A Review of the Application of Computer Vision Techniques in Sustainable Engineering of Open Pit Mines

Abstract

1. Introduction

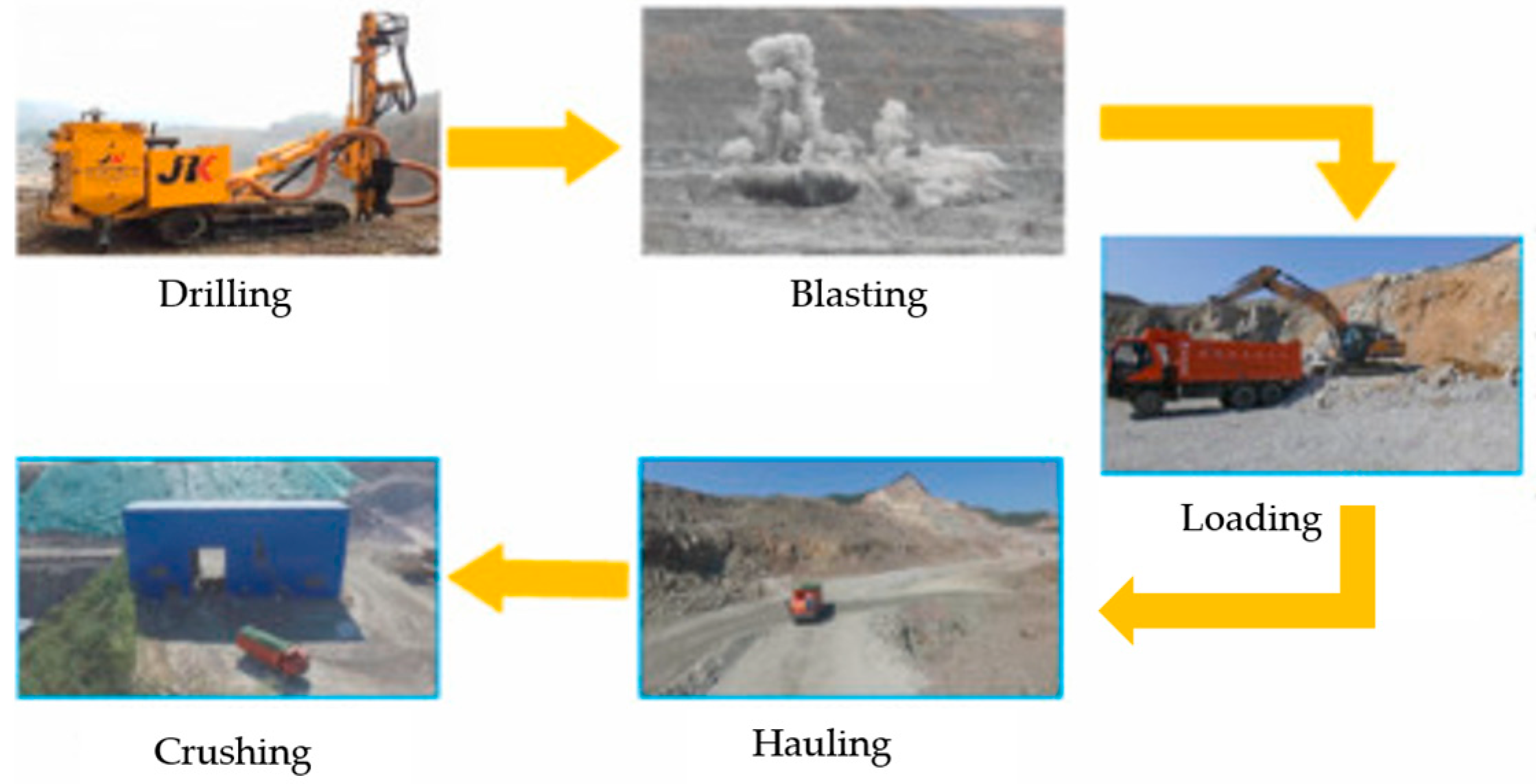

2. Current Research Status of CV in Various Aspects of Mining

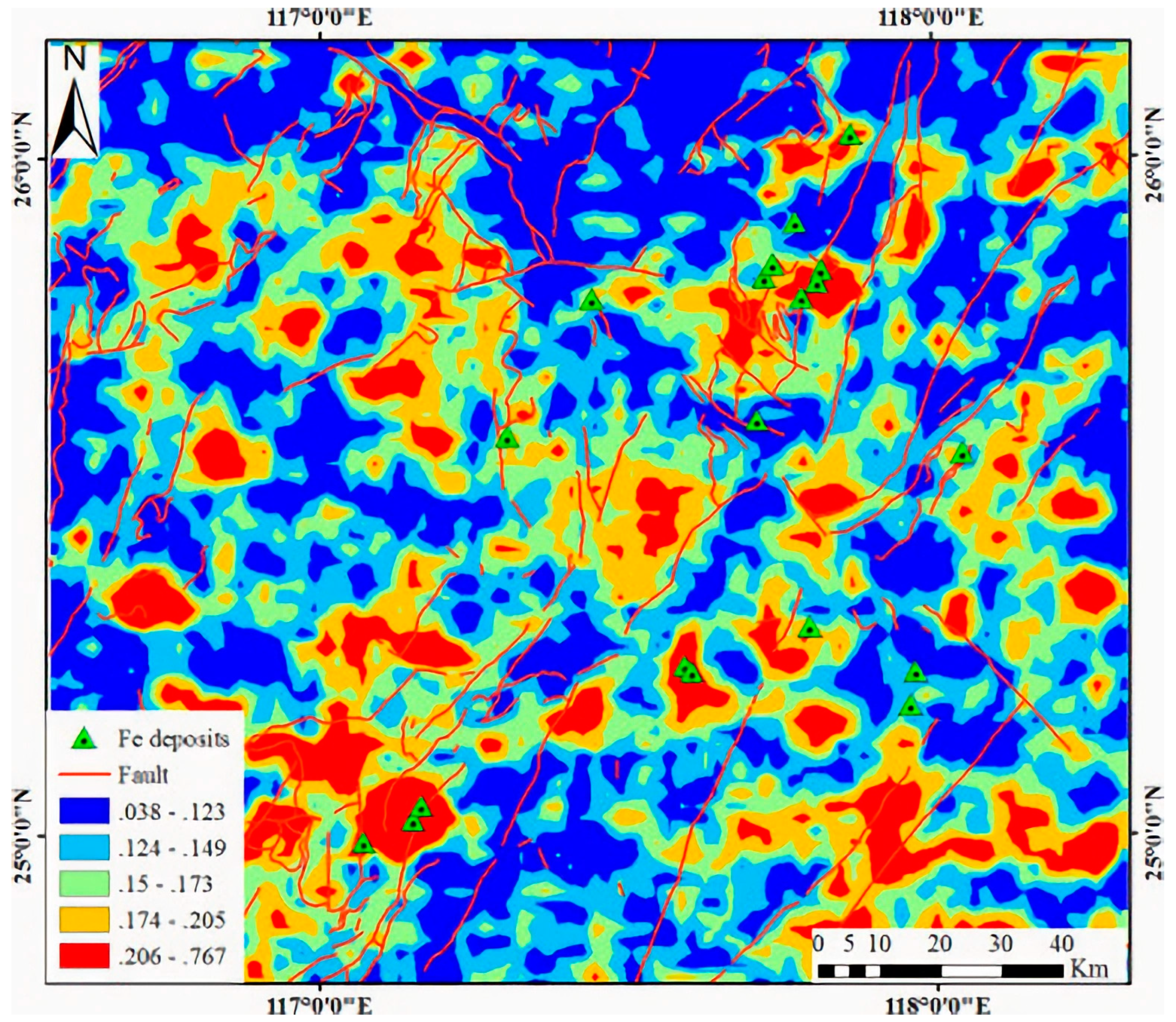

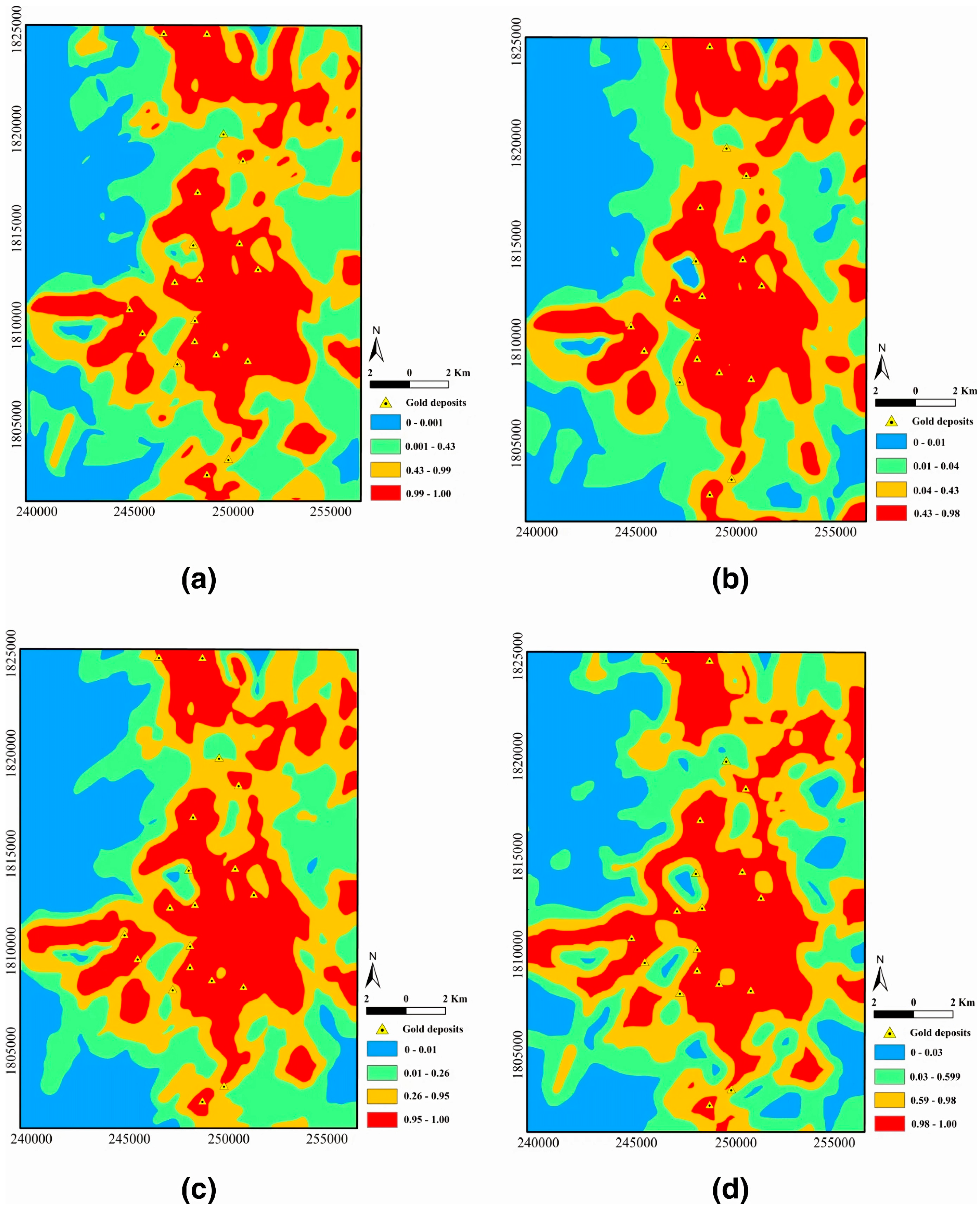

2.1. Current Research Status of CV in Exploration

2.2. Current Status of Research on CV in Drilling and Blasting

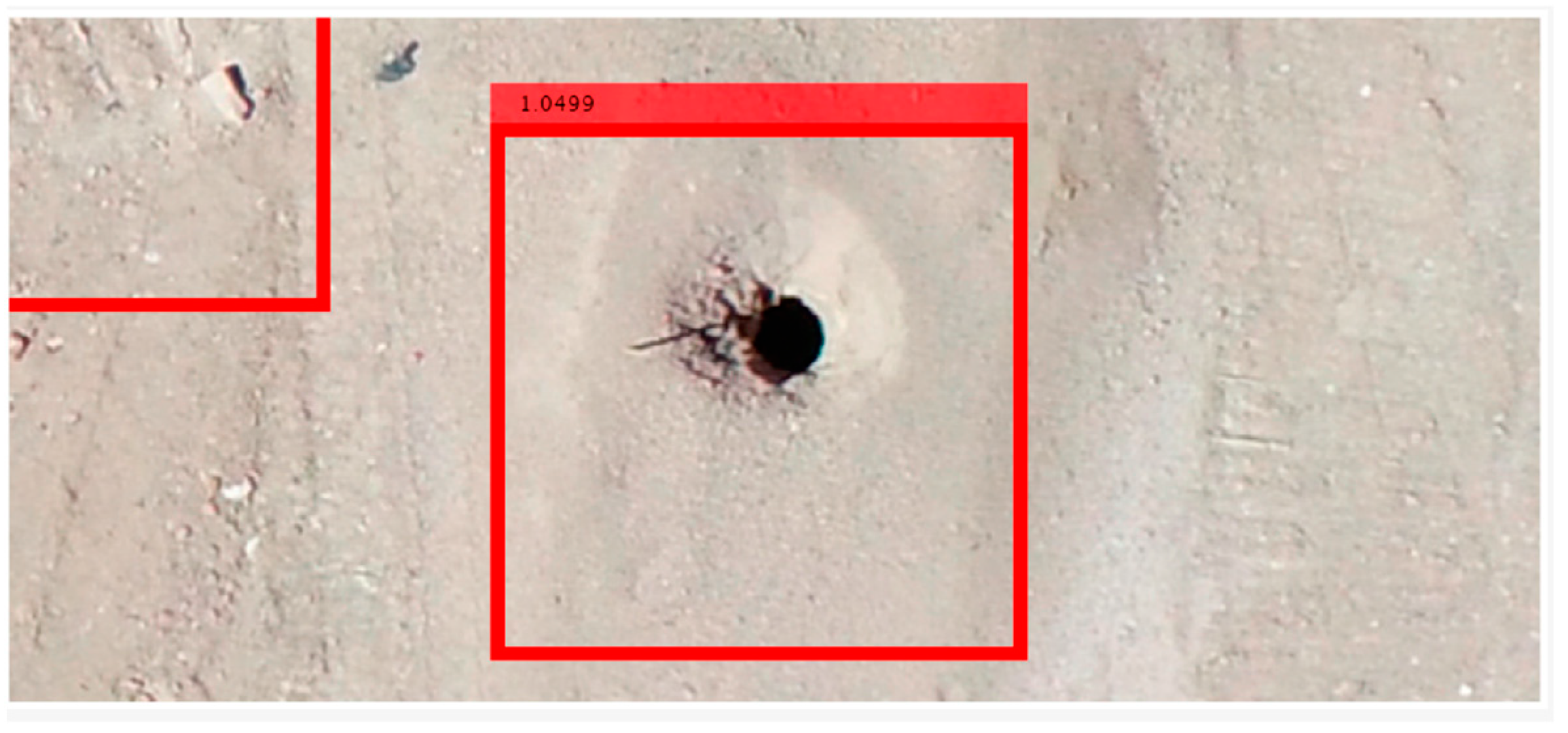

2.2.1. Current Research Status of CV in the Drilling Process

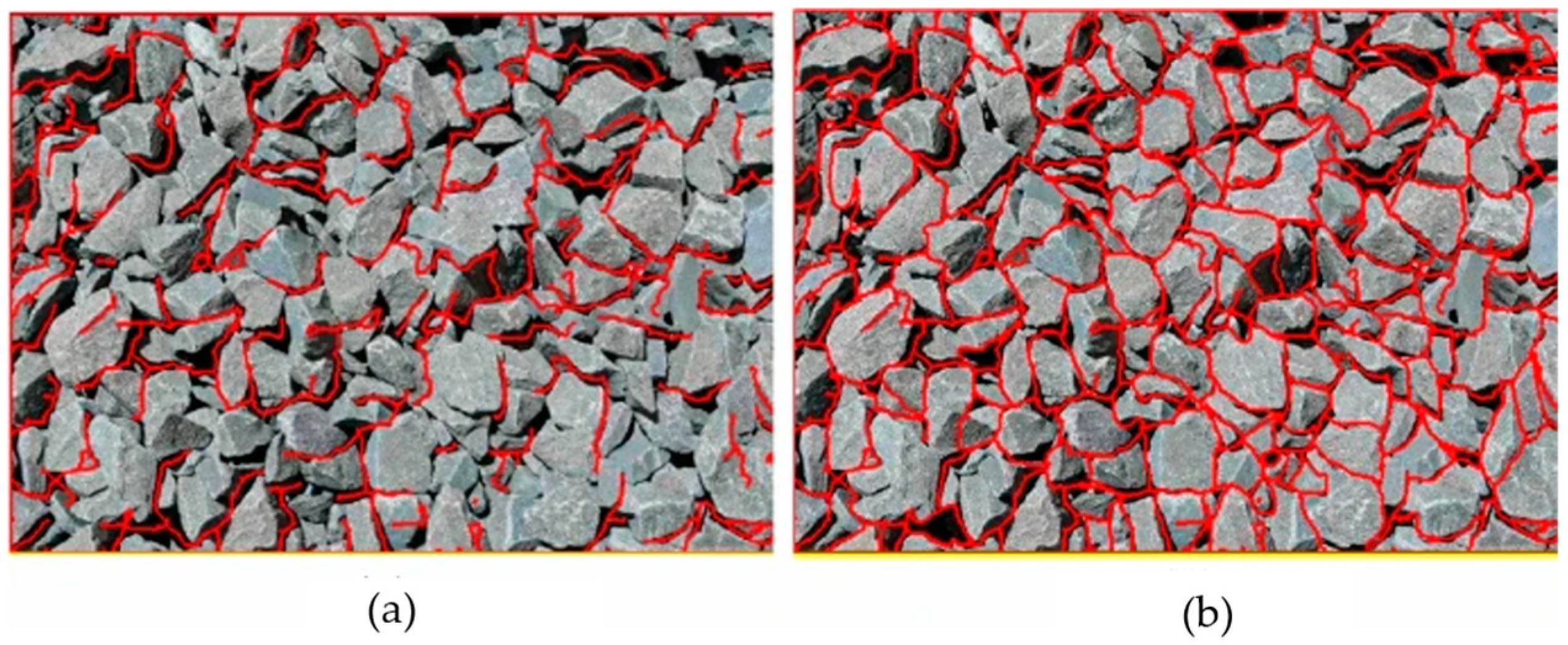

2.2.2. Current Research Status of CV in Blasting

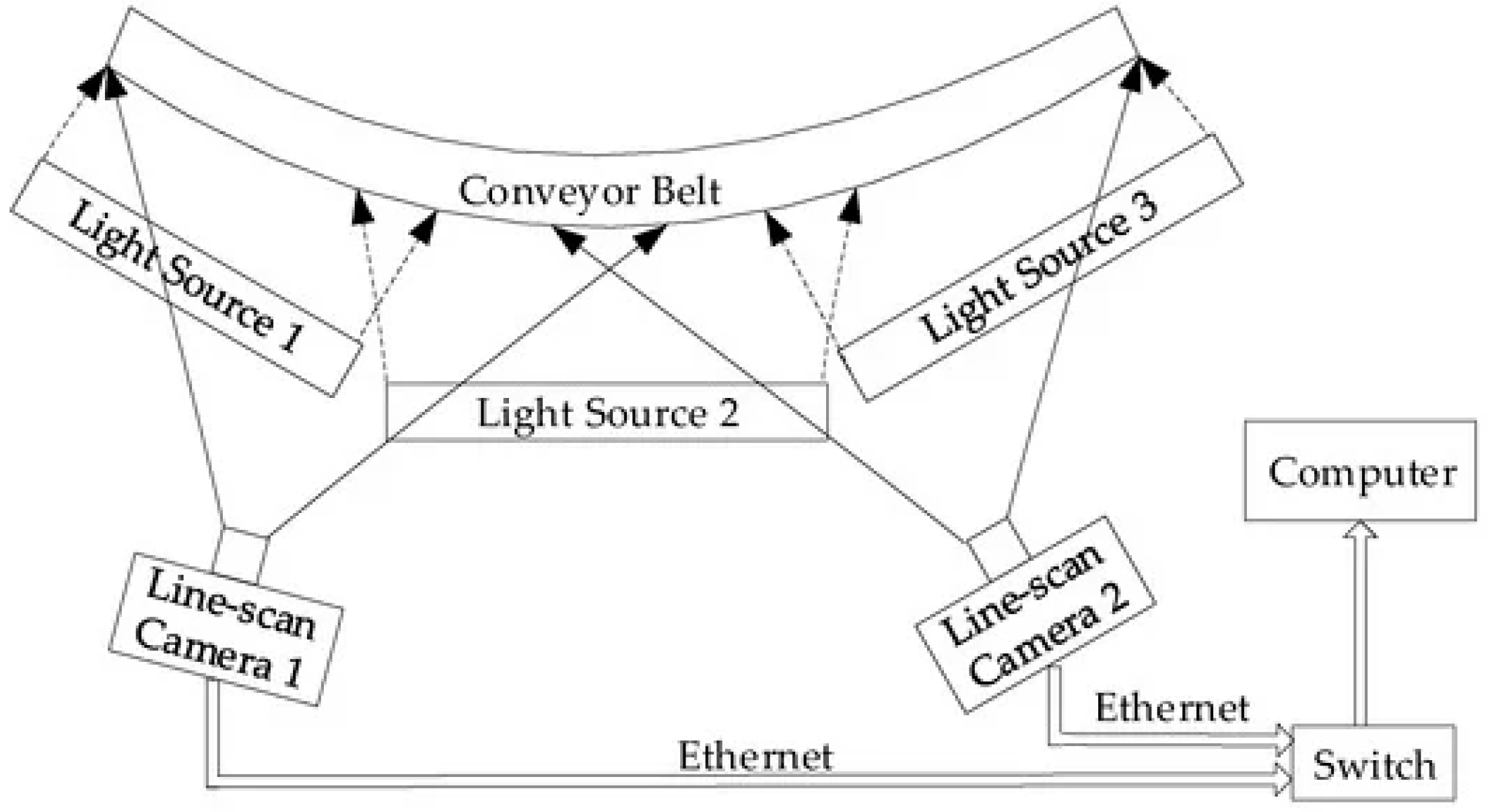

2.3. Current Status of Research on CV in the Transportation Process

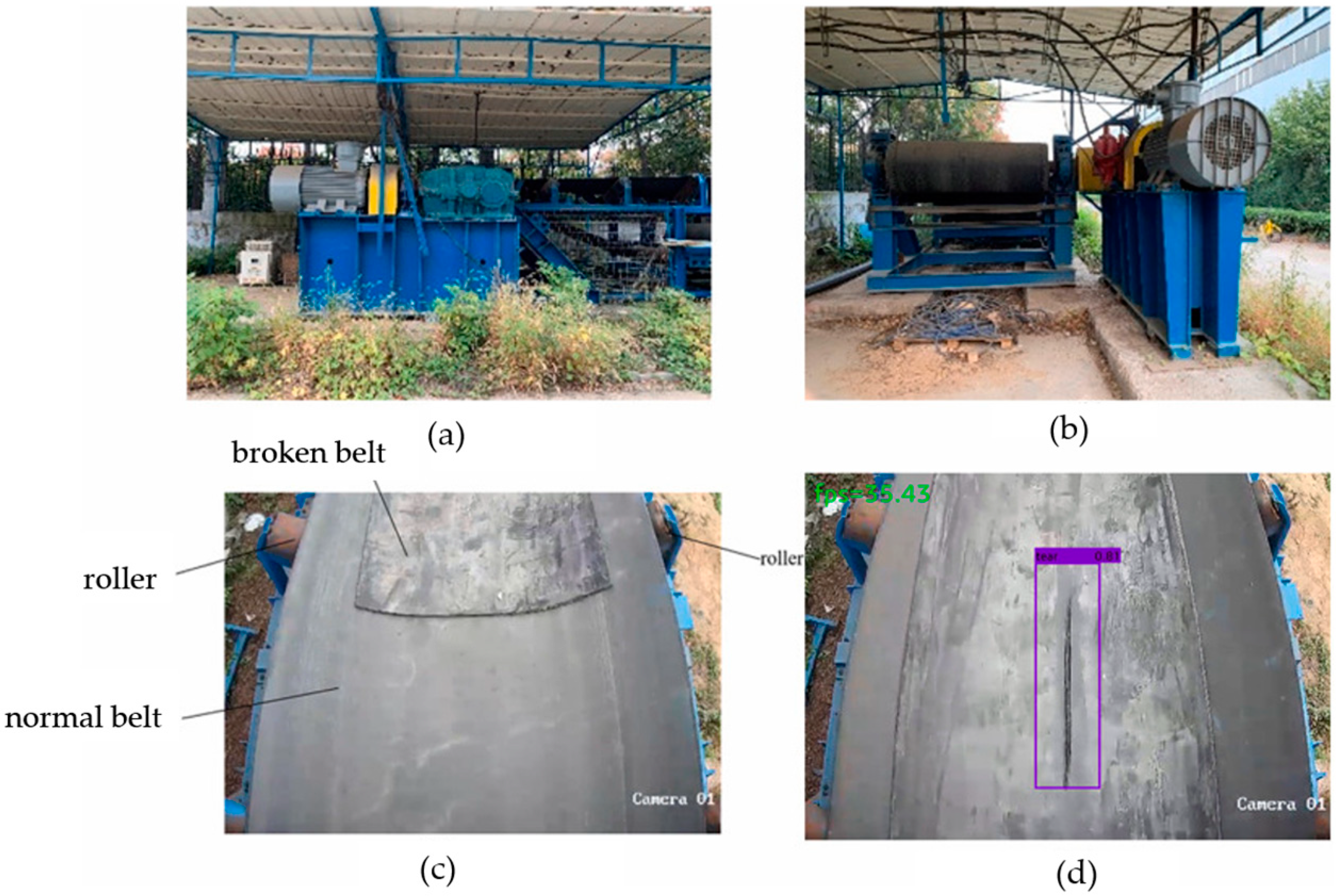

2.3.1. Detection of Belt Damage During Transportation

2.3.2. Belt Offset During Transportation

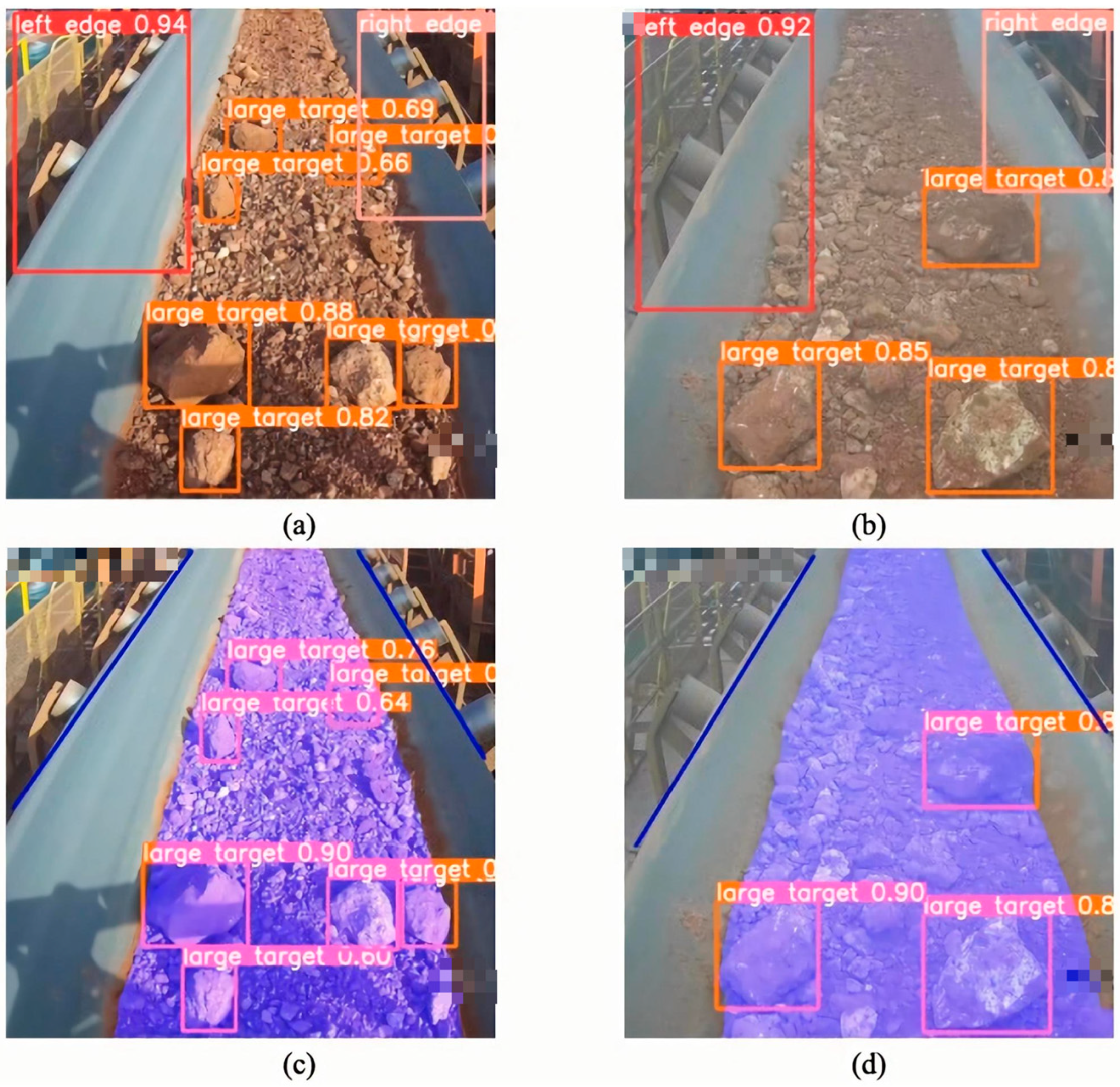

2.3.3. Detection of Foreign Objects During Transportation

2.4. Application of CV in Ensuring Personnel Safety During Mining

3. Conclusions

3.1. Summary

3.2. Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, L.; Xie, J.; Zhang, X.; Deng, J.; Ge, S.; Wang, F.Y. Mining 5.0: Concept and framework for intelligent mining systems in CPSS. IEEE Trans. Intell. Veh. 2023, 8, 3533–3536. [Google Scholar]

