Dilute Alloy Catalysts for the Synthesis of Isobutanol via the Guerbet Route: A Comprehensive Study

Abstract

1. Introduction

2. Results

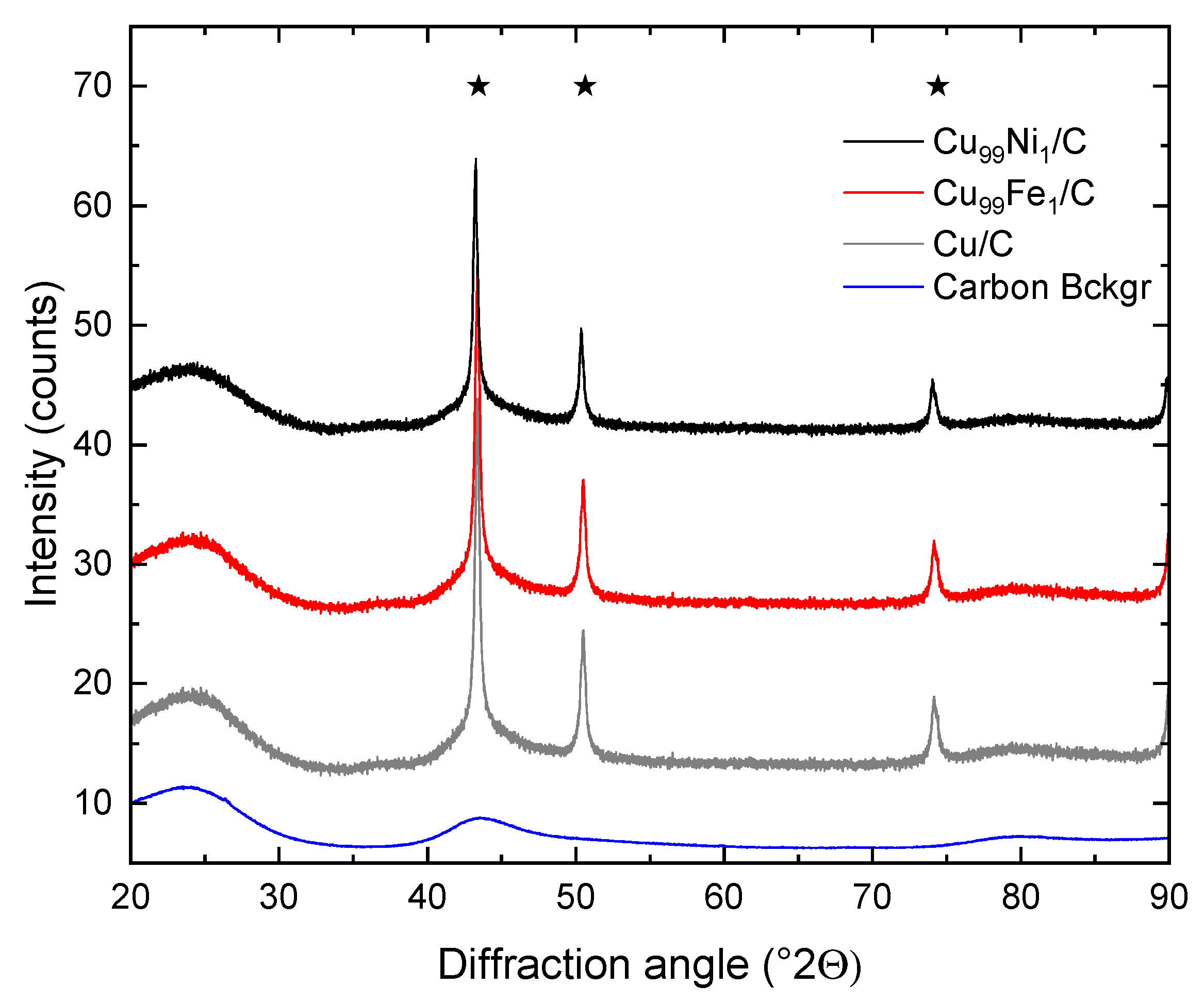

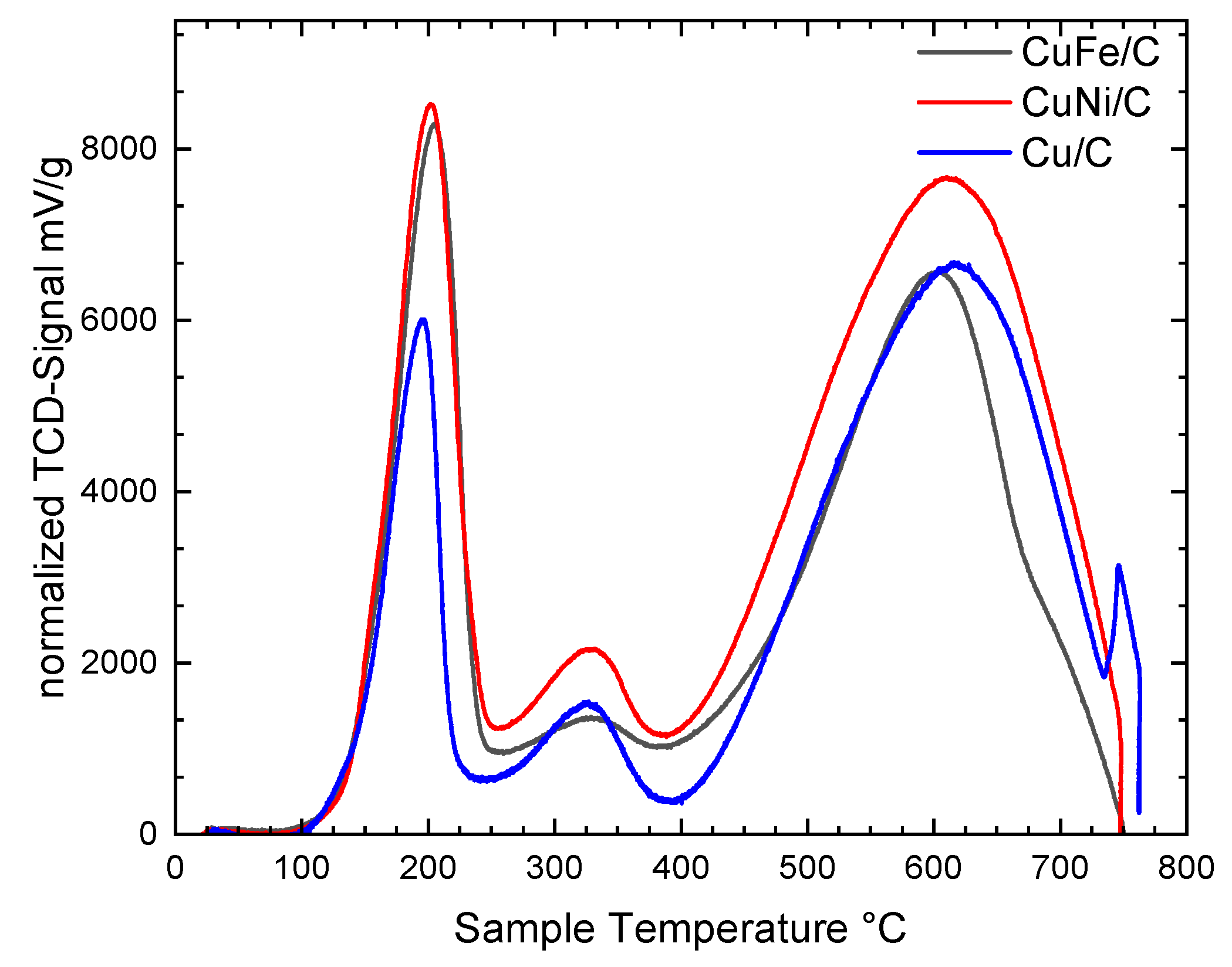

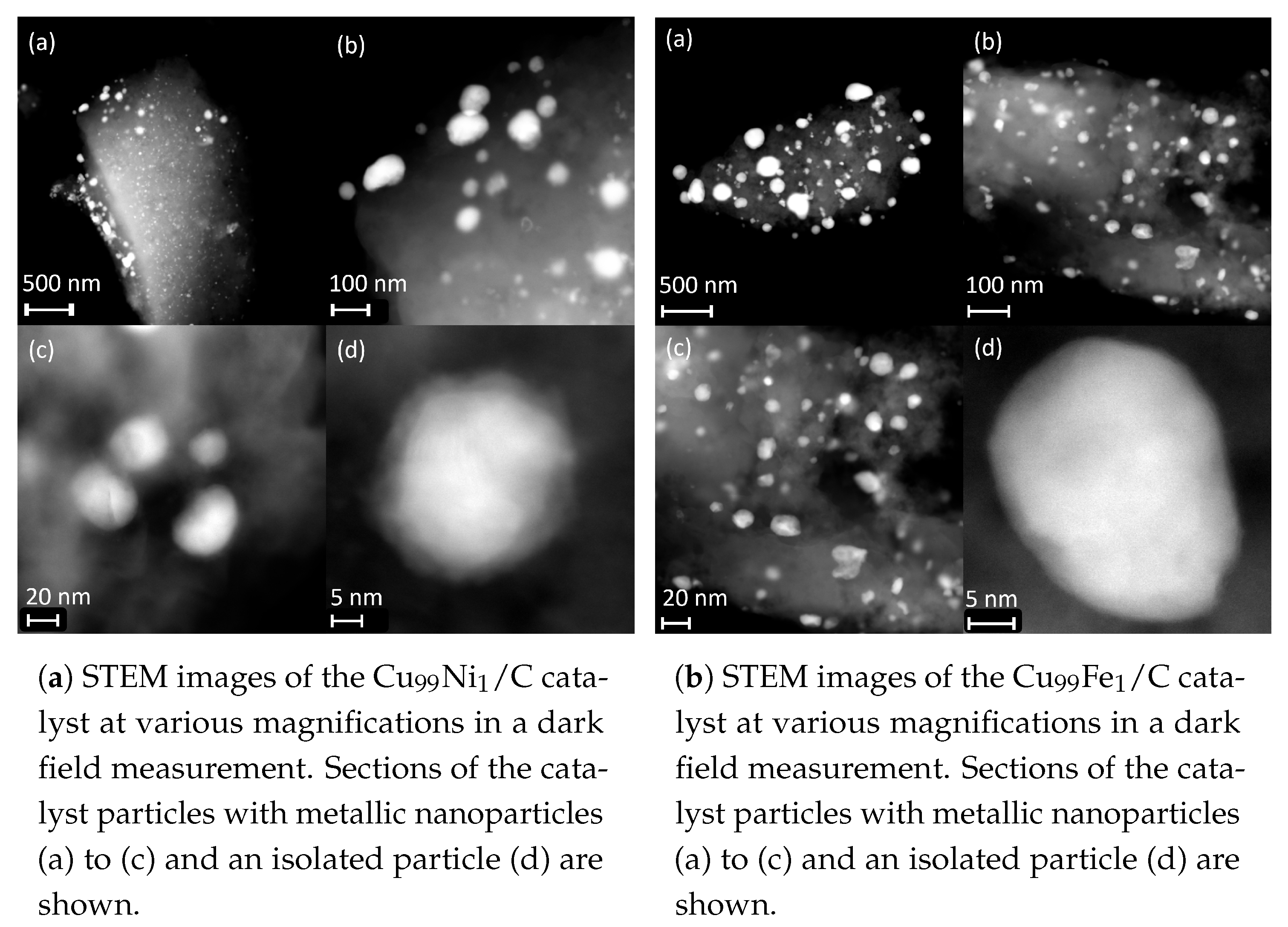

2.1. Characterization of Cu-Based Catalysts

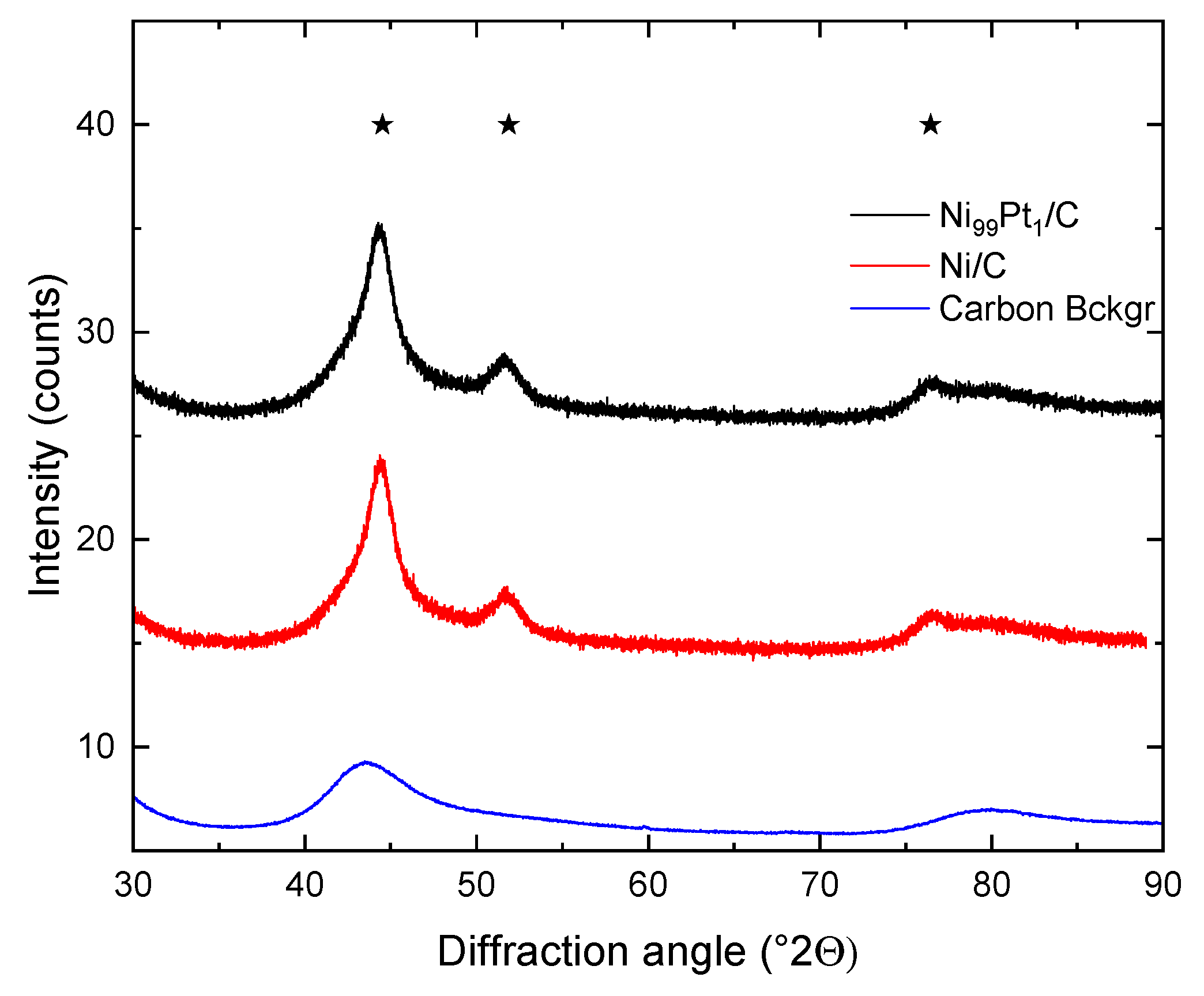

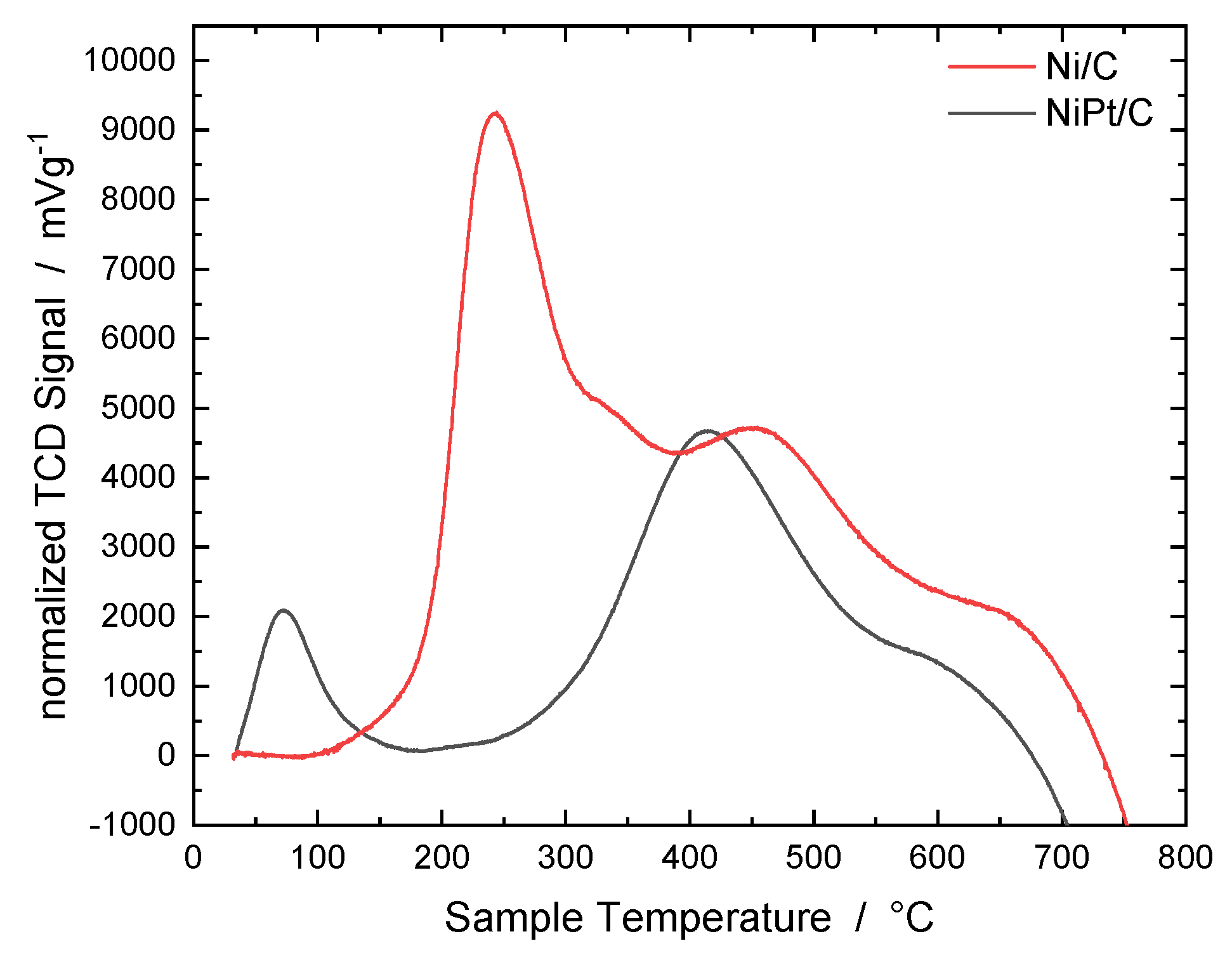

2.2. Characterization of the Ni Catalyst

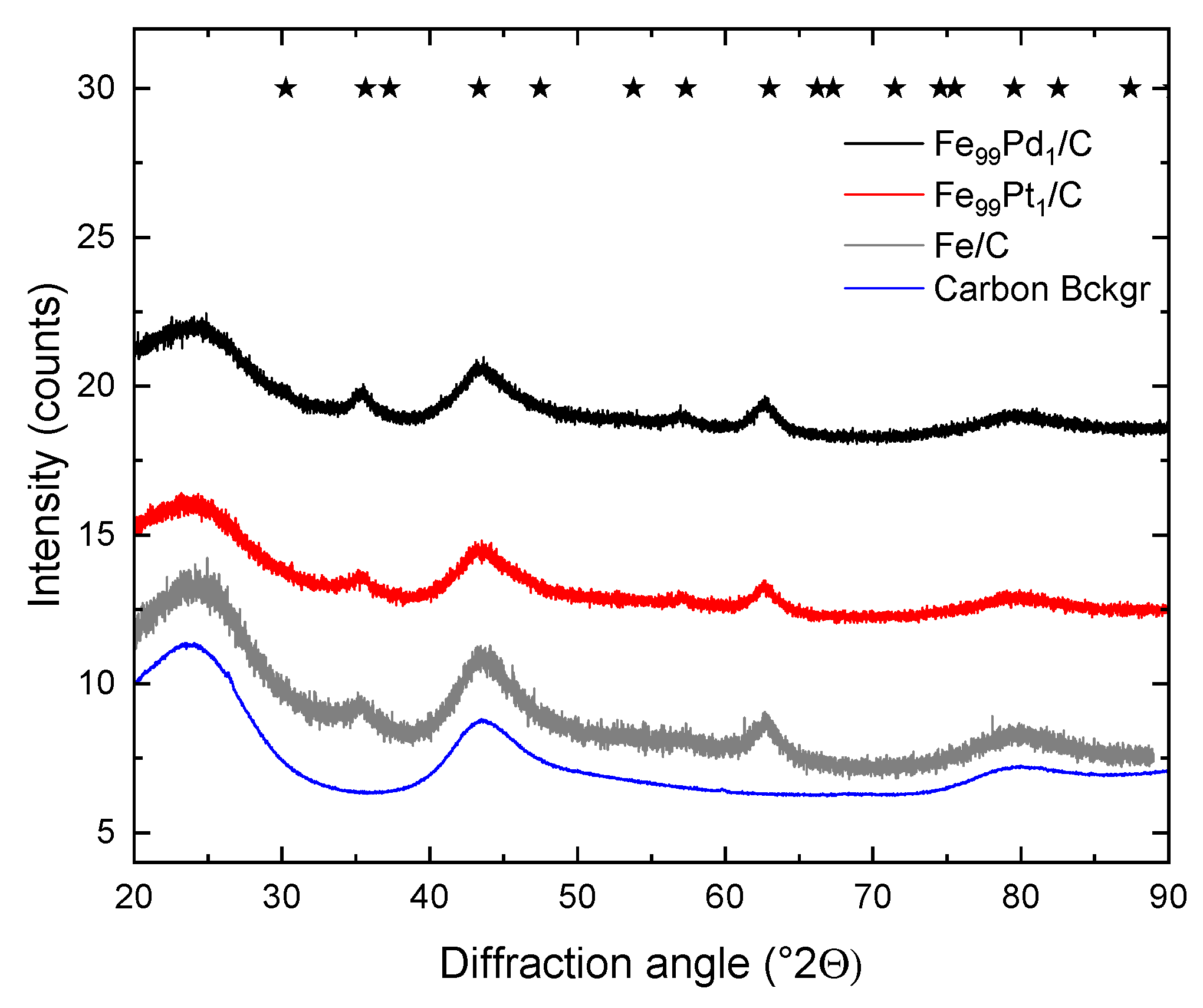

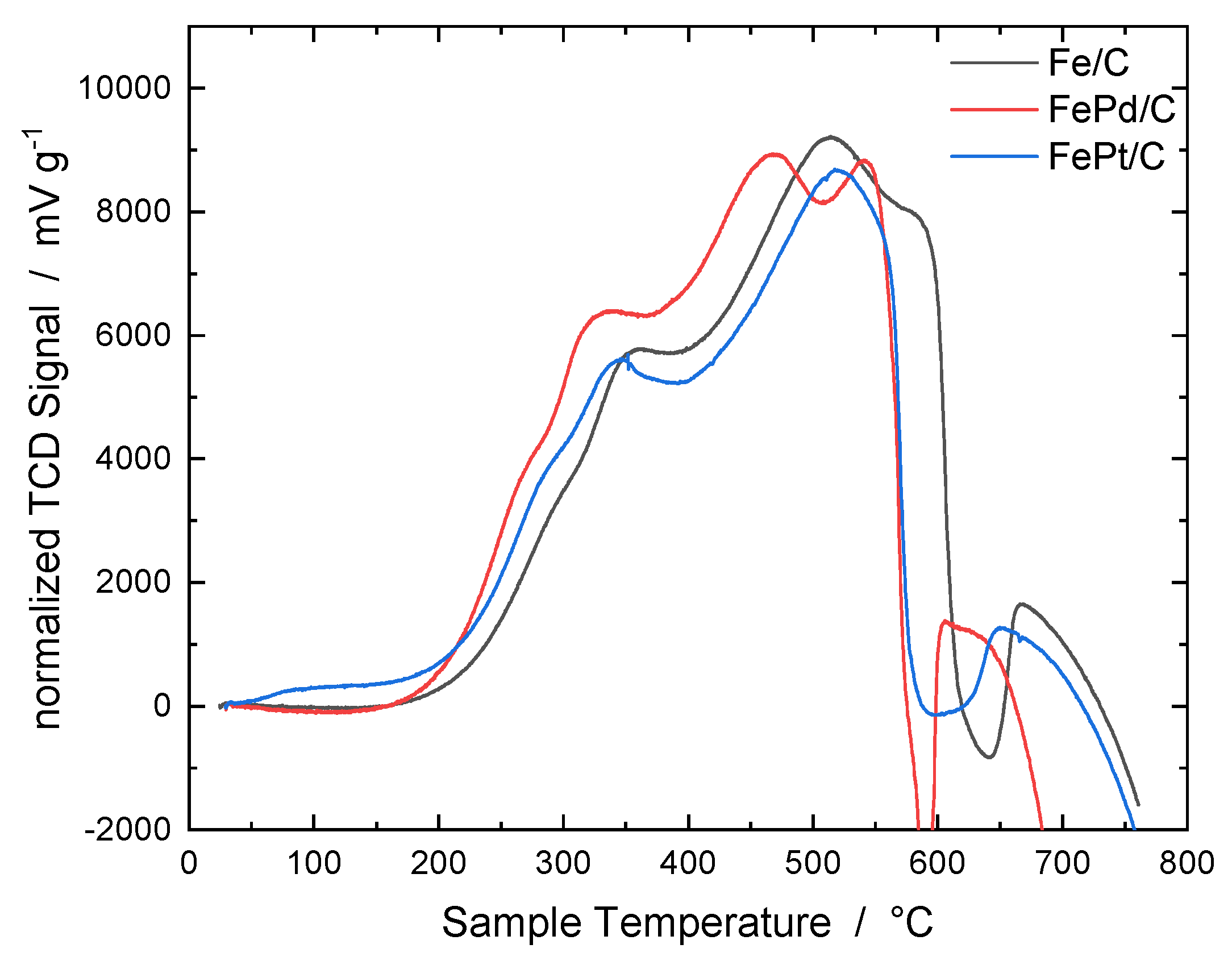

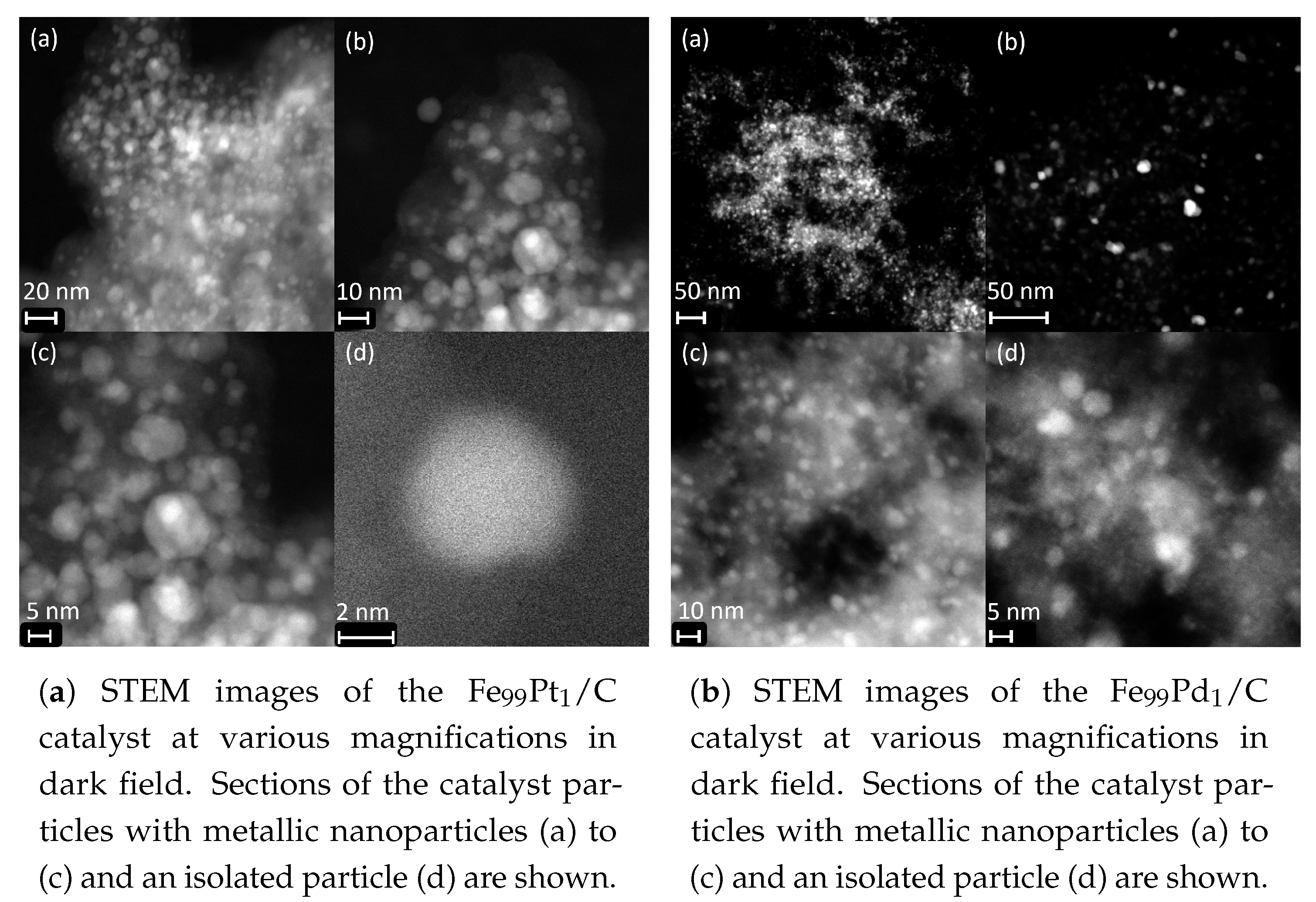

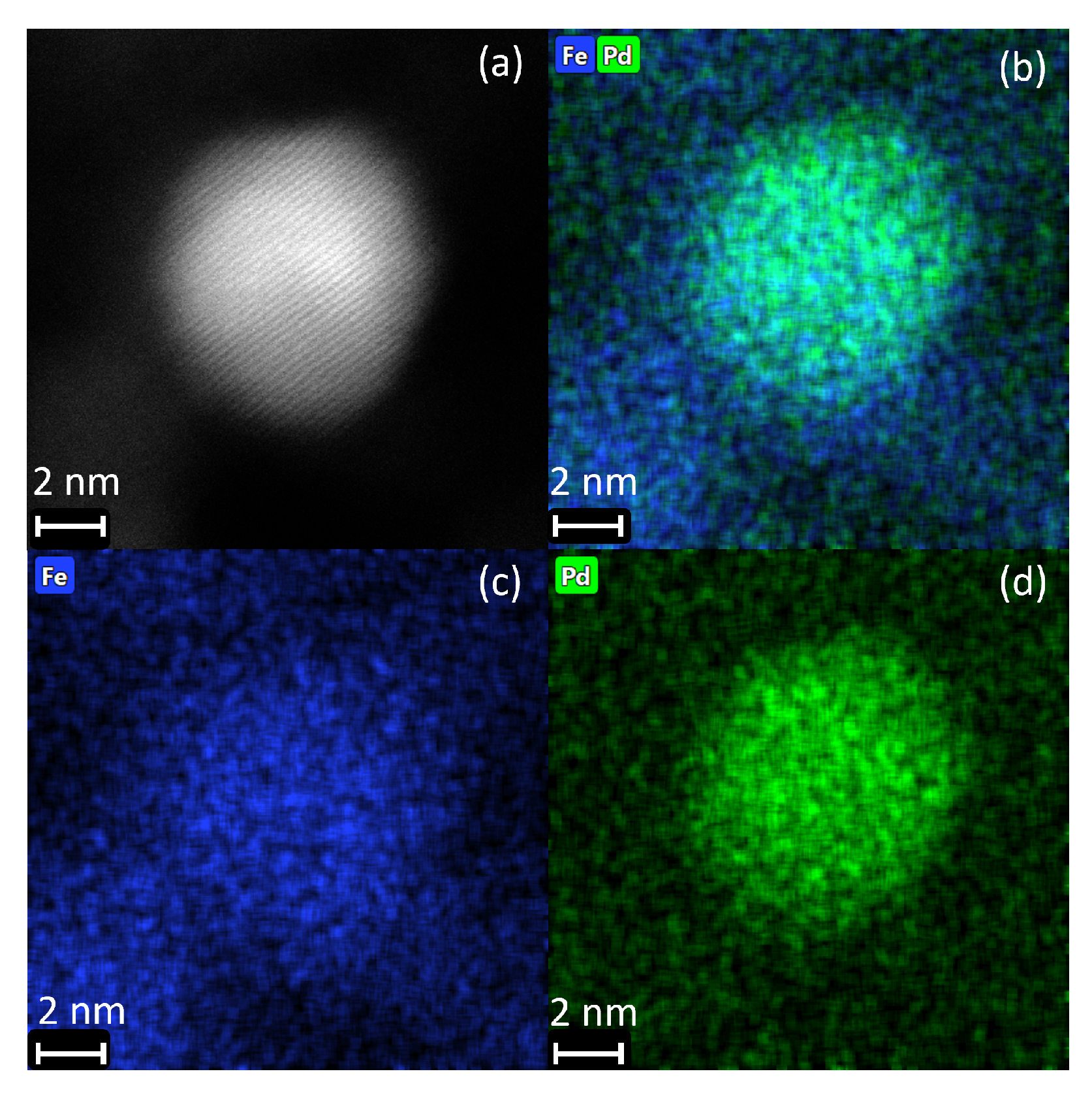

2.3. Characterization of the Fe Catalysts

2.4. Catalytic Experiments

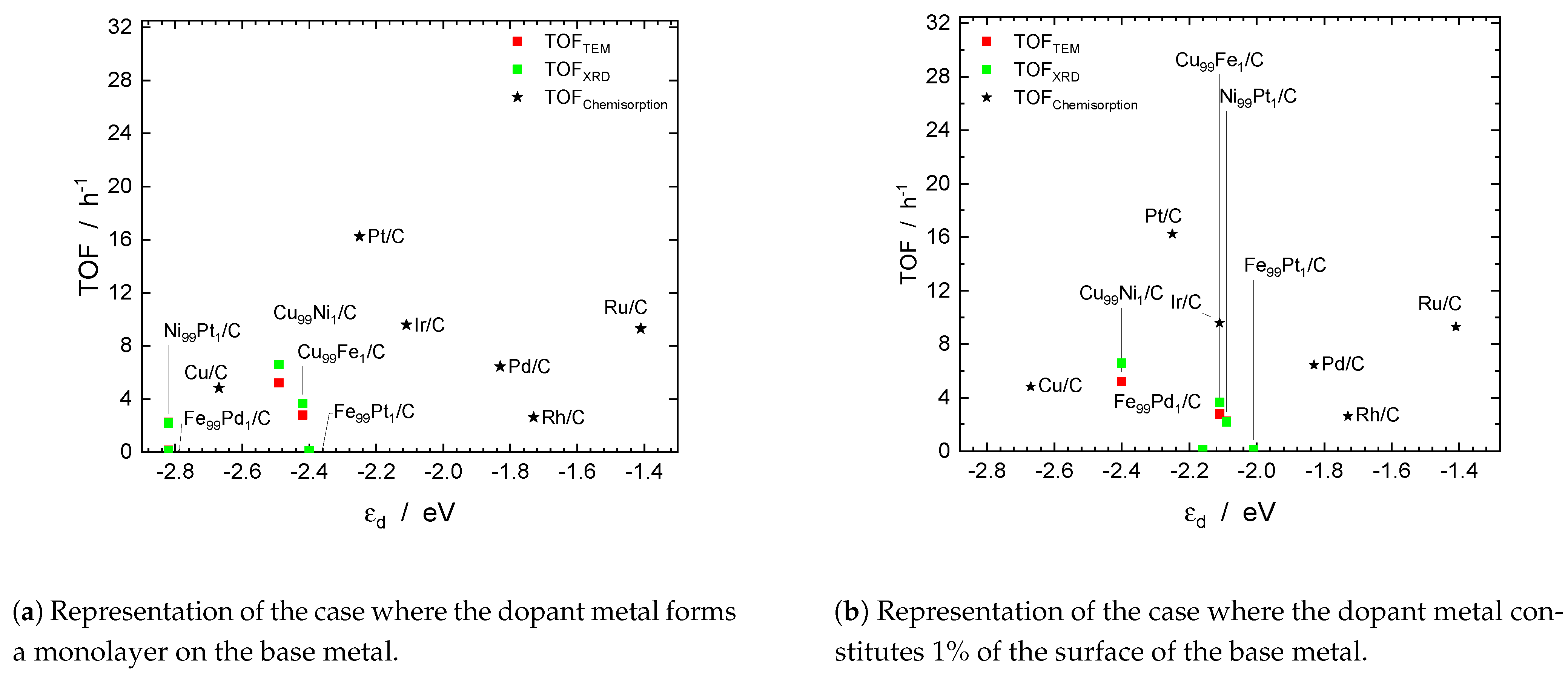

3. Discussion

4. Materials and Methods

4.1. Catalyst Synthesis

4.2. TEM

4.3. XRD

4.4. ICP–OES

