Single-Crystalline Si Stacked AlGaN/GaN High-Electron-Mobility Transistors with Enhanced Two-Dimensional Electron Gas Density

Abstract

1. Introduction

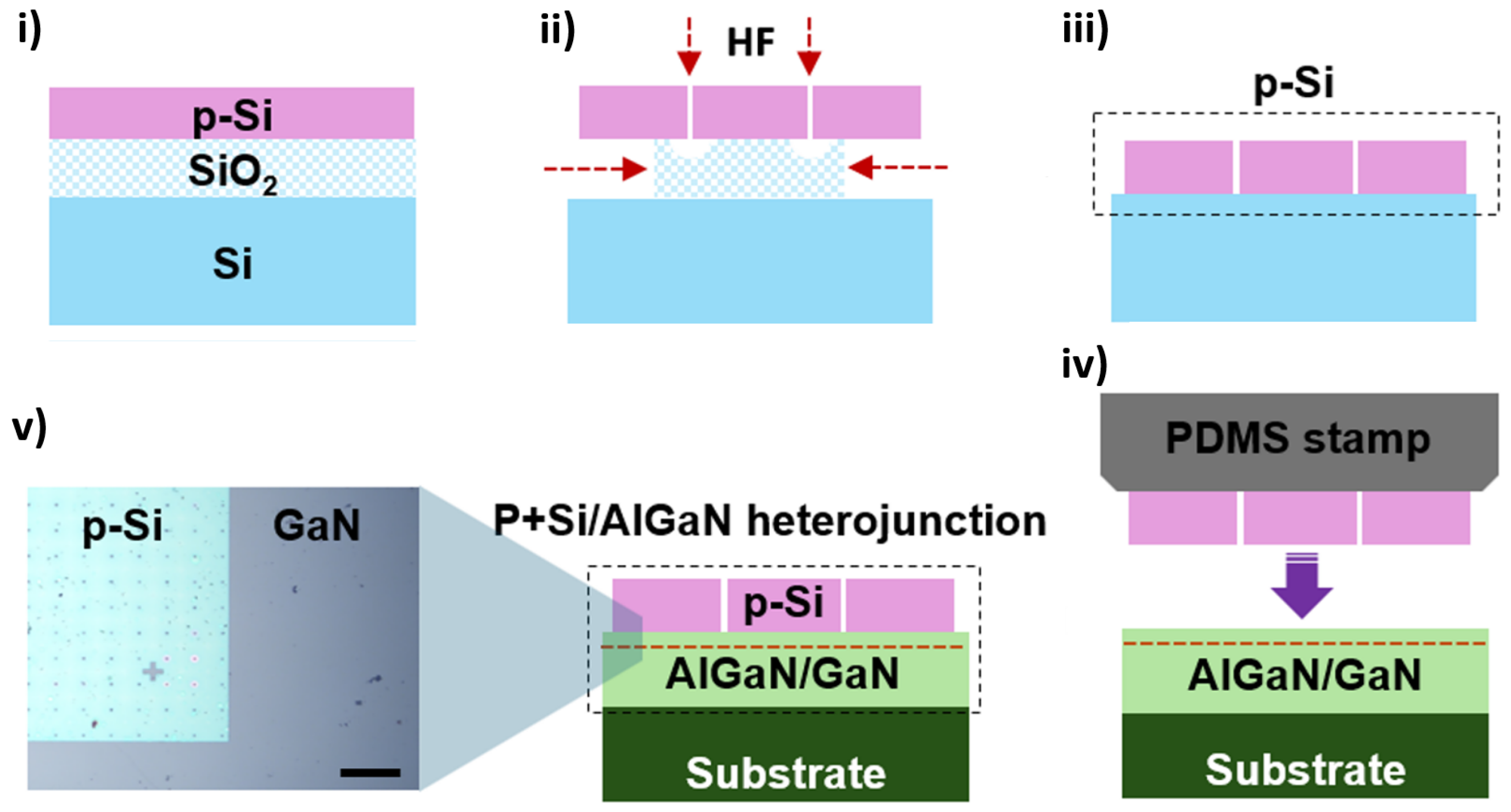

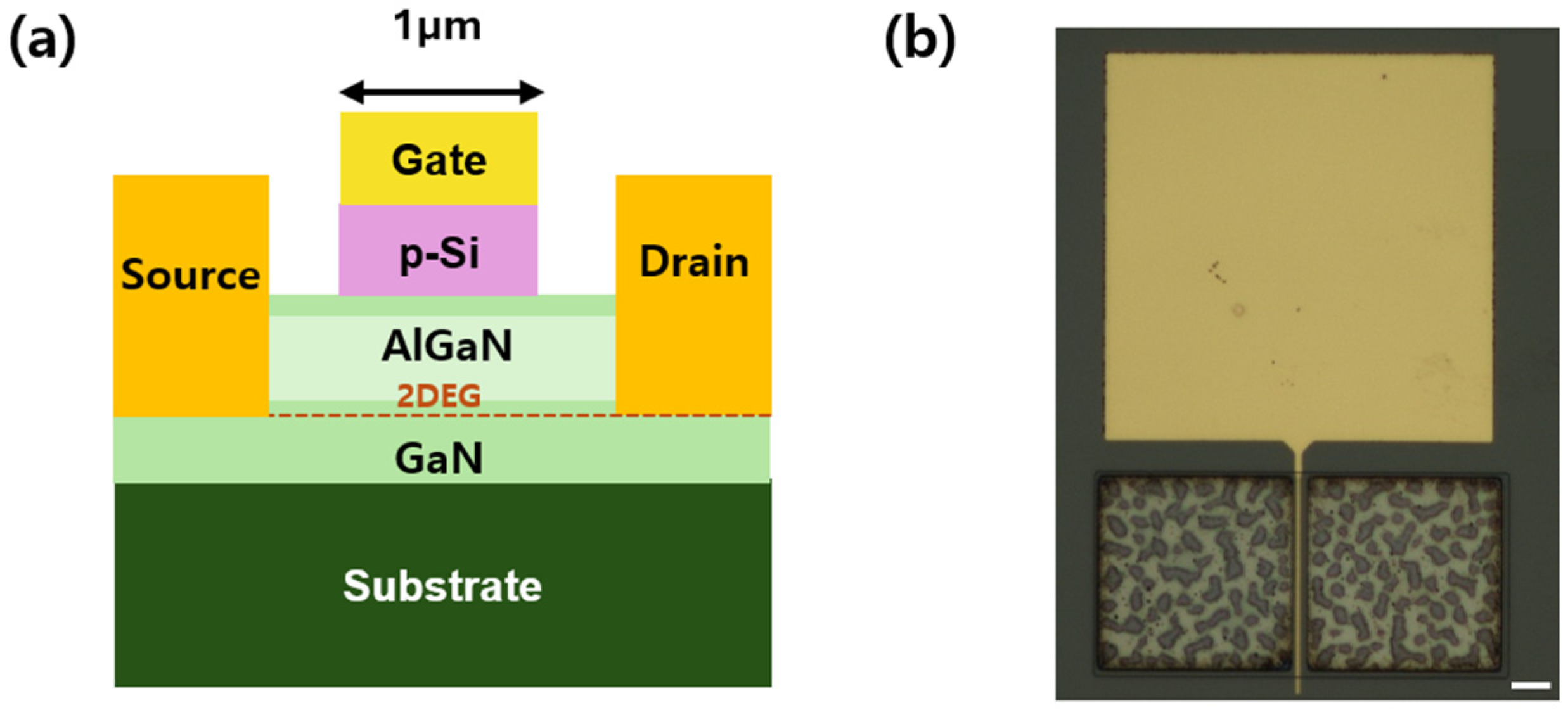

2. Methods

