Simple Electrochemical Synthesis of Polyethylenimine-Encapsulated Ag Nanoparticles from Solid AgCl Applied in Catalytic Reduction of H2O2

Abstract

:1. Introduction

2. Results and Discussion

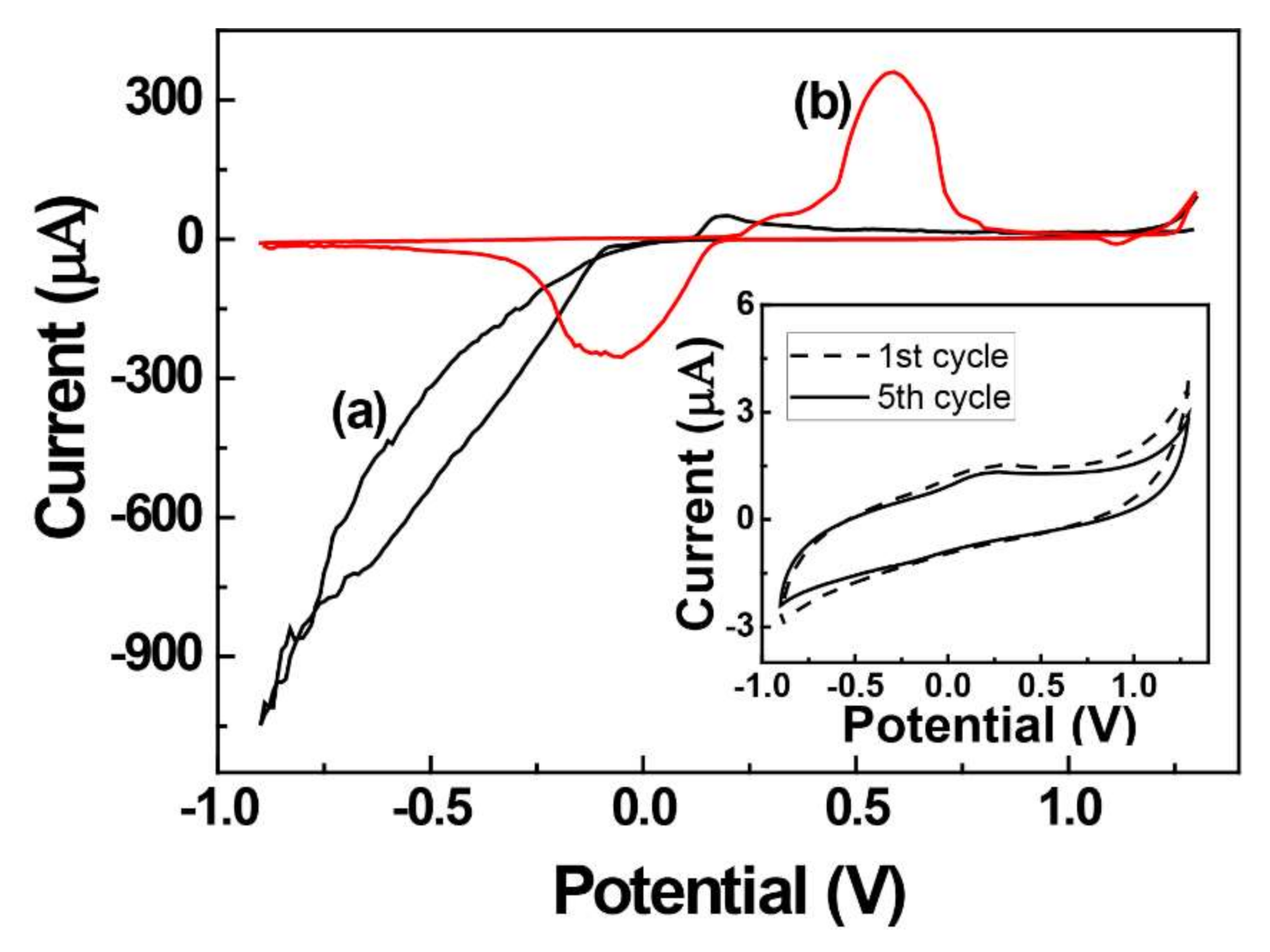

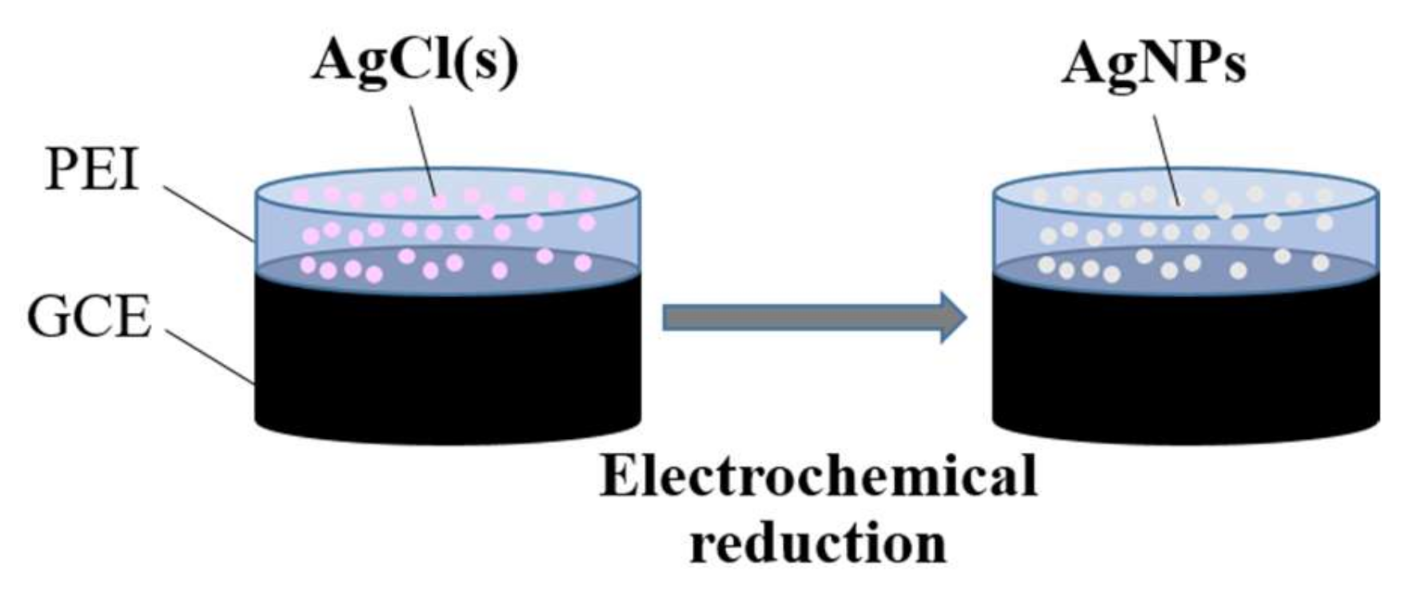

2.1. Electrochemical Reduction of AgCl to AgNPs

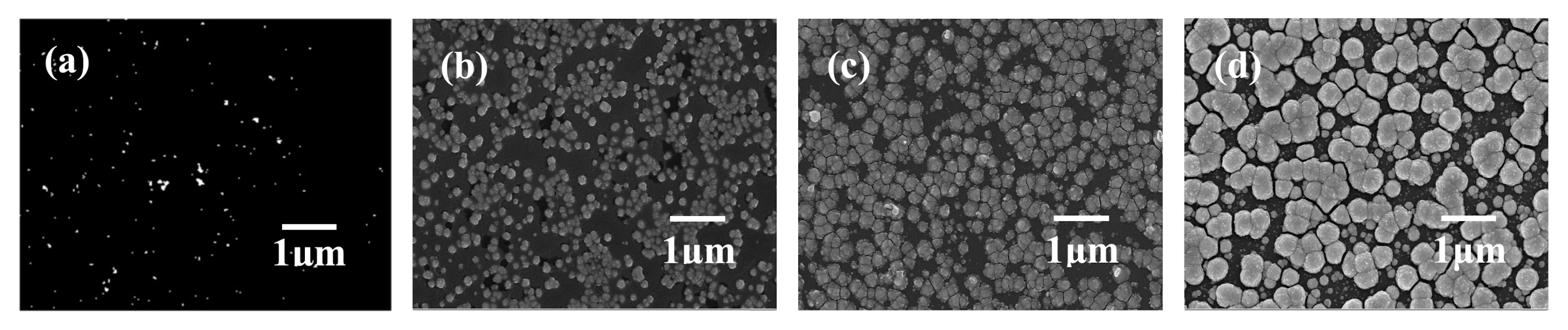

2.2. Characterization of AgNPs

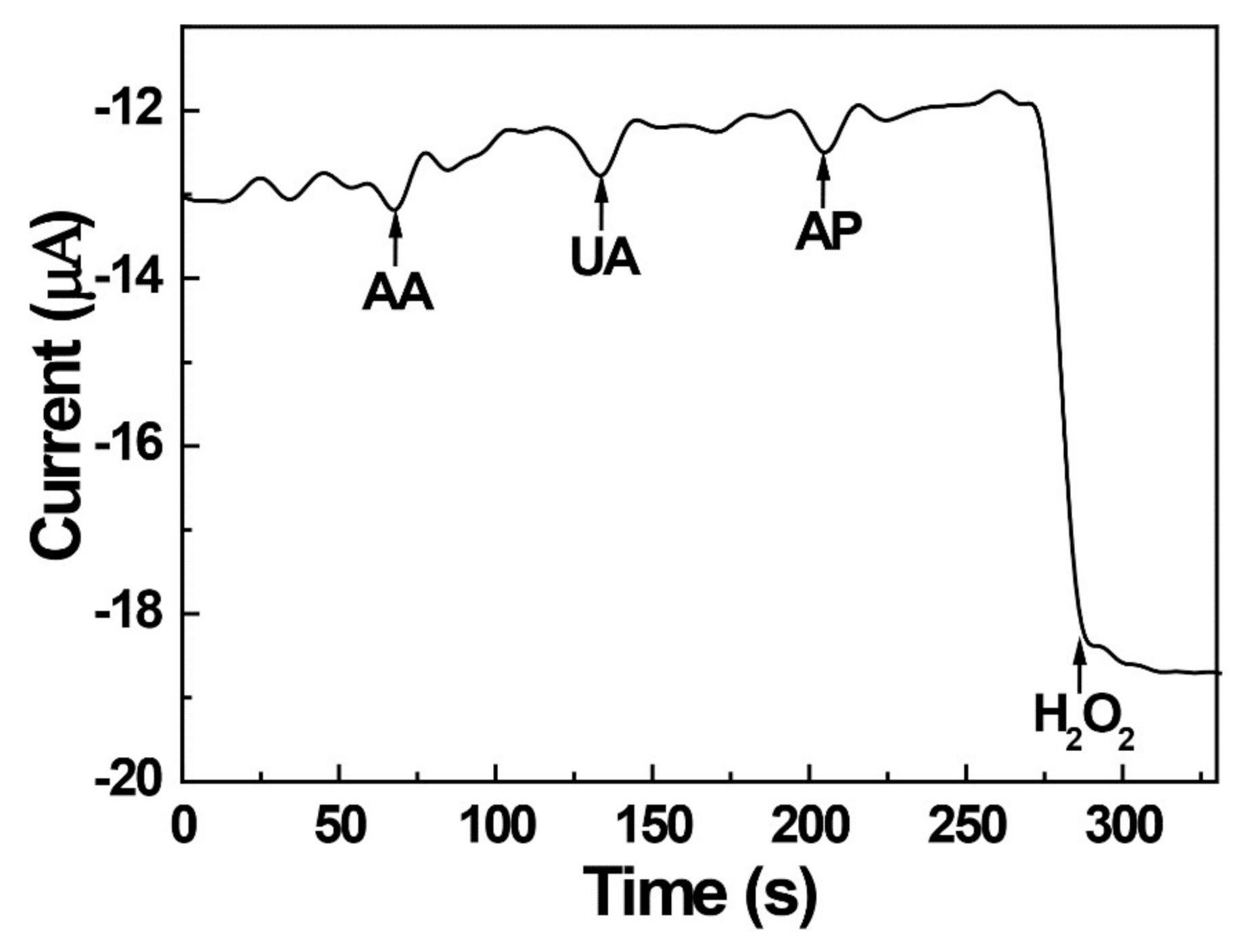

2.3. Electrochemical Catalytic Effect of AgNPs for H2O2 Reduction

3. Materials and Methods

3.1. Materials

3.2. Characterization

3.3. Preparation of PEI-Encapsulated AgNPs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Syafiuddin, A.; Salim, M.R.; Beng Hong