Fe-Mn-Al-Ni Shape Memory Alloy Additively Manufactured via Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Experimental

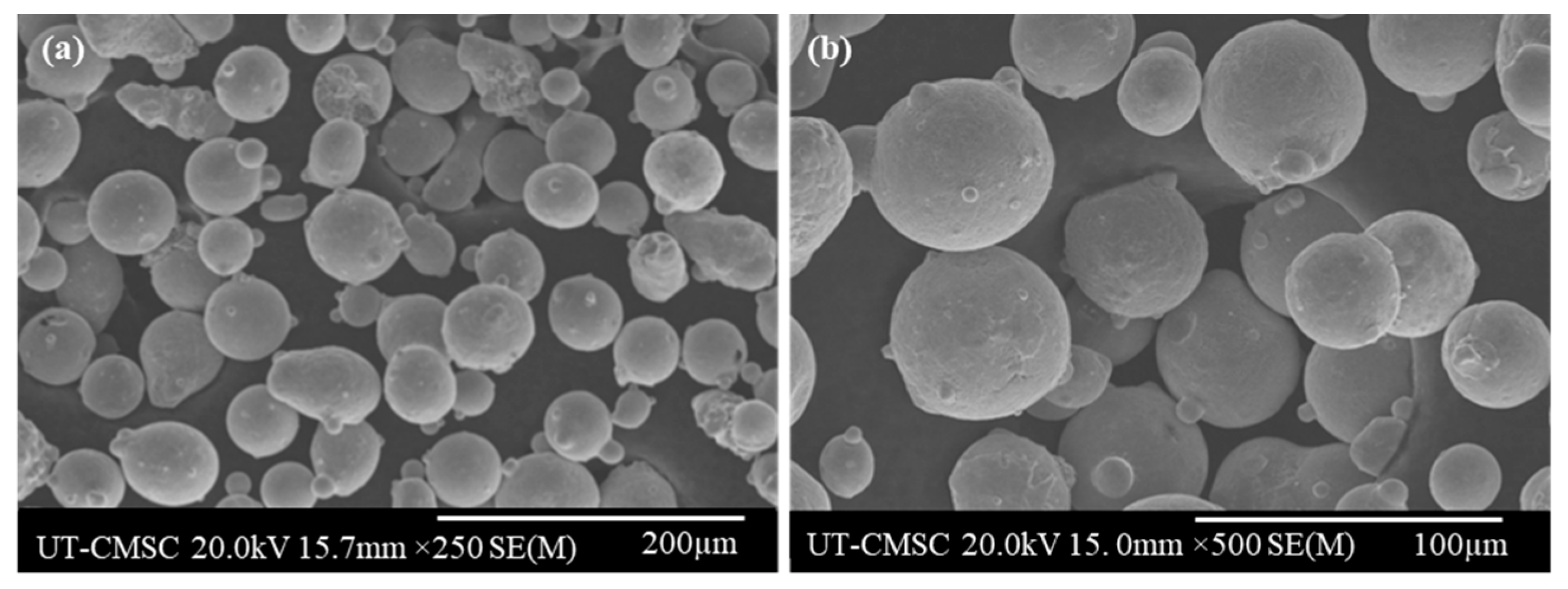

2.1. Material

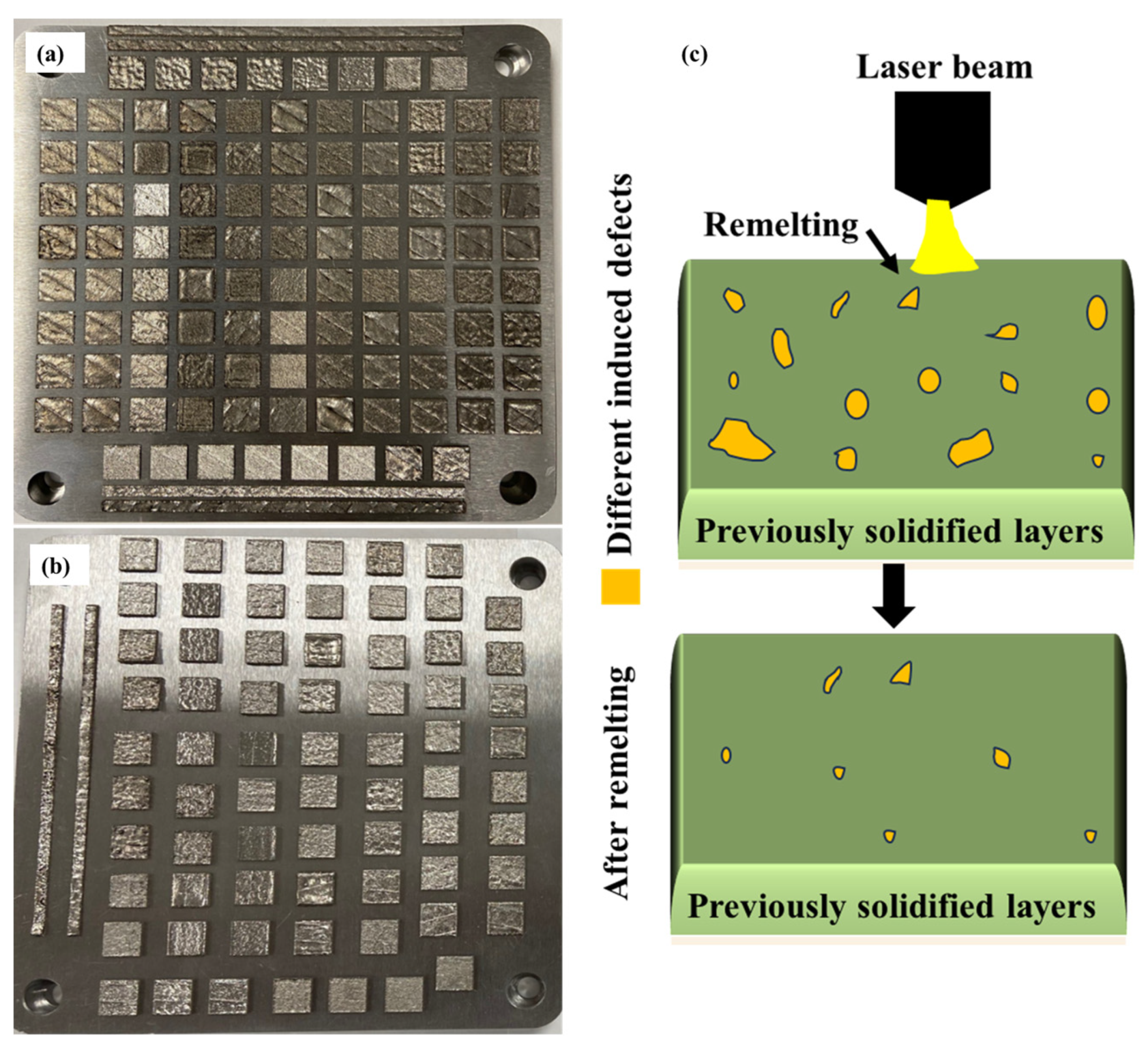

2.2. Fabrication and Optimization

2.3. Characterization

3. Result and Discussion

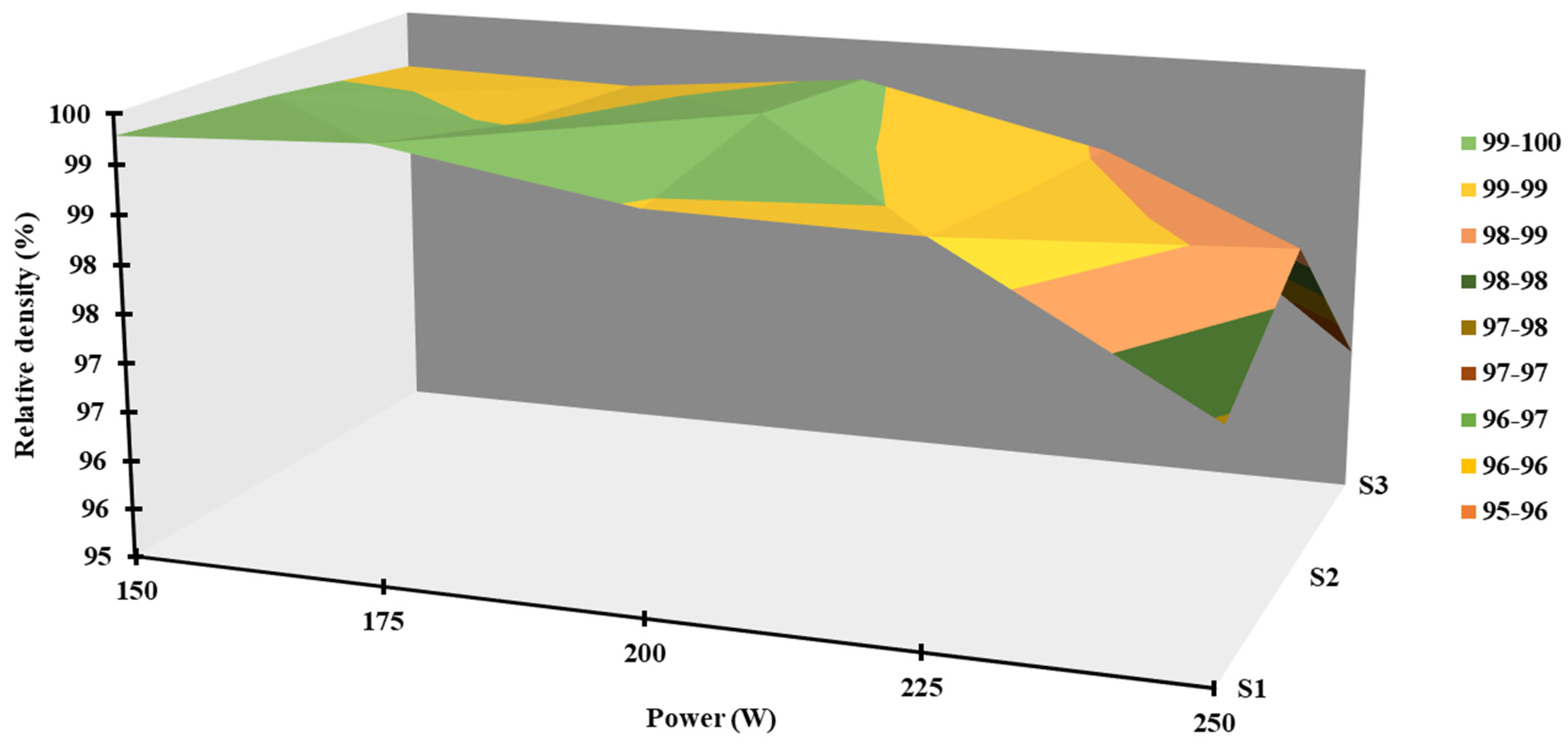

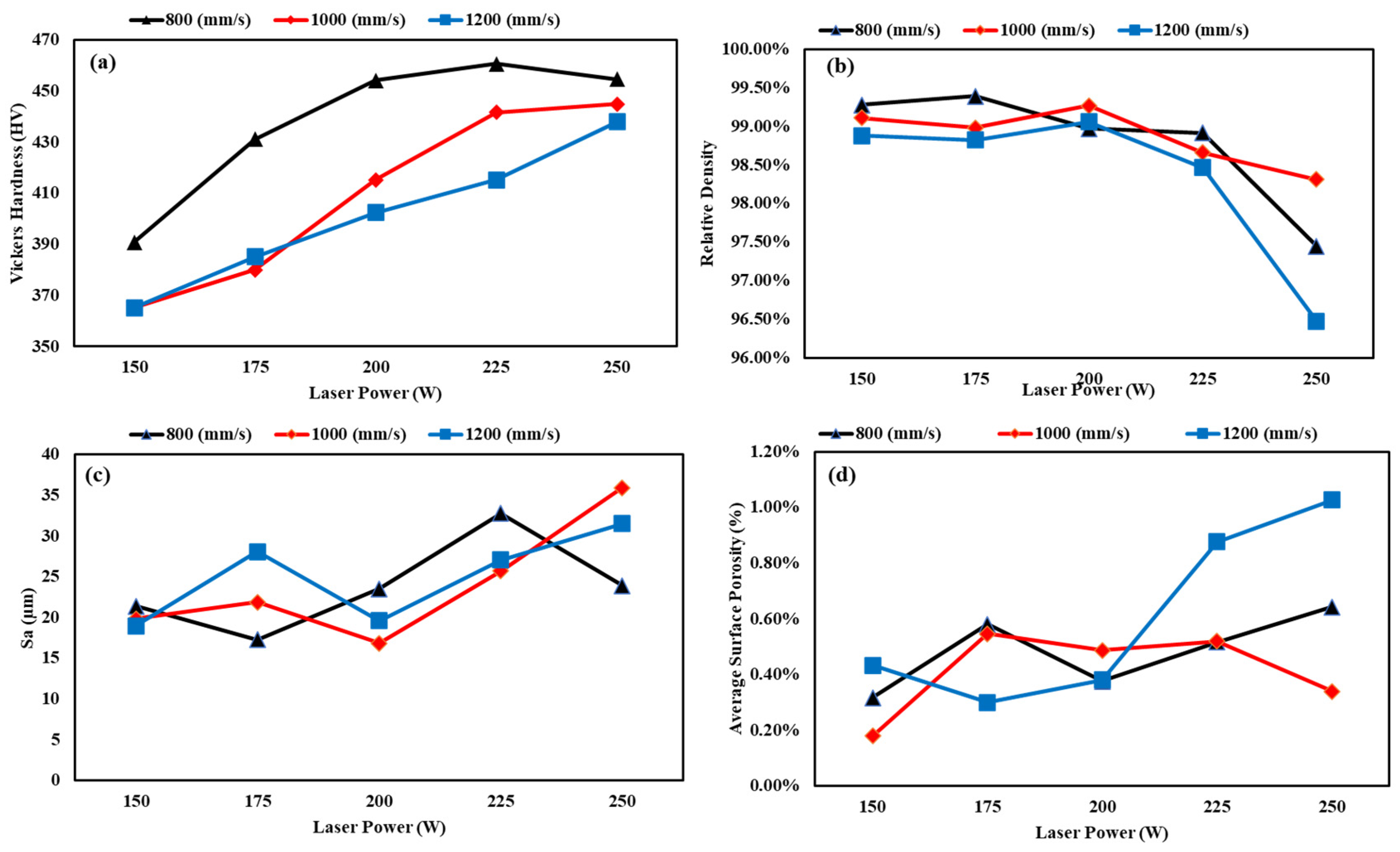

3.1. LPBF Processing Parameters Window