- Zhang, K.; Kang, L.; Chen, X.; He, M.; Zhu, C.; Li, D. A review of intelligent unmanned mining current situation and development trend. Energies 2022, 15, 513. [Google Scholar] [CrossRef]

- Ge, X.; Su, S.; Yu, H.; Chen, G.; Lu, X. Smart mine construction based on knowledge engineering and internet of things. Int. J. Perform. Eng. 2018, 14, 1060. [Google Scholar]

- Chen, L.; Zhan, W.; Tian, W.; He, Y.; Zou, Q. Deep integration: A multi-label architecture for road scene recognition. IEEE Trans. Image Process. 2019, 28, 4883–4898. [Google Scholar]

- Tang, K.; Luo, X.; Sun, L.; Xu, Y.; Fang, C. AI Empowers the Application of Industry Safety Intellectualization. In Proceedings of the 2019 2nd International Conference on Safety Produce Informatization (IICSPI), Chongqing, China, 28–30 November 2019; pp. 520–525. [Google Scholar]

- He, X.; Song, L. Status and future tasks of coal mining safety in China. Saf. Sci. 2012, 50, 894–898. [Google Scholar]

- Stothard, P.; Squelch, A.; Stone, R.; Van Wyk, E. Towards sustainable mixed reality simulation for the mining industry. Min. Technol. 2019, 128, 246–254. [Google Scholar]