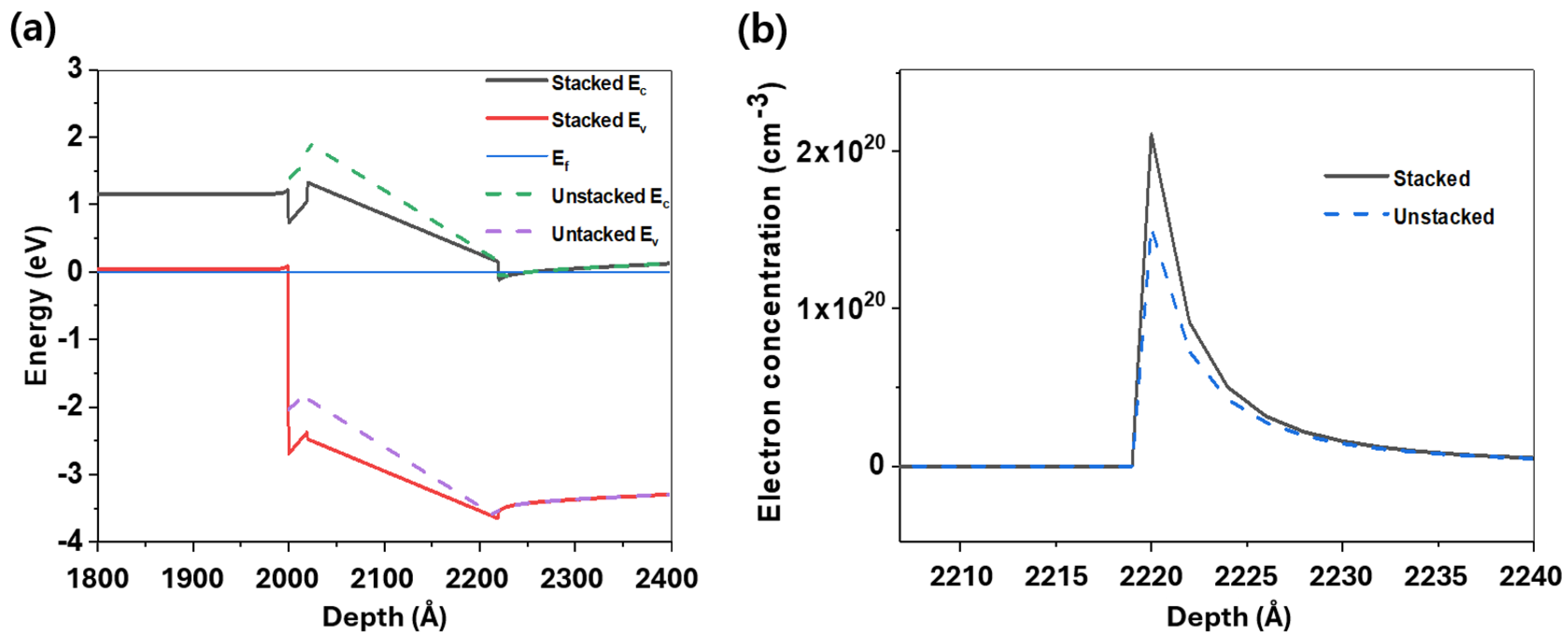

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, K.; Kim, T.J.; Zhang, H.; Liu, D.; Jung, Y.H.; Gong, J.; Ma, Z. AlGaN/GaN Schottky-Gate HEMTs with UV/O3-Treated Gate Interface. IEEE Electron Device Lett. 2020, 41, 1488. [Google Scholar] [CrossRef]

- Charfeddine, M.; Belmabrouk, H.; Zaidi, M.A.; Maaref, H. 2-D Theoretical Model for Current–Voltage Characteristics in AlGaN/GaN HEMT’s. J. Mod. Phys. 2012, 3, 881. [Google Scholar] [CrossRef]