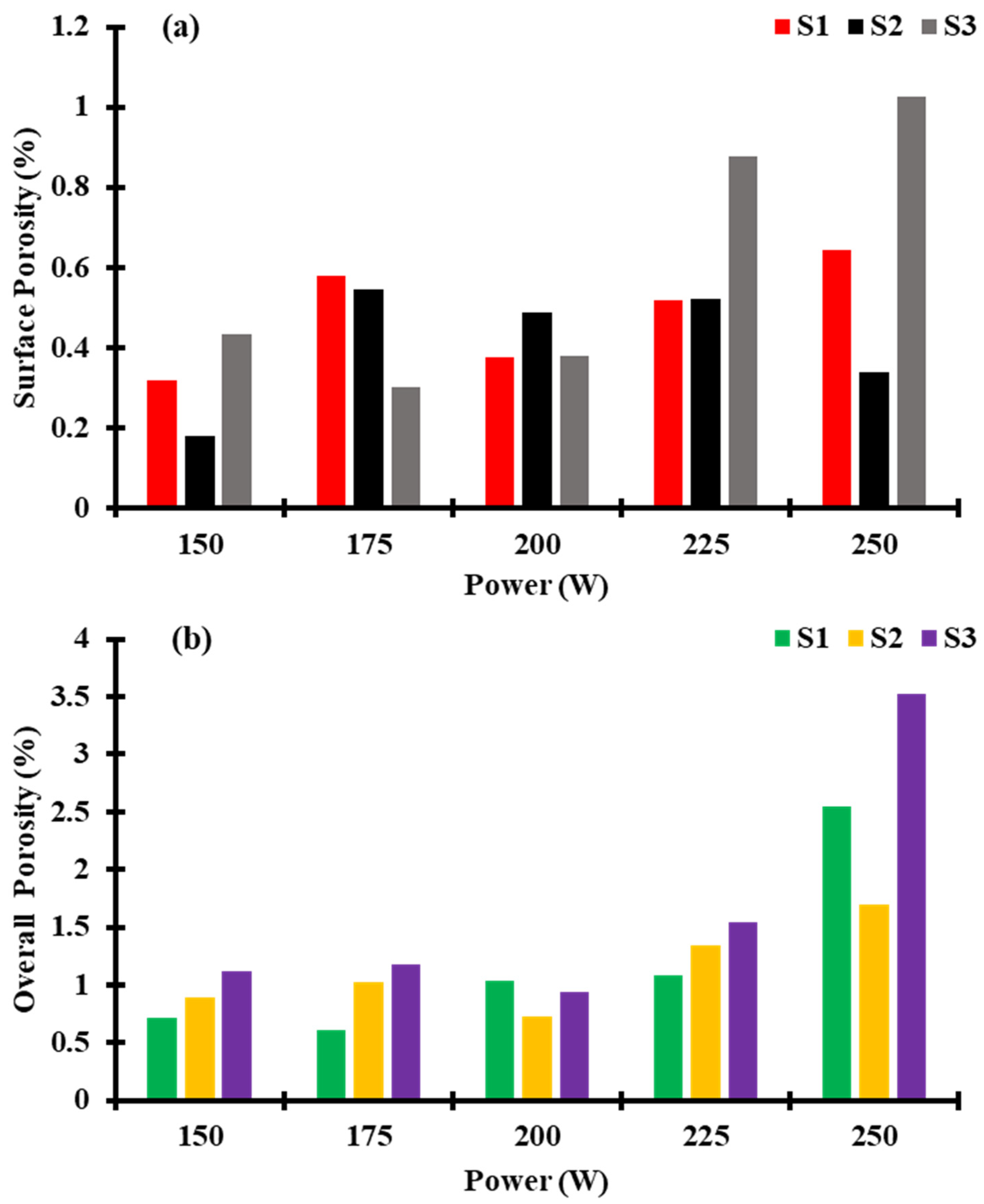

3.2. Porosity Evaluation

3.3. Microhardness Testing

3.4. Interaction Effect

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Af | Austenite finish temperature |

| As | Austenite start temperature |

| AM | Additive manufacturing |

| DOE | Design of experiment |

| EDM | Electric Discharge Machining |

| EDX | Energy-dispersive X-ray spectroscopy |

| HV | Vicker hardness |

| LPBF | Laser powder bed fusion |

| LR | Laser remelting |

| Mf | Martensite finish temperature |

| Ms | Martensite start temperature |

| Sa | Surface roughness |

| SE | Superelasticity |

| SEM | Scanning electron microscopy |

| SMA | Shape memory alloy |

| SME | Shape memory effect |

| VED | Volumetric energy density |

References

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Pan, M.-M.; Zhang, X.-M.; Zhou, D.; Misra, R.; Chen, P. Fe–Mn–Si–Cr–Ni based shape memory alloy: Thermal and stress-induced martensite. Mater. Sci. Eng. A 2020, 797, 140107. [Google Scholar] [CrossRef]

- Tanaka, Y.; Himuro, Y.; Omori, T.; Sutou, Y.; Kainuma, R.; Ishida, K. Martensitic transformation and shape memory effect in ausaged Fe–Ni–Si–Co alloys. Mater. Sci. Eng. A 2006, 438, 1030–1035. [Google Scholar] [CrossRef]

