Abstract

The effects of cold rolling reduction on the microstructure, recrystallization behavior, and magnetic properties of 3.0%Si-0.8%Al-0.3%Mn steel were studied by X-ray diffraction (XRD) and electron backscatter diffraction (EBSD). With the reduction rates of 78%, 85% and 87% in the cold rolled sheet, the width of the deformation band becomes narrower, the number of intragranular shear bands decreases, and the proportion of grain boundaries increases. The intensity of the α and γ fibers texture in the cold rolled sheet is enhanced, and the annealed sheet is dominated by the γ fibers texture and the content increases from 26.0% to 34.5%. During the recrystallization process, the Goss and γ-grains nucleate first. The λ-grains nucleate mainly at the grain boundaries of the deformed α-grains, and the α-grains ultimately recrystallize. With the increase in the cold rolling reduction rate, the γ-grains develop into the main texture due to a large amount of nucleation at the deformation band and grain boundary. The λ-grains with a high mobility do not have a numerical advantage, and the increase in the texture content is very small. The content of the unfavorable γ fiber texture in the annealed sheet increases, the magnetic induction intensity B50 decreases, Pe and Pt decrease significantly, and the critical grain size with the lowest iron loss decreases from 136.2 to 109.4 μm.

1. Introduction

Non-oriented silicon steel has excellent soft magnetic materials with low iron loss characteristics and is widely used in high-end home appliances, new energy vehicle drive motors, and high-efficiency industrial motors [1,2]. In the context of carbon neutralization and energy conservation and emission reduction, improving the energy conversion efficiency of these electrical devices to reduce energy loss requires higher magnetic properties of the iron core materials [3,4,5]. The increasing of Si content and reducing the thickness of the product are the most effective methods to reduce the loss of non-oriented silicon steel. Especially under the condition of high frequency service, the eddy current loss is dominant, and the loss of thin silicon steel is lower and the advantage is more obvious [6,7,8,9]. Due to the manufacturing cost, work efficiency and market demand, how to adjust the cold rolling process to prepare different specifications of high silicon non-oriented silicon steel with an excellent performance by one-time cold rolling is an urgent problem to be solved. The cold rolling reduction rate is also different in the production process of non-oriented silicon steel with different specifications. The change of cold rolling reduction rate will directly affect the deformation microstructure, thus affecting the formation of recrystallized grains and then changing the magnetic properties [10].

Based on previous studies [11,12,13,14], the effects of different cold rolling reduction rates (60~95%) on the number and characteristics of micro-shear bands of cold rolled bands were proved. Under the medium reduction rate (60~70%), there are a large number of shear bands in the cold rolled band. As the reduction rate (80~95%) increases, the number and area of shear bands in the band decrease significantly until the grain fragmentation is completely replaced by the fibrous structure. The cold rolling reduction rate further analyzes the formation of the recrystallization texture by changing the deformation texture and the deformation structure including the shear band, deformation band and grain boundary region. Studies [15,16,17] have shown that the recrystallization texture of non-oriented silicon steel is concentrated in the Goss, α, γ and λ textures, and the competition of the texture components during recrystallization is mainly concentrated between γ and Goss. With the increase in the cold rolling reduction, the recrystallization mechanism changes from shear band nucleation to deformation band and grain boundary nucleation, resulting in the weakening of the recrystallization Goss component and the enhancement of the λ and {111}<112> recrystallization texture components [18,19]. However, the competitive relationship between the α, λ and γ texture components during recrystallization and the grain growth of the annealed sheets with different cold rolling reduction rates still needs to be systematically studied.

In this study, the effects of the cold rolling reduction on the deformation structure and texture, recrystallization texture evolution and magnetic properties of cold rolled band were studied by using 3.0%Si-0.8%Al-0.3%Mn non-oriented silicon steel 2.3 mm thick hot rolled band as raw material. By systematically analyzing the formation and growth of the recrystallized grains and their transformation with cold rolling reduction, the microstructure and texture of the annealed sheet were controlled by the annealing temperature to optimize the final magnetic properties. This provides theoretical support for improving the magnetic properties of non-oriented silicon steel with different specifications.

