A MEMS Micro-g Capacitive Accelerometer Based on Through-Silicon-Wafer-Etching Process

Abstract

:1. Introduction

2. Materials and Methods

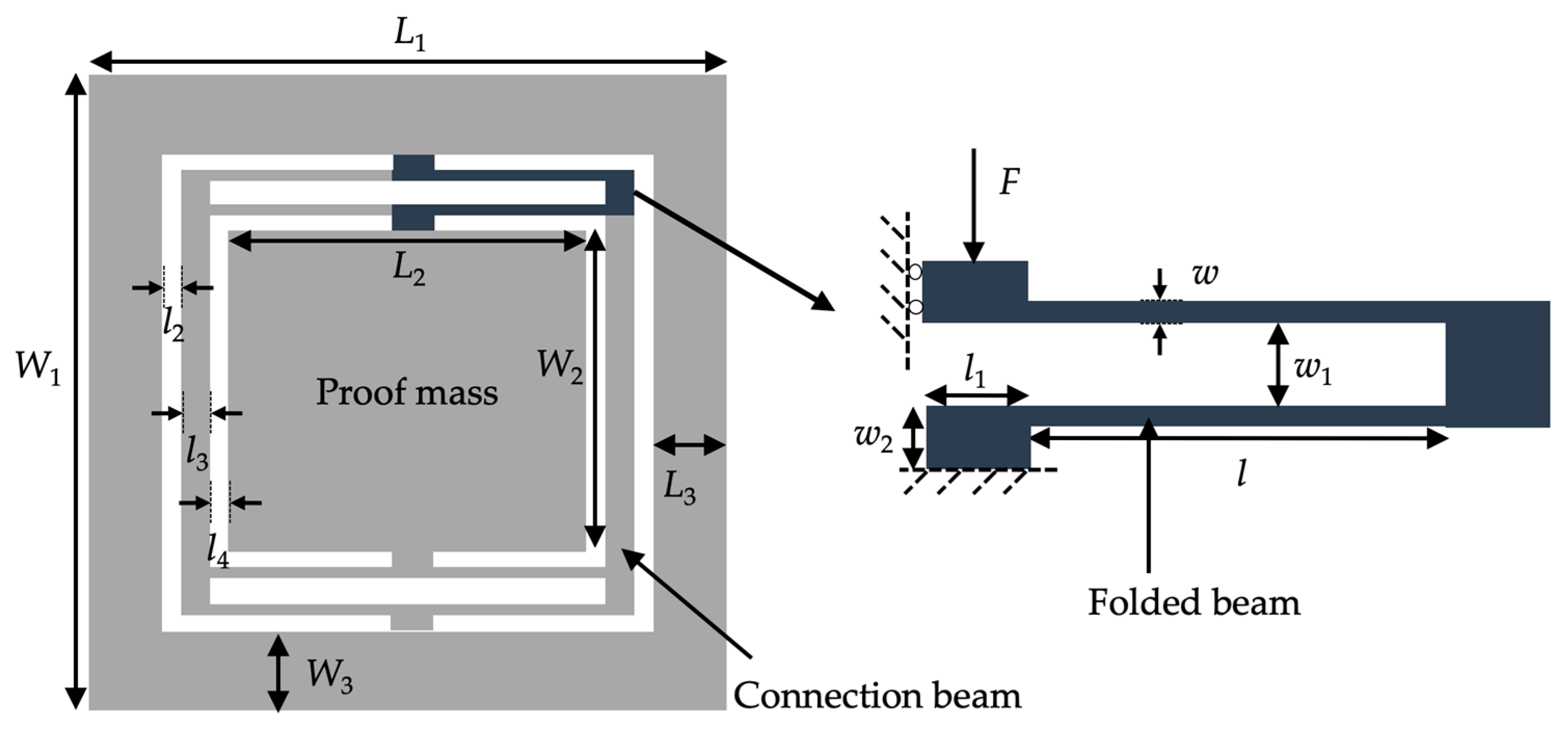

2.1. Spring-Mass Structure Design

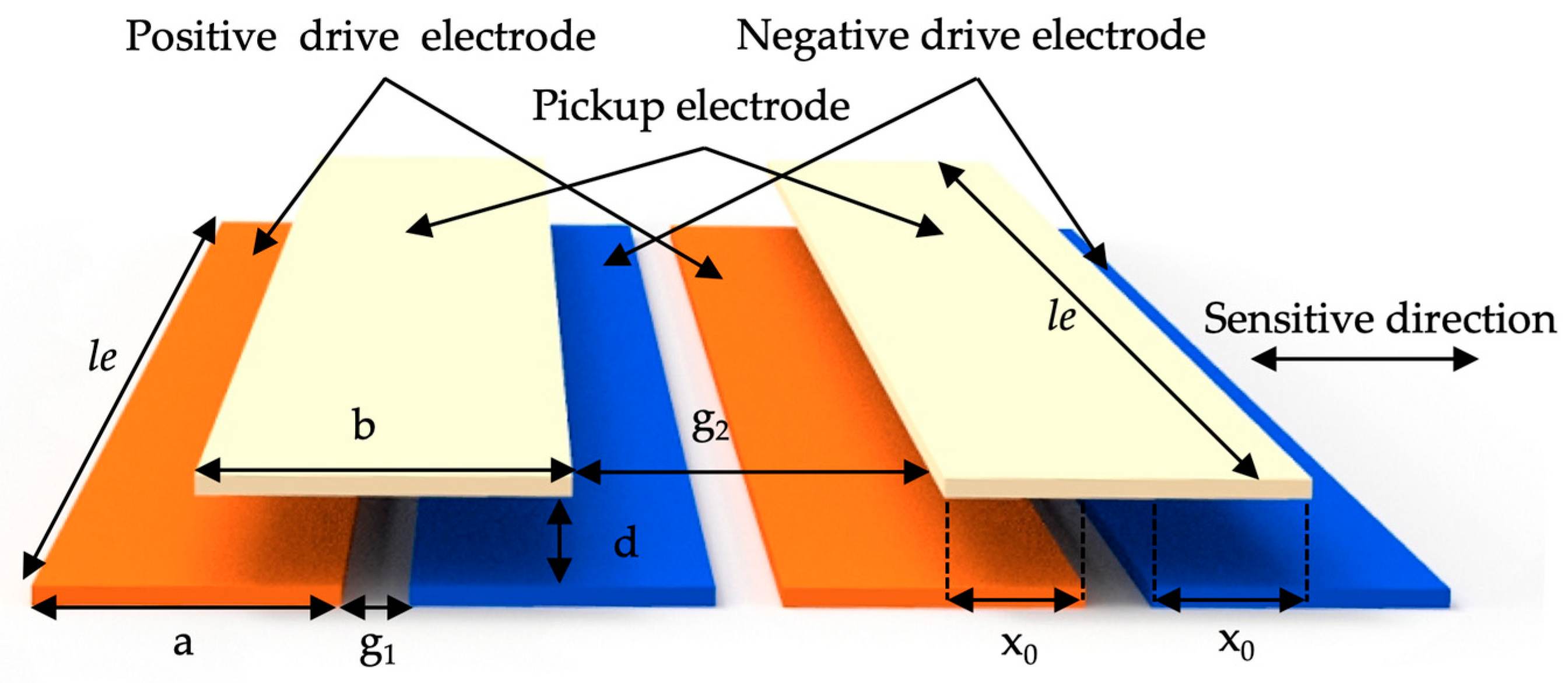

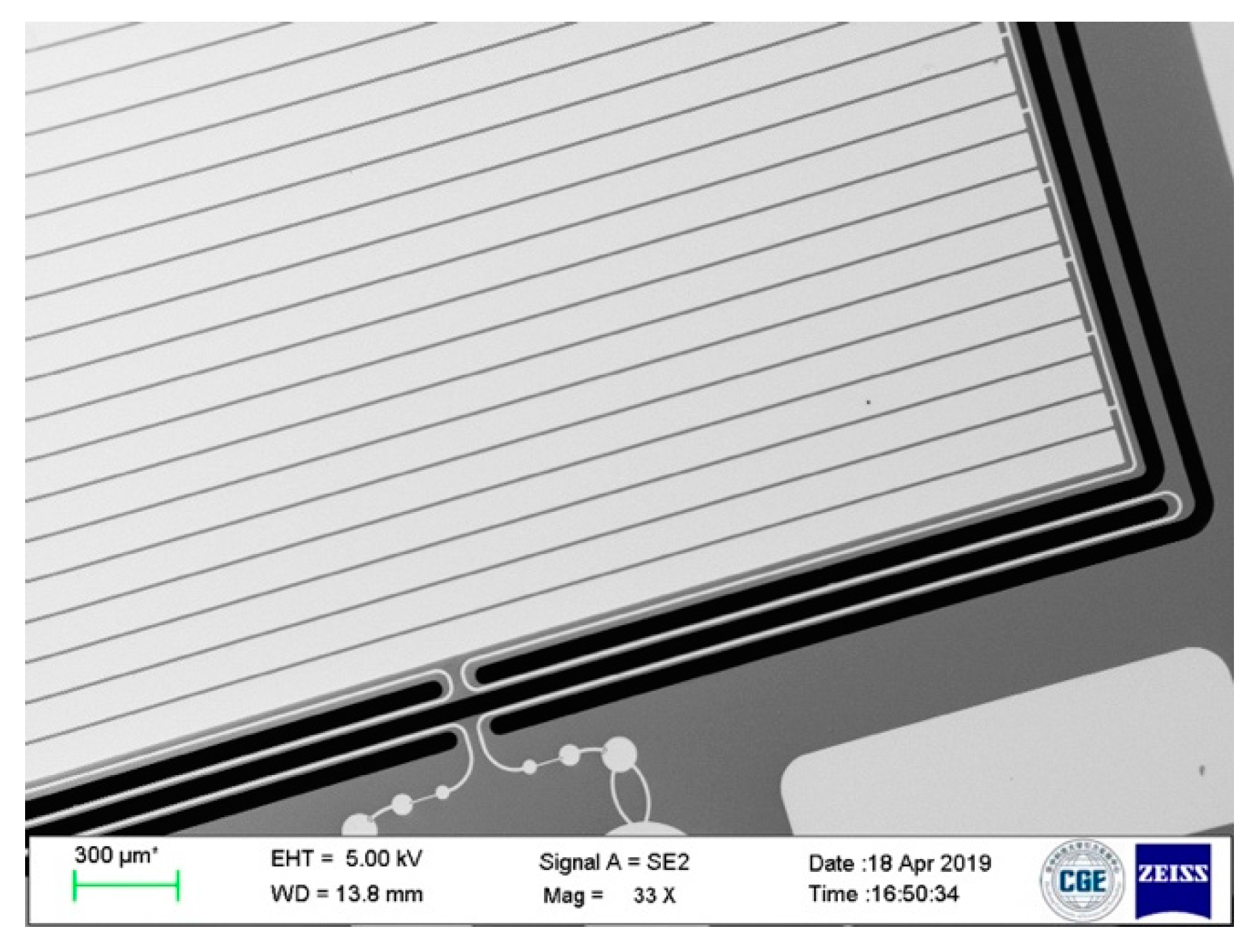

2.2. Area-Variation Capacitive Displacement Transducer Design

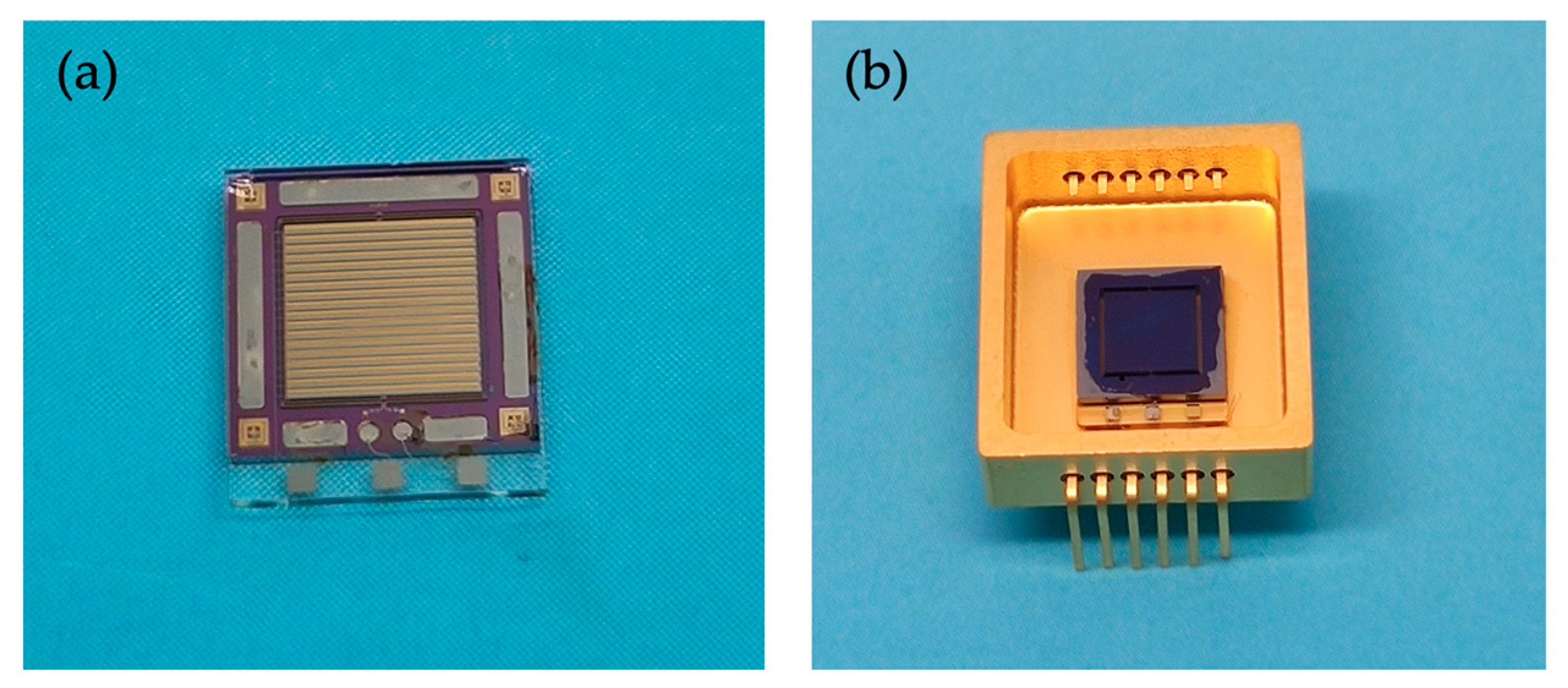

3. Fabrication Process

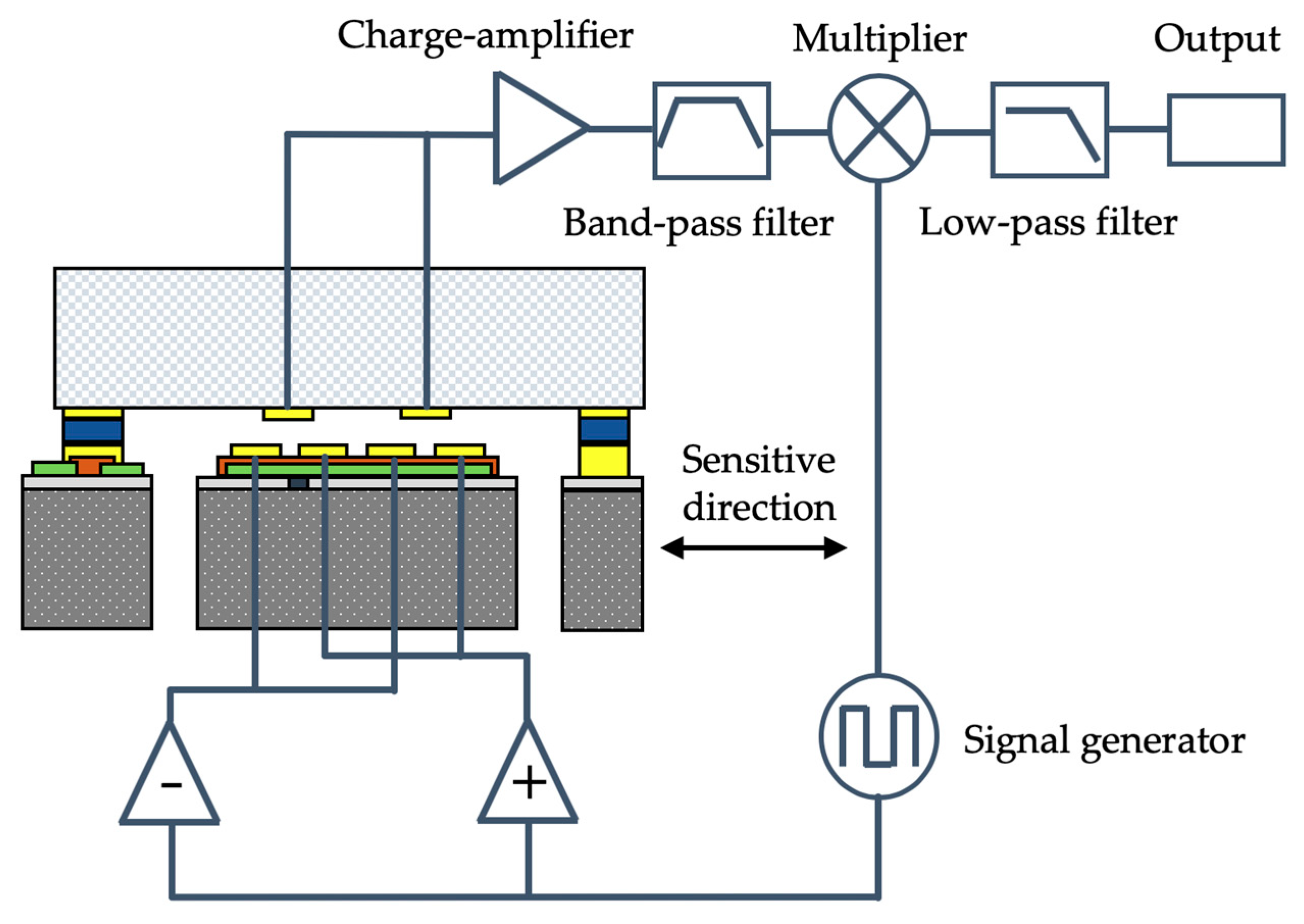

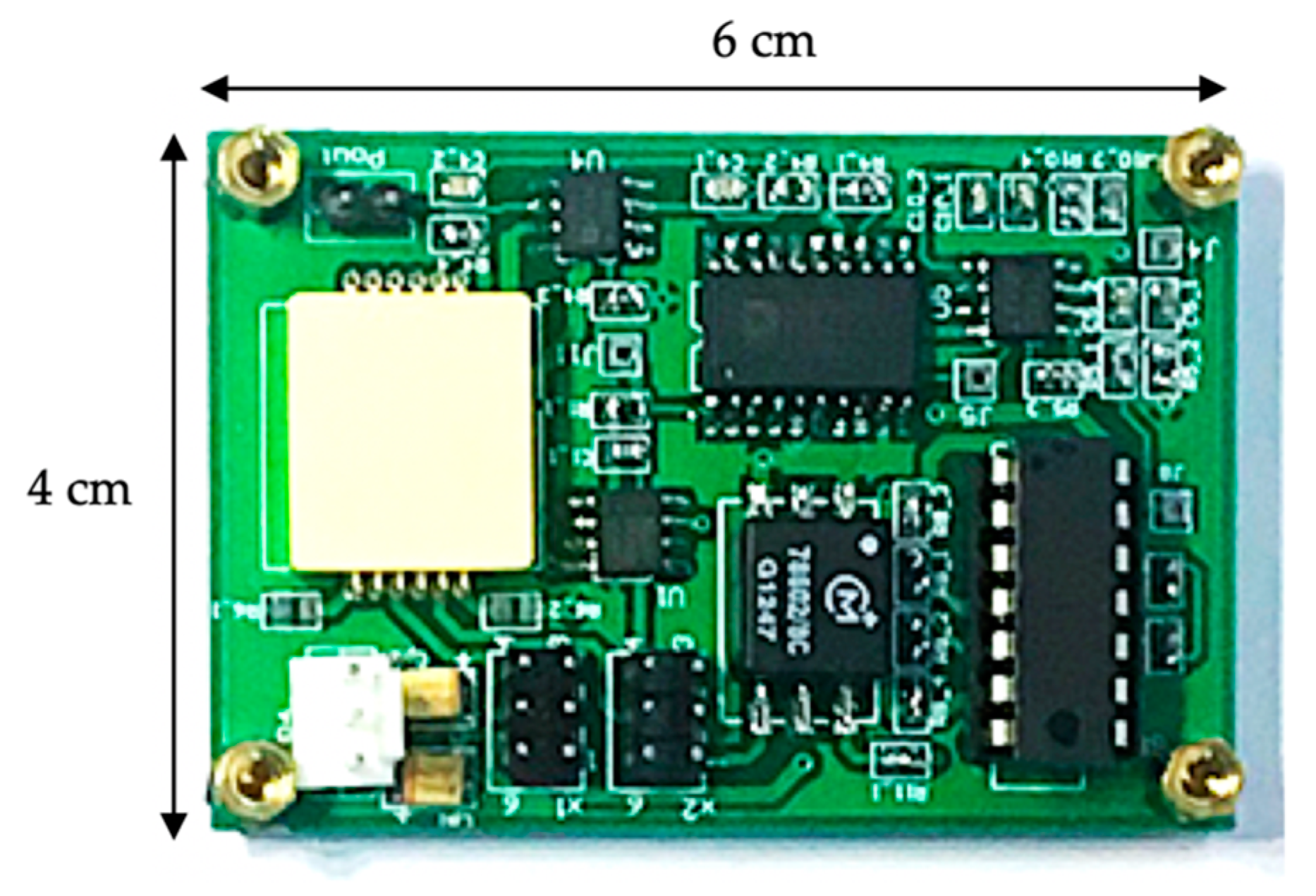

