Technologies Applied to Artificial Lighting in Indoor Agriculture: A Review

Abstract

1. Introduction

1.1. The Interest in Advancing Indoor Agriculture

1.2. Challenges of Indoor Agriculture

1.3. Essential Conditions of Indoor Agriculture

1.3.1. Efficient Use of Space

1.3.2. Light Optimization

1.3.3. Water Conservation

1.3.4. Automation and Mechanization

1.3.5. Precise Control and Adjustment of Growing Parameters

1.4. Artificial Light in Indoor Agriculture

2. Materials and Methods

2.1. Literature Search

- What lighting devices, as well as software, programs, or methods, are mostly used and manipulated in indoor agriculture?

- What are the trends and challenges in the technological applications of lighting in indoor agriculture?

2.2. Search Keywords

- Terms for indoor agriculture: Only the term “Agriculture” was used, as its combination with the other groups covered terms such as vertical farming, indoor agriculture, CEA, and plant factories, among others.

- Terms for artificial lighting: The key terms included “Light efficiency”, “Light spectra”, “Light-emitting diode lighting” combined with its acronym “LED”, “Light intensity”, and “Light”.

- Terms for technology: The terms used were “Artificial intelligence” combined with its acronym “AI”, “Internet of Things” combined with “IoT”, “Sensor”, and “Automation”.

