Abstract

Solar-to-fuel conversion is an innovative concept for green energy, attracting many researchers to explore them. Solar-driven photocatalysts have become an essential solution to provide valuable chemicals like hydrogen, hydrocarbon, and ammonia. For sustainable stability under solar irradiation, titanium dioxide is regarded as an acceptable candidate, further showing excellent photocatalytic activity. Incorporating the photo-sensitizers, including noble metal nanoparticles and polymeric carbon-based material, can improve its photoresponse and facilitate the electron transfer and collection. In this study, we synthesized the graphitic carbon nitride (g-C3N4) nanosheet incorporated with high crystalline TiO2 nanofibers (NF) as 1D/2D heterostructure catalyst for photocatalytic water splitting. The microstructure, optical absorption, crystal structure, charge carrier dynamics, and specific surface area were characterized systematically. The low bandgap of 2D g-C3N4 nanosheets (NS) as a sensitizer improves the specific surface area and photo-response in the visible region as the incorporated amount increases. Because of the band structure difference between TiO2 and g-C3N4, constructing the heterojunction formation, the superior separation of electron-hole is observed. The detection of reactive oxygen species and photo-assisted Kelvin probe microscopy are conducted to investigates the possible charge migration. The highest photocatalytic hydrogen production rate of Pd/TiO2/g-C3N4 achieves 11.62 mmol·h−1·g−1 under xenon lamp irradiation.

1. Introduction

The depletion of energy resources and growing environmental concerns due to the expanding world population have invigorated efforts to exploit alternative clean energy. Photocatalytic hydrogen production as an attractive approach for resolving energy and environmental issues has received unprecedented attention [1,2]. Since the sun is virtually inexhaustible, photocatalysis can keep converting solar energy into hydrogen fuel during the day. Furthermore, the photocatalyst is indispensable for solving the environmental issue as for its degradation and antibacterial capability. However, the photocatalytic efficiency is still limited because of the rapid recombination of photocarrier. The significant improvement of heterostructure construction for photocatalytic water-splitting further attracts much attention, studying interfacial engineering [3].

Among the several metal oxides, titanium dioxide (TiO2) has been seen as potential material according to its reasonable cost, nontoxicity, high stability, and eco-friendliness. TiO2 also shows excellent photocatalytic activity and photostability [4]. Therefore, many studies are devoted to TiO2 photocatalyst for photodegradation of organic pollutants [5], photocatalytic hydrogen production [6], and photo-reduction CO2 [7]. However, there are many obstacles on the road for obtaining high efficiencies TiO2 photocatalysts, such as narrow spectral response interval and high recombination rate of hole and electron. Thus, numerous studies have been devoted to overcoming these problems, such as surface modification [8,9], fabricated heterojunction [10,11], multidimensional structure [12,13].

A variety of dimensional structures, 0D, 1D, and 2D materials, have been employed to design the multidimensional photocatalyst. For 0D/1D heterojunction materials, the quantum effect can effectively activate and convert the H2O molecule. The inherent advantages of 1D material, high specific surface area, great exposed edge sites, and fast and long-distance electron transport can promote the charge separation. Therefore, the synergistic effect between 0D/1D material can remarkably enhance H2 evolution activity [14,15]. The emerging 1D/2D heterojunction materials also draw ever-growing research attention in the photocatalysis field. For designing the 2D nanomaterials, thin sheets or layers possess a significant number of active sites on the surface, a short diffusion pathway for facilitating excitons dissociation, superior electron mobility, and excellent catalyst supports ability [16,17]. Combined with the aforementioned advantages, 1D/2D heterojunction materials demonstrate rapid carrier transfer along the axial direction, restrain photocorrosion and agglomeration, prolonging the stability, and provide intimate interfaces between 1D/2D, favoring their versatility [18,19,20].

Graphitic carbon nitride (g-C3N4) as a 2D material has been highlighted as a promising metal-free photocatalyst because of its unique electrical, optical, structural, and physicochemical properties [21,22,23]. g-C3N4 is a visible-light-driven photocatalyst (Eg~2.7 eV) with a conduction band edge at −1.1 eV and valence band edge at 1.6 eV (vs. normal hydrogen electrode (NHE)). These fascinating properties allow g-C3N4 to be used in photodegradation [24], CO2 photoreduction [25], water splitting [26,27], etc. Though g-C3N4 possesses remarkable properties, its low absorption coefficient and high charge carriers recombination still limit g-C3N4 performance. To overcome these drawbacks, forming a composite material with other semiconductors is a good strategy. Li et al. summarized recently advanced in g-C3N4-based heterojunction photocatalysts [28]. To date, TiO2 [29], CdS [30,31], ZnIn2S4 [32], BiOCOOH [33], MoS2 [34,35], etc., have all been attempted to construct heterojunction g-C3N4-based heterojunction photocatalysts. 2D/1D nanostructured g-C3N4/ZnO demonstrates the formation of heterojunction effectively separates the charge carriers and thus enhances the photocatalytic activity [36]. 2D/1D nanostructured g-C3N4/TiO2 shows improved visible-light-driven photocatalytic activity and prolonged charge carrier lifetime [37,38].

Herein, we proposed a multidimensional heterostructure constructed by 2D g-C3N4 nanosheet incorporated with high crystalline 1D TiO2 nanofibers for the photocatalytic degradation and water splitting. To achieve superior hydrogen production yield, we also introduced 0D Pd NP as cocatalyst, enriching the active site and rectifying the carrier transport in the interface by Schottky junction. The morphology, optical absorption, crystal structure, composition, and specific surface area were characterized systematically. The charge transfer behavior was unveiled by using a photo-assisted kelvin probe microscope. The superior separation of electron-hole was attributed to the heterojunction formation, and the preferred transfer of TiO2 and g-C3N4 was interpreted. The nanoscale multidimensional Pd/TiO2/g-C3N4 catalyst showed a high hydrogen evolution rate and presented the great potential to address the environment and energy issue in the future.