- D’Emilia, G.; Di Gasbarro, D. Review of techniques for 2D camera calibration suitable for industrial vision systems. J. Phys. Conf. Ser. 2017, 841, 012030. [Google Scholar]

- Lee, S.H.; Yang, C.S. A real time object recognition and counting system for smart industrial camera sensor. IEEE Sens. J. 2017, 17, 2516–2523. [Google Scholar]

- Chatterjee, D.; Chaulya, S.K. Vision improvement system using image processing technique for adverse weather condition of opencast mines. Int. J. Min. Reclam. Environ. 2019, 33, 505–516. [Google Scholar] [CrossRef]

- Singh, U.; Rahman, A.; Mahato, S.K.; Surya, S.; Bajaj, M.; Jurado, F.; Kamel, S. Design of an Automatic Sorting Machine on the Conveyor Belt System Based on Product Temperature. In Proceedings of the 2022 IEEE International Conference on Automation/XXV Congress of the Chilean Association of Automatic Control (ICA-ACCA), Curicó, Chile, 24–28 October 2022; pp. 1–6. [Google Scholar]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 23–28 June 2014; pp. 580–587. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Simonyan, K. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Reed, S.; Anguelov, D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 7–12 June 2015; pp. 1–9. [Google Scholar]

- Huang, G.; Liu, Z.; Van Der Maaten, L.; Weinberger, K.Q. Densely connected convolutional networks. In Proceedings of the IEEE conference on computer vision and pattern recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 4700–4708. [Google Scholar]

- Zeng, F.; Zhou, J.; Wu, Q. A conveyor belt characterization information extraction method based on YOLOv5 and the skeleton method. Meas. Sci. Technol. 2023, 34, 115006. [Google Scholar] [CrossRef]

- Han, X.; Chang, J.; Wang, K.J.P.C.S. You only look once: Unified, real-time object detection. Procedia Comput. Sci. 2021, 183, 61–72. [Google Scholar] [CrossRef]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C. SSD: Single shot multibox detector. In Computer Vision—ECCV 2016, Proceedings of the 14th European Conference, Amsterdam, The Netherlands, 11–14 October 2016; Part I 14; Springer International Publishing: Cham, Switzerland, 2016; pp. 21–37. [Google Scholar]

- Guo, X.; Liu, X.; Zhou, H.; Stanislawski, R.; Królczyk, G.; Li, Z. Belt tear detection for coal mining conveyors. Micromachines 2022, 13, 449. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Mosalam, K.M. Deep transfer learning for image-based structural damage recognition. Comput.-Aided Civ. Infrastruct. Eng. 2018, 33, 748–768. [Google Scholar]

- Makhzani, A.; Shlens, J.; Jaitly, N.; Goodfellow, I.; Frey, B. Adversarial autoencoders. arXiv 2015, arXiv:1511.05644. [Google Scholar]

