Optimizing Optical Dielectrophoretic (ODEP) Performance: Position- and Size-Dependent Droplet Manipulation in an Open-Chamber Oil Medium

Abstract

1. Introduction

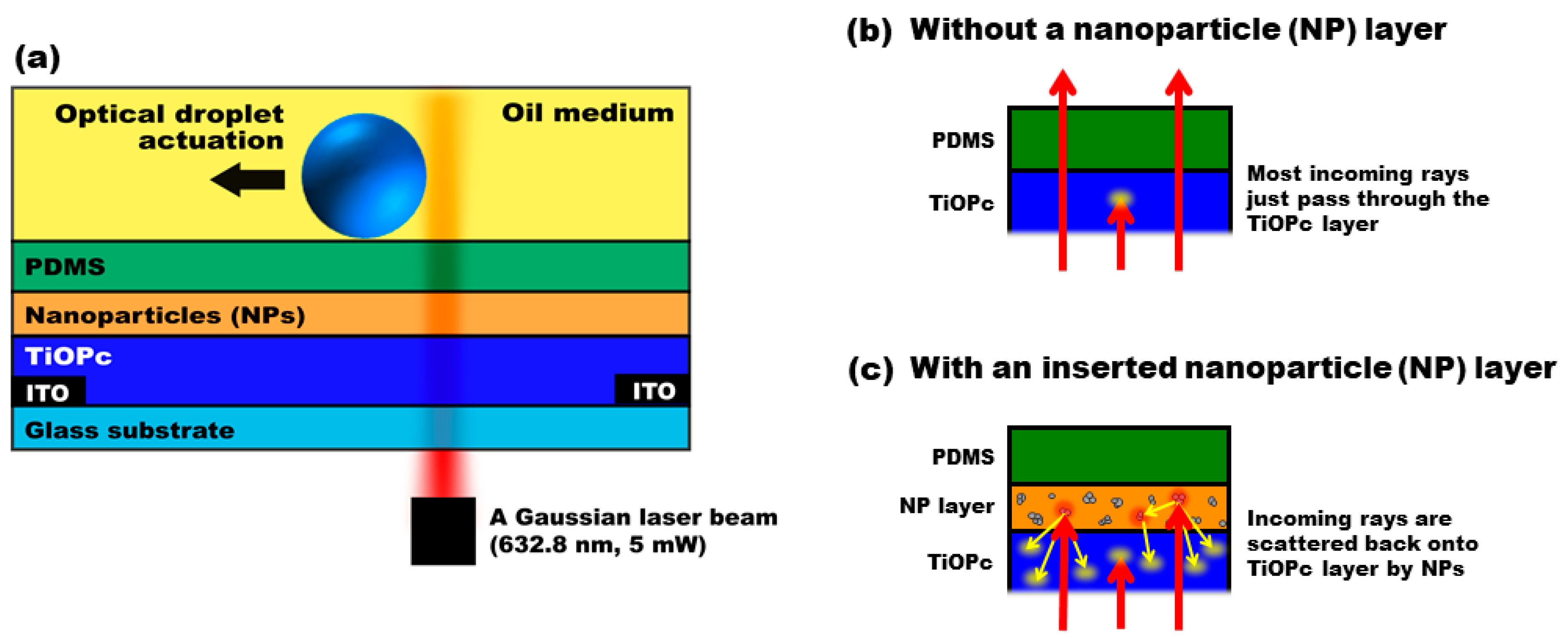

2. An Overview of a Light-Driven DEP Droplet Manipulation Platform

2.1. Device Structure and Its Fabrication

2.2. Droplet Actuation Principle on an FEOET Device

3. Numerical Simulation Study