4.5. Determination of the BET Surface Area

4.6. Temperature-Programmed Reduction

4.7. Calculation of Turnover Frequencies

5. Summary

6. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhong, W.; Liu, Y.; Zhang, D. Theoretical Study of Methanol Oxidation on the PtAu(111) Bimetallic Surface: CO Pathway vs. Non-Co Pathway. J. Phys. Chem. 2012, 116, 2994–3000. [Google Scholar] [CrossRef]

- Nguyen, L.; Zhang, S.; Wang, L.; Li, Y.; Yoshida, H.; Patlolla, A.; Takeda, S.; Frenkel, A.I.; Tao, F.F. Reduction of Nitric Oxide With Hydrogen on Catalysts of Singly Dispersed Bimetallic Sites Pt1Com and Pd1Con. ACS Catal. 2016, 6, 840–850. [Google Scholar] [CrossRef]

- Ouyang, M.; Papanikolaou, K.G.; Boubnov, A.; Hoffman, A.S.; Giannakakis, G.; Bare, S.R.; Stamatakis, M.; Flytzani-Stephanopoulos, M.; H. Sykes, E.C. Directing Reaction Pathways via in Situ Control of Active Site Geometries in PdAu Single-Atom Alloy Catalysts. Nat. Commun. 2021, 12, 1549. [Google Scholar] [CrossRef]

- Li, L.; Lu, Z.; Ould-Chikh, S.; Anjum, D.H.; Kanoun, M.B.; Scaranto, J.; Hedhili, M.N.; Khalid, S.; Laveille, P.; D’Souza, L.; et al. Controlled Surface Segregation Leads to Efficient Coke-Resistant Nickel/Platinum Bimetallic Catalysts for the Dry Reforming of Methane. Chemcatchem 2015, 7, 819–829. [Google Scholar] [CrossRef]

- Mankad, N.P. Selectivity Effects in Bimetallic Catalysis. Chem. Eur. J. 2016, 22, 5822–5829. [Google Scholar] [CrossRef]

- Fu, Q.; Meng, Y.; Fang, Z.; Hu, Q.; Xu, L.; Gao, W.; Huang, X.C.; Xue, Q.; Sun, Y.P.; Lu, F. Boron Nitride Nanosheet-Anchored Pd–Fe Core–Shell Nanoparticles as Highly Efficient Catalysts for Suzuki–Miyaura Coupling Reactions. ACS Appl. Mater. Interfaces 2017, 9, 2469–2476. [Google Scholar] [CrossRef]

