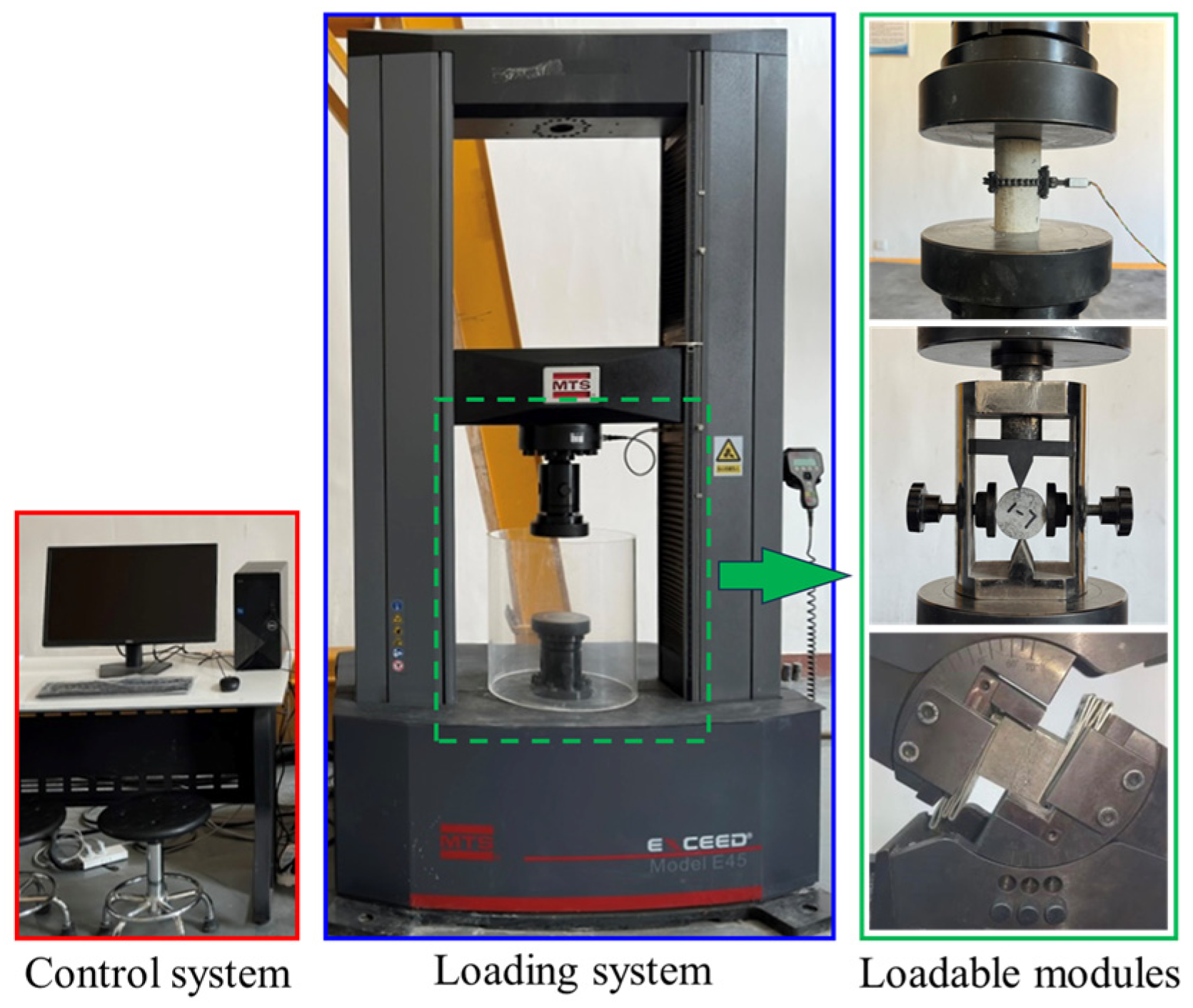

2.1. Experimental Preparation

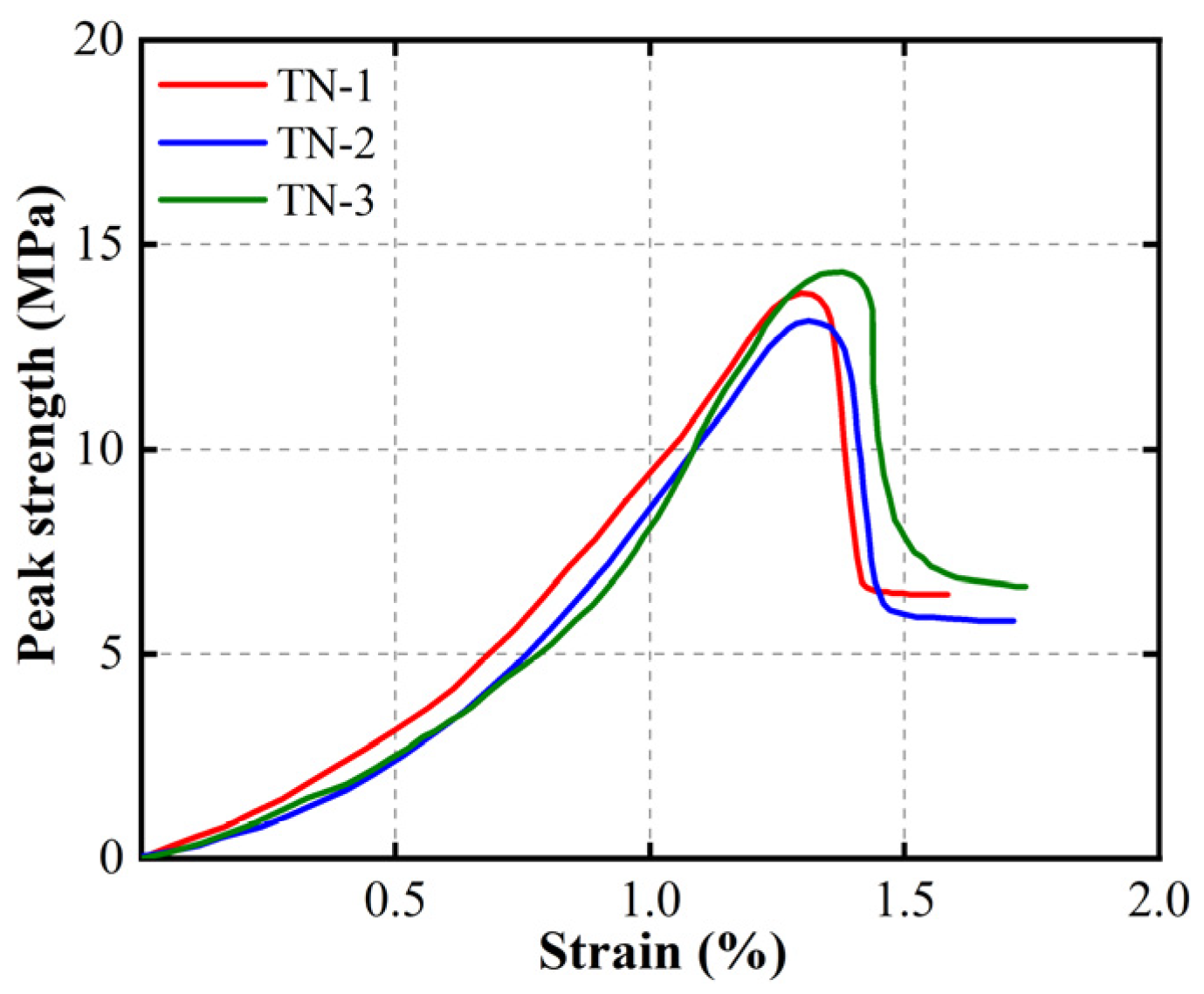

2.2. Experimental Results Analysis

2.3. Water-Induced Strength Degradation Patterns

3. Microscopic Damage Characteristics of Weakly Cemented Mudstone

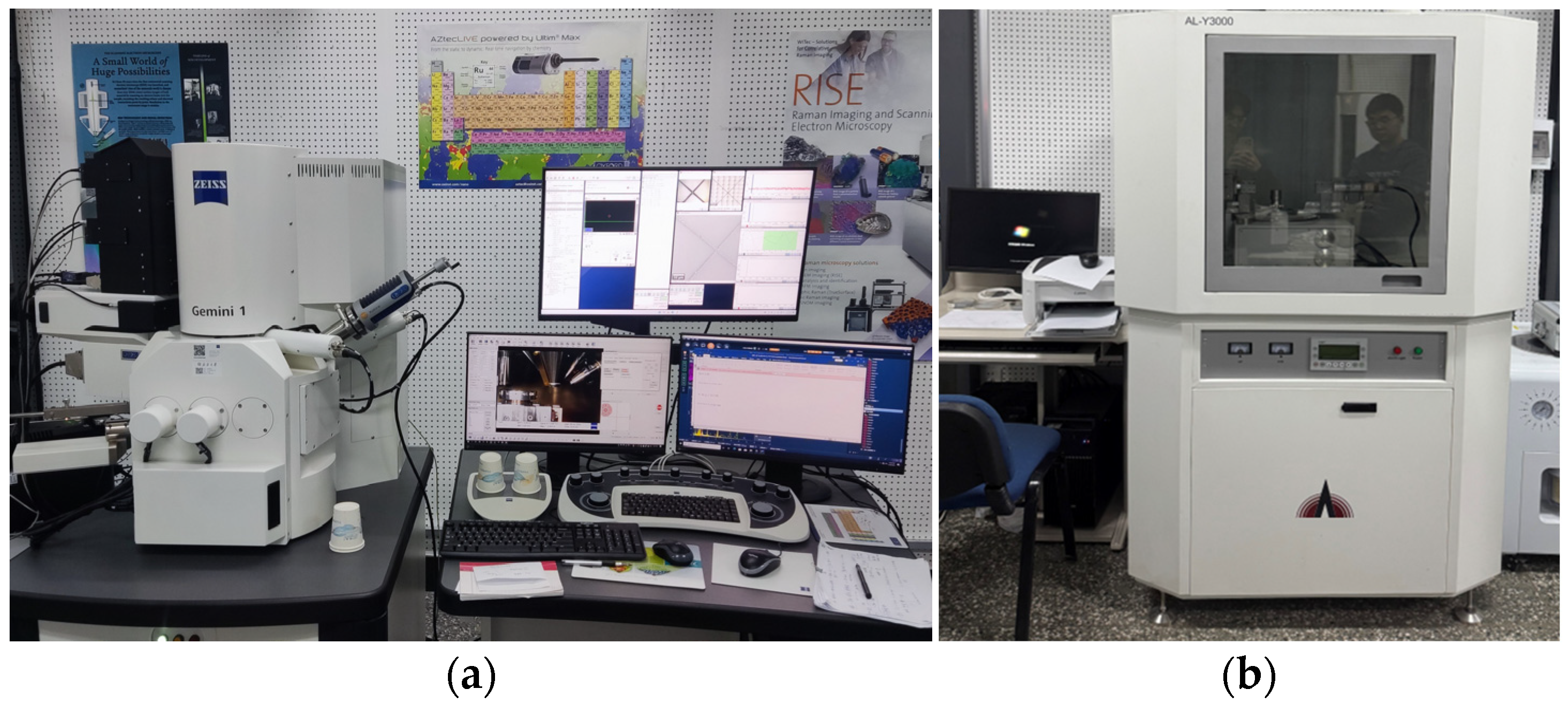

3.1. Experimental Preparation

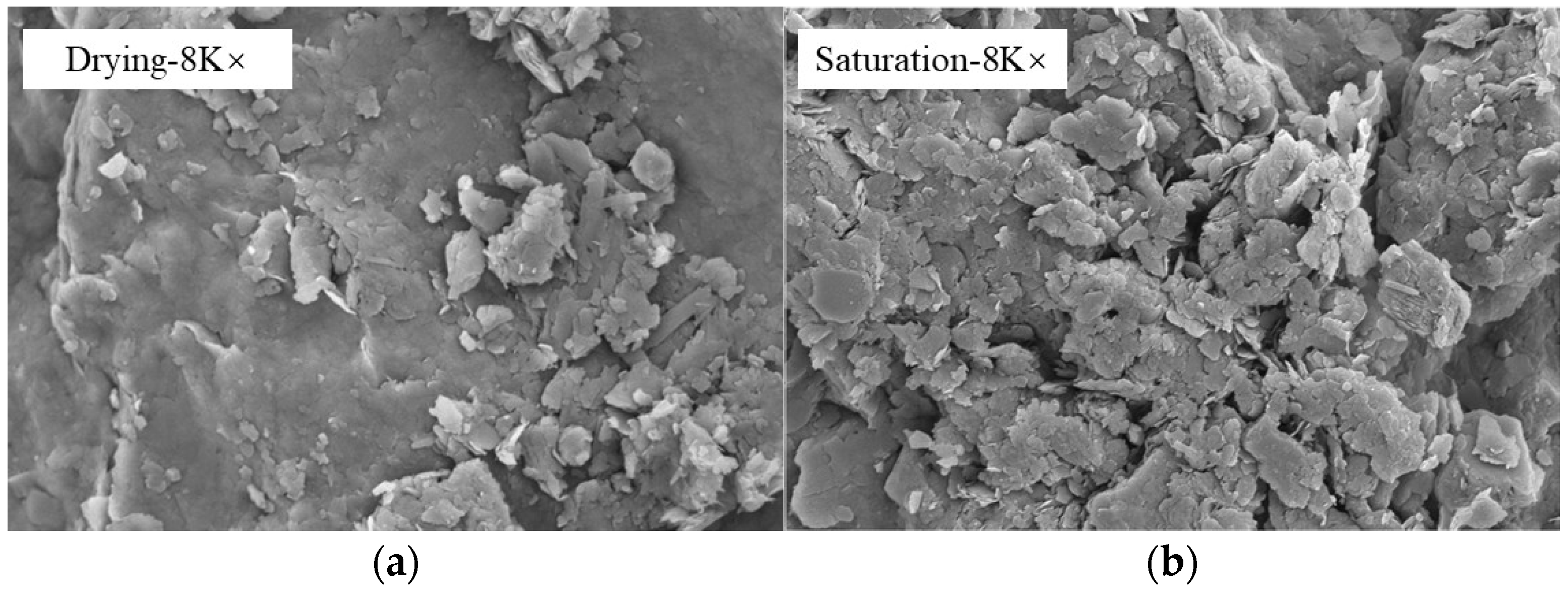

3.2. Microscopic Structural Test Results

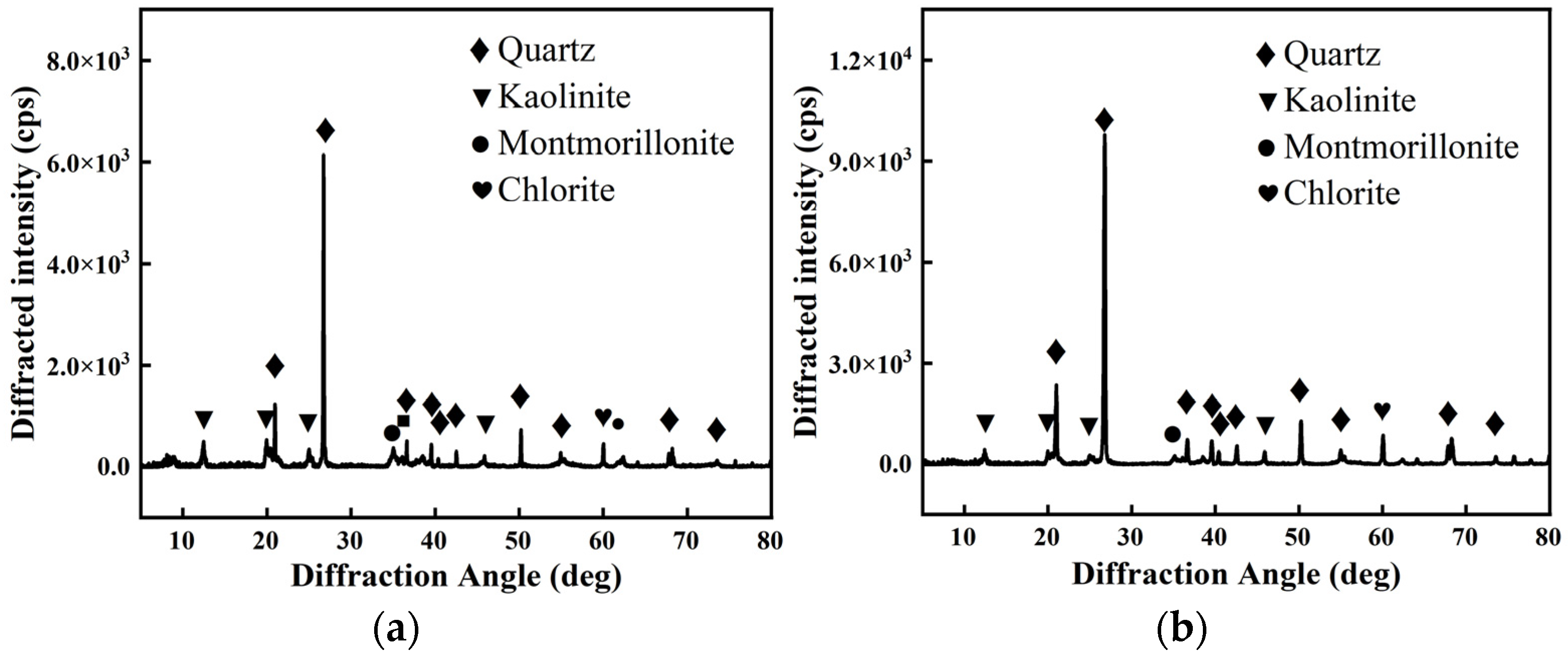

3.3. Mineral Composition Content Test Results

