Laterally Actuated Si-to-Si DC MEMS Switch for Power Switching Applications

Abstract

:1. Introduction

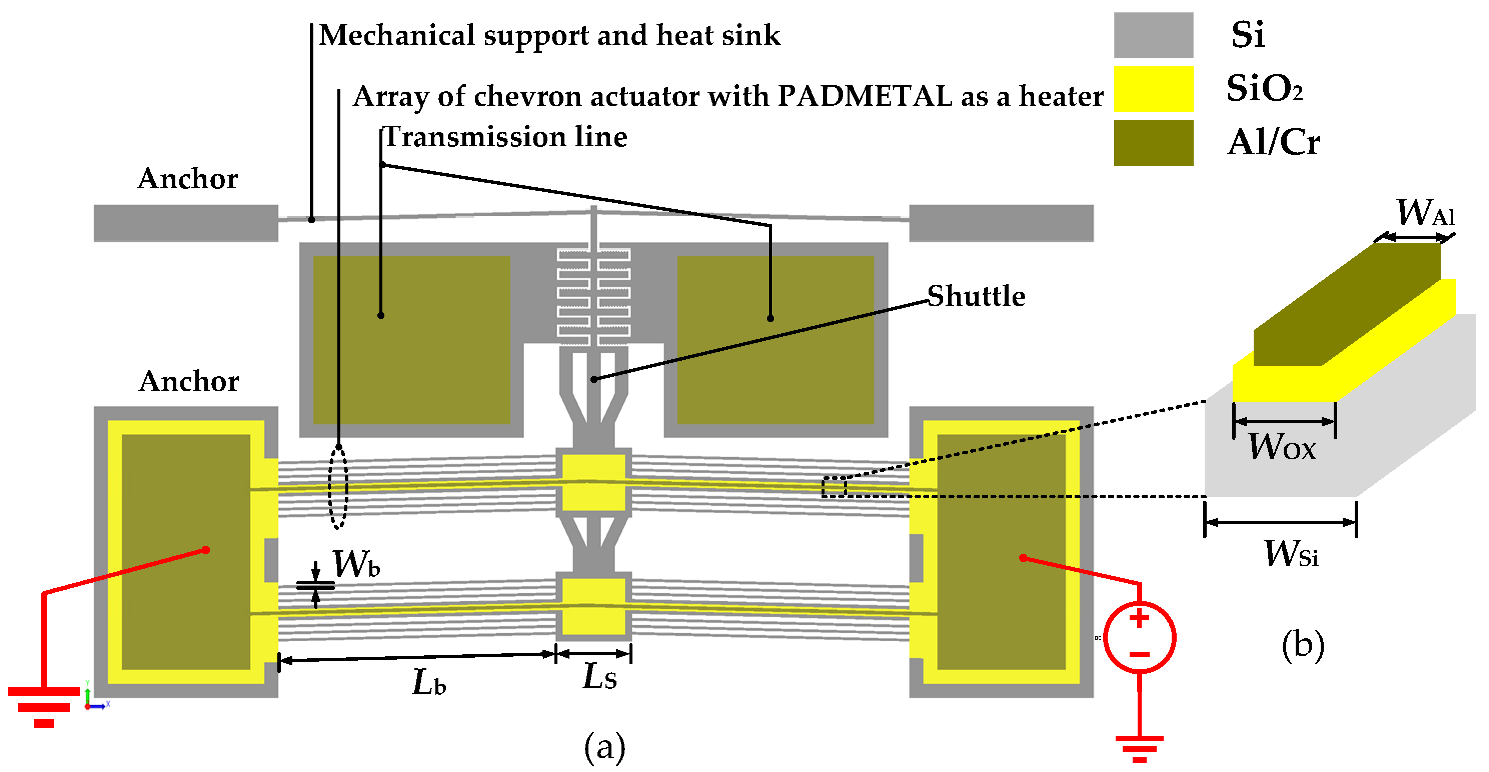

2. Design and Simulation

2.1. Design Configuration

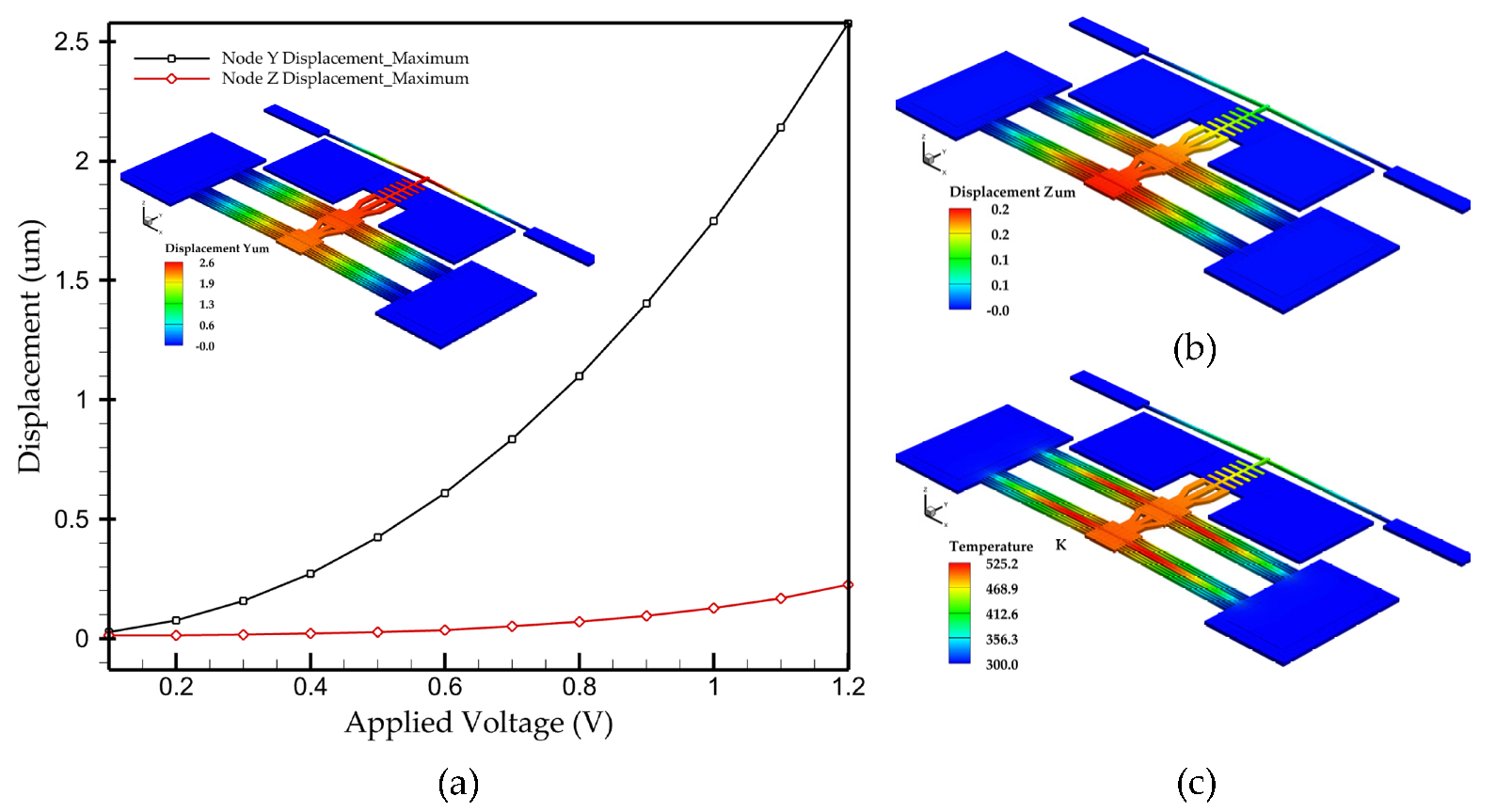

2.2. Simulation

3. Fabrication and Characterization

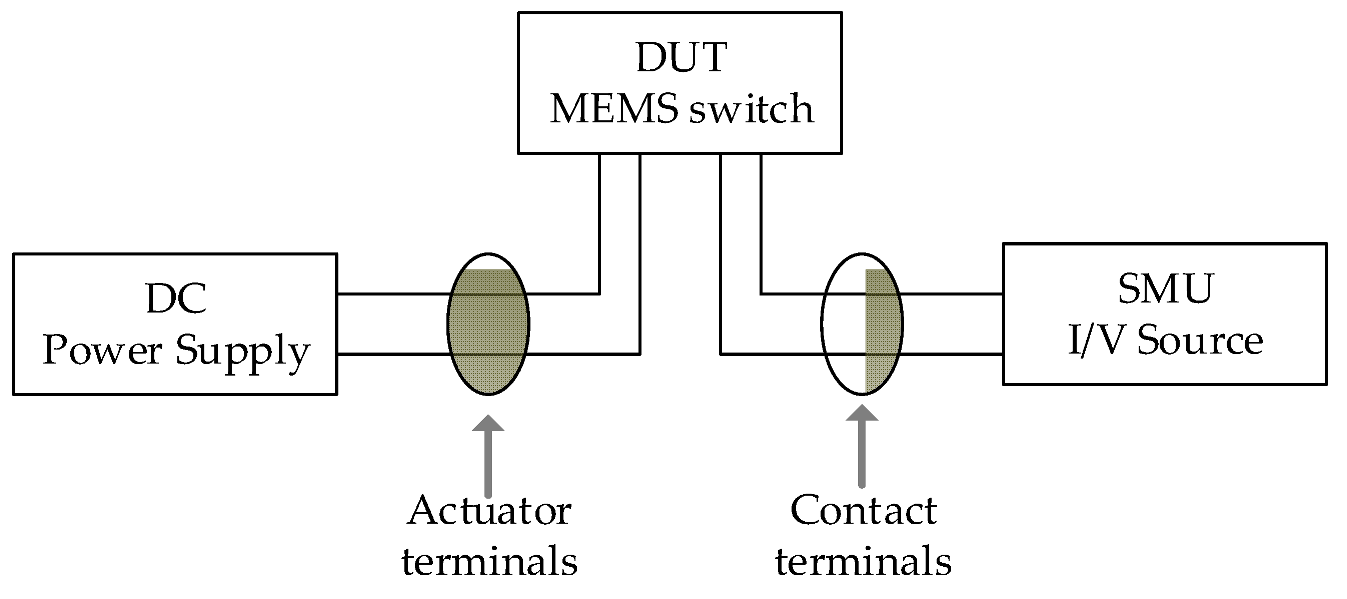

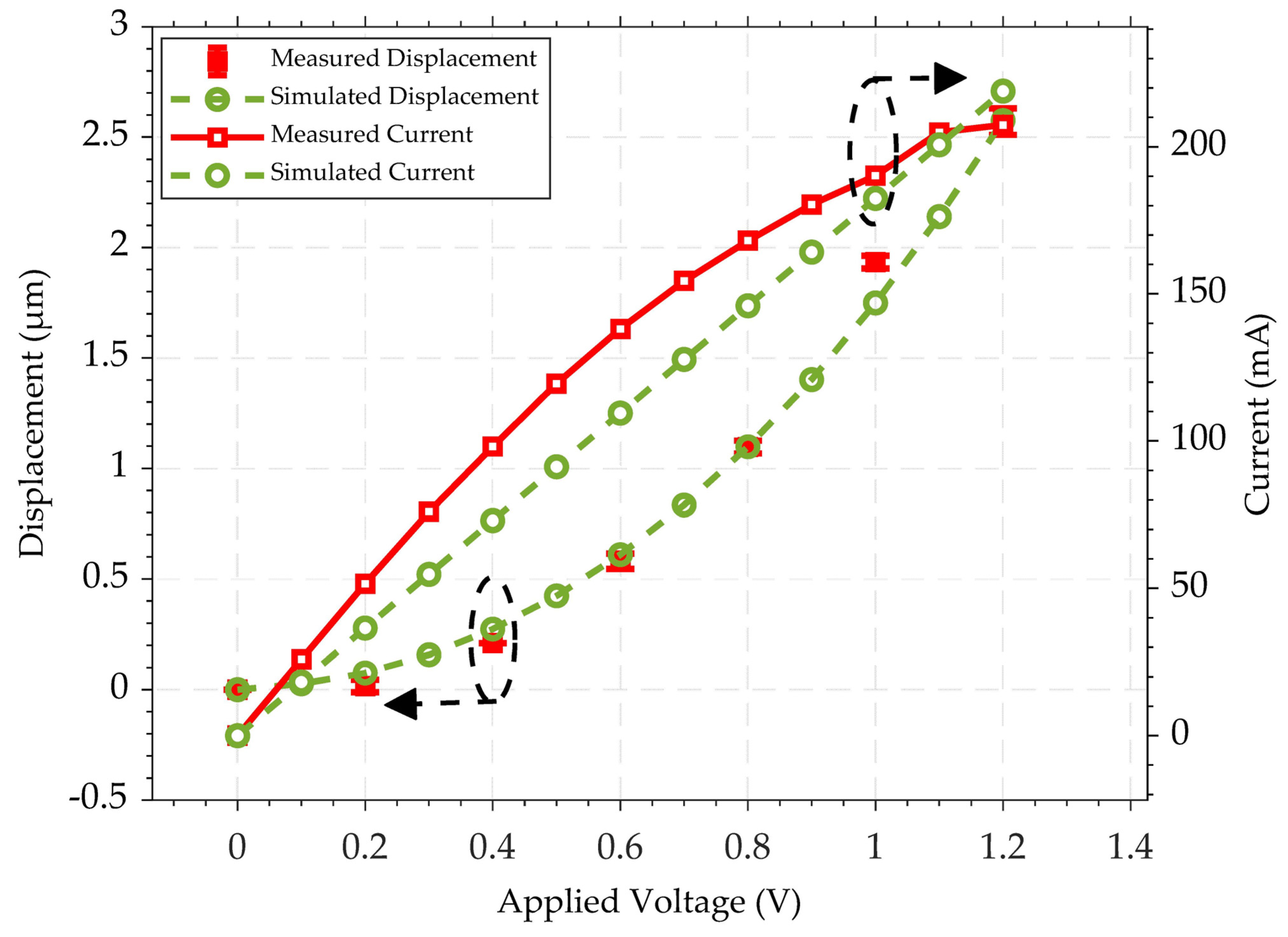

4. Measurements and Results

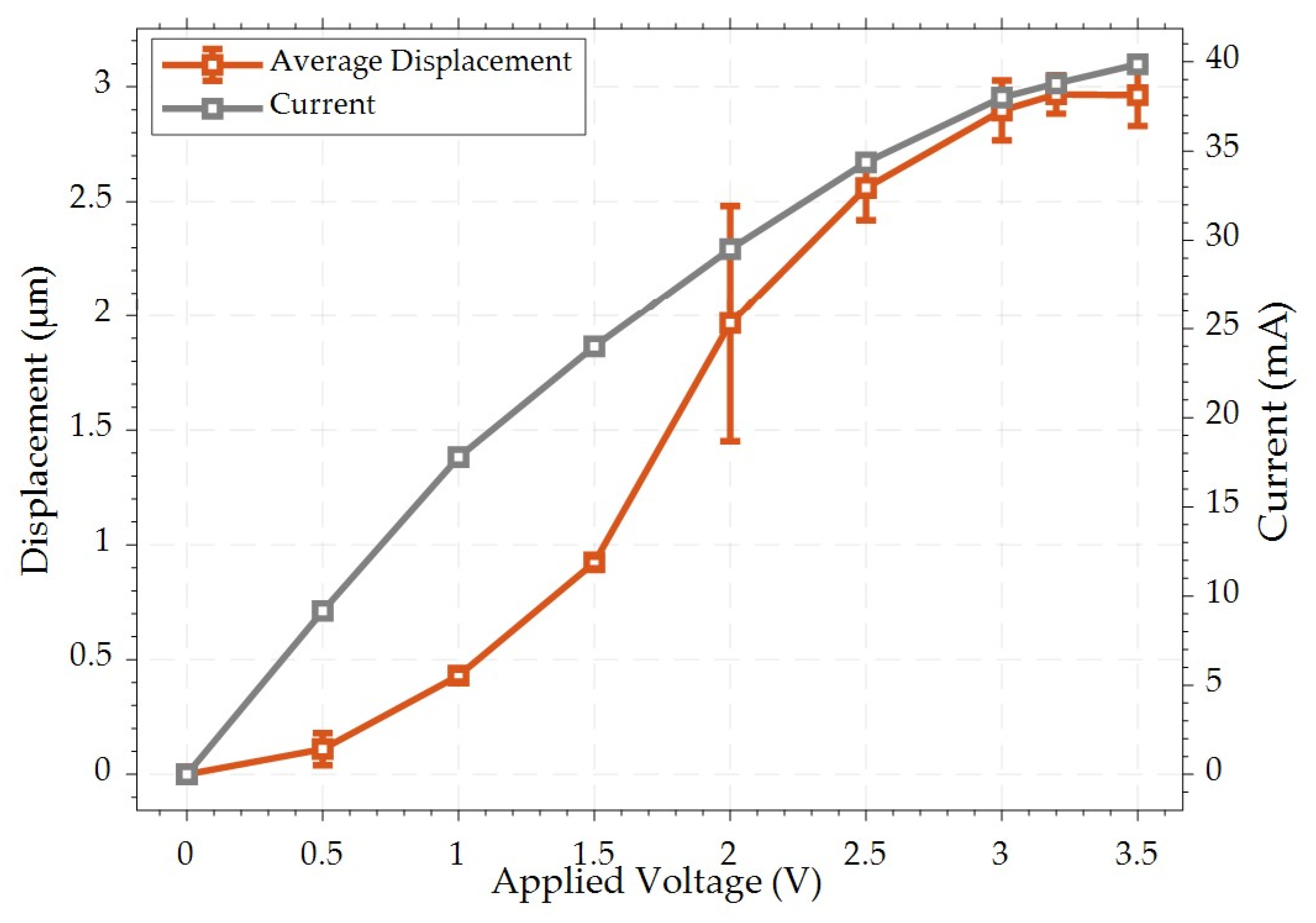

4.1. Displacement Measurement

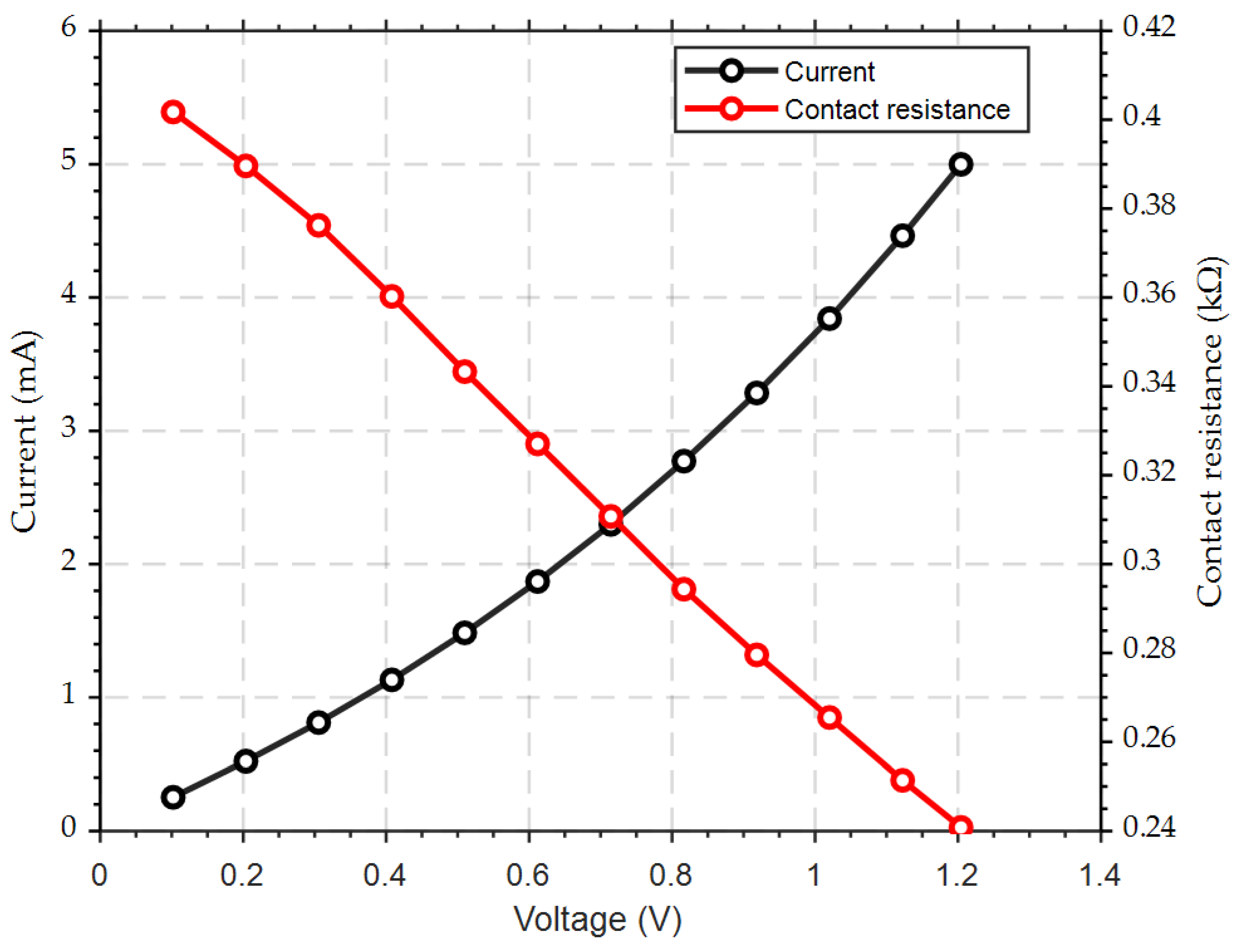

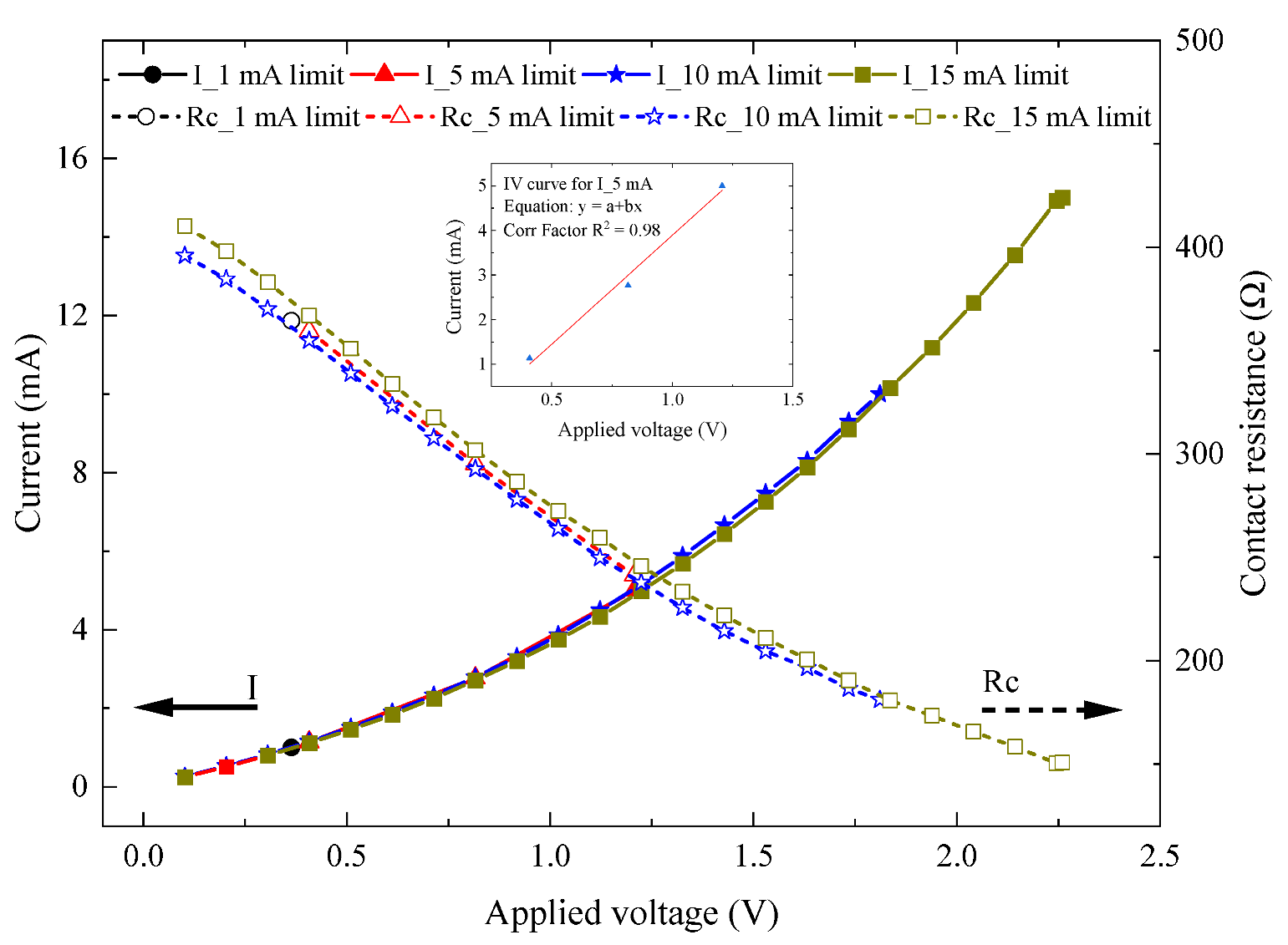

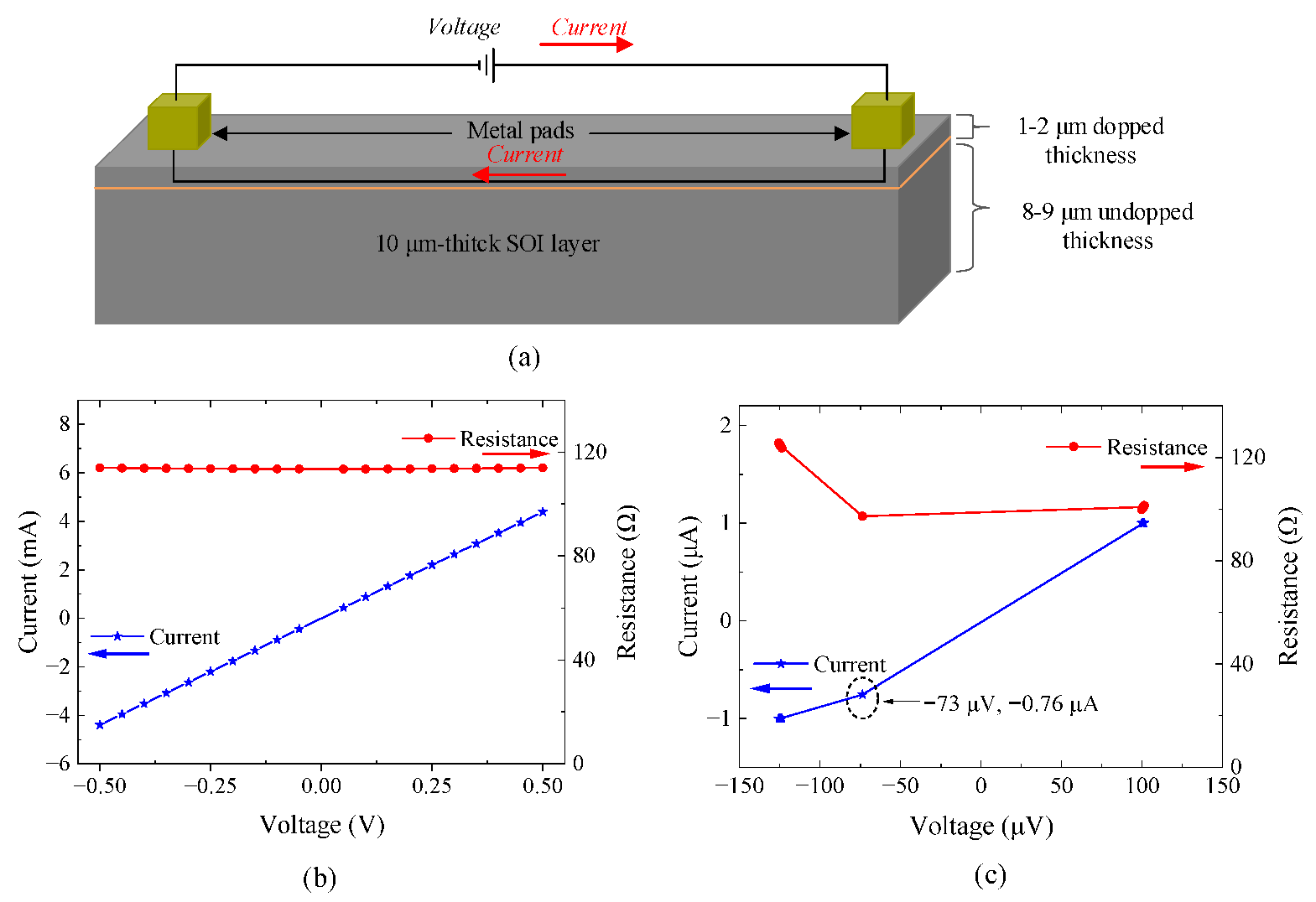

4.2. Contact Resistance Measurement

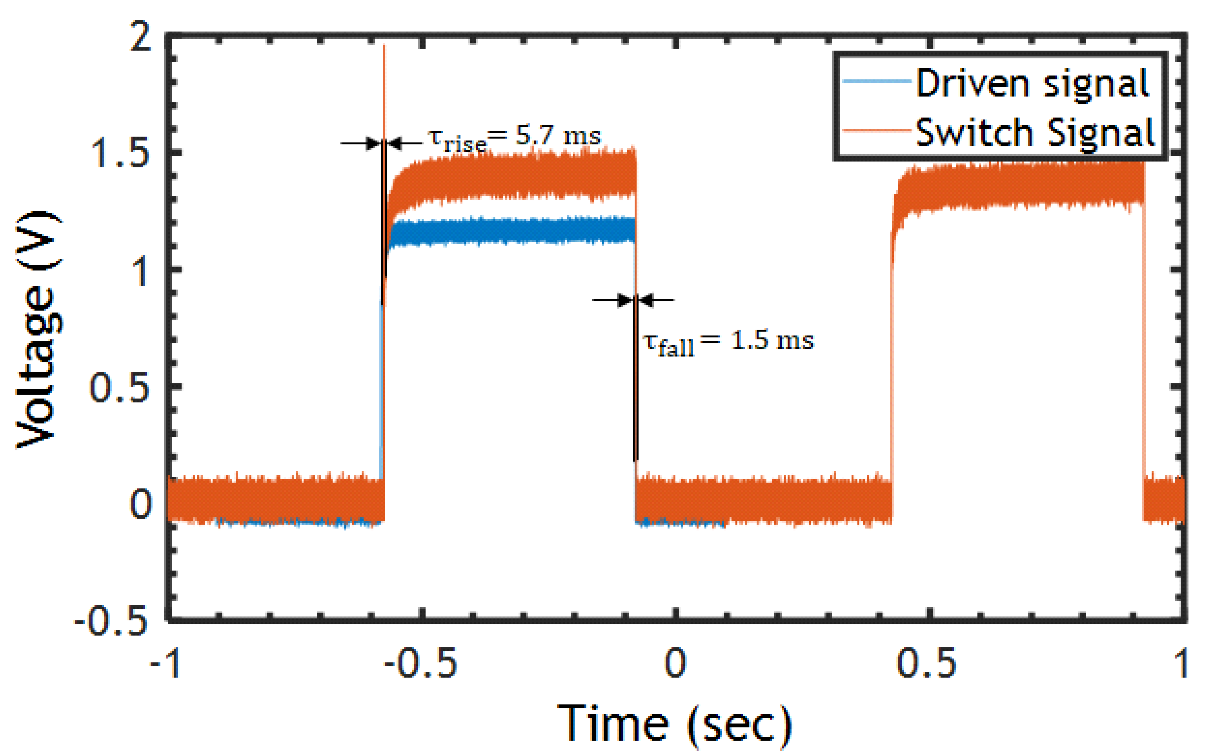

4.3. Switching Time

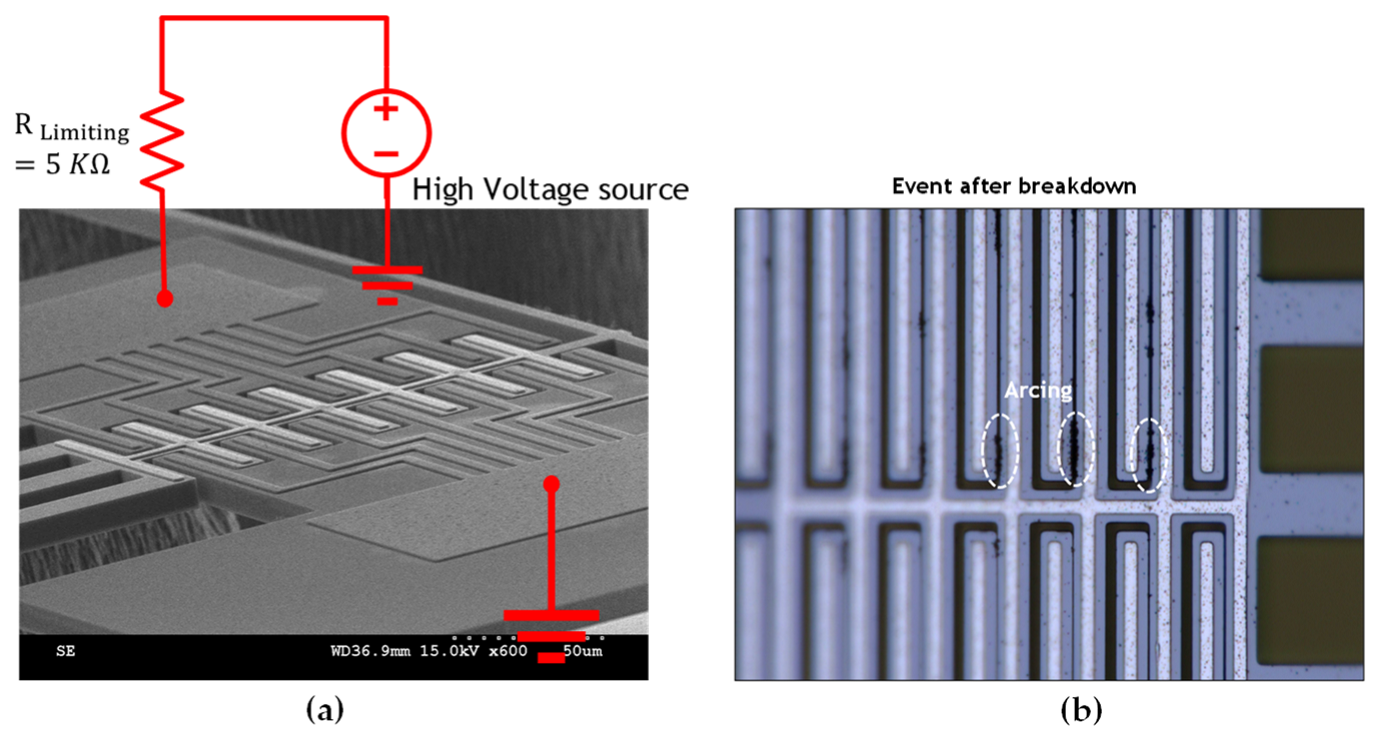

4.4. Breakdown Voltage Test

5. Discussion

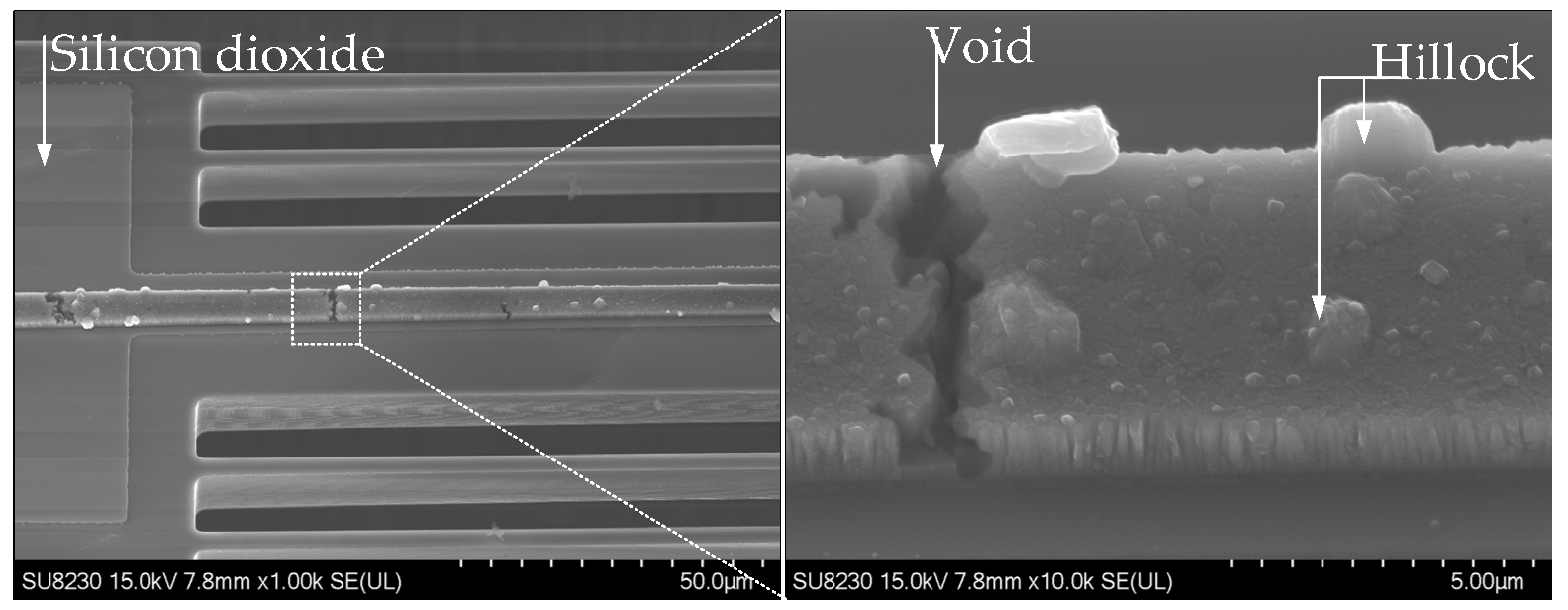