2. Materials and Methods

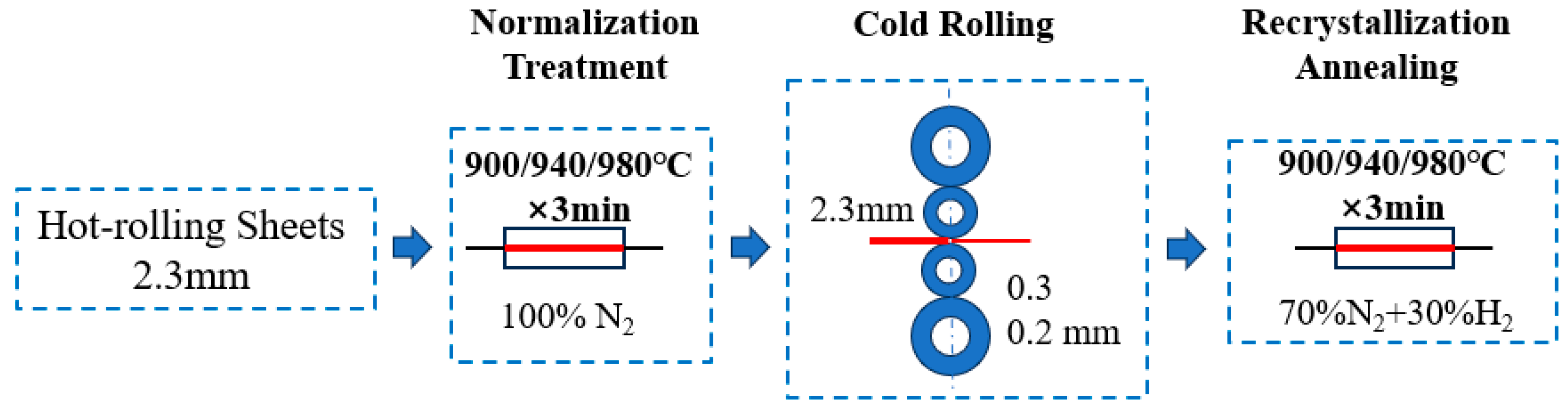

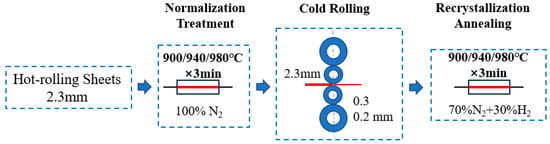

This experiment selected 2.3 mm thick non-oriented silicon steel hot-rolled sheet with the same hot rolling process conditions in the same furnace of industrial production as the experimental raw material. The main components (wt, %) were: C0.0023, Si3.11, Mn0.296, S0.0016, Al0.98, N0.0015 and Fe balance. The hot rolled sheets were subjected to a uniform normalization treatment at 950 °C for 3 min in a pure N2 atmosphere, and then air cooled to room temperature. The heat treatment process of the normalized sheet before cold rolling was consistent. After acid washing to remove the surface oxides, the normalized sheets were rolled to 0.5, 0.35 and 0.3 mm with reduction rates of 78%, 85% and 87%, respectively. The processing schematic diagram of non-oriented silicon steel in this experiment is shown in Figure 1.

Figure 1.

Processing route diagram of non-oriented silicon steel.

After standard grinding and polishing, the annealed samples were etched with 5% nitric acid alcohol solution. The metallographic structure was observed under an optical microscope (OM, DM4000, Wetzlar, Germany). The recrystallization ratio of the annealed band was estimated by Image-Pro Plus 6.0 software. The average grain size of the metallographic sample was measured according to the GB/T 6394-2002 linear intercept method. The iron loss (P1.5/50) and magnetic induction (B50) of 30 × 300 mm single chip was measured by a magnetic measuring instrument (NIM-2000E AC, Beijing, China). The microstructure characteristics were detected by scanning electron microscopy (SEM, ZEISS SUPRA 55VP, Oberkochen, Germany) with electron backscatter diffraction system. The orientation distribution function (ODF) analysis, distribution analysis of specific orientation grains and quantitative statistics were analyzed by OIM 7.3 software. The main texture content was calculated with a deviation angle of 15°. The macroscopic texture of the sample was measured by X-ray diffraction.