- He, J.; Cheng, W.C.; Wang, Q.; Cheng, K.; Yu, H.; Chai, Y. Recent Advances in GaN-Based Power HEMT Devices. Adv. Electron. Mater. 2021, 7, 2001045. [Google Scholar] [CrossRef]

- Hao, R.; Fu, K.; Yu, G.; Li, W.; Yuan, J.; Song, L.; Zhang, Z.; Sun, S.; Li, X.; Cai, Y.; et al. Normally-off p-GaN/AlGaN/GaN High Electron Mobility Transistors using Hydrogen Plasma Treatment. Appl. Phys. Lett. 2016, 109, 152106. [Google Scholar] [CrossRef]

- Kotani, J.; Yaita, J.; Yamada, A.; Nakamura, N.; Watanabe, K. Impact of n-GaN Cap Layer Doping on the Gate Leakage Behavior in AlGaN/GaN HEMTs Grown on Si and GaN Substrates. J. Appl. Phys. 2020, 127, 234501. [Google Scholar] [CrossRef]

- Su, L.Y.; Lee, F.; Huang, J.J. Enhancement-Mode GaN-Based High-Electron Mobility Transistors on the Si Substrate With a P-Type GaN Cap Layer. IEEE Trans. Electron Devices 2014, 61, 460. [Google Scholar] [CrossRef]

- Kim, H.; Thompson, R.M.; Tilak, V.; Prunty, T.R.; Shealy, J.R.; Eastman, L.F. Effects of SiN Passivation and High-Electric Field on AlGaN-GaN HFET Degradation. IEEE Electron Device Lett. 2003, 24, 421. [Google Scholar]

- Onojima, N.; Higashiwaki, M.; Suda, J.; Kimoto, T.; Mimura, T.; Matsui, T. Reduction in Potential Barrier Height of Heterostructures by Passivation. J. Appl. Phys. 2007, 101, 043703. [Google Scholar] [CrossRef]

- Li, H.; Keller, S.; DenBaars, S.P.; Mishra, U.K. Improved Properties of High-Al-Composition AlGaN/GaN High Electron Mobility Transistor Structures with Thin GaN Cap Layers. J. Appl. Phys. 2014, 53, 095504. [Google Scholar] [CrossRef]

- Liu, S.C.; Chen, B.Y.; Lin, Y.C.; Hsieh, T.E.; Wang, H.C.; Chang, E.Y. GaN MIS-HEMTs With Nitrogen Passivation for Power Device Applications. IEEE Electron Device Lett. 2014, 35, 1001. [Google Scholar]

- Shi, Y.; Huang, S.; Bao, Q.; Wang, X.; Wei, K.; Jiang, H. Normally OFF GaN-on-Si MIS-HEMTs Fabricated With LPCVD-SiNx Passivation and High-Temperature Gate Recess. IEEE Trans. Electron Devices 2016, 63, 614. [Google Scholar] [CrossRef]

- Chen, W.W.; Ma, X.H.; Hou, B.; Zhu, J.J.; Chen, Y.H.; Zheng, X.F.; Zhang, J.C.; Hao, Y. Impacts of SiN Passivation on the Degradation Modes of AlGaN/GaN High Electron Mobility Transistors under Reverse-Bias Stress. Appl. Phys. Lett. 2014, 105, 173507. [Google Scholar] [CrossRef]

- Nie, Z.; Wang, K.; Liu, X.; Wang, H. Effect of GaN Cap Thickness on the DC Performance of AlGaN/GaN HEMTs. Micromachines 2024, 15, 571. [Google Scholar] [CrossRef]

