Abstract

Digital Twin (DT) technology is emerging as a powerful tool for optimizing energy efficiency and industrial sustainability. By creating virtual replicas of physical systems, DTs enable real-time monitoring, predictive maintenance, and resource optimization, offering new opportunities to meet growing energy demands. Despite its potential, the comprehension of DT technology’s applications, benefits, and challenges remains limited. This systematic review explores the role of Digital Twins in energy efficiency across various industries. A structured literature search was conducted in IEEE Xplore, Elsevier, Springer, MDPI, and Google Scholar, following PRISMA 2020 guidelines. After applying the predefined inclusion criteria, 50 studies were selected for in-depth analysis. The findings highlight that DT implementation can lead to energy savings of up to 30%, reduce operational costs, and improve predictive maintenance strategies. Their impact is particularly notable in smart buildings, manufacturing, and industrial processes, where real-time data analytics contribute to better energy management. However, significant barriers remain, including high implementation costs, data security risks, and the complexity of integrating DTs with existing infrastructures. By synthesizing the current research, this review underscores the transformative potential of Digital Twins while identifying key challenges that need to be addressed for their wider adoption. Future efforts should focus on developing standardized methodologies, reducing implementation costs, and enhancing cybersecurity measures to maximize their benefits in energy efficiency and sustainability.

1. Introduction

The digital transformation has significantly reshaped industrial processes and structures, introducing new technologies and innovative resource management methods. Among these advancements, Digital Twins (DTs) have emerged as a groundbreaking technology capable of creating virtual replicas of physical systems. This technology facilitates real-time monitoring, analysis, and optimization, making it particularly promising for improving energy efficiency across various industries [1,2,3,4]. In a world facing escalating environmental challenges and an increasing demand for sustainability, optimizing energy consumption has become a critical priority for organizations worldwide.

Digital Twins provide an innovative approach to achieving energy efficiency by enabling the more precise and proactive management of energy usage [5,6,7,8,9]. Initially pioneered in the aerospace industry for monitoring and maintaining complex aircraft systems, the application of Digital Twins has expanded into diverse fields such as manufacturing, urban infrastructure, and building management. By offering real-time visibility and predictive simulation capabilities, Digital Twins allow for the identification of energy inefficiencies, the anticipation of potential failures, and the implementation of targeted interventions to enhance energy performance [10,11,12,13,14].

The advantages of Digital Twins in energy efficiency are multifaceted. For instance, they enable the simulation of various energy consumption scenarios, the assessment of different optimization strategies, and continuous system monitoring to detect deviations from optimal performance standards [15,16,17]. This capability is particularly beneficial in smart buildings, where interconnected systems such as heating, ventilation, air conditioning (HVAC), and lighting require synchronized management to minimize energy consumption [18,19,20,21,22,23]. Research indicates that integrating Digital Twins into building management can result in energy savings of up to 30% [10,24,25]. Additionally, Digital Twins contribute to the circular economy by supporting strategies for urban decarbonization [26,27,28,29,30]. They are widely utilized for modeling and simulating energy consumption across sectors such as waste management, industrial energy optimization, and smart grids [31,32,33,34,35]. However, despite their significant advantages, the adoption of Digital Twins presents both technical and organizational challenges [36,37,38,39,40].

Developing and maintaining accurate virtual models requires substantial investments in technology and skilled personnel. Additionally, effective data management including data collection, integration, and analysis remains a critical challenge. Security concerns also persist, as interconnected systems are vulnerable to cyber threats. Nonetheless, ongoing advancements in artificial intelligence (AI) and the Internet of Things (IoT) offer promising solutions to mitigate these challenges [41,42,43,44]. These obstacles include the complexity of implementation, high initial costs, the necessity for advanced technological infrastructure and specialized expertise, as well as concerns over data security. How can industries overcome these barriers to fully leverage the potential of Digital Twins?

This article aims to explore the applications of Digital Twins across different industrial sectors, highlighting their tangible benefits and the challenges associated with their implementation. Furthermore, it seeks to provide strategic recommendations to facilitate the integration of this transformative technology and maximize its impact on production efficiency, resource management, and sustainability.

To address these objectives, a rigorous research methodology was adopted, involving the systematic collection and analysis of data from academic and industrial literature sources, including IEEE Xplore, Elsevier, Springer, and MDPI. This approach enables the identification and synthesis of best practices and recent advancements in the field of Digital Twins. The following section details the methodology employed in this study.

2. Research Methodology

This state-of-the-art study was carried out to gain a better understanding of the applications of Digital Twins in different areas of industry. This study follows the PRISMA 2020 guidelines to ensure transparency and rigor in the selection and analysis of studies related to Digital Twin (DT) applications in the field of energy efficiency.

2.1. Eligibility Criteria (Integrated into Study Scope Section)

The selection of studies was guided by the PICO (Population, Intervention, Comparison, Outcomes) framework, ensuring a structured approach:

- Population (P): Studies focusing on Digital Twin applications in energy efficiency, industrial processes, smart buildings, and sustainability;

- Intervention (I): Implementation of Digital Twins for energy management, predictive maintenance, operational optimization, and real-time monitoring;

- Comparison (C): Studies comparing Digital Twin implementations with traditional energy management approaches;

- Outcomes (O): Key performance indicators such as energy savings, operational cost reductions, process optimization, and sustainability impacts.

These criteria align with the study’s scope, ensuring the selection of the relevant and high-quality literature.

2.2. Information Sources and Search Strategy (Integrated into Literature Review Approach Section)

A comprehensive search was conducted in the following academic databases: IEEE Xplore, Elsevier (ScienceDirect), SpringerLink, MDPI, and Google Scholar. The search strategy included a combination of relevant keywords (Table 1) and Boolean operators: (“Digital Twin” OR “DT”) AND (“Energy Efficiency” OR “Sustainability” OR “Industry 4.0” OR “Smart Buildings” OR “Predictive Maintenance”).

Table 1.

Keywords.

The last search was conducted on [7 September 2024], ensuring the inclusion of the most recent literature. This search strategy was designed to maximize the retrieval of relevant studies while minimizing bias.

2.3. Study Selection Process (Integrated into Selection and Screening Section)

To refine the results, the following strategies were employed:

- Use of main keywords: DT, Virtual Twin, Numerical Simulation, Industry 4.0, BIM, and smart grids.

- Combination of keywords: For example, “DT in manufacturing”, “DT in building”, or “Energy efficiency DT”.

- Inclusion criteria:

Peer-reviewed journal articles: Ensures methodological reliability and avoids biases from unreviewed publications;

Studies published in the last 10 years: Reflects the latest developments and trends in Digital Twin applications;

Focus on energy efficiency and Digital Twin applications: Ensures relevance to the research topic;

Quantifiable results (e.g., energy savings, cost reductions, and operational improvements): Enables meaningful comparisons and critical analysis.

- Exclusion criteria (very theoretical publications, off-topic articles, studies more than 10 years old):

Theoretical studies without practical application: These do not provide tangible insights into real-world implementations;

Studies older than 10 years: Digital Twin technology has evolved significantly, making older studies potentially outdated;

Non-English language papers: Ensures accessibility to widely recognized scientific research and avoids translation issues;

Duplicate publications: Prevents redundancy and potential bias from repeated findings;

- Title and abstract screening: Initial filtering based on relevance to Digital Twin applications in energy efficiency;

- Full-text assessment: In-depth evaluation of shortlisted studies against the inclusion criteria;