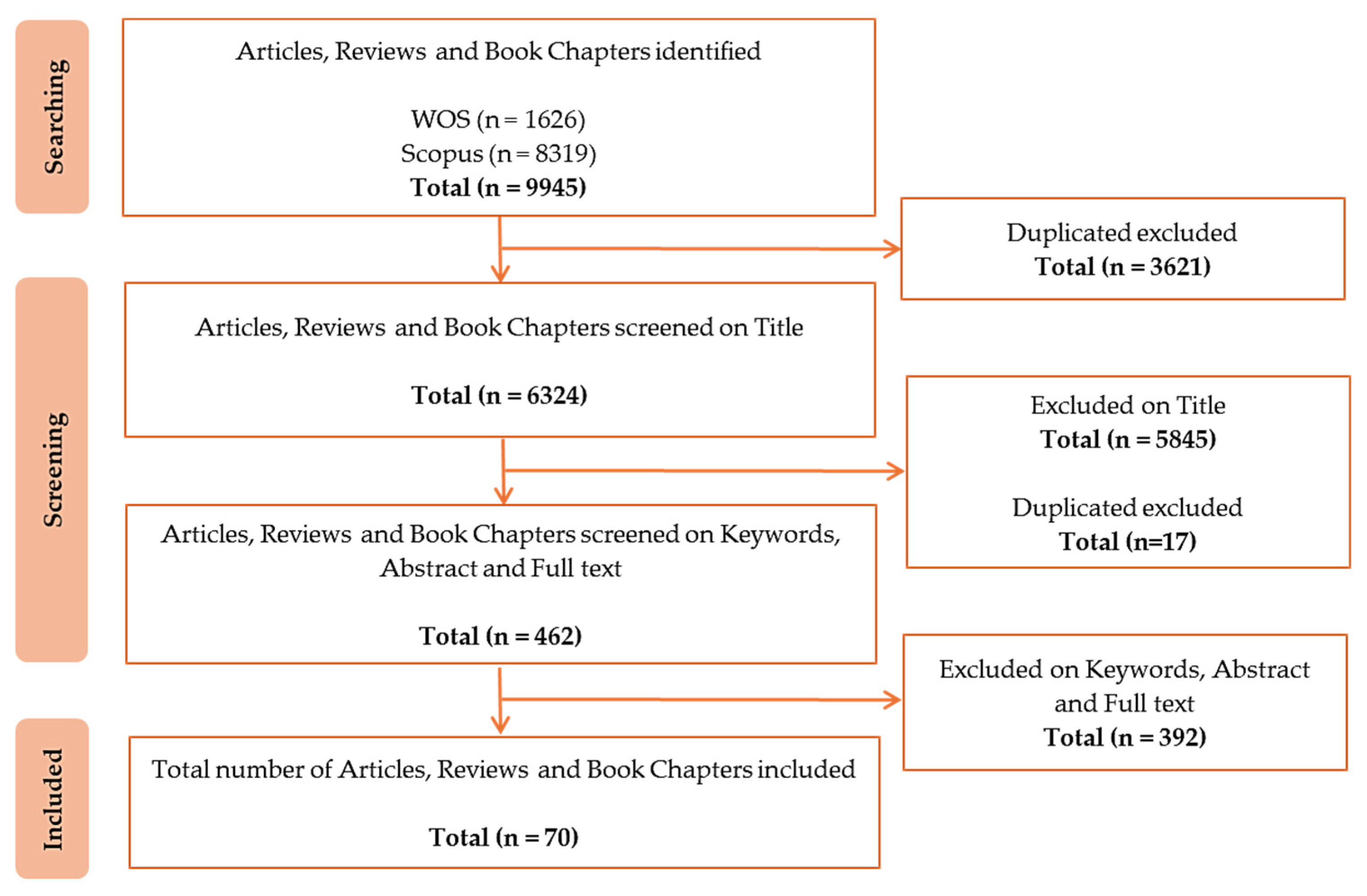

2.3. Screening and Selection Stage

3. Results

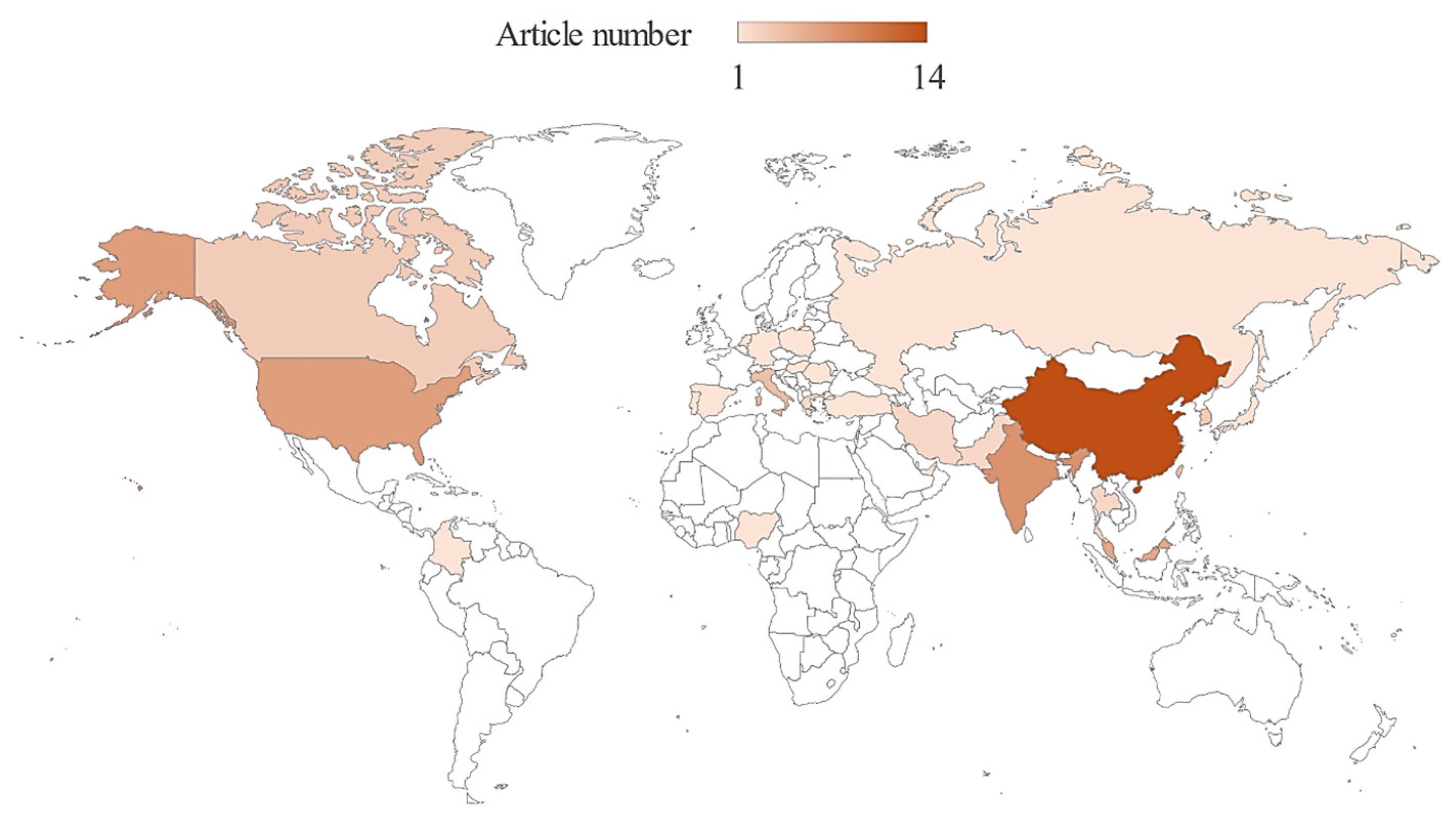

3.1. Literature Analysis

3.2. Technologies Used in Indoor Artificial Lighting of Plants

4. Discussion

4.1. Purposes and Applications of Indoor Artificial Lighting Technology

4.2. Primary Devices and Software, Program or Method System Used in Lighting Indoor Agriculture

4.3. Challenges, Future Research, and Trends in Artificial Lighting for Indoor

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dsouza, A.; Newman, L.; Graham, T.; Fraser, E.D.G. Exploring the Landscape of Controlled Environment Agriculture Research: A Systematic Scoping Review of Trends and Topics. Agric. Syst. 2023, 209, 103673. [Google Scholar] [CrossRef]

- Gómez, C.; Currey, C.J.; Dickson, R.W.; Kim, H.-J.; Hernández, R.; Sabeh, N.C.; Raudales, R.E.; Brumfield, R.G.; Laury-Shaw, A.; Wilke, A.K.; et al. Controlled Environment Food Production for Urban Agriculture. HortScience 2019, 54, 1448–1458. [Google Scholar] [CrossRef]

- Jensen, M.H. Controlled Environment Agriculture in Deserts, Tropics and Temperate Regions—A World Review. Acta Hortic. 2002, 578, 19–25. [Google Scholar]

- Mempel, H.; Jüttner, I.; Wittmann, S. The Potentials of Indoor Farming for Plant Production. at-Automatisierungstechnik 2021, 69, 287–296. [Google Scholar] [CrossRef]

- Ampim, P.A.Y.; Obeng, E.; Olvera-Gonzalez, E. Indoor Vegetable Production: An Alternative Approach to Increasing Cultivation. Plants 2022, 11, 2843. [Google Scholar] [CrossRef]

- Hamadani, H.; Rashid, S.M.; Parrah, J.D.; Khan, A.A.; Dar, K.A.; Ganie, A.A.; Gazal, A.; Dar, R.A.; Ali, A. Traditional Farming Practices and Its Consequences. In Microbiota and Biofertilizers, Vol 2: Ecofriendly Tools for Reclamation of Degraded Soil Environs; Dar, G.H., Bhat, R.A., Mehmood, M.A., Hakeem, K.R., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 119–128. ISBN 978-3-030-61010-4. [Google Scholar]

- Vatistas, C.; Avgoustaki, D.D.; Bartzanas, T. A Systematic Literature Review on Controlled-Environment Agriculture: How Vertical Farms and Greenhouses Can Influence the Sustainability and Footprint of Urban Microclimate with Local Food Production. Atmosphere 2022, 13, 1258. [Google Scholar] [CrossRef]

- Stein, E.W. The Transformative Environmental Effects Large-Scale Indoor Farming May Have on Air, Water, and Soil. Air Soil Water Res. 2021, 14, 1178622121995819. [Google Scholar] [CrossRef]