- Yu, H.; Tang, W.; Li, K.; Yin, H.; Zhou, S. Enhanced Catalytic Performance for Hydrogenation of Substituted Nitroaromatics Over Ir-Based Bimetallic Nanocatalysts. ACS Appl. Mater. Interfaces 2019, 11, 6958–6969. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, B.; Saleem, M.; Arshad, S.; Rashid, J.; Hussain, N.; Zaheer, M. One-Pot Synthesis of Heterobimetallic Metal–Organic Frameworks (MOFs) for Multifunctional Catalysis. Chem. Eur. J. 2019, 25, 10490–10498. [Google Scholar] [CrossRef] [PubMed]

- Sonal; Pant, K.K.; Upadhyayula, S. Efficient Utilization of Bimetallic Catalyst in Low H2/CO Environment Syngas for Liquid Fuel Production. J. Chem. Sci. 2017, 129, 1747–1754. [Google Scholar] [CrossRef]

- Cai, Z.; Yamada, I.; Yagi, S. ZIF-Derived Co9–xNixS8 Nanoparticles Immobilized on N-Doped Carbons as Efficient Catalysts for High-Performance Zinc–Air Batteries. ACS Appl. Mater. Interfaces 2020, 12, 5847–5856. [Google Scholar] [CrossRef] [PubMed]

- Hammer, B.; Nørskov, J.K. Electronic factors determining the reactivity of metal surfaces. Surf. Sci. 1995, 343, 211–220. [Google Scholar] [CrossRef]

- Häusler, J.; Pasel, J.; Woltmann, F.; Everwand, A.; Meledina, M.; Valencia, H.; Lipinska-Chwalek, M.; Mayer, J.; Peters, R. Elucidating the Influence of the D-Band Center on the Synthesis of Isobutanol. Catalysts 2021, 11, 406. [Google Scholar] [CrossRef]

- Wu, J.; Yang, H. Platinum-Based Oxygen Reduction Electrocatalysts. Accounts Chem. Res. 2013, 46, 1848–1857. [Google Scholar] [CrossRef]

