Recent Advances in Vertically Aligned Nanowires for Photonics Applications

Abstract

:1. Introduction

2. Operating Principles of Vertically Aligned Nanowires

3. Geometrical Variations

3.1. Nanowire Array Arrangements

3.2. Nanowire Morphology

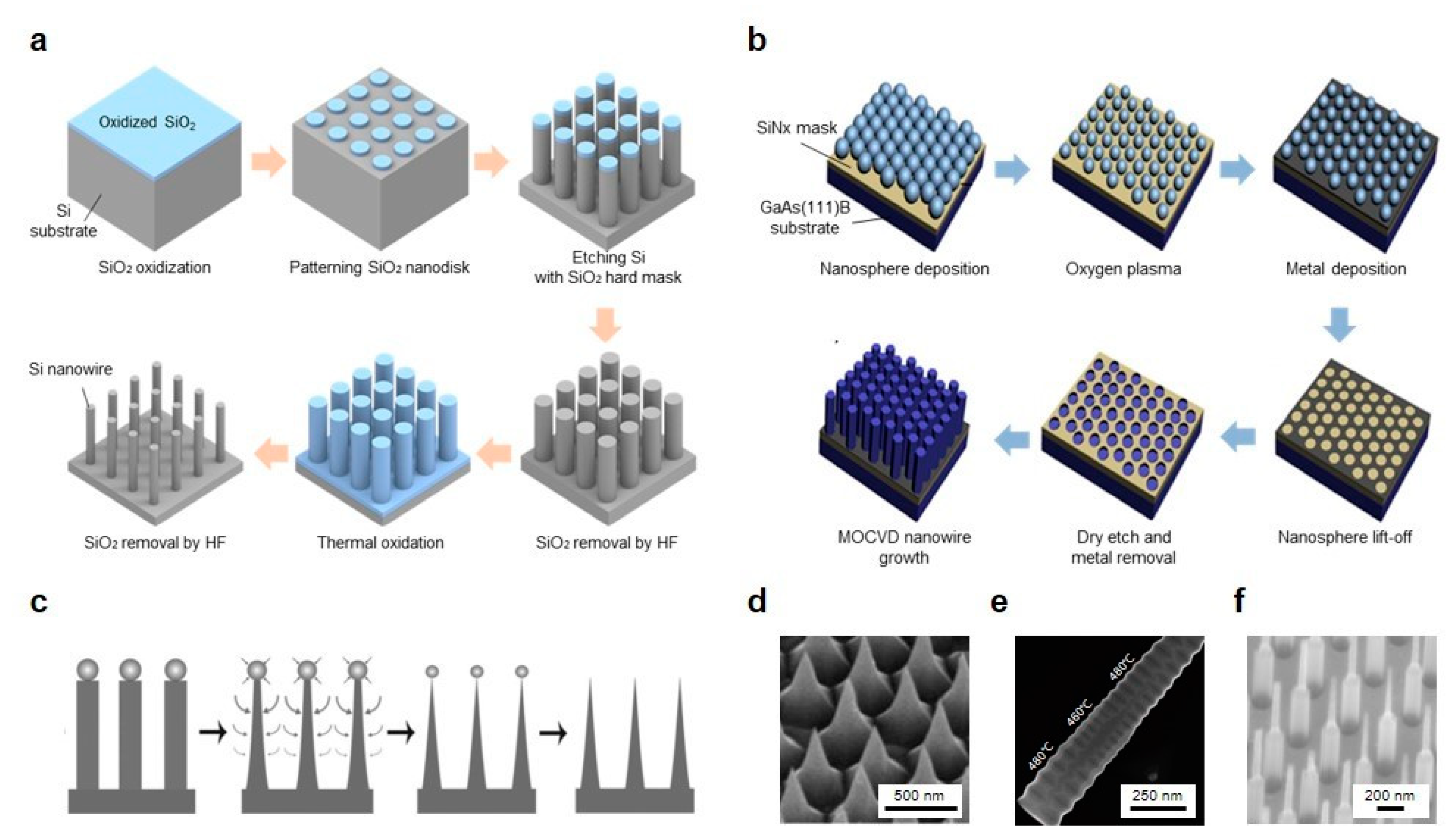

4. Fabrication Techniques

4.1. Top-Down Approach

4.2. Bottom-Up Approach

4.3. Shaping Methods

5. Photonics Applications of Vertical Nanowires

5.1. Light-Emitting Diodes (LEDs) and Lasers

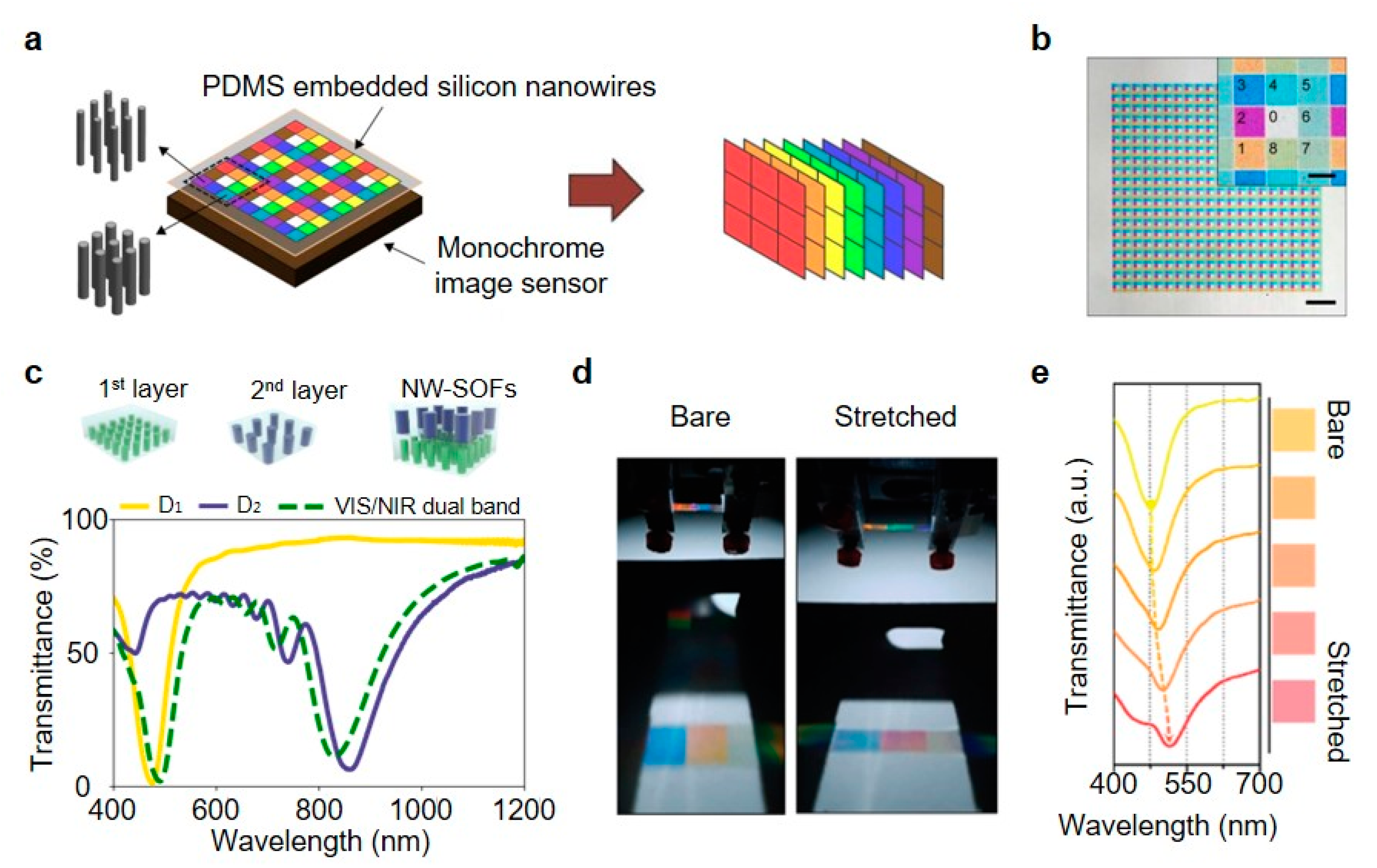

5.2. Spectral Filters

5.3. Coloration

5.4. Artificial Retina

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- In, H.J.; Field, C.R.; Pehrsson, P.E. Periodically porous top electrodes on vertical nanowire arrays for highly sensitive gas detection. Nanotechnology 2011, 22, 355501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liao, Q.L.; Jiang, H.; Zhang, X.W.; Qiu, Q.F.; Tang, Y.; Yang, X.K.; Liu, Y.L.; Huang, W.H. A single nanowire sensor for intracellular glucose detection. Nanoscale 2019, 11, 10702–10708. [Google Scholar] [CrossRef] [PubMed]

- Tang, N.; Zhou, C.; Qu, D.; Fang, Y.; Zheng, Y.; Hu, W.; Jin, K.; Wu, W.; Duan, X.; Haick, H. A Highly Aligned Nanowire-Based Strain Sensor for Ultrasensitive Monitoring of Subtle Human Motion. Small 2020, 16, 2001363. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; i Cabarrocas, P.R. Rational design of nanowire solar cells: From single nanowire to nanowire arrays. Nanotechnology 2019, 30, 194002. [Google Scholar] [CrossRef]