3.1. Photoconductivity Measurement of the Nanoparticle-Coated TiOPc Layer

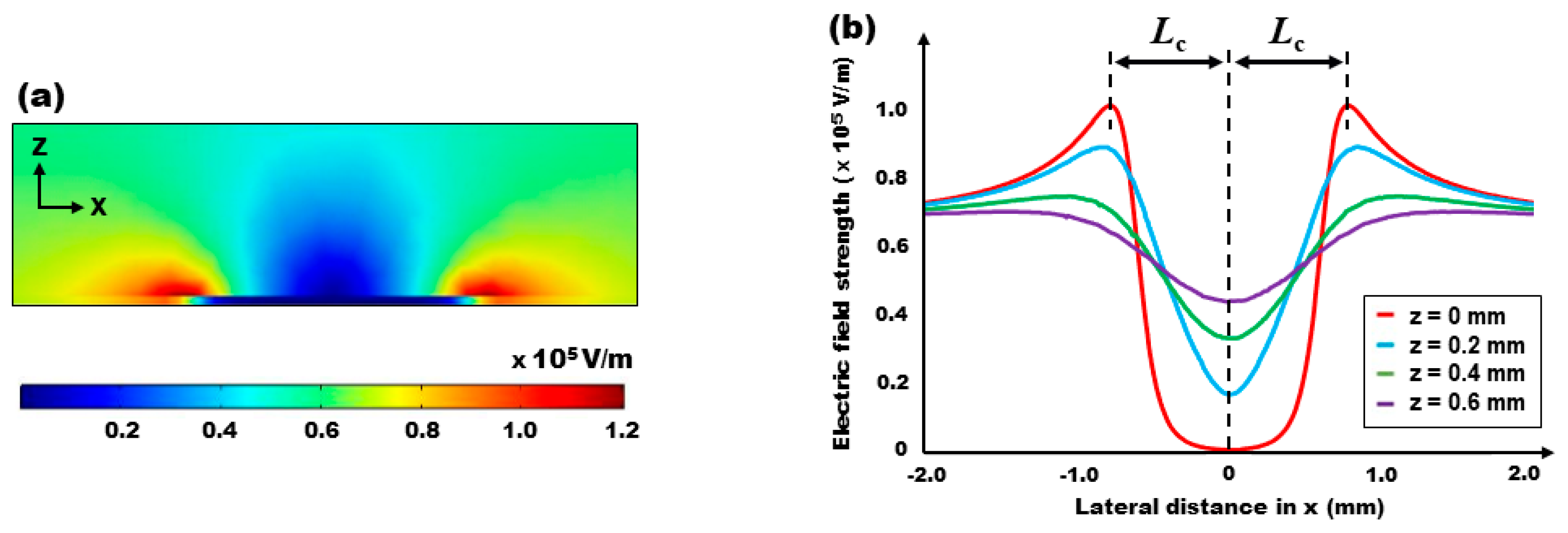

3.2. Light-Induced Electric Field Distributions

3.3. ODEP Force Calculation

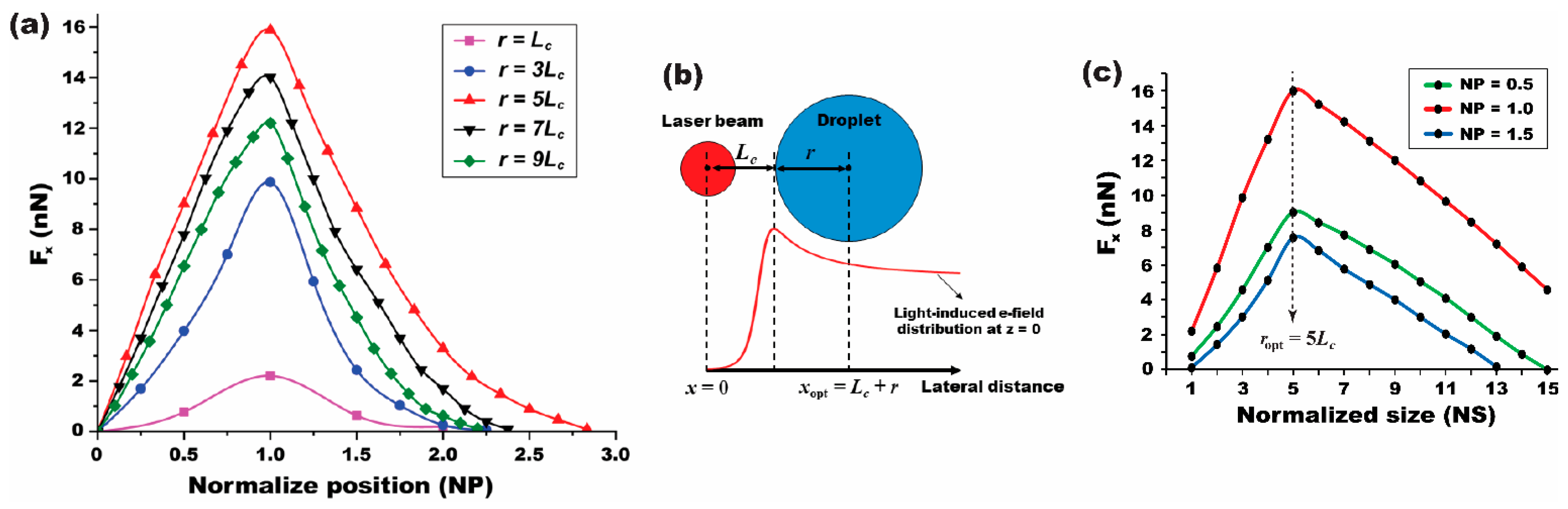

3.4. A Position-Dependent Effect

3.5. A Size-Dependent Effect

3.6. Optimal Position and Size of the Droplet

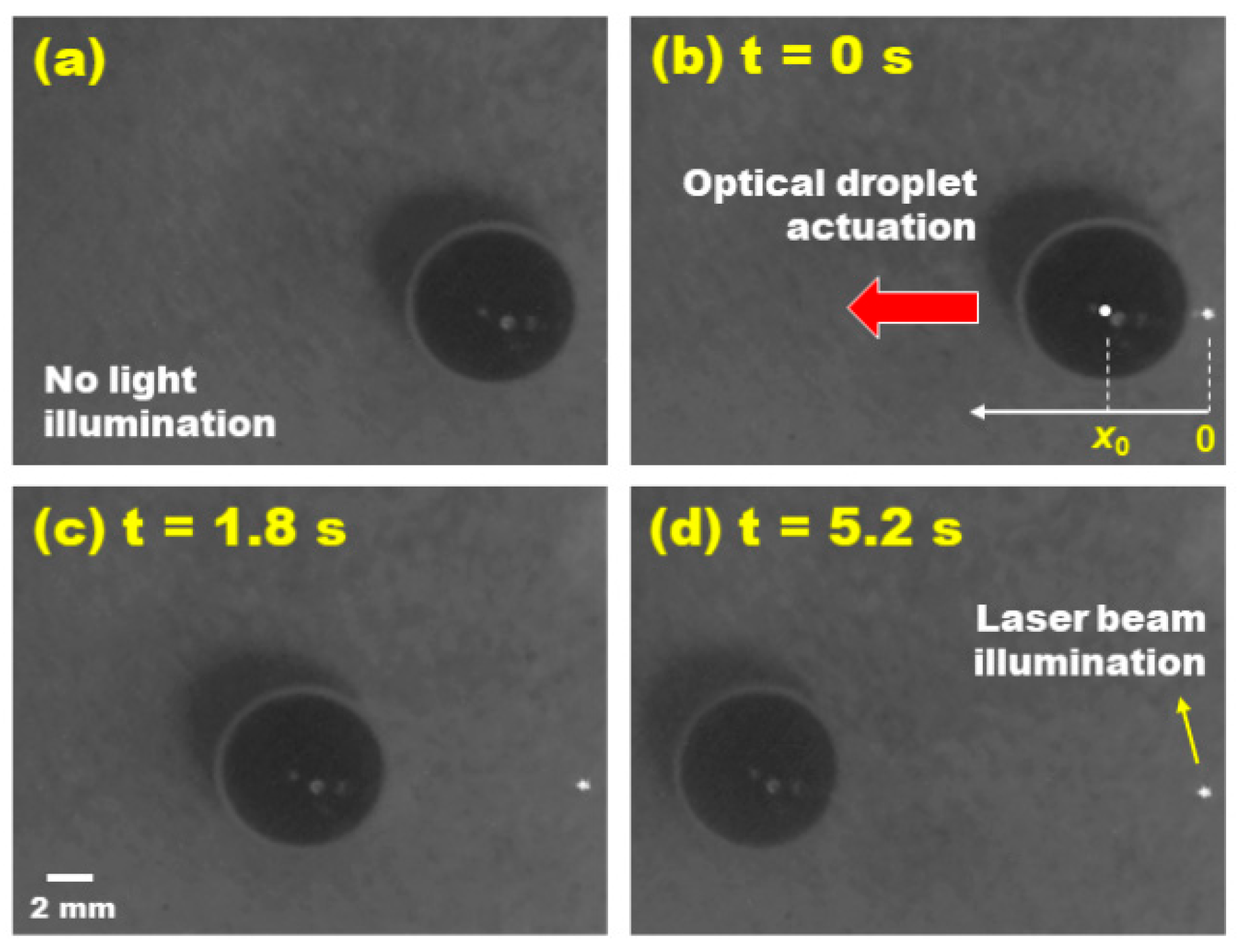