- Liu, Y.; Miao, C.; Li, X.; Ji, J.; Meng, D.; Wang, Y. A dynamic self-attention-based fault diagnosis method for belt conveyor idlers. Machines 2023, 11, 216. [Google Scholar] [CrossRef]

- Jiskani, I.M.; Cai, Q.; Zhou, W.; Shah, S.A.A. Green and climate-smart mining: A framework to analyze open-pit mines for cleaner mineral production. Resour. Policy 2021, 71, 102007. [Google Scholar]

- Dagdelen, K. Open pit optimization-strategies for improving economics of mining projects through mine planning. In Proceedings of the 17th International Mining Congress and Exhibition of Turkey, Ankara, Turkey, 19–22 June 2001; Volume 117, p. 121. [Google Scholar]

- Wang, Q.; Gu, Q.; Li, X.; Xiong, N. Comprehensive overview: Fleet management drives green and climate-smart open pit mine. Renew. Sustain. Energy Rev. 2024, 189, 113942. [Google Scholar] [CrossRef]

- Noriega, R.; Pourrahimian, Y. A systematic review of artificial intelligence and data-driven approaches in strategic open-pit mine planning. Resour. Policy 2022, 77, 102727. [Google Scholar] [CrossRef]

- Moon, C.; Whateley, M.; Evans, A. Introduction to Mineral Exploration; Blackwell Publishing: Hoboken, NJ, USA, 2005. [Google Scholar]