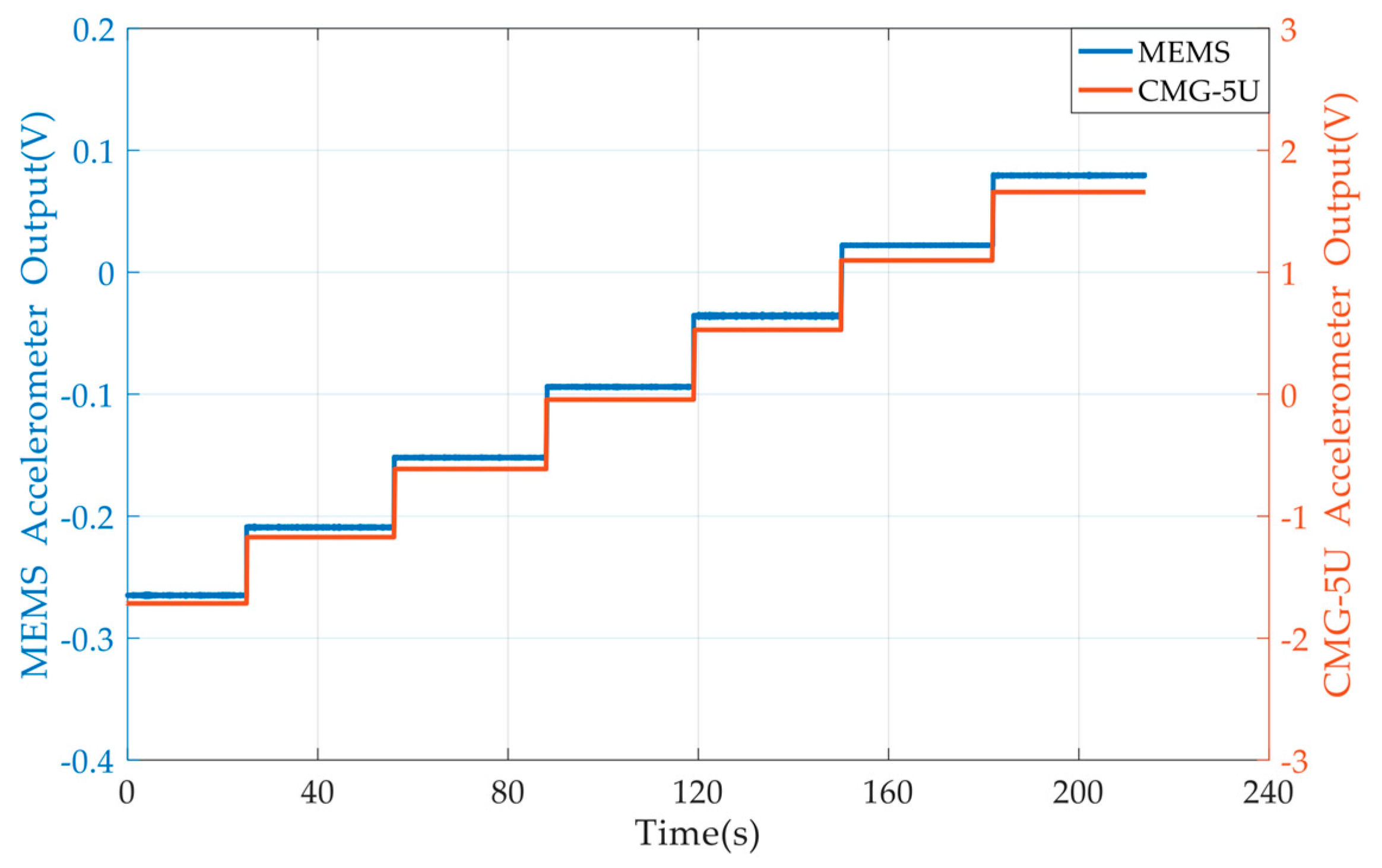

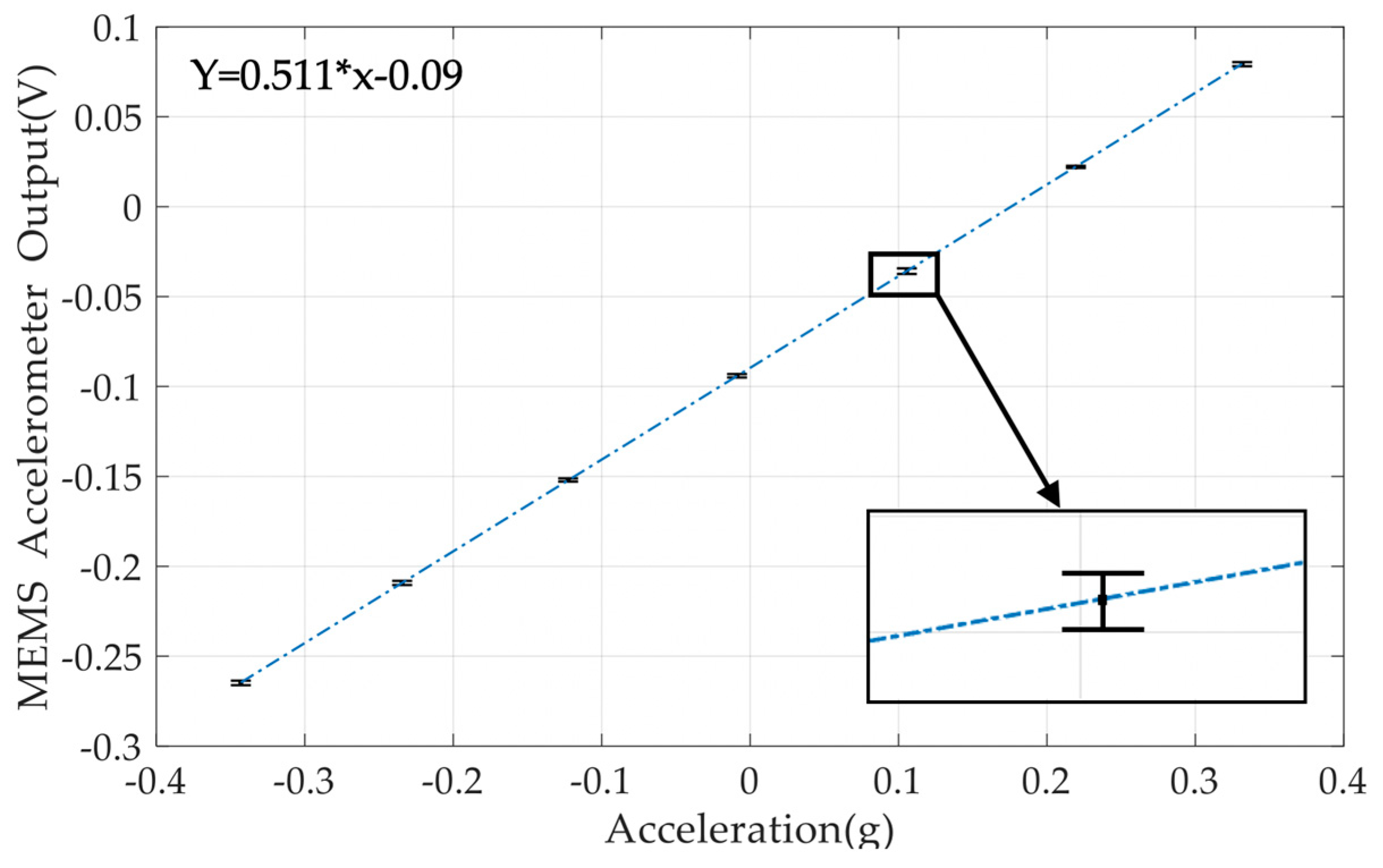

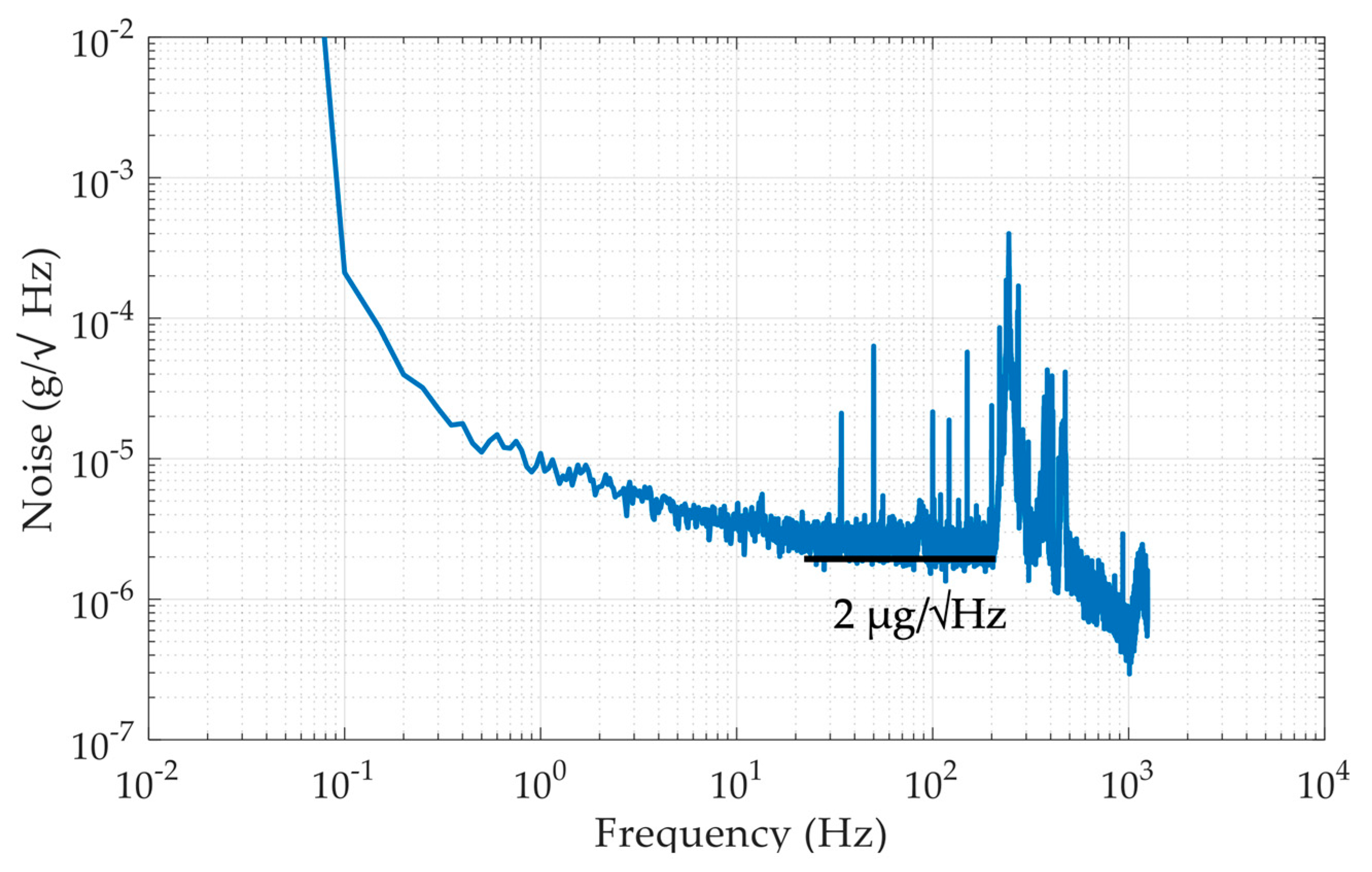

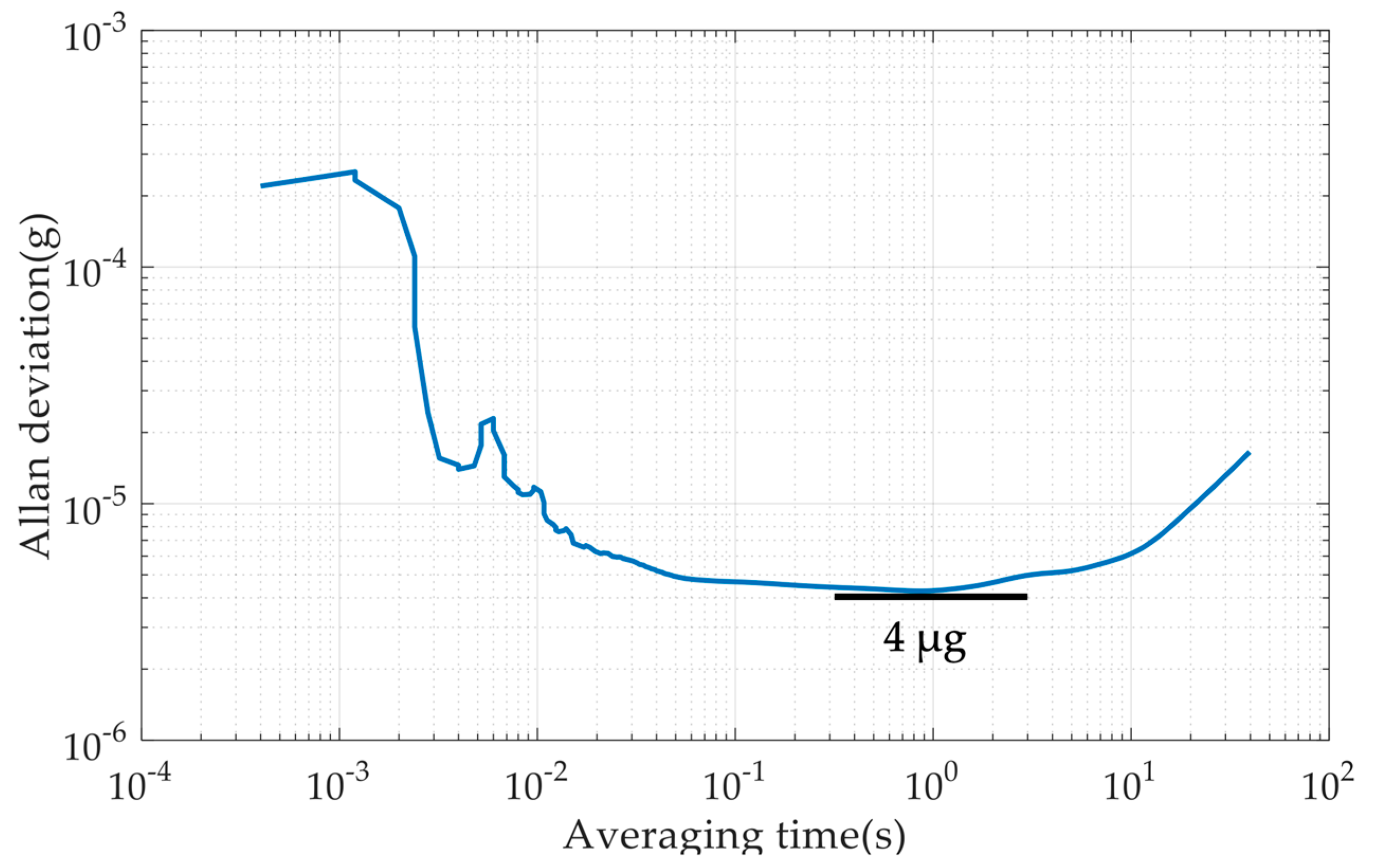

4. Experiments

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ciuti, G.; Ricotti, L.; Menciassi, A.; Dario, P. MEMS sensor technologies for human centred applications in healthcare, physical activities, safety and environmental sensing: A review on research activities in Italy. Sensors 2015, 15, 6441–6468. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Ghazilla, R.A.; Khairi, N.M.; Kasi, V. Reviews on various inertial measurement unit (IMU) sensor applications. Int. J. Signal Process. Syst. 2013, 1, 256–262. [Google Scholar] [CrossRef]

- Beeby, S.; Ensel, G.; Kraft, M. MEMS Mechanical Sensors; Artech House: Boston, MA, USA, 2004. [Google Scholar]

- Yazdi, N.; Ayazi, F.; Najafi, K. Micromachined inertial sensors. Proc. IEEE 1998, 86, 1640–1659. [Google Scholar] [CrossRef]

- Hindrichsen, C.C.; Larsen, J.; Thomsen, E.V.; Hansen, K.; Lou-Møller, R. Circular piezoelectric accelerometer for high band width application. In Proceedings of the Sensors, 2009 IEEE, Christchurch, New Zealand, 25–28 October 2009; pp. 475–478. [Google Scholar]

- Kobayashi, T.; Okada, H.; Akiyama, M.; Maeda, R.; Itoh, T. A digital output piezoelectric accelerometer using cmos-compatible AlN thin film. In Proceedings of the TRANSDUCERS 2009–2009 International Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009; pp. 1166–1169. [Google Scholar]

- Pike, W.T.; Calcutt, S.; Standley, I.M.; Mukherjee, A.G.; Temple, J.; Warren, T.; Charalambous, C.; Liu, H.; Stott, A.; McClean, J.B. A silicon seismic package (SSP) for planetary geophysics. In Proceedings of the 47th Lunar and Planetary Science Conference, The Woodlands, TX, USA, 21–25 March 2016. [Google Scholar]

- Wu, W.; Liu, J.; Fan, J.; Peng, D.; Liu, H.; Tu, L. A nano-g micromachined seismic sensor for levelling-free measurements. Sens. Actuators Phys. 2018, 280, 238–244. [Google Scholar] [CrossRef]

- Wang, J.; Li, X. A high-performance dual-cantilever high-shock accelerometer single sided micromachined in (111) silicon wafers. J. Microelectromech. Syst. 2010, 19, 1515–1520. [Google Scholar] [CrossRef]

- Haris, M.; Qu, H. A cmos-mems piezoresistive accelerometer with large proof mass. In Proceedings of the 5th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 20–23 January 2010; pp. 309–312. [Google Scholar]