3. Experimental Results

3.1. Microstructure and Texture Characteristics of Hot Rolled Sheet and Normalized Sheet

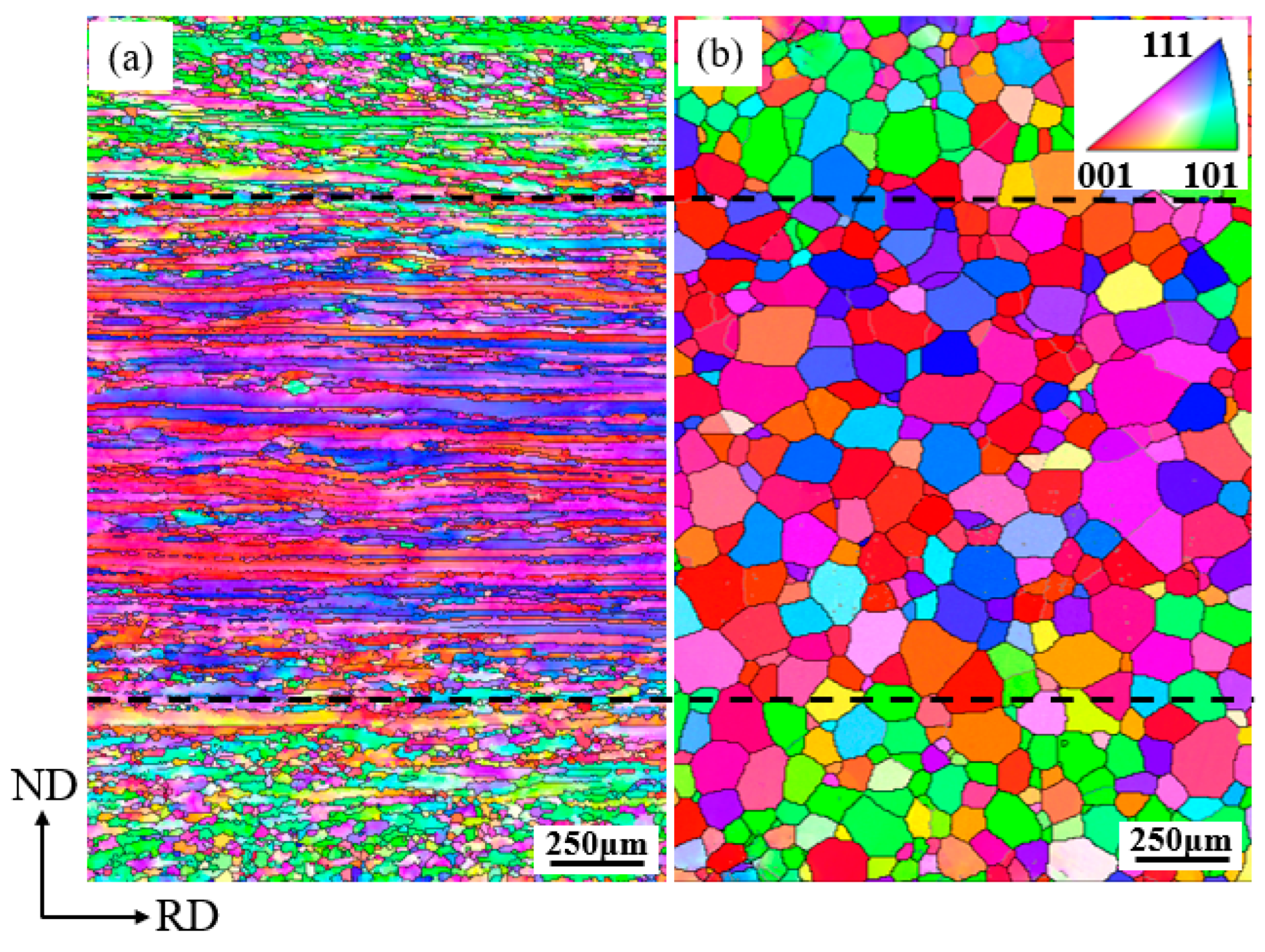

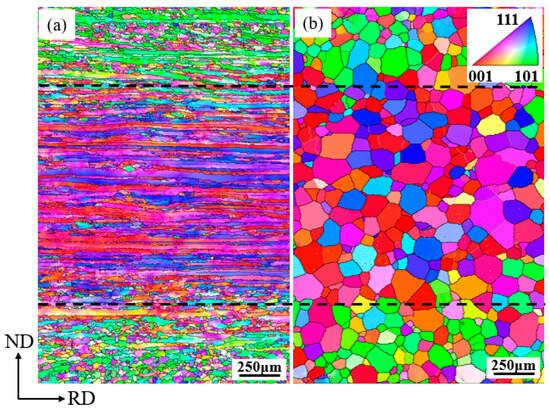

Figure 2a,c is the grain orientation diagram and macro texture of the hot rolled band. There are obvious differences in the microstructure and texture of the hot rolled sheet in the thickness direction. The surface layer is dominated by fine recrystallized grains, and the texture is dominated by a strong Goss texture, while the middle layer is dominated by deformed grains elongated along the rolling direction, and its texture is composed of strong α and λ fiber textures.

Figure 2.

Grain orientation distribution and ODF section (φ2 = 45°): (a,c) hot rolled bands; (b,d) normalized bands.

After the hot rolled sheet is normalized at 950 °C for 3 min, the fine equiaxed grains in the surface layer grow further, and the deformed microstructure in the central layer is completely recrystallized to form coarse grains. It can be seen from the grain orientation diagram of the normalized sheet in Figure 2b that the uniformity of the microstructure and the gradient of the texture in the thickness direction of the normalized sheet are improved. The surface layer of the normalized band is mainly composed of equiaxed grains with smaller {110} orientation, while the central layer is mainly composed of grains with larger {001} and {111} orientations. The grain size distribution of the normalized sheet was 85.3 μm using the method of equivalent circle diameter. Combined with the macro texture of the normalized band in Figure 2d, the strongest texture is {100}<011>, and the texture intensity is 5.6. Compared with the hot rolled sheet, the texture intensity of the α fiber decreases, and there is a tendency to change to a α* fiber texture [20].

