Analysis on Machining Performance of Nickel-Base Superalloy by Electrochemical Micro-milling with High-Speed Spiral Electrode

Abstract

:1. Introduction

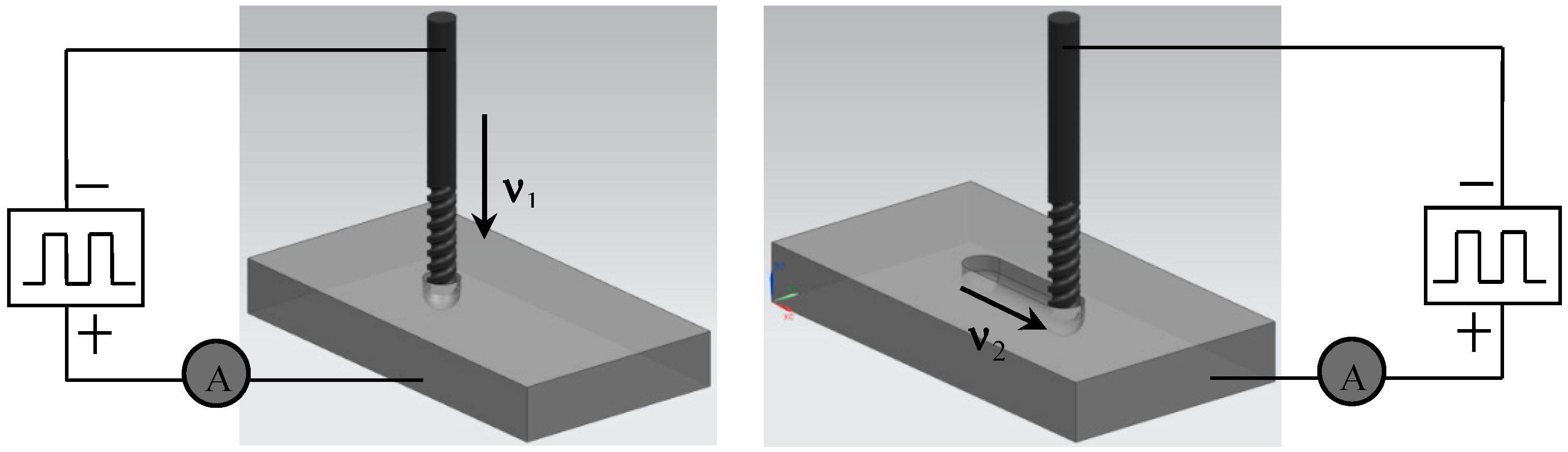

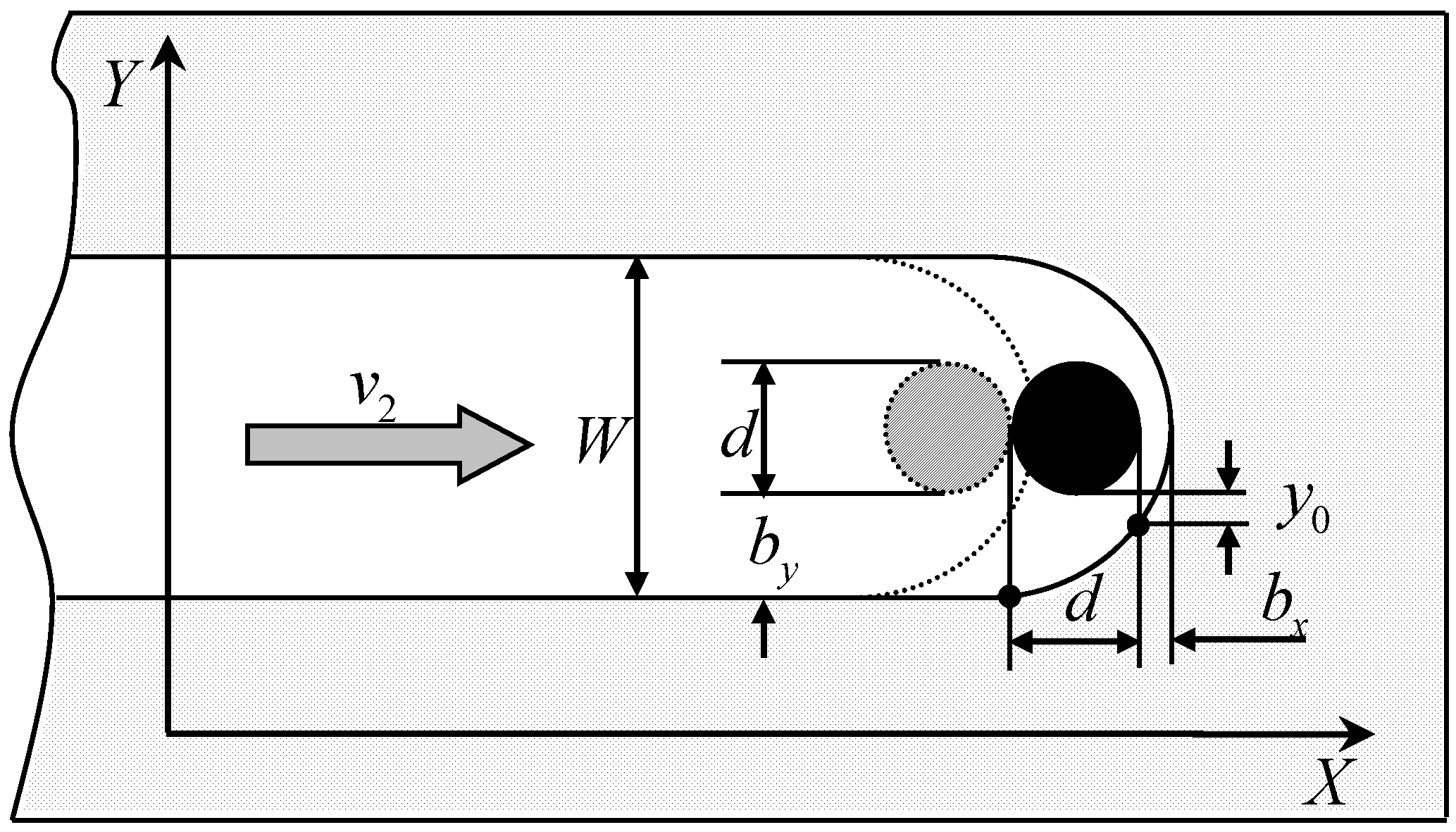

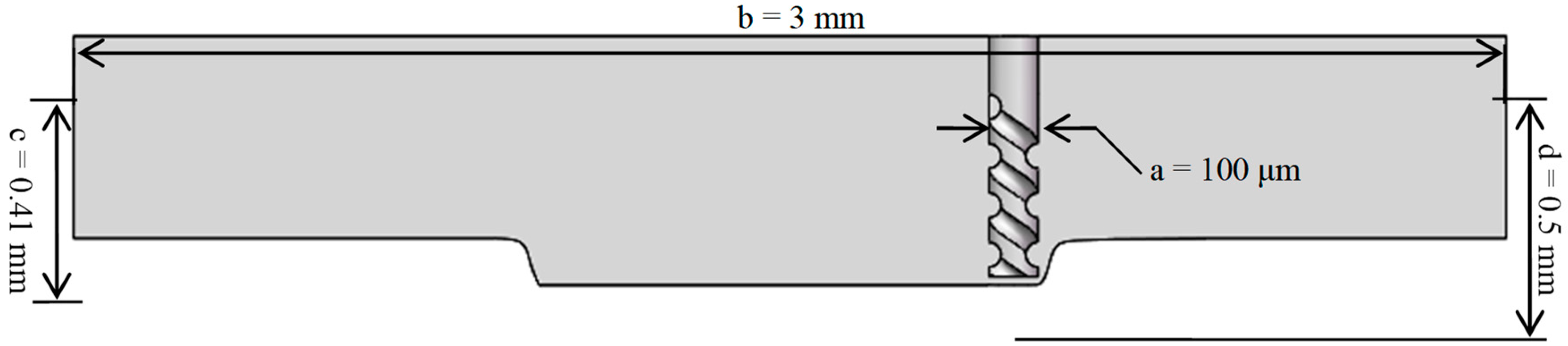

2. Principle of Electrochemical Micro-Milling

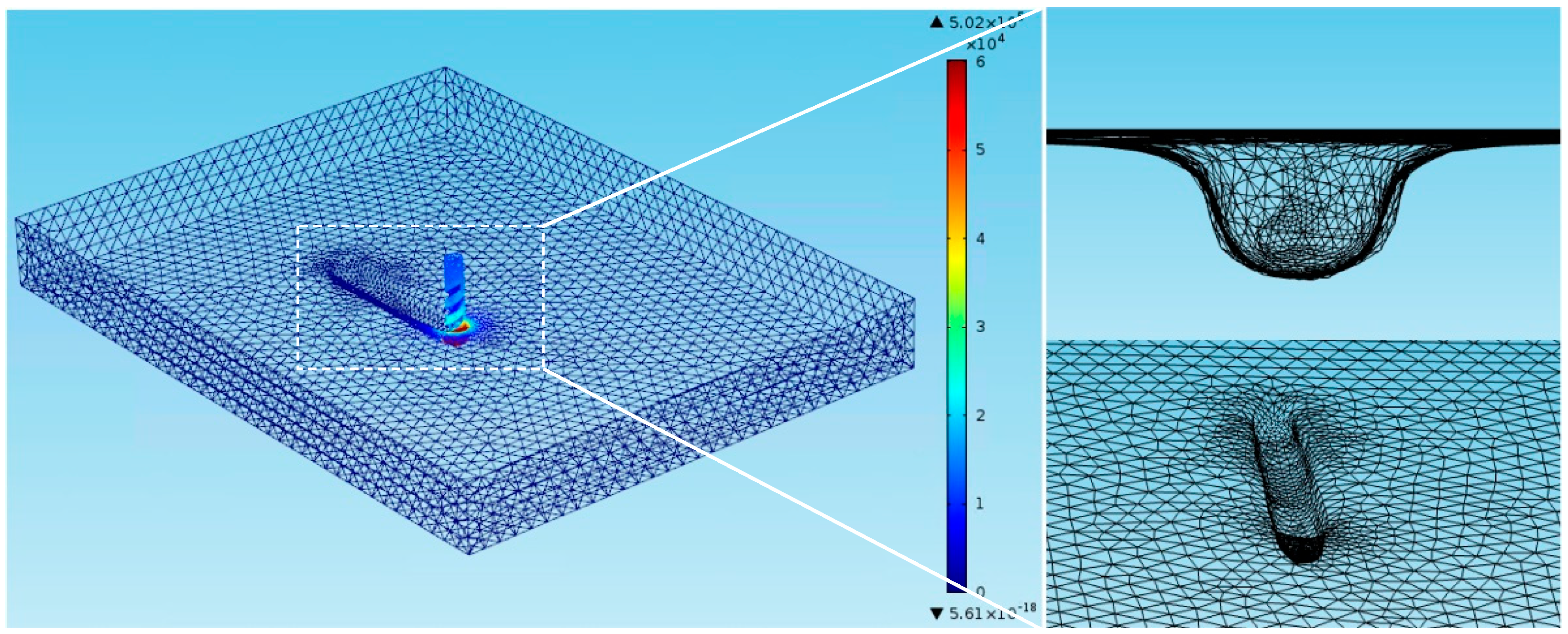

3. Analysis of Electric Field and Flow Field in Electrochemical Micro-Milling (EMM)