- Robertson, K.W.; LaPierre, R.R.; Krich, J.J. Efficient wave optics modeling of nanowire solar cells using rigorous coupled-wave analysis. Opt. Express 2019, 27, A133–A147. [Google Scholar] [CrossRef] [Green Version]

- Espinet-Gonzalez, P.; Barrigón, E.; Otnes, G.; Vescovi, G.; Mann, C.; France, R.M.; Welch, A.J.; Hunt, M.S.; Walker, D.; Kelzenberg, M.D.; et al. Radiation Tolerant Nanowire Array Solar Cells. ACS Nano 2019, 13, 12860–12869. [Google Scholar] [CrossRef]

- Meng, J.; Cadusch, J.J.; Crozier, K.B. Detector-Only Spectrometer Based on Structurally Colored Silicon Nanowires and a Reconstruction Algorithm. Nano Lett. 2020, 20, 320–328. [Google Scholar] [CrossRef]

- Bui, H.Q.T.; Velpula, R.T.; Jain, B.; Aref, O.H.; Nguyen, H.D.; Lenka, T.R.; Nguyen, H.P.T. Full-Color InGaN/AlGaN Nanowire Micro Light-Emitting Diodes Grown by Molecular Beam Epitaxy: A Promising Candidate for Next Generation Micro Displays. Micromachines 2019, 10, 492. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Li, Y.; Wang, B.; Hu, H.; Wei, B.; Yang, L. High Brightness Organic Light-Emitting Diodes with Capillary-Welded Hybrid Diameter Silver Nanowire/Graphene Layers as Electrodes. Micromachines 2019, 10, 517. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meng, J.; Li, S.; Crozier, K.B. Wavelength-Multiplexed Spectrometer Based on Silicon Nanowire Photodetector Array. In Proceedings of the 2017 European Conference on Lasers and Electro-Optics and European Quantum Electronics Conference, Munich, Germany, 25–29 June 2017; Optical Society of America: Washington, DC, USA, 2017. [Google Scholar]