3.4. Microscopic Structural Evolution of Rock Mass Under Water Infiltration

4. Fissure Development Characteristics of Overburden Rock in Weakly Cemented Strata Under Repeated Mining

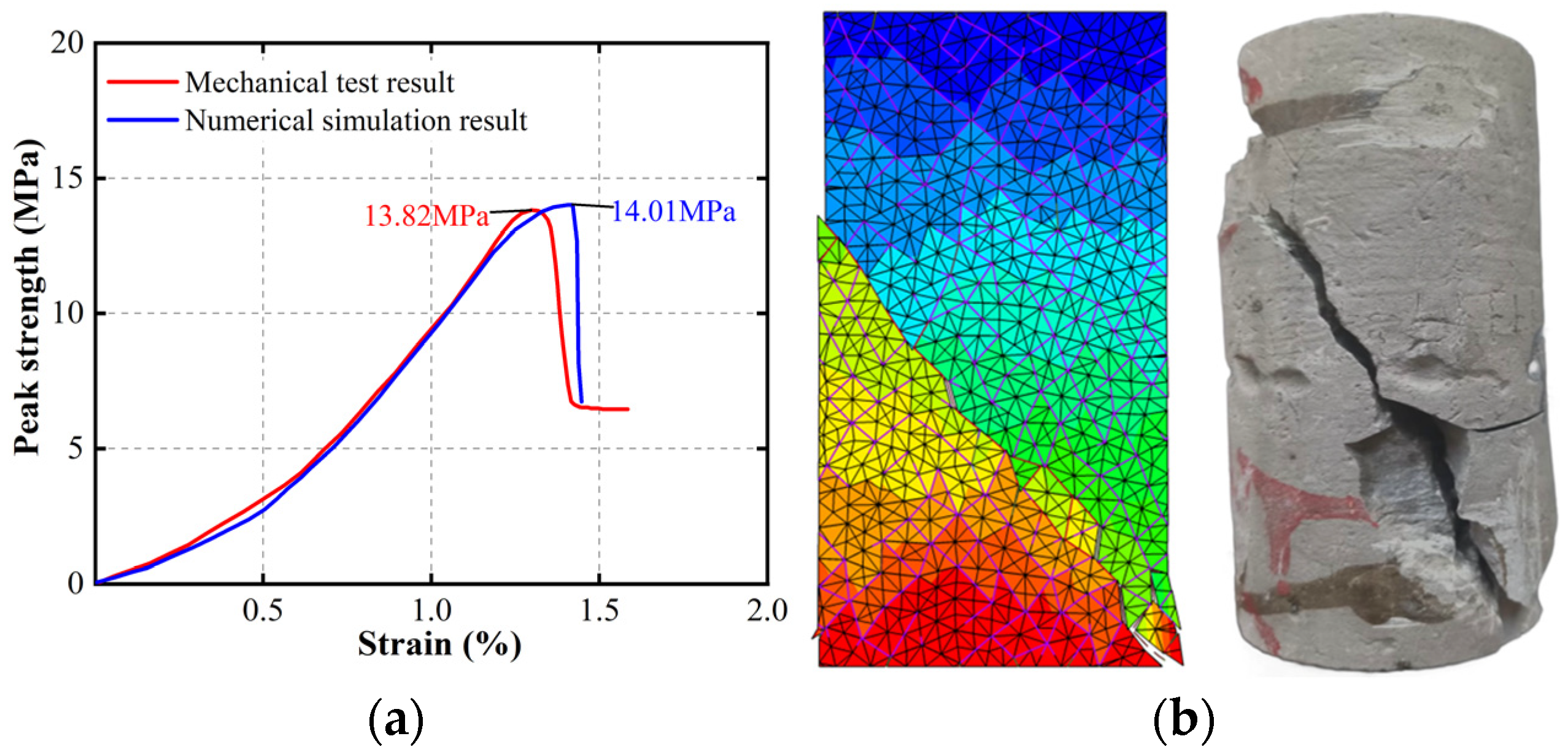

4.1. Numerical Calculation Model Construction

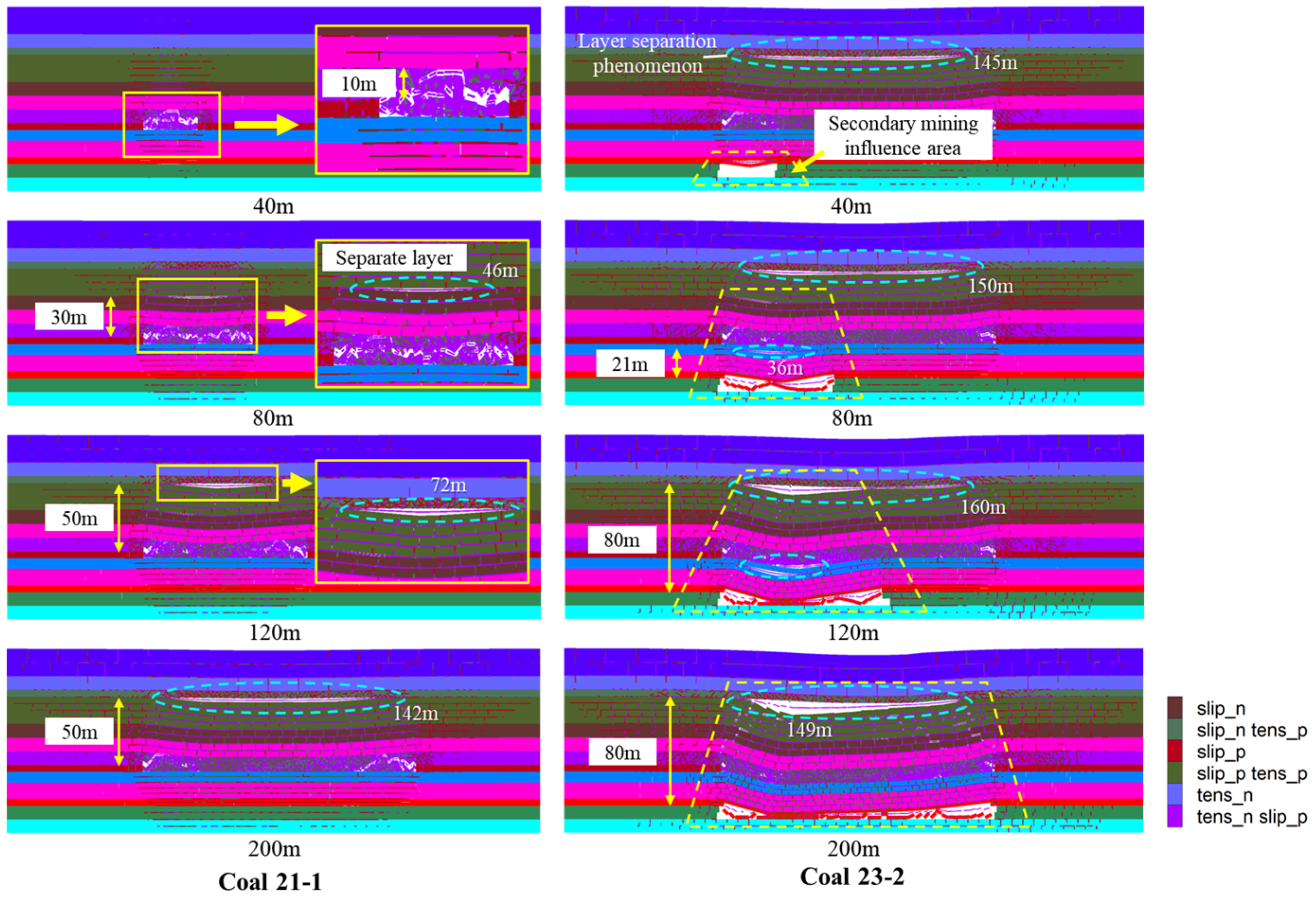

4.2. Failure Characteristics of Overburden Rock Under Repeated Mining Without Seepage

4.3. Failure Characteristics of Overburden Rock Under Repeated Mining with Seepage