2. Results and Discussion

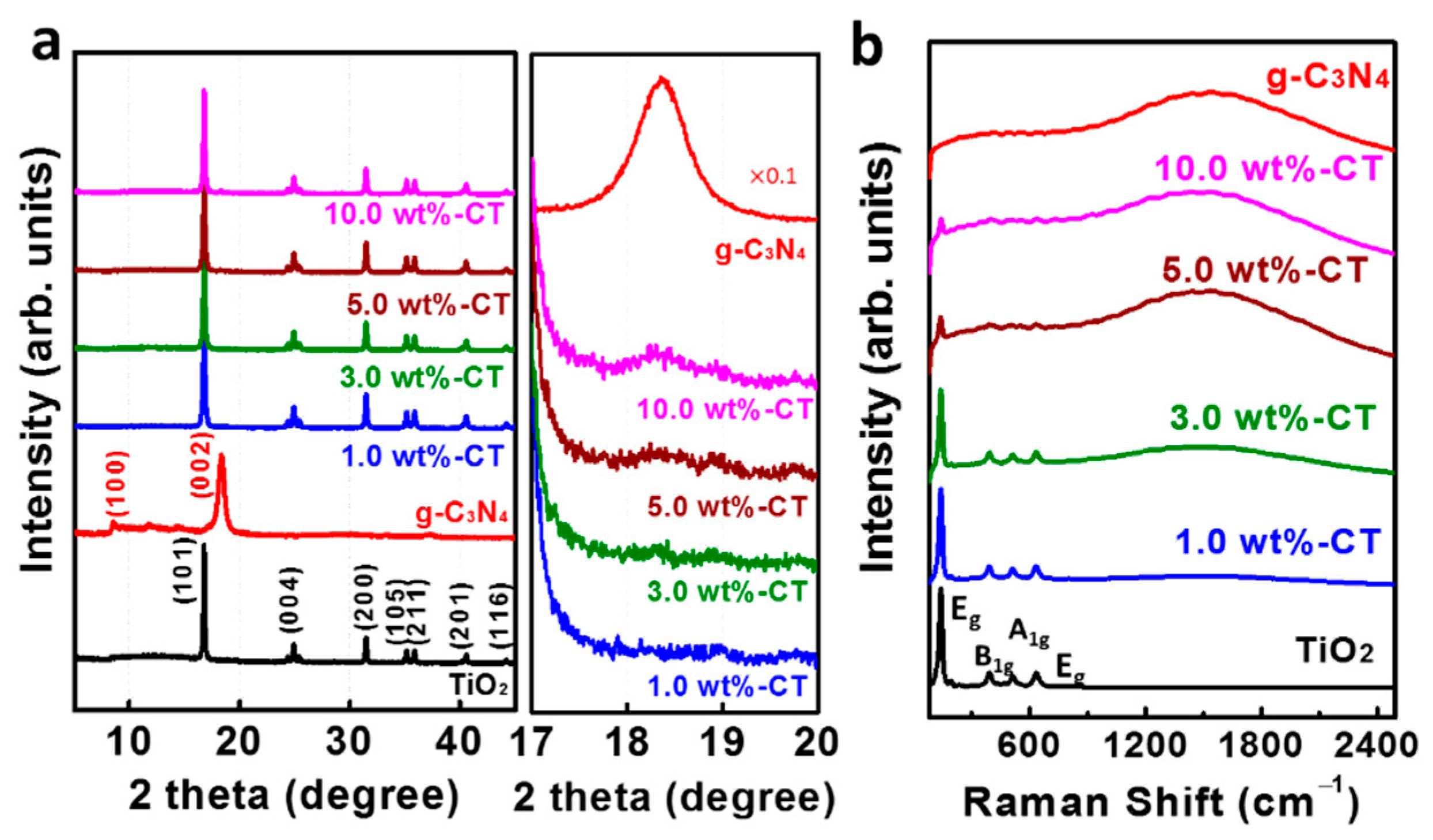

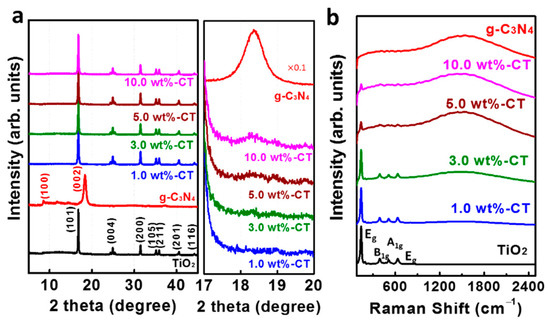

Multidimensional photocatalysts usually construct the heterostructure, then performing diverse crystal structure. To unveil the incorporation of g-C3N4 NS and TiO2 NF, we studied their crystal structure using the synchrotron X-ray spectroscopy, with a radiative wavelength of 1.025 Å. In Figure 1a, the typical peak at the 2θ of 16.5° was indexed to (101) plane of the reflection of anatase phase TiO2. Among various g-C3N4/TiO2 catalysts, the reflection of anatase TiO2 phase presented high intensity, indicating the perfect crystalline dominated by high crystalline TiO2 NF. The related crystallite size of anatase TiO2 in various TiO2 catalyst are all close to 34 nm, as reported in Table S1. Bulk g-C3N4 shows two diffraction peaks at 8.50 and 18.35°, assigned to the in-plane arrangement and out-of-plane of C-N atoms in heptazine. Both diffraction peaks were hardly observed in a series of g-C3N4/TiO2 catalysts. For the better resolution and detailed inspection of crystal structure examination, we further collected the magnified spectra with a slower scan rate of 0.005° s−1. In Figure 1b, we observed the diffraction peak of (002) plane of g-C3N4 NS appearing gradually as the incorporation concentration increased. Interestingly, the Raman spectra of various g-C3N4/TiO2 catalysts revealed a strong but broad peak, which becomes strong at Raman shift ranging from 1200 to 1800 cm−1. It further covered the typical vibration modes of anatase TiO2, including Eg (144 cm−1), B1g (397.9 cm−1), A1g (513.0 cm−1), and Eg (637.2 cm−1) [39]. These results indicated that the expected scattering of g-C3N4 NS coupled with incident light significantly improved the successful incorporation of g-C3N4 NS and TiO2 NF. Moreover, the evidence elaborated that the weak diffraction peak of (002) plane could speculate the laminate structure destruction by TiO2 NF embedded and layer disintegration.

Figure 1.

(a) Synchrotron X-ray spectra and (b) Raman spectra of the various g-C3N4/TiO2 catalysts.

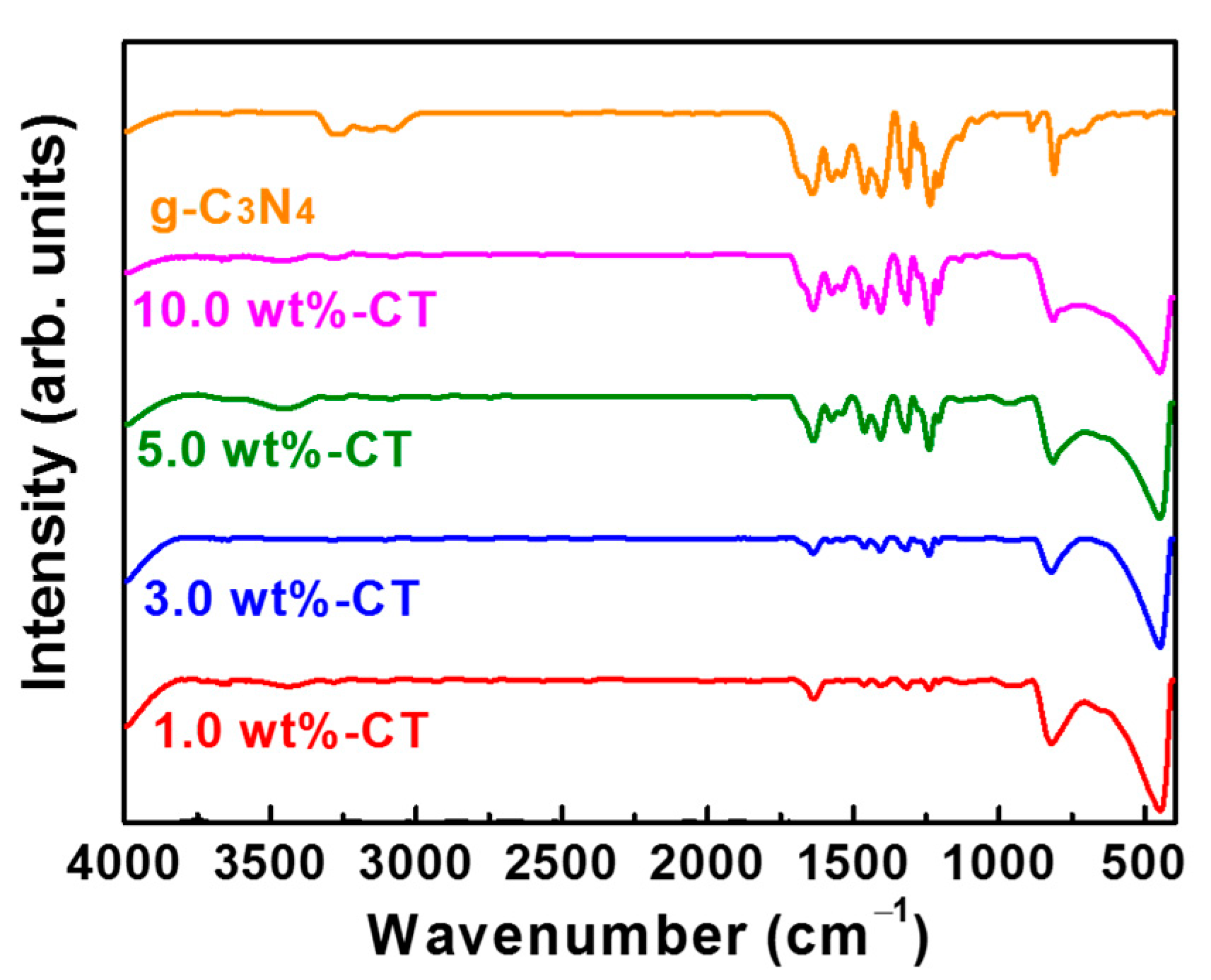

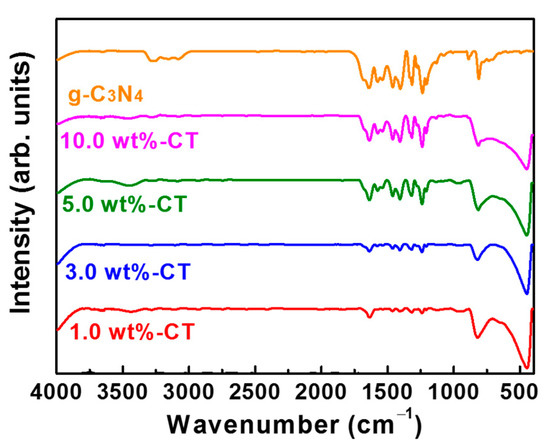

To elucidate the chemical structure of g-C3N4/TiO2 catalysts, we further studied the FTIR spectra, as shown in Figure 2. The peaks at 3300 cm−1 and 1200–1700 cm−1 were assigned to N-H and C-N stretching vibration. N breathing mode of heptazine appeared at 980 cm−1. The out-of-plane and in-plane bending vibration were indicated at 810 cm−1 and 690 cm−1, respectively [40]. We found that the peak at low wavenumbers might be assigned to the Eg band (144 cm−1) of anatase TiO2 because of the approximated energy difference of the photon between infrared absorption and Raman scattering. Obviously, with increasing amounts of g-C3N4 NS, the stretching vibrations became stronger.

Figure 2.

FTIR spectra of various g-C3N4/TiO2 catalysts.