- Hsu, C.L.; Wang, Y.C.; Chang, S.P.; Chang, S.J. Ultraviolet/Visible Photodetectors Based on p–n NiO/ZnO Nanowires Decorated with Pd Nanoparticles. ACS Appl. Nano Mater. 2019, 2, 6343–6351. [Google Scholar] [CrossRef]

- Abbas, S.; Kumar, M.; Kim, D.W.; Kim, J. Translucent Photodetector with Blended Nanowires–Metal Oxide Transparent Selective Electrode Utilizing Photovoltaic and Pyro-Phototronic Coupling Effect. Small 2019, 15, 1804346. [Google Scholar] [CrossRef] [PubMed]

- Dasgupta, N.P.; Sun, J.; Liu, C.; Brittman, S.; Andrews, S.C.; Lim, J.; Gao, H.; Yan, R.; Yang, P. 25th Anniversary Article: Semiconductor Nanowires—Synthesis, Characterization and Applications. Adv. Mater. 2014, 26, 2137–2184. [Google Scholar] [CrossRef]

- Elnathan, R.; Kwiat, M.; Patolsky, F.; Voelcker, N.H. Engineering vertically aligned semiconductor nanowire arrays for applications in the life sciences. Nano Today 2014, 9, 172–196. [Google Scholar] [CrossRef]

- Crozier, K.B.; Seo, K.; Park, H.; Solanki, A.; Li, S. Controlling the Light Absorption in a Photodetector Via Nanowire Waveguide Resonances for Multispectral and Color Imaging. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–12. [Google Scholar] [CrossRef]

- Yan, R.; Gargas, D.; Yang, P. Nanowire photonics. Nat. Photonics 2009, 3, 569–576. [Google Scholar] [CrossRef]

- Quan, L.N.; Kang, J.; Ning, C.Z.; Yang, P. Nanowires for Photonics. Chem. Rev. 2019, 119, 9153–9169. [Google Scholar] [CrossRef]

- Wagner, R.S.; Ellis, W.C. Vapor-liquid-solid mechanism of single crystal growth. Appl. Phys. Lett. 1964, 4, 89–90. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, P. Direct Observation of Vapor-Liquid-Solid Nanowire Growth. J. Am. Chem. Soc. 2001, 123, 3165–3166. [Google Scholar] [CrossRef]

- Pevzner, A.; Engel, Y.; Elnathan, R.; Ducobni, T.; Ben-Ishai, M.; Reddy, K.; Shpaisman, N.; Tsukernik, A.; Oksman, M.; Patolsky, F. Knocking Down Highly-Ordered Large-Scale Nanowire Arrays. Nano Lett. 2010, 10, 1202–1208. [Google Scholar] [CrossRef]

- Madaria, A.R.; Yao, M.; Chi, C.; Huang, N.; Lin, C.; Li, R.; Povinelli, M.L.; Dapkus, P.D.; Zhou, C. Toward Optimized Light Utilization in Nanowire Arrays Using Scalable Nanosphere Lithography and Selected Area Growth. Nano Lett. 2012, 12, 2839–2845. [Google Scholar] [CrossRef]

- Kim, H.; Zhang, A.; Lo, Y.H. Fabrication of vertical silicon nanowire photodetector arrays using nanoimprint lithography. In Advanced Fabrication Technologies for Micro/Nano Optics and Photonics III; International Society for Optics and Photonics, SPIE: Washington, DC, USA, 2010; Volume 7591, pp. 25–31. [Google Scholar]

- No, Y.S.; Gao, R.; Mankin, M.N.; Day, R.W.; Park, H.G.; Lieber, C.M. Encoding Active Device Elements at Nanowire Tips. Nano Lett. 2016, 16, 4713–4719. [Google Scholar] [CrossRef] [PubMed]

- Traviss, D.J.; Schmidt, M.K.; Aizpurua, J.; Muskens, O.L. Antenna resonances in low aspect ratio semiconductor nanowires. Opt. Express 2015, 23, 22771–22787. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Landreman, P.E.; Chalabi, H.; Park, J.; Brongersma, M.L. Fabry-Perot description for Mie resonances of rectangular dielectric nanowire optical resonators. Opt. Express 2016, 24, 29760–29772. [Google Scholar] [CrossRef] [PubMed]

- Aghaeipour, M.; Pistol, M.E.; Pettersson, H. Comparative study of absorption efficiency of inclined and vertical InP nanowires. In Physics, Simulation and Photonic Engineering of Photovoltaic Devices VI; Freundlich, A., Lombez, L., Sugiyama, M., Eds.; International Society for Optics and Photonics, SPIE: Washington, DC, USA, 2017; Volume 10099, pp. 72–76. [Google Scholar]

- Park, H.; Seo, K.; Crozier, K.B. Polymer-Embedded Arrays of Vertical Silicon Nanowires as Color Filters. In Conference on Lasers and Electro-Optics; Optical Society of America: Washington, DC, USA, 2012; p. CM3M.5. [Google Scholar]

- Solanki, A.; Park, H.; Crozier, K.B. Germanium Nanowires as Spectrally-selective Photodetectors in the Visible-to-Infrared. In CLEO; Optical Society of America: Washington, DC, USA, 2015; p. SM1G.1. [Google Scholar]

- Gu, L.; Tavakoli, M.M.; Zhang, D.; Zhang, Q.; Waleed, A.; Xiao, Y.; Tsui, K.H.; Lin, Y.; Liao, L.; Wang, J.; et al. 3D Arrays of 1024-Pixel Image Sensors based on Lead Halide Perovskite Nanowires. Adv. Mater. 2016, 28, 9713–9721. [Google Scholar] [CrossRef]