Kueh, A.; Hadibarata, T.; Nur, H. A review of silver nanoparticles: Research trends, global consumption, synthesis, properties, and future challenges. J. Chin. Chem. Soc. 2017, 64, 732–756. [Google Scholar] [CrossRef]

- Lee, S.H.; Jun, B.H. Silver nanoparticles: Synthesis and application for nanomedicine. Int. J. Mol. Sci. 2019, 20, 865. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Levard, C.; Hotze, E.M.; Lowry, G.V.; Brown, G.E., Jr. Environmental transformations of silver nanoparticles: Impact on stability and toxicity. Environ. Sci. Technol. 2012, 46, 6900–6914. [Google Scholar] [CrossRef] [PubMed]

- Tsuji, T.; Iryo, K.; Watanabe, N.; Tsuji, M. Preparation of silver nanoparticles by laser ablation in solution: Influence of laser wavelength on particle size. Appl. Surf. Sci. 2002, 202, 80–85. [Google Scholar] [CrossRef]

- Asanithi, P.; Chaiyakun, S.; Limsuwan, P. Growth of silver nanoparticles by DC magnetron sputtering. J. Nanomater. 2012, 2012, 963609. [Google Scholar] [CrossRef]

- Hussain, J.I.; Kumar, S.; Hashmi, A.A.; Khan, Z. Silver nanoparticles: Preparation, characterization, and kinetics. Adv. Mater. Lett. 2011, 2, 188–194. [Google Scholar] [CrossRef]

- Khan, Z.; Al-Thabaiti, S.A.; Obaid, A.Y.; Al-Youbi, A.O. Preparation and characterization of silver nanoparticles by chemical reduction method. Colloid. Surf. B Biointerfaces 2011, 82, 513–517. [Google Scholar] [CrossRef]

- Yin, B.; Ma, H.; Wang, S.; Chen, S. Electrochemical synthesis of silver nanoparticles under protection of poly(N-vinylpyrrolidone). J. Phys. Chem. B 2003, 107, 8898–8904. [Google Scholar] [CrossRef]

- Kuntyi, O.L.; Kytsya, A.R.; Mertsalo, I.P.; Mazur, A.S.; Zozula, G.I.; Bazylyak, L.I.; Topchak, R.V. Electrochemical synthesis of silver nanoparticles by reversible current in solutions of sodium polyacrylate. Colloid Polym. Sci. 2019, 297, 689–695. [Google Scholar] [CrossRef]

- Soliveri, G.; Ardizzone, S.; Yüksel, S.; Cialla-May, D.; Popp, J.; Schubert, U.S.; Hoeppener, H. Microwave-assisted silver nanoparticle film formation for SERS applications. J. Phys. Chem. C 2016, 120, 1237–1244. [Google Scholar] [CrossRef]