5. Evolution of Seepage in Weakly Cemented Strata Under Repeated Mining

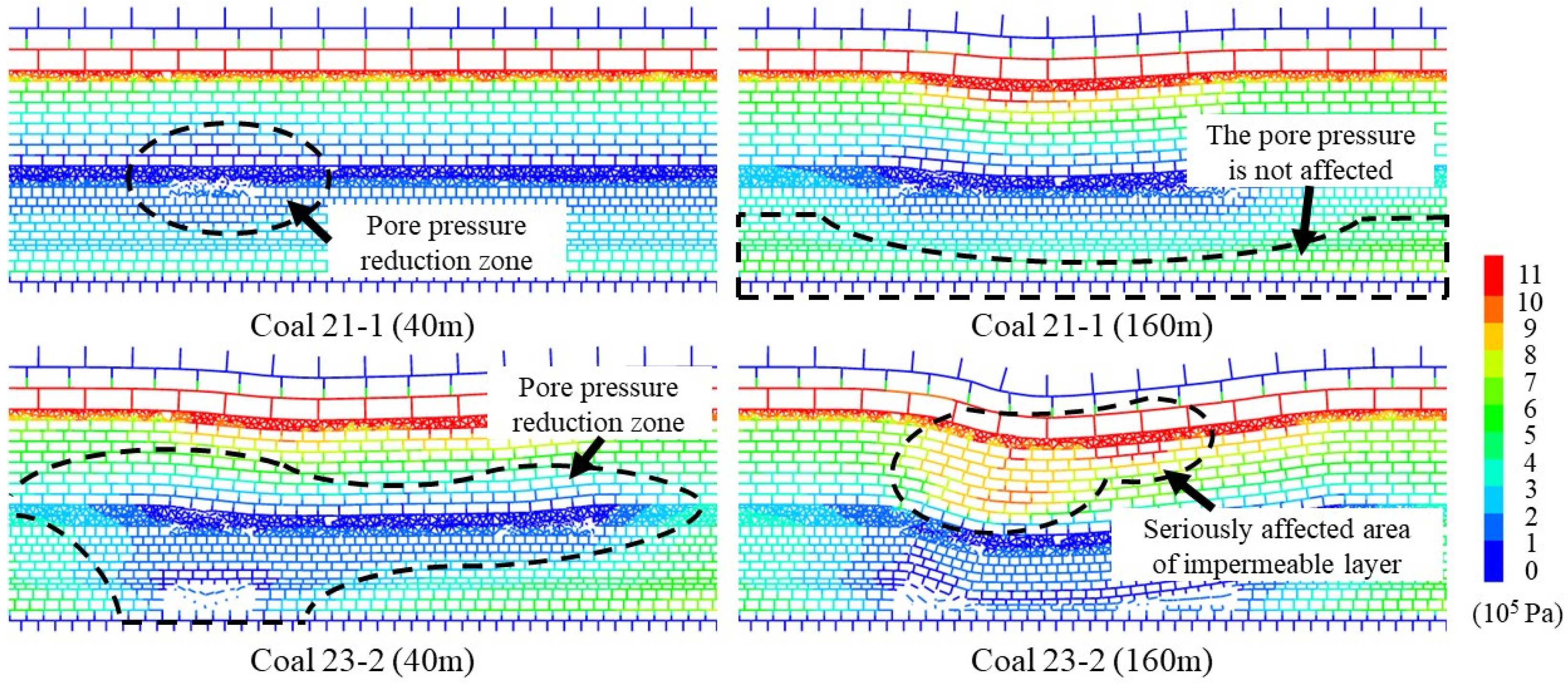

5.1. Pore Pressure Distribution

5.2. Development Patterns of Overburden Rock Fissures and Damage Characteristics

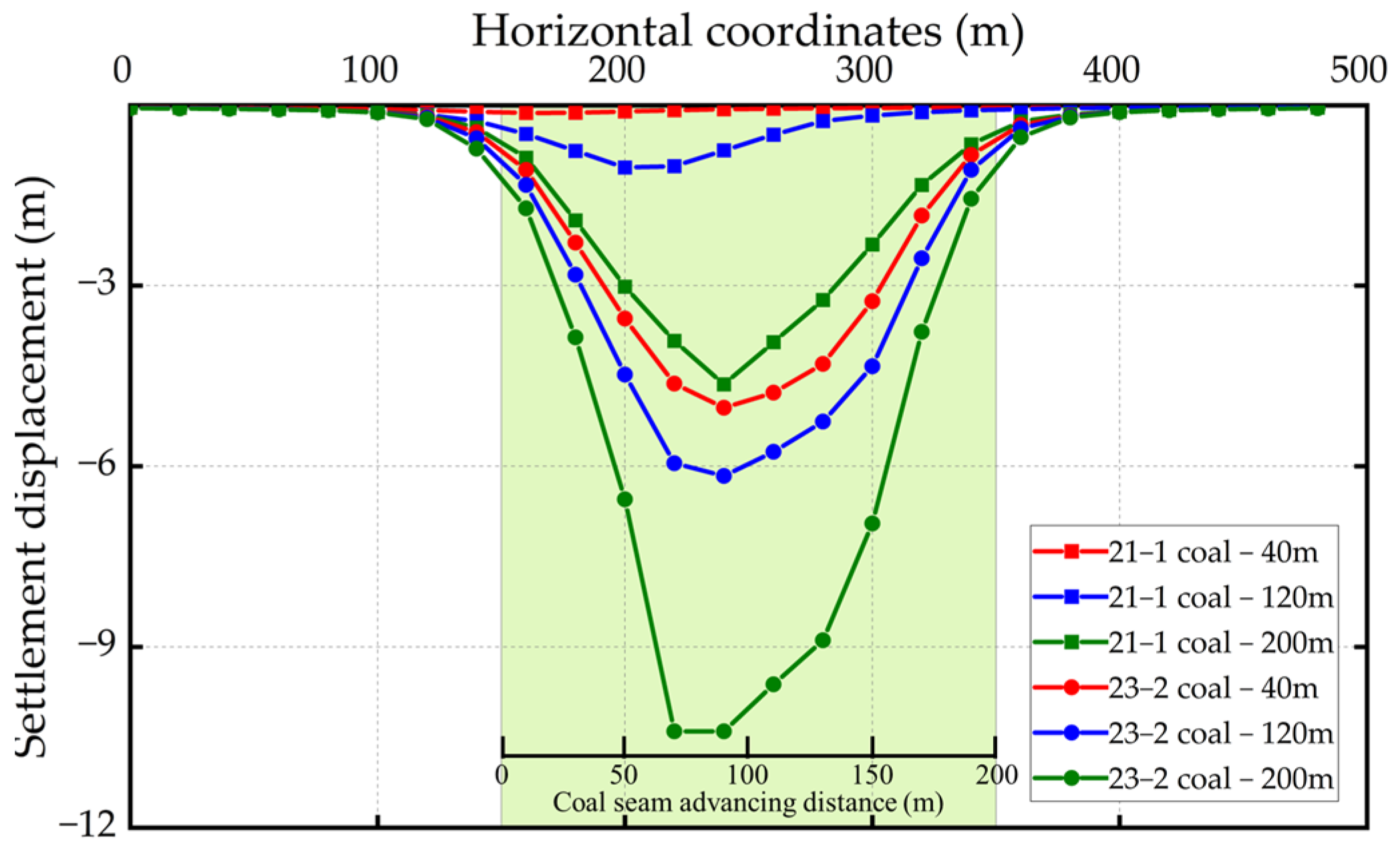

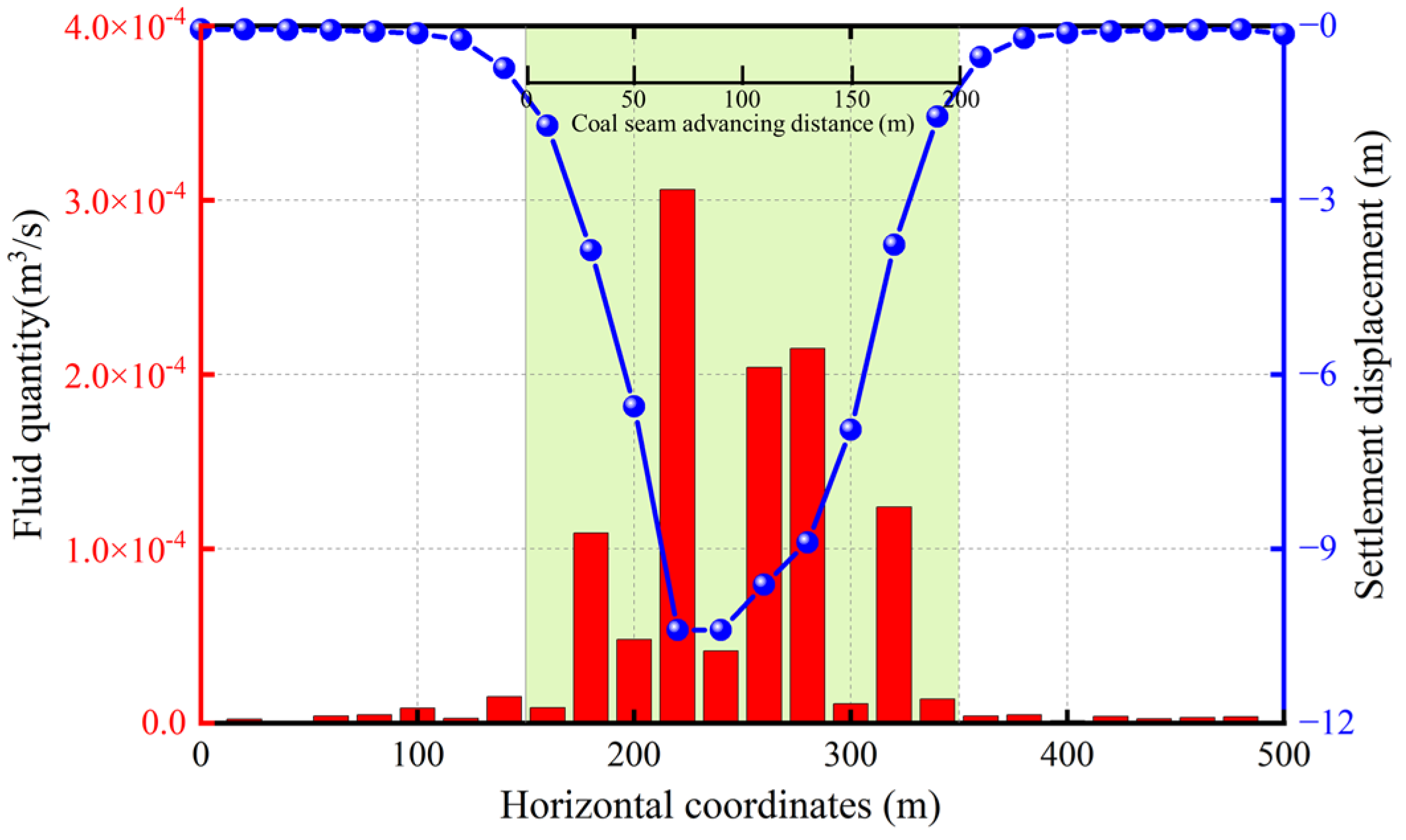

5.3. Overburden Rock Subsidence and Flow Characteristics

5.4. Discussion on Seepage-Fissure Coupling Mechanisms in Overburden Rock Under Repeated Mining

6. Conclusions

- (1)