- Wu, X.; Sun, Y.; Zeng, Y.; Li, X. Mechanistic Insights Into Oxazolone Synthesis by Bimetallic Au–Pd-Catalyzed Catalysis and Catalyst Design: DFT Investigations. J. Org. Chem. 2023, 88, 10693–10700. [Google Scholar] [CrossRef] [PubMed]

- Han, B.; Feng, X.; Ling, L.; Fan, M.; Liu, P.; Zhang, R.; Wang, Q. CO Oxidative Coupling to Dimethyl Oxalate Over Pd–Me (Me = Cu, Al) Catalysts: A Combined DFT and Kinetic Study. Phys. Chem. Chem. Phys. 2018, 20, 7317–7332. [Google Scholar] [CrossRef] [PubMed]

- Kitchin, J.R.; Nørskov, J.K.; Barteau, M.A.; Chen, J.G. Modification of the Surface Electronic and Chemical Properties of Pt(111) by Subsurface 3d Transition Metals. J. Chem. Phys. 2004, 120, 10240–10246. [Google Scholar] [CrossRef]

- Ahsan, A.; Puente Santiago, A.R.; Hong, Y.; Zhang, N.; Cano, M.; Rodriguez-Castellón, E.; Echegoyen, L.; Sreeprasad, T.S.; Noveron, J.C. Tuning of Trifunctional NiCu Bimetallic Nanoparticles Confined in a Porous Carbon Network with Surface Composition and Local Structural Distortions for the Electrocatalytic Oxygen Reduction, Oxygen and Hydrogen Evolution Reactions. J. Am. Chem. Soc. 2020, 142, 14688–14701. [Google Scholar] [CrossRef]

- Gao, Y.; Huo, X.; Li, T.; Jiang, R.; Zhu, Q.; Ren, H. Mechanisms and Energetics of Complete Ethylene Oxidation on a PdAu Bimetallic Catalyst From a Theoretical Perspective. J. Phys. Chem. 2022, 126, 9361–9370. [Google Scholar] [CrossRef]

- Gorzkowski, M.T.; Lewera, A. Probing the Limits of d-Band Center Theory: Electronic and Electrocatalytic Properties of Pd-Shell–Pt-Core Nanoparticles. J. Phys. Chem. 2015, 119, 18389–18395. [Google Scholar] [CrossRef]

- Hofmann, T.; Yu, T.H.; Folse, M.; Weinhardt, L.; Bär, M.; Zhang, Y.; Merinov, B.V.; Myers, D.J.; Goddard, W.A.; Heske, C. Using Photoelectron Spectroscopy and Quantum Mechanics to Determine d-Band Energies of Metals for Catalytic Applications. J. Phys. Chem. 2012, 116, 24016–24026. [Google Scholar] [CrossRef]

- Nikolla, E.; Schwank, J.W.; Linic, S. Measuring and Relating the Electronic Structures of Nonmodel Supported Catalytic Materials to Their Performance. J. Am. Chem. Soc. 2009, 131, 2747–2754. [Google Scholar] [CrossRef]

- Ruban, A.; Hammer, B.; Stoltze, P.; Skriver, H.; Nørskov, J. Surface electronic structure and reactivity of transition and noble metals: Communication presented at the First Francqui Colloquium, Brussels, 19–20 February 1996. J. Mol. Catal. Chem. 1997, 115, 421–429. [Google Scholar] [CrossRef]

- Tupy, S.A.; Karim, A.M.; Bagia, C.; Deng, W.; Huang, Y.; Vlachos, D.G.; Chen, J.G. Correlating Ethylene Glycol Reforming Activity with In Situ EXAFS Detection of Ni Segregation in Supported NiPt Bimetallic Catalysts. ACS Catal. 2012, 2, 2290–2296. [Google Scholar] [CrossRef]

- Li, L.; Zhao, G.; Lv, Z.; An, P.; Ao, J.; Song, M.; Zhao, J.; Liu, G. Optimizing Coordination Environment in Bimetallic Nipt Catalysts Boosts N-Dodecane Steam Reforming. Chem. Eng. J. 2023, 474, 145647. [Google Scholar] [CrossRef]

- Qiu, Y.P.; Shi, Q.; Zhou, L.L.; Chen, M.H.; Chen, C.; Tang, P.P.; Walker, G.S.; Wang, P. NiPt Nanoparticles Anchored onto Hierarchical Nanoporous N-Doped Carbon as an Efficient Catalyst for Hydrogen Generation from Hydrazine Monohydrate. ACS Appl. Mater. Interfaces 2020, 12, 18617–18624. [Google Scholar] [CrossRef]

- Zhong, Y.J.; Dai, H.B.; Zhu, M.; Wang, P. Catalytic decomposition of hydrous hydrazine over NiPt/La2O3 catalyst: A high-performance hydrogen storage system. Int. J. Hydrogen Energy 2016, 41, 11042–11049. [Google Scholar] [CrossRef]

- Kumar, A.; Ashok, A.; Bhosale, R.R.; Saleh, M.A.H.; Almomani, F.A.; Al-Marri, M.; Khader, M.M.; Tarlochan, F. In situ DRIFTS Studies on Cu, Ni and CuNi catalysts for Ethanol Decomposition Reaction. Catal. Lett. 2016, 146, 778–787. [Google Scholar] [CrossRef]

- Fang, W.; Liu, S.; Steffensen, A.K.; Schill, L.; Kastlunger, G.; Riisager, A. On the Role of Cu+ and CuNi Alloy Phases in Mesoporous CuNi Catalyst for Furfural Hydrogenation. ACS Catal. 2023, 13, 8437–8444. [Google Scholar] [CrossRef]

- Khort, A.; Romanovski, V.; Leybo, D.; Moskovskikh, D. CO oxidation and organic dyes degradation over graphene-Cu and graphene-CuNi catalysts obtained by solution combustion synthesis. Sci. Rep. 2020, 10, 16104. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Ding, J.; Chen, X.; Wang, Y.; Song, X.; Zhang, S. A 3D-printed CuNi alloy catalyst with a triply periodic minimal surface for the reverse water-gas shift reaction. J. Mater. Chem. 2023, 12, 314–320. [Google Scholar] [CrossRef]

- Xiao, K.; Qi, X.; Bao, Z.; Wang, X.; Zhong, L.; Fang, K.; Lin, M.; Sun, Y. CuFe, CuCo and CuNi nanoparticles as catalysts for higher alcohol synthesis from syngas: A comparative study. Catal. Sci. Technol. 2013, 3, 1591. [Google Scholar] [CrossRef]

- Wang, D.Y.; Chen, C.H.; Yen, H.C.; Lin, Y.L.; Huang, P.Y.; Hwang, B.J.; Chen, C.C. Chemical transformation from FePt to Fe1−xPtMx (M = Ru, Ni, Sn) nanocrystals by a cation redox reaction: X-ray absorption spectroscopic studies. J. Am. Chem. Soc. 2007, 129, 1538–1540. [Google Scholar] [CrossRef] [PubMed]

- Gupta, G.; Patel, M.N.; Ferrer, D.; Heitsch, A.T.; Korgel, B.A.; Jose-Yacaman, M.; Johnston, K.P. Stable Ordered FePt Mesoporous Silica Catalysts with High Loadings. Chem. Mater. 2008, 20, 5005–5015. [Google Scholar] [CrossRef]

- Marchenko, N.; Lacroix, L.M.; Ratel-Ramond, N.; Leitner, W.; Bordet, A.; Tricard, S. Bimetallic FexPt100–x Nanoparticles Immobilized on Supported Ionic Liquid Phases as Hydrogenation and Hydrodeoxygenation Catalysts: Influence of the Metal Content on Activity and Selectivity. ACS Appl. Nano Mater. 2023, 6, 20231–20239. [Google Scholar] [CrossRef]

- Metin, Ö.; Mendoza-Garcia, A.; Dalmızrak, D.; Gültekin, M.S.; Sun, S. FePd alloy nanoparticles assembled on reduced graphene oxide as a catalyst for selective transfer hydrogenation of nitroarenes to anilines using ammonia borane as a hydrogen source. Catal. Sci. Technol. 2016, 6, 6137–6143. [Google Scholar] [CrossRef]

- Wang, Y.; He, Q.; Guo, J.; Wang, J.; Luo, Z.; Shen, T.D.; Ding, K.; Khasanov, A.; Wei, S.; Guo, Z. Ultrafine FePd Nanoalloys Decorated Multiwalled Cabon Nanotubes toward Enhanced Ethanol Oxidation Reaction. ACS Appl. Mater. Interfaces 2015, 7, 23920–23931. [Google Scholar] [CrossRef]