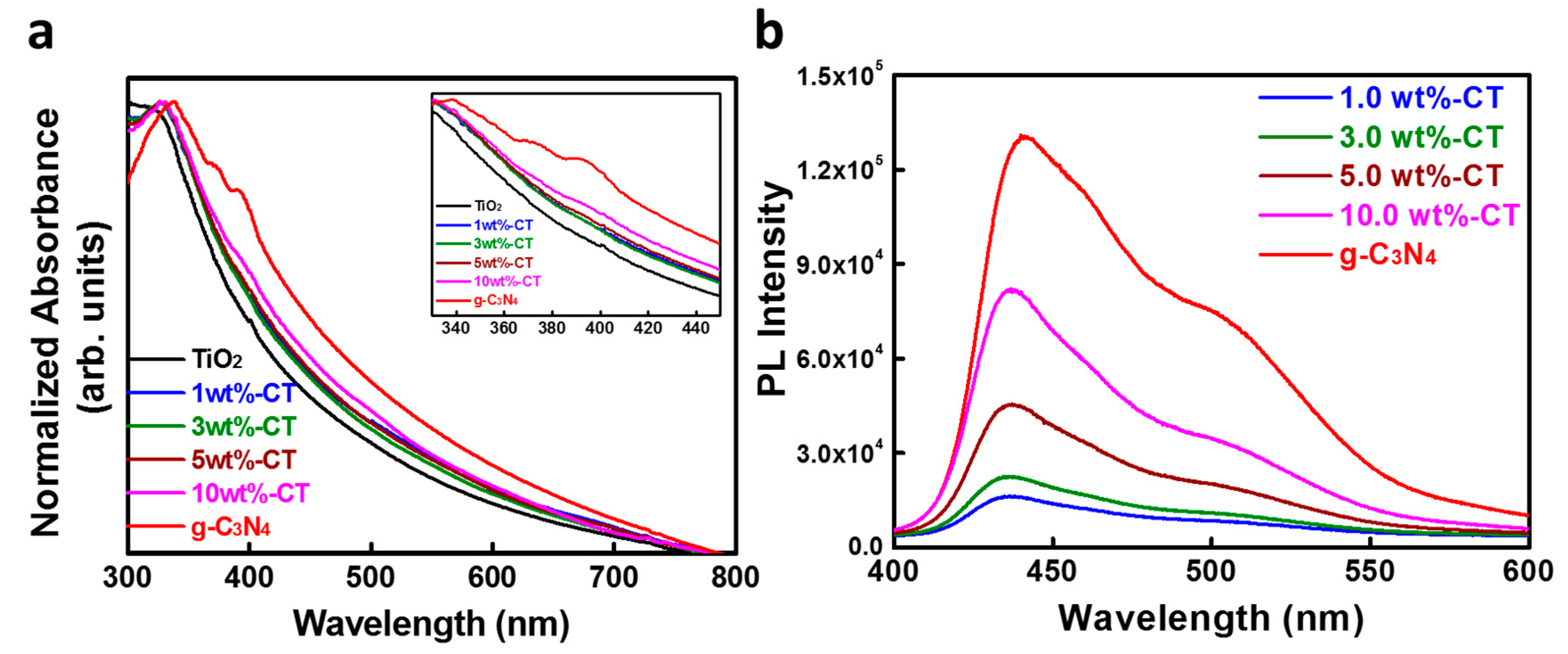

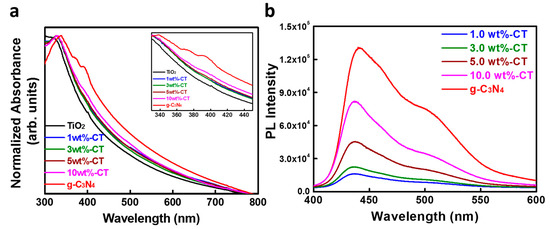

The optical properties are crucial factors for the photocatalytic activity. Pristine g-C3N4 revealed an absorption peak at around 380 nm, attributed to the π-π* transition in the aromatics. Incorporating g-C3N4 with TiO2 NF substantially improved the absorption of the composite photocatalyst in the visible region. We found a red-shift appeared in the absorbance spectra and became intensive with increasing the g-C3N4 amount (Figure 3a). It also was predictable to promote the overall activity of g-C3N4/TiO2 catalysts. The PL spectra are presented in Figure 3b; PL intensities were enhanced by incorporating g-C3N4 NS because of the strong emission by g-C3N4 NS. A slight red-shift was observed, being consistent with the absorption behavior. Notably, the board peak containing the second shoulder was attributed to the indirect radiative caused by a few structural defects trapping electrons in the in-plane g-C3N4 [41]. As incorporated with TiO2 forming a heterostructure, it might provide an available pathway for excited charge carriers migration.

Figure 3.

Optical properties of various g-C3N4/TiO2 catalysts; (a) absorbance spectra; and (b) PL spectra.

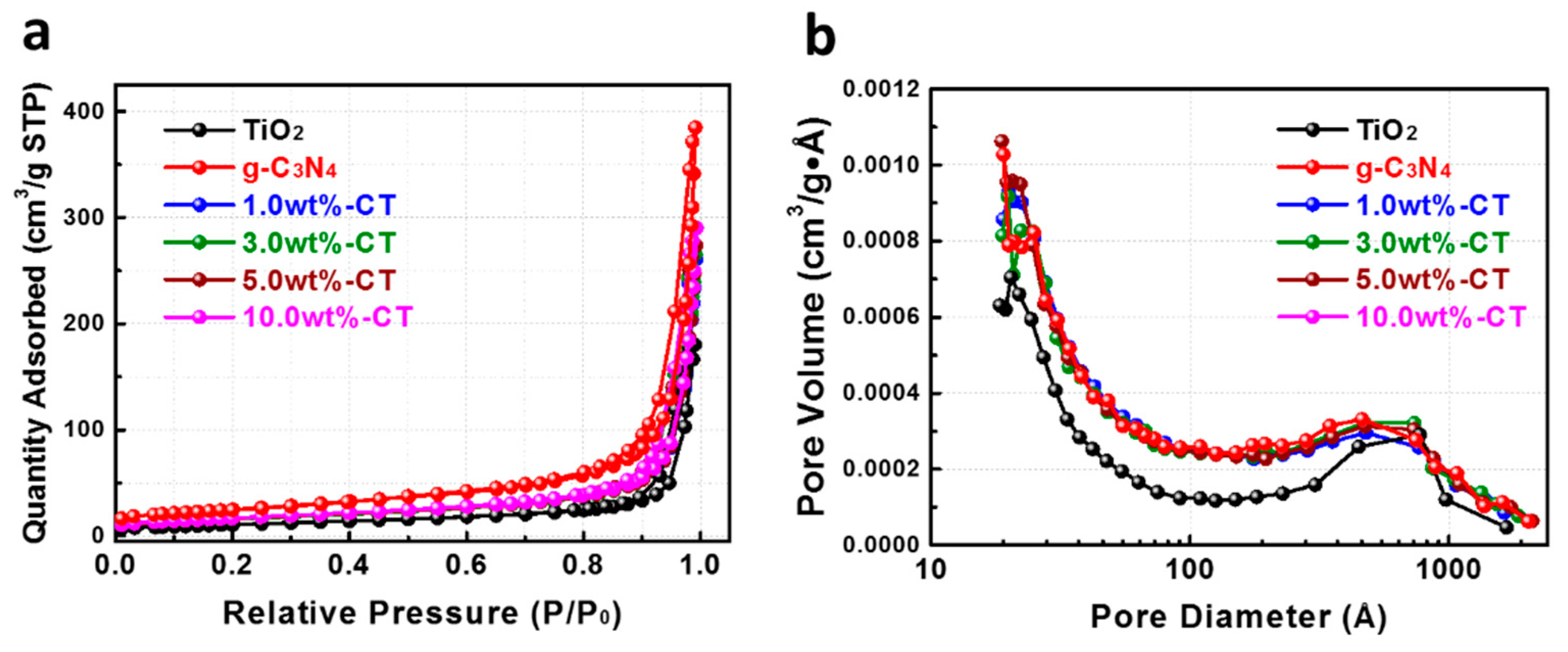

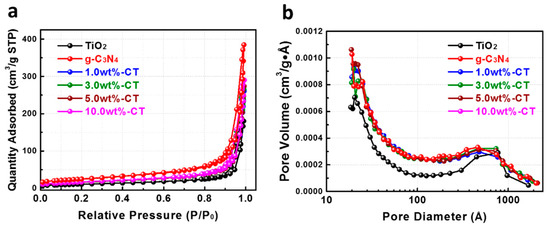

Two-dimensional g-C3N4 NS with the ultrathin structure constructed by few layers usually shows a high specific surface area, providing rich active sites on the photocatalyst surface compared to one-dimensional photocatalysts. Hence, we examined the surface features of g-C3N4/TiO2 catalysts by the Brunauer–Emmett–Teller (BET) and Barrett–Joyner–Halenda (BJH) method. The g-C3N4 NS shows the remarkable properties in SBET and pore features. The SBET of g-C3N4 NS is about 88.9 m2·g−1, and much higher than that of TiO2 NF (49.6 m2·g−1), as shown in Table 1. When the incorporation amount of g-C3N4 NS increased from 1.0 wt% to 10.0 wt%, the surface area of composites was gradually enhanced (Figure 4). At the same time, the BJH pore size and volume of g-C3N4/TiO2 catalysts were also amplified, inferring the cavities or tunnels were constructed in g-C3N4/TiO2 catalyst. It might be beneficial to aqueous penetration in the photocatalytic reaction.

Table 1.

BET specific surface area (SBET), pore size, and pore volume of various g-C3N4/TiO2 catalysts.

Figure 4.

(a) Nitrogen adsorption−desorption BET isotherm curves and (b) related pore distribution curves of various g-C3N4/TiO2 catalysts.