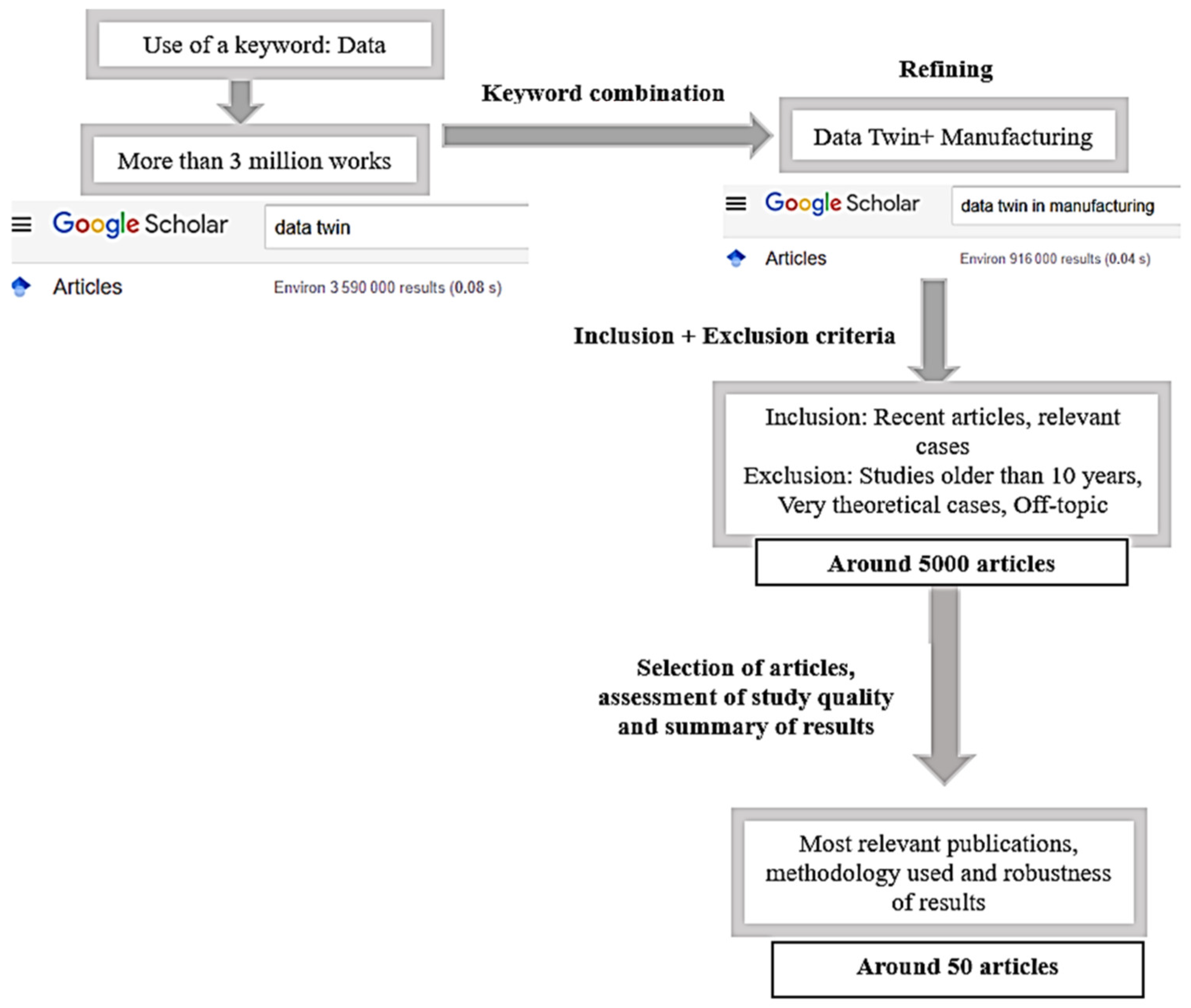

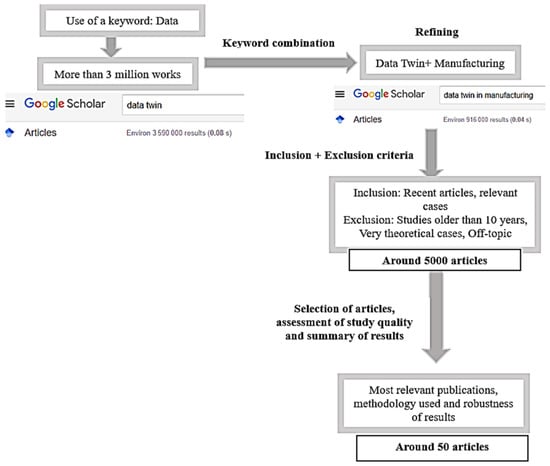

- Final inclusion: Only studies meeting all criteria were retained for synthesis.The PRISMA 2020 flow diagram (Figure 1) illustrates this process:

Figure 1. Methodology tree.

Figure 1. Methodology tree.- -

- 500,000 articles identified from databases;

- -

- 1500 articles screened after duplicate removal;

- -

- 150 full-text articles assessed for eligibility;

- -

- 50 studies included in the final review.

This structured selection process ensures transparency and replicability in identifying the most relevant studies.

2.4. Data Extraction and Risk of Bias Assessment (Integrated into Data Processing and Quality Assessment Section)

Data Extraction: A standardized data extraction sheet was used to collect information, including the following:

- -

- Study title, year, and author(s);

- -

- Study type (experimental, case study, review);

- -

- Digital Twin application area (industry, smart buildings, energy management, etc.);

- -

- Key findings on energy efficiency, cost savings, and sustainability impact.

Risk of Bias Assessment: The quality of the selected studies was evaluated based on predefined criteria, considering factors such as the following:

- -

- Study design and methodology;

- -

- Data collection processes;

- -

- Potential conflicts of interest;

- -

- Relevance and applicability to the research question.

A structured assessment was conducted to classify studies as having a low, moderate, or high risk of bias based on these parameters.

This process ensures that only high-quality studies contribute to the review’s findings.

2.5. Data Synthesis (Integrated into Data Analysis Section)

A thematic synthesis approach was applied:

- -

- Quantitative analysis measured energy efficiency improvements and cost savings;

- -

- Qualitative insights were used to highlight implementation challenges and opportunities;

- -

- Comparative tables summarize key findings across different Digital Twin application areas.

3. State of the Art of the Digital Twin and Its Applications in Various Fields

3.1. Digital Twin Concept

Digital Twin (DT) technology enables the creation of a virtual replica of a real-world system, allowing for its continuous monitoring, analysis, and optimization. It is essentially a digital counterpart that facilitates improved process efficiency, predictive maintenance, and enhanced decision-making. Given its ability to simulate and replicate physical systems, the Digital Twin system is closely linked to the concept of virtual modeling, which must be both precise and dynamically adaptable to real-time changes.

A Digital Twin system can take various forms, including simulation models that accurately mimic the behavior of machines, production lines, or entire industrial systems. According to Strielkowski et al. [1], Digital Twins help organizations to consolidate data into a single source of truth, leading to more efficient operations, improved decision-making, and faster maintenance interventions.

The effectiveness of Digital Twin applications depends on the quality and availability of real-world data. To construct accurate models, Digital Twins rely on real-time data acquisition, often integrating sensor networks to monitor operational conditions and optimize performance [2]. The scope and interpretation of Digital Twins vary across industries, with implementations spanning aerospace, manufacturing, construction, and smart infrastructure [3]. Table 2 presents key concepts and definitions related to Digital Twin technology [4]:

Table 2.

Digital Twin technology’s key concepts and their descriptions [4].

Qi et al. [5] identified the Digital Twin as one of the top 10 technological advancements and defined digitalization as the process of transforming a business through digital technologies to generate new revenue streams and enhance value creation opportunities [6].

3.2. Digital Twin Technologies

Digital technologies play a crucial role in addressing key challenges, particularly in optimizing the performance of energy systems [7]. One of the most promising solutions to this challenge is the Digital Twin (DT), a technology that enables the real-time simulation and monitoring of physical assets [8].

A Digital Twin is a virtual replica of a physical system, designed to simulate its behavior and performance under varying conditions [9,10]. To ensure accurate performance analysis, the virtual model is continuously synchronized with its physical counterpart through real-time data acquisition [11]. This synchronization is made possible by integrating data from multiple sources, such as sensors, industrial machines, and connected devices, to create a comprehensive and highly precise representation of the physical system [12].

Key Technologies Enabling Digital Twins

The development and functionality of Digital Twin models rely on various advanced technologies, including the following:

- -

- Simulation technologies: Enabling system modeling and real-time behavior replication;

- -

- Machine learning (ML) and Artificial Intelligence (AI): Facilitating predictive analytics and automated decision-making;

- -

- Big Data analytics: Managing and processing large volumes of real-time operational data;

- -

- Internet of Things (IoT): Collecting and transmitting real-time data from physical assets;

Cloud computing: Ensuring the scalable storage, computation, and remote accessibility of Digital Twins [13,14].

By integrating these technologies, analysts and industry stakeholders can develop high-fidelity Digital Twins that accurately reflect system behavior, performance variations, and complex operational processes.

Core Components of a Digital Twin

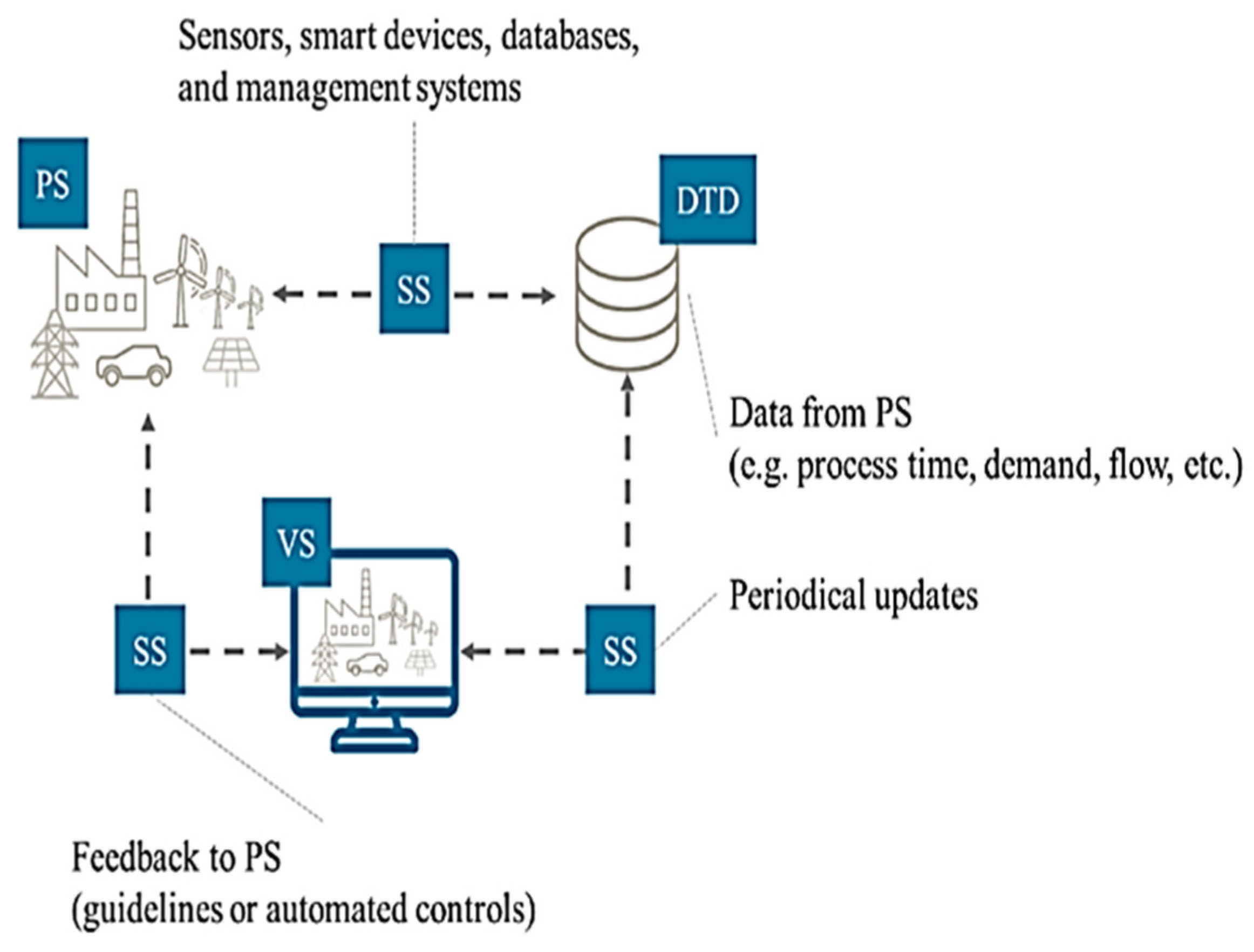

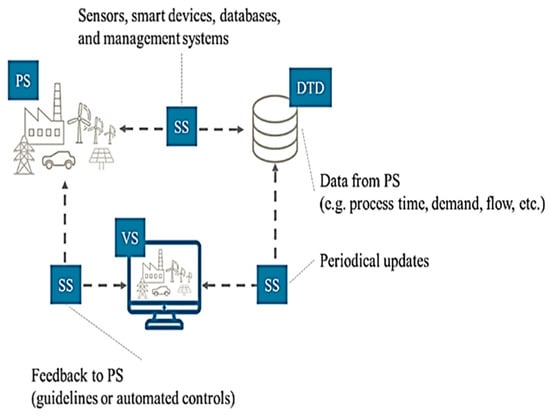

According to Tao and Zhang [10], a typical Digital Twin system is composed of four fundamental components:

- -

- Physical System (PS): Represents the real-world system, including machinery, infrastructure, and materials;

- -

- Virtual System (VS): A digital counterpart that continuously replicates the physical system’s behavior over time;

- -

- Service System (SS): A communication framework that facilitates data exchange and integration between the physical and virtual environments;

- -

- Digital Twin Data (DTD): The data ecosystem containing all information transmitted between the physical and virtual models.