4. Experimental Study

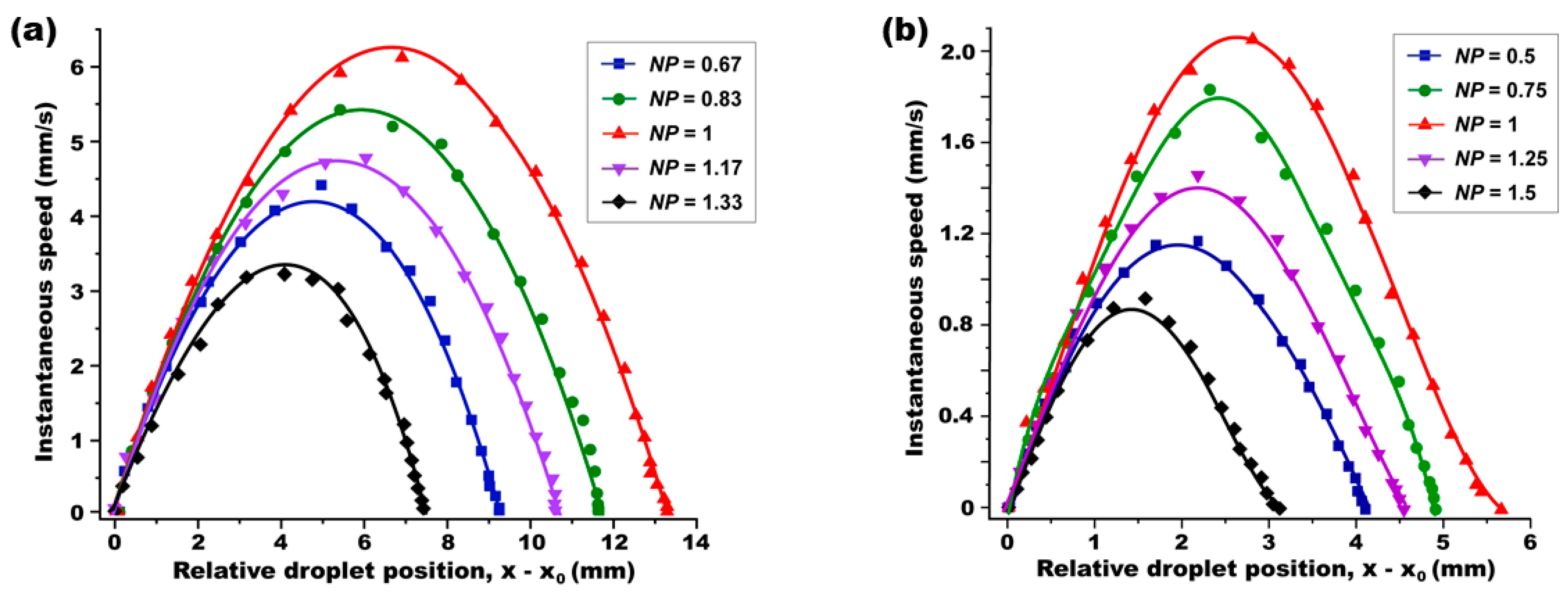

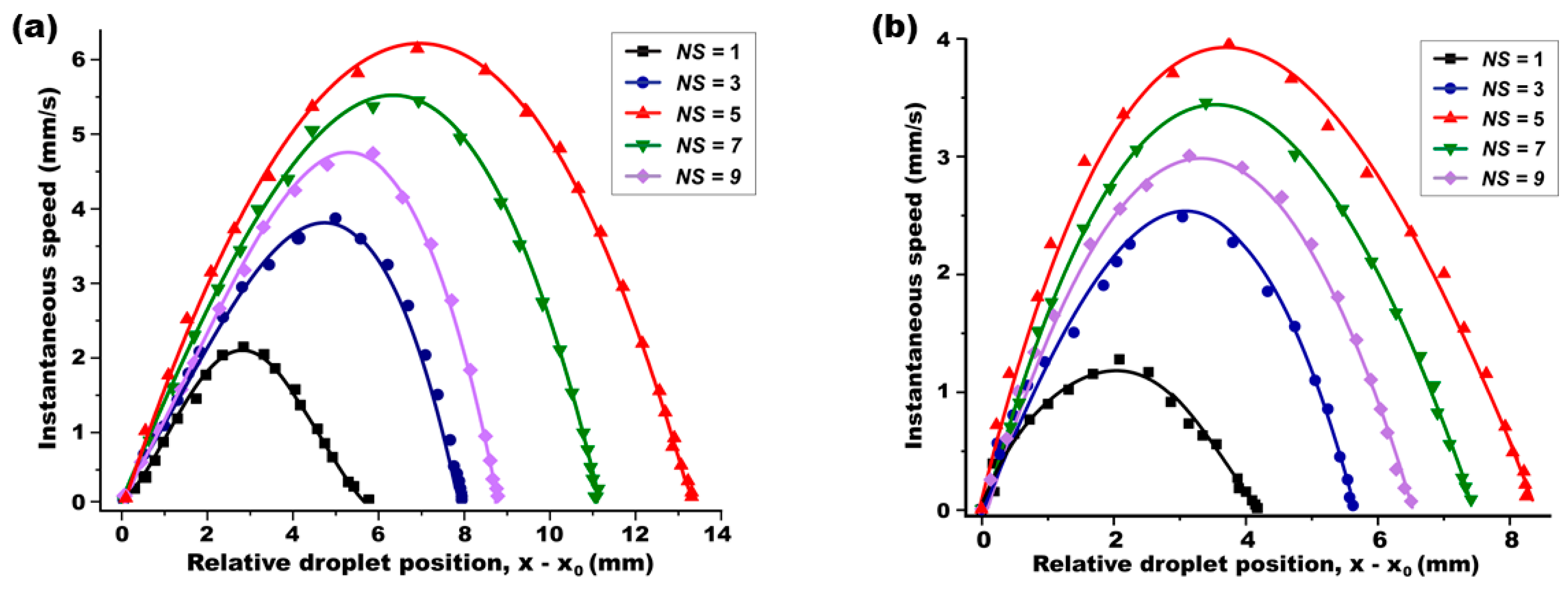

4.1. A Position-Dependent Experimental Study

4.2. A Size-Dependent Experimental Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, Y.; Howes, P.D.; deMello, A.J. Recent Advances in Droplet Microfluidics. Anal. Chem. 2020, 92, 132–149. [Google Scholar] [CrossRef] [PubMed]

- Thio, S.K.; Park, S.-Y. A review of optoelectrowetting (OEW): From fundamentals to lab-on-a-smartphone (LOS) applications to environmental sensors. Lab Chip 2022, 22, 3987–4006. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Zheng, T.; Li, M.; Wu, J.; Ji, H.; Zhang, J.; Zhao, W.; Guo, J. Droplet-based microfluidics systems in biomedical applications. Electrophoresis 2019, 40, 1580–1590. [Google Scholar] [CrossRef]