- Shkvarina, E.G.; Titov, A.A.; Shkvarin, A.S.; Plaisier, J.R.; Gigli, L.; Titov, A.N. Thermal stability of the layered modification of Cu0.5ZrTe2 in the temperature range 25–900 °C. Acta Crystallogr. Sect. Struct. Chem. 2018, 74, 1020–1025. [Google Scholar] [CrossRef]

- Lihl, F.; Ebel, H.; Baumgartner, W. Röntgenographische Untersuchungen zur Vegardschen Regel/X-Ray Investigations Concerning Vegard’s Law. Int. J. Mater. Res. 1971, 62, 42–45. [Google Scholar] [CrossRef]

- Ng, S.C.; Brockhouse, B.N.; Hallman, E.D. Characterization of large alloy single crystals by neutron diffraction. Mater. Res. Bull. 1967, 2, 69–73. [Google Scholar] [CrossRef]

- Otte, H.M. Lattice Parameter Determinations with an X–Ray Spectrogoniometer by the Debye–Scherrer Method and the Effect of Specimen Condition. J. Appl. Phys. 1961, 32, 1536–1546. [Google Scholar] [CrossRef]

- Janvelyan, N.; van Spronsen, M.A.; Wu, C.H.; Qi, Z.; Montemore, M.M.; Shan, J.; Zakharov, D.N.; Xu, F.; Boscoboinik, J.A.; Salmeron, M.B.; et al. Stabilization of a nanoporous NiCu dilute alloy catalyst for non-oxidative ethanol dehydrogenation. Catal. Sci. Technol. 2020, 10, 5207–5217. [Google Scholar] [CrossRef]

- Dandekar, A.; Baker, R.; Vannice, M.A. Characterization of activated carbon, graphitized carbon fibers and synthetic diamond powder using TPD and DRIFTS. Carbon 1998, 36, 1821–1831. [Google Scholar] [CrossRef]

- Kim, J.Y.; Rodriguez, J.A.; Hanson, J.C.; Frenkel, A.I.; Lee, P.L. Reduction of CuO and Cu2O with H2: H embedding and kinetic effects in the formation of suboxides. J. Am. Chem. Soc. 2003, 125, 10684–10692. [Google Scholar] [CrossRef] [PubMed]

- Choukroun, D.; Daems, N.; Kenis, T.; van Everbroeck, T.; Hereijgers, J.; Altantzis, T.; Bals, S.; Cool, P.; Breugelmans, T. Bifunctional Nickel–Nitrogen-Doped-Carbon-Supported Copper Electrocatalyst for CO2 Reduction. J. Phys. Chem. 2020, 124, 1369–1381. [Google Scholar] [CrossRef]

- Popov, A.A.; Varygin, A.D.; Plyusnin, P.E.; Sharafutdinov, M.R.; Korenev, S.V.; Serkova, A.N.; Shubin, Y.V. X-ray diffraction reinvestigation of the Ni-Pt phase diagram. J. Alloys Compd. 2022, 891, 161974. [Google Scholar] [CrossRef]

- Taniguchi, K.; Shinoda, K.; Cuya Huaman, J.L.; Yokoyama, S.; Uchikoshi, M.; Matsumoto, T.; Suzuki, K.; Miyamura, H.; Jeyadevan, B. Designed synthesis of highly catalytic Ni–Pt nanoparticles for fuel cell applications. SN Appl. Sci. 2019, 1, 124. [Google Scholar] [CrossRef]

- Guisbiers, G.; Mendoza-Pérez, R.; Bazán-Díaz, L.; Mendoza-Cruz, R.; Velázquez-Salazar, J.J.; José-Yacamán, M. Size and Shape Effects on the Phase Diagrams of Nickel-Based Bimetallic Nanoalloys. J. Phys. Chem. 2017, 121, 6930–6939. [Google Scholar] [CrossRef]

- Leteba, G.M.; Mitchell, D.R.G.; Levecque, P.B.J.; Macheli, L.; van Steen, E.; Lang, C.I. High-Index Core–Shell Ni–Pt Nanoparticles as Oxygen Reduction Electrocatalysts. ACS Appl. Nano Mater. 2020, 3, 5718–5731. [Google Scholar] [CrossRef]

- Wang, G.; van Hove, M.A.; Ross, P.N.; Baskes, M.I. Monte Carlo simulations of segregation in Pt-Ni catalyst nanoparticles. J. Chem. Phys. 2005, 122, 024706. [Google Scholar] [CrossRef]

- Iizumi, M.; Koetzle, T.F.; Shirane, G.; Chikazumi, S.; Matsui, M.; Todo, S. Structure of magnetite (Fe3O4) below the Verwey transition temperature. Acta Crystallogr. Sect. Struct. Crystallogr. Cryst. Chem. 1982, 38, 2121–2133. [Google Scholar] [CrossRef]

- Zwell, L.; Speich, G.R.; Leslie, W.C. Effects of Co, Cr, Ir, Pt, Re, Rh, and Ru on the lattice parameter and density of alpha iron. Metall. Trans. 1973, 4, 1990–1992. [Google Scholar] [CrossRef]

- Jozwiak, W.K.; Kaczmarek, E.; Maniecki, T.P.; Ignaczak, W.; Maniukiewicz, W. Reduction behavior of iron oxides in hydrogen and carbon monoxide atmospheres. Appl. Catal. A Gen. 2007, 326, 17–27. [Google Scholar] [CrossRef]

- Hensley, A.J.R.; Hong, Y.; Zhang, R.; Zhang, H.; Sun, J.; Wang, Y.; McEwen, J.S. Enhanced Fe2O3 Reducibility via Surface Modification with Pd: Characterizing the Synergy within Pd/Fe Catalysts for Hydrodeoxygenation Reactions. ACS Catal. 2014, 4, 3381–3392. [Google Scholar] [CrossRef]

- Fröhlich, G.; Sachtler, W.M.H. Reduction enhancement of Fe2O3 in physical mixtures with Pt/mordenite via Pt migration or ‘hydrogen spillover’. J. Chem. Soc. Faraday Trans. 1998, 94, 1339–1346. [Google Scholar] [CrossRef]

- Buschow, K.; van Engen, P.G.; Jongebreur, R. Magneto-optical properties of metallic ferromagnetic materials. J. Magn. Magn. Mater. 1983, 38, 1–22. [Google Scholar] [CrossRef]

- Kovács, A.; Schierholz, R.; Tillmann, K. FEI Titan G2 80-200 CREWLEY. J. Large Scale Res. Facil. 2016, 2, A43. [Google Scholar] [CrossRef]

- Doebelin, N.; Kleeberg, R. Profex: A graphical user interface for the Rietveld refinement program BGMN. J. Appl. Crystallogr. 2015, 48, 1573–1580. [Google Scholar] [CrossRef]

- Pielsticker, L.; Zegkinoglou, I.; Divins, N.J.; Mistry, H.; Chen, Y.T.; Kostka, A.; Boscoboinik, J.A.; Cuenya, B.R. Segregation Phenomena in Size-Selected Bimetallic CuNi Nanoparticle Catalysts. J. Phys. Chem. B 2018, 122, 919–926. [Google Scholar] [CrossRef]

- Crespo, P.; Hernando, A.; Yavari, R.; Drbohlav, O.; García Escorial, A.; Barandiarán, J.M.; Orúe, I. Magnetic behavior of metastable fcc Fe-Cu after thermal treatments. Phys. Rev. Condens. Matter 1993, 48, 7134–7139. [Google Scholar] [CrossRef]

- Delage, S.; Legrand, B.; Soisson, F.; Saúl, A. Dissolution modes of Fe/Cu and Cu/Fe deposits. Phys. Rev. Condens. Matter 1998, 58, 15810–15820. [Google Scholar] [CrossRef]

- Dulot, F.; Kierren, B.; Malterre, D. Influence of the initial step density on the growth mechanisms of the Fe/Cu(100) interface. Surf. Sci. 2001, 494, 229–237. [Google Scholar] [CrossRef]

- Shim, Y.; Amar, J.G. Step instabilities in Fe/Cu(100) growth. Phys. Rev. Mater. 2017, 1, 043403. [Google Scholar] [CrossRef]

- Cardarelli, F. Materials Handbook: A Concise Desktop Reference, 3rd ed.; Springer eBook Collection; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Wiberg, E.; Wiberg, N.; Fischer, G. Lehrbuch der Anorganischen Chemie, 102., stark umgearbeitete und verbesserte auflage ed.; Walter de Gruyter: Berlin, Germany; New York, NY, USA, 2007. [Google Scholar]