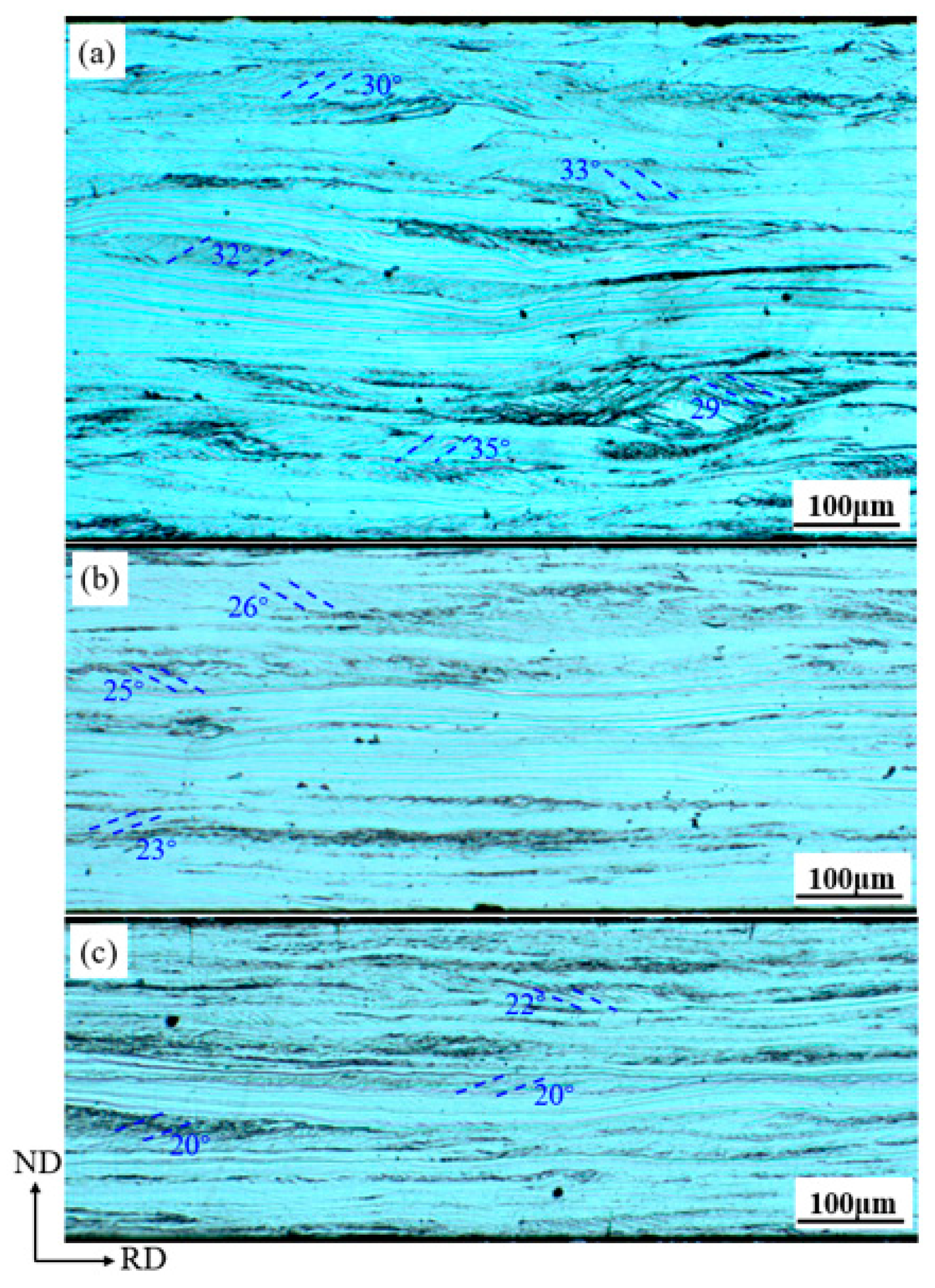

3.2. Microstructure and Texture Characteristics of Cold Rolled Sheet

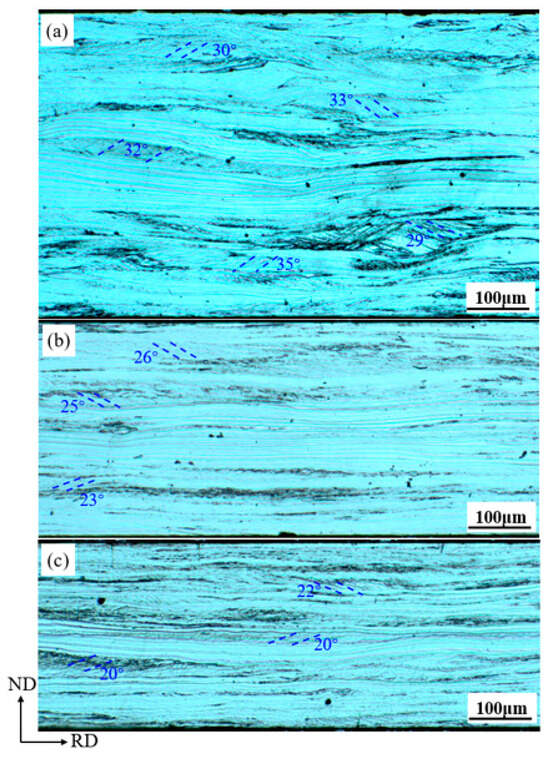

Figure 3 is the microstructure of the cold rolled sheet with 78%, 85% and 87% reduction. The microstructure of the cold rolled sheet is mainly composed of deformed grains elongated along the rolling direction, and some of the deformed grains have shear bands with 20~35° to the rolling surface. The cold rolling reduction rate of the deformed strip has a significant effect on the characteristics of the shear band. The difference of corrosion degree of the cold rolled sheet is related to the difference of the deformation storage energy [13,17]. The deformation band has low energy storage and a low corrosion degree, which is a bright band. The grain boundary position with higher hardness and the intragranular shear band formed by the γ grains with a higher Taylor factor and flow stress [19,21], both of which have higher cold storage capacity, a greater corrosion degree and a deeper color. When the cold rolling reduction rate is 78%, there are coarse intragranular shear bands in the wider deformed grains, and the inclination angle between the shear band and the rolling direction is 29~35°. When the cold rolling reduction rate is 85%, the deformation band becomes narrower, the shear band becomes thinner, and the inclination angle with the rolling direction is reduced to 23~26°. While the cold rolling reduction rate increases to 87%, the grains are fragmented, the number of deformation bands becomes greater, thin and narrow, and the overlap between some shear bands and the grain boundaries becomes blurred, and there are still a small number of short shear bands with clear structural characteristics. For the same grain size of normalized band before cold rolling, with the increase in the cold rolling reduction rate, the dislocation density and the cold rolling energy storage in cold rolled band increase, the width of the deformation band narrows, the proportion of grain boundary increases, and the number of intragranular shear bands and the inclination angle with rolling direction decrease.

Figure 3.

Microstructure of cold rolled sheets with different cold rolling reduction rates. (a) 0.5 mm; (b) 0.35 mm; (c) 0.3 mm.