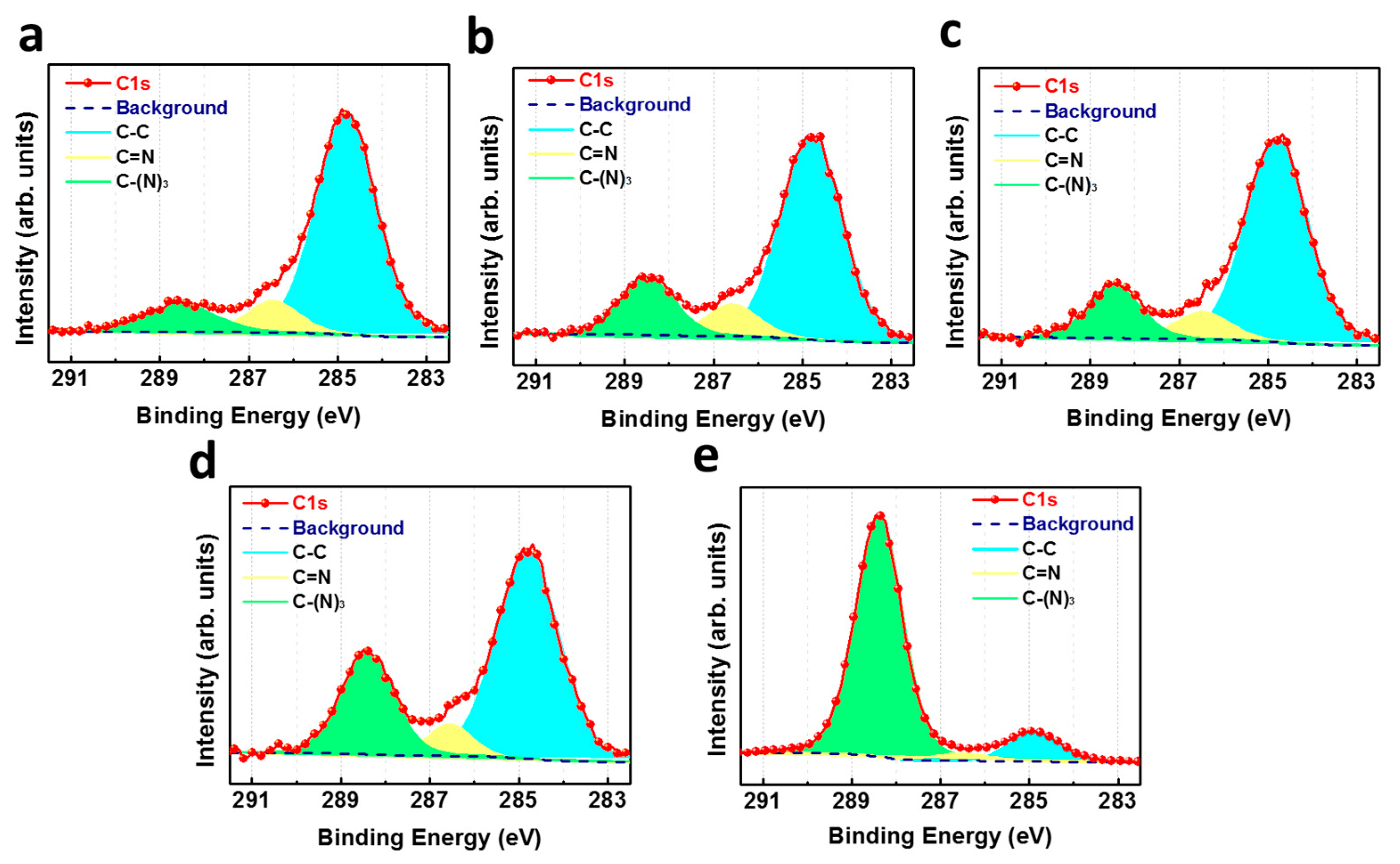

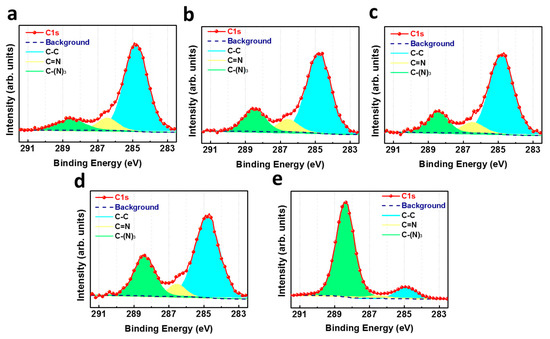

To obtain the elemental composition, we implemented the X-ray photoelectron spectroscopy to analyze the C1s orbital. The typical C–C bonding presented in all of the g-C3N4/TiO2 catalysts was assigned to the binding energy of 284.8 eV, suggesting the surface adsorption of carbon contamination and carbon dioxide (Figure 5). A low peak located at 286.6 eV was attributed to the C=N group [42]. Notably, we observed the increasing peak located at 288.6 eV referred to the C-N group, denoting the incorporation amount of g-C3N4 increased in the g-C3N4/TiO2 catalyst. We also studied their composition change by calculating the N/Ti and N/C atomic ratio, as reported in Table S2. Both ratios indicated the same tendency that the ratio of nitrogen to titanium and carbon increased with the increasing amount of g-C3N4.

Figure 5.

XPS spectra for C 1s orbital of g-C3N4/TiO2 catalyst with various g-C3N4 addition, (a) 1.0 wt% (b) 3.0 wt%, (c) 5.0 wt%, and (d) 10.0 wt%, and (e) pristine g-C3N4.

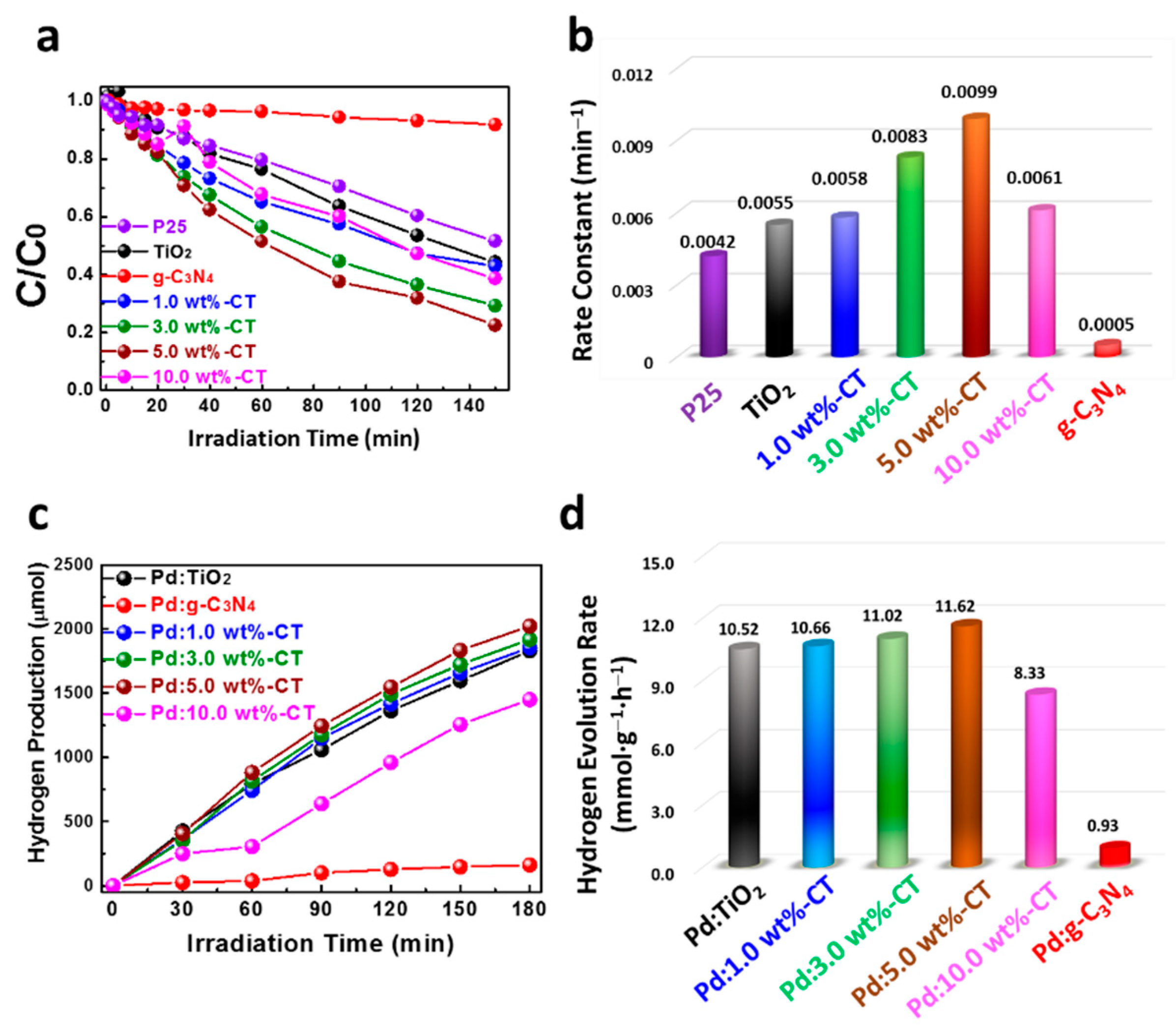

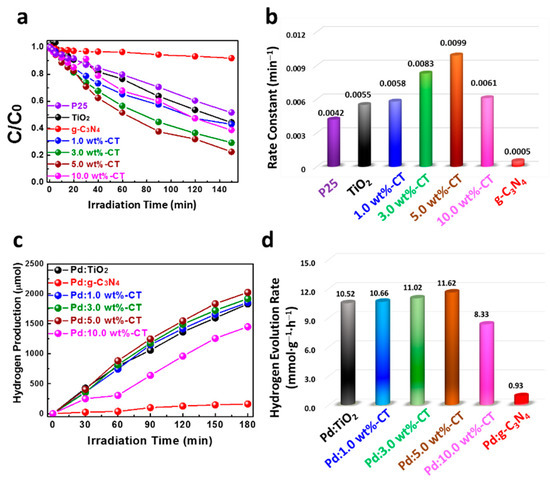

As mentioned above, the successful incorporation with the visible-driven g-C3N4 NS significantly improved several crucial factors for photocatalytic reaction, such as optical absorption, surface area, and heterojunction construction. To comprehend the optimal incorporation of g-C3N4 NS for the catalytic activities, we evaluated their photodegradation of organic dyes and photocatalytic hydrogen production. In the photodegradation of methyl orange (MO), the essential elements are rich reactive oxygen species (ROS), which are highly active in attacking the organic dye, leading to discoloration. The 2D/1D heterostructure of g-C3N4/TiO2 catalyst provides an alternative approach for the charge carrier migration, inhibiting the recombination and promoting the photo-excited electron-hole pairs to produce ROS efficiently. Figure 6a presented the photodegradation activity using various g-C3N4/TiO2 catalysts. Bulk g-C3N4 showed lower activity compared to TiO2 NF, which was attributed to low crystalline and structural defects in bulk g-C3N4. Notably, incorporating the visible-driven g-C3N4 NS with TiO2 NF enhanced the overall degradation activity, and its reaction rate constant was up to 0.0099 min−1 as the amount added to 5.0 wt%. Up to 10.0 wt%, discoloration behavior was inhibited (Figure 6b). It indicates that much more g-C3N4 might dominate the surface feature because of the significant enhancement of SBET and optical absorption, whereas influenced exposure of TiO2 active sites, leading to low intrinsic activity. Likewise, under the Xe lamp irradiation, the photocatalytic hydrogen production presented the tendency as the g-C3N4 amounts increased to 5.0 wt%, in which the hydrogen production rate was 11.62 mmol·h−1·g−1 (Figure 6c,d). Here, Pd NP decorated by the wet-impregnation method assisted the electron collection on the surface for proton reduction to hydrogen. Based on our best knowledge, excellent ordering in highly crystalline TiO2 NF retains the numbers of electron-hole pairs and avoids the recombination as irradiated. When Pd NP locates at the interface of a metal oxide such as TiO2, the Schottky barrier forms and facilitates electron rectification, not back to metal oxide as electron once passes through the interface [6]. Thus, the optimal 5.0 wt% g-C3N4/TiO2 catalyst with sufficient active sites and efficient charge transfer revealed significant photocatalytic activities.

Figure 6.

(a) Photodegradation of methyl orange and (b) the comparison chart of degradation rate; (c) photocatalytic hydrogen production and (d) the comparison chart of production rate.