- Yu, L.; Chen, M.C.W.; Cheung, K.C. Droplet-based microfluidic system for multicellular tumor spheroid formation and anticancer drug testing. Lab Chip 2010, 10, 2424–2432. [Google Scholar] [CrossRef]

- Song, H.; Chen, D.L.; Ismagilov, R.F. Reactions in droplets in microfluidic channels. Angew. Chem. Int. Ed. Engl. 2006, 45, 7336–7356. [Google Scholar] [CrossRef] [PubMed]

- Preetam, S.; Nahak, B.K.; Patra, S.; Toncu, D.C.; Park, S.; Syväjärvi, M.; Orive, G.; Tiwari, A. Emergence of microfluidics for next generation biomedical devices. Biosens. Bioelectron. X 2022, 10, 100106. [Google Scholar] [CrossRef]

- Park, S.-Y.; Wu, T.-H.; Chen, Y.; Teitell, M.A.; Chiou, P.-Y. High-speed droplet generation on demand driven by pulse laser-induced cavitation. Lab Chip 2011, 11, 1010–1012. [Google Scholar] [CrossRef] [PubMed]

- deMello, A.J. Control and detection of chemical reactions in microfluidic systems. Nature 2006, 442, 394–402. [Google Scholar] [CrossRef]

- Bilitewski, U.; Genrich, M.; Kadow, S.; Mersal, G. Biochemical analysis with microfluidic systems. Anal. Bioanal. Chem. 2003, 377, 556–569. [Google Scholar] [CrossRef]

- Clausell-Tormos, J.; Lieber, D.; Baret, J.-C.; El-Harrak, A.; Miller, O.J.; Frenz, L.; Blouwolff, J.; Humphry, K.J.; Köster, S.; Duan, H.; et al. Droplet-Based Microfluidic Platforms for the Encapsulation and Screening of Mammalian Cells and Multicellular Organisms. Chem. Biol. 2008, 15, 427–437. [Google Scholar] [CrossRef]

- Park, S.-Y.; Chiou, P.-Y. Light-Driven Droplet Manipulation Technologies for Lab-on-a-Chip Applications. Adv. OptoElectron. 2011, 2011, 909174. [Google Scholar] [CrossRef]

- Moragues, T.; Arguijo, D.; Beneyton, T.; Modavi, C.; Simutis, K.; Abate, A.R.; Baret, J.-C.; deMello, A.J.; Densmore, D.; Griffiths, A.D. Droplet-based microfluidics. Nat. Rev. Methods Primers 2023, 3, 32. [Google Scholar] [CrossRef]

- Sohrabi, S.; Kassir, N.; Keshavarz Moraveji, M. Retraction: Droplet microfluidics: Fundamentals and its advanced applications. RSC Adv. 2022, 12, 34566. [Google Scholar] [CrossRef]

- Brouzes, E.; Medkova, M.; Savenelli, N.; Marran, D.; Twardowski, M.; Hutchison, J.B.; Rothberg, J.M.; Link, D.R.; Perrimon, N.; Samuels, M.L. Droplet microfluidic technology for single-cell high-throughput screening. Proc. Natl. Acad. Sci. USA 2009, 106, 14195–14200. [Google Scholar] [CrossRef]

- Wang, J. On-chip enzymatic assays. Electrophoresis 2002, 23, 713–718. [Google Scholar] [CrossRef]

- Bui, M.-P.N.; Li, C.A.; Han, K.N.; Choo, J.; Lee, E.K.; Seong, G.H. Enzyme Kinetic Measurements Using a Droplet-Based Microfluidic System with a Concentration Gradient. Anal. Chem. 2011, 83, 1603–1608. [Google Scholar] [CrossRef] [PubMed]

- Thio, S.K.; Bae, S.W.; Park, S.-Y. Lab on a smartphone (LOS): A smartphone-integrated, plasmonic-enhanced optoelectrowetting (OEW) platform for on-chip water quality monitoring through LAMP assays. Sens. Actuators B Chem. 2022, 358, 131543. [Google Scholar] [CrossRef]

- Dong, X.; Liu, L.; Tu, Y.; Zhang, J.; Miao, G.; Zhang, L.; Ge, S.; Xia, N.; Yu, D.; Qiu, X. Rapid PCR powered by microfluidics: A quick review under the background of COVID-19 pandemic. Trends Anal. Chem 2021, 143, 116377. [Google Scholar] [CrossRef]

- Pekin, D.; Skhiri, Y.; Baret, J.-C.; Le Corre, D.; Mazutis, L.; Ben Salem, C.; Millot, F.; El Harrak, A.; Hutchison, J.B.; Larson, J.W.; et al. Quantitative and sensitive detection of rare mutations using droplet-based microfluidics. Lab Chip 2011, 11, 2156–2166. [Google Scholar] [CrossRef]

- Liang, H.; Song, Y. Microfluidic Synthesis of Organics. In Microfluidics: Fundamental, Devices and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 351–374. [Google Scholar]

- Jaouhari, T.; Zhang, F.; Tassaing, T.; Fery-Forgues, S.; Aymonier, C.; Marre, S.; Erriguible, A. Process intensification for the synthesis of ultra-small organic nanoparticles with supercritical CO2 in a microfluidic system. Chem. Eng. J. 2020, 397, 125333. [Google Scholar] [CrossRef]