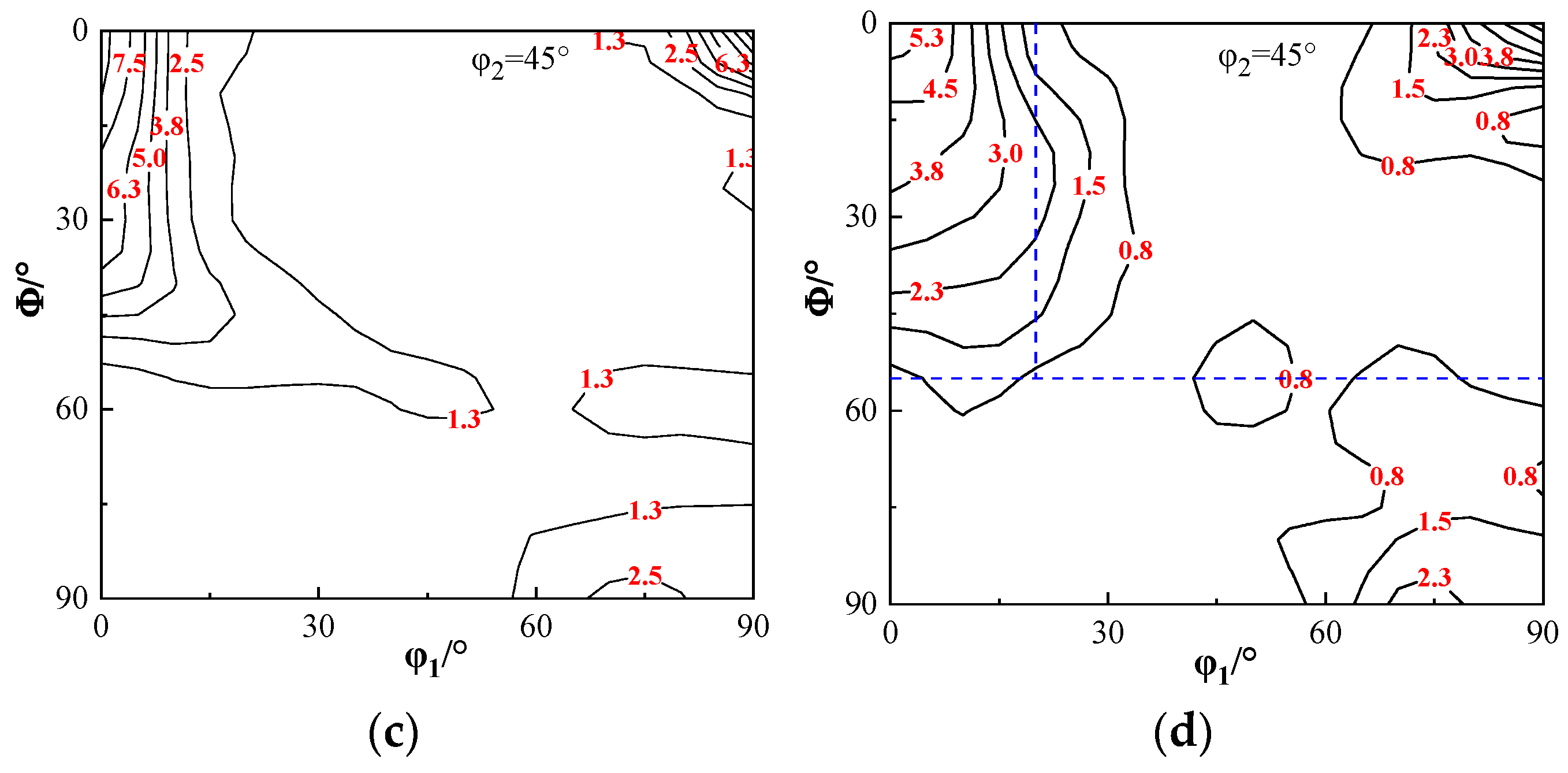

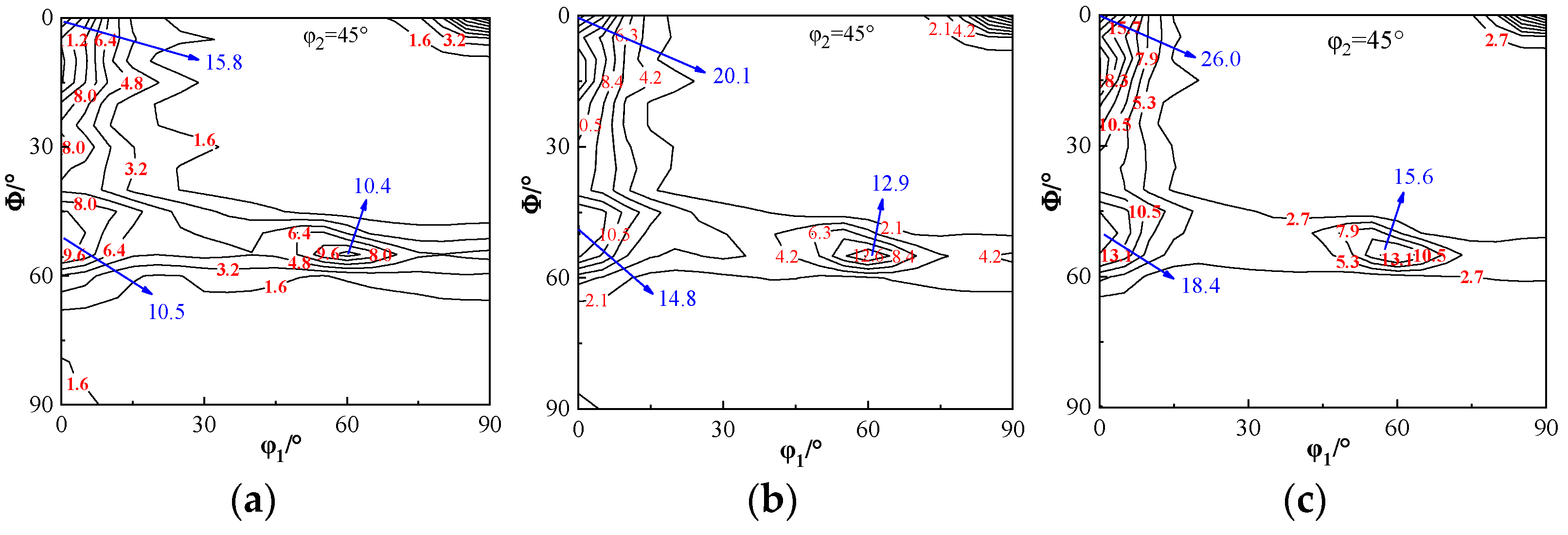

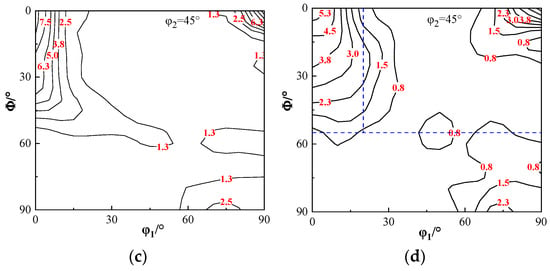

From the macroscopic texture of the cold rolled band in Figure 4, it can be seen that the samples with different thicknesses show a strong α fiber texture and weak γ fiber texture. The α and γ fiber textures have the highest strength at the {100}<110> and {111}<112> components, respectively. With the increase in the cold rolling reduction rate, the texture strength of α and γ fibers of cold rolled sheet increases continuously.

Figure 4.

ODF section (φ2 = 45°) of cold rolled sheets with different cold rolling reduction. (a) 0.5 mm; (b) 0.35 mm; (c) 0.3 mm.