- Itoh, M.; Kakuta, T.; Nagaoka, M.; Koyama, Y.; Sakamoto, M.; Kawasaki, S.; Umeda, N.; Kurihara, M. Direct transformation into silver nanoparticles via thermal decomposition of oxalate-bridging silver oleylamine complexes. J. Nanosci. Nanotechnol. 2009, 9, 6655–6660. [Google Scholar] [CrossRef] [PubMed]

- Siddiqi, K.S.; Husen, A.; Rao, R. A review on biosynthesis of silver nanoparticles and their biocidal properties. J. Nanobiotechnol. 2018, 16, 1–28. [Google Scholar] [CrossRef] [PubMed]

- Mohd Abdah, M.A.A.; Razali, N.S.M.; Lim, P.T.; Kulandaivalu, S.; Sulaiman, Y. One-step potentiostatic electrodeposition of polypyrrole/graphene oxide/multi-walled carbon nanotubes ternary nanocomposite for supercapacitor. Mater. Chem. Phys. 2018, 219, 120–128. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Yin, B.; Wang, S.; Jioo, Y.; Pan, W.; Huang, S.; Chen, S.; Meng, F. Synthesis of silver and gold nanoparticles by a novel electrochemical method. Chem. Phys. Chem. 2004, 5, 68–75. [Google Scholar] [CrossRef]

- Rodriguez-Sanchez, L.; Blanco, M.C.; Lopez-Quintela, M.A. Electrochemical synthesis of silver nanoparticles. J. Phys. Chem. B 2000, 104, 9683–9688. [Google Scholar] [CrossRef]

- Starowicz, M.; Stypuła, B.; Banaś, J. Electrochemical synthesis of silver nanoparticles. Electrochem. Commun. 2006, 8, 227–230. [Google Scholar] [CrossRef]

- Nešović, K.; Mišković-Stanković, V. A comprehensive review of the polymer-based hydrogels with electrochemically synthesized silver nanoparticles for wound dressing applications. Polym. Eng. Sci. 2020, 60, 1393–1419. [Google Scholar] [CrossRef]

- Gupta, R.; Jayachandran, K.; Gamare, J.S.; Rajeshwari, B.; Gupta, S.K.; Kamat, J.V. Fabrication of silver nanoparticles–polypyrrole composite modified electrode for electrocatalytic oxidation of hydrazine. Synth. Met. 2014, 195, 234–240. [Google Scholar]

- Xie, C.; Lu, X.; Wang, K. Pulse electrochemical synthesis of spherical hydroxyapatite and silver nanoparticles mediated by the polymerization of polypyrrole on metallic implants for biomedical applications. Part. Part. Syst. Charact. 2015, 32, 630–635. [Google Scholar] [CrossRef]

- Hosseini, M.; Momeni, M.M. Silver nanoparticles dispersed in polyaniline matrixes coated on titanium substrate as a novel electrode for electro-oxidation of hydrazine. J. Mater. Sci. 2010, 45, 3304–3310. [Google Scholar] [CrossRef]

- Cai, Z.; Xiong, H.; Zhu, Z.; Huang, H.; Li, L.; Huang, Y. Electrochemical synthesis of graphene/polypyrrole nanotube composites for multifunctional applications. Synth. Met. 2017, 227, 100–105. [Google Scholar] [CrossRef]

- Liu, X.; Wei, H.; Song, G.; Guo, H.; Lu, X. Sensitive detection of superoxide anion released from living cells using silver nanoparticles and functionalized multiwalled carbon nanotube composite. Sens. Actuators B Chem. 2017, 252, 503–510. [Google Scholar] [CrossRef]

- Wen, S.; Zheng, F.; Shen, M.; Shi, X. Synthesis of polyethyleneimine-stabilized gold nanoparticles for colorimetric sensing of heparin. Colloids Surf. A Physicochem. Eng. Aspects 2013, 419, 80–86. [Google Scholar] [CrossRef]