- Li, S.Q.; Solanki, A.; Frigerio, J.; Chrastina, D.; Isella, G.; Zheng, C.; Ahnood, A.; Ganesan, K.; Crozier, K.B. Vertical Ge–Si Nanowires with Suspended Graphene Top Contacts as Dynamically Tunable Multispectral Photodetectors. ACS Photonics 2019, 6, 735–742. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, Y.; Liu, Y.; Zhang, X. KOH post-etching-induced rough silicon nanowire array for H2 gas sensing application. Nanotechnology 2016, 27, 465502. [Google Scholar] [CrossRef]

- Lee, H.Y.; Shen, T.H.; Hu, C.Y.; Tsai, Y.Y.; Wen, C.Y. Producing Atomically Abrupt Axial Heterojunctions in Silicon–Germanium Nanowires by Thermal Oxidation. Nano Lett. 2017, 17, 7494–7499. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, X.; Wang, Z.; Zhang, T.; Yu, Y.; Zou, J.; Deng, W.; Zhu, Z. Inductively coupled plasma etching of the GaAs nanowire array based on self-assembled SiO2 nanospheres. Jpn. J. Appl. Phys. 2018, 58, 010908. [Google Scholar] [CrossRef]

- Snyder, A.W.; Love, J.D. Optical Waveguide Theory; Springer: Berlin/Heidelberg, Germany, 1983. [Google Scholar]

- Abujetas, D.R.; Paniagua-Domínguez, R.; Sánchez-Gil, J.A. Unraveling the Janus Role of Mie Resonances and Leaky/Guided Modes in Semiconductor Nanowire Absorption for Enhanced Light Harvesting. ACS Photonics 2015, 2, 921–929. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Leu, P.W. Tunable and selective resonant absorption in vertical nanowires. Opt. Lett. 2012, 37, 3756–3758. [Google Scholar] [CrossRef]

- Seo, K.; Wober, M.; Steinvurzel, P.; Schonbrun, E.; Dan, Y.; Ellenbogen, T.; Crozier, K.B. Multicolored Vertical Silicon Nanowires. Nano Lett. 2011, 11, 1851–1856. [Google Scholar] [CrossRef] [PubMed]

- Fountaine, K.T.; Whitney, W.S.; Atwater, H.A. Resonant absorption in semiconductor nanowires and nanowire arrays: Relating leaky waveguide modes to Bloch photonic crystal modes. J. Appl. Phys. 2014, 116, 153106. [Google Scholar] [CrossRef] [Green Version]

- Fountaine, K.T.; Kendall, C.G.; Atwater, H.A. Near-unity broadband absorption designs for semiconducting nanowire arrays via localized radial mode excitation. Opt. Express 2014, 22, A930–A940. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kelzenberg, M.D.; Boettcher, S.W.; Petykiewicz, J.A.; Turner-Evans, D.B.; Putnam, M.C.; Warren, E.L.; Spurgeon, J.M.; Briggs, R.M.; Lewis, N.S.; Atwater, H.A. Enhanced absorption and carrier collection in Si wire arrays for photovoltaic applications. Nat. Mater. 2010, 9, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.; Povinelli, M.L. Optimal design of aperiodic, vertical silicon nanowire structures for photovoltaics. Opt. Express 2011, 19, A1148–A1154. [Google Scholar] [CrossRef] [Green Version]

- Anderson, P.D.; Koleske, D.D.; Povinelli, M.L.; Subramania, G. Improving emission uniformity and linearizing band dispersion in nanowire arrays using quasi-aperiodicity. Opt. Mater. Express 2017, 7, 3634–3642. [Google Scholar] [CrossRef]

- Samsonova, Z.; Höfer, S.; Hollinger, R.; Kämpfer, T.; Uschmann, I.; Röder, R.; Trefflich, L.; Rosmej, O.; Förster, E.; Ronning, C.; et al. Hard X-ray Generation from ZnO Nanowire Targets in a Non-Relativistic Regime of Laser-Solid Interactions. Appl. Sci. 2018, 8, 1728. [Google Scholar] [CrossRef] [Green Version]

- Dhindsa, N.; Saini, S.S. Comparison of ordered and disordered silicon nanowire arrays: Experimental evidence of photonic crystal modes. Opt. Lett. 2016, 41, 2045–2048. [Google Scholar] [CrossRef]

- Fonseka, H.A.; Caroff, P.; Guo, Y.; Sanchez, A.M.; Tan, H.H.; Jagadish, C. Engineering the Side Facets of Vertical [100] Oriented InP Nanowires for Novel Radial Heterostructures. Nanoscale Res. Lett. 2019, 14, 399. [Google Scholar] [CrossRef]

- Schonbrun, E.; Seo, K.; Crozier, K.B. Reconfigurable Imaging Systems Using Elliptical Nanowires. Nano Lett. 2011, 11, 4299–4303. [Google Scholar] [CrossRef]

- Zhan, Y.; Li, X.; Wu, S.; Li, K.; Yang, Z.; Shang, A. Enhanced photoabsorption in front-tapered single-nanowire solar cells. Opt. Lett. 2014, 39, 5756–5759. [Google Scholar] [CrossRef]

- Solanki, A.; Crozier, K. Vertical germanium nanowires as spectrally-selective absorbers across the visible-to-infrared. Appl. Phys. Lett. 2014, 105, 191115. [Google Scholar] [CrossRef]

- Zhu, J.; Yu, Z.; Burkhard, G.F.; Hsu, C.M.; Connor, S.T.; Xu, Y.; Wang, Q.; McGehee, M.; Fan, S.; Cui, Y. Optical Absorption Enhancement in Amorphous Silicon Nanowire and Nanocone Arrays. Nano Lett. 2009, 9, 279–282. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, Y.J.; Lee, G.J.; Kim, S.; Min, J.W.; Jeong, S.Y.; Yoo, Y.J.; Lee, S.; Song, Y.M. Efficient Light Absorption by GaN Truncated Nanocones for High Performance Water Splitting Applications. ACS Appl. Mater. Interfaces 2018, 10, 28672–28678. [Google Scholar] [CrossRef]