The following schematic diagram (Figure 2) illustrates the interactions between these components, showcasing how they contribute to the creation of a fully functional Digital Twin architecture.

Figure 2.

Structure of a Digital Twin [10].

Digital Twin (DT) technology has a broad range of applications across various industries, including energy production, distribution, storage, and consumption. Its implementation enhances operational efficiency, predictive maintenance, and decision-making processes.

Amaral et al. [15] conducted a comprehensive review of Digital Twin applications in the energy sector, highlighting the technology’s role in optimizing energy systems, resource allocation, and infrastructure performance. Their study examined key techniques, benefits, and challenges associated with Digital Twin technology in renewable energy, power grids, and industrial energy management [10].

Borrowski [16] explored the application of Digital Twin technology in process management within an energy company, demonstrating its effectiveness in reducing operational inefficiencies and optimizing resource utilization. The study emphasized the methodological approach to minimizing the negative environmental and economic impacts of business activities.

The findings indicate that digitalization, when integrated with Digital Twin technology, leads to a productivity increase of 3–5% per year, while also reducing operational costs and enhancing overall efficiency. Digitalization further contributes to cost reduction strategies and ensures more sustainable energy management practices.

As a result, the implementation of Digital Twin technology in the energy sector has transformed business operations and decision-making frameworks, fostering data-driven optimization and predictive analytics.

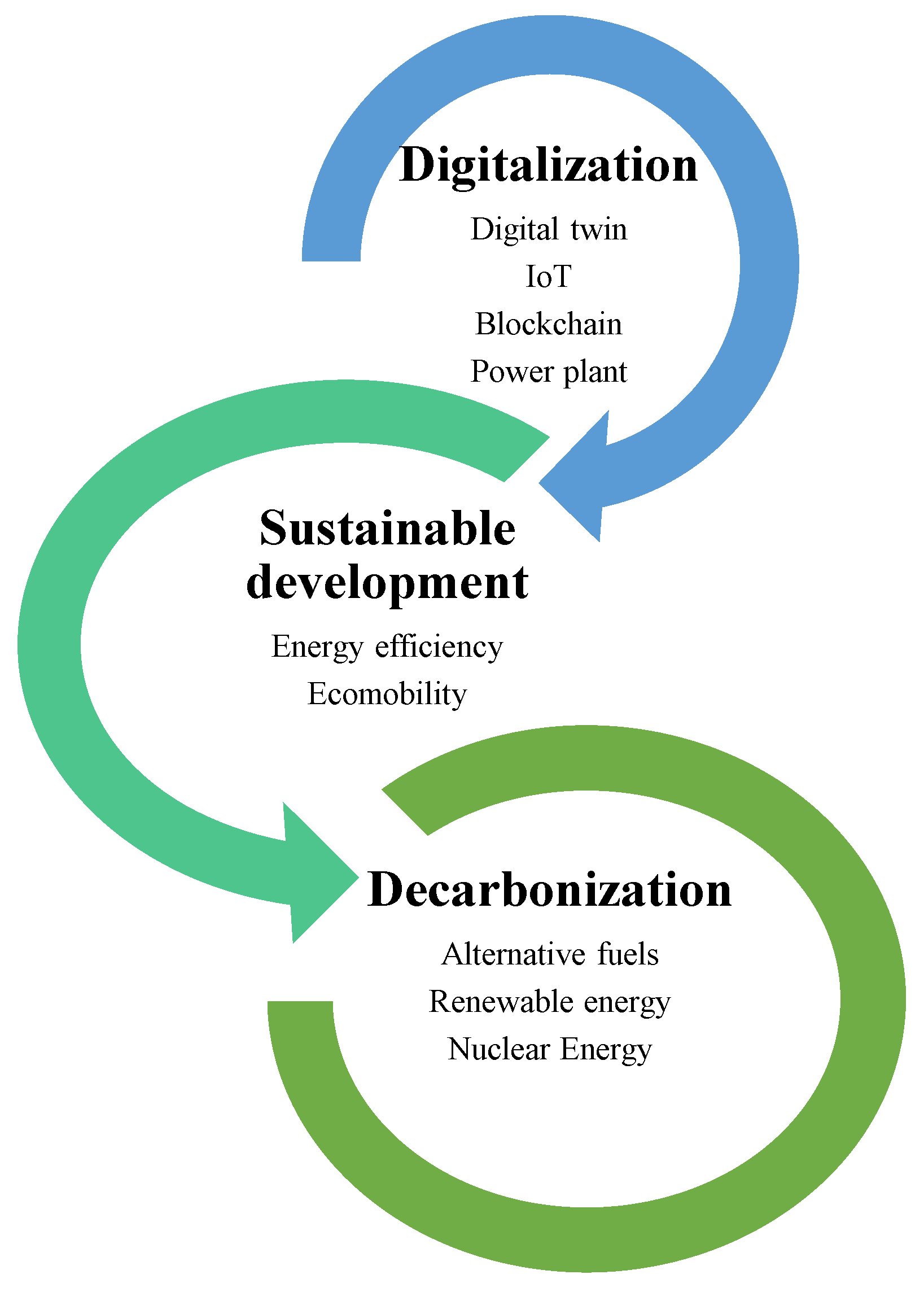

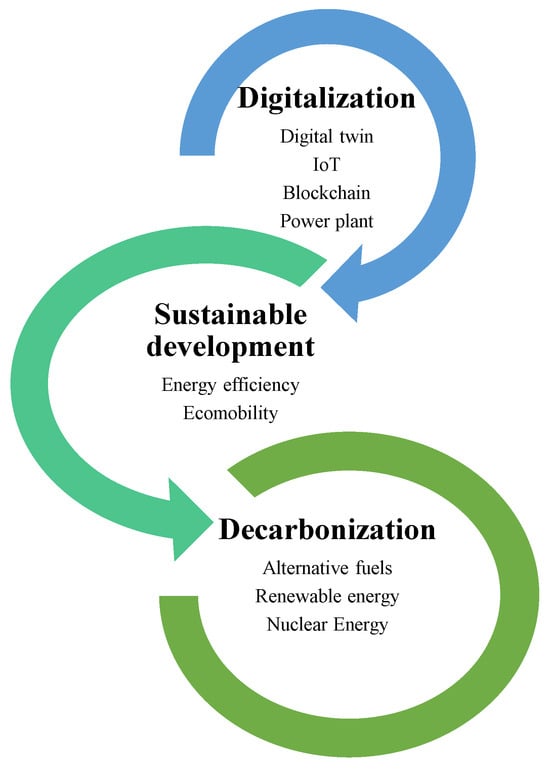

Figure 3 illustrates the evolution of Digital Twin applications in the development of energy sector processes, showcasing its impact on digital transformation, smart grid management, and energy sustainability [15].

Figure 3.

Development trends in the energy sector.

Digitalization plays a fundamental role in enhancing the safety, efficiency, availability, and durability of industrial systems. In the energy sector, it contributes significantly to energy efficiency by facilitating real-time data collection, processing, and analysis [16]. These data are then transformed into actionable insights, which are transmitted to connected devices that can automate operational adjustments, thereby optimizing energy consumption and system performance [17].

The integration of Industry 4.0 technologies, including the Internet of Things (IoT), machine-to-machine (M2M) communication, and machine learning, has further accelerated the automation and optimization of energy-related processes [18]. Digital systems equipped with real-time monitoring capabilities can efficiently control energy production, manage demand fluctuations, and identify operational inefficiencies. Additionally, radio frequency identification (RFID) technology, using Wi-Fi or cellular networks, allows for the precise tracking of assets and a reduction in faulty components, ensuring higher operational reliability.

The development of a Digital Twin system requires a structured approach, including the selection of the appropriate models, as well as their configuration, calibration, training, and integration to create a holistic digital representation of a physical asset or process.

A variety of mathematical models and simulations are employed to ensure the realistic behavior of Digital Twins. These models operate simultaneously in a coordinated manner to achieve the objectives of performance optimization, predictive analytics, and real-time decision-making [19]. The key modeling approaches include the following:

Physical and economic models: Utilizing numerical methods to solve equations related to system behavior, performance optimization, and energy efficiency;

Statistical models: Employing machine learning algorithms, such as neural networks, for pattern recognition, anomaly detection, and predictive maintenance;

Expert-based decision models: Incorporating rule-based systems and domain-specific knowledge in a machine-readable format to enhance decision-making accuracy.

By leveraging these models, Digital Twins enable a more comprehensive understanding of energy systems, allowing industries to anticipate failures, improve resource allocation, and optimize operational performance.

3.3. Digital Twin Applications

Digital Twins (DTs) have been applied across various sectors, although research in this field remains relatively limited. This section presents a non-exhaustive review of recent studies on Digital Twin applications, encompassing both research papers and review articles.

Kovalyov [20] explored the development of an energy management platform based on Digital Twin technology. This platform leverages advanced Industry 4.0 technologies to enhance product performance, reduce costs, and improve real-time decision-making. Architecturally, a digital asset twin is a highly interoperable digital model system, capable of accurately reflecting an asset’s real-time status, diagnosing anomalies, and triggering corrective actions when necessary [20].

In the context of power generation, Zhao et al. [21] applied hybrid modeling to optimize the operation of a flexible motor drive system in a 600 MW thermal power plant. Their approach, which integrated historical data and real-time simulations, resulted in significant energy savings, stopping 535,526 tons of coal consumption within two weeks.