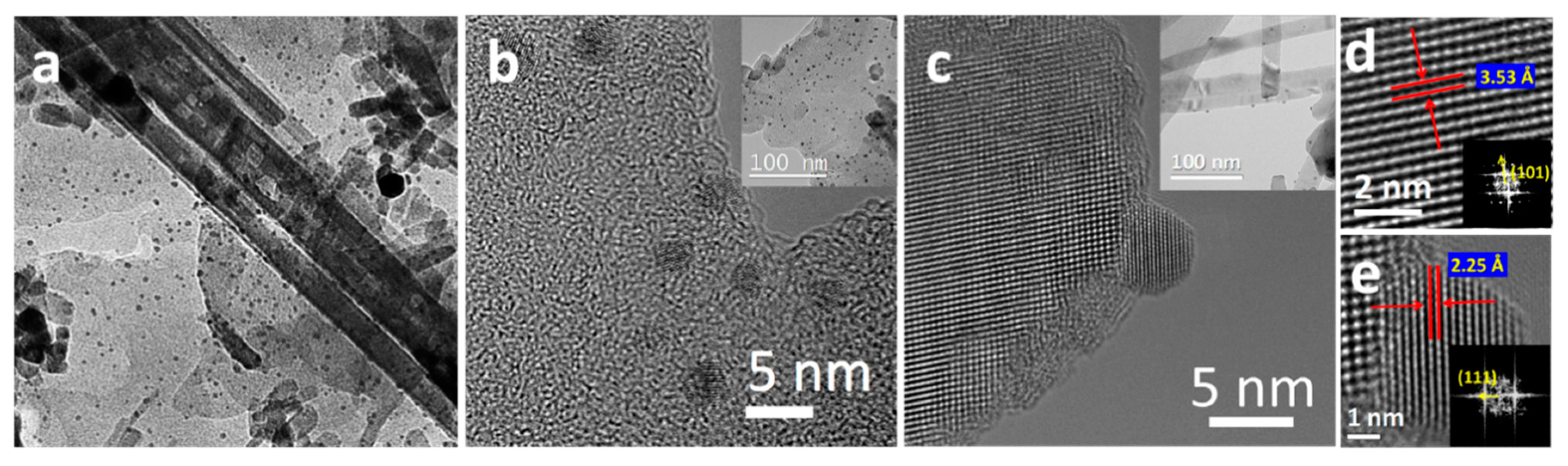

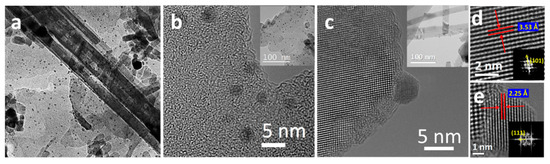

We conducted the spherical-aberration corrected field-emission transmission electron microscope to investigate the heterostructure of Pd/TiO2/g-C3N4 catalyst. Figure 7a revealed that TiO2 NF lay on the multi-layer of g-C3N4 NS and decorated with Pd NP. In the magnified image of g-C3N4 NS (Figure 7b), it presented an ultrathin sheet morphology, implying the bulk g-C3N4 was disintegrated by ultrasonic treatment. The topography was also reported in Figure S1, and the thickness is about 4.0 nm. In the case of TiO2 NF (Figure 7c), a high ordering of anatase TiO2 was observed, and the (101) plane with an interplanar spacing of 3.53 Å was referred to. (Figure 7d) Also, the Pd NP with a diameter of 3.0 nm was identified, and the typical (111) plane was observed, showing an interplanar spacing of 2.25 Å (Figure 7e).

Figure 7.

TEM images of (a) Pd/TiO2/g-C3N4 catalyst; magnified images of (b) g-C3N4 NS and (c) TiO2 NF decorated with Pd NP; HRTEM images of (d) TiO2 NF, and (e) Pd NP.

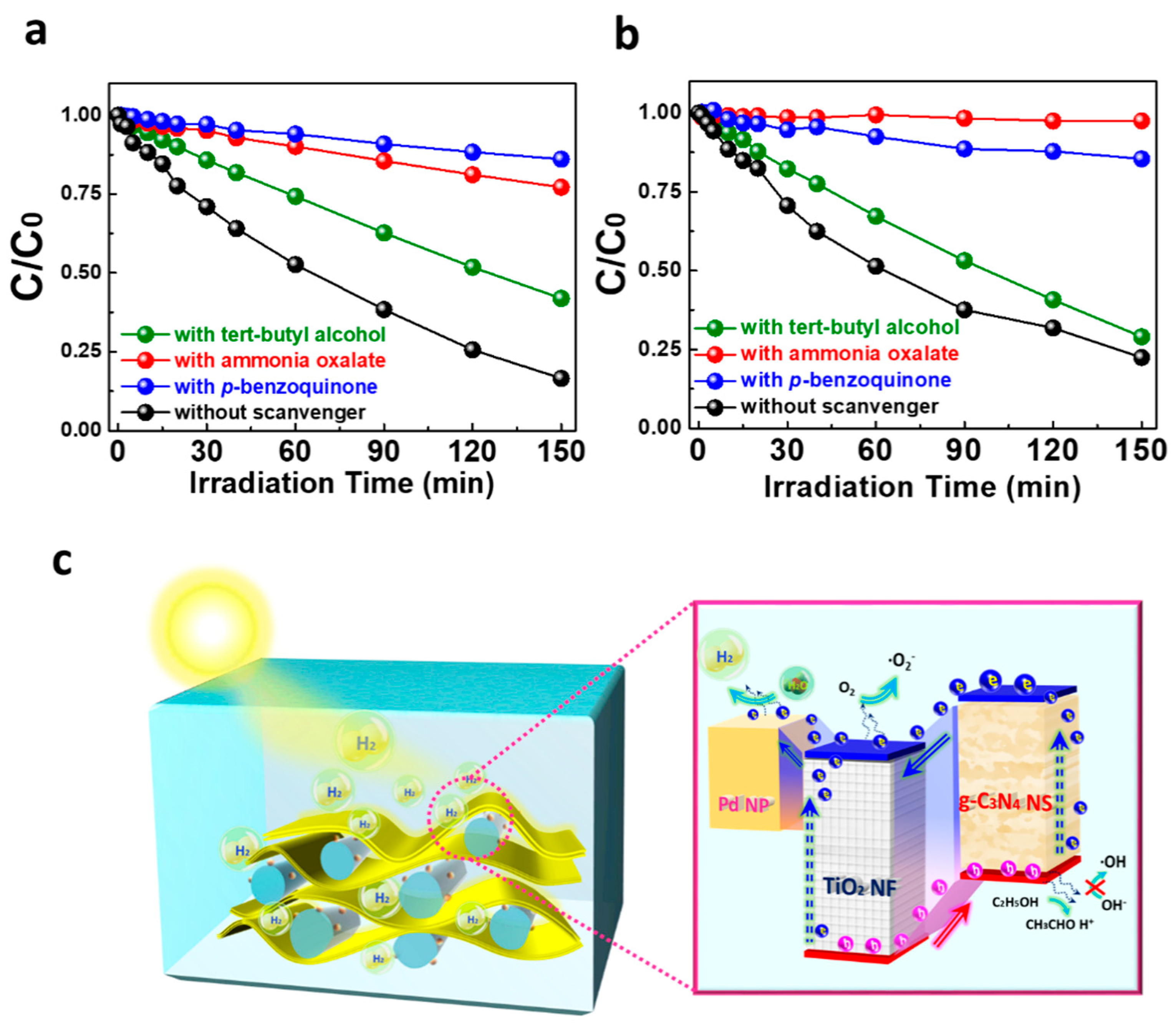

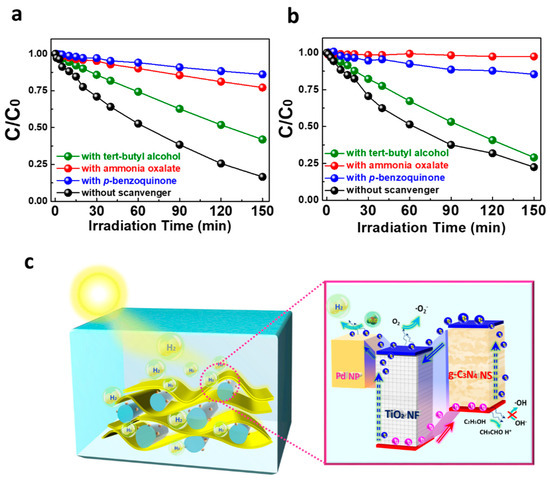

The scavengers were used to evaluate the reactive oxygen species (ROS) during the photodegradation to verify the charge transfer in the g-C3N4/TiO2 catalyst’s heterostructure. Tert-butyl alcohol (TBA) and p-benzoquinone (p-BQ) can investigate the role of relevant ROS, such as hydroxyl radical and superoxide radical, respectively. Ammonium oxalate (AO) can capture the hole that indirectly produces hydroxyl radical from the hydroxyl group. Figure 8a demonstrates the photodegradation using pristine TiO2 NF. The addition of BQ or AO into the degradation reaction inhibited the TiO2 activity. It elucidates the superoxide radicals derived by electrons and holes play a crucial role in the photodegradation. Similarly, a consistent phenomenon was observed in the photodegradation of g-C3N4/TiO2 catalyst (Figure 8b). Notably, with the addition of TBA using TiO2, the discoloration by TiO2 was still inhibited, implying a few hydroxyl radicals were produced. In contrast, g-C3N4/TiO2 revealed good discoloration behavior, but the degradation rate of methyl orange was inhibited slightly with TBA, implying few hydroxyl radicals existed. Based on our best knowledge, the hydroxyl radical was produced by the reaction of the TiO2-induced hole and a hydroxyl group. Combining the g-C3N4 NS, it provided the other pathway for the hole migration, indicating the change of the selectivity of hole which might migrate or react with the hydroxyl group on TiO2. Thus, the slight degradation activity can be attributed to the hole remaining on TiO2, which derived fewer hydroxyl radicals. We believed that most holes migrated from TiO2 NF to g-C3N4 NS, not producing hydroxyl radicals on the g-C3N4 NS due to the inappropriate valance band position for hole-induced oxidation of the hydroxyl group. Herein, we proposed the charge transfer mechanism in the as-constructed heterostructure (Figure 8c). Under the Xe lamp irradiation, electron-hole pairs formed in both catalysts and then separated. The holes of TiO2 NF prefer to transfer to the valance band of g-C3N4 NS and combined with localized holes, directly oxidizing the organic dye or sacrificing agent. The electrons of TiO2 retain in the conduction band. On the other hand, the electrons of g-C3N4 transfer to the conduction band of TiO2 NF and subsequently combine with local electrons to complete the photocatalytic degradation. Furthermore, as decorated Pd NP on the catalyst, electrons further passthrough the Schottky barrier and reduce protons to produce hydrogen.