- Benke, K.; Tomkins, B. Future Food-Production Systems: Vertical Farming and Controlled-Environment Agriculture. Sustain. Sci. Pract. Policy 2017, 13, 13–26. [Google Scholar] [CrossRef]

- de Sousa, R.; Bragança, L.; da Silva, M.V.; Oliveira, R.S. Challenges and Solutions for Sustainable Food Systems: The Potential of Home Hydroponics. Sustainability 2024, 16, 817. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Sultan, M.; Shamshiri, R.R.; Rahman, M.M.; Aleem, M.; Balasundram, S.K. Present Status and Challenges of Fodder Production in Controlled Environments: A Review. Smart Agric. Technol. 2023, 3, 100080. [Google Scholar] [CrossRef]

- Pomoni, D.I.; Koukou, M.K.; Vrachopoulos, M.G.; Vasiliadis, L. A Review of Hydroponics and Conventional Agriculture Based on Energy and Water Consumption, Environmental Impact, and Land Use. Energies 2023, 16, 1690. [Google Scholar] [CrossRef]

- Shrouf, A. Hydroponics, Aeroponic and Aquaponic as Compared with Conventional Farming. Am. Sci. Res. J. Eng. Technol. Sci. 2017, 27, 247–255. [Google Scholar]

- Dsouza, A.; Price, G.W.; Dixon, M.; Graham, T. A Conceptual Framework for Incorporation of Composting in Closed-Loop Urban Controlled Environment Agriculture. Sustainability 2021, 13, 2471. [Google Scholar] [CrossRef]

- Tomatis, F.; Egerer, M.; Correa-Guimaraes, A.; Navas-Gracia, L. Urban Gardening in a Changing Climate: A Review of Effects, Responses and Adaptation Capacities for Cities. Agriculture 2023, 13, 502. [Google Scholar] [CrossRef]

- Avgoustaki, D.D.; Xydis, G. How Energy Innovation in Indoor Vertical Farming Can Improve Food Security, Sustainability, and Food Safety? Adv. Food Secur. Sustain. 2020, 5, 1–51. [Google Scholar] [CrossRef]

- Garcia, A.L.; Griffith, M.A.C.; Buss, G.P.; Yang, X.; Griffis, J.L.; Bauer, S.; Singh, A.K. Controlled Environment Agriculture and Its Ability to Mitigate Food Insecurity. Agric. Sci. 2023, 14, 298–315. [Google Scholar] [CrossRef]

- Hati, A.J.; Singh, R.R. Smart Indoor Farms: Leveraging Technological Advancements to Power a Sustainable Agricultural Revolution. AgriEngineering 2021, 3, 728–767. [Google Scholar] [CrossRef]

- Coon, D.; Lindow, L.; Boz, Z.; Martin-Ryals, A.; Zhang, Y.; Correll, M. Reporting and Practices of Sustainability in Controlled Environment Agriculture: A Scoping Review. Environ. Syst. Decis. 2024, 44, 301–326. [Google Scholar] [CrossRef]

- Shamshiri, R.; Kalantari, F.; Ting, K.C.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z.M. Advances in Greenhouse Automation and Controlled Environment Agriculture: A Transition to Plant Factories and Urban Agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–22. [Google Scholar] [CrossRef]

- Ojo, M.O.; Zahid, A. Deep Learning in Controlled Environment Agriculture: A Review of Recent Advancements, Challenges and Prospects. Sensors 2022, 22, 7965. [Google Scholar] [CrossRef]

- Rathee, M.; Dalal, P.K.; Mehra, S. Integrated Pest Management under Protected Cultivation: A Review. J. Entomol. Zool. Stud. 2018, 6, 1201–1208. [Google Scholar]

- Langenfeld, N.J.; Pinto, D.F.; Faust, J.E.; Heins, R.; Bugbee, B. Principles of Nutrient and Water Management for Indoor Agriculture. Sustainability 2022, 14, 10204. [Google Scholar] [CrossRef]

- Son, J.E.; Kim, H.J.; Ahn, T.I. Hydroponic Systems. In Plant Factory, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 273–283. ISBN 978-0-12-816691-8. [Google Scholar]

- Lozano-Castellanos, L.; Gracia, L.M.; Lozano Castellanos, I.; Correa-Guimaraes, A. Structural Challenges and Solutions to Improve Indoor Agriculture. In Proceedings of the VI Ibero-American Congress of Smart Cities (ICSC-CITIES 2023), Mexico City, Mexico, 13–17 November 2023. [Google Scholar]

- de Souza, S.V.; Shasteen, K.C.; Seong, J.; Kubota, C.; Kacira, M.; Peterson, H.C. Production Planning in an Indoor Farm: Using Time and Space Requirements to Define an Efficient Production Schedule and Farm Size. Int. Food Agribus. Manag. Rev. 2024, 27, 237–255. [Google Scholar] [CrossRef]

- Kratzer, D.A.; Ellis, E.V. Farmworks: Building as a Machine for Growing Food. In Proceedings of the 2020 AIA/ACSA Intersections Research Conference: CARBON, Virtual, 30 September–3 October 2020. [Google Scholar]

- Lozano-Castellanos, L.F.; Navas-Gracia, L.M.; Correa-Guimaraes, A. Light Energy Efficiency in Lettuce Crop: Structural Indoor Designs Simulation. Plants 2023, 12, 3456. [Google Scholar] [CrossRef]

- Specht, K.; Siebert, R.; Hartmann, I.; Freisinger, U.B.; Sawicka, M.; Werner, A.; Thomaier, S.; Henckel, D.; Walk, H.; Dierich, A. Urban Agriculture of the Future: An Overview of Sustainability Aspects of Food Production in and on Buildings. Agric. Hum. Values 2014, 31, 33–51. [Google Scholar] [CrossRef]

- Despommier, D. Vertical Farms, Building a Viable Indoor Farming Model for Cities. Field Actions Sci. Rep. J. Field Actions 2019, 20, 68–73. [Google Scholar]

