Suspended 2D Materials: A Short Review

Abstract

1. Introduction

2. Fabrication Techniques of Suspended 2D Materials

3. The Properties of Suspended 2D Materials

4. Applications of Suspended 2D Materials

5. Perspective and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bonaccorso, F.; Sun, Z.; Hasan, T.; Ferrari, A.C. Graphene photonics and optoelectronics. Nat. Photonics 2010, 4, 611–655. [Google Scholar] [CrossRef]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.D.; Yao, W.; Xiao, D.; Heinz, T.F. Spin and pseudospins in layered transition metal dichalcogenides. Nat. Phys. 2014, 10, 343–350. [Google Scholar] [CrossRef]

- Bolotin, K.I.; Sikes, K.J.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H.L. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef]

- Dai, Y.Y.; Wang, Y.D.; Das, S.; Xue, H.; Bai, X.Y.; Hulkko, E.; Zhang, G.Y.; Yang, X.X.; Dai, Q.; Sun, Z.P. Electrical Control of Interband Resonant Nonlinear Optics in Monolayer MoS2. ACS Nano 2020, 14, 8442–8448. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Huang, D.; Cheng, J.; Fan, X.; Zhang, Z.; Shan, Y.; Yi, Y.; Dai, Y.; Shi, L.; Liu, K.; et al. Gate-tunable third-order nonlinear optical response of massless Dirac fermions in graphene. Nat. Photonics 2018, 12, 430–436. [Google Scholar] [CrossRef]

- Chiout, A.; Brochard-Richard, C.; Marty, L.; Bendiab, N.; Zhao, M.Q.; Johnson, A.T.C.; Oehler, F.; Ouerghi, A.; Chaste, J. Extreme mechanical tunability in suspended MoS2 resonator controlled by Joule heating. npj 2D Mater. Appl. 2023, 7, 20. [Google Scholar] [CrossRef]

- Autere, A.; Jussila, H.; Dai, Y.Y.; Wang, Y.D.; Lipsanen, H.; Sun, Z.P. Nonlinear Optics with 2D Layered Materials. Adv. Mater. 2018, 30, 1465. [Google Scholar] [CrossRef]

- Xue, H.; Wang, Y.D.; Dai, Y.Y.; Kim, W.; Jussila, H.; Qi, M.; Susoma, J.; Ren, Z.Y.; Dai, Q.; Zhao, J.L.; et al. A MoSe2/WSe2 Heterojunction-Based Photodetector at Telecommunication Wavelengths. Adv. Funct. Mater. 2018, 28, 1804388. [Google Scholar] [CrossRef]

- Du, L.; Molas, M.R.; Huang, Z.; Zhang, G.; Wang, F.; Sun, Z. Moiré photonics and optoelectronics. Science 2023, 379, eadg0014. [Google Scholar] [CrossRef]

- Fiori, G.; Bonaccorso, F.; Iannaccone, G.; Palacios, T.; Neumaier, D.; Seabaugh, A.; Banerjee, S.K.; Colombo, L. Electronics based on two-dimensional materials. Nat. Nanotechnol. 2014, 9, 768–779. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.X.; Chen, Y.J.; Jiang, C.B. Strain engineering of two-dimensional materials: Methods, properties, and applications. InfoMat 2021, 3, 397–420. [Google Scholar] [CrossRef]

- Abd-Elrahim, A.G.; Chun, D.-M. Facile one-step deposition of Co3O4-MoS2 nanocomposites using a vacuum kinetic spray process for non-enzymatic H2O2 sensing. Surf. Interfaces 2020, 21, 100748. [Google Scholar] [CrossRef]

- Abd-Elrahim, A.G.; Chun, D.-M. Heterostructured Mn3O4-2D material nanosheets: One-step vacuum kinetic spray deposition and non-enzymatic H2O2 sensing. Ceram. Int. 2021, 47, 35111–35123. [Google Scholar] [CrossRef]

- Abd-Elrahim, A.G.; Chun, D.-M. Facile one-step deposition of ZnO-graphene nanosheets hybrid photoanodes for enhanced photoelectrochemical water splitting. J. Alloys Compd. 2021, 870, 159430. [Google Scholar] [CrossRef]

- Abd-Elrahim, A.G.; Chun, D.-M. Room-temperature deposition of ZnO-graphene nanocomposite hybrid photocatalysts for improved visible-light-driven degradation of methylene blue. Ceram. Int. 2021, 47, 12812–12825. [Google Scholar] [CrossRef]

- Chen, X.; Yu, H.; Gao, Y.; Wang, L.; Wang, G. The marriage of two-dimensional materials and phase change materials for energy storage, conversion and applications. EnergyChem 2022, 4, 100071. [Google Scholar] [CrossRef]

- Khan, K.; Tareen, A.K.; Aslam, M.; Zhang, Y.; Wang, R.; Ouyang, Z.; Gou, Z.; Zhang, H. Recent advances in two-dimensional materials and their nanocomposites in sustainable energy conversion applications. Nanoscale 2019, 11, 21622–21678. [Google Scholar] [CrossRef]

- Rhodes, D.; Chae, S.H.; Ribeiro-Palau, R.; Hone, J. Disorder in van der Waals heterostructures of 2D materials. Nat. Mater. 2019, 18, 541–549. [Google Scholar] [CrossRef]

- Zhao, T.E.; Guo, J.X.; Li, T.T.; Wang, Z.; Peng, M.; Zhong, F.; Chen, Y.; Yu, Y.Y.; Xu, T.F.; Xie, R.Z.; et al. Substrate engineering for wafer-scale two-dimensional material growth: Strategies, mechanisms, and perspectives. Chem. Soc. Rev. 2023, 52, 1650–1671. [Google Scholar] [CrossRef]

- Chae, W.H.; Cain, J.D.; Hanson, E.D.; Murthy, A.A.; Dravid, V.P. Substrate-induced strain and charge doping in CVD-grown monolayer MoS2. Appl. Phys. Lett. 2017, 111, 143106. [Google Scholar] [CrossRef]

- Liang, J.; Zhang, J.; Li, Z.Z.; Hong, H.; Wang, J.H.; Zhang, Z.H.; Zhou, X.; Qiao, R.X.; Xu, J.Y.; Gao, P.; et al. Monitoring Local Strain Vector in Atomic-Layered MoSe2 by Second-Harmonic Generation. Nano Lett. 2017, 17, 7539–7543. [Google Scholar] [CrossRef]

- Peng, Z.W.; Chen, X.L.; Fan, Y.L.; Srolovitz, D.J.; Lei, D.Y. Strain engineering of 2D semiconductors and graphene: From strain fields to band-structure tuning and photonic applications. Light-Sci. Appl. 2020, 9, 190. [Google Scholar] [CrossRef] [PubMed]

- Castriota, M.; Politano, G.G.; Vena, C.; De Santo, M.P.; Desiderio, G.; Davoli, M.; Cazzanelli, E.; Versace, C. Variable Angle Spectroscopic Ellipsometry investigation of CVD-grown monolayer graphene. Appl. Surf. Sci. 2019, 467–468, 213–220. [Google Scholar] [CrossRef]