3.1. Analysis of Electric Field and Current Density

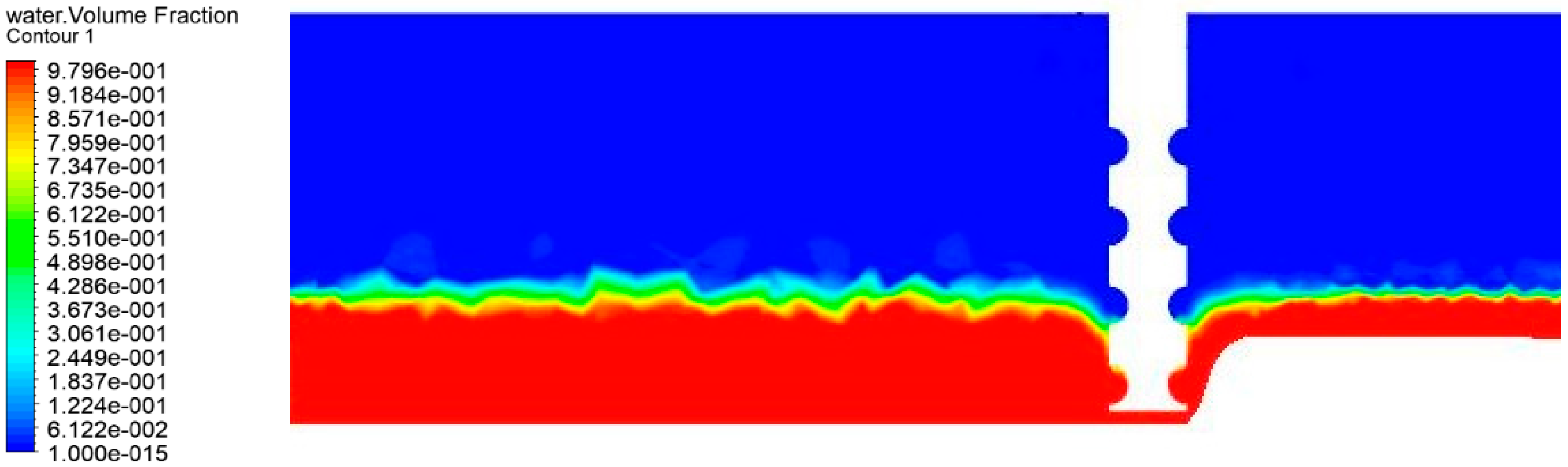

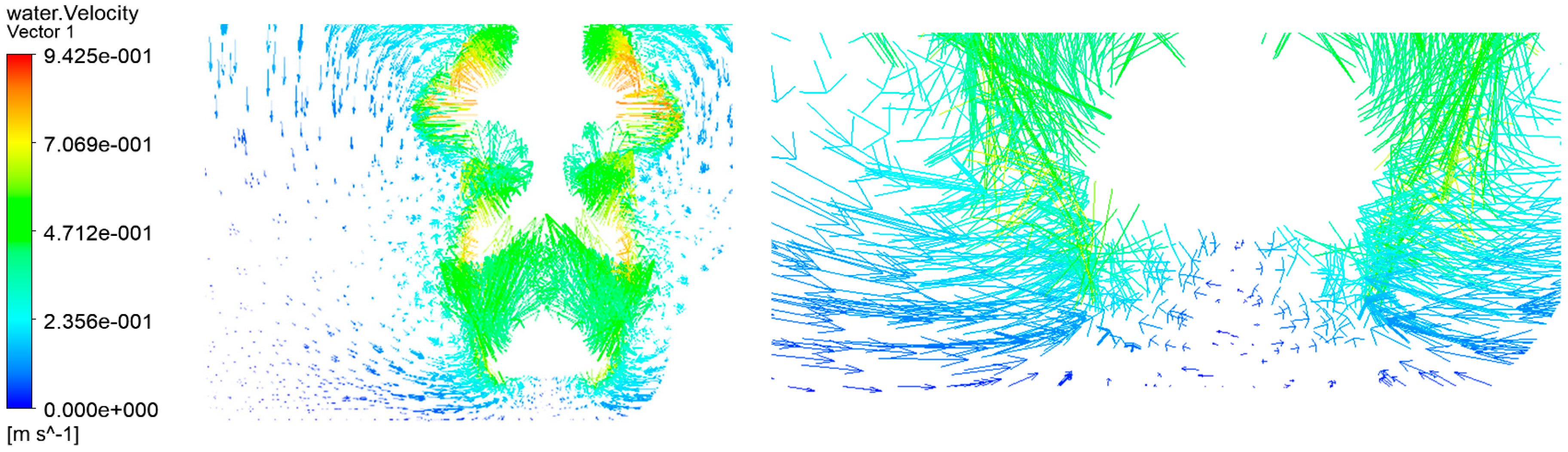

3.2. Analysis of Flow Field in Machining Gap

4. Results and Discussion

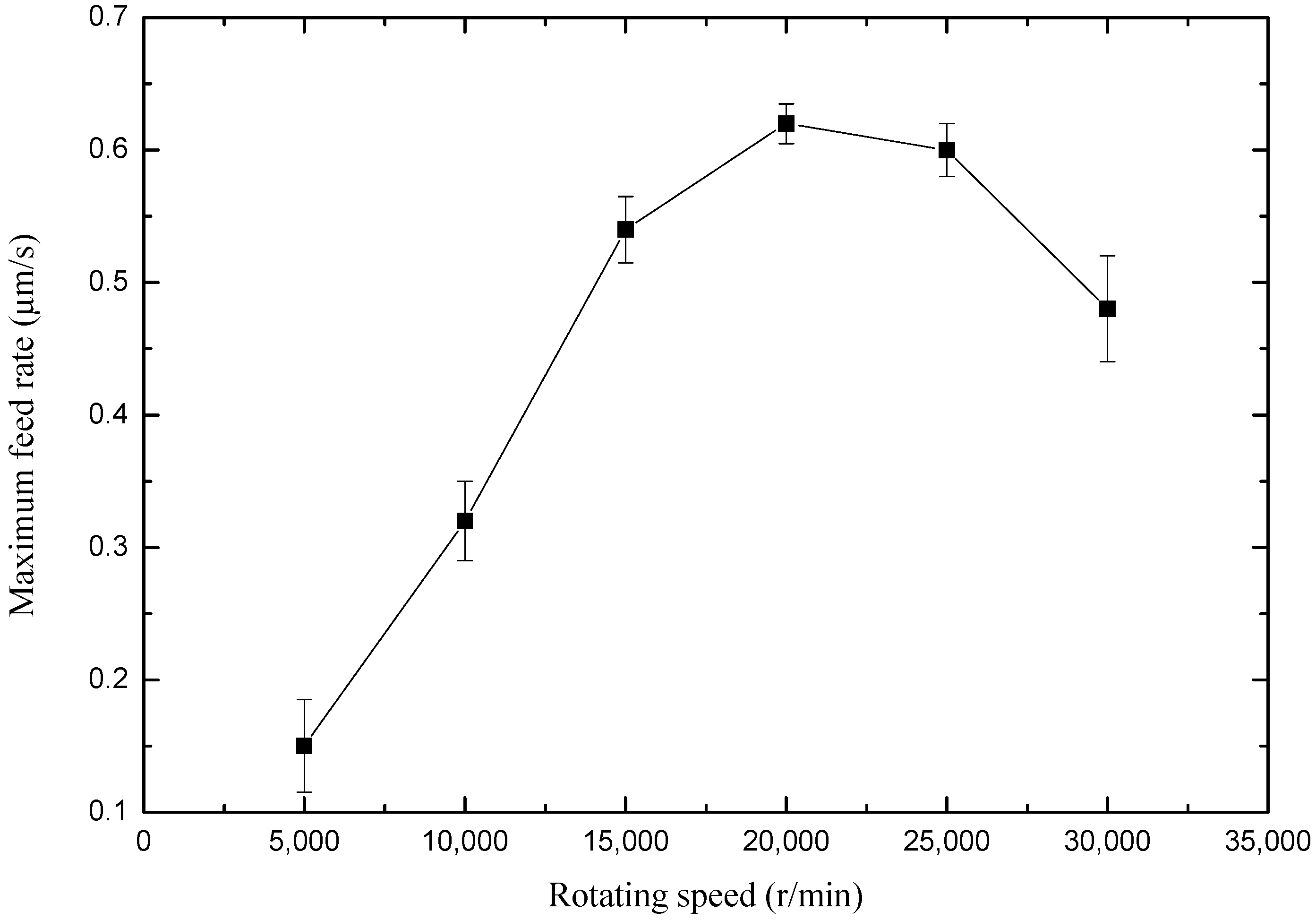

4.1. Influence of Rotating Speed on Maximum Feed Rate

4.2. Influence of Peak Voltage on Machining Precision

4.3. Influence of Pulse Width on Machining Precision

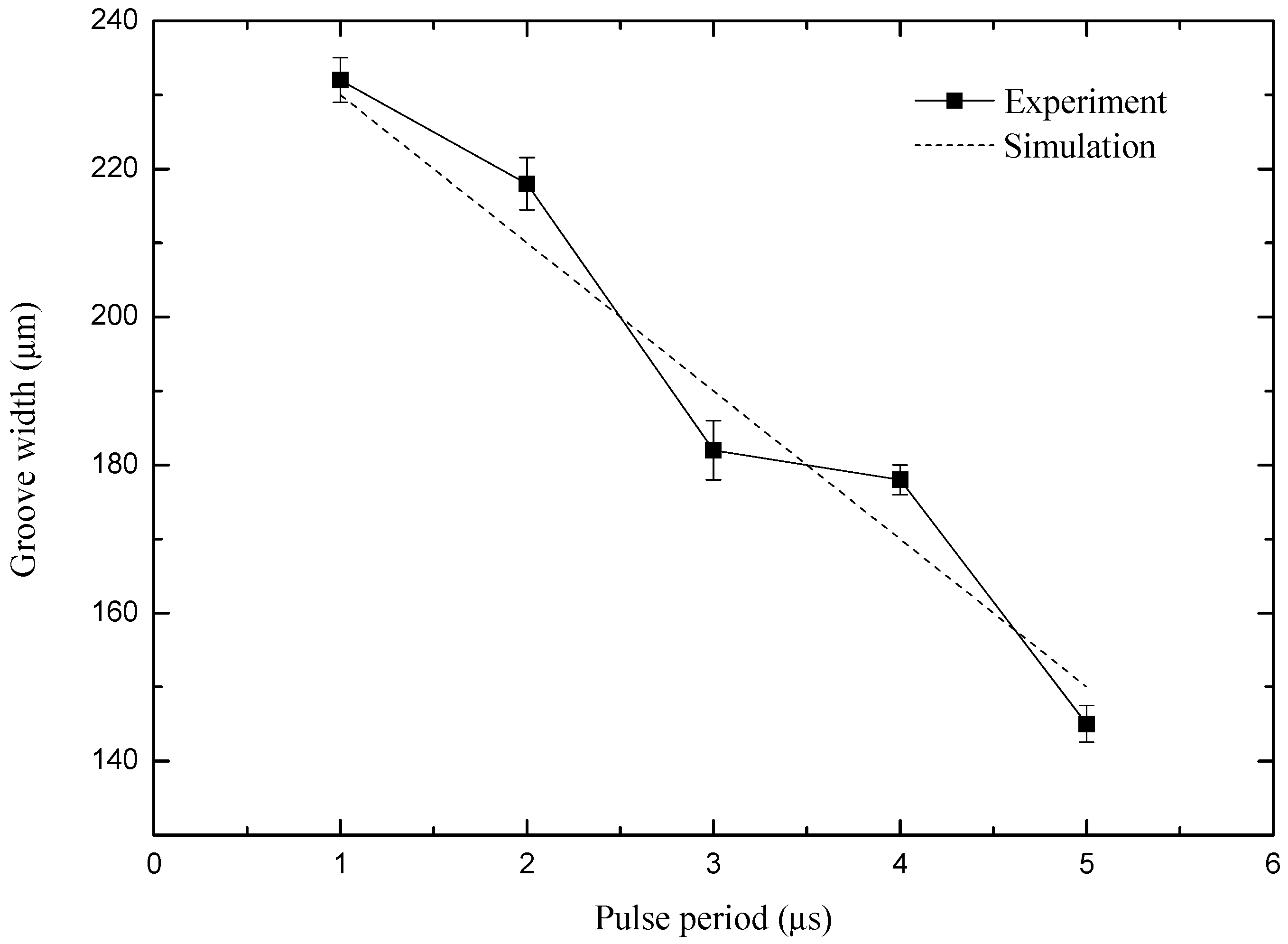

4.4. Influence of Pulse Period on Machining Precision