Digitalization’s impact on energy efficiency varies significantly across different regions due to differences in technological infrastructure, financial investment, policy frameworks, and workforce skills. Heymann et al. [22] analyzed megatrends in digitalization across multiple geographic locations, highlighting how local economic and regulatory environments influence digital transformation progress.

Similarly, Li et al. [23] investigated the future role of digitalization in energy demand and consumption across 47 economic sectors. Their findings demonstrated that digitalization could reduce energy consumption by 30%, primarily through system optimization and digital control mechanisms. The study projected that by 2050, nearly all energy sectors will be electrified, accelerating the transition toward renewable energy adoption.

Kuniawan et al. [24] examined the role of digitalization in industrial waste recycling and decarbonization. Their research estimated that by 2030, digital transformation could contribute 15% to the global economy, while simultaneously reducing municipal waste management costs by 30–35%. Optimized waste collection strategies and resource efficiency measures were highlighted as key benefits of Industry 4.0-driven waste management solutions [25].

By integrating green and digital innovation, digitalization plays a crucial role in establishing circular economy models that limit environmental impact and promote sustainable resource utilization [26]. Rissman et al. [27] further explored technological and policy frameworks for achieving global industrial decarbonization, emphasizing that clean energy adoption, regulatory frameworks, and climate policies will be primary drivers of carbon neutrality efforts.

Pierce et al. [28] developed a Digital Twin-based decarbonization strategy for energy modeling on the urban scale, using University College Dublin (Ireland) as a case study. Their model analyzed real-time energy consumption and heat production patterns, providing actionable insights for reducing carbon emissions in campus infrastructure.

Zhu et al. [29] conducted a systematic review on optimizing energy distribution systems for building decarbonization. Their study emphasized that AI-driven load flexibility, IoT integration, and advanced optimization algorithms are key catalysts for the future development of smart cities. The proposed architectural framework outlined how energy production and distribution can be dynamically managed within smart buildings, enhancing overall sustainability and efficiency.

3.4. Digital Twin for Energy Efficiency Improvements

Digital Twins have shown significant potential for optimizing energy efficiency in various sectors. Key areas of impact include the following:

- -

- HVAC systems in smart buildings: Real-time monitoring and optimization reduce energy consumption by up to 30%;

- -

- Smart grids: Digital Twins enhance the energy distribution efficiency and facilitate predictive maintenance;

- -

- Predictive maintenance: By analyzing real-time data, Digital Twins improve failure prediction and extend equipment lifespan. Several studies [25,26,27,28,29,30] have demonstrated these benefits, yet challenges remain in validating the results across different real-world settings. As discussed in the State of the Art, Digital Twin (DT) technology is primarily used to optimize costs and time. When combined with decarbonization strategies, it has particularly impactful applications in the energy sector, where it enhances operational efficiency and sustainability.

In industrial energy management, the integration of Digital Twins plays a crucial role in reducing carbon emissions and improving performance. Wang et al. [30] examined the fusion of digital technologies and the energy industry, focusing on four key dimensions: foundation, conditions, applications, and performance. Their findings highlight that technological and institutional innovation is a key driver of industrial digital transformation.

You et al. [31] explored how Digital Twins facilitate energy system integration, particularly in the daily planning of energy loads and the management of renewable energy uncertainties. Their study demonstrated that the implementation of a Digital Twin model reduces additional operational costs by 63.5%. To address the various challenges associated with these uncertainties, the authors developed a machine learning-based scheduling method that optimizes energy distribution. This approach enhances the interaction between virtual and physical industrial energy systems, ensuring real-time adaptability to fluctuating energy demands.

Beyond cost reduction, Digital Twins also play a crucial role in energy efficiency and sustainability. Riedelsheimer et al. [32] worked on a methodology for developing Digital Twins specifically designed to improve energy savings and environmental sustainability. Their study introduced a structured approach that transitioned from a generalized framework to scenario-based methodologies, integrating existing best practices with emerging digital solutions.

Chowdhury et al. [33] focused on strategies to reduce energy demand in the UK industrial sector. Their research identified key areas where Digital Twins could drive efficiency gains, including optimizing steam network systems, improving waste heat recovery technologies, and integrating bioenergy solutions. Their findings underscored that steam-related inefficiencies account for a significant portion of energy losses in industrial settings, and that implementing heat recovery solutions could lead to substantial energy savings.

These studies illustrate the transformative potential of Digital Twins in the energy sector. By reducing costs, enabling predictive maintenance, and optimizing energy distribution, this technology is a key enabler of industrial sustainability.

Studies have shown that steam-related industrial processes suffer significant energy losses due to inefficiencies and thermodynamic limitations, representing a major source of waste in industrial operations. One of the most effective solutions to mitigate these losses is the implementation of steam and heat recovery technologies [33].

Chinathai et al. [34] investigated the role of digitalization in energy-intensive industries and developed a Digital Life Cycle Assessment Management Framework. Their research assessed the current state of digital transformation in manufacturing and proposed a structured approach to achieving smarter and more sustainable production processes. By leveraging data analytics, they demonstrated that energy consumption in machining industries could be predicted more accurately, enabling proactive energy management.

Ghobakhloo et al. [35] examined how Industry 4.0 contributes to energy sustainability, particularly in the energy sector. Their findings highlight that industrial digitalization is reshaping energy management by introducing smart automation, real-time monitoring, and predictive analytics. However, they emphasized that the transition towards a fully digitalized energy industry remains a complex and gradual process, requiring technological advancements and infrastructure modernization.

Beyond industrial applications, Digital Twin technology is increasingly being integrated into the building sector to optimize energy consumption and reduce carbon emissions. Several studies have focused on how Digital Twins, IoT, and AI-driven analytics enhance energy efficiency in buildings.

Arsiwala et al. [36] demonstrated that Digital Twins can automate the monitoring and control of equivalent carbon dioxide (eCO2) levels in buildings, improving indoor air quality and optimizing energy use. Their study highlighted the critical role of Building Information Modeling (BIM) and IoT in Digital Twin applications. The integration of IoT sensors enables real-time facility management, while AI-driven machine learning algorithms help to predict carbon emissions by analyzing collected data.

Gao et al. [37] explored the use of Digital Twins in port operations, specifically in optimizing energy consumption for automated container terminals. Their approach focused on enhancing logistical efficiency and minimizing energy waste in large-scale industrial transport hubs.

In the construction sector, Digital Twin technology has been applied to prefabricated building processes. By integrating sensors to capture real-time data during prefabrication, Digital Twins facilitate quality control, process optimization, and material efficiency. This intelligent approach to construction reduces waste and enhances sustainability, making Digital Twins a key enabler of smart construction practices [38].

This overview of the existing research highlights the diverse and transformative applications of Digital Twins across multiple industries. From industrial manufacturing to smart buildings and intelligent transport systems, this technology offers a significant opportunity to improve energy efficiency and sustainability.

The next section will examine the advantages and challenges associated with the large-scale implementation of Digital Twins.

3.5. The Benefits and Challenges of Digital Twins

Digital Twins offer numerous advantages, but also present certain challenges. Table 3 below outlines the key benefits of Digital Twin technology, as identified in recent studies [39,40].

Table 3.

Advantages of Digital Twins.

Despite its numerous benefits, Digital Twin technology still faces challenges that need to be addressed for further improvement. Table 4 below presents key challenges identified in the literature.

Table 4.

Challenges associated with Digital Twins.

While Digital Twins (DTs) offer significant advantages, their widespread adoption is often hindered by several key challenges. This section examines the main barriers to implementation and explores potential solutions.

3.5.1. High Computational Costs and Energy Demands

The deployment of Digital Twins requires substantial computing power to process real-time data streams, conduct predictive simulations, and maintain synchronization with physical assets. These demands lead to high operational costs and significant energy consumption, particularly in industries with complex DT models, such as smart grids and industrial automation.

To mitigate these challenges, edge computing is emerging as a promising solution. By distributing processing power closer to data sources, edge computing reduces latency and energy consumption while maintaining real-time analytics capabilities.

3.5.2. Cybersecurity Risks

Digital Twins handle vast amounts of sensitive operational data, making them attractive targets for cyberattacks, including data breaches, ransomware, and industrial espionage. The risk is even greater when DTs are integrated with cloud-based infrastructures, where vulnerabilities can be exploited.

One approach to enhancing security is the use of blockchain technology, which enables secure, decentralized, and immutable data records. This technology is being explored to protect DT transactions, ensure data integrity, and strengthen cybersecurity frameworks.

3.5.3. Interoperability with Legacy Infrastructure

Many industries, particularly with older buildings, industrial plants, and energy grids, rely on legacy systems that were not originally designed for integration with real-time digital models. Retrofitting these infrastructures for Digital Twin implementation presents both technical and financial challenges.

To address this issue, researchers and industry leaders are developing middleware platforms and standardized communication protocols (e.g., OPC UA, MQTT) to bridge compatibility gaps between outdated systems and modern Digital Twin frameworks. These solutions aim to facilitate smoother transitions and reduce implementation costs.

3.5.4. Case Study: Challenges in Unsuccessful Digital Twin Implementation

A notable example of failed Digital Twin adoption occurred during an ambitious smart city project in Europe. The initiative struggled with data integration failures, unexpectedly high infrastructure costs, and stakeholder resistance due to a lack of familiarity with DT technology. Despite significant initial investment, the project was ultimately scaled back due to interoperability constraints and cybersecurity concerns.

This case highlights the importance of phased deployment, stakeholder engagement, and cross-sector collaboration when implementing Digital Twins on a large scale.

3.5.5. Addressing These Barriers for Future Adoption

Overcoming these challenges is essential for the successful deployment and scaling of Digital Twins across industries. While they enhance real-time remote monitoring and predictive maintenance [39], they also pose risks related to data security and interoperability when integrated with legacy systems [41,42].

As shown in Table 3, the benefits of Digital Twins include improved decision-making, increased operational efficiency, and enhanced risk assessment [40]. However, as summarized in Table 4, implementation is often hindered by the lack of standardized tools, high initial costs, and cybersecurity vulnerabilities [43,44].

These findings emphasize the need for further research into standardized Digital Twin frameworks and emerging solutions such as blockchain for security and edge computing for cost-effective real-time processing. Addressing these aspects will be crucial in ensuring the long-term viability and scalability of Digital Twin technology in various industries.