- Nájera, C.; Gallegos-Cedillo, V.M.; Ros, M.; Pascual, J.A. Role of Spectrum-Light on Productivity, and Plant Quality over Vertical Farming Systems: Bibliometric Analysis. Horticulturae 2023, 9, 63. [Google Scholar] [CrossRef]

- Lozano-Castellanos, L.; Sánchez-Hernández, E.; Correa-Guimaraes, A.; Gracia, L.M.; Martín-Gil, J.; Martin-Ramos, P. Efectos de Diversos Tipos de Luz Artificial Sobre Los Fitoquímicos de Lactuca sativa L. Var. Great Lakes 118. In XII Congreso Ibérico de Agroingeniería.: Libro de Actas; Escuela Tecnica Superior en Ingeniería Agronómica: Valencia, Spain, 2023. [Google Scholar]

- Frutos-Totosa, A.; Hernández-Adasme, C.; Martínez, V.; Mestre, T.; Díaz-Mula, H.M.; Botella, M.A.; Flores, P.; Martínez-Moreno, A. Light Spectrum Effects on Rocket and Lamb’s Lettuce Cultivated in a Vertical Indoor Farming System. Sci. Hortic. 2023, 321, 112221. [Google Scholar] [CrossRef]

- van Iersel, M.W. Optimizing LED Lighting in Controlled Environment Agriculture. In Light Emitting Diodes for Agriculture: Smart Lighting; Dutta Gupta, S., Ed.; Springer: Singapore, 2017; pp. 59–80. ISBN 978-981-10-5807-3. [Google Scholar]

- Niu, Y.; Lyu, H.; Liu, X.; Zhang, M.; Li, H. Photosynthesis Prediction and Light Spectra Optimization of Greenhouse Tomato Based on Response of Red–Blue Ratio. Sci. Hortic. 2023, 318, 112065. [Google Scholar] [CrossRef]

- Dutta Gupta, S.; Agarwal, A. Artificial Lighting System for Plant Growth and Development: Chronological Advancement, Working Principles, and Comparative Assessment. In Light Emitting Diodes for Agriculture: Smart Lighting; Dutta Gupta, S., Ed.; Springer: Singapore, 2017; pp. 1–25. ISBN 978-981-10-5807-3. [Google Scholar]

- Engler, N.; Krarti, M. Review of Energy Efficiency in Controlled Environment Agriculture. Renew. Sustain. Energy Rev. 2021, 141, 110786. [Google Scholar] [CrossRef]

- Neo, D.C.J.; Ong, M.M.X.; Lee, Y.Y.; Teo, E.J.; Ong, Q.; Tanoto, H.; Xu, J.; Ong, K.S.; Suresh, V. Shaping and Tuning Lighting Conditions in Controlled Environment Agriculture: A Review. ACS Agric. Sci. Technol. 2022, 2, 3–16. [Google Scholar] [CrossRef]

- Hadj Abdelkader, O.; Bouzebiba, H.; Pena, D.; Aguiar, A.P. Energy-Efficient IoT-Based Light Control System in Smart Indoor Agriculture. Sensors 2023, 23, 7670. [Google Scholar] [CrossRef] [PubMed]

- Cocetta, G.; Casciani, D.; Bulgari, R.; Musante, F.; Kołton, A.; Rossi, M.; Ferrante, A. Light Use Efficiency for Vegetables Production in Protected and Indoor Environments. Eur. Phys. J. Plus 2017, 132, 43. [Google Scholar] [CrossRef]

- de Castro Silva, M.G.; Hüther, C.M.; Ramos, B.B.; da Silva Araújo, P.; da Silva Hamacher, L.; Pereira, C.R. AA Global Overview of Hydroponics: Nutrient Film Technique. Rev. Eng. Agric. 2021, 29, 138–145. [Google Scholar] [CrossRef]

- Rani, R.S.; Kumar, H.V.H.; Mani, A.; Reddy, B.S.; Rao, C.S. Soilless Cultivation Technique, Hydroponics—A Review. Curr. J. Appl. Sci. Technol. 2022, 41, 22–30. [Google Scholar] [CrossRef]

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153. [Google Scholar] [CrossRef]

- Edan, Y.; Han, S.; Kondo, N. Automation in Agriculture. In Springer Handbook of Automation; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1095–1128. [Google Scholar]

- Subeesh, A.; Mehta, C.R. Automation and Digitization of Agriculture Using Artificial Intelligence and Internet of Things. Artif. Intell. Agric. 2021, 5, 278–291. [Google Scholar] [CrossRef]

- Kumar, S.; Bairwa, D.S.; Kumar, K.; Yadav, R.K.; Yadav, L.P. Climate Regulation in Protected Structures: A Review. J. Agric. Ecol. 2022, 13, 20–34. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Sultan, M.; Monfet, D.; Rahman, M.S.; Zhang, Y.; Zahid, A.; Bilal, M.; Ahsan, T.M.A.; Achour, Y. A Critical Review on Efficient Thermal Environment Controls in Indoor Vertical Farming. J. Clean. Prod. 2023, 425, 138923. [Google Scholar] [CrossRef]

- Eldridge, B.M.; Manzoni, L.R.; Graham, C.A.; Rodgers, B.; Farmer, J.R.; Dodd, A.N. Getting to the Roots of Aeroponic Indoor Farming. New Phytol. 2020, 228, 1183–1192. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Ahamed, T. Artificial Lighting Systems for Plant Growth and Development in Indoor Farming. In IoT and AI in Agriculture: Self-Sufficiency in Food Production to Achieve Society 5.0 and SDG’s Globally; Springer: Singapore, 2023. [Google Scholar]

- Mitchell, C.A.; Sheibani, F. LED Advancements for Plant-Factory Artificial Lighting. In Plant Factory, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 167–184. ISBN 978-0-12-816691-8. [Google Scholar]

- Bernardo, M.; Fajardo, A.; Medina, R. End-Product of Solar-Sharing Smart Lighting Artificial Intelligence Driven Platform for High-Valued Crops (Lactuca sativa) on Indoor Hydroponics Syste. In Proceedings of the 2022 IEEE 10th Conference on Systems, Process & Control (ICSPC), Malacca, Malaysia, 17 December 2022; pp. 160–165. [Google Scholar]