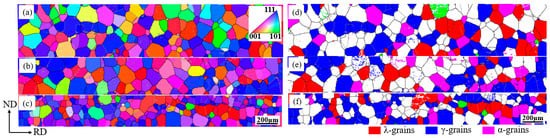

3.3. Microstructure and Texture Characteristics of Annealed Sheet

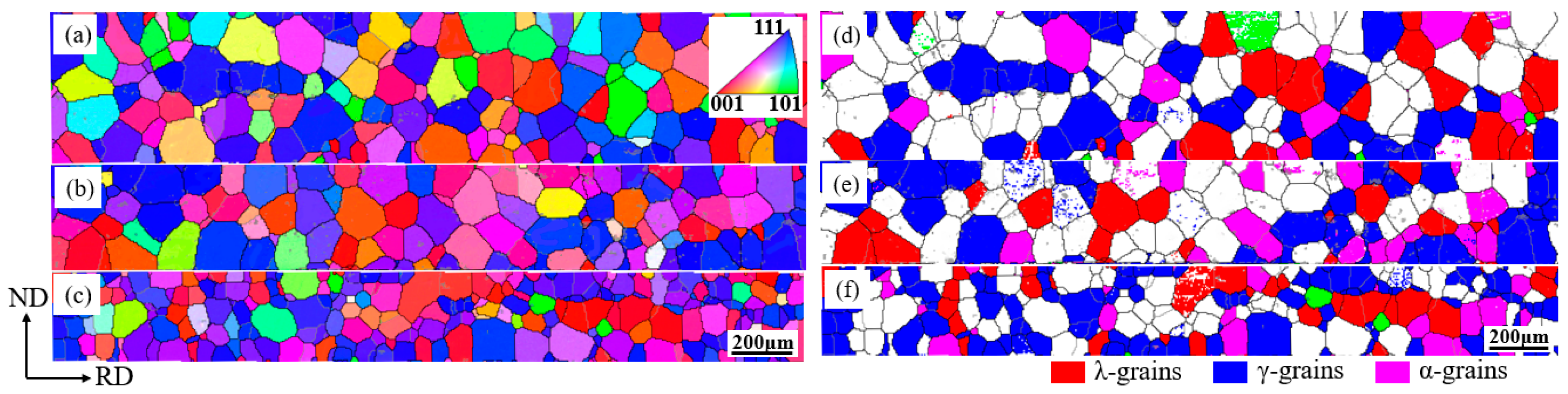

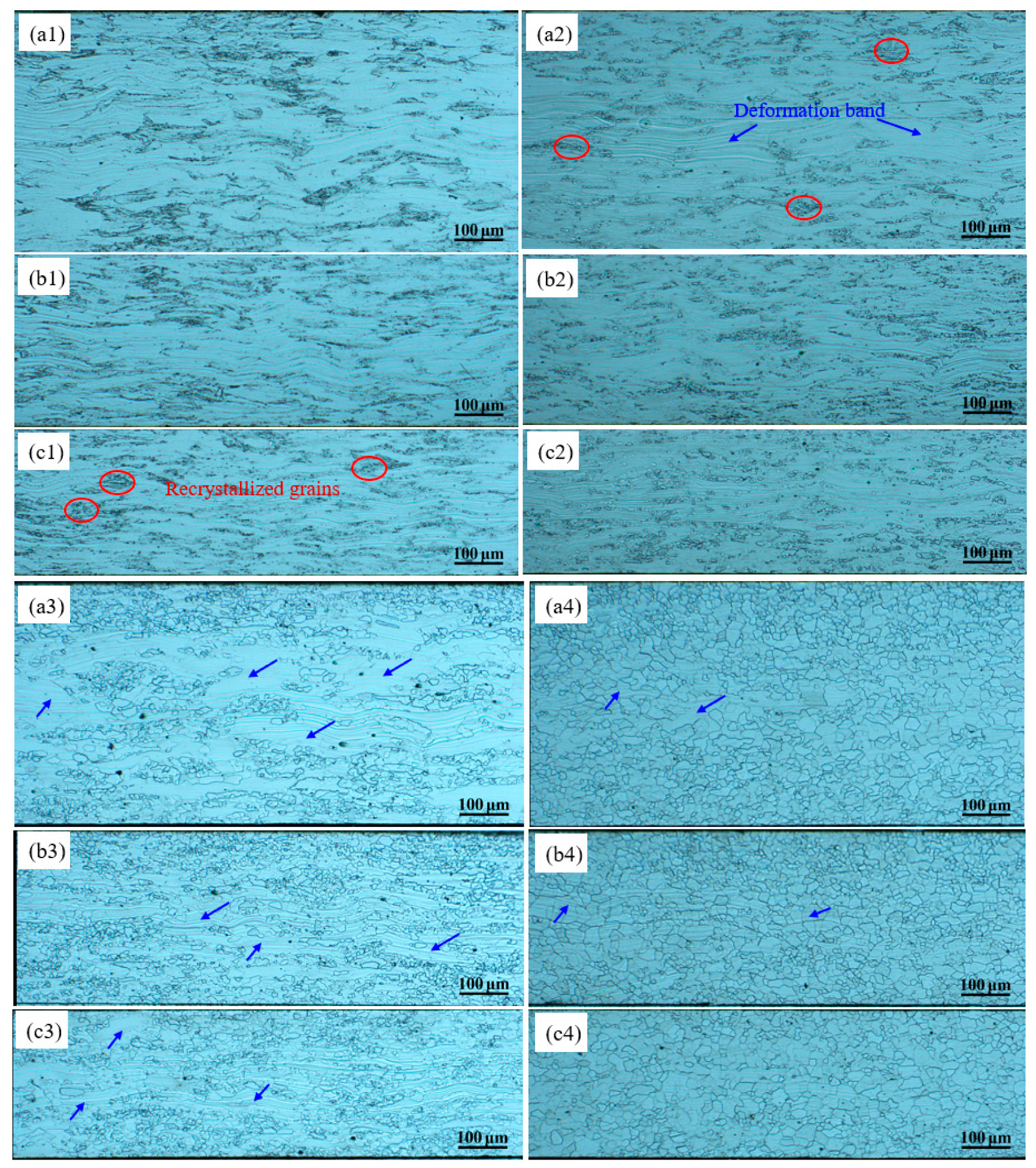

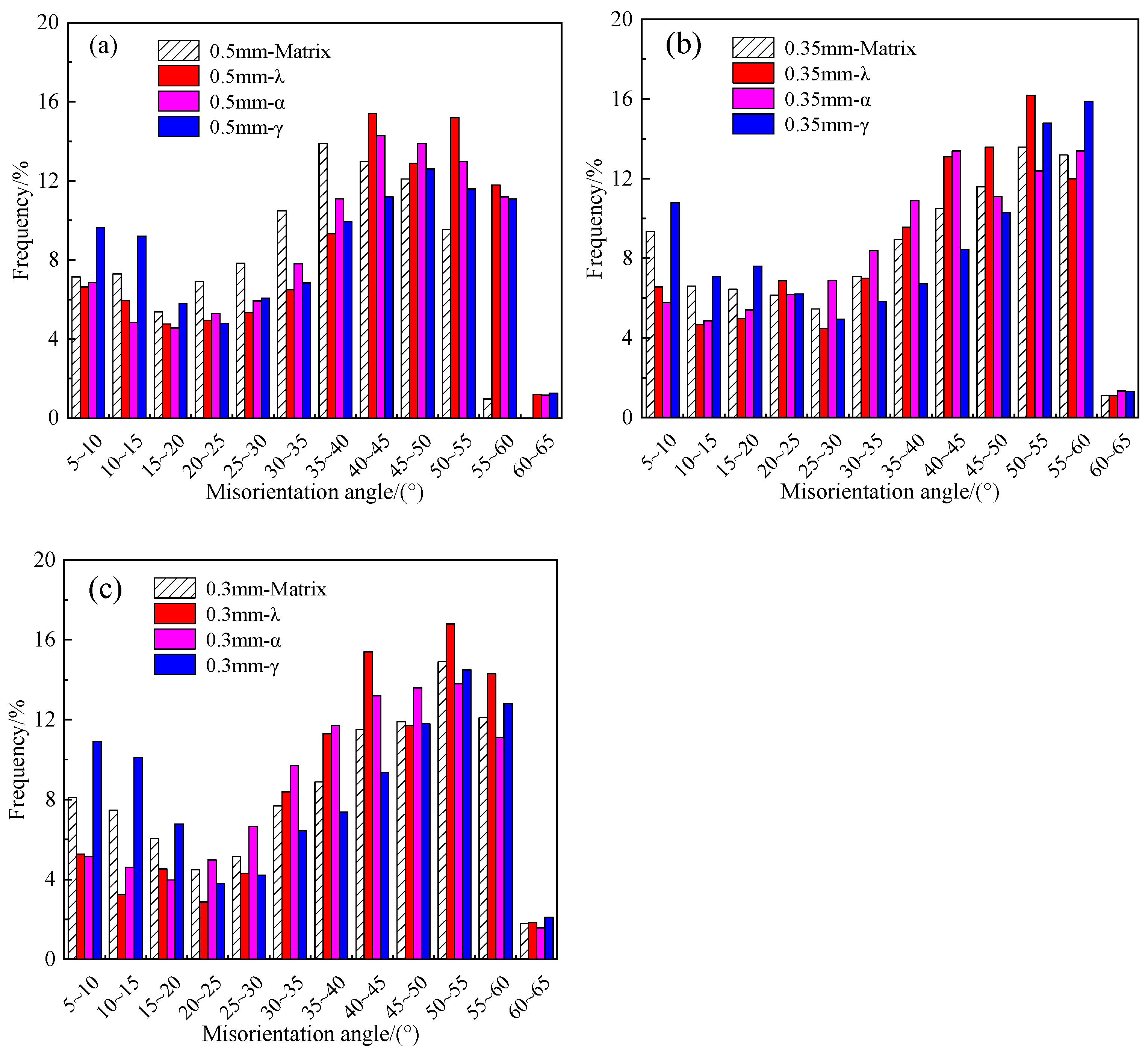

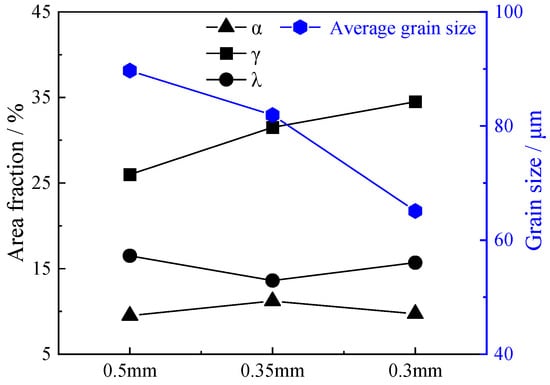

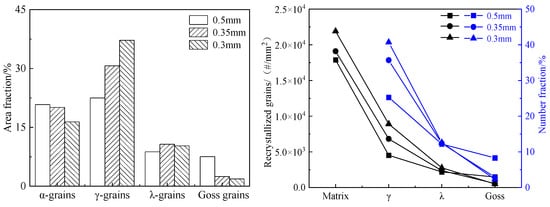

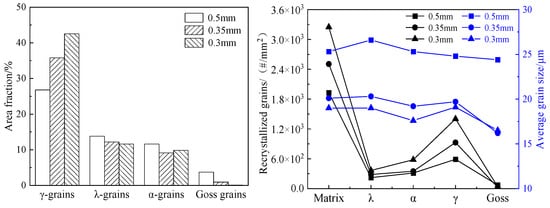

The substructures of different deformed microstructures in cold rolled sheets caused by different cold rolling reduction rates have a significant effect on the evolution of the microstructure and texture during subsequent annealing. After annealing at 940 °C for 3 min, the recrystallized nucleus and grain growth occurred in the deformed matrix of the cold rolled sheet, and the microstructure after annealing was equiaxed ferrite grains. The special grain orientation and texture content after annealing are shown in Figure 5 and Figure 6. The average grain sizes of the annealed sheet with thicknesses of 0.5, 0.35 and 0.3 mm are 89.7, 81.9 and 65.1 μm, respectively. The main factors affecting the microstructure of the annealed sheet are the nucleation rate (N) and grain growth rate (G) during the recrystallization process. With the increase in the cold rolling reduction rate, the accumulation of deformation energy storage and the grain boundary density of the cold rolled sheet will increase, and the energy storage driving the grain nucleation will increase, resulting in a faster increase in N and an increase in N/G. Due to the fact that the recrystallized grain size is d ∝ G/N, the recrystallized grains are refined, meaning that the grain size is smaller under the same annealing conditions [9,22,23]. The annealed sheet is dominated by a γ fiber texture. With the increase in the cold rolling reduction, the γ texture is continuously enhanced, and the area fractions are 26.0, 31.3 and 34.5%, respectively.

Figure 5.

Grain orientation and special texture orientation of annealed sheet at 940 °C for 3 min. (a,d) 0.5 mm; (b,e) 0.35 mm; (c,f) 0.3 mm.

Figure 6.

Changes of special texture area fraction and average grain size of annealed sheet at 940 °C for 3 min.