3.6. Application of the Digital Twin in Different Sectors

3.6.1. The Building Industry

Although still in its early stages, the application of Digital Twin (DT) technology in the construction industry holds significant potential for addressing proactive challenges and improving project efficiency. Currently, Digital Twin applications in construction focus primarily on life cycle analysis and the design phase, where Building Information Modeling (BIM) serves as a fundamental tool [46].

The construction industry is inherently complex, large-scale, and costly in the long term [47]. The emergence and rapid advancement of Industry 4.0 technologies have introduced innovative solutions that are transforming multiple industries, including construction [48]. The integration of Digital Twins with smart data analytics, real-time monitoring, and predictive modeling has the potential to enhance project management, optimize resource utilization, and improve overall sustainability.

This section provides a comprehensive review of recent research on the application of Digital Twins in construction. Table 5 summarizes key studies exploring how Digital Twin technology is being implemented in various construction processes.

Table 5.

Application of Digital Twins in construction.

3.6.2. Industrial Sector

With the rise of Industry 4.0, Digital Twin (DT) technology is being increasingly adopted across multiple industries. While its primary application focuses on improving energy efficiency, it is also widely used to optimize manufacturing processes, particularly in terms of time and cost reduction. This section explores the various applications of Digital Twins across different industrial sectors.

In the manufacturing industry, Digital Twin technology is gradually being integrated into various levels of production, ranging from individual machine tools to entire production lines, workshops, and even full-scale factories [16]. The Digital Twin system is generally structured into three levels:

- -

- The Unit Level: This represents the smallest scale of Digital Twin implementation in intelligent manufacturing, serving as the foundation for the broader Digital Twin system on the shop floor level. At this stage, virtual models simulate the operating mechanisms of machine tools [20];

- -

- The Shop Floor Level: At this level, Digital Twins are used for analysis and prediction, including machining process condition assessments [21] and preventive maintenance planning for equipment [22];

- -

- The Factory Level: This encompasses a holistic integration of Digital Twins throughout an entire manufacturing plant, enabling real-time visualization, control, and optimization.

Research efforts in Digital Twin-based manufacturing are focused on several key areas. In visualization, studies explore multimodal interfaces [23] and cross-platform status display solutions [24]. In control applications, research emphasizes product failure analysis [25] and real-time quality control processes [26]. These innovations contribute to the development of smart factories, where Digital Twin technology enhances operational efficiency, predictive maintenance, and production optimization.

3.6.3. Mobility Sector

Beyond its applications in manufacturing, construction, and energy, Digital Twin (DT) technology is also transforming the mobility and transportation sectors. This section highlights key applications that demonstrate the role of Digital Twins in optimizing transport systems.

Like many other industries, the transport sector is highly energy-intensive, accounting for approximately one-fifth of global CO2 emissions, with vehicles alone responsible for 21% of total carbon emissions. This pressing environmental challenge has accelerated the development of Internet of Vehicles (IoV) technology, a critical component of future smart cities [74]. IoV combines the Internet of Things (IoT) and the Internet of Mobile Things (IoM) to optimize traffic flow, reduce congestion, and improve urban mobility management.

In their research, El Azzaoui et al. [74] proposed a decentralized IoV management system to lower the carbon footprint of vehicular transportation. To achieve this, they developed a Digital Twin of a vehicle within an intelligent environment, enabling the real-time simulation and monitoring of vehicle performance and environmental impact.

Similarly, Ken Chen et al. [75] explored the use of Digital Twins in aviation, developing a prototype digital airport tower system. This tangible Digital Twin supports collaborative air traffic management (ATM) operations using Microsoft HoloLens 2, allowing users to share a real-time, interactive view of airport traffic dynamics. Their study highlights the potential of Digital Twins in enhancing situational awareness, improving decision-making, and optimizing air traffic control efficiency [75].

These examples illustrate the growing role of Digital Twin technology in transportation, offering innovative solutions to reduce emissions, enhance traffic efficiency, and modernize infrastructure management.

3.6.4. Energy Applications Across Sectors

The integration of Digital Twin (DT) technology into the manufacturing and energy sectors is a key driver of digital transformation, significantly enhancing energy management and optimization. By enabling predictive maintenance, improved design processes, and the modernization of the existing infrastructure, Digital Twins contribute to higher energy efficiency and the seamless integration of renewable energy sources. Ongoing research aims to further refine and classify this technology to facilitate its large-scale adoption in the energy sector [76].

The industrial sector remains one of the largest consumers of thermal energy, playing a major role in global emissions. Industrial activities account for approximately 35.2% of global CO2-equivalent emissions, with 69% of these emissions linked to energy consumption [77]. Given this impact, numerous researchers have explored the key drivers, barriers, and success factors associated with energy management systems. Their findings emphasize the importance of a systematic, easy-to-implement approach [78], the development of key energy performance indicators [79], the alignment of energy strategies with long-term sustainability goals [80], and the removal of obstacles to effective energy management [81]. These studies also highlight the critical success factors for energy saving initiatives, underlining the need for data-driven decision-making in industrial energy optimization.

As a powerful digital tool, Digital Twin technology offers unprecedented potential for optimizing physical assets and industrial processes, enabling businesses to develop efficient, low-carbon solutions. By leveraging real-time data analytics, simulation models, and AI-driven insights, Digital Twins can play a pivotal role in reducing greenhouse gas emissions and driving the transition toward sustainable industrial practices.

Digital Twin applications in the energy sector focus on optimizing energy management and consumption, particularly in power generation, distribution, and smart grid operations. Additionally, Digital Twins are increasingly adopted in industrial manufacturing to enhance energy efficiency, improve process optimization, and integrate renewable energy sources. By modifying operational models, this technology transforms industrial processes, enabling real-time energy optimization and reducing overall consumption.

Classification and Design of Digital Twins in the Energy Sector

This section presents a classification of Digital Twin (DT) applications and their design methodologies in the energy sector, with the objective of minimizing energy consumption and enhancing efficiency.

To achieve this, several key research questions are addressed:

- -

- How do academia and industry characterize DT technology? What criteria are used to classify and prioritize different DT models, leading to the development of Energy Digital Twins (EDT)?;

- -

- Which energy manufacturers are investing in EDT technology? How can they implement it effectively in their operations?;

- -

- What methods, algorithms, and techniques are used to develop EDTs? At what stages of the energy management process are these developments applied?;

- -

- What are the main research directions for EDT applications in the energy industry?

Key Contributions of This Study

This research makes several important contributions to the literature:

The introduction of a new multidimensional classification framework for Digital Twin technology;

The identification of current limitations in the adoption of Digital Twins for industrial energy management;

A proposed framework for implementing Digital Twins at industrial sites and local energy networks;

A generalized definition of Digital Twins as digital or virtual representations that replicate, simulate, and interact with physical entities, enabling continuous decision-making optimization.

3.7. Key Functions of Energy Digital Twins

The functions described in this section are based on state-of-the-art applications and methodologies, as outlined in the previous sections. These functions illustrate the critical role of Energy Digital Twins (EDTs) in optimizing energy systems.

One of the fundamental capabilities of an EDT is process observation, which enables real-time monitoring with greater accuracy than the traditional methods. By integrating real-time sensor data and historical system behavior into a virtual model, EDTs allow for the continuous supervision and diagnosis of energy systems. For instance, Hu et al. [82] applied a parallel LSTM–autoencoder model in indoor climate control, achieving efficient fault prediction. Abo-Khalil et al. [83] further demonstrated the use of DTs in real-time hybrid simulation platforms for power system stability, supporting continuous feedback control.

In the context of process prediction and preventive maintenance, EDTs leverage machine learning to identify anomalies before they escalate into failures. Zhong et al. [84] emphasized the alignment of predictive models with live asset behavior to enhance decision-making, while Guo et al. [85] introduced a statistical framework for real-time Remaining Useful Life (RUL) estimation. This approach was extended by Aivaliotis and Georgoulias [86], who proposed RUL-based opportunistic maintenance scheduling across multi-component systems. In industrial scenarios, Falekas and Karlis [87] also highlighted DTs in the predictive maintenance of electrical machines through integrated simulation and diagnostics.

Real-time process optimization is another key function enabled by EDTs. Unlike traditional optimization methods that depend on static parameters, EDTs dynamically adapt to operational disturbances. Davies et al. [88] showed that MATLAB-based DTs for CNC systems improved scheduling flexibility and fault recovery. Additionally, Kabir et al. [89] reviewed IoT-integrated DTs and their role in energy efficiency, enabling adaptive control in smart energy systems. In PV systems, Alao et al. [90] discussed how DTs are applied for performance optimization and real-time monitoring under variable conditions.

Beyond traditional system-level benefits, DTs are now instrumental in managing complex energy hubs. He et al. [91] proposed a machine learning-based DT approach to monitor and manage interconnected hubs in real time. A broader overview by Das et al. [92] supports this trend, emphasizing how DTs and AI are converging to support smart grids, renewable energy integration, and electric vehicle energy management.

Taken together, these advanced functions—real-time monitoring, predictive diagnostics, and dynamic optimization—position Energy Digital Twins as a cornerstone for next-generation industrial energy systems, offering exceptional gains in resilience, adaptability, and operational intelligence.

3.8. Service Phase: EDT Tasks

In the service phase, Energy Digital Twins (EDTs) are pivotal in delivering advanced functionalities such as predictive maintenance, fault detection, real-time diagnostics, and virtual testing. These applications extend beyond traditional monitoring by enabling proactive interventions and minimizing system downtime.

A major application of EDTs is predictive maintenance, where the real-time monitoring of the equipment conditions is combined with data-driven prediction models. Zhong et al. [84] emphasized the capacity of Digital Twins to track system status in real time and optimize maintenance decisions accordingly. Similarly, Falekas and Karlis [87] reviewed the application of EDTs in electrical machines, highlighting their dual role in diagnostics and operational control.

Fault detection and failure diagnostics are also central to service-oriented EDTs. For instance, Kaitouni et al. [93] implemented a digital twin-based system for distributed photovoltaic (PV) infrastructures, which enabled early-stage fault detection across complex, decentralized systems. Complementarily, Cao et al. [94] integrated machine learning models in a DT framework to detect and locate failures in solar energy-based systems.