- Salah Uddin, M.; Asaduzzaman, M.; Farzana, R.; Samaun Hasan, M.; Rahman, M.; Allayear, S.M. Implementation of Smart Indoor Agriculture System and Predictive Analysis. In Advances in Computing and Data Sciences: Third International Conference, ICACDS 2019, Ghaziabad, India, 12–13 April 2019, Revised Selected Papers, Part I 3; Springer: Singapore, 2019. [Google Scholar]

- Kozai, T. Why LED Lighting for Urban Agriculture? Springer: Singapore, 2016. [Google Scholar]

- Bugbee, B. Economics of LED Lighting. In Light Emitting Diodes for Agriculture: Smart Lighting; Springer: Singapore, 2017; pp. 81–99. ISBN 978-981-10-5806-6. [Google Scholar]

- Cooper, H. Research Synthesis and Meta-Analysis: A Step-by-Step Approach; Sage Publications: Thousand Oaks, CA, USA, 2017; ISBN 978-1-4833-3115-7. [Google Scholar]

- Wielgat, R.; Ko£odziej, A.; Candela, L.; Lisowska-Lis, A.; Jasielski, J.; Chlastawa, Ł.; Touhami, M.; Jaramillo, A.M.F. A Concept of Smart Agro-Photovoltaic Tunnels. IEEE Access 2024, 12, 40765–40794. [Google Scholar] [CrossRef]

- Mengi, E.; Becker, C.J.; Sedky, M.; Yu, S.-Y.; Zohdi, T.I. A Digital-Twin and Rapid Optimization Framework for Optical Design of Indoor Farming Systems. Comput. Mech. 2024, 74, 31–43. [Google Scholar] [CrossRef]

- Pu, L.; Li, Y.; Gao, P.; Zhang, H.; Hu, J. A Photosynthetic Rate Prediction Model Using Improved RBF Neural Network. Sci. Rep. 2022, 12, 9563. [Google Scholar] [CrossRef] [PubMed]

- Ghiasi, M.; Wang, Z.; Mehrandezh, M.; Paranjape, R. A Systematic Review of Optimal and Practical Methods in Design, Construction, Control, Energy Management and Operation of Smart Greenhouses. IEEE Access 2024, 12, 2830–2853. [Google Scholar] [CrossRef]

- D Stevens, J.; Murray, D.; Diepeveen, D.; Toohey, D. Adaptalight: An Inexpensive PAR Sensor System for Daylight Harvesting in a Micro Indoor Smart Hydroponic System. Horticulturae 2022, 8, 105. [Google Scholar] [CrossRef]

- Hu, G.; You, F. AI-Enabled Cyber-Physical-Biological Systems for Smart Energy Management and Sustainable Food Production in a Plant Factory. Appl. Energy 2024, 356, 122334. [Google Scholar] [CrossRef]

- Hatzopoulos, A.T.; Tsiakmakis, K.; Delimaras, V.; Stoupas, F.T.; Vassios, V.D.; Papadopoulou, M.S. Automated Controlled Chamber for Measuring Plant Growth. Int. Rev. Electr. Eng. 2023, 18, 252. [Google Scholar] [CrossRef]

- Zhou, D.-F. Automated Plant Light Replenishment Control Based Population Intelligence Algorithms in Agricultural Iot Environment. J. Netw. Intell. 2023, 8, 1426–1439. [Google Scholar]

- Cappelli, I.; Fort, A.; Pozzebon, A.; Tani, M.; Trivellin, N.; Vignoli, V.; Bruzzi, M. Autonomous IoT Monitoring Matching Spectral Artificial Light Manipulation for Horticulture. Sensors 2022, 22, 4046. [Google Scholar] [CrossRef]

- Kaur, G.; Upadhyaya, P.; Chawla, P. Comparative Analysis of IoT-Based Controlled Environment and Uncontrolled Environment Plant Growth Monitoring System for Hydroponic Indoor Vertical Farm. Environ. Res. 2023, 222, 115313. [Google Scholar] [CrossRef]

- Van Delden, S.H.; SharathKumar, M.; Butturini, M.; Graamans, L.J.A.; Heuvelink, E.; Kacira, M.; Kaiser, E.; Klamer, R.S.; Klerkx, L.; Kootstra, G.; et al. Current Status and Future Challenges in Implementing and Upscaling Vertical Farming Systems. Nat. Food 2021, 2, 944–956. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.-L.; Huang, C.-C.; Chen, H.-W. Design and Implementation of Artificial Intelligence of Things for Tea (Camellia sinensis L.) Grown in a Plant Factory. Agronomy 2022, 12, 2384. [Google Scholar] [CrossRef]

- Ku, H.-H.; Liu, C.-H.; Wang, W.-C. Design of an Artificial Intelligence of Things Based Indoor Planting Model for Mentha Spicata. Processes 2022, 10, 116. [Google Scholar] [CrossRef]

- Karim, K.N.A.; Razali, M.H.H.; Shamsi, S.M.; Masrek, M.N. Development of Intelligent System for Alert Notification in Indoor Planting. AETiC 2021, 5, 108–113. [Google Scholar] [CrossRef]

- Eo, Y.J.; Kim, S.; Oh, J.H.; Lee, K.N.; Kim, C.; Lee, S.M.; Do, Y.R. Development of PAR Sensor Applicable to Greenhouses and Smart Farms Using a Ripple-Free Red/Blue TiO2 /SiO2 Dual-Band Bandpass Filter. ACS Appl. Electron. Mater. 2022, 4, 6125–6132. [Google Scholar] [CrossRef]

- Alsayaydeh, J.A.J.; Yusof, M.F.; Magenthiran, M.S.; Hamzah, R.A.; Mustaffa, I.; Herawan, S.G. Empowering Crop Cultivation: Harnessing Internet of Things for Smart Agriculture Monitoring. Int. J. Electr. Comput. Eng. 2024, 14, 6023. [Google Scholar] [CrossRef]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy Efficient Operation and Modeling for Greenhouses: A Literature Review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Erekath, S.; Seidlitz, H.; Schreiner, M.; Dreyer, C. Food for Future: Exploring Cutting-Edge Technology and Practices in Vertical Farm. Sustain. Cities Soc. 2024, 106, 105357. [Google Scholar] [CrossRef]