- Waltereit, P.; Müller, S.; Bellmann, K.; Buchheim, C.; Goldhahn, R.; Köhler, K.; Kirste, L.; Baeumler, M.; Dammann, M.; Bronner, W.; et al. Impact of GaN Cap Thickness on Optical, Electrical, and Device Properties in AlGaN/GaN High Electron Mobility Transistor Structures. J. Appl. Phys. 2009, 106, 023535. [Google Scholar] [CrossRef]

- Ahmeda, K.; Ubochi, B.; Alqaysi, M.H.; Al-Khalidi, A.; Wasige, E.; Kalna, K. The Role of SiN/GaN Cap Interface Charge and GaN Cap Layer to Achieve Enhancement Mode GaN MIS-HEMT Operation. Microelectron. Reliab. 2020, 115, 113965. [Google Scholar] [CrossRef]

- Greco, G.; Iucolano, F.; Roccaforte, F. Review of Technology for Normally-Off HEMTs with p-GaN Gate. Mater. Sci. Semicond. Process. 2018, 78, 96. [Google Scholar] [CrossRef]

- Abdulsalam, A.; Dutta, G. On the Threshold Voltage of Normally-OFF AlGaN/GaN Heterostructure Field Effect Transistors (HFETs) with p-(Al)GaN Gate. Semicond. Sci. Technol. 2019, 35, 015020. [Google Scholar] [CrossRef]

- Bakeroot, B.; Stockman, A.; Posthuma, N.; Stoffels, S.; Decoutere, S. Analytical Model for the Threshold Voltage of p -(Al)GaN High-Electron-Mobility Transistors. IEEE Trans. Electron Devices 2018, 65, 79. [Google Scholar] [CrossRef]

- Posthuma, N.E.; You, S.; Liang, H.; Ronchi, N.; Kang, X.; Wellekens, D.; Saripalli, Y.N.; Decoutere, S. Impact of Mg Out-Diffusion and Activation on the p-GaN Gate HEMT Device Performance. In Proceedings of the 2016 28th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Prague, Czech Republic, 12–16 June 2016; pp. 95–98. [Google Scholar]

- Kim, K. Band Alignment of Stacked Crystalline Si/GaN pn Heterostructures Interfaced with an Amorphous Region Using X-Ray Photoelectron Spectroscopy. Materials 2024, 17, 6099. [Google Scholar] [CrossRef] [PubMed]

- Kiefer, A.M.; Paskiewicz, D.M.; Clausen, A.M.; Buchwald, W.R.; Soref, R.A.; Lagally, M.G. Si/Ge Junctions Formed by Nanomembrane Bonding. ACS Nano 2011, 5, 1179. [Google Scholar] [CrossRef]

- Tai, Y.C.; Yeh, P.L.; An, S.; Cheng, H.H.; Kim, M.; Chang, G.E. Strain-free GeSn Nanomembranes Enabled by Transfer-Printing Techniques for Advanced Optoelectronic Applications. Nanotechnology 2020, 31, 445301. [Google Scholar] [CrossRef]

- Murukesan, K.; Efthymiou, L.; Udrea, F. Physical Understanding of A Normally Off p-GaN/AlGaN/GaN HEMT Gate Stack and A Review of VTH Measurement Techniques. J. Phys. D Appl. Phys. 2024, 58, 025102. [Google Scholar] [CrossRef]

- Bhat, Z.; Ahsan, S.A. Physics-Based Analytical Modeling of p-GaN/AlGaN/GaN HEMTs. In Proceedings of the 2022 IEEE 19th India Council International Conference (INDICON), Kochi, India, 24–26 November 2022. [Google Scholar]

- Heikman, S.; Keller, S.; Wu, Y.; Speck, J.S.; DenBaars, S.P.; Mishra, U.K. Polarization Effects in AlGaN/GaN and GaN/AlGaN/GaN Heterostructures. J. Appl. Phys. 2003, 93, 10114. [Google Scholar] [CrossRef]