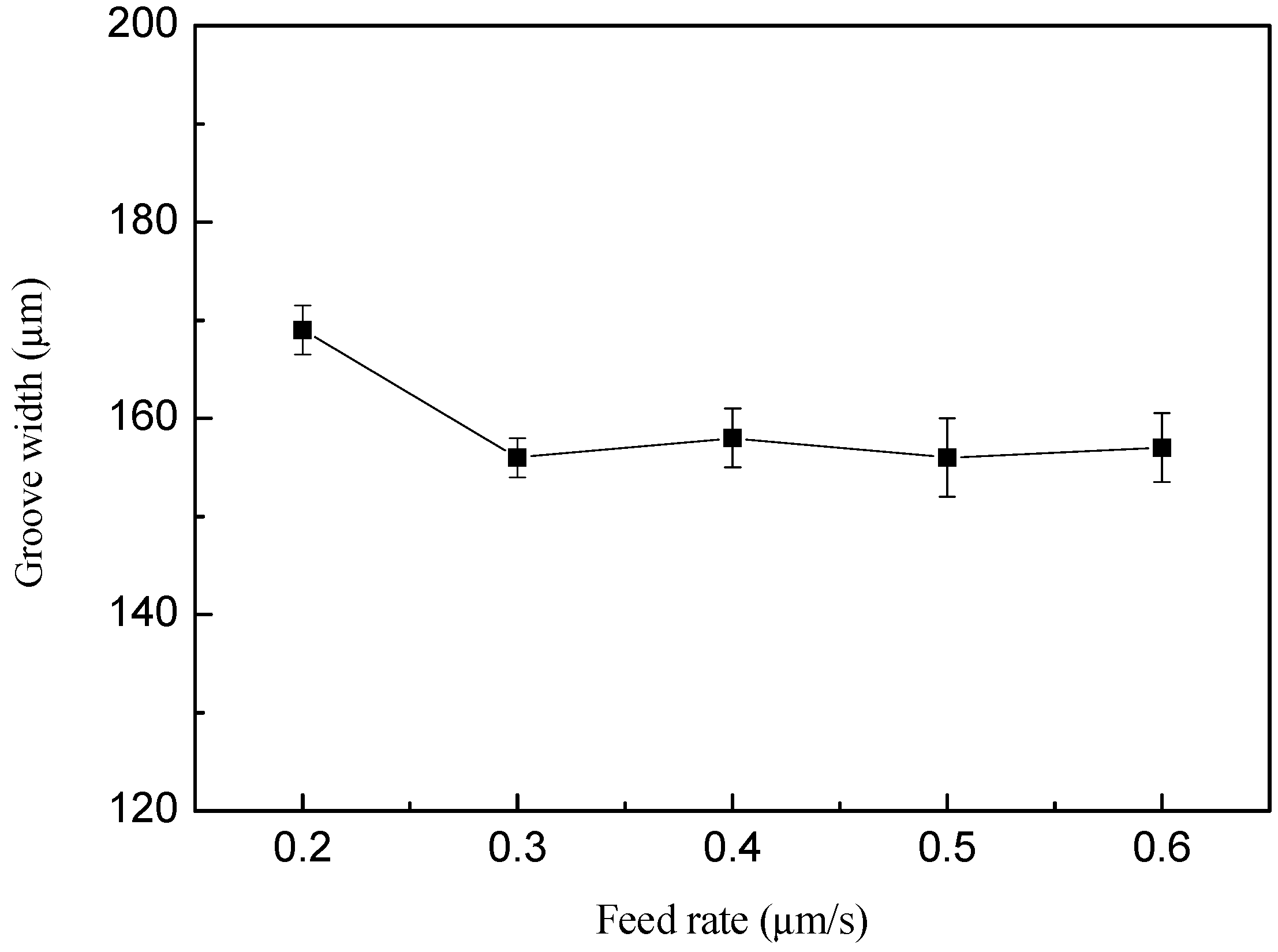

4.5. Influence of Feed Rate on Machining Precision

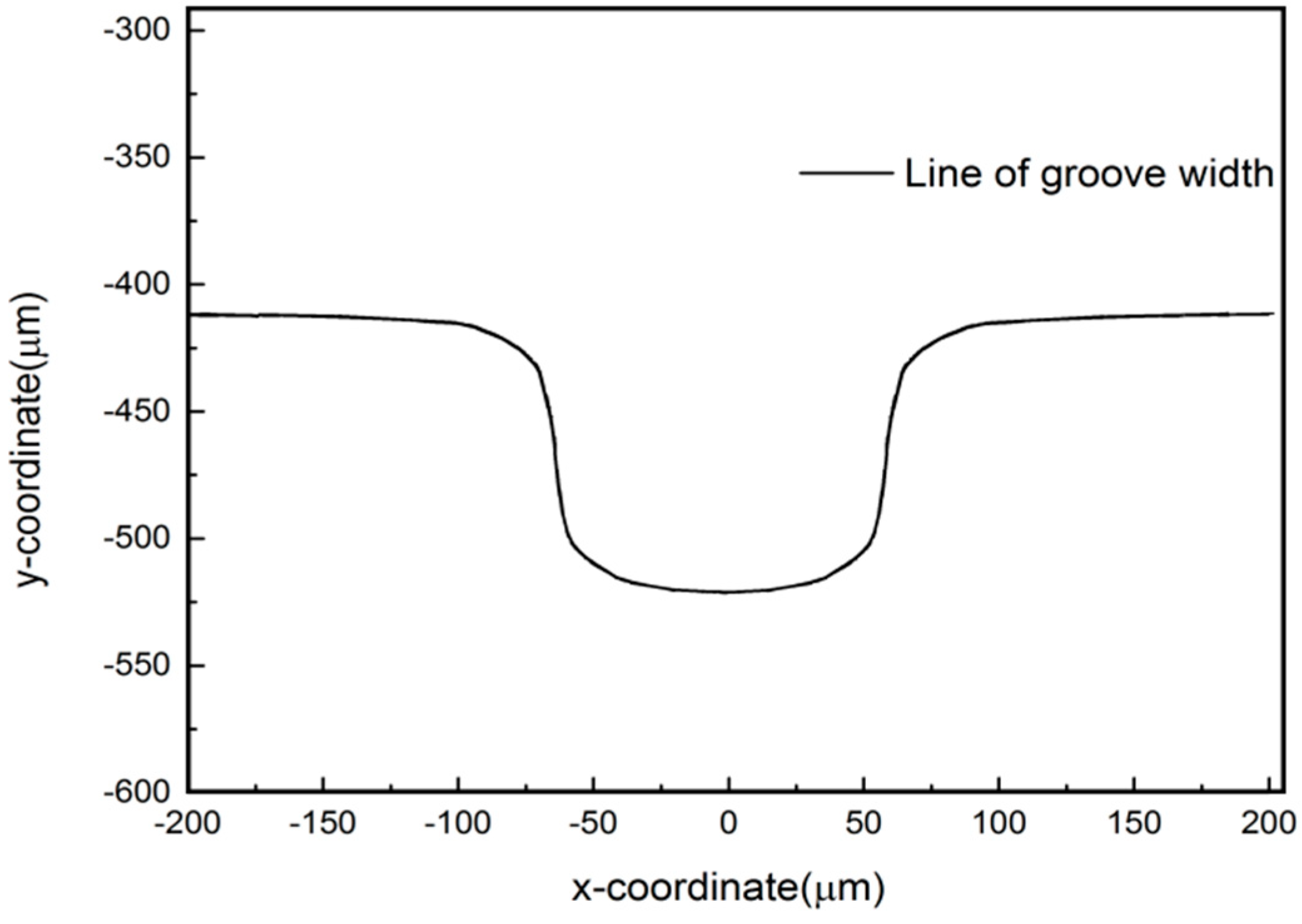

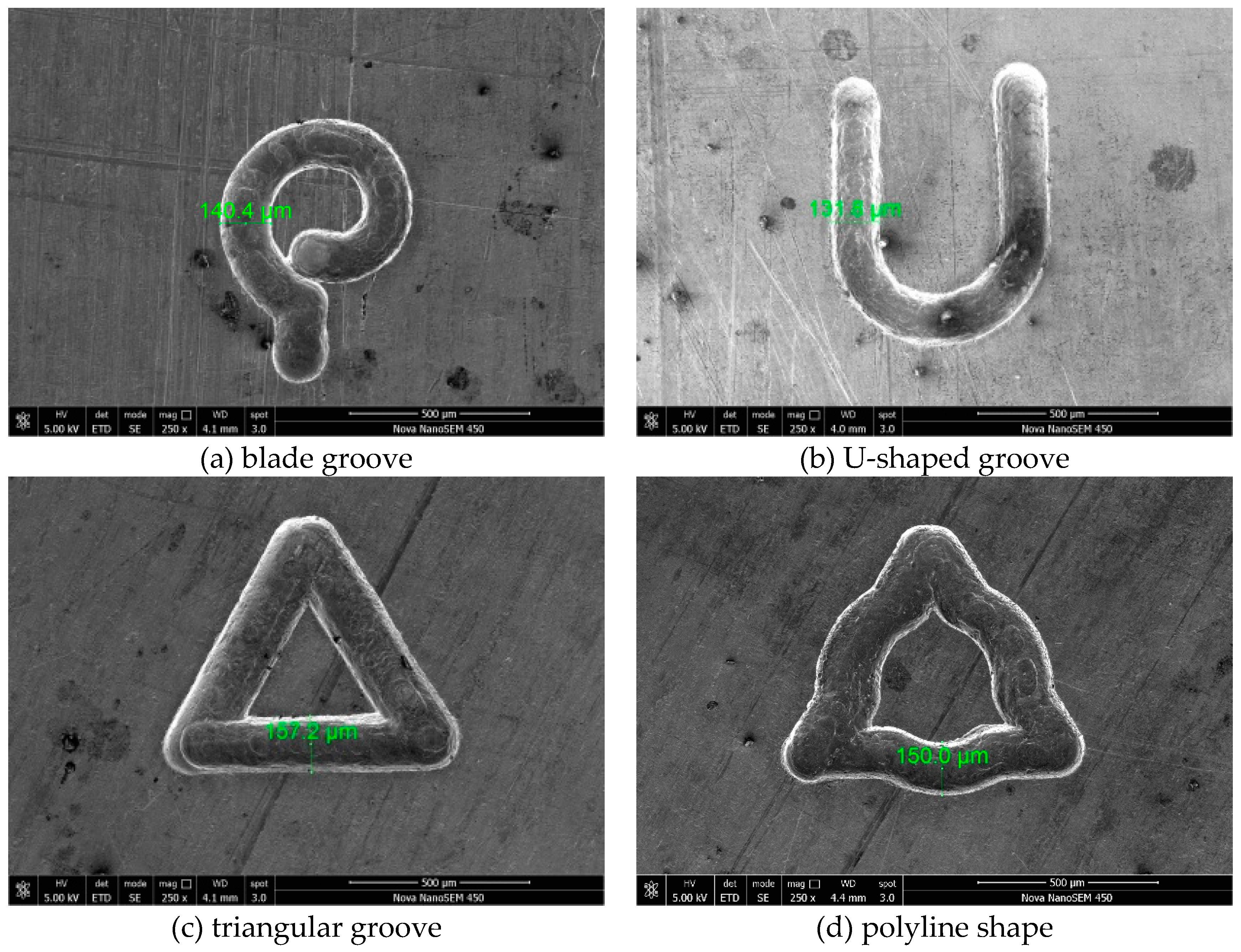

4.6. Machining Results

5. Conclusions

- (1)

- The electrochemical micro-milling model with high-speed rotating was established based on the finite element analysis method, and the change of workpiece surface profile is predicted by the simulation of machining electric field. Through