Real-time alerting and fault tracking capabilities were demonstrated in energy hubs and HVAC infrastructure. Hosamo et al. [95] proposed a DT-based framework for air handling units, achieving reliable fault identification through automated diagnostics. Similarly, Singh et al. [96] built an intelligent DT system for industrial AC machines, combining predictive analytics with real-time sensors for proactive service planning.

From a broader perspective, Rojas et al. [97] conducted a systematic literature review of AI-driven maintenance in the mining sector, demonstrating the benefits of DTs for fault detection and intelligent asset management. Bofill et al. [98] highlighted the challenges and opportunities in DT-based fault monitoring, underlining their potential in large-scale grid-connected systems.

Additionally, virtual testing environments supported by EDTs enable the simulation of fault scenarios without physical intervention. Abo-Khalil [83] introduced a hybrid simulation platform for power systems, showcasing how virtual DT environments can stress-test systems under realistic failure conditions. Finally, Rana [99] emphasized that combining digital twins with data-driven analytics leads to significant improvements in failure response time, operational safety, and maintenance efficiency.

Collectively, these developments position EDTs as key enablers of a service-oriented digital infrastructure. They facilitate a shift from reactive maintenance to predictive and adaptive service models, strengthening reliability, efficiency, and system resilience across the energy value chain.

3.9. Relationship Between EDT and AI: General Application

The integration of artificial intelligence (AI) and machine learning (ML) algorithms into Digital Twin (DT) technology requires a deep understanding of their potential applications in industrial and energy processes. Traditional AI-driven optimization methods, such as simulated annealing and evolutionary optimization, are effective in reducing complex search spaces and are widely utilized for process optimization and system integration. Meanwhile, data-driven approaches, such as recurrent neural networks (RNNs) and dynamic mode decomposition with control (DMD-c), allow for the development of black-box or hybrid models, which are particularly useful for systems that are difficult to model using first-principles methods.

Digital Twin technology presents numerous opportunities across various fields of product engineering. However, its current applications are often focused on specific disciplines rather than fully integrated solutions. Recent advances in information technology have expanded the possibilities for product development, leveraging increased computational power, advanced simulation tools, and connected data integration. Today, Digital Twins are being modeled across multiple disciplines to optimize system performance, predictive maintenance, and real-time decision-making.

A Digital Twin consists of three primary components: the physical system, the virtual system, and the service system, along with Digital Twin Data that continuously connect these elements [4,100]. Digital Twins are not limited to individual products, and can also represent complex production systems [101]. With developments in Industry 4.0, including real-time information systems, IoT integration, advanced sensors, and precise component traceability, Digital Twin applications are becoming more sophisticated and cost-effective.

The increasing availability of online measurement data and operational insights has made it possible to create more detailed and dynamic Digital Twins for production environments. This advancement enables rapid responses to deviations and malfunctions, and in some cases, cyber-physical production systems can autonomously initiate corrective actions [102,103].

The use of Digital Twins varies depending on whether they are implemented during the conceptual and detailed design phases or strictly within the production process. In manufacturing, Digital Twins have already been integrated into system simulations, ensuring proper operational behavior, predicting performance outcomes, optimizing production workflows, and supporting error correction. The digital product twin further enhances these capabilities by continuously collecting operational data, providing deeper insights into long-term system performance and predictive analytics [101].

In some cases, human resource management systems are also incorporated into Digital Twin frameworks, expanding their utility to workforce planning and training [104]. Additionally, human–machine interaction is being modeled within Digital Twins, particularly in advanced robotics and automation. Human–robot collaboration models within Digital Twins provide valuable insights, allowing industries to test and optimize operational programs before real-world implementation, reducing risks and improving system efficiency [105].

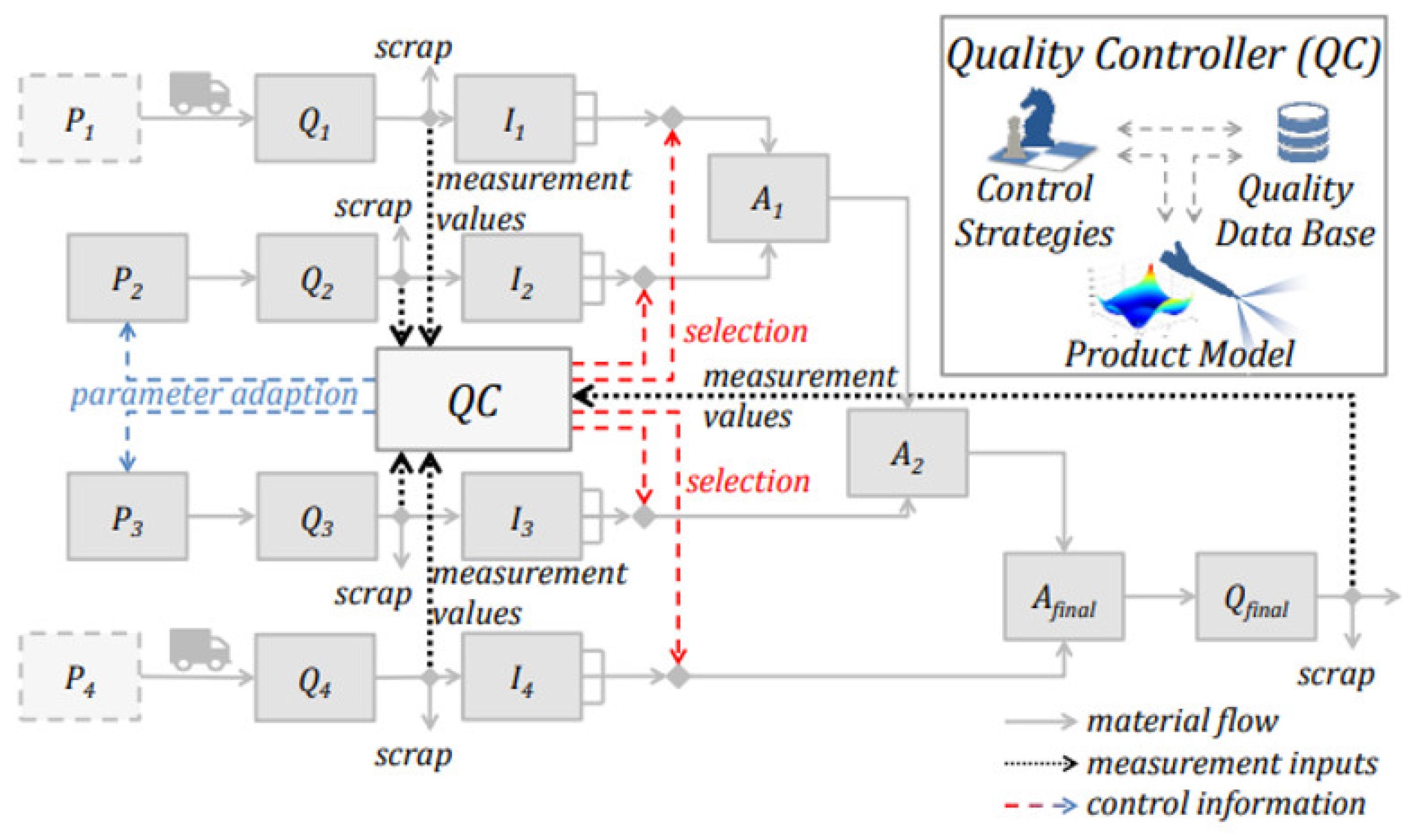

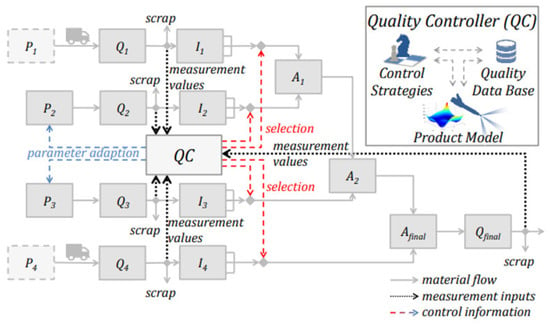

Furthermore, Digital Twins now integrate uncertainty modeling for key manufacturing processes, including production-integrated online metrology (Q), inventory management (I), and assembly processes (A). This comprehensive integration, illustrated in Figure 4, enhances decision-making capabilities at various levels, ultimately optimizing production efficiency and system adaptability [106].

Figure 4.

Visualization of the digital production twin by integrating the quality controller comprising control strategies, measurement data, and functional product model [89].

The integration of linked Digital Twins is a key enabler for expanding the possibilities of high-precision manufacturing beyond existing technological limitations. This approach is not only relevant to the automotive sector, but also extends to other fields such as medical technology and drive technology [106].

However, achieving seamless connectivity between Digital Twins in artificial environments presents several challenges that require further investigation and formalization. A well-structured framework is needed to support the holistic use of Digital Twins across the entire product development cycle. This framework should address key aspects such as collective understanding, standardized interfaces, and efficient data flow to ensure broad industrial adoption.

In conclusion, Digital Twins offer significant opportunities across various stages of product development. Current implementations that integrate product twins with production twins into digital production twins demonstrate initial efforts to merge production knowledge with digital models.

The increasing maturity of digital technologies, such as the Internet of Things, big data, and cloud computing, has driven the development and adoption of Digital Twin technology. In the energy sector, while promising concepts and case studies have emerged, many gaps remain unexplored.

The modern green energy system provides a structured approach to achieving carbon neutrality and peak emissions reduction. A defining feature of digitalized green energy systems is their connectivity with the internet, which enhances their intelligence and adaptability [107].

In recent years, Digital Twins have been widely studied as a key technology for intelligent systems, alongside the Internet of Things (IoT) and artificial intelligence (AI). Additionally, smart manufacturing technologies, such as the optimization of key manufacturing features and production framework improvements, benefit significantly from Digital Twin integration [108,109].

3.10. Classifications of DTs

The Digital Twin (DT) is an interconnected, multi-physical, multi-scale, and probabilistic simulation of a complex product system. Its classification and analysis are inherently multifaceted, multidisciplinary, and highly integrated. Expanding on the description of the DT, the following classification outlines its role in operations, particularly in simulation, virtual–real connectivity, model structuring, and data processing.

After reviewing multiple studies, it can be concluded that the primary function of DTs in operations is as modeling and simulation tools, while their application as a virtual–real connection system with data processing are less prevalent [110,111,112,113].