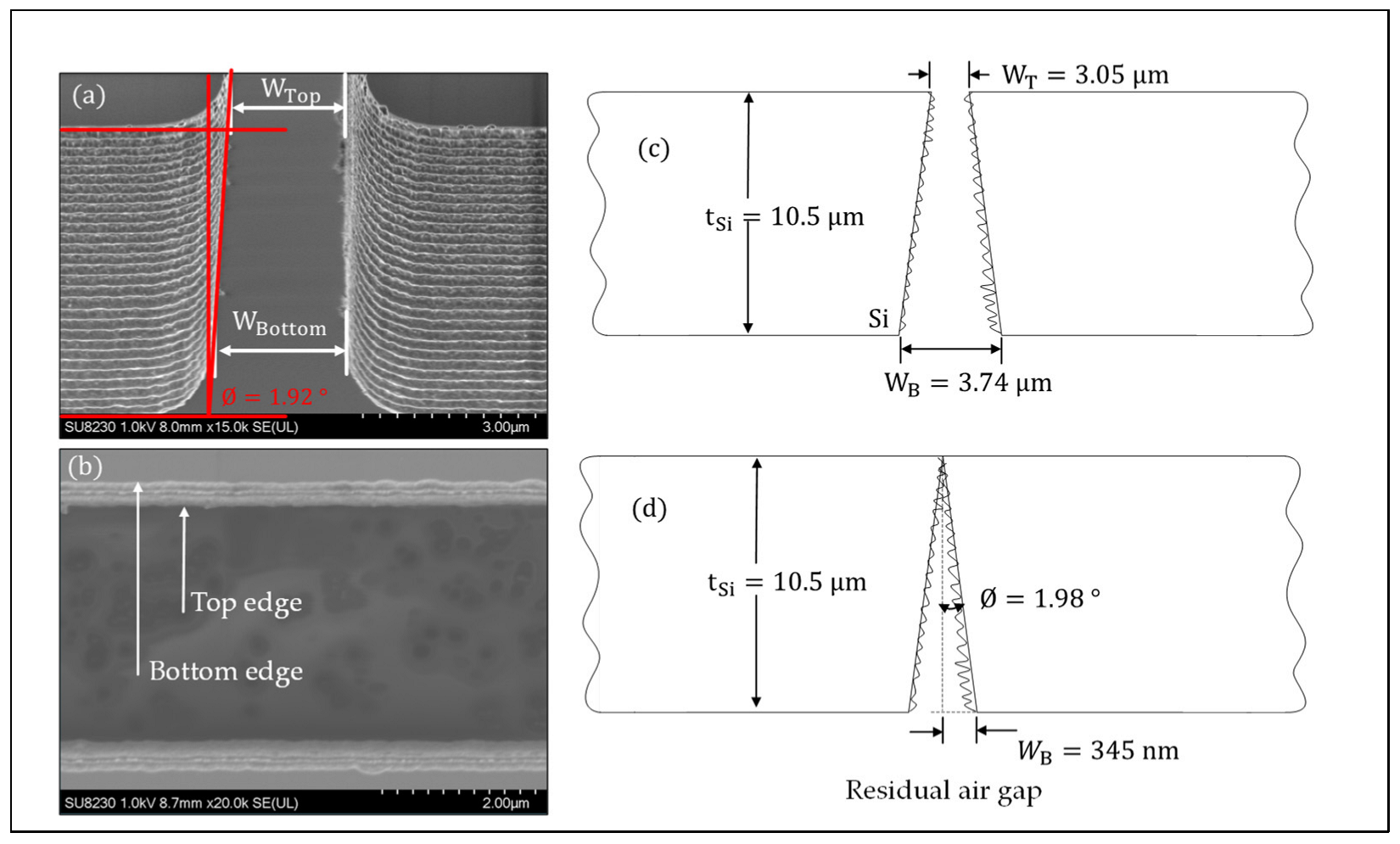

5.1. Sidewall Topography Characterization

5.2. Manual Activation of the MEMS Switches with a Probe Needle

5.3. Comparison with State-of-the-Art MEMS Switches

6. Conclusions and Perspective

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pal, J.; Zhu, Y.; Lu, J.; Dao, D.; Khan, F. High Power and Reliable SPST/SP3T RF MEMS Switches for Wireless Applications. IEEE Electron Device Lett. 2016, 37, 1219–1222. [Google Scholar] [CrossRef]

- Keimel, C.; Claydon, G.; Li, B.; Park, J.N.; Valdes, M.E. Microelectromechanical-Systems-Based Switches for Power Applications. IEEE Trans. Ind. Appl. 2012, 48, 1163–1169. [Google Scholar] [CrossRef]

- Pothier, A.; Hitier, S.; El khatib, M.; Blondy, P.; Orlianges, J.C.; Champeaux, C.; Catherinot, A.; Vendier, O.; Cazaux, J.L. MEMS DC contact micro relays on ceramic