- Haidari, M.M.; Kim, H.; Kim, J.H.; Park, M.; Lee, H.; Choi, J.S. Doping effect in graphene-graphene oxide interlayer. Sci. Rep. 2020, 10, 8258. [Google Scholar] [CrossRef]

- Politano, G.G.; Vena, C.; Desiderio, G.; Versace, C. Variable angle spectroscopic ellipsometry characterization of turbostratic CVD-grown bilayer and trilayer graphene. Opt. Mater. 2020, 107, 110165. [Google Scholar] [CrossRef]

- Hwang, Y.; Kim, T.; Shin, N. Interlayer Energy Transfer and Photoluminescence Quenching in MoSe2/Graphene van der Waals Heterostructures for Optoelectronic Devices. ACS Appl. Nano Mater. 2021, 4, 12034–12042. [Google Scholar] [CrossRef]

- Pollmann, E.; Sleziona, S.; Foller, T.; Hagemann, U.; Gorynski, C.; Petri, O.; Madauss, L.; Breuer, L.; Schleberger, M. Large-Area, Two-Dimensional MoS2 Exfoliated on Gold: Direct Experimental Access to the Metal-Semiconductor Interface. ACS Omega 2021, 6, 15929–15939. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Zhang, Y.; Zhou, L.; Li, B.; Gu, L. Photoluminescence and Fluorescence Quenching of Graphene Oxide: A Review. Nanomaterials 2022, 12, 2444. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.; Hu, D.; Geng, X.; Liu, H.; Wan, Y.; Guo, Z.; Yang, P. 2D gold supercrystal-MoS2 hybrids: Photoluminescence quenching. Mater. Lett. 2019, 255, 126531. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Gweon, G.H.; Fedorov, A.V.; First, P.N.; de Heer, W.A.; Lee, D.H.; Guinea, F.; Castro Neto, A.H.; Lanzara, A. Substrate-induced bandgap opening in epitaxial graphene. Nat. Mater. 2007, 6, 770–775. [Google Scholar] [CrossRef] [PubMed]

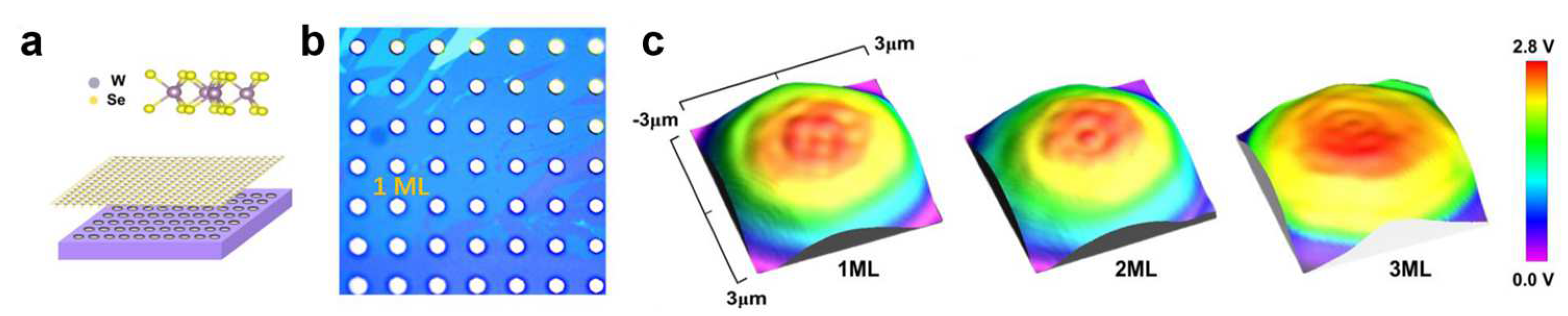

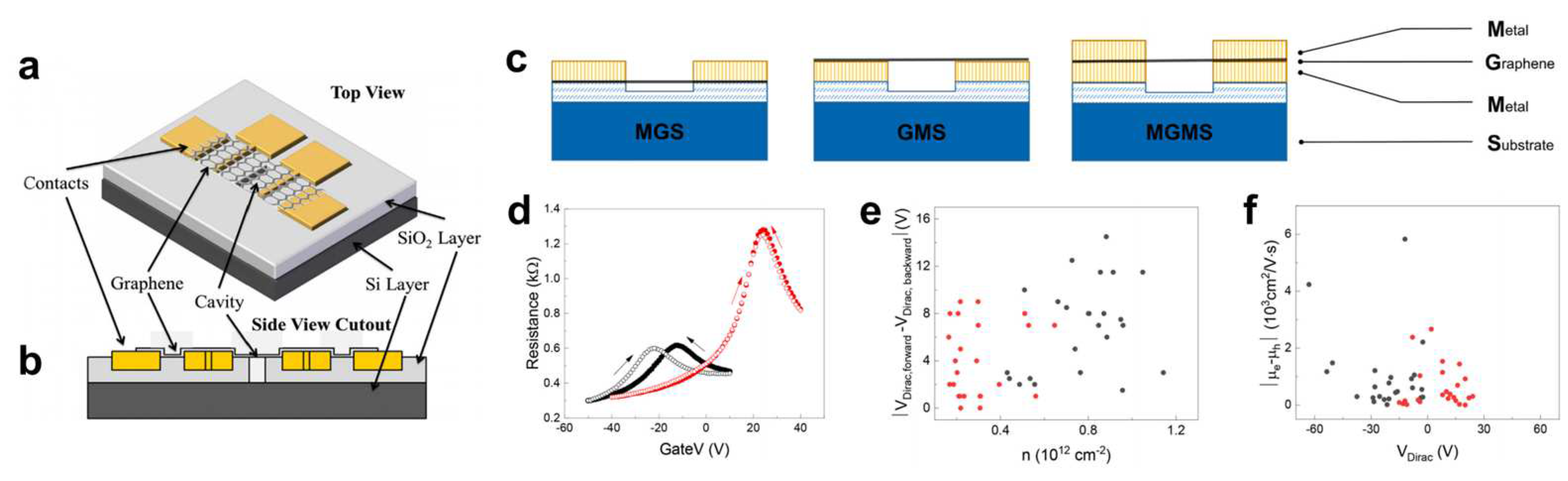

- Huang, Y.; Wang, Y.K.; Huang, X.Y.; Zhang, G.H.; Han, X.; Yang, Y.; Gao, Y.A.; Meng, L.; Wang, Y.S.; Geng, G.Z.; et al. An efficient route to prepare suspended monolayer for feasible optical and electronic characterizations of two-dimensional materials. InfoMat 2022, 4, e12274. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, G.; Li, B.W. Substrate coupling suppresses size dependence of thermal conductivity in supported graphene. Nanoscale 2013, 5, 532–536. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Skachko, I.; Duerr, F.; Luican, A.; Andrei, E.Y. Fractional quantum Hall effect and insulating phase of Dirac electrons in graphene. Nature 2009, 462, 192–195. [Google Scholar] [CrossRef]