- Bua, C.; Adami, D.; Giordano, S. GymHydro: An Innovative Modular Small-Scale Smart Agriculture System for Hydroponic Greenhouses. Electronics 2024, 13, 1366. [Google Scholar] [CrossRef]

- Amado, D.J.M.; Santamaria, L.M.; Charry, C.A.P. High Power LED Lighting System for the Precision Agriculture. ARPN J. Eng. Appl. Sci. 2020, 15, 2444–2450. [Google Scholar]

- Harun, A.N.; Mohamed, N.; Ahmad, R.; Rahim, A.R.A.; Ani, N.N. Improved Internet of Things (IoT) Monitoring System for Growth Optimization of Brassica Chinensis. Comput. Electron. Agric. 2019, 164, 104836. [Google Scholar] [CrossRef]

- Ng, H.T.; Tham, Z.K.; Abdul Rahim, N.A.; Rohim, A.W.; Looi, W.W.; Ahmad, N.S. IoT-Enabled System for Monitoring and Controlling Vertical Farming Operations. Int. J. Reconfig. Embed. Syst. 2023, 12, 453. [Google Scholar] [CrossRef]

- Rajendiran, G.; Rethnaraj, J. IoT-Integrated Machine Learning-Based Automated Precision Agriculture-Indoor Farming Techniques: In Advances in Media, Entertainment, and the Arts; Nguyen, T.V.T., Vo, N.T.M., Eds.; IGI Global: New York, NY, USA, 2024; pp. 289–317. ISBN 9798369306390. [Google Scholar]

- Jamal, J.; Azizi, S.; Abdollahpouri, A.; Ghaderi, N.; Sarabi, B.; Silva-Ordaz, A.; Castaño-Meneses, V.M. Monitoring Rocket (Eruca sativa) Growth Parameters Using the Internet of Things under Supplemental LEDs Lighting. Sens. Bio-Sens. Res. 2021, 34, 100450. [Google Scholar] [CrossRef]

- Harun, A.N.; Ahmad, R.; Mohamed, N.; Rahim, A.R.A.; Kaidi, H.M. Morphological and Physiological Responses of Brassica Chinensis on Different Far-Red (FR) Light Treatments Using Internet-of-Things (IoT) Technology. Agriculture 2021, 11, 728. [Google Scholar] [CrossRef]

- Theparod, T.; Harnsoongnoen, S. Narrow-Band Light-Emitting Diodes (LEDs) Effects on Sunflower (Helianthus annuus) Sprouts with Remote Monitoring and Recording by Internet of Things Device. Sensors 2022, 22, 1503. [Google Scholar] [CrossRef]

- Pimentel, J.; Balázs, L.; Friedler, F. Optimization of Vertical Farms Energy Efficiency via Multiperiodic Graph-Theoretical Approach. J. Clean. Prod. 2023, 416, 137938. [Google Scholar] [CrossRef]

- Zhao, X.; Peng, J.; Zhang, L.; Yang, X.; Qiu, Y.; Cai, C.; Hu, J.; Huang, T.; Liang, Y.; Li, Z.; et al. Optimizing the Quality of Horticultural Crop: Insights into Pre-Harvest Practices in Controlled Environment Agriculture. Front. Plant Sci. 2024, 15, 1427471. [Google Scholar] [CrossRef]

- Carotti, L.; Potente, G.; Pennisi, G.; Ruiz, K.B.; Biondi, S.; Crepaldi, A.; Orsini, F.; Gianquinto, G.; Antognoni, F. Pulsed LED Light: Exploring the Balance between Energy Use and Nutraceutical Properties in Indoor-Grown Lettuce. Agronomy 2021, 11, 1106. [Google Scholar] [CrossRef]

- Kim, K.-Y.; Huh, J.-H.; Ko, H.-J. Research on Crop Growing Factory: Focusing on Lighting and Environmental Control with Technological Proposal. Energies 2021, 14, 2624. [Google Scholar] [CrossRef]

- Hsu, H.H.; Zhang, X.; Xu, K.; Wang, Y.; Wang, Q.; Luo, G.; Xing, M.; Zhong, W. Self-Powered and Plant-Wearable Hydrogel as LED Power Supply and Sensor for Promoting and Monitoring Plant Growth in Smart Farming. Chem. Eng. J. 2021, 422, 129499. [Google Scholar] [CrossRef]

- Sung, W.-T.; Weng, C.-H.; Hsiao, S.-J. Smart Greenhouse Control via NB-IoT. Intell. Autom. Soft Comput. 2022, 34, 1971–1988. [Google Scholar] [CrossRef]

- Nirbita, P.; Chan, K.-Y.; How Thien, G.S.; Lee, C.-L. Smart Hydroponic Farming System Integrated with LED Grow Lights. Pertanika J. Sci. Technol. 2024, 32, 685–701. [Google Scholar] [CrossRef]

- Kuankid, S.; Aurasopon, A. The Effect of LED Lighting on Lettuce Growth in a Vertical IoT-Based Indoor Hydroponic System. Int. J. Online Biomed. Eng. 2022, 18, 70–84. [Google Scholar] [CrossRef]

- Han, B.; Yang, X.; Ren, J.; Liu, L.; Zhao, E.; Zhu, X.; Zhu, J.; Ma, H.; Li, A.; Teng, P. Thermally Stable Deep-Red Emitting Sr2GdTaO6:Mn4+ Double Perovskites for Indoor Plant Growth LEDs. Mater. Today Chem. 2022, 23, 100737. [Google Scholar] [CrossRef]

- Bantis, F.; Chatzigeorgiou, I.; Sismanis, M.; Ntinas, G.K.; Koukounaras, A. Vegetable Production in PFALs: Control of Micro-Environmental Factors, Principal Components and Automated Systems. Agriculture 2024, 14, 642. [Google Scholar] [CrossRef]