- Miao, M.; Hu, Q.; Hao, Y.; Dong, H.; Wang, L.; Shi, Y.; Shen, S. A bulk micromachined Si-on-glass tunneling accelerometer with out-of-plane sensing capability. In Proceedings of the 2nd IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Bangkok, Thailand, 16–19 January 2007; pp. 235–240. [Google Scholar]

- Liu, C.H.; Kenny, T.W. A high-precision, wide-bandwidth micromachined tunneling accelerometer. J. Microelectromech. Syst. 2001, 10, 425–433. [Google Scholar]

- Zou, X.; Seshia, A.A. A high-resolution resonant mems accelerometer. In Proceedings of the 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 1247–1250. [Google Scholar]

- Wang, Y.; Zhang, J.; Yao, Z.; Lin, C.; Zhou, T.; Su, Y.; Zhao, J. A MEMS Resonant Accelerometer With High Performance of Temperature Based on Electrostatic Spring Softening and Continuous Ring-Down Technique. IEEE Sens. J. 2018, 18, 7023–7031. [Google Scholar] [CrossRef]

- Yin, Y.; Fang, Z.; Liu, Y.; Han, F. Temperature-Insensitive Structure Design of Micromachined Resonant Accelerometers. Sensors 2019, 19, 1544. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Pandit, M.; Sobreviela, G.; Steinmann, P.; Mustafazade, A.; Zou, X.; Seshia, A. JMEMS Letters A Resonant MEMS Accelerometer With 56ng Bias Stability and 98ng/Hz1/2 Noise Floor. J. Microelectromech. Syst. 2019, 28, 324–326. [Google Scholar] [CrossRef]

- Littler, I.C.; Gray, M.B.; Lam, T.T.; Chow, J.H.; Shaddock, D.A.; McClelland, D.E. Optical-fiber accelerometer array: Nano-g infrasonic operation in a passive 100 km loop. IEEE Sens. J. 2010, 10, 1117–1124. [Google Scholar] [CrossRef]

- Zandi, K.; Wong, B.; Zou, J.; Kruzelecky, R.V.; Jamroz, W.; Peter, Y.A. In-plane silicon on-insulator optical mems accelerometer using waveguide fabry-perot microcavity with silicon/air bragg mirrors. In Proceedings of the IEEE 23rd International Conference on Micro Electro Mechanical Systems (MEMS), Hong Kong, China, 24–28 January 2010; pp. 839–842. [Google Scholar]

- Chen, S.J.; Shen, C.H. A novel two-axis cmos accelerometer based on thermal convection. IEEE Trans. Instrum. Meas. 2008, 57, 1572–1577. [Google Scholar] [CrossRef]

- Ma, A.H.; Leung, A.M. Leung, Three-axis thermal accelerometer based on buckled cantilever microstructure. In Proceedings of the IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 1492–1495. [Google Scholar]

- Phan, K.; Mauritz, A.; Homburg, F. A novel elastomer-based magnetoresistive accelerometer. Sens. Actuators Phys. 2008, 145, 109–115. [Google Scholar] [CrossRef]

- Abbaspour-Sani, E.; Huang, R.-S.; Kwok, C.Y. A novel electromagnetic accelerometer. IEEE Electron Device Lett. 1994, 15, 272–273. [Google Scholar] [CrossRef]

- Zhou, X.; Che, L.; Wu, J.; Li, X.; Wang, Y. A novel sandwich capacitive accelerometer with a symmetrical structure fabricated from a D-SOI wafer. J. Micromech. Microeng. 2012, 22, 085031. [Google Scholar] [CrossRef]

- Xie, H.; Fedder, G.K. Vertical comb-finger capacitive actuation and sensing for CMOS-MEMS. Sens. Actuators Phys. 2002, 95, 212–221. [Google Scholar] [CrossRef]

- Zhang, D.; Drissen, W.; Breguet, J.M.; Clavel, R.; Michler, J. A high-sensitivity and quasi-linear capacitive sensor for nanomechanical testing applications. J. Micromech. Microeng. 2009, 19, 075003. [Google Scholar] [CrossRef]

- Zhang, W.M.; Yan, H.; Peng, Z.K.; Meng, G. Electrostatic pull-in instability in MEMS/NEMS: A review. Sens. Actuators Phys. 2014, 214, 187–218. [Google Scholar] [CrossRef]

- Milligan, D.J.; Homeijer, B.D.; Walmsley, R.G. An ultra-low noise mems accelerometer for seismic imaging. In Proceedings of the IEEE Sensors, Limerick, Ireland, 28–31 October 2011; pp. 1281–1284. [Google Scholar]

- Liu, H.; Pike, W.T.; Dou, G. Design, fabrication and characterization of a micro-machined gravity gradiometer suspension. In Proceedings of the 2014 IEEE SENSORS, Valencia, Spain, 2–5 November 2014. [Google Scholar]

- Guralp, CMG-5U, Datasheet. Available online: http://www.guralp.com/documents/DAS-050-0002.pdf (accessed on 5 June 2019).

- Colibrys, MS9010, Datasheet. Available online: https://www.colibrys.com/product/ms9000-mems-accelerometer/ (accessed on 5 June 2019).

- Physical-Logic, MAXL-OL-2020, Datasheet. Available online: http://physical-logic.com/wp-content/uploads/2019/04/MAXL-OL-2020-Performance-Datasheet-B06.pdf (accessed on 5 June 2019).

- Analog, ADXL356B, Datasheet. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/ADXL356-357.pdf (accessed on 5 June 2019).