- Ji, J.; Zhao, Y.; Guo, L.; Liu, B.; Ji, C.; Yang, P. Interfacial organic synthesis in a simple droplet-based microfluidic system. Lab Chip 2012, 12, 1373–1377. [Google Scholar] [CrossRef]

- Qin, J.; Wang, Z.; Chen, Y.; Mo, S.; Liu, J. Thermocapillary flow-induced core release from double-emulsion droplets in microchannels. Droplet 2023, 2, 54. [Google Scholar] [CrossRef]

- Wang, J.-X.; Zhang, F.-Y.; Li, S.-Y.; Cheng, Y.-P.; Yan, W.-C.; Wang, F.; Xu, J.-L.; Sui, Y. Numerical Studies on the Controlled Thermocapillary Migration of a Sessile Droplet. Ind. Eng. Chem. Res. 2023, 62, 18792–18799. [Google Scholar] [CrossRef]

- Won, B.J.; Lee, W.; Song, S. Estimation of the thermocapillary force and its applications to precise droplet control on a microfluidic chip. Sci. Rep. 2017, 7, 3062. [Google Scholar] [CrossRef] [PubMed]

- Thio, S.K.; Bae, S.W.; Park, S.-Y. Plasmonic nanoparticle-enhanced optoelectrowetting (OEW) for effective light-driven droplet manipulation. Sens. Actuators B Chem. 2020, 308, 127704. [Google Scholar] [CrossRef]

- Li, J.; Kim, C.-J.C. Current commercialization status of electrowetting-on-dielectric (EWOD) digital microfluidics. Lab Chip 2020, 20, 1705–1712. [Google Scholar] [CrossRef] [PubMed]

- Thio, S.K.; Jiang, D.; Park, S.-Y. Electrowetting-driven solar indoor lighting (e-SIL): An optofluidic approach towards sustainable buildings. Lab Chip 2018, 18, 1725–1735. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Dalton, C.; Crabtree, H.J.; Nilsson, G.; Kaler, K.V.I.S. Continuous dielectrophoretic cell separation microfluidic device. Lab Chip 2007, 7, 239–248. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X. Dielectrophoretic microfluidic device for separation of red blood cells and platelets: A model-based study. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 89. [Google Scholar] [CrossRef]

- Kwizera, E.A.; Sun, M.; White, A.M.; Li, J.; He, X. Methods of Generating Dielectrophoretic Force for Microfluidic Manipulation of Bioparticles. ACS Biomater. Sci. Eng. 2021, 7, 2043–2063. [Google Scholar] [CrossRef]

- Namgung, B.; Lee, T.; Tan, J.K.S.; Poh, D.K.H.; Park, S.; Chng, K.Z.; Agrawal, R.; Park, S.-Y.; Leo, H.L.; Kim, S. Vibration motor-integrated low-cost, miniaturized system for rapid quantification of red blood cell aggregation. Lab Chip 2020, 20, 3930–3937. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Cha, B.; Jeon, J.S.; Park, J. Acoustofluidic control of chemical concentration within picoliter droplets in a disposable microfluidic chip. Sens. Actuators B Chem. 2023, 393, 134132. [Google Scholar] [CrossRef]

- Jung, J.H.; Destgeer, G.; Ha, B.; Park, J.; Sung, H.J. On-demand droplet splitting using surface acoustic waves. Lab Chip 2016, 16, 3235–3243. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Kim, J.; Kang, J.W.; Kwon, S.B.; Hong, J. Compact Three-Dimensional Digital Microfluidic Platforms with Programmable Contact Charge Electrophoresis Actuation. Langmuir 2022, 38, 5759–5764. [Google Scholar] [CrossRef] [PubMed]

- Bishop, K.J.M.; Drews, A.M.; Cartier, C.A.; Pandey, S.; Dou, Y. Contact Charge Electrophoresis: Fundamentals and Microfluidic Applications. Langmuir 2018, 34, 6315–6327. [Google Scholar] [CrossRef]

- Chen, Q.; Yuan, Y.J. A review of polystyrene bead manipulation by dielectrophoresis. RSC Adv. 2019, 9, 4963–4981. [Google Scholar] [CrossRef]

- Barik, A.; Zhang, Y.; Grassi, R.; Nadappuram, B.P.; Edel, J.B.; Low, T.; Koester, S.J.; Oh, S.-H. Graphene-edge dielectrophoretic tweezers for trapping of biomolecules. Nat. Commun. 2017, 8, 1867. [Google Scholar] [CrossRef]

- Waheed, W.; Alazzam, A.; Al-Khateeb, A.N.; Abu-Nada, E. Multiple Particle Manipulation under Dielectrophoresis Effect: Modeling and Experiments. Langmuir 2020, 36, 3016–3028. [Google Scholar] [CrossRef]

- Manaresi, N.; Romani, A.; Medoro, G.; Altomare, L.; Leonardi, A.; Tartagni, M.; Guerrieri, R. A CMOS chip for individual cell manipulation and detection. IEEE J. Solid-State Circuits 2003, 38, 2297–2305. [Google Scholar] [CrossRef]