- Arulkumaran, S.; Egawa, T.; Ishikawa, H. Studies on the Influences of i-GaN, n-GaN, p-GaN and InGaN Cap Layers in AlGaN/GaN High-Electron-Mobility Transistors. Jpn. J. Appl. Phys. 2005, 44, 2953. [Google Scholar] [CrossRef]

- Swamy, N.S.; Dutta, A.K. Analytical Models for the 2DEG Density, AlGaN Layer Carrier Density, and Drain Current for AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2018, 65, 936. [Google Scholar] [CrossRef]

- Baskaran, S.; Mohanbabu, A.; Anbuselvan, N.; Mohankumar, N.; Godwinraj, D.; Sarkar, C.K. Modeling of 2DEG Sheet Carrier Density and DC Characteristics in Spacer based AlGaN/AlN/GaN HEMT Devices. Superlattices Microstruct. 2013, 64, 470. [Google Scholar] [CrossRef]

- Kim, K.; Jang, J.; Kim, H. Negative Differential Resistance in Si/GaAs Tunnel Junction Formed by Single Crystalline Nanomembrane Transfer Method. Results Phys. 2021, 25, 104279. [Google Scholar] [CrossRef]

- Malik, A.; Sharma, C.; Laishram, R.; Bag, R.K.; Rawal, D.S.; Vinayak, S.; Sharma, R.K. Role of AlGaN/GaN Interface Traps on Negative Threshold Voltage Shift in AlGaN/GaN HEMT. Solid-State Electron. 2018, 142, 8. [Google Scholar] [CrossRef]

- Efthymiou, L.; Longobardi, G.; Camuso, G.; Chien, T.; Chen, M.; Udrea, F. On the Physical Operation and Optimization of the p-GaN Gate in Normally-off GaN HEMT Devices. Appl. Phys. Lett. 2017, 110, 123502. [Google Scholar] [CrossRef]

- Hwang, I.; Oh, J.; Choi, H.S.; Kim, J.; Choi, H.; Kim, J. Source-Connected p-GaN Gate HEMTs for Increased Threshold Voltage. IEEE Electron Device Lett. 2013, 34, 605–607. [Google Scholar] [CrossRef]

- Nanjo, T.; Takeuchi, M.; Suita, M.; Oishi, T.; Abe, Y.; Tokuda, Y.; Aoyagi, Y. Remarkable Breakdown Voltage Enhancement in AlGaN Channel High Electron Mobility Transistors. Appl. Phys. Lett. 2008, 92, 263502. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ham, G.; Shin, E.; Yoon, S.; Yang, J.; Choi, Y.; Lim, G.; Kim, K. Single-Crystalline Si Stacked AlGaN/GaN High-Electron-Mobility Transistors with Enhanced Two-Dimensional Electron Gas Density. Micromachines 2025, 16, 1214. https://doi.org/10.3390/mi16111214

Ham G, Shin E, Yoon S, Yang J, Choi Y, Lim G, Kim K. Single-Crystalline Si Stacked AlGaN/GaN High-Electron-Mobility Transistors with Enhanced Two-Dimensional Electron Gas Density. Micromachines. 2025; 16(11):1214. https://doi.org/10.3390/mi16111214

Chicago/Turabian StyleHam, Goeun, Eungyeol Shin, Sangwon Yoon, Jihoon Yang, Youngjin Choi, Gunwoo Lim, and Kwangeun Kim. 2025. "Single-Crystalline Si Stacked AlGaN/GaN High-Electron-Mobility Transistors with Enhanced Two-Dimensional Electron Gas Density" Micromachines 16, no. 11: 1214. https://doi.org/10.3390/mi16111214

APA StyleHam, G., Shin, E., Yoon, S., Yang, J., Choi, Y., Lim, G., & Kim, K. (2025). Single-Crystalline Si Stacked AlGaN/GaN High-Electron-Mobility Transistors with Enhanced Two-Dimensional Electron Gas Density. Micromachines, 16(11), 1214. https://doi.org/10.3390/mi16111214