- Yuan, Z.; Cai, N.; Du, Y.; He, Y.; Yeung, E.S. Sensitive and selective detection of copper ions with highly stable polyethyleneimine-protected silver nanoclusters. Anal. Chem. 2014, 86, 419–426. [Google Scholar] [CrossRef]

- Gao, X.; Li, Y.; Zhang, Q.; Li, S.; Chen, Y.; Lee, J.M. Polyethyleneimine-assisted synthesis of high-quality platinum/graphene hybrids: The effect of molecular weight on electrochemical properties. J. Mater. Chem. A 2015, 3, 12000–12004. [Google Scholar] [CrossRef]

- Welch, C.M.; Banks, C.E.; Simm, A.O.; Compton, R.G. Silver nanoparticle assemblies supported on glassy-carbon electrodes for the electro-analytical detection of hydrogen peroxide. Anal. Bioanal. Chem. 2005, 382, 12–21. [Google Scholar] [CrossRef]

- Xu, S.X.; Huang, X.; Chen, Y.; Liu, Y.; Zhao, W.; Sun, Z.; Zhu, Y.; Liu, X.; Wong, C.P. Silver nanoparticle-enzyme composite films for hydrogen peroxide detection. ACS Appl. Nano Mater. 2019, 2, 5910–5921. [Google Scholar] [CrossRef]

- Khan, A.Y.; Bandyopadhyaya, R. Silver nanoparticle impregnated mesoporous silica as a non-enzymatic amperometric sensor for an aqueous solution of hydrogen peroxide. J. Electroanal. Chem. 2014, 727, 184–190. [Google Scholar] [CrossRef]

- Yin, J.; Qi, X.; Yang, L.; Hao, G.; Li, J.; Zhong, J. A hydrogen peroxide electrochemical sensor based on silver nanoparticles decorated silicon nanowire arrays. Electrochimica Acta 2011, 56, 3884–3889. [Google Scholar] [CrossRef]

- Ghosale, A.; Shrivas, K.; Shankar, R.; Ganesan, V. Low-cost paper electrode fabricated by direct writing with silver nanoparticle-based ink for detection of hydrogen peroxide in wastewater. Anal. Chem. 2017, 89, 776–782. [Google Scholar] [CrossRef]

- Wang, N.; Miller, C.J.; Wang, P.; Waite, T.D. Quantitative determination of trace hydrogen peroxide in the presence of sulfide using the Amplex Red/horseradish peroxidase assay. Anal. Chim. Acta 2017, 963, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Yuen, J.W.M.; Benzie, I.F.F. Hydrogen peroxide in urine as a potential biomarker of whole body oxidative stress. Free Radic. Res. 2003, 37, 1209–1213. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.R.; Wertz, P.W.; Dawson, D.V.; Cobb, D.S.; Denehy, G. The relationship of hydrogen peroxide exposure protocol to bleaching efficacy. Oper. Dent. 2013, 38, 177–185. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Smirnoff, N.; Arnaud, D. Hydrogen peroxide metabolism and functions in plant. New Phytol. 2019, 221, 1197–1214. [Google Scholar] [CrossRef] [PubMed]

- He, P.; Liu, H.; Li, Z.; Liu, Y.; Xu, X.; Li, J. Electrochemical deposition of silver in room-temperature ionic liquids and its surface-enhanced Raman scattering effect. Langmuir 2004, 20, 10260–10267. [Google Scholar] [CrossRef]

- Cloake, S.J.; Toh, H.S.; Lee, P.T.; Salter, C.; Johnston, C.; Compton, R.G. Anodic stripping voltammetry of silver nanoparticles: Aggregation leads to incomplete stripping. ChemistryOpen 2015, 4, 22–26. [Google Scholar] [CrossRef]