substrate for space communication switching network. In Proceedings of the 2005 European Microwave Conference, Paris, France, 4–6 October 2005; Volume 1, p. 4. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Aimaier, N.; Nobert, G.; Pham, T.; Constantin, N.; Blaquiere, Y.; Cowan, G. A Reconfigurable Power System-in-Package Module using GaN HEMTs and IC Bare Dies on LTCC Substrate: Design—Implementation—Experiment and Future Directions. In Proceedings of the 2022 20th IEEE Interregional NEWCAS Conference (NEWCAS), Quebec City, QC, Canada, 19–22 June 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar] [CrossRef]

- Maciel, J.; Majumder, S.; Lampen, J.; Guthy, C. Rugged and reliable ohmic MEMS switches. In Proceedings of the 2012 IEEE/MTT-S International Microwave Symposium Digest, Montreal, QC, Canada, 17–22 June 2012; pp. 1–3. [Google Scholar] [CrossRef]

- Rebeiz, G.M. RF MEMS; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar] [CrossRef]

- Song, Y.-H.; Han, C.-H.; Kim, M.-W.; Lee, J.O.; Yoon, J.-B. An Electrostatically Actuated Stacked-Electrode MEMS Relay with a Levering and Torsional Spring for Power Applications. J. Microelectromech. Syst. 2012, 21, 1209–1217. [Google Scholar] [CrossRef]

- Bakri-Kassem, M.; Mansour, R.R. High Power Latching RF MEMS Switches. IEEE Trans. Microw. Theory Tech. 2015, 63, 222–232. [Google Scholar] [CrossRef]

- Pal, J.; Zhu, Y.; Lu, J.; Dao, D.V.; Khan, F. RF MEMS switches for smart antennas. Microsyst. Technol. 2015, 21, 487–495. [Google Scholar] [CrossRef]

- Stefanini, R.; Chatras, M.; Blondy, P.; Rebeiz, G.M. Miniature MEMS Switches for RF Applications. J. Microelectromech. Syst. 2011, 20, 1324–1335. [Google Scholar] [CrossRef]