Figure 8.

The photodegradation curves of (a) TiO2 NF and (b) 5.0 wt% g-C3N4/TiO2 catalyst toward the methyl orange with various scavengers, and (c) the scheme of the charge transfer mechanism.

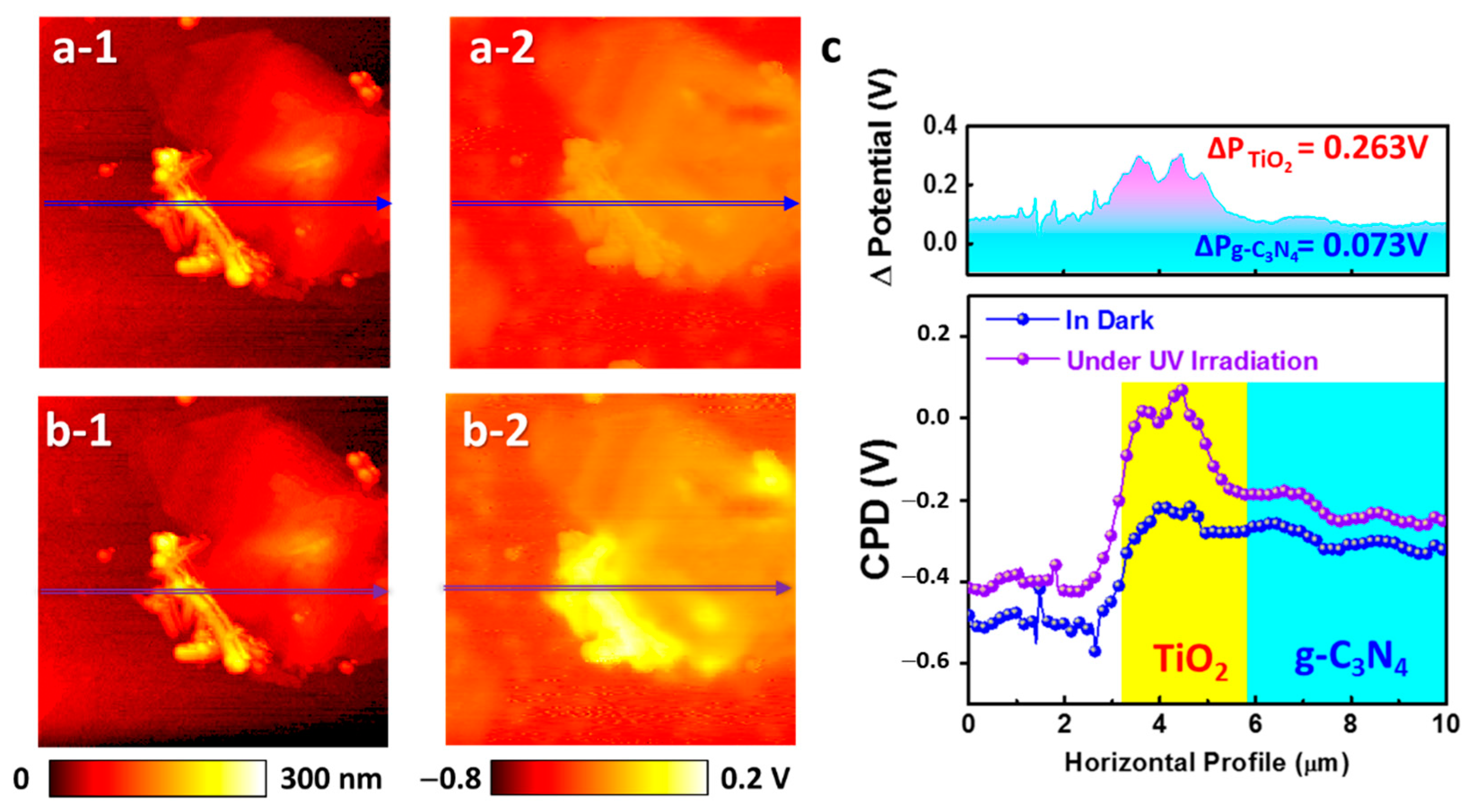

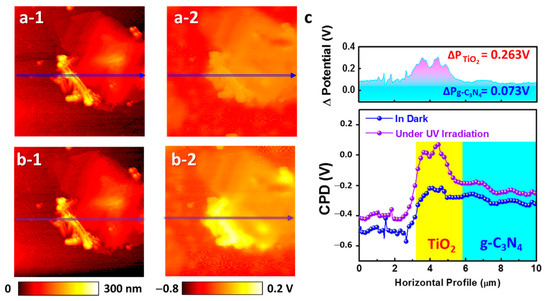

To clarify the charge transfer in the heterostructure of g-C3N4/TiO2, we measured the surface potential and calculated the contact potential difference (CPD) with/without UV irradiation (Figure 9). The surface topographic images for TiO2 NF and g-C3N4 NS clearly observe the TiO2 NF laid on g-C3N4 NS in Figure 9a-1. We further conducted the surface potential mapping in this area. In dark (Figure 9a-2), both TiO2 NF and g-C3N4 NS presented similar CPD due to the successful construction of heterostructure, causing the fermi level alignment. As UV irradiated to the g-C3N4/TiO2 (Figure 9b-1), the surface potential of TiO2 increased significantly instead of that of g-C3N4 (Figure 9b-2). The slight increment of surface potential on g-C3N4 (0.073 mV) suggested an overall fermi level increase, indicating a positive work function shift (Figure 9c). It also indicated that the photo-induced electrons might migrate to TiO2, whose average potential change (∆P) is about 0.263 V. A dramatic increment in potential which is observed in the interface between TiO2 NF and g-C3N4 NS implied electrons transfer. This result elucidated the g-C3N4/TiO2 constructed with the type II heterojunction. The photo-assisted KPFM would help verify the heterojunctions and the charge migration in the multidimensional photocatalyst.

Figure 9.

Topographic images of g-C3N4/TiO2 catalyst (a-1) in dark, and (b-1) under UV irradiation; the surface potential images of g-C3N4/TiO2 catalyst (a-2) in dark, and (b-2) under UV irradiation; (c) horizontal profile for the surface potential mapping of g-C3N4/TiO2 catalyst, and related potential change (upper).

3. Materials and Methods

3.1. Synthesis of Catalyst

Titanium dioxide nanofibers (TiO2 NF) were prepared by the hydrothermal method and further calcined in the air, according to our previous work [43]. About 2.50 g anatase TiO2 powder (Acros, 98%, Geel, Belgium) was gradually poured in 62.5 mL of 10.0 M NaOH (Fisher Scientific, >97%, Fair Lawn, NJ, USA) aqueous solution in a Teflon-lined autoclave. The mixture solution was vigorously agitated for 30 min, followed by heating to 150 °C for 24 h. Sodium titanate nanofibers were obtained and subsequently washed by diluted hydrochloric acid (HCl, Acros, 37%, Geel, Belgium) to eliminate sodium ions. Then, hydrogen titanate nanofibers was washed with distilled water until neutralized and then collected by filtration. Finally, the sample was dried at 80 °C in the oven. The highly crystalline TiO2 NFs were obtained after the calcination of hydrogen titanate at 600 °C. On the other hand, bulk graphitic carbon nitride (g-C3N4) was synthesized by thermal polymerization at 550 °C. For the excellent dispersion in aqueous and the disintegration of bulk status, bulk g-C3N4 was vigorously agitated in aqueous by ultrasonicator. To further obtain the g-C3N4/TiO2 catalysts, 0.50 g TiO2 NFs were suspended in 100.0 mL of DI water and subsequently irradiated under a UV-B lamp for activation of TiO2. Various amounts of g-C3N4, including 1.0, 3.0, 5.0, 10.0 wt%, were added into the solution and stirred for 30 min. After drying, various g-C3N4/TiO2 catalysts were acquired and named as CT. For improving the hydrogen production ability, 1.0 wt% palladium nanoparticles were deposited on as-prepared catalysts by the wet-impregnation method. Palladium (II) acetate (Pd(OCOCH3)2, ACROS, 99.9%, Geel, Belgium) was dissolved in a mixture of ethanol and acetone with a volume ratio of 1:1. Then, 0.60 g g-C3N4/TiO2 catalysts were further added to the solution and stirred for 3 h. After dried at 80 °C, remained powder was calcined at 350 °C for 3 h under the mixture flow of 15% H2 in N2 buffer. Finally, the multidimensional Pd/TiO2/g-C3N4 catalyst was obtained.