- Park, S.-Y.; Teitell, M.A.; Chiou, E.P.Y. Single-sided continuous optoelectrowetting (SCOEW) for droplet manipulation with light patterns. Lab Chip 2010, 10, 1655–1661. [Google Scholar] [CrossRef]

- Jamshidi, A.; Pauzauskie, P.J.; Schuck, P.J.; Ohta, A.T.; Chiou, P.-Y.; Chou, J.; Yang, P.; Wu, M.C. Dynamic manipulation and separation of individual semiconducting and metallic nanowires. Nat. Photonics 2008, 2, 86–89. [Google Scholar] [CrossRef]

- Chiou, P.Y.; Ohta, A.T.; Wu, M.C. Massively parallel manipulation of single microparticles using optical images. Nature 2005, 463, 370–372. [Google Scholar] [CrossRef]

- Hsu, H.-y.; Ohta, A.T.; Chiou, P.-Y.; Jamshidi, A.; Neale, S.L.; Wu, M.C. Phototransistor-based optoelectronic tweezers for dynamic cell manipulation in cell culture media. Lab Chip 2010, 10, 165–172. [Google Scholar] [CrossRef]

- Valley, J.K.; NingPei, S.; Jamshidi, A.; Hsu, H.-Y.; Wu, M.C. A unified platform for optoelectrowetting and optoelectronic tweezers. Lab Chip 2011, 11, 1292–1297. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Thio, S.; Park, S.-Y.; Bae, S. An automated 3D-printed smartphone platform integrated with optoelectrowetting (OEW) microfluidic chip for on-chip monitoring of viable algae in water. Harmful Algae 2019, 88, 101638. [Google Scholar] [CrossRef]

- Baroud, C.N.; Gallaire, F.; Dangla, R. Dynamics of microfluidic droplets. Lab Chip 2010, 10, 2023–2045. [Google Scholar] [CrossRef]

- Park, S.-Y.; Pan, C.; Wu, T.-H.; Kloss, C.; Kalim, S.; Callahan, C.E.; Teitell, M.; Chiou, E.P.Y. Floating electrode optoelectronic tweezers: Light-driven dielectrophoretic droplet manipulation in electrically insulating oil medium. Appl. Phys. Lett. 2008, 92, 151101. [Google Scholar] [CrossRef] [PubMed]

- Park, S.-Y.; Kalim, S.; Callahan, C.; Teitell, M.A.; Chiou, E.P.Y. A light-induced dielectrophoretic droplet manipulation platform. Lab Chip 2009, 9, 3228–3235. [Google Scholar] [CrossRef]

- Thio, S.K.; Park, S.-Y. Optical Dielectrophoretic (DEP) Manipulation of Oil-Immersed Aqueous Droplets on a Plasmonic-Enhanced Photoconductive Surface. Micromachines 2022, 13, 112. [Google Scholar] [CrossRef] [PubMed]

- Chou, W.-P.; Wang, H.-M.; Chang, J.-H.; Chiu, T.-K.; Hsieh, C.-H.; Liao, C.-J.; Wu, M.-H. The utilization of optically-induced-dielectrophoresis (ODEP)-based virtual cell filters in a microfluidic system for continuous isolation and purification of circulating tumour cells (CTCs) based on their size characteristics. Sens. Actuators B Chem. 2017, 241, 245–254. [Google Scholar] [CrossRef]

- Huang, S.-B.; Chen, J.; Wang, J.; Yang, C.-L.; Wu, M.-H. A New Optically-Induced Dielectrophoretic (ODEP) Force-Based Scheme for Effective Cell Sorting. Int. J. Electrochem. Sci. 2012, 7, 12656–12667. [Google Scholar] [CrossRef]

- Chiu, T.-K.; Chou, W.-P.; Huang, S.-B.; Wang, H.-M.; Lin, Y.-C.; Hsieh, C.-H.; Wu, M.-H. Application of optically-induced-dielectrophoresis in microfluidic system for purification of circulating tumour cells for gene expression analysis—Cancer cell line model. Sci. Rep. 2016, 6, 32851. [Google Scholar] [CrossRef]

- Yang, S.-M.; Yu, T.-M.; Huang, H.-P.; Ku, M.-Y.; Tseng, S.-Y.; Tsai, C.-L.; Chen, H.-P.; Hsu, L.; Liu, C.-H. Light-driven manipulation of picobubbles on a titanium oxide phthalocyanine-based optoelectronic chip. Appl. Phys. Lett. 2011, 98, 153512. [Google Scholar] [CrossRef]

- Wang, W.-B.; Li, X.-g.; Wang, S.-r.; Hou, W. The preparation of high photosensitive TiOPc. Dye. Pigment. 2007, 72, 38–41. [Google Scholar] [CrossRef]

- Bo, Z.; Yang, Y.; Chen, J.; Yu, K.; Yan, J.; Cen, K. Plasma-enhanced chemical vapor deposition synthesis of vertically oriented graphene nanosheets. Nanoscale 2013, 5, 5180–5204. [Google Scholar] [CrossRef] [PubMed]