- Feldman, B.E.; Martin, J.; Yacoby, A. Broken-symmetry states and divergent resistance in suspended bilayer graphene. Nat. Phys. 2009, 5, 889–893. [Google Scholar] [CrossRef]

- Locatelli, A.; Knox, K.R.; Cvetko, D.; Mentes, T.O.; Nino, M.A.; Wang, S.C.; Yilmaz, M.B.; Kim, P.; Osgood, R.M.; Morgante, A. Corrugation in Exfoliated Graphene: An Electron Microscopy and Diffraction Study. ACS Nano 2010, 4, 4879–4889. [Google Scholar] [CrossRef]

- Wu, S.W.; Liu, W.T.; Liang, X.G.; Schuck, P.J.; Wang, F.; Shen, Y.R.; Salmeron, M. Hot Phonon Dynamics in Graphene. Nano Lett. 2012, 12, 5495–5499. [Google Scholar] [CrossRef]

- Jin, W.C.; Yeh, P.C.; Zaki, N.; Zhang, D.T.; Liou, J.T.; Sadowski, J.T.; Barinov, A.; Yablonskikh, M.; Dadap, J.I.; Sutter, P.; et al. Substrate interactions with suspended and supported monolayer MoS2: Angle-resolved photoemission spectroscopy. Phys. Rev. B 2015, 91, 121409. [Google Scholar] [CrossRef]

- Dolleman, R.J.; Blanter, Y.M.; van der Zant, H.S.J.; Steeneken, P.G.; Verbiest, G.J. Phonon scattering at kinks in suspended graphene. Phys. Rev. B 2020, 101, 115411. [Google Scholar] [CrossRef]

- Hu, H.; Yu, R.W.; Teng, H.C.; Hu, D.B.; Chen, N.; Qu, Y.P.; Yang, X.X.; Chen, X.Z.; McLeod, A.S.; Alonso-Gonzalez, P.; et al. Active control of micrometer plasmon propagation in suspended graphene. Nat. Commun. 2022, 13, 1465. [Google Scholar] [CrossRef]

- Wang, F.L.; Stepanov, P.; Gray, M.; Lau, C.N.; Itkis, M.E.; Haddon, R.C. Ionic Liquid Gating of Suspended MoS2 Field Effect Transistor Devices. Nano Lett. 2015, 15, 5284–5288. [Google Scholar] [CrossRef] [PubMed]

- Jin, T.; Kang, J.; Su Kim, E.; Lee, S.; Lee, C. Suspended single-layer MoS2 devices. J. Appl. Phys. 2013, 114, 164509. [Google Scholar] [CrossRef]

- Lau, C.N.; Bao, W.; Velasco, J. Properties of suspended graphene membranes. Mater. Today 2012, 15, 238–245. [Google Scholar] [CrossRef]

- Shi, J.; Wu, X.; Wu, K.; Zhang, S.; Sui, X.; Du, W.; Yue, S.; Liang, Y.; Jiang, C.; Wang, Z.; et al. Giant Enhancement and Directional Second Harmonic Emission from Monolayer WS2 on Silicon Substrate via Fabry-Pérot Micro-Cavity. ACS Nano 2022, 16, 13933–13941. [Google Scholar] [CrossRef]

- Liu, L.; Gong, P.; Liu, K.; Nie, A.; Liu, Z.; Yang, S.; Xu, Y.; Liu, T.; Zhao, Y.; Huang, L.; et al. Scalable Van der Waals Encapsulation by Inorganic Molecular Crystals. Adv. Mater. 2022, 34, e2106041. [Google Scholar] [CrossRef] [PubMed]

- Sattari-Esfahlan, S.M.; Kim, H.G.; Hyun, S.H.; Choi, J.H.; Hwang, H.S.; Kim, E.T.; Park, H.G.; Lee, J.H. Low-Temperature Direct Growth of Amorphous Boron Nitride Films for High-Performance Nanoelectronic Device Applications. ACS Appl. Mater. Interfaces 2023, 15, 7274–7281. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.; Jiang, J.; Wang, J.; Yu, M.; Tu, T.; Gao, X.; Tang, J.; Zhang, C.; Zhang, Y.; Zhou, X.; et al. Strain-Free Layered Semiconductors for 2D Transistors with On-State Current Density Exceeding 1.3 mA um−1. Nano Lett. 2022, 22, 3770–3776. [Google Scholar] [CrossRef] [PubMed]

- Vu, Q.A.; Fan, S.; Lee, S.H.; Joo, M.-K.; Yu, W.J.; Lee, Y.H. Near-zero hysteresis and near-ideal subthreshold swing in h-BN encapsulated single-layer MoS2 field-effect transistors. 2D Mater. 2018, 5, 031001. [Google Scholar] [CrossRef]

- Ahmed, Z.; Afzalian, A.; Schram, T.; Jang, D.; Verreck, D.; Smets, Q.; Schuddinck, P.; Chehab, B.; Sutar, S.; Arutchelvan, G.; et al. Introducing 2D-FETs in Device Scaling Roadmap using DTCO. In Proceedings of the 2020 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 12–18 December 2020. [Google Scholar]

- Huang, Y.; Pan, Y.H.; Yang, R.; Bao, L.H.; Meng, L.; Luo, H.L.; Cai, Y.Q.; Liu, G.D.; Zhao, W.J.; Zhou, Z.; et al. Universal mechanical exfoliation of large-area 2D crystals. Nat. Commun. 2020, 11, 2453. [Google Scholar] [CrossRef]

- Huang, X.Y.; Zhang, L.; Liu, L.W.; Qin, Y.; Fu, Q.; Wu, Q.; Yang, R.; Lv, J.P.; Ni, Z.H.; Liu, L.; et al. Raman spectra evidence for the covalent-like quasi-bonding between exfoliated MoS2 and Au films. Sci. China-Inf. Sci. 2021, 64, 140406. [Google Scholar] [CrossRef]