- Xu, Y.N. Investigation and research on the mine geological environment: Present status and outlook. Geol. Bull. China 2008, 27, 1235–1244. [Google Scholar]

- Oldenburg, D.W.; Pratt, D.A. Geophysical inversion for mineral exploration: A decade of progress in theory and practice. In Proceedings of the Exploration, Toronto, ON, Canada, 9–12 September 2007; Volume 7, pp. 61–95. [Google Scholar]

- Govett, G.J.S. (Ed.) Rock Geochemistry in Mineral Exploration; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Chen, Y.; Wu, W. Mapping mineral prospectivity using an extreme learning machine regression. Ore Geol. Rev. 2017, 80, 200–213. [Google Scholar] [CrossRef]

- Xiong, Y.; Zuo, R.; Carranza, E.J.M. Mapping mineral prospectivity through big data analytics and a deep learning algorithm. Ore Geol. Rev. 2018, 102, 811–817. [Google Scholar] [CrossRef]

- Zuo, R.; Xiong, Y.; Wang, Z.; Wang, J.; Kreuzer, O.P. A new generation of artificial intelligence algorithms for mineral prospectivity mapping. Nat. Resour. Res. 2023, 32, 1859–1869. [Google Scholar] [CrossRef]

- Xiong, Y.; Zuo, R. Recognition of geochemical anomalies using a deep autoencoder network. Comput. Geosci. 2016, 86, 75–82. [Google Scholar] [CrossRef]

- Liu, Y.P.; Zhu, L.X.; Zhou, Y.Z. Application of Convolutional Neural Network in prospecting prediction of ore deposits: Taking the Zhaojikou Pb-Zn ore deposit in Anhui Province as a case. Acta Petrol. Sin. 2018, 34, 3217–3224. [Google Scholar]

- Wu, B.; Li, X.; Yuan, F.; Li, H.; Zhang, M. Transfer learning and siamese neural network based identification of geochemical anomalies for mineral exploration: A case study from the CuAu deposit in the NW Junggar area of northern Xinjiang Province, China. J. Geochem. Explor. 2022, 232, 106904. [Google Scholar] [CrossRef]

- Zuo, R.; Xu, Y. Graph deep learning model for mapping mineral prospectivity. Math. Geosci. 2023, 55, 1–21. [Google Scholar] [CrossRef]

- Shi, L.; Xu, Y.; Zuo, R. A Heterogeneous Graph Construction Method for Mineral Prospectivity Mapping. Nat. Resour. Res. 2024, 33, 1365–1376. [Google Scholar] [CrossRef]

- Xiao, D.; Vu, Q.H.; Le, B.T.; Ha, T.T.L. A method for mapping and monitoring of iron ore stopes based on hyperspectral remote sensing-ground data and a 3D deep neural network. Neural Comput. Appl. 2023, 35, 12221–12232. [Google Scholar] [CrossRef]

- Li, J.G.; Zhan, K. Intelligent mining technology for an underground metal mine based on unmanned equipment. Engineering 2018, 4, 381–391. [Google Scholar] [CrossRef]

- Xu, S.; Li, Y.; Liu, J.; Zhang, F. Optimization of blasting parameters for an underground mine through prediction of blasting vibration. J. Vib. Control 2019, 25, 1585–1595. [Google Scholar]

- Bui, X.N.; Bui, H.B.; Nguyen, H. A review of artificial intelligence applications in mining and geological engineering. In Proceedings of the International Conference on Innovations for Sustainable and Responsible Mining, ISRM 2020, Hanoi, Vietnam, 15–17 October 2020; Springer International Publishing: Cham, Switzerland, 2021; Volume 1, pp. 109–142. [Google Scholar]

- Nikkhah, A.; Vakylabad, A.B.; Hassanzadeh, A.; Niedoba, T.; Surowiak, A. An evaluation on the impact of ore fragmented by blasting on mining performance. Minerals 2022, 12, 258. [Google Scholar] [CrossRef]

- Cai, M.; Li, P.; Tan, W.; Ren, F. Key engineering technologies to achieve green, intelligent, and sustainable development of deep metal mines in China. Engineering 2021, 7, 1513–1517. [Google Scholar]

- Du, Y.; Zhang, H.; Liang, L.; Zhang, J.; Song, B. Applications of machine vision in coal mine fully mechanized tunneling faces: A review. IEEE Access 2023, 11, 102871–102898. [Google Scholar]

- Valencia, J.; Emami, E.; Battulwar, R.; Jha, A.; Gomez, J.A.; Moniri-Morad, A.; Sattarvand, J. Blasthole Location Detection Using Support Vector Machine and Convolutional Neural Networks on UAV Images and Photogrammetry Models. Electronics 2024, 13, 1291. [Google Scholar] [CrossRef]

- Guo, A.; Li, H.; Zuo, Z.; Zhang, Q. Research on Borehole Identification Under Tunnel Blasting Based on YOLOv5. In Proceedings of the 2024 8th International Conference on Robotics, Control and Automation (ICRCA), Shanghai, China, 12–14 January 2024; pp. 395–399. [Google Scholar]

- Jin, C.; Liang, J.; Fan, C.; Chen, L.; Wang, Q.; Lu, Y.; Wang, K. Study on segmentation of blasting fragment images from open-pit mine based on U-CARFnet. PLoS ONE 2023, 18, e0291115. [Google Scholar]

- Yang, Z.; Wu, H.; Ding, H.; Liang, J.; Guo, L. Enhanced U-Net model for rock pile segmentation and particle size analysis. Miner. Eng. 2023, 203, 108352. [Google Scholar]

- He, P.; Xu, Y.; Jiang, F.; Wang, G.; Xiao, Z.; Zheng, C. A rapid evaluation method of blasting effect based on optimized image segmentation algorithm and application in engineering. Sci. Rep. 2024, 14, 4783. [Google Scholar]

- Bahraini, M.S.; Atighi, I. A novel intelligent stereo vision approach for blast-induced fragmentation size distribution: Case study at Golgohar open-pit mine, Iran. Miner. Eng. 2024, 215, 108822. [Google Scholar]

- Vu, T.; Bao, T.; Hoang, Q.V.; Drebenstetd, C.; Hoa, P.V.; Thang, H.H. Measuring blast fragmentation at Nui Phao open-pit mine, Vietnam using the Mask R-CNN deep learning model. Min. Technol. 2021, 130, 232–243. [Google Scholar]

- Zolotukhin, V. Application of the ecological closed transport systems in mining industry. Int. Multidiscip. Sci. GeoConf. SGEM 2019, 19, 57–64. [Google Scholar]

- Krol, R.; Kawalec, W.; Gladysiewicz, L. An effective belt conveyor for underground ore transportation systems. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042047. [Google Scholar]

- Gong, X.; Zhao, M.; Wu, Y.; Qin, S. Study on Fuzzy Comprehensive Evaluation Model for the Safety of Mine Belt Conveyor. MATEC Web Conf. 2017, 136, 02001. [Google Scholar]

- He, G.; Yu, B.; Li, S.; Zhu, Y. Comprehensive evaluation of ecological security in mining area based on PSR–ANP–GRAY. Environ. Technol. 2018, 39, 3013–3019. [Google Scholar] [PubMed]