- Shamsi Roodbarsar, P.; Mousavi Seyedi, S.R.; Kalantari, D.; Ghasemi, K. Evaluation of the Effects of Artificial Light on Some Plant Characteristics in the Design and Construction of a Small-Scale Plant Factory. J. Agric. Mach. 2023, 13, 213–226. [Google Scholar] [CrossRef]

- Luo, K.; Chen, Y.; Lin, R.; Liang, C.; Zhang, Q. A Portable Agriculture Environmental Sensor with a Photovoltaic Power Supply and Dynamic Active Sleep Scheme. Electronics 2024, 13, 2606. [Google Scholar] [CrossRef]

- Vineela, V.; Bhavya, P.; Sandeep, B. Agricultural Crop Monitoring and Controlling Using IoT. Int. J. Eng. Adv. Technol. 2019, 8, 897–900. [Google Scholar] [CrossRef]

- Yajima, D.; Toyoda, T.; Kirimura, M.; Araki, K.; Ota, Y.; Nishioka, K. Agrivoltaic System: Estimation of Photosynthetic Photon Flux Density under Solar Panels Based on Solar Irradiation Data Using All-Climate Solar Spectrum Model. Clean. Eng. Technol. 2023, 12, 100594. [Google Scholar] [CrossRef]

- Chen, M.; Lee, T.-F.; Pan, J.-I. An Enhanced Lightweight Dynamic Pseudonym Identity Based Authentication and Key Agreement Scheme Using Wireless Sensor Networks for Agriculture Monitoring. Sensors 2019, 19, 1146. [Google Scholar] [CrossRef]

- Decardi-Nelson, B.; You, F. Artificial Intelligence Can Regulate Light and Climate Systems to Reduce Energy Use in Plant Factories and Support Sustainable Food Production. Nat. Food 2024, 5, 869–881. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Hua, S.; Lai, Q. Automatic Control System of Balancing Agricultural Stereo Cultivation Based on Wireless Sensors. IEEE Sens. J. 2021, 21, 17517–17524. [Google Scholar] [CrossRef]

- Mahajan, H.B.; Badarla, A.; Junnarkar, A.A. CL-IoT: Cross-Layer Internet of Things Protocol for Intelligent Manufacturing of Smart Farming. J. Ambient. Intell. Hum. Comput. 2021, 12, 7777–7791. [Google Scholar] [CrossRef]

- Syed, A.-A.; Khan, Z.A.; Chattha, S.H.; Shaikh, I.A.; Ali, M.N.H.A.; Bughio, Z.U.R.; Dahri, S.H.; Buriro, G.B. Comparative Assessment of Hydroponic and Geoponic Cultivation Systems for Sustainable Spinach Cultivation. Pak. J. Agric. Res. 2021, 34, 678–688. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, Z.; Yang, J.; Ren, J.; Rao, Y.; Zhang, W. Data-Driven Decision Support Scheme for Multi-Area Light Environment Control in Greenhouse. Comput. Electron. Agric. 2023, 211, 108033. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, F.; Li, M.; Zhang, Z.; Liu, W. Design and Applications of Multichannel Photosynthetic Photon Flux Density Sensor for Artificial Lighting. Opt. Eng. 2019, 58, 1. [Google Scholar] [CrossRef]

- Song, Y.; Bi, J.; Wang, X. Design and Implementation of Intelligent Monitoring System for Agricultural Environment in IoT. Internet Things 2024, 25, 101029. [Google Scholar] [CrossRef]

- Dong, Y.; Hansen, H. Design of an Internet of Things (IoT)-Based Photosynthetically Active Radiation (PAR) Monitoring System. AgriEngineering 2024, 6, 773–785. [Google Scholar] [CrossRef]

- Beyaz, A.; Gül, V. Determination of Low-Cost Arduino Based Light Intensity Sensors Effectiveness for Agricultural Applications. Braz. Arch. Biol. Technol. 2022, 65, e22220172. [Google Scholar] [CrossRef]

- Volosciuc, C.; Bogdan, R.; Blajovan, B.; Stângaciu, C.; Marcu, M. GreenLab, an IoT-Based Small-Scale Smart Greenhouse. Future Internet 2024, 16, 195. [Google Scholar] [CrossRef]

- Hitti, Y.; Buzatu, I.; Verme, M.D.; Lefsrud, M.; Golemo, F.; Durand, A. GrowSpace: A Reinforcement Learning Environment for Plant Architecture. Comput. Electron. Agric. 2024, 217, 108613. [Google Scholar] [CrossRef]

- Eteng, I.; Ugbe, C.; Oladimeji, S. Implementing Smart Farming Using Internet Technology and Data Analytics: A Prototype of a Rice Farm. East.-Eur. J. Enterp. Technol. 2022, 3, 48–62. [Google Scholar] [CrossRef]

- Ur Rehman, A.; Razzaq, A.; Altaf, A.; Qadri, S.; Hussain, A.; Nawaz Khan, A.; Tausif-ur-Rehman; Sarfraz, Z. Indoor Smart Farming by Inducing Artificial Climate for High Value-Added Crops in Optimal Duration. Int. J. Agric. Biol. Eng. 2023, 16, 240–246. [Google Scholar] [CrossRef]

- Butsenko, E.; Kurdyumov, A.; Semin, A. Intelligent Automation System on a Single-Board Computer Platform for the Agro-Industrial Sector. Mathematics 2020, 8, 1480. [Google Scholar] [CrossRef]

- Rokade, A.; Singh, M.; Malik, P.K.; Singh, R.; Alsuwian, T. Intelligent Data Analytics Framework for Precision Farming Using IoT and Regressor Machine Learning Algorithms. Appl. Sci. 2022, 12, 9992. [Google Scholar] [CrossRef]

- Bersani, C.; Ruggiero, C.; Sacile, R.; Soussi, A.; Zero, E. Internet of Things Approaches for Monitoring and Control of Smart Greenhouses in Industry 4.0. Energies 2022, 15, 3834. [Google Scholar] [CrossRef]