- Weakly cemented mudstone is highly water sensitive. After water infiltration, the clay mineral content decreases significantly, and the development of microcracks increases substantially. The uniaxial compressive strength, tensile strength, and shear strength of the samples decline sharply, with the moisture content increasing from 0% to 3.27%. Specifically, the uniaxial compressive strength, peak strain, and elastic modulus decreased by 59.83%, 56.08%, and 26.09%, respectively.

- (2)

- In the absence of seepage, the fissure development zone in the overburden rock shifts from a trapezoidal to an inverted trapezoidal shape as mining progresses through both coal seams. A complete water-conducting channel first forms above the left-side setup entry, and the expansion area consists of fissures caused by overburden rock-sliding failure. With seepage effects, the presence of pore pressure and fissure water significantly accelerates the development of fissures in the overburden rock, further expanding the caving range. Seepage causes large-scale fissure initiation and expansion to occur 80 m earlier than without seepage.

- (3)

- During coal seam mining, the excavation of the upper coal seam reduces the pore water pressure in the roof, causing the pressure reduction zone to shift from a trapezoidal to an “M” shape. The high pore pressure above the goaf migrates downward. By the time mining of the lower coal seam is complete, a seepage channel forms near the left-side setup entry and continues to expand. The overburden rock in this area is particularly affected by mining disturbance.