- Zheng, B.; Wong, L.P.; Wu, L.Y.L.; Chen, Z. Cyclic voltammetric study of high speed silver electrodeposition and dissolution in low cyanide solutions. Int. J. Electrochem. 2016, 2016, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Prieto, P.; Nistor, V.; Nouneh, K.; Oyama, M.; Abd-Lefdil, M.; Díaz, R. XPS study of silver, nickel and bimetallic silver—Nickel nanoparticles prepared by seed-mediated growth. App. Surf. Sci. 2012, 258, 8807–8813. [Google Scholar] [CrossRef]

- Fan, Y.; Bao, Y.; Song, Z.; Sun, Z.; Wang, D.; Han, D.; Niua, L. Controllable synthesis of coloured Ag0/AgCl with spectral analysis for photocatalysis. RSC Adv. 2018, 8, 24812–24818. [Google Scholar] [CrossRef] [Green Version]

- Crist, B.V. Handbooks of Monochromatic XPS Spectra; XPS International LLC: Mountain View, CA, USA, 1999; pp. 1–4, 313–317. [Google Scholar]

- Lopez-Salido, I.; Lim, D.C.; Kim, Y.D. Ag nanoparticles on highly ordered pyrolytic graphite (HOPG) surfaces studied using STM and XPS. Surf. Sci. 2005, 588, 6–18. [Google Scholar] [CrossRef]

- Marinho, H.S.; Real, C.; Cyrne, L.; Soares, H.; Antunes, F. Hydrogen peroxide sensing, signaling and regulation of transcription factors. Redox Biol. 2014, 2, 535–562. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.; Heikes, B.G.; O’Sullivan, D.W. Hydrogen peroxide and organic hydroperoxide in the troposphere: A review. Atmos. Environ. 2000, 34, 3475–3494. [Google Scholar] [CrossRef]

- Rameshkumar, P.; Viswanathan, P.; Ramasamy, R. Silicate sol-gel stabilized silver nanoparticles for sensor applications toward mercuric ions, hydrogen peroxide and nitrobenzene. Sens. Actuators B Chem. 2014, 202, 1070–1077. [Google Scholar] [CrossRef]

- Li, B.L.; Chen, J.R.; Luo, H.Q.; Li, N.B. Electrocatalytic activity of polymer-stabilized silver nanoclusters for hydrogen peroxide reduction. J. Electroanal. Chem. 2013, 706, 64–68. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, H.; Song, Y.; Liu, L.; He, Z.; Wan, L.; Chen, S.; Xiang, Y.; Chen, S.; Chen, J. Architecture of poly(o-phenylenediamine)-Ag nanoparticle composites for a hydrogen peroxide sensor. Electrochim. Acta 2012, 60, 314–320. [Google Scholar] [CrossRef]

- Song, Y.; Cui, K.; Wang, L.; Chen, S. The electrodeposition of Ag nanoparticles on a type I collagen-modified glassy carbon electrode and their applications as a hydrogen peroxide sensor. Nanotechnology 2009, 20, 105501. [Google Scholar] [CrossRef]

- Goug, K.Y.; Kumar, V.S.; Hayat, A. Polymer scaffold layers of screen-printed electrodes for homogeneous deposition of silver nanoparticles: Application to the amperometric detection of hydrogen peroxide. Microchim. Acta 2019, 186, 810. [Google Scholar]

- Chen, L.; Wang, Y.; Ban, H.; Yu, S.; Hu, Z. An amperometric sensitive hydrogen peroxide sensor based on a silver nanoparticle-doped polyimide-modified glassy carbon electrode. Int. J. Electrochem. Sci. 2018, 13, 10961–10972. [Google Scholar]

- Zhang, K.; Zhang, N.; Xu, J.; Wang, H.; Wang, C.; Shi, H.; Liu, C. Silver nanoparticles/poly(2-(N-morpholine) ethane sulfonic acid) modified electrode for electrocatalytic sensing of hydrogen peroxide. J. Appl. Electrochem. 2011, 41, 1419–1423. [Google Scholar] [CrossRef]