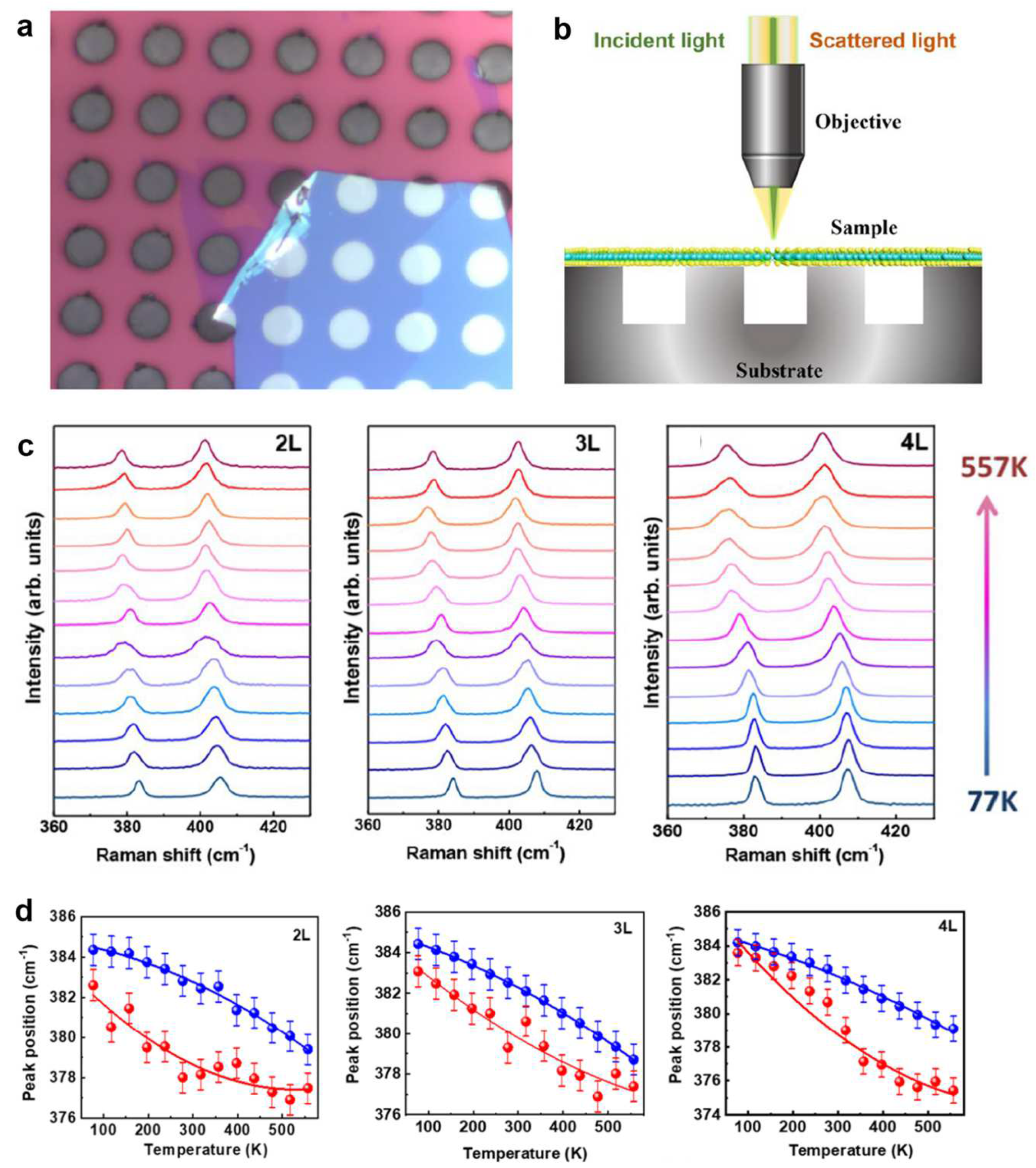

- Lin, Z.; Liu, W.; Tian, S.; Zhu, K.; Huang, Y.; Yang, Y. Thermal expansion coefficient of few-layer MoS2 studied by temperature-dependent Raman spectroscopy. Sci. Rep. 2021, 11, 7037. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.S.; Jin, J.Y.; Liu, J.; Sun, L.F.; Yang, C.C.; Li, Y.J. Molten liquid metal motion assisted preparation of suspended graphene arrays. Mater. Lett. 2022, 314, 131874. [Google Scholar] [CrossRef]

- Meyer, J.C.; Geim, A.K.; Katsnelson, M.I.; Novoselov, K.S.; Booth, T.J.; Roth, S. The structure of suspended graphene sheets. Nature 2007, 446, 60–63. [Google Scholar] [CrossRef] [PubMed]

- Ci, H.N.; Chen, J.T.; Ma, H.; Sun, X.L.; Jiang, X.Y.; Liu, K.C.; Shan, J.Y.; Lian, X.Y.; Jiang, B.; Liu, R.J.; et al. Transfer-Free Quasi-Suspended Graphene Grown on a Si Wafer. Adv. Mater. 2022, 34, 2206389. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, H.; Kaneko, T.; Shibuta, Y.; Ohno, M.; Maekawa, Y.; Kato, T. Wafer-scale fabrication and growth dynamics of suspended graphene nanoribbon arrays. Nat. Commun. 2016, 7, 11797. [Google Scholar] [CrossRef] [PubMed]

- Hamer, M.J.; Hopkinson, D.G.; Clark, N.; Zhou, M.W.; Wang, W.D.; Zou, Y.C.; Kelly, D.J.; Bointon, T.H.; Haigh, S.J.; Gorbachev, R.V. Atomic Resolution Imaging of CrBr3 Using Adhesion-Enhanced Grids. Nano Lett. 2020, 20, 6582–6589. [Google Scholar] [CrossRef] [PubMed]

- Chaste, J.; Hnid, I.; Khalil, L.; Si, C.; Durnez, A.; Lafosse, X.; Zhao, M.Q.; Johnson, A.T.C.; Zhang, S.B.; Bang, J.; et al. Phase Transition in a Memristive Suspended MoS2 Monolayer Probed by Opto- and Electro-Mechanics. ACS Nano 2020, 14, 13611–13618. [Google Scholar] [CrossRef]

- Dai, C.H.; Rho, Y.; Pham, K.; McCormick, B.; Blankenship, B.W.; Zhao, W.Y.; Zhang, Z.C.; Crommie, M.F.; Wang, F.; Grigoropoulos, C.P.; et al. Kirigami Engineering of Suspended Graphene Transducers. Nano Lett. 2022, 22, 5301–5306. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.R.; Hong, J.H.; You, Y.G.; Campbell, E.E.B.; Jhang, S.H. Suspended MoTe2 field effect transistors with ionic liquid gate. Appl. Phys. Lett. 2021, 119, 223105. [Google Scholar] [CrossRef]

- Chen, H.; Li, J.; Chen, X.; Zhang, D.; Zhou, P. Dramatic switching behavior in suspended MoS2 field-effect transistors. Semicond. Sci. Technol. 2018, 33, 024001. [Google Scholar] [CrossRef]

- Wang, P.J.; Ding, J.; Chen, W.W.; Li, S.Q.; Zhang, B.H.; Lu, H.; Li, J.; Li, Y.; Fu, Q.; Dai, T.G.; et al. Plasmonic Feynman Gate Based on Suspended Graphene Nano-Ribbon Waveguides at THz Wavelengths. IEEE Photonics J. 2019, 11, 4801109. [Google Scholar] [CrossRef]

- Safinezhad, A.; Eslami, M.R.; Jafari Jozani, K.; Rezaei, M.H. Ultra-compact all-optical reversible Feynman gate based on suspended graphene plasmonic waveguides. Opt. Quantum Electron. 2022, 54, 295. [Google Scholar] [CrossRef]

- Liu, X.; Hu, S.; Luo, J.; Li, X.; Wu, J.; Chi, D.; Ang, K.W.; Yu, W.; Cai, Y. Suspended MoS2 Photodetector Using Patterned Sapphire Substrate. Small 2021, 17, e2100246. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Jiang, Y.; Tan, C.; Li, Y.; Chen, Y.; Li, Z.; Gao, L.; Yang, L.; Wang, Z. Strain Tune Suspended MoS2 for Polarization Photodetection. Phys. Status Solidi (RRL) Rapid Res. Lett. 2023, 2300101. [Google Scholar] [CrossRef]