- (4)

- Under repeated mining conditions, both the number and length of fissures in the overburden rock continue to increase. After mining of the upper coal seam, the increase in fissure number slows while fissure length stabilizes. At 70 m from the setup entry, both the fissure water flow rate and overburden subsidence reach their peak. The dynamic evolution of the overburden seepage field drives the migration of formation water and pore pressure. Water infiltration causes hydration damage to the overburden structure while migrating pore pressure leads to the formation of numerous new fissures. Persistent fissure water infiltration and seepage pressure facilitate the expansion of the water flowing fracture zone. Subsequent overburden fracturing and secondary fissure propagation further intensify water migration, diminishing both the bearing capacity and water-resistance property of the overburden. As a result, weakly cemented overburden rock in mining areas sustains markedly increased damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Li, J.; Sun, Y.; Sun, C.; Xu, J.; Rong, H.; Lu, Z. Advance of multi-scale study on both analytic models and water-rock interaction characteristics of mudstone. J. China Coal Soc. 2022, 47, 1138–1154. [Google Scholar]

- Li, G.; Sun, C.; He, J.; Sun, Y.; Dong, Y.; Zhao, H. Macro and mesoscale simulation study of the strength-weakening property of soft mudstone affected by water. J. China Univ. Min. Technol. 2019, 48, 935–942. [Google Scholar]

- Ji, H.; Sun, L.; Song, C.; Zhang, Y.; Wang, J.; Meng, Z. Research progress on stability control of surrounding rock in weakly cemented strata engineering in western China mining area. Coal Sci. Technol. 2023, 51, 117–127. [Google Scholar]

- Sun, L.; Ji, H.; Yang, B. Physical and mechanical characteristic of rocks with weakly cemented strata in Western representative mining area. J. China Coal Soc. 2019, 44, 866–874. [Google Scholar]

- Zhao, Z. Study on water-rock interaction mechanisms and mechanical behaviors of single rock fractures. Chin. J. Rock Mech. Eng. 2021, 40, 3063–3073. [Google Scholar]

- Wang, Y.; Yan, L.; Mao, S.; Chen, T. Multi-scale deterioration mechanism of mudstone under water-rock-stress relaxation coupling effect. J. Eng. Geol. 2025, 1–13. [Google Scholar]

- Miao, S.; Yang, P.; Huang, Z.; Wang, H.; Liang, M. Effects of confining pressure on failure mechanism of porous and weakly cemented rock and compaction-damage constitutive model. J. China Univ. Min. Technol. 2023, 52, 229–240. [Google Scholar]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Determination of the Extent of the Rock Destruction Zones around a Gasification Channel on the Basis of Strength Tests of Sandstone and Claystone Samples Heated at High Temperatures up to 1200 °C and Exposed to Water. Energies 2021, 14, 6464. [Google Scholar] [CrossRef]

- Han, P.H.; Zhang, C.; He, X.; Wang, X.; Qiao, Y. DEM fluid-solid coupling method for progressive failure simulation of roadways in a fault structure area with water-rich roofs. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 194. [Google Scholar] [CrossRef]

- Fan, Z. Permeability Evolution and Groundwater Migration Characteristics of Floor with Large Dip Angle and High Pressure; China University of Mining and Technology: Xuzhou, China, 2022. [Google Scholar]

- Zhang, C.; Huang, X.; Wang, Y.; Shi, X.; Wang, F.; Han, P. Simulation method and engineering application of fluid solid coupling for water immersion weakening in coal mining. Coal Sci. Technol. 2025, 1–11. [Google Scholar]

- Zhang, S.; Fan, G.; Zhang, D.; Li, W.; Fan, Z. Mining-induced permeability evolution in weakly cemented strata under stress-damage-seepage coupling. J. Min. Saf. Eng. 2024, 41, 1230–1240. [Google Scholar]

- Wang, W.Q.; Li, Z.H.; Xu, J.; Wang, Y.; Fan, X.; Li, S. Evolution mechanism of water-conducting fissures in overlying rock strata with karst caves under the influence of coal mining. Geofluids 2022, 2022, 4064759. [Google Scholar] [CrossRef]

- Xu, X.L.; Zhang, N.; Tian, S.C. Division of mining-induced fracture and permeability of overlying strata. J. Min. Saf. Eng. 2014, 31, 564–568. [Google Scholar]

- Khanal, M.; Guo, H.; Adhikary, D. 3D numerical study of underground coal mining-induced strata deformation and subsequent permeability change. Geotech. Geol. Eng. 2019, 37, 235–249. [Google Scholar] [CrossRef]

- Li, H.X.; Cao, Z.G.; Wu, B.Y.; Chi, M.; Zhang, B. Experimental study on characteristics of grounawater fracture in coal mine overlying rock. Coal Sci. Technol. 2023, 51, 168–176. [Google Scholar]

- Xu, Z.M.; Han, Y.H.; Chen, T.C.; Chen, G.; Huan, B.; Zhao, R.; Sun, Y. Mining-induced overburden failure and height prediction in jurassic weakly cemented roof. J. Eng. Geol. 2023, 31, 1474–1485. [Google Scholar]

- Poulsen, D.; Adhikary, D.; Guo, H. Simulating mining-induced strata permeability changes. Eng. Geol. 2018, 237, 208–216. [Google Scholar] [CrossRef]

- Li, X.P.; Liu, Y.Q.; Ren, X.P.; Wu, X.; Zhou, C. Roof breaking characteristics and mining pressure appearance laws in close-distance coal seams. Energy Explor. Exploit. 2023, 41, 728–744. [Google Scholar] [CrossRef]

- Li, Y.; Ren, Y.Q.; Lei, X.H.; Wang, N.; Jin, X. Numerical modeling and onsite detection analysis of upward mining feasibility of residual coal from multi-gobs in close-multiple coal seams. Min. Metall. Explor. 2023, 40, 1153–1169. [Google Scholar] [CrossRef]

- Liu, H. Study on the Mechanism and Classification of Water-Preserved Mining for Ultra-Thick Coal Seam at Weak Cemented Stratum in Ili; China University of Mining and Technology: Xuzhou, China, 2020. [Google Scholar]

- Liu, H.; Cao, W.; Cao, Z.; Sun, J.; Yu, B.; Zhao, H. Influence of stress path on the mechanical behavior of laterally confined coal: Laboratory investigation. Constr. Build. Mater. 2025, 466, 140287. [Google Scholar] [CrossRef]

- Zhen, W.; Liu, H.; Chi, M.; Liu, X.; Cao, W.; Chen, Z. Investigation into the Influence of Stress Conditions on the Permeability Characteristics of Weakly Cemented Sandstone. Appl. Sci. 2023, 13, 12105. [Google Scholar] [CrossRef]

- Li, H.; Sun, J.; Guo, G.; Tang, C.; Zheng, H.; Zhang, L.; Meng, F. Evolution characteristics and development height prediction method of water-conducting crack zone in thick weak cemented overlying strata. Coal Sci. Technol. 2024, 1–13. [Google Scholar]