- Krylyuk, S.; Davydov, A.V.; Levin, I. Tapering Control of Si Nanowires Grown from SiCl4 at Reduced Pressure. ACS Nano 2011, 5, 656–664. [Google Scholar] [CrossRef] [PubMed]

- Ko, M.; Baek, S.H.; Song, B.; Kang, J.W.; Kim, S.A.; Cho, C.H. Periodically Diameter-Modulated Semiconductor Nanowires for Enhanced Optical Absorption. Adv. Mater. 2016, 28, 2504–2510. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, Y.H.; Choi, S.H.; Lee, W. Curved Silicon Nanowires with Ribbon-like Cross Sections by Metal-Assisted Chemical Etching. ACS Nano 2011, 5, 5242–5248. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.; Zhang, C.; Tuan, C.C.; Chen, X.; Gao, J.; Wong, C.P. Controlling Kink Geometry in Nanowires Fabricated by Alternating Metal-Assisted Chemical Etching. Nano Lett. 2017, 17, 1014–1019. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.W.; Chuang, V.P.; Boles, S.T.; Ross, C.A.; Thompson, C.V. Densely Packed Arrays of Ultra-High-Aspect-Ratio Silicon Nanowires Fabricated using Block-Copolymer Lithography and Metal-Assisted Etching. Adv. Funct. Mater. 2009, 19, 2495–2500. [Google Scholar] [CrossRef]

- Hobbs, R.G.; Petkov, N.; Holmes, J.D. Semiconductor Nanowire Fabrication by Bottom-Up and Top-Down Paradigms. Chem. Mater. 2012, 24, 1975–1991. [Google Scholar] [CrossRef] [Green Version]

- Dhindsa, N.; Chia, A.; Boulanger, J.; Khodadad, I.; LaPierre, R.; Saini, S.S. Highly ordered vertical GaAs nanowire arrays with dry etching and their optical properties. Nanotechnology 2014, 25, 305303. [Google Scholar] [CrossRef] [PubMed]

- Dhindsa, N.; Kohandani, R.; Saini, S.S. Length dependent optical characteristics analysis for semiconductor nanowires. Nanotechnology 2020, 31, 224001. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Lee, J.K.; Han, S.J.; Lee, S. A Novel Top-Down Fabrication Process for Vertically-Stacked Silicon-Nanowire Array. Appl. Sci. 2020, 10, 1146. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Fang, H.; Zhu, J. Fabrication of Silicon Nanowire Arrays with Controlled Diameter, Length and Density. Adv. Mater. 2007, 19, 744–748. [Google Scholar] [CrossRef]

- Song, H.S.; Lee, G.J.; Yoo, D.E.; Kim, Y.J.; Yoo, Y.J.; Lee, D.W.; Siva, V.; Kang, I.S.; Song, Y.M. Reflective color filter with precise control of the color coordinate achieved by stacking silicon nanowire arrays onto ultrathin optical coatings. Sci. Rep. 2019, 9, 3350. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, J.; Higuchi, K.; Maenaka, K. Vertical Si nanowire with ultra-high-aspect-ratio by combined top-down processing technique. Microsyst. Technol. 2013, 19, 433–438. [Google Scholar] [CrossRef]

- Lee, G.J.; Park, K.; Kim, M.S.; Chang, S.; Seok, T.J.; Park, H.G.; Ju, G.; Kim, K.; Song, Y.M. Selective and Sensitive Photon Sieve Based on III–V Semiconductor Nanowire Forest Fabricated by Lithography-Free Process. Adv. Opt. Mater. 2020, 10, 2000198. [Google Scholar] [CrossRef]

- Waleed, A.; Tavakoli, M.M.; Gu, L.; Wang, Z.; Zhang, D.; Manikandan, A.; Zhang, Q.; Zhang, R.; Chueh, Y.L.; Fan, Z. Lead-Free Perovskite Nanowire Array Photodetectors with Drastically Improved Stability in Nanoengineering Templates. Nano Lett. 2017, 17, 523–530. [Google Scholar] [CrossRef]

- Tavakoli, M.M.; Waleed, A.; Gu, L.; Zhang, D.; Tavakoli, R.; Lei, B.; Su, W.; Fang, F.; Fan, Z. A non-catalytic vapor growth regime for organohalide perovskite nanowires using anodic aluminum oxide templates. Nanoscale 2017, 9, 5828–5834. [Google Scholar] [CrossRef]

- Cui, H.; Lü, Y.Y.; Yang, G.W.; Chen, Y.M.; Wang, C.X. Step-Flow Kinetics Model for the Vapor–Solid–Solid Si Nanowires Growth. Nano Lett. 2015, 15, 3640–3645. [Google Scholar] [CrossRef]

- Xu, S.; Wei, Y.; Kirkham, M.; Liu, J.; Mai, W.; Davidovic, D.; Snyder, R.L.; Wang, Z.L. Patterned Growth of Vertically Aligned ZnO Nanowire Arrays on Inorganic Substrates at Low Temperature without Catalyst. J. Am. Chem. Soc. 2008, 130, 14958–14959. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Wu, W.; Guo, R.; Yuan, D.; Das, S.; Wang, Z.L. Wafer-Scale High-Throughput Ordered Growth of Vertically Aligned ZnO Nanowire Arrays. Nano Lett. 2010, 10, 3414–3419. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Song, Y.; Zhang, Z.; Sun, H.; Han, Y.; Li, Y.; Zhang, L.; Xue, Z.; Di, Z.; Wang, S. Vapor-solid-solid grown Ge nanowires at integrated circuit compatible temperature by molecular beam epitaxy. J. Appl. Phys. 2017, 122, 094304. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.M.; Connor, S.T.; Tang, M.X.; Cui, Y. Wafer-scale silicon nanopillars and nanocones by Langmuir–Blodgett assembly and etching. Appl. Phys. Lett. 2008, 93, 133109. [Google Scholar] [CrossRef]