- Gao, R.; Miao, C.; Li, X. Adaptive multi-view image mosaic method for conveyor belt surface fault online detection. Appl. Sci. 2021, 11, 2564. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, Q.; Yin, Y.; Fan, Y.; Su, Z.; Zhang, S. Damage detection method of mining conveyor belt based on deep learning. IEEE Sens. J. 2022, 22, 10870–10879. [Google Scholar]

- Zhang, M.; Sun, N.; Zhang, Y.; Zhou, M.; Shen, Y.; Shi, H. A centernet-based direct detection method for mining conveyer belt damage. J. Ambient. Intell. Humaniz. Comput. 2023, 14, 4477–4487. [Google Scholar]

- Wang, G.; Liu, Z.; Zhang, L.; Xiang, L.; Sun, H. Machine vision-based conveyor belt tear detection in a harsh environment. Meas. Sci. Technol. 2022, 33, 084006. [Google Scholar]

- Wu, X.; Wang, C.; Tian, Z.; Huang, X.; Wang, Q. Research on Belt Deviation Fault Detection Technology of Belt Conveyors Based on Machine Vision. Machines 2023, 11, 1039. [Google Scholar] [CrossRef]

- Zhang, M.; Shi, H.; Yu, Y.; Zhou, M. A computer vision based conveyor deviation detection system. Appl. Sci. 2020, 10, 2402. [Google Scholar] [CrossRef]

- Zhang, M.; Shi, H.; Zhang, Y.; Yu, Y.; Zhou, M. Deep learning-based damage detection of mining conveyor belt. Measurement 2021, 175, 109130. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, K.; Cao, Y.; Li, M.; Hao, N.; Zhang, Y. A deep learning-based method for deviation status detection in intelligent conveyor belt system. J. Clean. Prod. 2022, 363, 132575. [Google Scholar]

- Ni, Y.; Cheng, H.; Hou, Y.; Guo, P. Study of conveyor belt deviation detection based on improved YOLOv8 algorithm. Sci. Rep. 2024, 14, 26876. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zeng, M.; Dong, Y.; Rao, G.; Huang, X.; Mo, X. FastBeltNet: A dual-branch light-weight network for real-time conveyor belt edge detection. J. Real-Time Image Process. 2024, 21, 123. [Google Scholar]

- Zhang, M.; Cao, Y.; Jiang, K.; Li, M.; Liu, L.; Yu, Y.; Zhou, M.; Zhang, Y. Proactive measures to prevent conveyor belt Failures: Deep Learning-based faster foreign object detection. Eng. Fail. Anal. 2022, 141, 106653. [Google Scholar]

- Luo, B.; Kou, Z.; Han, C.; Wu, J.; Liu, S. A Faster and Lighter Detection Method for Foreign Objects in Coal Mine Belt Conveyors. Sensors 2023, 23, 6276. [Google Scholar] [CrossRef]

- Dai, L.; Zhang, X.; Gardoni, P.; Lu, H.; Liu, X.; Krolczyk, G.; Li, Z. A new machine vision detection method for identifying and screening out various large foreign objects on coal belt conveyor lines. Complex Intell. Syst. 2023, 9, 5221–5234. [Google Scholar]

- Zhang, M.; Jiang, K.; Cao, Y.; Li, M.; Wang, Q.; Li, D.; Zhang, Y. A new paradigm for intelligent status detection of belt conveyors based on deep learning. Measurement 2023, 213, 112735. [Google Scholar] [CrossRef]

- Laurence, D. Safety rules and regulations on mine sites–the problem and a solution. J. Saf. Res. 2005, 36, 39–50. [Google Scholar] [CrossRef]

- Lang, L.; Qi, H. The study of driver fatigue monitor algorithm combined PERCLOS and AECS. In Proceedings of the 2008 International Conference on Computer Science and Software Engineering, Wuhan, China, 12–14 December 2008; Volume 1, pp. 349–352. [Google Scholar]

- Chen, Y.; Lu, C.; Tian, S.; Gu, Q.; Jiang, S.; Li, X.; Zou, Y. Monitoring and detecting coal miners’ fatigue status using MPA-LSSVM in the vision of smart mine. Process Saf. Environ. Prot. 2023, 179, 774–783. [Google Scholar]

- Tian, F.; Chen, T.; Zhang, J. Research on improved Retinex-based image enhancement method for mine monitoring. Appl. Sci. 2023, 13, 2672. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, Z.; Geng, Z. Safety monitoring method of moving target in underground coal mine based on computer vision processing. Sci. Rep. 2022, 12, 17899. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Baek, J.; Choi, Y. Smart helmet-based personnel proximity warning system for improving underground mine safety. Appl. Sci. 2021, 11, 4342. [Google Scholar] [CrossRef]

- Yao, W.; Wang, A.; Nie, Y.; Lv, Z.; Nie, S.; Huang, C.; Liu, Z. Study on the recognition of coal miners’ unsafe behavior and status in the hoist cage based on machine vision. Sensors 2023, 23, 8794. [Google Scholar] [CrossRef]