- Li, F.; Wang, J.; Li, P.; Huang, K. Research on movement behavior and failure mechanism of overlying strata caused by mining at mountainous field. Rock Soil Mech. 2016, 37, 1089–1095. [Google Scholar]

- Liang, B.; Xing, J.; Sun, W.; Fang, S. Mechanisms and three-dimensional spatial characteristics of fissures induced under the influence of fracture of mining overburden rocks. Coal Sci. Technol. 2024, 53, 1–13. [Google Scholar]

- Liu, Z.; Zhao, G. Investigation on overburden failure characteristic and height of water—conducted fracture zone due to fully mechanized caving mining. Min. Saf. Environ. Prot. 2021, 48, 12–18. [Google Scholar]

- Zhang, J.; Li, Q.; Cao, Z.; Wen, J.; Chi, M.; Du, W.; Zhao, H. Analysis method of mining seepage field. J. China Coal Soc. 2023, 48, 3628–3645. [Google Scholar]

- Jia, W.; Zhang, M.; Liang, X.; Xie, S. Study on geostress and pore pressure affected to directional hydraulic fracturing effect. Coal Sci. Technol. 2018, 46, 151–157. [Google Scholar]

- Wang, D.; Pang, X.; Wei, J.; Zhang, H.; Yao, B.; Wei, L.; Tang, J. Effect of gas properties and pore pressure on the microcrack propagation in coal. Coal Sci. Technol. 2023, 51, 183–192. [Google Scholar]

- Liang, Y.; Yang, K.; Yang, Z.; Li, Q.; Chen, Q.; Sun, W. Hydro-mechanical-damage coupling effect of hydraulic fracturing in fractured dual-medium coal masses. Comput. Geotech. 2025, 178, 106909. [Google Scholar] [CrossRef]

- Hua, T.; Shen, L.; Wang, Z.; Li, Z.; Xu, Z.M. Numerical simulation of rock hydraulic fracturing based on peridynamics and quantitative analysis of fracture network. Rock Soil Mech. 2024, 45, 612–622. [Google Scholar]

- Xiao, Y.; Lan, Z.; Shi, H.; Dai, D.; Li, S. Influence of reservoir pressure field change on hydraulic fracture propagation during fracturing. China Min. Mag. 2021, 30, 140–145. [Google Scholar]

| Sample ID | Moisture Content (%) | Peak Strength (MPa) | Peak Strain (%) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| UN-1 | 0 | 18.52 | 1.48 | 2.30 |

| UN-2 | 1.32 | 14.20 | 1.31 | 2.08 |

| UN-3 | 2.86 | 10.97 | 1.14 | 1.88 |

| UN-4 | 3.27 | 7.44 | 0.65 | 1.70 |

| Sample ID | Moisture Content (%) | Tensile Strength (MPa) |

|---|---|---|

| LN-1 | 0 | 1.04 |

| LN-2 | 1.44 | 0.76 |

| LN-3 | 3.45 | 0.37 |

| Sample ID | Moisture Content (%) | Normal Stress (MPa) | Shear Stress (MPa) |

|---|---|---|---|

| SN-1 | 0 | 5.9 | 10.3 |

| SN-2 | 1.90 | 5.3 | 9.2 |

| SN-3 | 3.31 | 2.6 | 4.4 |

| Moisture Condition | Quartz Content (%) | Clay Mineral Content (%) | Clay Minerals | ||

|---|---|---|---|---|---|

| Kaolinite (%) | Montmorillonite (%) | Chlorite (%) | |||

| Drying | 64.87 | 35.13 | 4.15 | 11.05 | 19.93 |

| Saturation | 76.20 | 23.80 | 3.28 | 10.52 | 10.00 |

| Lithology | Density (kg·m−3) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Cohesion (MPa) | Tensile Strength (MPa) | Internal Friction Angle (°) | Thickness (m) |

|---|---|---|---|---|---|---|---|

| Gravelly sandstone | 2300 | 6.0 | 5.47 | 2.0 | 2.0 | 50 | 30 |

| Mudstone (aquifer) | 2300 | 2.5 | 1.1 | 2.4 | 1.2 | 40 | 5 |

| Gravel–sandstone | 2200 | 24.0 | 10.5 | 2.1 | 0.9 | 28 | 20 |

| Mudstone | 2400 | 6.5 | 3.2 | 2.2 | 1.1 | 33 | 10 |

| Sandy mudstone | 2600 | 18.5 | 9.0 | 1.3 | 0.85 | 30 | 10 |

| Mudstone | 2400 | 6.5 | 2.5 | 1.1 | 0.8 | 32 | 10 |

| Coal 21-1 | 1240 | 6.7 | 2.2 | 1.1 | 0.7 | 35 | 5 |

| Medium sandstone | 2430 | 8.5 | 4.0 | 1.6 | 1.1 | 35 | 8 |

| Sandy mudstone | 2600 | 19.5 | 8.5 | 1.5 | 1.7 | 30 | 12 |

| Mudstone | 2500 | 7.8 | 3.5 | 2.8 | 1.4 | 33 | 5 |

| Coal 23-2 | 1240 | 8.5 | 2.5 | 1.6 | 1.1 | 40 | 10 |

| Siltstone | 2330 | 21.5 | 9.3 | 1.86 | 1.6 | 45 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Y.; Zhen, W.; Huang, H.; Zhang, Y.; Tang, Q.; Liu, H. Research on the Fissure Development and Seepage Evolution Patterns of Overburden Rock in Weakly Cemented Strata Under Repeated Mining. Sustainability 2025, 17, 2780. https://doi.org/10.3390/su17062780

Xia Y, Zhen W, Huang H, Zhang Y, Tang Q, Liu H. Research on the Fissure Development and Seepage Evolution Patterns of Overburden Rock in Weakly Cemented Strata Under Repeated Mining. Sustainability. 2025; 17(6):2780. https://doi.org/10.3390/su17062780

Chicago/Turabian StyleXia, Yang, Wenyuan Zhen, Haishan Huang, Yu Zhang, Qinghe Tang, and Honglin Liu. 2025. "Research on the Fissure Development and Seepage Evolution Patterns of Overburden Rock in Weakly Cemented Strata Under Repeated Mining" Sustainability 17, no. 6: 2780. https://doi.org/10.3390/su17062780

APA StyleXia, Y., Zhen, W., Huang, H., Zhang, Y., Tang, Q., & Liu, H. (2025). Research on the Fissure Development and Seepage Evolution Patterns of Overburden Rock in Weakly Cemented Strata Under Repeated Mining. Sustainability, 17(6), 2780. https://doi.org/10.3390/su17062780