- Abedi, H.; Baghbaderani, K.S.; Alafaghani, A.; Nematollahi, M.; Kordizadeh, F.; Attallah, M.M.; Qattawi, A.; Elahinia, M. Neural network modeling of NiTiHf shape memory alloy transformation temperatures. J. Mater. Eng. Perform. 2022, 31, 10258–10270. [Google Scholar] [CrossRef]

- Ghosh, P.; Rao, A.; Srinivasa, A.R. Design of multi-state and smart-bias components using shape memory alloy and shape memory polymer composites. Mater. Des. 2013, 44, 164–171. [Google Scholar] [CrossRef]

- Ryklina, E.; Prokoshkin, S.; Khmelevskaya, I.; Shakhmina, A. One-way and two-way shape memory effect in thermomechanically treated TiNi-based alloys. Mater. Sci. Eng. A 2008, 481, 134–137. [Google Scholar] [CrossRef]

- Li, H.F.; Qiu, K.J.; Zhou, F.Y.; Li, L.; Zheng, Y.F. Design and development of novel antibacterial Ti-Ni-Cu shape memory alloys for biomedical application. Sci. Rep. 2016, 6, 37475. [Google Scholar] [CrossRef]

- Song, S.-H.; Lee, J.-Y.; Rodrigue, H.; Choi, I.-S.; Kang, Y.J.; Ahn, S.-H. 35 Hz shape memory alloy actuator with bending-twisting mode. Sci. Rep. 2016, 6, 21118. [Google Scholar] [CrossRef]

- Druker, A.V.; Perotti, A.; Esquivel, I.; Malarría, J. A manufacturing process for shaft and pipe couplings of Fe–Mn–Si–Ni–Cr shape memory alloys. Mater. Des. 2014, 56, 878–888. [Google Scholar] [CrossRef]

- Huang, H.; Mosalam, K.M.; Chang, W.-S. Adaptive tuned mass damper with shape memory alloy for seismic application. Eng. Struct. 2020, 223, 111171. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Y. Effect of annealing on the transformation behavior and superelasticity of NiTi shape memory alloy. Scr. Mater. 2001, 45, 153–160. [Google Scholar] [CrossRef]

- Niendorf, T.; Brenne, F.; Krooß, P.; Vollmer, M.; Günther, J.; Schwarze, D.; Biermann, H. Microstructural evolution and functional properties of Fe-Mn-Al-Ni shape memory alloy processed by selective laser melting. Met. Mater. Trans. A 2016, 47, 2569–2573. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Reconciling viability and cost-effective shape memory alloy options—A review of copper and iron based shape memory metallic systems. Eng. Sci. Technol. Int. J. 2016, 19, 1582–1592. [Google Scholar] [CrossRef]

- Tseng, L.; Ma, J.; Wang, S.; Karaman, I.; Chumlyakov, Y. Effects of crystallographic orientation on the superelastic response of FeMnAlNi single crystals. Scr. Mater. 2016, 116, 147–151. [Google Scholar] [CrossRef]

- Mazzer, E.M.; da Silva, M.R.; Gargarella, P. Revisiting Cu-based shape memory alloys: Recent developments and new perspectives. J. Mater. Res. 2022, 37, 162–182. [Google Scholar] [CrossRef]

- Zareie, S.; Issa, A.S.; Seethaler, R.J.; Zabihollah, A. Recent advances in the applications of shape memory alloys in civil infrastructures: A review. Structures 2020, 27, 1535–1550. [Google Scholar] [CrossRef]

- Tanaka, Y.; Himuro, Y.; Kainuma, R.; Sutou, Y.; Omori, T.; Ishida, K. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 2010, 327, 1488–1490. [Google Scholar] [CrossRef]

- Omori, T.; Ando, K.; Okano, M.; Xu, X.; Tanaka, Y.; Ohnuma, I.; Kainuma, R.; Ishida, K. Superelastic effect in polycrystalline ferrous alloys. Science 2011, 333, 68–71. [Google Scholar] [CrossRef]

- Choi, W.S.; Pang, E.L.; Choi, P.-P.; Schuh, C.A. FeNiCoAlTaB superelastic and shape-memory wires with oligocrystalline grain structure. Scr. Mater. 2020, 188, 1–5. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, C.; Harrington, T.; Casalena, L.; Wang, H.; Shin, S.; Vecchio, K.S. Multifunctional non-equiatomic high entropy alloys with superelastic, high damping, and excellent cryogenic properties. Adv. Eng. Mater. 2019, 21, 1800941. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A.; Anaele, J.U. Structural vibration mitigation—A concise review of the capabilities and applications of Cu and Fe based shape memory alloys in civil structures. J. Build. Eng. 2019, 22, 22–32. [Google Scholar] [CrossRef]

- Omori, T.; Kainuma, R. Martensitic transformation and superelasticity in Fe–Mn–Al-based shape memory alloys. Shape Mem. Superelast. 2017, 3, 322–334. [Google Scholar] [CrossRef]