- Saenz, G.A.; Karapetrov, G.; Curtis, J.; Kaul, A.B. Ultra-high Photoresponsivity in Suspended Metal-Semiconductor-Metal Mesoscopic Multilayer MoS2 Broadband Detector from UV-to-IR with Low Schottky Barrier Contacts. Sci. Rep. 2018, 8, 1276. [Google Scholar] [CrossRef]

- Thakar, K.; Mukherjee, B.; Grover, S.; Kaushik, N.; Deshmukh, M.; Lodha, S. Multilayer ReS2 Photodetectors with Gate Tunability for High Responsivity and High-Speed Applications. ACS Appl. Mater. Interfaces 2018, 10, 36512–36522. [Google Scholar] [CrossRef]

- Zhong, W.; Liu, Y.; Yang, X.; Wang, C.; Xin, W.; Li, Y.; Liu, W.; Xu, H. Suspended few-layer GaS photodetector with sensitive fast response. Mater. Des. 2021, 212, 110233. [Google Scholar] [CrossRef]

- Jia, H.; Yang, R.; Nguyen, A.E.; Alvillar, S.N.; Empante, T.; Bartelsb, L.; Feng, P.X.L. Large-scale arrays of single- and few-layer MoS2 nanomechanical resonators. Nanoscale 2016, 8, 10677–10685. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Oksanen, M.; Sillanpaa, M.A.; Craighead, H.G.; Parpia, J.M.; Hakonen, P.J. Stamp transferred suspended graphene mechanical resonators for radio frequency electrical readout. Nano Lett. 2012, 12, 198–202. [Google Scholar] [CrossRef]

- Jung, M.; Rickhaus, P.; Zihlmann, S.; Eichler, A.; Makk, P.; Schonenberger, C. GHz nanomechanical resonator in an ultraclean suspended graphene p-n junction. Nanoscale 2019, 11, 4355–4361. [Google Scholar] [CrossRef]

- Singh, V.; Irfan, B.; Subramanian, G.; Solanki, H.S.; Sengupta, S.; Dubey, S.; Kumar, A.; Ramakrishnan, S.; Deshmukh, M.M. Coupling between quantum Hall state and electromechanics in suspended graphene resonator. Appl. Phys. Lett. 2012, 100, 233103. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Q.; Cui, T.H. Ultra-sensitive suspended graphene nanocomposite cancer sensors with strong suppression of electrical noise. Biosens. Bioelectron. 2012, 31, 105–109. [Google Scholar] [CrossRef] [PubMed]

- Lemme, M.C.; Wagner, S.; Lee, K.; Fan, X.; Verbiest, G.J.; Wittmann, S.; Lukas, S.; Dolleman, R.J.; Niklaus, F.; van der Zant, H.S.J.; et al. Nanoelectromechanical Sensors Based on Suspended 2D Materials. Research 2020, 2020, 8748602. [Google Scholar] [CrossRef] [PubMed]

- Masurkar, N.; Varma, S.; Mohana Reddy Arava, L. Supported and Suspended 2D Material-Based FET Biosensors. Electrochem 2020, 1, 260–277. [Google Scholar] [CrossRef]

- Suzuki, D.; Li, K.; Ishibashi, K.; Kawano, Y. A Terahertz Video Camera Patch Sheet with an Adjustable Design based on Self-Aligned, 2D, Suspended Sensor Array Patterning. Adv. Funct. Mater. 2021, 31, 2008931. [Google Scholar] [CrossRef]

- Gupta, R.K.; Alqahtani, F.H.; Dawood, O.M.; Carini, M.; Criado, A.; Prato, M.; Garlapati, S.K.; Jones, G.; Sexton, J.; Persaud, K.C.; et al. Suspended graphene arrays for gas sensing applications. 2D Mater. 2020, 8, 025006. [Google Scholar] [CrossRef]

- Regmi, A.; Shin, D.; Kim, J.-H.; Choi, S.; Chang, J. Suspended graphene sensor with controllable width and electrical tunability via direct-write functional fibers. J. Manuf. Process. 2020, 58, 458–465. [Google Scholar] [CrossRef]

- Wang, Q.; Lei, Y.; Wang, Y.; Liu, Y.; Song, C.; Zeng, J.; Song, Y.; Duan, X.; Wang, D.; Li, Y. Atomic-scale engineering of chemical-vapor-deposition-grown 2D transition metal dichalcogenides for electrocatalysis. Energy Environ. Sci. 2020, 13, 1593–1616. [Google Scholar] [CrossRef]

- Hu, C.X.; Shin, Y.; Read, O.; Casiraghi, C. Dispersant-assisted liquid-phase exfoliation of 2D materials beyond graphene. Nanoscale 2021, 13, 460–484. [Google Scholar] [CrossRef] [PubMed]

- Hoang, A.T.; Qu, K.; Chen, X.; Ahn, J.H. Large-area synthesis of transition metal dichalcogenides via CVD and solution-based approaches and their device applications. Nanoscale 2021, 13, 615–633. [Google Scholar] [CrossRef]

- Liu, J.P.; Liu, H.B.; Peng, W.C.; Li, Y.; Zhang, F.B.; Fan, X.B. High-yield exfoliation of MoS2 (WS2) monolayers towards efficient photocatalytic hydrogen evolution. Chem. Eng. J. 2022, 431, 133286. [Google Scholar] [CrossRef]

- Zhu, W.S.; Gao, X.; Li, Q.; Li, H.P.; Chao, Y.H.; Li, M.J.; Mahurin, S.M.; Li, H.M.; Zhu, H.Y.; Dai, S. Controlled Gas Exfoliation of Boron Nitride into Few-Layered Nanosheets. Angew. Chem. Int. Ed. 2016, 55, 10766–10770. [Google Scholar] [CrossRef] [PubMed]

- Abd-Elrahim, A.G.; Chun, D.-M. Kinetically induced one-step heterostructure formation of Co3O4-Ni(OH)2-graphene ternary nanocomposites to enhance oxygen evolution reactions. J. Alloys Compd. 2022, 906, 164159. [Google Scholar] [CrossRef]

- Abdolhosseinzadeh, S.; Zhang, C.J.; Schneider, R.; Shakoorioskooie, M.; Nuesch, F.; Heier, J. A Universal Approach for Room-Temperature Printing and Coating of 2D Materials. Adv. Mater. 2022, 34, e2103660. [Google Scholar] [CrossRef]

- Moses, O.A.; Gao, L.; Zhao, H.; Wang, Z.; Lawan Adam, M.; Sun, Z.; Liu, K.; Wang, J.; Lu, Y.; Yin, Z.; et al. 2D materials inks toward smart flexible electronics. Mater. Today 2021, 50, 116–148. [Google Scholar] [CrossRef]