- Balamurugan, A.; Chen, S.M. Silver nanograins incorporated PEDOT modified electrode for electrocatalytic sensing of hydrogen peroxide. Electroanalysis 2009, 21, 1419–1423. [Google Scholar] [CrossRef]

- Barry Halliwell, B.; Lee, H.L.; Tsin, P.Y.; Lim, S.; Kelly, R. Establishing biomarkers of oxidative stress: The measurement of hydrogen peroxide in human urine. Curr. Med. Chem. 2004, 11, 1085–1092. [Google Scholar] [CrossRef] [PubMed]

- Long, L.H.; Evans, P.J.; Halliwell, B. Hydrogen peroxide in human urine: Implications for antioxidant defense and redox regulation. Biochem. Biophys. Res. Commun. 1999, 262, 605–609. [Google Scholar] [CrossRef] [PubMed]

- Halliwella, B.; Clement, M.V.; Long, L.H. Hydrogen peroxide in the human body. FEBS Lett. 2000, 486, 10–13. [Google Scholar] [CrossRef] [Green Version]

| Electrode | Silver Salt/Synthesis | Method | Detection Limit (μM) | Dynamic Range (μM) | Ref. |

|---|---|---|---|---|---|

| AgNPs/TPDT/GCE | AgNO3/ES | LSV | 0.5 | 0.5–3.5 | [44] |

| AgNCs/PEI/GCE | AgNO3/CS | CA | 1.8 | 10–1440 | [45] |

| AgNPs/PoPD/GCE | AgNO3/CS | CA | 1.5 | 6.0–67,300 | [46] |

| AgNPs/collagen/GCE | AgNO3/ES | CA | 0.7 | 5.0–40,600 | [47] |

| AgNPs/HDMA, PEG/SPCE | AgNO3/ES | CA | 1.5 | 10–180 | [48] |

| AgNPs/PI/GCG | Commercial AgNPs | CA | 8.6 | 10–1000 | [49] |

| AgNPs/PMES/GCE | AgNO3/ES | CA | 0.18 | 0.6–540 | [50] |

| AgNPs/PEDOT/ITO | AgNO3/ES | CA | 7 | - | [51] |

| AgNPs/PEI/GCE | AgCl/ES | CV | 1.66 | 2–1000 | This work |

| Sample | Spiked (μM) | Found (μM) | Recovery (%) |

|---|---|---|---|

| 1 | 2.5 | 2.42 | 96.8 |

| 2 | 2.5 | 2.37 | 94.8 |

| 3 | 2.5 | 2.59 | 103.6 |

| Average | 2.5 | 2.46 | 98.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.T.; Park, D.-S. Simple Electrochemical Synthesis of Polyethylenimine-Encapsulated Ag Nanoparticles from Solid AgCl Applied in Catalytic Reduction of H2O2. Catalysts 2020, 10, 1416. https://doi.org/10.3390/catal10121416

Kim KT, Park D-S. Simple Electrochemical Synthesis of Polyethylenimine-Encapsulated Ag Nanoparticles from Solid AgCl Applied in Catalytic Reduction of H2O2. Catalysts. 2020; 10(12):1416. https://doi.org/10.3390/catal10121416

Chicago/Turabian StyleKim, Kyung Tae, and Deog-Su Park. 2020. "Simple Electrochemical Synthesis of Polyethylenimine-Encapsulated Ag Nanoparticles from Solid AgCl Applied in Catalytic Reduction of H2O2" Catalysts 10, no. 12: 1416. https://doi.org/10.3390/catal10121416

APA StyleKim, K. T., & Park, D.-S. (2020). Simple Electrochemical Synthesis of Polyethylenimine-Encapsulated Ag Nanoparticles from Solid AgCl Applied in Catalytic Reduction of H2O2. Catalysts, 10(12), 1416. https://doi.org/10.3390/catal10121416