- Vollmer, M.; Segel, C.; Krooß, P.; Günther, J.; Tseng, L.W.; Karaman, I.; Weidner, A.; Biermann, H.; Niendorf, T. On the effect of gamma phase formation on the pseudoelastic performance of polycrystalline Fe–Mn–Al–Ni shape memory alloys. Scr. Mater. 2015, 108, 23–26. [Google Scholar] [CrossRef]

- Xia, J.; Omori, T.; Kainuma, R. Abnormal grain growth in Fe–Mn–Al–Ni shape memory alloy with higher Al content. Scr. Mater. 2020, 187, 355–359. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Abedi, H.; Javan, R.; Nematollahi, M.R.; Safaei, K.; Al-Gamal, A.; Elahinia, M.; Qattawi, A. A Physics-Based Model of Laser Powder Bed Fusion of NiTi Shape Memory Alloy: Laser Single Track and Melt Pool Dimension Prediction. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, Columbus, OH, USA, 30 October–3 November 2022; p. V02AT02A030. [Google Scholar]

- Druzgalski, C.; Ashby, A.; Guss, G.; King, W.; Roehling, T.; Matthews, M. Process optimization of complex geometries using feed forward control for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 34, 101169. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Shao, S.; Khonsari, M.; Guo, S.; Meng, W.; Li, N. Overview: Additive manufacturing enabled accelerated design of ni-based alloys for improved fatigue life. Addit. Manuf. 2019, 29, 100779. [Google Scholar] [CrossRef]

- Alafaghani, A.A.; Qattawi, A. Investigating the effect of fused deposition modeling processing parameters using Taguchi design of experiment method. J. Manuf. Process. 2018, 36, 164–174. [Google Scholar] [CrossRef]

- Shiva, S.; Palani, I.A.; Mishra, S.K.; Paul, C.P.; Kukreja, L.M. Investigations on the influence of composition in the development of Ni–Ti shape memory alloy using laser based additive manufacturing. Opt. Laser Technol. 2015, 69, 44–51. [Google Scholar] [CrossRef]

- Dada, M.; Popoola, P.; Mathe, N.; Pityana, S.; Adeosun, S.; Aramide, O.; Lengopeng, T. Process optimization of high entropy alloys by laser additive manufacturing. Eng. Rep. 2020, 2, e12252. [Google Scholar] [CrossRef]

- Alafaghani, A.; Ablat, M.A.; Abedi, H.; Al Gamal, A.; Qattawi, A. Homogenization and Solution Annealing Heat Treatments of Powder Bed Fused Inconel 718. JOM 2022, 74, 4772–4786. [Google Scholar] [CrossRef]

- Alagha, A.N.; Hussain, S.; Zaki, W. Additive manufacturing of shape memory alloys: A review with emphasis on powder bed systems. Mater. Des. 2021, 204, 109654. [Google Scholar] [CrossRef]

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of additive manufacturing: Overview of 4D and 3D printed smart and advanced materials and their applications. Chem. Eng. J. 2021, 403, 126162. [Google Scholar] [CrossRef]

- Abedi, H.; Algamal, A.; Abdollahzadeh, M.; Nematollahi, M.; Alafaghani, A.; Bayati, P.; Elahinia, M.; Qattawi, A. Predicting Transformation Temperatures of Additively Manufactured NiTiHf Shape Memory Alloy Using Neural Network Modeling. JOM 2023, 75, 4515–4525. [Google Scholar] [CrossRef]

- Xue, L.; Atli, K.; Picak, S.; Zhang, C.; Zhang, B.; Elwany, A.; Arroyave, R.; Karaman, I. Controlling martensitic transformation characteristics in defect-free NiTi shape memory alloys fabricated using laser powder bed fusion and a process optimization framework. Acta Mater. 2021, 215, 117017. [Google Scholar] [CrossRef]

- Zhu, J.-N.; Borisov, E.; Liang, X.; Huizenga, R.; Popovich, A.; Bliznuk, V.; Petrov, R.; Hermans, M.; Popovich, V. Controlling microstructure evolution and phase transformation behavior in additive manufacturing of nitinol shape memory alloys by tuning hatch distance. J. Mater. Sci. 2022, 57, 6066–6084. [Google Scholar] [CrossRef]

- Xue, L.; Atli, K.; Zhang, C.; Hite, N.; Srivastava, A.; Leff, A.; Wilson, A.; Sharar, D.; Elwany, A.; Arroyave, R.; et al. laser powder bed fusion of defect-free NiTi shape memory alloy parts with superior tensile superelasticity. Acta Mater. 2022, 229, 117781. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends. J. Manuf. Process. 2022, 75, 375–414. [Google Scholar] [CrossRef]

- Oliveira, J.P.; LaLonde, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Almotari, A.; Alafaghani, A.; Ali, M.; Al Gamal, A.; Abedi, H.; Qattawi, A. Influence of Modified Heat Treatments and Build Orientations on the Microstructure of Additively Manufactured IN718. In Proceedings of the International Manufacturing Science and Engineering Conference, American Society of Mechanical Engineers, New Brunswick, NJ, USA, 12–16 June 2023; p. V001T01A028. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, L.; Zhao, L.; Lin, D.; Liu, M.; Qi, X.; Han, Y. Process-microstructure-properties of CuAlNi shape memory alloys fabricated by laser powder bed fusion. J. Mater. Sci. Technol. 2023, 152, 1–15. [Google Scholar] [CrossRef]