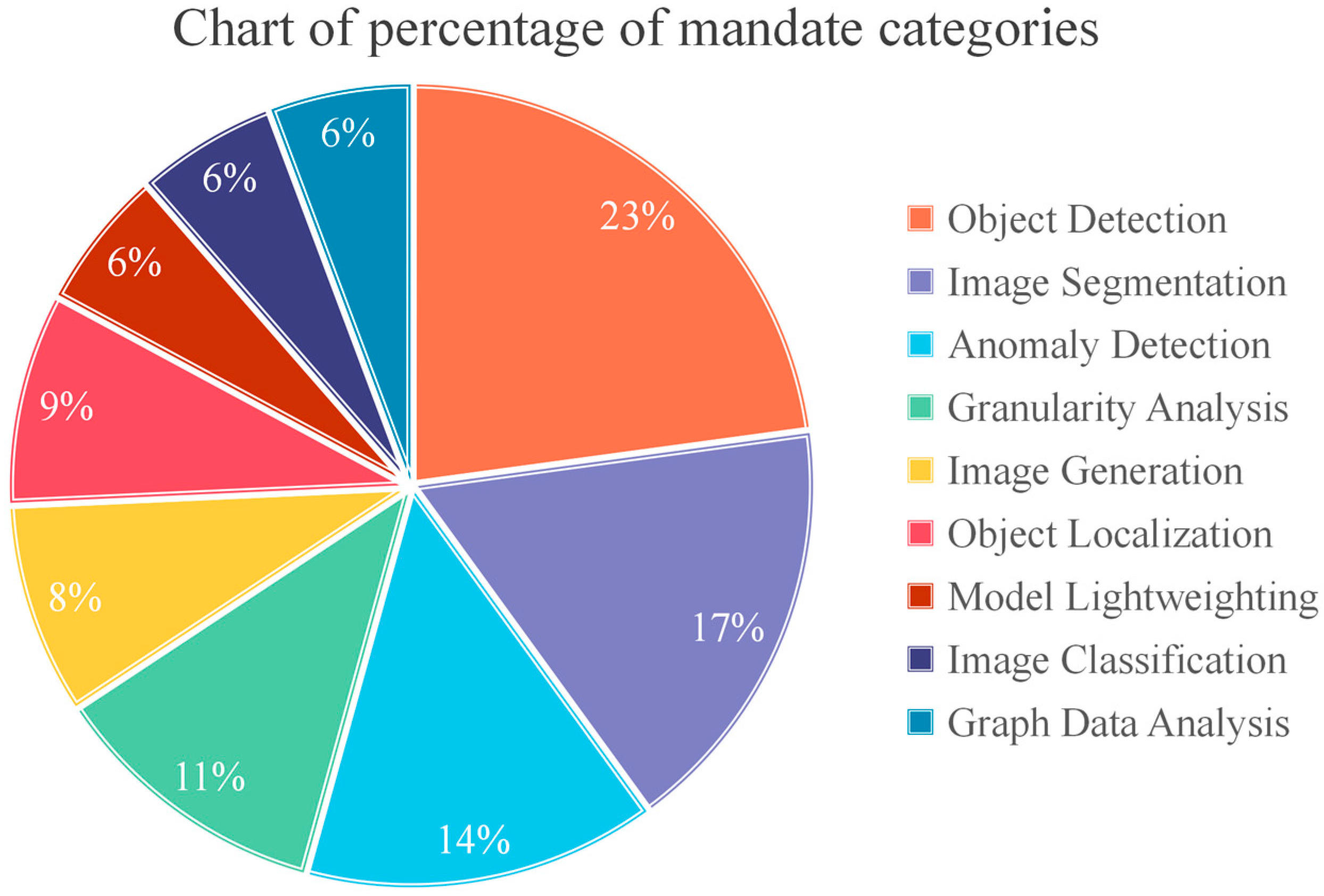

| Main Category | Quantity |

|---|---|

| Object Detection | 16 |

| Image Segmentation | 8 |

| Anomaly Detection | 6 |

| Granularity Analysis | 5 |

| Image Generation | 4 |

| Object Localization | 3 |

| Model Lightweighting | 3 |

| Image Classification | 2 |

| Graph Data Analysis | 2 |

| Image Stitching | 2 |

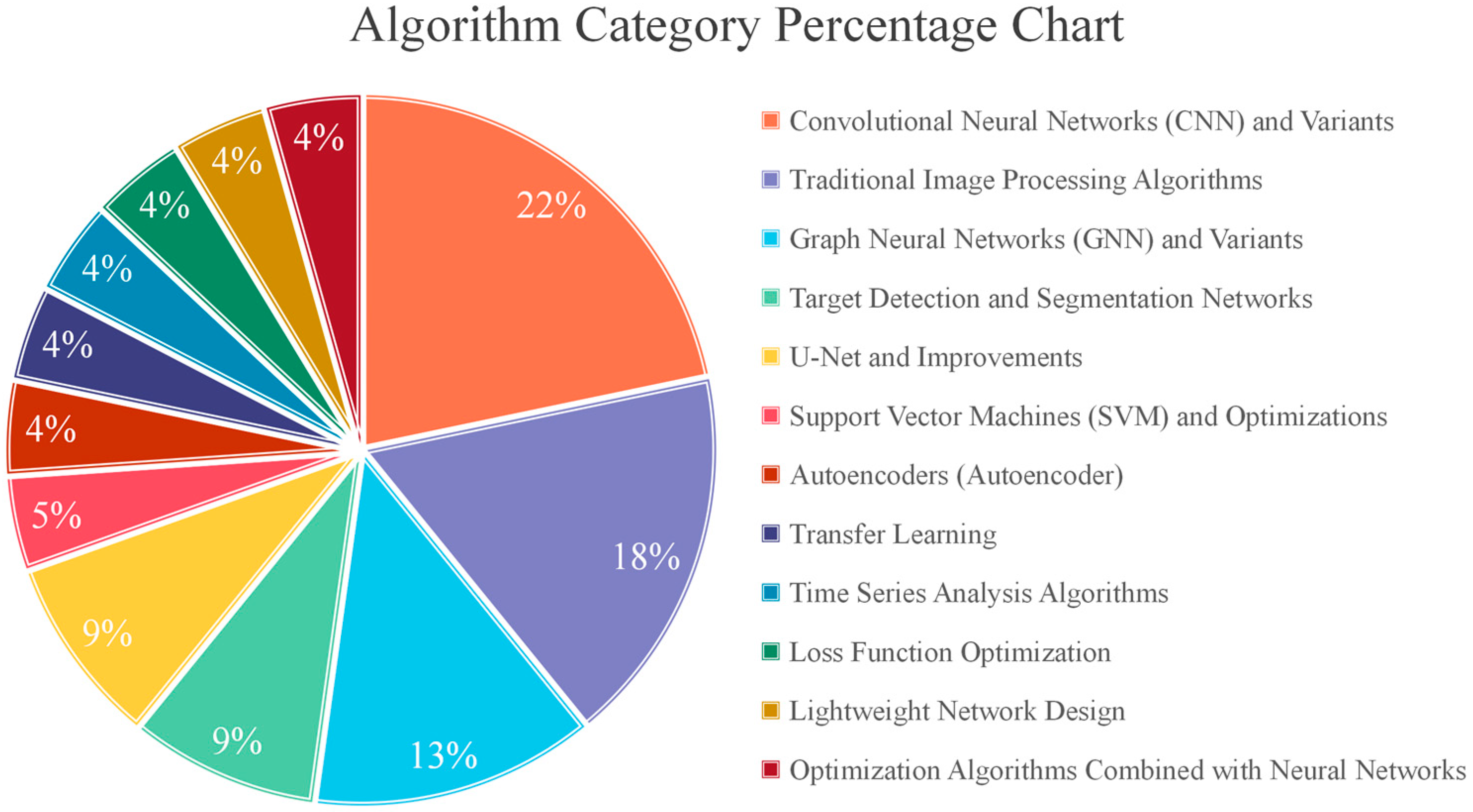

| Category | Quantity |

|---|---|

| Convolutional Neural Networks (CNN) and Variants | 17 |

| Traditional Image Processing Algorithms | 5 |

| Graph Neural Networks (GNN) and Variants | 4 |

| Target Detection and Segmentation Networks | 3 |

| U-Net and Improvements | 2 |

| Support Vector Machines (SVM) and Optimizations | 2 |

| Autoencoders (Autoencoder) | 1 |

| Transfer Learning | 1 |

| Time Series Analysis Algorithms | 1 |

| Loss Function Optimization | 1 |

| Lightweight Network Design | 1 |

| Optimization Algorithms Combined with Neural Networks | 1 |

| Image Enhancement Algorithms | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, D.; Qu, F.; Wang, Z.; Ji, Y.; Xu, J. A Review of the Application of Computer Vision Techniques in Sustainable Engineering of Open Pit Mines. Sustainability 2025, 17, 3051. https://doi.org/10.3390/su17073051

Shan D, Qu F, Wang Z, Ji Y, Xu J. A Review of the Application of Computer Vision Techniques in Sustainable Engineering of Open Pit Mines. Sustainability. 2025; 17(7):3051. https://doi.org/10.3390/su17073051

Chicago/Turabian StyleShan, Di, Fuming Qu, Zheng Wang, Yaming Ji, and Jianwei Xu. 2025. "A Review of the Application of Computer Vision Techniques in Sustainable Engineering of Open Pit Mines" Sustainability 17, no. 7: 3051. https://doi.org/10.3390/su17073051

APA StyleShan, D., Qu, F., Wang, Z., Ji, Y., & Xu, J. (2025). A Review of the Application of Computer Vision Techniques in Sustainable Engineering of Open Pit Mines. Sustainability, 17(7), 3051. https://doi.org/10.3390/su17073051