- Lindvall, N.; Sun, J.; Yurgens, A. Transfer-free fabrication of suspended graphene grown by chemical vapor deposition. In Proceedings of the 2012 7th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Kyoto, Japan, 5–8 March 2012; pp. 19–22. [Google Scholar]

- Huang, Y.; Sutter, E.; Shi, N.N.; Zheng, J.B.; Yang, T.Z.; Englund, D.; Gao, H.J.; Sutter, P. Reliable Exfoliation of Large-Area High-Quality Flakes of Graphene and Other Two-Dimensional Materials. ACS Nano 2015, 9, 10612–10620. [Google Scholar] [CrossRef]

- Velicky, M.; Donnelly, G.E.; Hendren, W.R.; McFarland, S.; Scullion, D.; DeBenedetti, W.J.I.; Correa, G.C.; Han, Y.M.; Wain, A.J.; Hines, M.A.; et al. Mechanism of Gold-Assisted Exfoliation of Centimeter-Sized Transition-Metal Dichalcogenide Monolayers. ACS Nano 2018, 12, 10463–10472. [Google Scholar] [CrossRef]

- Liu, F.; Wu, W.J.; Bai, Y.S.; Chae, S.H.; Li, Q.Y.; Wang, J.; Hone, J.; Zhu, X.Y. Disassembling 2D van der Waals crystals into macroscopic monolayers and reassembling into artificial lattices. Science 2020, 367, 903–906. [Google Scholar] [CrossRef]

- Luo, H.L.; Li, X.Y.; Zhao, Y.C.; Yang, R.; Bao, L.H.; Hao, Y.F.; Gao, Y.N.; Shi, N.N.; Guo, Y.; Liu, G.D.; et al. Simultaneous generation of direct- and indirect-gap photoluminescence in multilayer MoS2 bubbles. Phys. Rev. Mater. 2020, 4, 074006. [Google Scholar] [CrossRef]

- Lloyd, D.; Liu, X.H.; Boddeti, N.; Cantley, L.; Long, R.; Dunn, M.L.; Bunch, J.S. Adhesion, Stiffness, and Instability in Atomically Thin MoS2 Bubbles. Nano Lett. 2017, 17, 5329–5334. [Google Scholar] [CrossRef]

- Stolyarova, E.; Stolyarov, D.; Bolotin, K.; Ryu, S.; Liu, L.; Rim, K.T.; Klima, M.; Hybertsen, M.; Pogorelsky, I.; Pavlishin, I.; et al. Observation of Graphene Bubbles and Effective Mass Transport under Graphene Films. Nano Lett. 2009, 9, 332–337. [Google Scholar] [CrossRef] [PubMed]

- Villarreal, R.; Lin, P.C.; Faraji, F.; Hassani, N.; Bana, H.; Zarkua, Z.; Nair, M.N.; Tsai, H.C.; Auge, M.; Junge, F.; et al. Breakdown of Universal Scaling for Nanometer-Sized Bubbles in Graphene. Nano Lett. 2021, 21, 8103–8110. [Google Scholar] [CrossRef] [PubMed]

- Prydatko, A.V.; Belyaeva, L.A.; Jiang, L.; Lima, L.M.C.; Schneider, G.F. Contact angle measurement of free-standing square-millimeter single-layer graphene. Nat. Commun. 2018, 9, 4185. [Google Scholar] [CrossRef]

- Yue, K.; Gao, W.; Huang, R.; Liechti, K.M. Analytical methods for the mechanics of graphene bubbles. J. Appl. Phys. 2012, 112, 083512. [Google Scholar] [CrossRef]

- Bertolazzi, S.; Brivio, J.; Kis, A. Stretching and Breaking of Ultrathin MoS2. ACS Nano 2011, 5, 9703–9709. [Google Scholar] [CrossRef] [PubMed]

- Castellanos-Gomez, A.; Poot, M.; Steele, G.A.; van der Zant, H.S.J.; Agrait, N.; Rubio-Bollinger, G. Elastic Properties of Freely Suspended MoS2 Nanosheets. Adv. Mater. 2012, 24, 772–775. [Google Scholar] [CrossRef]

- Huang, J.Y.; Qi, L.; Li, J. In situ imaging of layer-by-layer sublimation of suspended graphene. Nano Res. 2010, 3, 43–50. [Google Scholar] [CrossRef]

- Sharbidre, R.S.; Byen, J.C.; Yun, G.Y.; Ryu, J.K.; Lee, C.J.; Hong, S.G.; Bramhe, S.; Kim, T.N. Residue Free Fabrication of Suspended 2D Nanosheets for in-situ TEM Nanomechanics. Kor. J. Mater. Res. 2018, 28, 627–632. [Google Scholar] [CrossRef]

- Shin, H.; Lee, S.B. Fabrication of suspended graphene field-effect transistors by the sandwich method. Curr. Appl. Phys. 2023, 48, 42–46. [Google Scholar] [CrossRef]

- Lemme, M.C.; Bell, D.C.; Williams, J.R.; Stern, L.A.; Baugher, B.W.H.; Jarillo-Herrero, P.; Marcus, C.M. Etching of Graphene Devices with a Helium Ion Beam. ACS Nano 2009, 3, 2674–2676. [Google Scholar] [CrossRef]

- Nagyte, V.; Kelly, D.J.; Felten, A.; Picardi, G.; Shin, Y.Y.; Alieva, A.; Worsley, R.E.; Parvez, K.; Dehm, S.; Krupke, R.; et al. Raman Fingerprints of Graphene Produced by Anodic Electrochemical Exfoliation. Nano Lett. 2020, 20, 3411–3419. [Google Scholar] [CrossRef] [PubMed]

- Alem, N.; Erni, R.; Kisielowski, C.; Rossell, M.D.; Gannett, W.; Zettl, A. Atomically thin hexagonal boron nitride probed by ultrahigh-resolution transmission electron microscopy. Phys. Rev. B 2009, 80, 155425. [Google Scholar] [CrossRef]

- Archanjo, B.S.; Barboza, A.P.M.; Neves, B.R.A.; Malard, L.M.; Ferreira, E.H.M.; Brant, J.C.; Alves, E.S.; Plentz, F.; Carozo, V.; Fragneaud, B.; et al. The use of a Ga+ focused ion beam to modify graphene for device applications. Nanotechnology 2012, 23, 255305. [Google Scholar] [CrossRef]

- Sepioni, M.; Nair, R.R.; Rablen, S.; Narayanan, J.; Tuna, F.; Winpenny, R.; Geim, A.K.; Grigorieva, I.V. Limits on Intrinsic Magnetism in Graphene. Phys. Rev. Lett. 2010, 105, 207205. [Google Scholar] [CrossRef] [PubMed]

- Bolotin, K.I.; Sikes, K.J.; Hone, J.; Stormer, H.L.; Kim, P. Temperature-Dependent Transport in Suspended Graphene. Phys. Rev. Lett. 2008, 101, 096802. [Google Scholar] [CrossRef]