- Huang, Y.; Fleming, T.G.; Clark, S.J.; Marussi, S.; Fezzaa, K.; Thiyagalingam, J.; Leung, C.L.A.; Lee, P.D. Keyhole fluctuation and pore formation mechanisms during laser powder bed fusion additive manufacturing. Nat. Commun. 2022, 13, 1170. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Liu, J.; Cui, X.; Jin, G.; Liu, Z.; Chen, Y.; Feng, X. Effect of remelting on microstructure and magnetic properties of Fe-Co-based alloys produced by laser additive manufacturing. J. Phys. Chem. Solids 2019, 130, 210–216. [Google Scholar] [CrossRef]

- Zhou, J.; Han, X.; Li, H.; Liu, S.; Yi, J. Investigation of layer-by-layer laser remelting to improve surface quality, microstructure, and mechanical properties of laser powder bed fused AlSi10Mg alloy. Mater. Des. 2021, 210, 110092. [Google Scholar] [CrossRef]

- Li, Z.; He, J.; Ding, X.; Lian, G.; Liu, M.; Chen, J.; Dai, P. Tailoring the surface microstructures and enhancing wear performance of Al0.5CoCrFeNiSi0.25 high-entropy alloys via laser remelting. Surf. Coat. Technol. 2023, 452, 129129. [Google Scholar] [CrossRef]

- Yu, W.; Sing, S.L.; Chua, C.K.; Tian, X. Influence of re-melting on surface roughness and porosity of AlSi10Mg parts fabricated by selective laser melting. J. Alloys Compd. 2019, 792, 574–581. [Google Scholar] [CrossRef]

- Liu, D.; Yue, W.; Kang, J.; Wang, C. Effect of Laser Remelting Strategy on the Forming Ability of Cemented Carbide Fabricated by Laser Powder Bed Fusion (L-PBF). Materials 2022, 15, 2380. [Google Scholar] [CrossRef]

- Brodie, E.G.; Medvedev, A.E.; Frith, J.E.; Dargusch, M.S.; Fraser, H.L.; Molotnikov, A. Remelt processing and microstructure of selective laser melted Ti25Ta. J. Alloys Compd. 2020, 820, 153082. [Google Scholar] [CrossRef]

- Ali, M.; Almotari, A.; Al Gamal, A.; Alafaghani, A.; Abedi, H.; Qattawi, A. Effect of in-situ laser polishing on microstructure, surface characteristics, and phase transformation of lpbf martensitic stainless steel. In Proceedings of the International Manufacturing Science and Engineering Conference, American Society of Mechanical Engineers, New Brunswick, NJ, USA, 12–16 June 2023; p. V001T01A027. [Google Scholar] [CrossRef]

- Pérez-Cerrato, M.; Fraile, I.; Gómez-Cortés, J.F.; Urionabarrenetxea, E.; Ruiz-Larrea, I.; González, I.; Nó, M.L.; Burgos, N.; Juan, J.M.S. Designing for Shape Memory in Additive Manufacturing of Cu–Al–Ni Shape Memory Alloy Processed by Laser Powder Bed Fusion. Materials 2022, 15, 6284. [Google Scholar] [CrossRef]

- Ferretto, I.; Kim, D.; Della Ventura, N.M.; Shahverdi, M.; Lee, W.; Leinenbach, C. Laser powder bed fusion of a Fe–Mn–Si shape memory alloy. Addit. Manuf. 2021, 46, 102071. [Google Scholar] [CrossRef]

- Tamari, S. Optimum design of the constant-volume gas pycnometer for determining the volume of solid particles. Meas. Sci. Technol. 2004, 15, 549–558. [Google Scholar] [CrossRef]

- Ast, O.; Perez, M.; Carlet, S. PuAl alloys density measurements using gas pycnometer: First results. J. Alloys Compd. 2007, 444, 226–229. [Google Scholar] [CrossRef]

- Wits, W.W.; Carmignato, S.; Zanini, F.; Vaneker, T.H. Porosity testing methods for the quality assessment of selective laser melted parts. CIRP Ann. 2016, 65, 201–204. [Google Scholar] [CrossRef]

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM: West Conshohocken, PA, USA, 2017.