- Cheng, S.; Lin, H.C.; Huang, Y.H.; Yang, S.C. Fabrication of periodic arrays of needle-like Si nanowires on (001)Si and their enhanced field emission characteristics. RSC Adv. 2017, 7, 23935–23941. [Google Scholar] [CrossRef] [Green Version]

- Dhindsa, N.; Saini, S.S. Top-down fabricated tapered GaAs nanowires with sacrificial etching of the mask. Nanotechnology 2017, 28, 235301. [Google Scholar] [CrossRef]

- Caroff, P.; Dick, K.A.; Johansson, J.; Messing, M.E.; Deppert, K.; Samuelson, L. Controlled polytypic and twin-plane superlattices in iii–v nanowires. Nat. Nanotechnol. 2009, 4, 50–55. [Google Scholar] [CrossRef]

- Wendisch, F.J.; Abazari, M.; Mahdavi, H.; Rey, M.; Vogel, N.; Musso, M.; Diwald, O.; Bourret, G.R. Morphology-Graded Silicon Nanowire Arrays via Chemical Etching: Engineering Optical Properties at the Nanoscale and Macroscale. ACS Appl. Mater. Interfaces 2020, 12, 13140–13147. [Google Scholar] [CrossRef] [Green Version]

- Dan, Y.; Chen, K.; Crozier, K.B. Self-aligned process for forming microlenses at the tips of vertical silicon nanowires by atomic layer deposition. J. Vac. Sci. Technol. A 2015, 33, 01A109. [Google Scholar] [CrossRef] [Green Version]

- Kumar, G.; Tang, H.X.; Schroers, J. Nanomoulding with amorphous metals. Nature 2009, 457, 868–872. [Google Scholar] [CrossRef]

- Hasan, M.; Kumar, G. High-throughput drawing and testing of metallic glass nanostructures. Nanoscale 2017, 9, 3261–3268. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Meduri, C.S.; Blawzdziewicz, J.; Kumar, G. Nanoshaping of glass forming metallic liquids by stretching: Evading lithography. Nanotechnology 2018, 30, 075302. [Google Scholar] [CrossRef] [PubMed]

- Johnson, J.C.; Yan, H.; Schaller, R.D.; Haber, L.H.; Saykally, R.J.; Yang, P. Single Nanowire Lasers. J. Phys. Chem. B 2001, 105, 11387–11390. [Google Scholar] [CrossRef]

- Lai, E.; Kim, W.; Yang, P. Vertical nanowire array-based light emitting diodes. Nano Res. 2008, 1, 123–128. [Google Scholar] [CrossRef] [Green Version]

- Gargas, D.J.; Toimil-Molares, M.E.; Yang, P. Imaging Single ZnO Vertical Nanowire Laser Cavities Using UV-laser Scanning Confocal Microscopy. J. Am. Chem. Soc. 2009, 131, 2125–2127. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.H.; Kim, Y.J.; Hong, Y.J.; Jeon, S.R.; Bae, S.; Hong, B.H.; Yi, G.C. Flexible Inorganic Nanostructure Light-Emitting Diodes Fabricated on Graphene Films. Adv. Mater. 2011, 23, 4614–4619. [Google Scholar] [CrossRef]

- Rajan Philip, M.; Choudhary, D.D.; Djavid, M.; Bhuyian, M.N.; Bui, T.H.Q.; Misra, D.; Khreishah, A.; Piao, J.; Nguyen, H.D.; Le, K.Q.; et al. Fabrication of Phosphor-Free III-Nitride Nanowire Light-Emitting Diodes on Metal Substrates for Flexible Photonics. ACS Omega 2017, 2, 5708–5714. [Google Scholar] [CrossRef] [Green Version]

- Hartensveld, M.; Ouin, G.; Liu, C.; Zhang, J. Effect of KOH passivation for top-down fabricated InGaN nanowire light emitting diodes. J. Appl. Phys. 2019, 126, 183102. [Google Scholar] [CrossRef]

- Asad, M.; Wang, R.; Ra, Y.H.; Gavirneni, P.; Mi, Z.; Wong, W.S. Optically invariant InGaN nanowire light-emitting diodes on flexible substrates under mechanical manipulation. NPJ Flex. Electron. 2019, 3, 16. [Google Scholar] [CrossRef]

- Chesin, J.; Gradecak, S. Comparing directed efficiency of III-nitride nanowire light-emitting diodes. J. Nanophotonics 2014, 8, 1–14. [Google Scholar]

- Wang, R.; Ra, Y.H.; Wu, Y.; Zhao, S.; Nguyen, H.P.T.; Shih, I.; Mi, Z. Tunable, full-color nanowire light emitting diode arrays monolithically integrated on Si and sapphire. In Gallium Nitride Materials and Devices XI; International Society for Optics and Photonics, SPIE: Washington, DC, USA, 2016; Volume 9748, pp. 165–173. [Google Scholar]

- Sekiguchi, H.; Kishino, K.; Kikuchi, A. Emission color control from blue to red with nanocolumn diameter of InGaN/GaN nanocolumn arrays grown on same substrate. Appl. Phys. Lett. 2010, 96, 231104. [Google Scholar] [CrossRef]