3.2. Material Characterization

The crystal structures of various g-C3N4/TiO2 catalysts were characterized by synchrotron X-ray spectroscopy (λ~1.025 Å) on beamline 13A1 of the National Synchrotron Radiation Research Center (NSRRC) in Taiwan. It was recorded from 2θ between 5 and 45 with a 0.01° step at 0.05° s−1. The magnified X-ray spectra were obtained from 2θ between 17.00 and 20.00 with a 0.01° step at 0.005° s−1. The chemical structure was analyzed using Fourier-transform infrared spectroscopy (FT-IR, Tensor 27, Bruker, Karlsruhe, Germany) in the range of 4000 to 450 cm−1 with a resolution of 2.0 cm−1. In the absorbance characterization, catalyst powders were dispersed in the DI water and then placed in a quartz cuvette. The absorbance spectra were measured by UV–VIS spectrophotometer (V-730, JASCO, Tokyo, Japan). For the photoluminescence measurement, catalysts were squeezed as the pellet and determined by photoluminescence spectrophotometer (UniDron-TRPL, CL technology, New Taipei City, Taiwan) with an excitation of 375 nm laser. The surface feature of photocatalysts, including specific surface area, pore size, and pore volume, were investigated by surface area and porosity analyzer (ASAP 2020, Micromeritics, Norcross, GA, USA). The X-ray photoelectron spectrometer with an X-ray source of Al Kα (K-alpha X-ray photoelectron spectrometer, Thermo Fisher Scientific, Waltham, MA, USA) was used to analyze the chemical state and precise composition. The morphology of Pd/TiO2/g-C3N4 catalysts was observed by using the spherical-aberration corrected field-emission transmission electron microscope (JEM-ARM200FTH, JEOL, Tokyo, Japan).

3.3. Photocatalytic Experiment

We implemented two methods, including photodegradation of methyl orange (C6H4(OH)2, Acros, 99.5%, Geel, Belgium) and photocatalytic hydrogen production, to evaluate the photocatalytic activity of various g-C3N4/TiO2 catalysts. In the former part, 20.0 mg of the catalyst was dispersed in the 10.0 ppm of methyl orange aqueous, further stirred for 60 min in the dark to lower the surface adsorption error. The suspension was then irradiated to two UV-B lamps (G8T5E 8W, SANKYO DENKI, Kanagawa, Japan) at ambient conditions under continuous stirring. The distance of lamps-to-reactor was kept about 5.0 cm. At the optimal time interval, we sampled about 3.0 mL of the suspension. Before the absorbance spectra examination, these samples were centrifuged for 15 min at 5000 rpm. The concentration of residue dye in the supernatant was estimated by using a UV–VIS spectrophotometer (V-730, JASCO, Tokyo, Japan) in the 400–900 nm, followed by recalculated from the calibration equation.

In the photocatalytic hydrogen production, the experiment was conducted in the Labsolar 6A system (Perfectlight Technology, Beijing, China) with a 300.0 mL glass reactor under 300 W Xenon irradiation. Total of 50.0 mg catalyst was dispersed in the 100.0 mL mixture of equivolume deionized water and ethanol. The hydrogen concentration was determined by online gas chromatography with a barrier ionization discharge detector (Shimadzu, Nexis GC-2030, with helium as a carrier gas, Kyoto, Japan) at a time interval of 30 min for 3 h.

For the investigation of different reactive oxygen species, we used the specific scavengers including p-benzoquinone (Acros, 99%, Geel, Belgium), ammonia oxalate (VETEC, 98%, trademark of Sigma-Aldrich, St. Louis, MO, USA), and tert-butyl alcohol (J.T.Baker, ≥99.0%, Phillipsburg, NJ, USA) in the photodegradation of 5.0 ppm methyl orange for the captivity of superoxide radicals, holes, and hydroxyl radicals.

4. Conclusions

Multidimensional Pd/TiO2/g-C3N4 catalysts were fabricated for the photocatalytic hydrogen production under xenon lamp irradiation. Constructing the heterostructure of 2D g-C3N4 NS and 1D TiO2 NF can associate both advantages, such as the enhanced specific surface area, optical absorption in the visible region, and excellent charge transfer. The Pd NP decoration on the optimal g-C3N4/TiO2 catalyst improved the overall hydrogen production up to 11.62 mmol·h−1·g−1. Through the ROS detection and KPFM investigation, we clarified the charge transfer behavior belonged to type II heterojunction. The photo-induced electrons prefer to migrate from g-C3N4 NS to TiO2 NF, reducing proton for hydrogen evolution on Pd cocatalyst. It also contributed to the excellent and rational electron-holes separation, inhibiting the recombination. In summary, the 0D/1D/2D multidimensional Pd/TiO2/g-C3N4 catalyst demonstrated excellent feasibility for the photocatalytic material design, also showing high activity under solar irradiation for solving the energy crisis and environmental concerns in the future.

Supplementary Materials

The following are available online at https://www.mdpi.com/2073-4344/11/1/59/s1, Figure S1: Surface topographic image of g-C3N4 NS. Table S1: The calculated crystallite size of anatase TiO2 in various catalysts. Table S2: The calculated atomic ratio.

Author Contributions

T.-H.L. and K.-P.C. performed the research and analyzed the data; T.-H.L. and Y.-H.C. wrote the paper. T.-H.L. and J.-C.W. revised the paper. M.-C.W. was the supervisor and revised the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Science and Technology, Taiwan, Project No. 106-2221-E-182-057-MY3, 108-2119-M-002-005, 109-2221-E-182-059, and 109-3116-F-002-002-CC2, Chang Gung University (QZRPD181) and Chang Gung Memorial Hospital, Linkou (CMRPD2H0163 and BMRPC74).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study and supporting information are available.

Acknowledgments

The authors appreciate Ming-Tao Lee (BL-13A1) and Jyh-Fu Lee (BL-17C1) at National Synchrotron Radiation Research Centre for useful discussion and suggestions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, S.S.; Takata, T.; Domen, K. Particulate Photocatalysts for Overall Water Splitting. Nat. Rev. Mater. 2017, 2, 17. [Google Scholar] [CrossRef]

- Wang, Y.O.; Suzuki, H.; Xie, J.J.; Tomita, O.; Martin, D.J.; Higashi, M.; Kong, D.; Abe, R.; Tang, J.W. Mimicking Natural Photosynthesis: Solar to Renewable H2 Fuel Synthesis by Z-scheme Water Splitting Systems. Chem. Rev. 2018, 118, 5201–5241. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Li, C.; Domen, K. Recent Developments in Heterogeneous Photocatalysts for Solar-driven Overall Water Splitting. Chem. Soc. Rev. 2019, 48, 2109–2125. [Google Scholar] [CrossRef] [PubMed]

- Kang, X.L.; Liu, S.H.; Dai, Z.D.; He, Y.P.; Song, X.Z.; Tan, Z.Q. Titanium Dioxide: From Engineering to Applications. Catalysts 2019, 9, 32. [Google Scholar] [CrossRef]

- Wu, M.C.; Lin, T.H.; Hsu, K.H.; Hsu, J.F. Photo-induced Disinfection Property and Photocatalytic Activity Based on the Synergistic Catalytic Technique of Ag Doped TiO2 Nanofibers. Appl. Surf. Sci. 2019, 484, 326–334. [Google Scholar] [CrossRef]

- Wu, M.C.; Huang, W.K.; Lin, T.H.; Lu, Y.J. Photocatalytic Hydrogen Production and Photodegradation of Organic Dyes of Hydrogenated TiO2 Nanofibers Decorated Metal Nanoparticles. Appl. Surf. Sci. 2019, 469, 34–43. [Google Scholar] [CrossRef]

- Xu, F.Y.; Zhang, J.J.; Zhu, B.C.; Yu, J.G.; Xu, J.S. CuInS2 Sensitized TiO2 Hybrid Nanofibers for Improved Photocatalytic CO2 Reduction. Appl. Catal. B Environ. 2018, 230, 194–202. [Google Scholar] [CrossRef]

- Wu, M.C.; Hsiao, K.C.; Chang, Y.H.; Chan, S.H. Photocatalytic Hydrogen Evolution of Palladium Nanoparticles Decorated Black TiO2 Calcined in Argon Atmosphere. Appl. Surf. Sci. 2018, 430, 407–414. [Google Scholar] [CrossRef]

- Yin, G.H.; Huang, X.Y.; Chen, T.Y.; Zhao, W.; Bi, Q.Y.; Xu, J.; Han, Y.F.; Huang, F.Q. Hydrogenated Blue Titania for Efficient Solar to Chemical Conversions: Preparation, Characterization, and Reaction Mechanism of CO2 Reduction. ACS Catal. 2018, 8, 1009–1017. [Google Scholar] [CrossRef]

- Wu, M.C.; Hsiao, K.C.; Chang, Y.H.; Kordas, K. Core-shell Heterostructures of Rutile and Anatase TiO2 Nanofibers for Photocatalytic Solar Energy Conversion. ACS Appl. Nano Mater. 2019, 2, 1970–1979. [Google Scholar] [CrossRef]

- Ansón-Casaos, A.; Hernández-Ferrer, J.; Vallan, L.; Xie, H.; Lira-Cantú, M.; Benito, A.M.; Maser, W.K. Functionalized Carbon Dots on TiO2 for Perovskite Photovoltaics and Stable Photoanodes for Water Splitting. Int. J. Hydrogen Energy 2020. [Google Scholar] [CrossRef]

- Geng, R.; Yin, J.J.; Zhou, J.X.; Jiao, T.F.; Feng, Y.; Zhang, L.X.; Chen, Y.; Bai, Z.H.; Peng, Q.M. In Situ Construction of Ag/TiO2/g-C3N4 Heterojunction Nanocomposite Based on Hierarchical Co-assembly with Sustainable Hydrogen Evolution. Nanomaterials 2020, 10, 13. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Ferrer, J.; Ansón-Casaos, A.; Víctor-Román, S.; Sanahuja-Parejo, O.; Martínez, M.T.; Villacampa, B.; Benito, A.M.; Maser, W.K. Photoactivity Improvement of TiO2 Electrodes by Thin Hole Transport Layers of Reduced Graphene Oxide. Electrochim. Acta 2019, 298, 279–287. [Google Scholar] [CrossRef]

- Chen, Q.H.; Zhang, M.M.; Li, J.Y.; Zhang, G.D.; Xin, Y.J.; Chai, C. Construction of Immobilized 0D/1D Heterostructure Photocatalyst Au/CuS/CdS/TiO2 NBs with Enhanced Photocatalytic Activity towards Moxifloxacin Degradation. Chem. Eng. J. 2020, 389, 12. [Google Scholar] [CrossRef]