- Gao, P.; Lu, M.; Xu, J.; Zhang, H.; Li, Y.; Hu, J. IPECM Platform: An Open-Source Software for Greenhouse Environment Regulation Using Machine Learning and Optimization Algorithm. Comput. Electron. Agric. 2024, 217, 108564. [Google Scholar] [CrossRef]

- Raj, J.S.; Iliyasu, A.M.; Bestak, R.; Baig, Z.A. Real-Time Monitoring of Crop in Agriculture Using Wireless Sensor Networks. In Innovative Data Communication Technologies and Application: Proceedings of ICIDCA 2020; Springer: Singapore, 2021; Volume 59. [Google Scholar]

- Zhu, M.; Shang, J. Remote Monitoring and Management System of Intelligent Agriculture under the Internet of Things and Deep Learning. Wirel. Commun. Mob. Comput. 2022, 2022, 1206677. [Google Scholar] [CrossRef]

- Reza, M.N.; Islam, M.N.; Iqbal, M.Z.; Kabir, M.S.N.; Chowdhury, M.; Gulandaz, M.A.; Ali, M.; Jang, M.-K.; Chung, S.-O. Spatial, Temporal, and Vertical Variability of Ambient Environmental Conditions in Chinese Solar Greenhouses during Winter. Appl. Sci. 2023, 13, 9835. [Google Scholar] [CrossRef]

- Kaur, A.; Sonawane, V.; Rosha, P. Energy Efficiency Optimization Strategies for Greenhouse-Based Crop Cultivation: A Review. Can. J. Chem. Eng. 2024, 102, 1051–1065. [Google Scholar] [CrossRef]

- Mengi, E.; Samara, O.A.; Zohdi, T.I. Crop-Driven Optimization of Agrivoltaics Using a Digital-Replica Framework. Smart Agric. Technol. 2023, 4, 100168. [Google Scholar] [CrossRef]

- Gao, P.; Li, B.; Bai, J.; Lu, M.; Feng, P.; Wu, H.; Hu, J. Method for Optimizing Controlled Conditions of Plant Growth Using U-Chord Curvature. Comput. Electron. Agric. 2021, 185, 106141. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, J.; Zhang, B.; Wang, Z.; Xing, L.; Zhang, H.; Hu, J. Obtaining a Light Intensity Regulation Target Value Based on the Tomato Dry Weight Model. Sci. Hortic. 2022, 295, 110879. [Google Scholar] [CrossRef]

- Fu, Q.; Li, X.; Zhang, G.; Ma, Y. Revolutionizing Solar Greenhouses: A Lighting Environment Control System for Renewable Vegetable Cultivation, Empowered by Roller Shutter Control. J. Food Process Eng. 2024, 47, e14494. [Google Scholar] [CrossRef]

- Valenzeno, D.P.; Pottier, R.H.; Mathis, P.; Douglas, R.H. Photobiological Techniques; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 978-1-4615-3840-0. [Google Scholar]

| AND | Artificial Lighting Terms | AND | ||||||

|---|---|---|---|---|---|---|---|---|

| “Light Efficiency” | “Light Spectra” | “Light-Emitting Diode” OR “LED” | “Light Intensity” | “Light” | ||||

| Technology terms | “Artificial intelligence” OR “AI” | 126 | 54 | 1666 | 70 | 842 | “Agriculture” | Indoor agriculture term |

| “Internet of Things” OR “IoT” | 75 | 28 | 493 | 55 | 373 | |||

| “Sensor” | 243 | 152 | 1857 | 214 | 1619 | |||

| “Automation” | 40 | 4 | 235 | 14 | 159 | |||

| Total results | 8319 | |||||||

| AND | Artificial Lighting Terms | AND | ||||||

|---|---|---|---|---|---|---|---|---|

| “Light Efficiency” | “Light Spectra” | “Light-Emitting Diode” OR “LED” | “Light Intensity” | “Light” | ||||

| Technology terms | “Artificial intelligence” OR “AI” | 34 | 7 | 2 | 10 | 140 | “Agriculture” | Indoor agriculture term |

| “Internet of Things” OR “IoT” | 52 | 11 | 16 | 68 | 243 | |||

| “Sensor” | 97 | 58 | 34 | 106 | 585 | |||

| “Automation” | 27 | 4 | 4 | 20 | 108 | |||

| Total results | 1626 | |||||||

| Technologies | Application | Source |

|---|---|---|

Lighting control

|

| [18,47,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92] |

Interconnected network Internet of Things (IoT)

|

| [18,39,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,87,88,89,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117] |

Simulations

|

| [28,47,57,58,66,100,101,107,118,119,120] |

Complementary energy sources

|

| [56,60,86,93,95,104,106,116,121] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozano-Castellanos, L.F.; Navas-Gracia, L.M.; Lozano-Castellanos, I.C.; Correa-Guimaraes, A. Technologies Applied to Artificial Lighting in Indoor Agriculture: A Review. Sustainability 2025, 17, 3196. https://doi.org/10.3390/su17073196

Lozano-Castellanos LF, Navas-Gracia LM, Lozano-Castellanos IC, Correa-Guimaraes A. Technologies Applied to Artificial Lighting in Indoor Agriculture: A Review. Sustainability. 2025; 17(7):3196. https://doi.org/10.3390/su17073196

Chicago/Turabian StyleLozano-Castellanos, Luisa F., Luis Manuel Navas-Gracia, Isabel C. Lozano-Castellanos, and Adriana Correa-Guimaraes. 2025. "Technologies Applied to Artificial Lighting in Indoor Agriculture: A Review" Sustainability 17, no. 7: 3196. https://doi.org/10.3390/su17073196

APA StyleLozano-Castellanos, L. F., Navas-Gracia, L. M., Lozano-Castellanos, I. C., & Correa-Guimaraes, A. (2025). Technologies Applied to Artificial Lighting in Indoor Agriculture: A Review. Sustainability, 17(7), 3196. https://doi.org/10.3390/su17073196