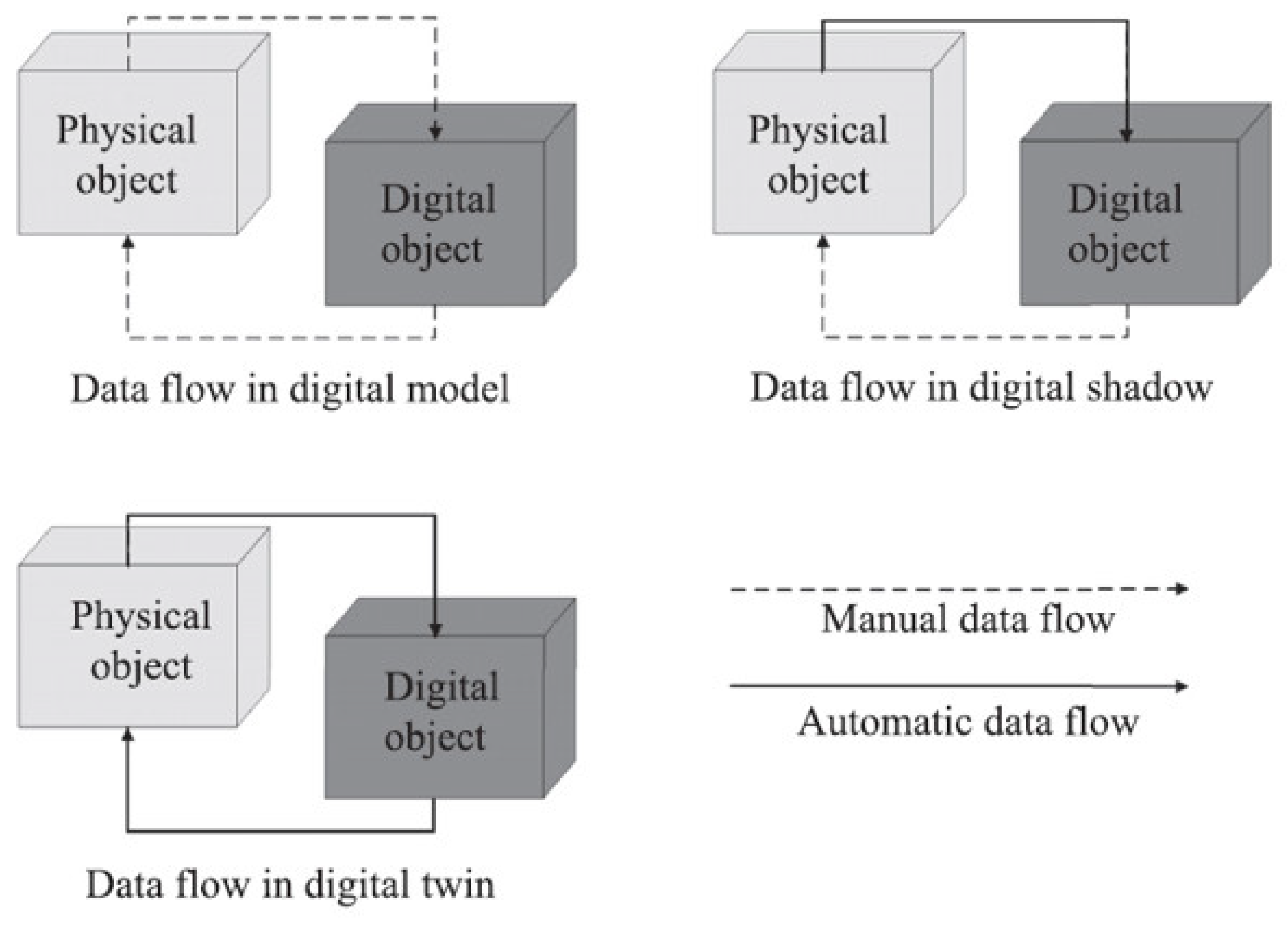

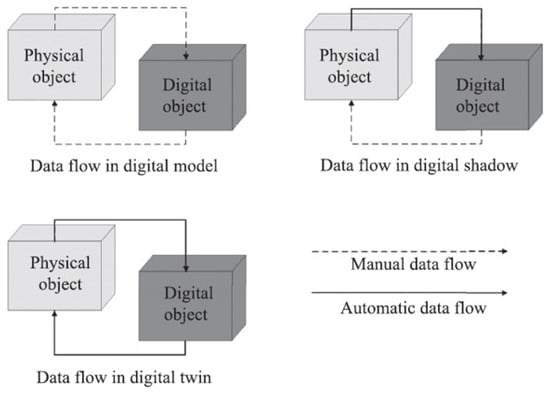

This classification is illustrated in Figure 5, where Werner Kritzinger et al. [97] propose a framework categorizing DTs into three distinct subcategories: digital model, digital shadow, and Digital Twin.

Figure 5.

Data flows in digital model, digital shadow, and Digital Twin [114].

The digital model represents a scenario where changes in the state of the physical system do not directly influence the digital system, nor does the digital system affect the physical counterpart.

The digital shadow signifies that a change in the physical system triggers a corresponding change in the digital system, but the reverse does not occur.

The Digital Twin is a fully interactive system where changes in the physical object directly alter the digital object and vice versa, ensuring real-time synchronization.

This classification provides a structured understanding of DTs and highlights their varied levels of integration between the physical and digital domains.

Maintaining strict synchronization between physical systems and their virtual models remains a challenge. To address this, data updates and rotations must be adjusted based on system scale, ensuring that periodic updates and duplications of the Digital Twin align effectively with real-world dynamics.

3.11. DTs in Smart Energy Applications

In energy applications, Digital Twins (DTs) can be categorized into different layers based on their level of integration. Various DT-based technologies and methodologies can be grouped according to potential future application scenarios.

DTs in smart energy applications are generally classified into four key levels: low-carbon cities, smart grids, electrified transportation, and advanced energy storage systems [115].

One critical area of application is artificial furnaces in high-intensity industries, where challenges include enhancing efficiency, reliability, and flexibility while simultaneously reducing energy consumption. Energy optimization in these systems not only improves competitiveness and cost efficiency, but also mitigates environmental impact.

Antolin-Urbaneja et al. [116] propose five key strategies to address these challenges:

- -

- Enhancing refractory materials;

- -

- Developing heat recovery systems using phase change materials (PCMs);

- -

- Exploring alternative energy sources;

- -

- Integrating advanced monitoring and control devices;

- -

- Creating a holistic decision-support tool.

Furnaces can generally be classified as electrical or chemical, with chemical furnaces relying on hydrocarbon oxidation [117]. Research in this area focuses on developing new refractory materials [118,119] and implementing heat recovery systems for exhaust gases [120] to improve durability and prevent issues like corrosion and erosion.

A Digital Twin provides a detailed virtual representation of these systems by collecting and analyzing data on material properties, operational conditions, and system behavior. These data are continuously updated through models and real-time monitoring, allowing for predictive maintenance and improved performance optimization. From a simulation perspective, Digital Twin technology represents a significant advancement compared to traditional simulation methods. It enables the evolution of physical systems into more complex digital environments by integrating software functions, such as drive and sensor connectivity within cyber-physical systems (CPS) [121].

Key challenges in this domain include the development of nano-particle-based refractory materials, the design of a PCM-based heat recovery system, and the integration of alternative fuels like syngas with natural gas through a new burner design. Data collected through advanced acquisition systems will be processed to develop intelligent algorithms, supporting a holistic decision-making tool aimed at improving efficiency, flexibility, reliability, and safety in furnace operations.

3.12. Research Gaps in Digital Twin Applications

Despite the extensive research on Digital Twin (DT) applications, several critical gaps remain. One major challenge is the lack of consistency in reported efficiency improvements across different industries. While some studies suggest energy savings of up to 30%, others report limited efficiency gains due to implementation challenges and variations in industry-specific processes.

Additionally, the existing literature lacks comparative analyses that explain why DT efficiency varies across sectors such as manufacturing, smart buildings, and energy distribution. Without such comparisons, it is difficult to identify key factors influencing performance variations and develop industry-specific optimization strategies.

Another significant research gap is the lack of standardization in DT methodologies. Different studies apply varying performance parameters, making it challenging to establish generalizable conclusions about DT effectiveness. The absence of common evaluation criteria limits the ability to benchmark Digital Twin models across industries.

Furthermore, few studies address long-term performance challenges, including the potential degradation of DT models over time due to evolving operational conditions and outdated data integration techniques. Ensuring the continued accuracy and reliability of Digital Twin systems requires adaptive methodologies that account for real-world changes.

This is precisely the reason why we have conducted this review study, in order to bridge this gap, particularly by examining the application of Digital Twins in energy efficiency across different sectors.

This study also aims to identify the best practices and propose recommendations for the effective integration of Digital Twins into energy management strategies. By outlining key technological enablers, challenges, and sector-specific variations, our findings will contribute to the development of more standardized, efficient, and scalable DT applications.

- -

- This review underscores the need for further empirical studies that achieve the following:

- -

- Compare Digital Twin applications across industries;

- -

- Investigate the root causes of efficiency variations;

- -

- Propose standardized assessment frameworks to enhance consistency and applicability;

By addressing these gaps, our study contributes to the advancement of Digital Twin technology and its widespread, efficient adoption for energy optimization in diverse industrial sectors.

4. Results Analysis and Discussion

4.1. Results Analysis

4.1.1. Understanding Digital Twins and Their Applications

Digital Twins (DTs) have emerged as a transformative technology with vast applications across multiple industries, particularly in energy management, manufacturing, and smart infrastructure. These virtual replicas of physical systems integrate real-time data and advanced analytics to enhance decision-making, optimize operations, and improve efficiency. By systematically reviewing the existing literature, this study has identified key categories of Digital Twins and analyzed their impact on energy efficiency, cost reduction, and sustainability.

Three main types of Digital Twins have been identified. The Digital Twin Prototype (DTP) is used during the design phase, allowing engineers to create digital models that represent the physical and functional characteristics of a product before its physical fabrication. The Digital Twin Instance (DTI) represents the actual physical asset throughout its operational lifecycle, continuously updated with real-time data from sensors and other sources. Finally, the Digital Twin Aggregate (DTA) integrates multiple DTIs, providing a holistic view of an entire infrastructure or industrial network, enabling large-scale optimization.