- Jette, E.R.; Foote, F. Precision Determination of Lattice Constants. J. Chem. Phys. 1935, 3, 605–616. [Google Scholar] [CrossRef]

- Zenou, V.Y.; Fowler, D.E.; Gautier, R.; Barnett, S.A.; Poeppelmeier, K.R.; Marks, L.D. Redox and phase behavior of Pd-substituted (La,Sr)CrO3 perovskite solid oxide fuel cell anodes. Solid State Ionics 2016, 296, 90–105. [Google Scholar] [CrossRef]

- Hong, K.H.; McNally, G.M.; Coduri, M.; Attfield, J.P. Synthesis, Crystal Structure, and Magnetic Properties of MnFe3O5. Z. Anorg. Allg. Chem. 2016, 642, 1355–1358. [Google Scholar] [CrossRef]

- Didier, C.; Pang, W.K.; Guo, Z.; Schmid, S.; Peterson, V.K. Phase Evolution and Intermittent Disorder in Electrochemically Lithiated Graphite Determined Using in Operando Neutron Diffraction. Chem. Mater. 2020, 32, 2518–2531. [Google Scholar] [CrossRef]

| Material | Phase | (nm) | w(Phase) 1 % | d(Crystallite) (nm) |

|---|---|---|---|---|

| Cu/C | Cu | 0.36165 ± 0.00012 | 100 | 37.4 ± 1.9 |

| Cu99Ni/C | NiO | – | 2–6 | 42.44 ± 0.26 |

| Cu100Ni0 | 0.36157 ± 0.00029 | 94 ± 4 | 28.4 ± 2.6 | |

| Cu99Fe/C | Cu | 0.361570 ± 0.000014 | 100 | 34.6 ± 0.6 |

| Material | Peak | °C | H2 Consumption mmol/g | % | Cu mmol/g | Cu wt% | |

|---|---|---|---|---|---|---|---|

| Cu/C | I | 188 | 0.163 | 14.64 | CuO → Cu | 0.1627 | 4.42 |

| II | 313 | 0.074 | 6.67 | CuO → Cu | 0.074 | ||

| III | 607 | 0.875 | 78.69 | Cu2O → Cu | 0.437 | ||

| Cu99Ni/C | I | 197 | 0.2828 | 18.44 | CuO → Cu | 0.2828 | 6.32 |

| II | 318 | 0.112 | 7.30 | CuO → Cu | 0.112 | ||

| III | 602 | 1.139 | 74.25 | Cu2O → Cu | 0.570 | ||

| Cu99Fe/C | I | 198 | 0.2628 | 23.34 | CuO → Cu | 0.2628 | 4.93 |

| II | 328 | 0.117 | 10.37 | CuO → Cu | 0.117 | ||

| III | 590 | 0.746 | 66.29 | Cu2O → Cu | 0.373 |

| Material | Peak | °C | H2 Consumption mmol/g | Metal mmol/g | wt% | |

|---|---|---|---|---|---|---|

| Ni/C | I | 238 | 0.190 | Ni2O3 → Ni | 0.127 | 6.65 |

| II | 278 | 0.308 | NiO → Ni | 0.308 | ||

| III | 448 | 0.699 | NiO → Ni | 0.700 | ||

| IV | 650 | 0.100 | Activated carbon | |||

| Ni99Pt/C | I | 76 | 0.071 | Ni2O3(Pt) → Ni | 0.047 | 3.06 |

| II | 420 | 0.474 | NiO → Ni | 0.474 | ||

| III | 583 | 0.089 | Activated carbon |

| Material | Peak | °C | H2 Consumption mmol/g | % | n(Fe) mmol/g | |

|---|---|---|---|---|---|---|

| Fe/C | I | 338 | 0.0280 | 20.11 | Fe2O3 → Fe3O4 | 1.8765 |

| II | 523 | 0.1075 | 77.36 | Fe3O4 → FeO | 3.6087 | |

| III | 595 | 0.0035 | 2.53 | FeO → Fe | 0.0393 | |

| IV | 626 | −0.0158 | Activated carbon | |||

| V | −0.0298 | |||||

| Fe99Pd/C | I | 312 | 0.0202 | 24.98 | Fe2O3 → Fe3O4 | 2.2381 |

| II | 476 | 0.0574 | 71.01 | Fe3O4 → FeO | 3.1808 | |

| III | 548 | 0.0032 | 4.01 | FeO → Fe | 0.0599 | |

| IV | 586 | −0.0060 | Activated carbon | |||

| V | −0.1034 | |||||

| Fe99Pt/C | I | 342 | 0.0383 | 32.93 | Fe2O3 → Fe3O4 | 2.8071 |

| II | 529 | 0.0745 | 64.13 | Fe3O4 → FeO | 2.7334 | |

| III | 558 | 0.0034 | 2.94 | FeO → Fe | 0.0418 | |

| IV | 590 | −0.0227 | Activated carbon | |||

| V | −0.0130 |

| No. | Catalyst | Selectivity (Yield) in % | ||||

|---|---|---|---|---|---|---|

| % | Acetaldehyde | 1-Propanol | i-Butanol | 2-Methylbutan-1-ol | ||

| 1 | Cu/C | – | – | – | – | |

| 2 | Cu99Ni1/C 1 | 0.35 | – | 7.64 (0.03) | 53.62 (0.19) | 31.09 (0.11) |

| 3 | Cu99Fe1/C 2 | 0.41 | 7.96 (0.03) | – | 24.40 (0.10) | 62.25 (0.25) |

| 4 | Ni/C | 0.07 | 57.53 (0.04) | 23.57 (0.02) | 18.90 (0.01) | – |

| 5 | Ni99Pt1/C 3 | 0.60 | – | 4.37 (0.03) | 52.95 (0.32) | 21.74 (0.13) |

| 6 | Fe/C | – | – | – | – | |

| 7 | Fe99Pd1/C | 0.08 | 70.02 (0.06) | – | 29.98 (0.03) | – |

| 8 | Fe99Pt1/C 4 | 0.09 | 41.36 (0.04) | 20.85 (0.02) | 20.18 (0.02) | – |

| No. | Composition | A(BET) | |

|---|---|---|---|

| 1 | 3.6% | Ni99.77Pt0.23/C | 725.64 |

| 2 | 3.9% | Cu99.97Ni0.03/C | 732.78 |

| 3 | 4.5% | Cu99.94Fe0.06/C | 734.94 |

| 4 | 4.1% | Fe99.62Pd0.38/C | 744.10 |

| 5 | 3.5% | Fe99.59Pt0.41/C | 761.84 |

| No. | Catalyst | 1 | 2 | 3 | ci-ButOH | TOF in 1/h | ||

|---|---|---|---|---|---|---|---|---|

| eV | eV | nm | nm | mmol/L | XRD | TEM | ||

| 1 | CuNi/C | −2.40 | −2.49 | 28.40 | 22.30 | 3.01 | 6.59 | 5.20 |

| 2 | CuFe/C | −2.11 | −2.42 | 34.64 | 26.31 | 1.60 | 3.65 | 2.78 |

| 3 | NiPt/C | −2.09 | −2.82 | 5.10 | 5.31 | 5.12 | 2.16 | 2.24 |

| 4 | FePd/C | −2.16 | −2.24 | 3.98 | 4.95 | 0.40 | 0.11 | 0.14 |

| 5 | FePt/C | −2.01 | −2.40 | 3.97 | 4.75 | 0.30 | 0.10 | 0.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Häusler, J.; Pasel, J.; Wöllhaf, C.; Peters, R.; Stolten, D. Dilute Alloy Catalysts for the Synthesis of Isobutanol via the Guerbet Route: A Comprehensive Study. Catalysts 2024, 14, 215. https://doi.org/10.3390/catal14030215

Häusler J, Pasel J, Wöllhaf C, Peters R, Stolten D. Dilute Alloy Catalysts for the Synthesis of Isobutanol via the Guerbet Route: A Comprehensive Study. Catalysts. 2024; 14(3):215. https://doi.org/10.3390/catal14030215

Chicago/Turabian StyleHäusler, Johannes, Joachim Pasel, Clemens Wöllhaf, Ralf Peters, and Detlef Stolten. 2024. "Dilute Alloy Catalysts for the Synthesis of Isobutanol via the Guerbet Route: A Comprehensive Study" Catalysts 14, no. 3: 215. https://doi.org/10.3390/catal14030215

APA StyleHäusler, J., Pasel, J., Wöllhaf, C., Peters, R., & Stolten, D. (2024). Dilute Alloy Catalysts for the Synthesis of Isobutanol via the Guerbet Route: A Comprehensive Study. Catalysts, 14(3), 215. https://doi.org/10.3390/catal14030215