- Uvarov, I.; Kupriyanov, A. Stiction-protected MEMS switch with low actuation voltage. Microsyst. Technol. 2019, 25, 3243–3251. [Google Scholar] [CrossRef]

- Czaplewski, D.A.; Nordquist, C.D.; Dyck, C.W.; Patrizi, G.A.; Kraus, G.M.; Cowan, W.D. Lifetime limitations of ohmic, contacting RF MEMS switches with Au, Pt and Ir contact materials due to accumulation of ‘friction polymer’ on the contacts. J. Micromech. Microeng. 2012, 22, 105005. [Google Scholar] [CrossRef]

- Newman, H.S.; Ebel, J.L.; Judy, D.; Maciel, J. Lifetime Measurements on a High-Reliability RF-MEMS Contact Switch. IEEE Microw. Wirel. Compon. Lett. 2008, 18, 100–102. [Google Scholar] [CrossRef]

- Ma, B.; You, Z.; Ruan, Y.; Chang, S.; Zhang, G. Electrostatically actuated MEMS relay arrays for high-power applications. Microsyst. Technol. 2016, 22, 911–920. [Google Scholar] [CrossRef]

- Zhang, Y.; Gong, Z.; Liu, H.; Liu, Z. Power Handling Capability Enhanced RF MEMS Switch Using Modified-Width Cantilevers Structure. In Proceedings of the 2021 IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 25–29 April 2021; pp. 695–698. [Google Scholar] [CrossRef]

- Iannacci, J. RF-MEMS Technology for High-Performance Passives: The Challenge of 5G Mobile Applications; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Sharma, S.; Nabavi, S.; Rabih, A.A.S.; Ménard, M.; Nabki, F. Hybrid MEMS Actuator With 3 Degrees-of- Freedom for Efficient Planar Optical Switching. J. Microelectromech. Syst. 2023, 32, 593–603. [Google Scholar] [CrossRef]

- Rabih, A.A.S.; Nabavi, S.; Ménard, M.; Nabki, F. A 3 Degrees-of-Freedom Electrothermal Micro-Positioner for Optical Chip-to-Chip Alignment. J. Microelectromech. Syst. 2024, 33, 260–273. [Google Scholar] [CrossRef]

- Rajagopalan, J. Microelectromechanical Systems (MEMS)-Based Testing of Materials. In Handbook of Mechanics of Materials; Schmauder, S., Chen, C.-S., Chawla, K.K., Chawla, N., Chen, W., Kagawa, Y., Eds.; Springer: Singapore, 2019; pp. 1955–1979. [Google Scholar]

- Agrawal, V. A latching MEMS relay for DC and RF applications. In Proceedings of the 50th IEEE Holm Conference on Electrical Contacts and the 22nd International Conference on Electrical Contacts Electrical Contacts, 2004, Seattle, WA, USA, 23 September 2004; pp. 222–225. [Google Scholar] [CrossRef]

- Shojaei-Asanjan, D.; Bakri-Kassem, M.; Mansour, R.R. Analysis of Thermally Actuated RF-MEMS Switches for Power Limiter Applications. J. Microelectromech. Syst. 2019, 28, 107–113. [Google Scholar] [CrossRef]