| Symbol | Parameters | Unit | Value |

|---|---|---|---|

| L1 | Sensor length | mm | 6.5 |

| W1 | Sensor width | mm | 6.4 |

| L2 | Proof-mass length | mm | 4.2 |

| W2 | Proof-mass width | mm | 4 |

| L3 | Frame length | mm | 1 |

| W3 | Frame width | mm | 1 |

| l | Folded beam length | mm | 2 |

| l1 | Linkage length | µm | 200 |

| l2 | Connection beam gap to frame | µm | 50 |

| l3 | Connection beam width | µm | 50 |

| l4 | Connection beam gap to mass | µm | 50 |

| w | Folded beam width | µm | 16 |

| w1 | Folded beam gap | µm | 50 |

| w2 | Linkage width | µm | 50 |

| t | Wafer thickness | µm | 500 |

| f0 | Fundamental frequency | Hz | 295.2 |

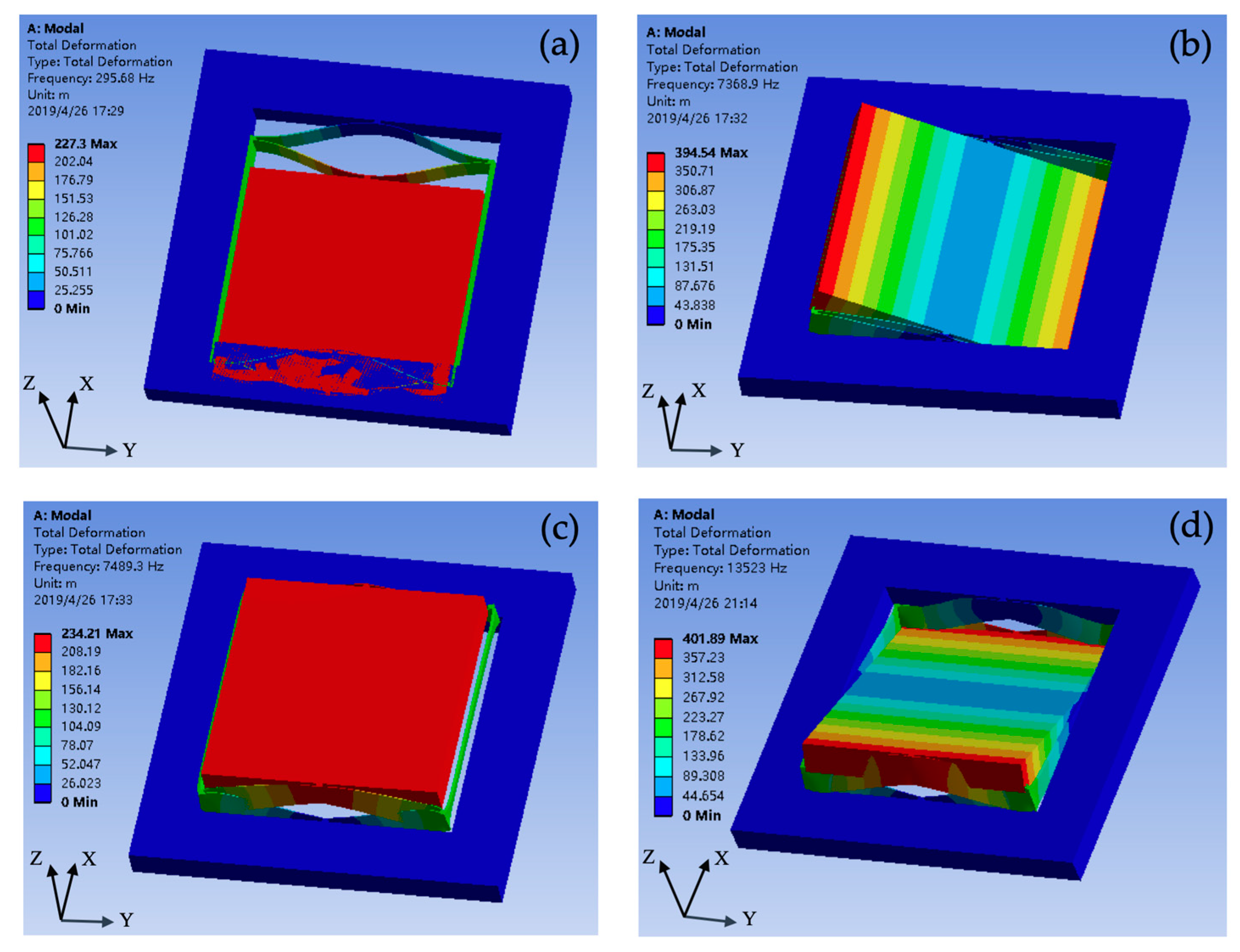

| Parameters | Sym. | With Connection Beams | Without Connection Beams |

|---|---|---|---|

| Fundamental frequency | fx | 295.7 Hz | 308.4 Hz |

| Rotational frequency about X-axis | fα | 7368.9 Hz | 5918.0 Hz |

| Out-of-plane translational frequency | fz | 7489.3 Hz | 4474.8 Hz |

| Rotational frequency about Y-axis | fβ | 13,523 Hz | 7958.7 Hz |

| Rejection ratio | fα/fx | 24.9 | 19.2 |

| Rejection ratio | fz/fx | 25.3 | 14.5 |

| Rejection ratio | fβ/fx | 45.7 | 25.8 |

| Cross-sensitivity in displacement | z/x | 0.16% | 0.48% |

| Symbol | Parameters | Unit | Value |

|---|---|---|---|

| a | Drive electrode width | µm | 100 |

| b | Pickup electrode width | µm | 110 |

| g1 | Drive electrode separation | µm | 10 |

| g2 | Pickup electrode separation | µm | 110 |

| le | Electrode length | mm | 4 |

| d | Gap between the drive electrodes and pickup electrodes | µm | 10 |

| N | Number of periods | / | 18 |

| MEMS Cap. Acc. | Range (g) | Noise Floor (μg/Hz1/2) | Die size (mm3) | Operation | Cap. Sensing |

|---|---|---|---|---|---|

| MS9010 [30] | ±10 | 18 @100 Hz | <8.9 × 8.9 × 3.2 | Open-loop | Gap-variation |

| MAXL-OL-2020 [31] | ±20 | 4 @100 Hz | <8.9 × 8.9 × 3.2 | Open-loop | Gap-variation |

| ADXL 356B [32] | ±20 | 80 @100 Hz | <6.0 × 6.0 × 2.2 | Closed-loop | Gap-variation |

| This work | ±20 | 2 @100 Hz | 6.5 × 6.4 × 1.6 | Open-loop | Area-variation |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, K.; Wei, X.; Zhang, S.; Zhang, M.; Hu, C.; Liu, H.; Tu, L.-C. A MEMS Micro-g Capacitive Accelerometer Based on Through-Silicon-Wafer-Etching Process. Micromachines 2019, 10, 380. https://doi.org/10.3390/mi10060380

Rao K, Wei X, Zhang S, Zhang M, Hu C, Liu H, Tu L-C. A MEMS Micro-g Capacitive Accelerometer Based on Through-Silicon-Wafer-Etching Process. Micromachines. 2019; 10(6):380. https://doi.org/10.3390/mi10060380

Chicago/Turabian StyleRao, Kang, Xiaoli Wei, Shaolin Zhang, Mengqi Zhang, Chenyuan Hu, Huafeng Liu, and Liang-Cheng Tu. 2019. "A MEMS Micro-g Capacitive Accelerometer Based on Through-Silicon-Wafer-Etching Process" Micromachines 10, no. 6: 380. https://doi.org/10.3390/mi10060380

APA StyleRao, K., Wei, X., Zhang, S., Zhang, M., Hu, C., Liu, H., & Tu, L.-C. (2019). A MEMS Micro-g Capacitive Accelerometer Based on Through-Silicon-Wafer-Etching Process. Micromachines, 10(6), 380. https://doi.org/10.3390/mi10060380