- Deng, B.; Pang, Z.Q.; Chen, S.L.; Li, X.; Meng, C.X.; Li, J.Y.; Liu, M.X.; Wu, J.X.; Qi, Y.; Dang, W.H.; et al. Wrinkle-Free Single-Crystal Graphene Wafer Grown on Strain-Engineered Substrates. ACS Nano 2017, 11, 12337–12345. [Google Scholar] [CrossRef]

- Mayorov, A.S.; Elias, D.C.; Mukhin, I.S.; Morozov, S.V.; Ponomarenko, L.A.; Novoselov, K.S.; Geim, A.K.; Gorbachev, R.V. How Close Can One Approach the Dirac Point in Graphene Experimentally? Nano Lett. 2012, 12, 4629–4634. [Google Scholar] [CrossRef] [PubMed]

- Mun, J.H.; Cho, B.J. Synthesis of Monolayer Graphene Having a Negligible Amount of Wrinkles by Stress Relaxation. Nano Lett. 2013, 13, 2496–2499. [Google Scholar] [CrossRef] [PubMed]

- Mun, J.H.; Oh, J.G.; Bong, J.H.; Xu, H.; Loh, K.P.; Cho, B.J. Wrinkle-free graphene with spatially uniform electrical properties grown on hot-pressed copper. Nano Res. 2015, 8, 1075–1080. [Google Scholar] [CrossRef]

- Shi, Y.M.; Dong, X.C.; Chen, P.; Wang, J.L.; Li, L.J. Effective doping of single-layer graphene from underlying SiO2 substrates. Phys. Rev. B 2009, 79, 115402. [Google Scholar] [CrossRef]

- Chen, J.H.; Jang, C.; Xiao, S.D.; Ishigami, M.; Fuhrer, M.S. Intrinsic and extrinsic performance limits of graphene devices on SiO2. Nat. Nanotechnol. 2008, 3, 206–209. [Google Scholar] [CrossRef]

- Li, Q.A.; Cheng, Z.G.; Li, Z.J.; Wang, Z.H.; Fang, Y. Fabrication of suspended graphene devices and their electronic properties. Chin. Phys. B 2010, 19, 4. [Google Scholar]

- Feldman, B.E.; Krauss, B.; Smet, J.H.; Yacoby, A. Unconventional Sequence of Fractional Quantum Hall States in Suspended Graphene. Science 2012, 337, 1196–1199. [Google Scholar] [CrossRef] [PubMed]

- Ki, D.K.; Fal’ko, V.I.; Abanin, D.A.; Morpurgo, A.F. Observation of Even Denominator Fractional Quantum Hall Effect in Suspended Bilayer Graphene. Nano Lett. 2014, 14, 2135–2139. [Google Scholar] [CrossRef]

- Ki, D.K.; Morpurgo, A.F. High-Quality Multiterminal Suspended Graphene Devices. Nano Lett. 2013, 13, 5165–5170. [Google Scholar] [CrossRef][Green Version]

- Guo, Y.; Huang, Y.; Du, S.; Sun, C.; Tian, S.; Luo, H.; Liu, B.; Zhou, X.; Li, J.; Gu, C. Real-space light-reflection mapping of atomically thin WSe2 flakes revealing the gradient local strain. Mater. Res. Express 2020, 7, 035904. [Google Scholar] [CrossRef]

- Rostami, H.; Roldán, R.; Cappelluti, E.; Asgari, R.; Guinea, F. Theory of strain in single-layer transition metal dichalcogenides. Phys. Rev. B 2015, 92, 195402. [Google Scholar] [CrossRef]

- Liao, Y.T.; Peng, S.Y.; Chuang, K.W.; Liao, Y.C.; Kuramitsu, Y.; Woon, W.Y. Exploring the mechanical properties of nanometer-thick elastic films through micro-drop impinging on large-area suspended graphene. Nanoscale 2021, 14, 42–48. [Google Scholar] [CrossRef]

- Yoshida, M.; Kudo, K.; Nohara, M.; Iwasa, Y. Metastable Superconductivity in Two-Dimensional IrTe2 Crystals. Nano Lett. 2018, 18, 3113–3117. [Google Scholar] [CrossRef]