- Gockel, J.; Sheridan, L.; Koerper, B.; Whip, B. The influence of additive manufacturing processing parameters on surface roughness and fatigue life. Int. J. Fatigue 2019, 124, 380–388. [Google Scholar] [CrossRef]

- Pegues, J.; Roach, M.; Williamson, R.S.; Shamsaei, N. Surface roughness effects on the fatigue strength of additively manufactured Ti-6Al-4V. Int. J. Fatigue 2018, 116, 543–552. [Google Scholar] [CrossRef]

- Benardos, P.G.; Vosniakos, G.-C. Predicting surface roughness in machining: A review. Int. J. Mach. Tools Manuf. 2003, 43, 833–844. [Google Scholar] [CrossRef]

- Charles, A.; Elkaseer, A.; Paggi, U.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Down-facing surfaces in laser powder bed fusion of Ti6Al4V: Effect of dross formation on dimensional accuracy and surface texture. Addit. Manuf. 2021, 46, 102148. [Google Scholar] [CrossRef]

- Ali, M.; Almotari, A.; Algamal, A.; Qattawi, A. Recent Advancements in Post Processing of Additively Manufactured Metals Using Laser Polishing. J. Manuf. Mater. Process. 2023, 7, 115. [Google Scholar] [CrossRef]

- Obeidi, M.A.; Mussatto, A.; Dogu, M.N.; Sreenilayam, S.P.; McCarthy, E.; Ahad, I.U.; Keaveney, S.; Brabazon, D. Laser surface polishing of Ti-6Al-4V parts manufactured by laser powder bed fusion. Surf. Coat. Technol. 2022, 434, 128179. [Google Scholar] [CrossRef]

- Gor, M.; Dobriyal, A.; Wankhede, V.; Sahlot, P.; Grzelak, K.; Kluczyński, J.; Łuszczek, J. Density prediction in powder bed fusion additive manufacturing: Machine learning-based techniques. Appl. Sci. 2022, 12, 7271. [Google Scholar] [CrossRef]

- Wang, S.; Ning, J.; Zhu, L.; Yang, Z.; Yan, W.; Dun, Y.; Xue, P.; Xu, P.; Bose, S.; Bandyopadhyay, A. Role of porosity defects in metal 3D printing: Formation mechanisms, impacts on properties and mitigation strategies. Mater. Today 2022, 59, 133–160. [Google Scholar] [CrossRef]

- Bakhshivash, S.; Asgari, H.; Russo, P.; Dibia, C.F.; Ansari, M.; Gerlich, A.P.; Toyserkani, E. Printability and microstructural evolution of Ti-5553 alloy fabricated by modulated laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2019, 103, 4399–4409. [Google Scholar] [CrossRef]

- Eliasu, A.; Czekanski, A.; Boakye-Yiadom, S. Effect of laser powder bed fusion parameters on the microstructural evolution and hardness of 316L stainless steel. Int. J. Adv. Manuf. Technol. 2021, 113, 2651–2669. [Google Scholar] [CrossRef]

- Tseng, L.; Ma, J.; Hornbuckle, B.; Karaman, I.; Thompson, G.; Luo, Z.; Chumlyakov, Y. The effect of precipitates on the superelastic response of [1 0 0] oriented FeMnAlNi single crystals under compression. Acta Mater. 2015, 97, 234–244. [Google Scholar] [CrossRef]

| Element | Fe | Mn | Al | Ni |

|---|---|---|---|---|

| (at. %) | Balance | 34.04 | 14.87 | 6.98 |

| Process Type | Laser Power, P (W) | Scanning Speed, v (mm/s) | Hatching Space, h (mm) | Volumetric Energy Density, VED (J/mm3) |

|---|---|---|---|---|

| Fabrication | 150 | 800 | 0.09 | 69.44 |

| 1000 | 55.56 | |||

| 1200 | 46.30 | |||

| 175 | 800 | 0.09 | 81.02 | |

| 1000 | 64.81 | |||

| 1200 | 54.01 | |||

| 200 | 800 | 0.09 | 92.59 | |

| 1000 | 74.07 | |||

| 1200 | 61.73 | |||

| 225 | 800 | 0.09 | 104.17 | |

| 1000 | 83.33 | |||

| 1200 | 69.44 | |||

| 250 | 800 | 0.09 | 115.74 | |

| 1000 | 92.59 | |||

| 1200 | 77.16 | |||

| Remelting | 100 | 800 | 0.09 | 46.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhamdi, I.; Algamal, A.; Almotari, A.; Ali, M.; Gandhi, U.; Qattawi, A. Fe-Mn-Al-Ni Shape Memory Alloy Additively Manufactured via Laser Powder Bed Fusion. Crystals 2023, 13, 1505. https://doi.org/10.3390/cryst13101505

Alhamdi I, Algamal A, Almotari A, Ali M, Gandhi U, Qattawi A. Fe-Mn-Al-Ni Shape Memory Alloy Additively Manufactured via Laser Powder Bed Fusion. Crystals. 2023; 13(10):1505. https://doi.org/10.3390/cryst13101505

Chicago/Turabian StyleAlhamdi, Ismail, Anwar Algamal, Abdalmageed Almotari, Majed Ali, Umesh Gandhi, and Ala Qattawi. 2023. "Fe-Mn-Al-Ni Shape Memory Alloy Additively Manufactured via Laser Powder Bed Fusion" Crystals 13, no. 10: 1505. https://doi.org/10.3390/cryst13101505

APA StyleAlhamdi, I., Algamal, A., Almotari, A., Ali, M., Gandhi, U., & Qattawi, A. (2023). Fe-Mn-Al-Ni Shape Memory Alloy Additively Manufactured via Laser Powder Bed Fusion. Crystals, 13(10), 1505. https://doi.org/10.3390/cryst13101505