4.1.2. Enhancing Energy Performance

One of the most significant contributions of Digital Twins lies in their ability to optimize energy consumption, particularly in manufacturing and construction. Through real-time monitoring and predictive analytics, DTs enable precise adjustments to operational parameters, resulting in significant energy savings.

In industrial settings, such as thermal power plants, Digital Twins have demonstrated the ability to reduce fuel consumption by up to 10 percent. This is achieved by improving combustion efficiency and enabling the real-time monitoring of equipment, ensuring optimal performance while minimizing energy waste. Similarly, in the building sector, DTs have been integrated into energy management systems, dynamically controlling heating, ventilation, and air conditioning (HVAC) systems. Studies indicate that this approach has led to energy savings ranging between 15 and 20 percent by reducing inefficiencies and adapting energy use to real-time demands.

4.1.3. Cost Reduction and Operational Efficiency

Beyond energy optimization, Digital Twins contribute significantly to cost reduction across industries. Predictive maintenance, enabled by DTs, allows for the early detection of potential failures, preventing costly breakdowns and unplanned downtime. As a result, maintenance costs in energy-intensive industries have been reduced by 20 to 30 percent.

Moreover, Digital Twins facilitate real-time workflow analysis, identifying inefficiencies and enabling corrective actions before they escalate into major operational challenges. By integrating DTs into daily operations, companies have reported overall cost reductions of 5 to 10 percent, highlighting the financial viability of this technology. These findings emphasize that the long-term savings and operational improvements brought by DTs outweigh the initial investment required for implementation.

4.1.4. Digital Twins and Decarbonization Efforts

As industries and cities seek to reduce their carbon footprint, Digital Twins are proving to be a powerful tool in advancing decarbonization strategies. By optimizing industrial processes, DTs have contributed to reducing carbon emissions by 15 to 25 percent. Real-time monitoring and automation enable industries to transition to more sustainable practices, minimizing waste and optimizing energy consumption.

In urban environments, the integration of Digital Twins into waste management systems has led to a 20 percent improvement in efficiency. By accurately predicting waste volumes and optimizing collection routes, DTs help to reduce the energy consumption and emissions associated with waste transportation and processing. These applications demonstrate the potential of Digital Twins to contribute to global sustainability efforts, making them a crucial component in the transition to greener industries and smart cities.

4.1.5. Challenges in Implementing Digital Twins

Despite the promising benefits, the widespread adoption of Digital Twins is hindered by several challenges. One of the primary obstacles is data quality and integration. The accuracy and effectiveness of DTs heavily depend on the quality of collected data, and inconsistent or incomplete data can lead to inaccurate predictions and inefficient decision-making.

Another major challenge is the complexity of integrating DTs into existing infrastructures. Many industries rely on legacy systems that were not designed to communicate with real-time digital models, requiring extensive modifications and investments. Additionally, the implementation of DTs requires substantial computational resources, posing financial and technical constraints, particularly for smaller organizations.

Cybersecurity risks further complicate the deployment of Digital Twins. Since DTs handle vast amounts of sensitive operational data, they are vulnerable to cyber threats, including data breaches and unauthorized access. Addressing these risks requires robust cybersecurity protocols and data protection measures.

4.1.6. Clarification of Digital Twins and Related Technologies

A Digital Twin is a virtual representation of a physical system that continuously integrates real-time data from sensors and other inputs, enabling predictive analytics and decision-making. However, the concept of Digital Twins is sometimes conflated with other related but distinct technologies.

Building Information Modeling (BIM) is often confused with Digital Twins, yet it primarily focuses on static representations used for design, construction, and facility management. Unlike DTs, BIM does not inherently include real-time sensor data or predictive analytics. However, BIM models can be enhanced with Digital Twin capabilities through integration with IoT- and AI-based analytics. Similarly, Internet of Things (IoT)-based monitoring systems collect real-time data from physical assets, but do not facilitate bidirectional interaction and advanced simulations inherent to Digital Twins. Traditional computational simulations model system behavior under predefined conditions, whereas Digital Twins continuously synchronize with physical systems, providing dynamic insights and real-time decision-making capabilities.

To standardize the implementation of Digital Twins, international frameworks provide structured methodologies. ISO 23247 [122], the Digital Twin Framework for Manufacturing, offers guidelines for DT deployment in industrial applications, ensuring consistency and interoperability. Likewise, ISO 19650 [123] defines standards for integrating BIM with DTs in construction and infrastructure projects. These frameworks help establish clear distinctions between Digital Twins and other digital technologies, supporting their effective implementation across various sectors.

In conclusion, the findings of this study underscore the transformative potential of Digital Twins in optimizing energy consumption, reducing operational costs, and supporting sustainability efforts. Through predictive maintenance, real-time monitoring, and automated optimization, DTs enable industries to achieve significant efficiency gains while minimizing environmental impact.

However, challenges related to data security, integration complexity, and initial investment costs must be addressed to maximize their adoption and benefits. Future research should focus on developing standardized methodologies, expanding the scope of DT applications, and exploring innovative solutions to overcome existing barriers. Advancements in AI, blockchain, and the IoT are expected to play a crucial role in addressing these challenges, paving the way for broader DT implementation.

As industries continue to evolve, Digital Twins will play an increasingly essential role in shaping the future of energy management and industrial operations. By investing in this technology and addressing its associated challenges, organizations can unlock new opportunities for efficiency, resilience, and sustainability in the digital era.

4.2. Discussion

4.2.1. Comparison with Previous Studies

The results of this study confirm and extend the findings of previous research on Digital Twins, demonstrating their potential to improve decision-making, optimize energy performance, and contribute to decarbonization efforts. Strielkowski et al. [1] highlighted that integrating Digital Twins into decision-making processes enhances both the accuracy and speed of strategic decisions through real-time data analysis. Our findings support this assertion, particularly in the energy sector, where the continuous monitoring and analysis of operational data enable immediate adjustments that optimize energy consumption and reduce inefficiencies. A similar effect has been observed in healthcare, as noted by Fuller et al. [124], where Digital Twins have been used to improve resource allocation and patient management. While our study focuses on energy applications, the underlying principle remains the same: the ability to make more informed decisions through predictive analytics and real-time system monitoring.

The impact of Digital Twins on energy performance has also been extensively studied. Li et al. [23] examined their role in power plants and found that integrating Digital Twins into combustion processes and predictive maintenance strategies led to a significant reduction in fuel consumption, by up to 10%. Our study corroborates these findings, further emphasizing their potential in optimizing energy efficiency in industrial processes. Similarly, Riedelsheimer et al. [32] observed reductions in operating costs in renewable energy systems, where real-time monitoring and predictive adjustments of wind turbine and solar panel performance led to greater efficiency.

In addition to efficiency gains, the role of Digital Twins in reducing carbon emissions has been widely recognized. Zhao et al. [66] explored their impact on the decarbonization of the manufacturing sector and reported a 15–25% reduction in carbon emissions. Our findings align with these results, particularly in the optimization of industrial processes and urban waste management, both of which contribute to lowering CO2 emissions. However, Heymann et al. [22] pointed out that the effectiveness of Digital Twins can vary significantly depending on local policies and infrastructure. Our study reinforces this argument, demonstrating that national contexts strongly influence energy efficiency gains and emission reductions, highlighting the necessity of supportive policies and investment in infrastructure to ensure successful implementation.

Another critical advantage of Digital Twins is their role in predictive maintenance and cost reduction. Tao et al. [10] showed that predictive maintenance, facilitated by Digital Twins, can lower maintenance costs by 20–30%. Our study confirms these benefits, particularly in thermal power plants and building energy management systems, where early fault detection and data-driven maintenance strategies lead to similar savings. Additionally, Uhlemann et al. [113] emphasized the overall cost reductions resulting from improved operational efficiency. Our findings indicate that companies integrating Digital Twins experience a 5–10% reduction in operating costs, further reinforcing their financial viability.

4.2.2. Implications for the Energy Sector

The results of this study carry significant implications for the energy sector, particularly in the transition towards renewable energy and the improvement of energy infrastructure resilience. Digital Twins facilitate the management of wind and solar farms by enabling real-time adjustments to maximize energy production and minimize losses. This capacity is crucial for integrating renewable energy sources into the grid, as highlighted by Riedelsheimer et al. [32]. Moreover, Digital Twins contribute to infrastructure resilience by ensuring continuous monitoring and predictive maintenance. By detecting anomalies before they cause system failures, they enhance the stability and reliability of power grids, a finding that aligns with the work of Li et al. [23].

4.2.3. Limitations

Despite their advantages, the implementation of Digital Twins presents several challenges. One of the primary obstacles is the high initial investment required for hardware, software, and personnel training. Businesses must carefully evaluate the upfront costs against long-term benefits, which can be a deterrent for some organizations, as discussed by Uhlemann et al. [113].

Another major challenge lies in data management. The accuracy and effectiveness of Digital Twins depend on the quality of the data collected. Poor data quality or security vulnerabilities can lead to incorrect decisions, as highlighted by Tao et al. [10]. Ensuring data integrity and implementing robust cybersecurity measures are therefore crucial for the successful deployment of this technology.

Finally, the adoption of Digital Twins requires specialized training and user acceptance. Many industries face a skills gap when integrating advanced digital technologies. As Heymann et al. [22] noted, investing in training programs is essential to ensure that staff can fully leverage the capabilities of Digital Twins. Without adequate training, companies may struggle to maximize the benefits of these systems.

4.2.4. Recommendations for Future Research

To enhance the adoption and effectiveness of Digital Twins, several avenues for future research should be explored. One critical area is the development of standardized methods for data integration and management. Establishing uniform standards will improve interoperability between different Digital Twin systems and ensure data consistency across industries.

Additionally, research should investigate the application of Digital Twins beyond the energy sector. Expanding their use in fields such as healthcare, logistics, and transportation could unlock further benefits and drive innovation. Understanding how Digital Twins function in diverse industrial and geographical contexts will also be valuable in identifying best practices and optimizing their implementation.

Lastly, large-scale comparative studies should be conducted to assess the effectiveness of Digital Twins across various industries. Such studies would provide insights into the factors influencing their success and help develop guidelines for overcoming implementation challenges.

In conclusion, Digital Twins represent a transformative technology with vast potential to optimize energy efficiency, reduce costs, and support sustainability efforts. While challenges remain, continued research, investment in technological infrastructure, and workforce training will be essential in fully realizing the benefits of this innovative approach.

5. Conclusions