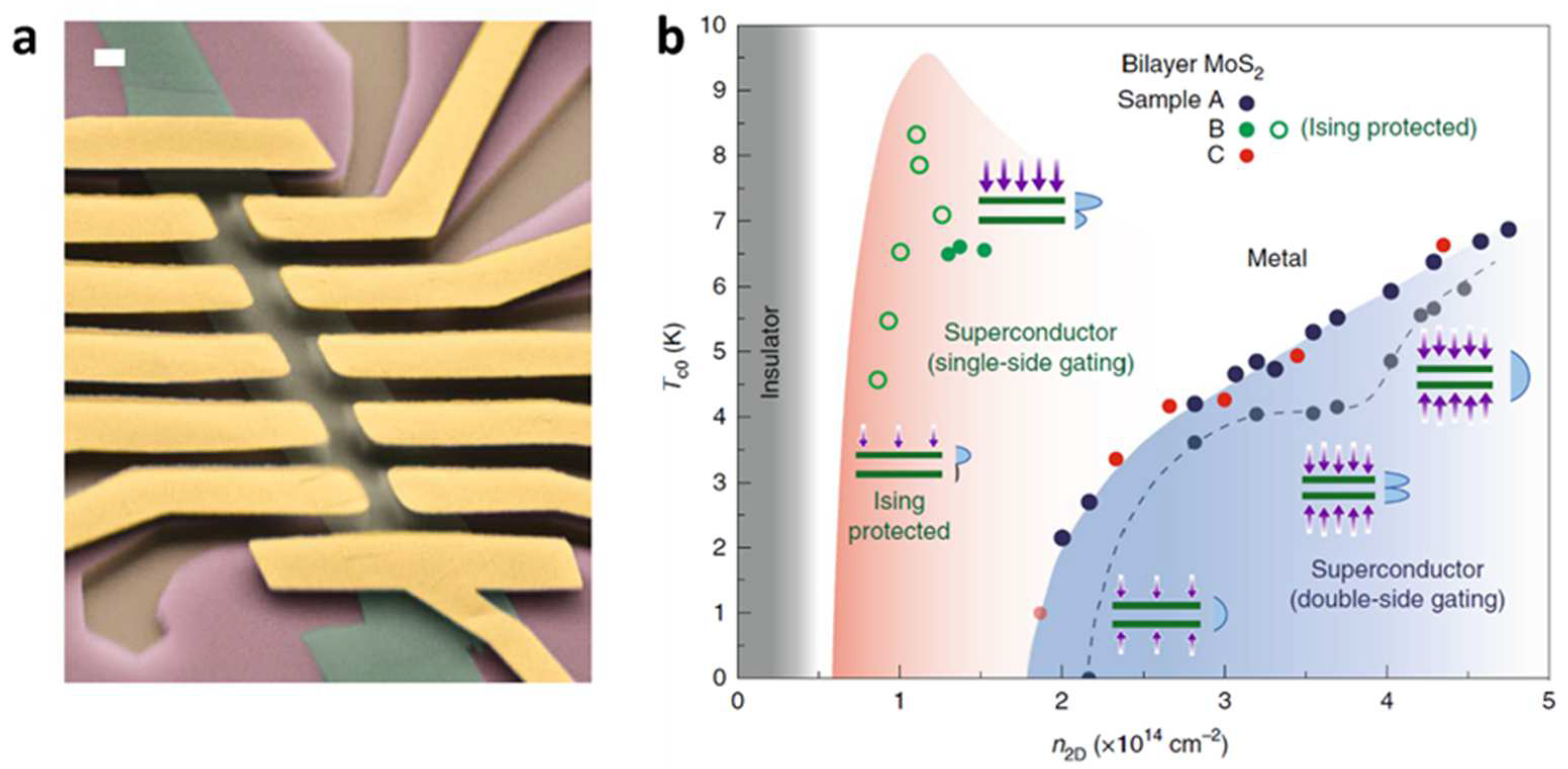

- Lu, J.M.; Zheliuk, O.; Leermakers, I.; Yuan, N.F.Q.; Zeitler, U.; Law, K.T.; Ye, J.T. Evidence for two-dimensional Ising superconductivity in gated MoS2. Science 2015, 350, 1353–1357. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; MacDonald, A.H.; Martin, I. Theory of Phonon-Mediated Superconductivity in Twisted Bilayer Graphene. Phys. Rev. Lett. 2018, 121, 257001. [Google Scholar] [CrossRef]

- Potirniche, I.-D.; Maciejko, J.; Nandkishore, R.; Sondhi, S.L. Superconductivity of disordered Dirac fermions in graphene. Phys. Rev. B 2014, 90, 094516. [Google Scholar] [CrossRef]

- Zheliuk, O.; Lu, J.M.; Chen, Q.H.; Yumin, A.A.E.; Golightly, S.; Ye, J.T. Josephson coupled Ising pairing induced in suspended MoS2 bilayers by double-side ionic gating. Nat. Nanotechnol. 2019, 14, 1123–1128. [Google Scholar] [CrossRef] [PubMed]

- Brumme, T.; Calandra, M.; Mauri, F. First-principles theory of field-effect doping in transition-metal dichalcogenides: Structural properties, electronic structure, Hall coefficient, and electrical conductivity. Phys. Rev. B 2015, 91, 155436. [Google Scholar] [CrossRef]

- Ye, J.T.; Zhang, Y.J.; Akashi, R.; Bahramy, M.S.; Arita, R.; Iwasa, Y. Superconducting Dome in a Gate-Tuned Band Insulator. Science 2012, 338, 1193–1196. [Google Scholar] [CrossRef]

- Mizuno, N.; Nielsen, B.; Du, X. Ballistic-like supercurrent in suspended graphene Josephson weak links. Nat. Commun. 2013, 4, 2716. [Google Scholar] [CrossRef]

- Han, S.Q.; Zhou, S.Y.; Mei, L.Y.; Guo, M.L.; Zhang, H.Y.; Li, Q.N.; Zhang, S.; Niu, Y.K.; Zhuang, Y.; Geng, W.P.; et al. Nanoelectromechanical Temperature Sensor Based on Piezoresistive Properties of Suspended Graphene Film. Nanomaterials 2023, 13, 1103. [Google Scholar] [CrossRef]

- Smith, A.D.; Vaziri, S.; Niklaus, F.; Fischer, A.C.; Sterner, M.; Delin, A.; Östling, M.; Lemme, M.C. Pressure sensors based on suspended graphene membranes. Solid-State Electron. 2013, 88, 89–94. [Google Scholar] [CrossRef]

- Chen, Y.M.; He, S.M.; Huang, C.H.; Huang, C.C.; Shih, W.P.; Chu, C.L.; Kong, J.; Li, J.; Su, C.Y. Ultra-large suspended graphene as a highly elastic membrane for capacitive pressure sensors. Nanoscale 2016, 8, 3555–3564. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-M.; Lee, C.-K.; Yoon, S.-U.; Kim, K.-S.; Hwangbo, Y. Residue-free suspended graphene transferred by perforated template. Nanotechnology 2022, 33, 165301. [Google Scholar] [CrossRef]

- Fan, X.; Smith, A.D.; Forsberg, F.; Wagner, S.; Schröder, S.; Akbari, S.S.A.; Fischer, A.C.; Villanueva, L.G.; Östling, M.; Lemme, M.C.; et al. Manufacture and characterization of graphene membranes with suspended silicon proof masses for MEMS and NEMS applications. Microsyst. Nanoeng. 2020, 6, 17. [Google Scholar] [CrossRef] [PubMed]

- Surwade, S.P.; Smirnov, S.N.; Vlassiouk, I.V.; Unocic, R.R.; Veith, G.M.; Dai, S.; Mahurin, S.M. Water desalination using nanoporous single-layer graphene. Nat. Nanotechnol. 2015, 10, 459–464. [Google Scholar] [CrossRef] [PubMed]

- Yoon, H.W.; Cho, Y.H.; Park, H.B. Graphene-based membranes: Status and prospects. Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2016, 374, 20150024. [Google Scholar] [CrossRef] [PubMed]

| Graphene | Suspended Graphene | |

|---|---|---|

| Mobility 1 | 2000–15,000 cm2/Vs | 250,000 cm2/Vs |

| Thermal conductivity 2 | 600 W/mK | 2000–5000 W/mK |

| Tensile strains | — | 1% |

| MoS2 | Suspended MoS2 | |

|---|---|---|

| Mobility 1 | 0.1 cm2/Vs | 0.9 cm2/Vs |

| On/off ratio 1 | 104 | 105 |

| Young modulus 2 | — | 0.33 ± 0.07 Tpa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Xue, T.; Han, X.; Huang, X.; Zhang, D.; Huang, M.; Yan, J.; Zhao, J.; Laxmi, V.; Liu, L.; et al. Suspended 2D Materials: A Short Review. Crystals 2023, 13, 1337. https://doi.org/10.3390/cryst13091337

Dai Y, Xue T, Han X, Huang X, Zhang D, Huang M, Yan J, Zhao J, Laxmi V, Liu L, et al. Suspended 2D Materials: A Short Review. Crystals. 2023; 13(9):1337. https://doi.org/10.3390/cryst13091337

Chicago/Turabian StyleDai, Yunyun, Tongtong Xue, Xu Han, Xinyu Huang, Decheng Zhang, Mengting Huang, Jiahao Yan, Jinghan Zhao, Vijay Laxmi, Liwei Liu, and et al. 2023. "Suspended 2D Materials: A Short Review" Crystals 13, no. 9: 1337. https://doi.org/10.3390/cryst13091337

APA StyleDai, Y., Xue, T., Han, X., Huang, X., Zhang, D., Huang, M., Yan, J., Zhao, J., Laxmi, V., Liu, L., Xu, X., Wang, Y., & Huang, Y. (2023). Suspended 2D Materials: A Short Review. Crystals, 13(9), 1337. https://doi.org/10.3390/cryst13091337