- Wu, M.C.; Chen, C.H.; Huang, W.K.; Hsiao, K.C.; Lin, T.H.; Chan, S.H.; Wu, P.Y.; Lu, C.F.; Chang, Y.H.; Lin, T.F.; et al. Improved Solar-driven Photocatalytic Performance of Highly Crystalline Hydrogenated TiO2 Nanofibers with Core-Shell Structure. Sci. Rep. 2017, 7, 12. [Google Scholar] [CrossRef]

- Zhou, X.J.; Shao, C.L.; Li, X.H.; Wang, X.X.; Guo, X.H.; Liu, Y.C. Three Dimensional Hierarchical Heterostructures of g-C3N4 Nanosheets/TiO2 Nanofibers: Controllable Growth via Gas-solid Reaction and Enhanced Photocatalytic Activity under Visible Light. J. Hazard. Mater. 2018, 344, 113–122. [Google Scholar] [CrossRef]

- Zhu, M.S.; Kim, S.; Mao, L.; Fujitsuka, M.; Zhang, J.Y.; Wang, X.C.; Majima, T. Metal-free Photocatalyst for H2 Evolution in Visible to Near-infrared Region: Black Phosphorus/Graphitic Carbon Nitride. J. Am. Chem. Soc. 2017, 139, 13234–13242. [Google Scholar] [CrossRef]

- Hao, R.R.; Wang, G.H.; Tang, H.; Sun, L.L.; Xu, C.; Han, D.Y. Template-free Preparation of Macro/Mesoporous g-C3N4/TiO2 Heterojunction Photocatalysts with Enhanced Visible Light Photocatalytic Activity. Appl. Catal. B Environ. 2016, 187, 47–58. [Google Scholar] [CrossRef]

- Tao, R.; Li, X.H.; Li, X.W.; Shao, C.L.; Liu, Y.C. TiO2/SrTiO3/g-C3N4 Ternary Heterojunction Nanofibers: Gradient Energy Band, Cascade Charge Transfer, Enhanced Photocatalytic Hydrogen Evolution, and Nitrogen Fixation. Nanoscale 2020, 12, 8320–8329. [Google Scholar] [CrossRef]

- Wang, C.J.; Zhao, Y.L.; Xu, H.; Li, Y.F.; Wei, Y.C.; Liu, J.; Zhao, Z. Efficient Z-scheme Photocatalysts of Ultrathin g-C3N4-wrapped Au/TiO2-Nanocrystals for Enhanced Visible-Light-Driven Conversion of CO2 with H2O. Appl. Catal. B Environ. 2020, 263, 13. [Google Scholar] [CrossRef]

- Fu, J.W.; Yu, J.G.; Jiang, C.J.; Cheng, B. g-C3N4-based Heterostructured Photocatalysts. Adv. Energy Mater. 2018, 8, 31. [Google Scholar] [CrossRef]

- Kumar, S.; Karthikeyan, S.; Lee, A.F. g-C3N4-based Nanomaterials for Visible Light-Driven Photocatalysis. Catalysts 2018, 8, 47. [Google Scholar] [CrossRef]

- Ong, W.J.; Tan, L.L.; Ng, Y.H.; Yong, S.T.; Chai, S.P. Graphitic carbon nitride (g-C3N4)-based Photocatalysts for Artificial Photosynthesis and Environmental Remediation: Are We A Step Closer to Achieving Sustainability? Chem. Rev. 2016, 116, 7159–7329. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wang, Z.P.; Zhu, Y.F. Enhanced Visible-Light-Driven Photocatalytic Disinfection Performance and Organic Pollutant Degradation Activity of Porous g-C3N4 Nanosheets. ACS Appl. Mater. Interfaces 2017, 9, 27727–27735. [Google Scholar] [CrossRef]

- Ong, W.J. 2D/2D Graphitic Carbon Nitride (g-C3N4) Heterojunction Nanocomposites for Photocatalysis: Why Does Face-to-Face Interface Matter? Front. Mater. 2017, 4, 10. [Google Scholar] [CrossRef]

- Mun, S.J.; Park, S.J. Graphitic Carbon Nitride Materials for Photocatalytic Hydrogen Production via Water Splitting: A Short Review. Catalysts 2019, 9, 17. [Google Scholar] [CrossRef]

- Naseri, A.; Samadi, M.; Pourjavadi, A.; Moshfegh, A.Z.; Ramakrishna, S. Graphitic carbon nitride (g-C3N4)-based Photocatalysts for Solar Hydrogen Generation: Recent Advances and Future Development Directions. J. Mater. Chem. A 2017, 5, 23406–23433. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, M.; Cheng, B.; Shao, Y. Recent Advances in g-C3N4-based Heterojunction Photocatalysts. J. Mater. Sci. Technol. 2020, 56, 1–17. [Google Scholar] [CrossRef]

- Zhu, Z.D.; Murugananthan, M.; Gu, J.; Zhang, Y.R. Fabrication of a Z-scheme g-C3N4/Fe-TiO2 Photocatalytic Composite with Enhanced Photocatalytic Activity under Visible Light Irradiation. Catalysts 2018, 8, 16. [Google Scholar] [CrossRef]

- Ji, C.; Du, C.; Steinkruger, J.D.; Zhou, C.; Yang, S.Y. In-situ Hydrothermal Fabrication of CdS/g-C3N4 Nanocomposites for Enhanced Photocatalytic Water Splitting. Mater. Lett. 2019, 240, 128–131. [Google Scholar] [CrossRef]

- Liu, X.M.; Liu, Y.; Zhang, W.K.; Zhong, Q.Y.; Ma, X.Y. In Situ Self-assembly of 3d Hierarchical 2D/2D CdS/g-C3N4 Hereojunction with Excellent Photocatalytic Performance. Mater. Sci. Semicond. Process 2020, 105, 9. [Google Scholar] [CrossRef]

- Lin, B.; Li, H.; An, H.; Hao, W.B.; Wei, J.J.; Dai, Y.Z.; Ma, C.S.; Yang, G.D. Preparation of 2D/2D g-C3N4 Nanosheet@ZnIn2S4 Nanoleaf Heterojunctions with Well-designed High-speed Charge Transfer Nanochannels towards High Efficiency Photocatalytic Hydrogen Evolution. Appl. Catal. B Environ. 2018, 220, 542–552. [Google Scholar] [CrossRef]

- Cui, Y.Q.; Zhang, X.Y.; Zhang, H.X.; Cheng, Q.F.; Cheng, X.W. Construction of BiOCOOH/g-C3N4 Composite Photocatalyst and Its Enhanced Visible Light Photocatalytic Degradation of Amido Black 10b. Sep. Purif. Technol. 2019, 210, 125–134. [Google Scholar] [CrossRef]

- Qin, H.; Guo, R.T.; Liu, X.Y.; Pan, W.G.; Wang, Z.Y.; Shi, X.; Tang, J.Y.; Huang, C.Y. Z-scheme MoS2/g-C3N4 Heterojunction for Efficient Visible Light Photocatalytic CO2 Reduction. Dalton Trans. 2018, 47, 15155–15163. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.W.; Fujitsuka, M.; Kim, S.; Majima, T. Faster Electron Injection and More Active Sites for Efficient Photocatalytic H2 Evolution in g-C3N4/MoS2 Hybrid. Small 2018, 14, 9. [Google Scholar] [CrossRef] [PubMed]

- Kumaresan, N.; Sinthiya, M.M.A.; Sarathbavan, M.; Ramamurthi, K.; Sethuraman, K.; Babu, R.R. Synergetic Effect of g-C3N4/ZnO Binary Nanocomposites Heterojunction on Improving Charge Carrier Separation through 2D/1D Nanostructures for Effective Photocatalytic Activity under The Sunlight Irradiation. Sep. Purif. Technol. 2020, 244, 116356. [Google Scholar] [CrossRef]

- Ji, H.; Du, P.; Zhao, D.; Li, S.; Sun, F.; Duin, E.C.; Liu, W. 2D/1D Graphitic Carbon Nitride/Titanate Nanotubes Heterostructure for Efficient Photocatalysis of Sulfamethazine under Solar Light: Catalytic “Hot Spots” at the Rutile–Anatase–Titanate Interfaces. Appl. Catal. B Environ. 2020, 263, 118357. [Google Scholar] [CrossRef]

- Tan, Y.G.; Shu, Z.; Zhou, J.; Li, T.T.; Wang, W.B.; Zhao, Z.L. One-step Synthesis of Nanostructured g-C3N4/TiO2 Composite for Highly Enhanced Visible-Light Photocatalytic H2 Evolution. Appl. Catal. B Environ. 2018, 230, 260–268. [Google Scholar] [CrossRef]

- Ohsaka, T.; Izumi, F.; Fujiki, Y. Raman spectrum of anatase TiO2. J. Raman Spectrosc. 1978, 7, 321–324. [Google Scholar] [CrossRef]

- Martin, D.J.; Qiu, K.; Shevlin, S.A.; Handoko, A.D.; Chen, X.; Guo, Z.; Tang, J. Highly Efficient Photocatalytic H2 Evolution from Water Using Visible Light and Structure-Controlled Graphitic Carbon Nitride. Angew. Chem. Int. Ed. 2014, 53, 9240–9245. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Zhao, J.; Guo, L.; Osterloh, F.E. Structure Defects in g-C3N4 Limit Visible Light Driven Hydrogen Evolution and Photovoltage. J. Mater. Chem. A 2014, 2, 20338–20344. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Z.-G.; He, H.-W.; Wang, X.-X.; Zhang, J.; Zhang, Q.-Q.; Tong, Y.-F.; Liu, H.-L.; Ramakrishna, S.; Yan, S.-Y.; et al. One-step Synthesis Heterostructured g-C3N4/TiO2 Composite for Rapid Degradation of Pollutants in Utilizing Visible Light. Nanomaterials 2018, 8, 842. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.-C.; Wu, P.-Y.; Lin, T.-H.; Lin, T.-F. Photocatalytic Performance of Cu-doped TiO2 Nanofibers Treated by The Hydrothermal Synthesis and Air-thermal Treatment. Appl. Surf. Sci. 2018, 430, 390–398. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).