the simulation of machining flow field, it was found that the gas core formed around the electrodes has a role of electrolyte promotion and secondary electrolysis prevention.

- (2)

- The influence of the key machining parameters on the machining precision was studied through experiments. The experimental results show that EMM localization can be improved by using the power supply of low peak voltage, high frequency, and short pulse on time.

- (3)

- By optimizing the machining parameters and using the spiral electrode with the diameter of 100 μm, a series of micro-graphic structures with the width about 150 μm were obtained on the Nickel-base superalloy 718, which demonstrates that EMM with high-speed spiral electrode is a highly promising technology for fabricating metal complex micro-structures with higher machining efficiency and stability.

- (4)

- Because of the high-speed rotation of the electrodes, the size of the electrode was limited and can not be too small in the present study. In the near future, the effect of ultrasonic vibration-assisted EMM on the improvement of machining quality could be studied in detail.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Bhattacharyya, B.; Munda, J. Experimental investigation on the influence of electrochemical machining parameters on machining rate and accuracy in micromachining domain. Int. J. Mach. Tools Manuf. 2003, 43, 1301–1310. [Google Scholar] [CrossRef]

- Danilov, I.; Hackert-Oschätzchen, M.; Zinecker, M.; Meichsner, G.; Edelmann, J.; Schubert, A. Process Understanding of Plasma Electrolytic Polishing through Multiphysics Simulation and Inline Metrology. Micromachines 2019, 10, 214. [Google Scholar] [CrossRef] [PubMed]

- Ruszkiewicz, B.J.; Gendreau, E.; Niaki, F.A.; Mears, L. Electroplastic Drilling of Low-and High-Strength Steels. J. Manuf. Sci. Eng. 2018, 140, 061017. [Google Scholar] [CrossRef]