- Kishino, K.; Nagashima, K.; Yamano, K. Monolithic Integration of InGaN-Based Nanocolumn Light-Emitting Diodes with Different Emission Colors. Appl. Phys. Express 2013, 6, 012101. [Google Scholar] [CrossRef]

- Guan, N.; Dai, X.; Babichev, A.V.; Julien, F.H.; Tchernycheva, M. Flexible inorganic light emitting diodes based on semiconductor nanowires. Chem. Sci. 2017, 8, 7904–7911. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dai, X.; Messanvi, A.; Zhang, H.; Durand, C.; Eymery, J.; Bougerol, C.; Julien, F.H.; Tchernycheva, M. Flexible Light-Emitting Diodes Based on Vertical Nitride Nanowires. Nano Lett. 2015, 15, 6958–6964. [Google Scholar] [CrossRef] [Green Version]

- Guan, N.; Dai, X.; Messanvi, A.; Zhang, H.; Yan, J.; Gautier, E.; Bougerol, C.; Julien, F.H.; Durand, C.; Eymery, J.; et al. Flexible White Light Emitting Diodes Based on Nitride Nanowires and Nanophosphors. ACS Photonics 2016, 3, 597–603. [Google Scholar] [CrossRef] [Green Version]

- Maiman, T.H. Stimulated Optical Radiation in Ruby. Nature 1960, 187, 493–494. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, X.; Wu, Y.; Mi, Z. An electrically pumped 239 nm AlGaN nanowire laser operating at room temperature. Appl. Phys. Lett. 2016, 109, 191106. [Google Scholar] [CrossRef]

- Röder, R.; Sidiropoulos, T.P.H.; Buschlinger, R.; Riediger, M.; Peschel, U.; Oulton, R.F.; Ronning, C. Mode Switching and Filtering in Nanowire Lasers. Nano Lett. 2016, 16, 2878–2884. [Google Scholar] [CrossRef]

- Stettner, T.; Kostenbader, T.; Ruhstorfer, D.; Bissinger, J.; Riedl, H.; Kaniber, M.; Koblmüller, G.; Finley, J.J. Direct Coupling of Coherent Emission from Site-Selectively Grown III–V Nanowire Lasers into Proximal Silicon Waveguides. ACS Photonics 2017, 4, 2537–2543. [Google Scholar] [CrossRef]

- Hollinger, R.; Malevich, P.; Shumakova, V.; Ališauskas, S.; Zapf, M.; Röder, R.; Pugžlys, A.; Baltuška, A.; Ronning, C.; Spielmann, C.; et al. Strong Light-Field Driven Nanolasers. Nano Lett. 2019, 19, 3563–3568. [Google Scholar] [CrossRef] [Green Version]

- Hollinger, R.; Gupta, D.; Zapf, M.; Röder, R.; Kartashov, D.; Ronning, C.; Spielmann, C. Single nanowire defined emission properties of ZnO nanowire arrays. J. Phys. D: Appl. Phys. 2019, 52, 295101. [Google Scholar] [CrossRef]

- Chen, R.; Tran, T.T.D.; Ng, K.W.; Ko, W.S.; Chuang, L.C.; Sedgwick, F.G.; Chang-Hasnain, C. Nanolasers grown on silicon. Nat. Photonics 2011, 5, 170–175. [Google Scholar] [CrossRef]

- Kim, H.; Lee, W.J.; Farrell, A.C.; Morales, J.S.D.; Senanayake, P.; Prikhodko, S.V.; Ochalski, T.J.; Huffaker, D.L. Monolithic InGaAs Nanowire Array Lasers on Silicon-on-Insulator Operating at Room Temperature. Nano Lett. 2017, 17, 3465–3470. [Google Scholar] [CrossRef] [PubMed]

- Behzadirad, M.; Nami, M.; Wostbrock, N.; Zamani Kouhpanji, M.R.; Feezell, D.F.; Brueck, S.R.J.; Busani, T. Scalable Top-Down Approach Tailored by Interferometric Lithography to Achieve Large-Area Single-Mode GaN Nanowire Laser Arrays on Sapphire Substrate. ACS Nano 2018, 12, 2373–2380. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Abedzadeh, N.; Walia, J.; Patchett, S.; Saini, S.S. Color Matrix Refractive Index Sensors Using Coupled Vertical Silicon Nanowire Arrays. Nano Lett. 2012, 12, 4228–4234. [Google Scholar] [CrossRef]

- Park, H.; Crozier, K.B. Multispectral imaging with vertical silicon nanowires. Sci. Rep. 2013, 3, 2460. [Google Scholar] [CrossRef]

- Park, H.; Dan, Y.; Seo, K.; Yu, Y.J.; Duane, P.K.; Wober, M.; Crozier, K.B. Filter-Free Image Sensor Pixels Comprising Silicon Nanowires with Selective Color Absorption. Nano Lett. 2014, 14, 1804–1809. [Google Scholar] [CrossRef]

- Lee, G.J.; Kim, Y.J.; Song, H.S.; Yoo, D.E.; Lee, D.W.; Kang, I.S.; Song, Y.M. The Facile Implementation of Soft/Tunable Multiband Optical Filters by Stacking Vertical Silicon Nanowire Arrays for Smart Sensing. Adv. Intell. Syst. 2019, 1, 1900072. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.J.; Yoo, Y.J.; Kang, M.H.; Ko, J.H.; Park, M.R.; Yoo, D.E.; Lee, D.W.; Kim, K.; Kang, I.S.; Song, Y.M. Mechanotunable optical filters based on stretchable silicon nanowire arrays. Nanophotonics 2020, 10, 20200062. [Google Scholar] [CrossRef] [Green Version]