- Qiu, J.; Lang, J.; Schmidt, M. An Electrothermally-Actuated Bistable MEMS Relay for Power Applications. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Daneshmand, M.; Fouladi, S.; Mansour, R.R.; Lisi, M.; Stajcer, T. Thermally-actuated latching RF MEMS switch. In Proceedings of the 2009 IEEE MTT-S International Microwave Symposium Digest, Boston, MA, USA, 7–12 June 2009; pp. 1217–1220. [Google Scholar] [CrossRef]

- Mahameed, R.; Rebeiz, G.M. A High-Power Temperature-Stable Electrostatic RF MEMS Capacitive Switch Based on a Thermal Buckle-Beam Design. J. Microelectromech. Syst. 2010, 19, 816–826. [Google Scholar] [CrossRef]

- Wang, L.; Jin, Y. A push-pull double-contact MEMS relay fabricated by MetalMUMPs process. Microsyst. Technol. 2017, 23, 2257–2262. [Google Scholar] [CrossRef]

- Soon, B.W.; Qian, Y.; Ng, E.J.; Hong, V.A.; Yang, Y.; Ahn, C.H.; Kenny, T.W.; Lee, C. Investigation of a Vacuum Encapsulated Si-to-Si Contact Microswitch Operated From −60 °C to 400 °C. J. Microelectromech. Syst. 2015, 24, 1906–1915. [Google Scholar] [CrossRef]

- Zhu, Y.; Pal, J. Low-Voltage and High-Reliability RF MEMS Switch with Combined Electrothermal and Electrostatic Actuation. Micromachines 2021, 12, 1237. [Google Scholar] [CrossRef]

- Meszmer, P.; Hahn, S.; Hiller, K.; Wunderle, B. Highly Miniaturized MEMS-Based Test Platforms for Thermo-Mechanical and Reliability Characterization of Nano-Functional Elements − Technology and Functional Test Results. Phys. Status Solidi (A) 2019, 216, 1800936. [Google Scholar] [CrossRef]

- Bengashier, M.; Grech, I.; Casha, O.; Portelli, B.; Farrugia, R. Mechanical Contact Type RF-MEMS Switches for Microwave Band Applications. In Proceedings of the 2023 Symposium on Design, Test, Integration & Packaging of MEMS/MOEMS (DTIP), Valetta, Malta, 28–31 May 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Shuaibu, A.H.; Nabki, F.; Blaquière, Y. A MEMS Electrothermal Actuator Designed for a DC Switch Aimed at Power Switching Applications and High Voltage Resilience. In Proceedings of the 2022 20th IEEE Interregional NEWCAS Conference (NEWCAS), Quebec City, QC, Canada, 19–22 June 2022; pp. 317–321. [Google Scholar] [CrossRef]

- Cowen, A.; Hames, G.; Glukh, K.; Hardy, B. PiezoMUMPs™ Design Handbook; MEMSCAP Inc.: Durham, NC, USA, 2014; p. 28. [Google Scholar]

- Coutu, R.A.; LaFleur, R.S.; Walton, J.P.K.; Starman, L.A. Thermal Management Using MEMS Bimorph Cantilever Beams. Exp. Mech. 2016, 56, 1293–1303. [Google Scholar] [CrossRef]

- Available online: https://aluminium-guide.com/melting-point-aluminium/ (accessed on 24 June 2020).

- Science Corporation. Available online: https://science.xyz/docs/d/mems-piezo/index (accessed on 3 October 2023).

- Benouattas, N.; Tamaarat, B.; Bouabellou, A.; Halimi, R.; Mosser, A. Electrical properties of Cr/Si(p) structures. Solid-State Electron. 1999, 43, 439–446. [Google Scholar] [CrossRef]

- Ta, Q. Local Synthesis and Direct Integration of Carbon Nanotubes into Microsystems for Sensor Applications. Ph.D. Thesis, Buskerud and Vestfold University College, Drammen, Norway, 2014. [Google Scholar]

- Available online: https://cleanroom.byu.edu/ohmic-schottky (accessed on 9 February 2014).

- Card, H.C. Aluminum—Silicon Schottky barriers and ohmic contacts in integrated circuits. IEEE Trans. Electron Devices 1976, 23, 538–544. [Google Scholar] [CrossRef]

- Osoba, B.; Almeida, S.F.; Sikder, U.; Ye, Z.A.; Hu, X.; Esatu, T.K.; Liu, T.-J.K. Study of MEM Relay Contact Design and Body-Bias Effects on on-State Resistance Stability. J. Microelectromech. Syst. 2020, 29, 1531–1536. [Google Scholar] [CrossRef]

- Grogg, D.; Drechsler, U.; Knoll, A.; Duerig, U.; Pu, Y.; Hagleitner, C.; Despont, M. Curved in-plane electromechanical relay for low power logic applications. J. Micromech. Microeng. 2013, 23, 025024. [Google Scholar] [CrossRef]

| Geometry Parameter | Symbol | Value |

|---|---|---|

| Length of the chevron actuator | 500 μm | |

| Length of the shuttle | 110 μm | |

| Width of the chevron actuator | 6 μm | |

| Width of the chevron actuator | 21 μm | |

| Width of the Padoxide | 11 μm | |

| Width of Padmetal | 5 μm | |

| Angle of chevron beams | β | 1.4° |

| Ref. | Actuation | Material | Motion | Actuation Voltage | ||

|---|---|---|---|---|---|---|

| [26] | Electrostatic | Si-to-Si | Lateral | ~35 kΩ | - | |

| [29] | Electrostatic | Si-to-Si | In-plane | ~18 V | No data | - |

| [39] | Electrostatic | Tungsten (W) | Out-of-plane | 11.3 V | ~7.5 kΩ | - |

| [40] | Electrostatic | Platinum (Pt) | In-plane | 20 V | 4.4-to-4.6 kΩ | - |

| This work | Electrothermal | Si-to-Si | In-plane | 1.2 V | 0.15 kΩ | 350 V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shuaibu, A.H.; Rabih, A.A.S.; Blaquière, Y.; Nabki, F. Laterally Actuated Si-to-Si DC MEMS Switch for Power Switching Applications. Micromachines 2024, 15, 1295. https://doi.org/10.3390/mi15111295

Shuaibu AH, Rabih AAS, Blaquière Y, Nabki F. Laterally Actuated Si-to-Si DC MEMS Switch for Power Switching Applications. Micromachines. 2024; 15(11):1295. https://doi.org/10.3390/mi15111295

Chicago/Turabian StyleShuaibu, Abdurrashid Hassan, Almur A. S. Rabih, Yves Blaquière, and Frederic Nabki. 2024. "Laterally Actuated Si-to-Si DC MEMS Switch for Power Switching Applications" Micromachines 15, no. 11: 1295. https://doi.org/10.3390/mi15111295

APA StyleShuaibu, A. H., Rabih, A. A. S., Blaquière, Y., & Nabki, F. (2024). Laterally Actuated Si-to-Si DC MEMS Switch for Power Switching Applications. Micromachines, 15(11), 1295. https://doi.org/10.3390/mi15111295