- Hameed, S.; González Rojas, H.; Perat Benavides, J.; Nápoles Alberro, A.; Sánchez Egea, A.J. Influence of the regime of electropulsing-assisted machining on the plastic deformation of the layer being cut. Materials 2018, 11, 886. [Google Scholar] [CrossRef] [PubMed]

- Schuster, R.; Kirchner, V.; Allongue, P.; Ertl, G. Electrochemical micromachining. Science 2000, 289, 98–101. [Google Scholar] [CrossRef] [PubMed]

- Schuster, R. Electrochemical microstructuring with short voltage pulses. ChemPhysChem 2007, 8, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Kock, M.; Kirchner, V.; Schuster, R. Electrochemical micromachining with ultrashort voltage pulses—A versatile method with lithographical precision. Electrochim. Acta 2003, 48, 3213–3219. [Google Scholar] [CrossRef]

- Staemmler, L.; Hofmann, K.; Kück, H. Hybrid tooling by a combination of high speed cutting and electrochemical milling with ultrashort voltage pulses. Microsyst. Technol. 2008, 14, 249–254. [Google Scholar] [CrossRef]

- Klocke, F.; Zeis, M.; Harst, S.; Klink, A.; Veselovac, D.; Baumgärtner, M. Modeling and simulation of the electrochemical machining (ECM) material removal process for the manufacture of aero engine components. Procedia CIRP 2013, 8, 265–270. [Google Scholar] [CrossRef]

- Kim, B.H.; Ryu, S.H.; Choi, D.K.; Chu, C.N. Micro electrochemical milling. J. Micromech. Microeng. 2004, 15, 124. [Google Scholar] [CrossRef]

- Kim, B.H.; Na, C.W.; Lee, Y.S.; Choi, D.K.; Chu, C.N. Micro electrochemical machining of 3D micro structure using dilute sulfuric acid. CIRP Ann. Manuf. Technol. 2005, 54, 191–194. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, D.; Zhu, L. Micro electrochemical milling of complex structures by using in situ fabricated cylindrical electrode. Int. J. Adv. Manuf. Technol. 2012, 60, 977–984. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, D.; Zeng, Y.; Yu, H. Development of microelectrodes for electrochemical micromachining. Int. J. Adv. Manuf. Technol. 2011, 55, 195–203. [Google Scholar] [CrossRef]

- Yuan, Y.; Han, L.; Huang, D.; Su, J.; Tian, Z.; Tian, Z.; Zhan, D. Electrochemical micromachining under mechanical motion mode. Electrochim. Acta 2015, 183, 3–7. [Google Scholar] [CrossRef]

- Xu, L.; Zhao, C. Nanometer-scale accuracy electrochemical micromachining with adjustable inductance. Electrochim. Acta 2017, 248, 75–78. [Google Scholar] [CrossRef]

- Kozak, J.; Gulbinowicz, D.; Gulbinowicz, Z. Themathematical modeling and computersimulation of pulse electrochemical micromachining. Eng. Lett. 2008, 16, 556–561. [Google Scholar]

- Rathod, V.; Doloi, B.; Bhattacharyya, B. Fabrication of microgrooves with varied cross-sections by electrochemical micromachining. Int. J. Adv. Manuf. Technol. 2017, 92, 505–518. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, Y.; Guo, C.; Deng, S.; Kong, H. Experimental Research on Machining Localization and Surface Quality in Micro Electrochemical Milling of Nickel-Based Superalloy. Micromachines 2018, 9, 402. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Niu, J.; Guo, C.; Li, M. Simulation and experimental investigation on micro electrochemical drilling of micro-holes with ultra short pulse voltage. Int. J. Adv. Manuf. Technol. 2019, 14, 67–81. [Google Scholar] [CrossRef]

- Frank, T.; Shi, J.; Burns, A.D. Validation of Eulerian multiphase flow models for nuclear safety application. In Proceeding of the Third International Symposium on Two-Phase Modelling and Experimentation, Pisa, Italy, 22–25 September 2004. [Google Scholar]

| Parameters | Values |

|---|---|

| Applied voltage (V) | 5.5–7.5 |

| Pulse width (ns) | 450–650 |

| Pulse period (μs) | 1–5 |

| RRotational speed (r/min) | 55,000–30,000 |

| Cathodal electrode | 100 μm WC electrode |

| Workpiece material | Super alloy 718 |

| Electrolyte | 5% NaNO3 solution |

| Feed rate (μm/s) | 0.2–0.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Xu, X.; Guo, C.; Kong, H. Analysis on Machining Performance of Nickel-Base Superalloy by Electrochemical Micro-milling with High-Speed Spiral Electrode. Micromachines 2019, 10, 476. https://doi.org/10.3390/mi10070476

Liu Y, Xu X, Guo C, Kong H. Analysis on Machining Performance of Nickel-Base Superalloy by Electrochemical Micro-milling with High-Speed Spiral Electrode. Micromachines. 2019; 10(7):476. https://doi.org/10.3390/mi10070476

Chicago/Turabian StyleLiu, Yong, Xiaodong Xu, Chunsheng Guo, and Huanghai Kong. 2019. "Analysis on Machining Performance of Nickel-Base Superalloy by Electrochemical Micro-milling with High-Speed Spiral Electrode" Micromachines 10, no. 7: 476. https://doi.org/10.3390/mi10070476