- Raiford, J.A.; Oyakhire, S.T.; Bent, S.F. Applications of atomic layer deposition and chemical vapor deposition for perovskite solar cells. Energy Environ. Sci. 2020, 13, 1997–2023. [Google Scholar] [CrossRef]

- Chiou, P.Y.; Park, S.-Y.; Wu, M.C. Continuous optoelectrowetting for picoliter droplet manipulation. Appl. Phys. Lett. 2008, 93, 221110. [Google Scholar] [CrossRef]

- Jiang, D.; Park, S.-Y. Light-driven 3D droplet manipulation on flexible optoelectrowetting devices fabricated by a simple spin-coating method. Lab Chip 2016, 16, 1831–1839. [Google Scholar] [CrossRef]

- Bartelt, J.A.; Beiley, Z.M.; Hoke, E.T.; Mateker, W.R.; Douglas, J.D.; Collins, B.A.; Tumbleston, J.R.; Graham, K.R.; Amassian, A.; Ade, H.; et al. The Importance of Fullerene Percolation in the Mixed Regions of Polymer–Fullerene Bulk Heterojunction Solar Cells. Adv. Energy Mater. 2013, 3, 364–374. [Google Scholar] [CrossRef]

- Uddin, A.; Yang, X. Surface Plasmonic Effects on Organic Solar Cells. J. Nanosci. Nanotechnol. 2014, 14, 1099–1119. [Google Scholar] [CrossRef]

- Afify, H.A.; El-Nahass, M.M.; Gadallah, A.S.; Atta Khedr, M. Carrier transport mechanisms and photodetector characteristics of Ag/TiOPc/p-Si/Al hybrid heterojunction. Mater. Sci. Semicond. Process. 2015, 39, 324–331. [Google Scholar] [CrossRef]

- Li, X.; Carey, J.E.; Sickler, J.W.; Pralle, M.U.; Palsule, C.; Vineis, C.J. Silicon photodiodes with high photoconductive gain at room temperature. Opt. Express 2012, 20, 5518–5523. [Google Scholar] [CrossRef]

- Wang, L.; Hasanzadeh Kafshgari, M.; Meunier, M. Optical Properties and Applications of Plasmonic-Metal Nanoparticles. Adv. Funct. Mater. 2020, 30, 2005400. [Google Scholar] [CrossRef]

- Pethig, R. Review article-dielectrophoresis: Status of the theory, technology, and applications. Biomicrofluidics 2010, 4, 022811. [Google Scholar] [CrossRef]

- Kadaksham, A.T.J.; Singh, P.; Aubry, N. Dielectrophoresis of nanoparticles. Electrophoresis 2004, 25, 3625–3632. [Google Scholar] [CrossRef]

- Abd Rahman, N.; Ibrahim, F.; Yafouz, B. Dielectrophoresis for Biomedical Sciences Applications: A Review. Sensors 2017, 17, 449. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, X.-B.; Gascoyne, P.R.C. General expressions for dielectrophoretic force and electrorotational torque derived using the Maxwell stress tensor method. J. Electrost. 1997, 39, 277–295. [Google Scholar] [CrossRef]

- Al-Jarro, A.; Paul, J.; Thomas, D.W.P.; Crowe, J.; Sawyer, N.; Rose, F.R.A.; Shakesheff, K.M. Direct calculation of Maxwell stress tensor for accurate trajectory prediction during DEP for 2D and 3D structures. J. Phys. D Appl. Phys. 2007, 40, 71. [Google Scholar] [CrossRef]

- Çetin, B.; Li, D. Dielectrophoresis in microfluidics technology. Electrophoresis 2011, 32, 2410–2427. [Google Scholar] [CrossRef] [PubMed]

- Lapizco-Encinas, B.H.; Rito-Palomares, M. Dielectrophoresis for the manipulation of nanobioparticles. Electrophoresis 2007, 28, 4521–4538. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, M.A.; Park, S.-Y. Optimizing Optical Dielectrophoretic (ODEP) Performance: Position- and Size-Dependent Droplet Manipulation in an Open-Chamber Oil Medium. Micromachines 2024, 15, 119. https://doi.org/10.3390/mi15010119

Islam MA, Park S-Y. Optimizing Optical Dielectrophoretic (ODEP) Performance: Position- and Size-Dependent Droplet Manipulation in an Open-Chamber Oil Medium. Micromachines. 2024; 15(1):119. https://doi.org/10.3390/mi15010119

Chicago/Turabian StyleIslam, Md Aminul, and Sung-Yong Park. 2024. "Optimizing Optical Dielectrophoretic (ODEP) Performance: Position- and Size-Dependent Droplet Manipulation in an Open-Chamber Oil Medium" Micromachines 15, no. 1: 119. https://doi.org/10.3390/mi15010119

APA StyleIslam, M. A., & Park, S.-Y. (2024). Optimizing Optical Dielectrophoretic (ODEP) Performance: Position- and Size-Dependent Droplet Manipulation in an Open-Chamber Oil Medium. Micromachines, 15(1), 119. https://doi.org/10.3390/mi15010119