- Gu, Y.; Zhang, L.; Yang, J.K.W.; Yeo, S.P.; Qiu, C.W. Color generation via subwavelength plasmonic nanostructures. Nanoscale 2015, 7, 6409–6419. [Google Scholar] [CrossRef] [Green Version]

- James, T.D.; Mulvaney, P.; Roberts, A. The Plasmonic Pixel: Large Area, Wide Gamut Color Reproduction Using Aluminum Nanostructures. Nano Lett. 2016, 16, 3817–3823. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Huang, C.; Hao, C.; Sun, S.; Zhang, L.; Zhang, C.; Duan, Z.; Wang, K.; Jin, Z.; Zhang, N.; et al. Lead Halide Perovskite Nanostructures for Dynamic Color Display. ACS Nano 2018, 12, 8847–8854. [Google Scholar] [CrossRef] [PubMed]

- Flauraud, V.; Reyes, M.; Paniagua-Domínguez, R.; Kuznetsov, A.I.; Brugger, J. Silicon Nanostructures for Bright Field Full Color Prints. ACS Photonics 2017, 4, 1913–1919. [Google Scholar] [CrossRef]

- Cao, L.; Fan, P.; Barnard, E.S.; Brown, A.M.; Brongersma, M.L. Tuning the Color of Silicon Nanostructures. Nano Lett. 2010, 10, 2649–2654. [Google Scholar] [CrossRef]

- Park, H.; Seo, K.; Crozier, K.B. Adding colors to polydimethylsiloxane by embedding vertical silicon nanowires. Appl. Phys. Lett. 2012, 101, 193107. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.J.; Yoo, Y.J.; Lee, G.J.; Yoo, D.E.; Lee, D.W.; Siva, V.; Song, H.; Kang, I.S.; Song, Y.M. Enlarged Color Gamut Representation Enabled by Transferable Silicon Nanowire Arrays on Metal–Insulator–Metal Films. ACS Appl. Mater. Interfaces 2019, 11, 11849–11856. [Google Scholar] [CrossRef]

- Lee, G.J.; Choi, C.; Kim, D.H.; Song, Y.M. Bioinspired Artificial Eyes: Optic Components, Digital Cameras and Visual Prostheses. Adv. Funct. Mater. 2018, 28, 1705202. [Google Scholar] [CrossRef]

- Mathieson, K.; Loudin, J.; Goetz, G.; Huie, P.; Wang, L.; Kamins, T.I.; Galambos, L.; Smith, R.; Harris, J.S.; Sher, A.; et al. Photovoltaic retinal prosthesis with high pixel density. Nat. Photonics 2012, 6, 391–397. [Google Scholar] [CrossRef]

- Lorach, H.; Goetz, G.; Smith, R.; Lei, X.; Mandel, Y.; Kamins, T.; Mathieson, K.; Huie, P.; Harris, J.; Sher, A.; et al. Photovoltaic restoration of sight with high visual acuity. Nat. Med. 2015, 21, 476–482. [Google Scholar] [CrossRef] [Green Version]

- Choi, C.; Choi, M.K.; Liu, S.; Kim, M.S.; Park, O.K.; Im, C.; Kim, J.; Qin, X.; Lee, G.J.; Cho, K.W.; et al. Human eye-inspired soft optoelectronic device using high-density MoS2-graphene curved image sensor array. Nat. Commun. 2017, 8, 1664. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Jung, S.; Park, S.; Ahn, J.; Hong, S.; Yoo, H.; Lee, M.H.; Cho, D.I. Fabrication and Evaluation of Silicon Nanowire Photodetectors on Flexible Substrate for Retinal Prosthetic System. Sens. Mater. 2012, 24, 205–220. [Google Scholar]

- Bosse, B.; Damle, S.; Akinin, A.; Jing, Y.; Bartsch, D.U.; Cheng, L.; Oesch, N.; Lo, Y.H.; Cauwenberghs, G.; Freeman, W.R. In Vivo Photovoltaic Performance of a Silicon Nanowire Photodiode–Based Retinal Prosthesis. Investig. Ophthalmol. Vis. Sci. 2018, 59, 5885–5892. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, M.S.; Lee, G.J.; Choi, C.; Kim, M.S.; Lee, M.; Liu, S.; Cho, K.W.; Kim, H.M.; Cho, H.; Choi, M.K.; et al. An aquatic-vision-inspired camera based on a monocentric lens and a silicon nanorod photodiode array. Nat. Electron. 2020, 10, 1–8. [Google Scholar]

- Gu, L.; Poddar, S.; Lin, Y.; Long, Z.; Zhang, D.; Zhang, Q.; Shu, L.; Qiu, X.; Kam, M.; Javey, A.; et al. A biomimetic eye with a hemispherical perovskite nanowire array retina. Nature 2020, 581, 278–282. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Qin, N.; Chong, Y.; Diao, Y.; Yiliguma; Wang, Z.; Xue, T.; Jiang, M.; Zhang, J.; Zheng, G. Nanowire arrays restore vision in blind mice. Nat. Commun. 2018, 9, 786. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wald, G. The Receptors of Human Color Vision. Science 1964, 145, 1007–1016. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.; Lee, G.J.; Song, Y.M. Recent Advances in Vertically Aligned Nanowires for Photonics Applications. Micromachines 2020, 11, 726. https://doi.org/10.3390/mi11080726

Chang S, Lee GJ, Song YM. Recent Advances in Vertically Aligned Nanowires for Photonics Applications. Micromachines. 2020; 11(8):726. https://doi.org/10.3390/mi11080726

Chicago/Turabian StyleChang, Sehui, Gil Ju Lee, and Young Min Song. 2020. "Recent Advances in Vertically Aligned Nanowires for Photonics Applications" Micromachines 11, no. 8: 726. https://doi.org/10.3390/mi11080726