4. Analysis and Discussion

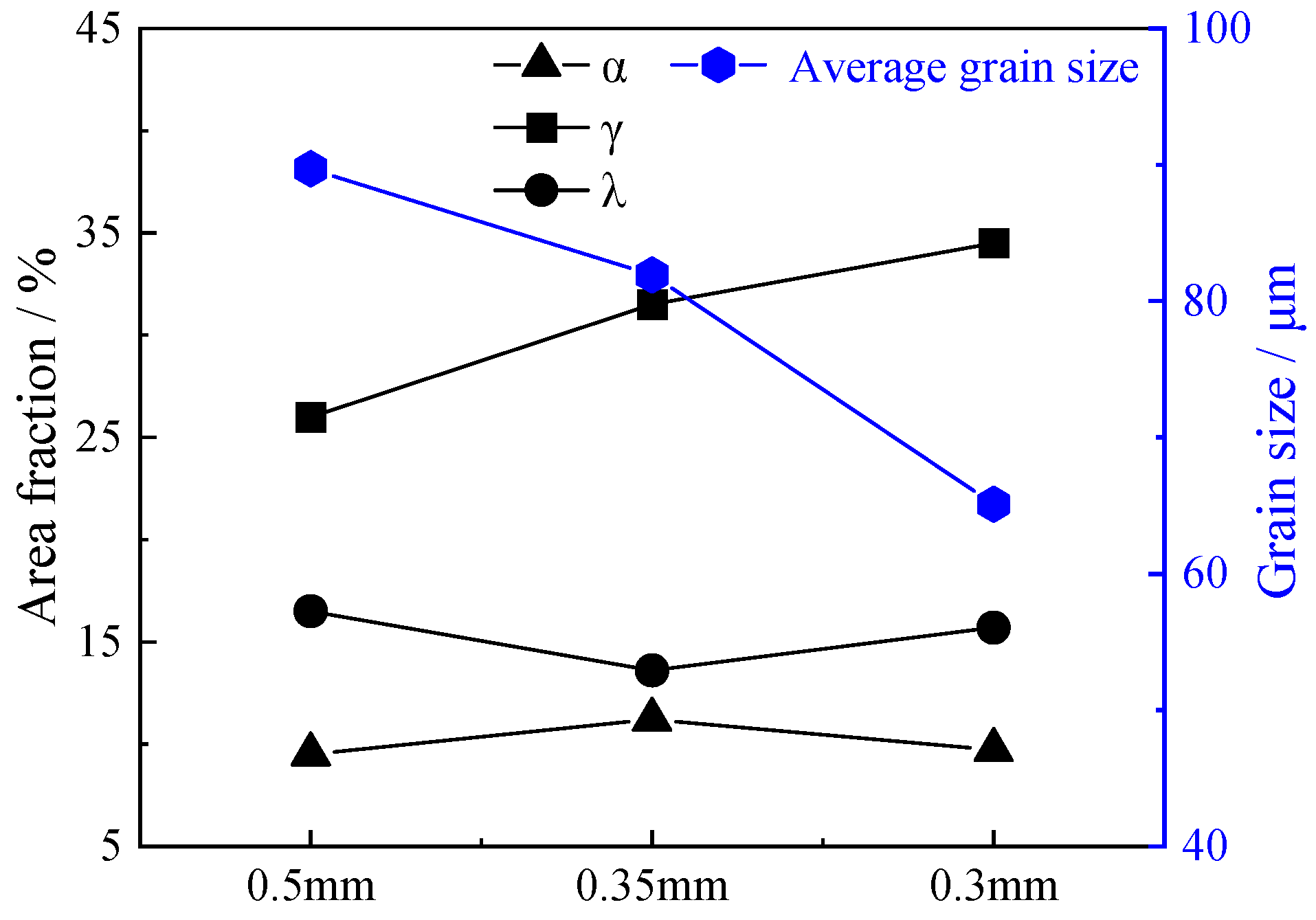

4.1. Recrystallization Kinetics

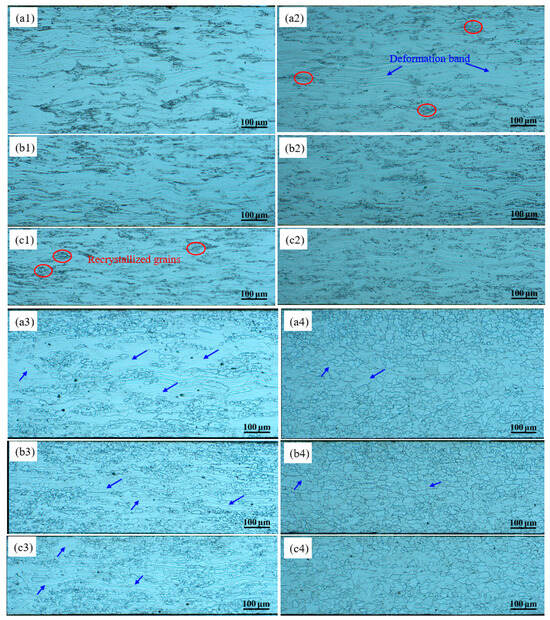

In order to further study the effect of the cold rolling reduction rate on the recrystallization of the deformed structure of the cold rolled sheet during annealing, the cold rolled sheet of 0.5, 0.35 and 0.3 mm were annealed in the annealing temperature range of 600~800 °C for 3 min, respectively. The recrystallization structure of the cold rolled sheet at different annealing temperatures is shown in Figure 7. After annealing at 640 °C, the cold rolled sheets of 0.5 and 0.35 mm only recovered to a certain extent, and no recrystallization occurred, while the cold rolled sheets of 0.3 mm nucleated first by a small number of small grains at the grain boundary and the intragranular shear band. When the annealing temperature is 660 °C, the 0.5 and 0.35 mm cold rolled sheets accumulate a small amount of recrystallized grains at a higher energy storage position, and the small grains previously nucleated in the 0.3 mm cold rolled sheet grow to a certain extent. Under the annealing condition of 700 °C, the recrystallization degree of the three is further expanded. At this time, with the increase in the cold rolling reduction rate, the recrystallization ratio of the cold rolled sheet increases, while the proportion and width of the deformed microstructure which is difficult to recrystallize in the band decrease. When the annealing temperature is increased to 760 °C, most of the samples are recrystallized, and there is a small amount of deformed structure surrounded by the recrystallized grains along the rolling direction in 0.5 and 0.35 mm cold rolled bands.

Figure 7.

The recrystallization microstructure evolution of cold rolled sheets with thickness of 0.5 mm, 0.35 mm and 0.3 mm at different annealing temperatures. (a1,b1,c1) 640 °C × 3 min; (a2,b2,c2) 660 °C × 3 min; (a3,b3,c3) 700 °C × 3 min; (a4,b4,c4) 760 °C × 3 min.

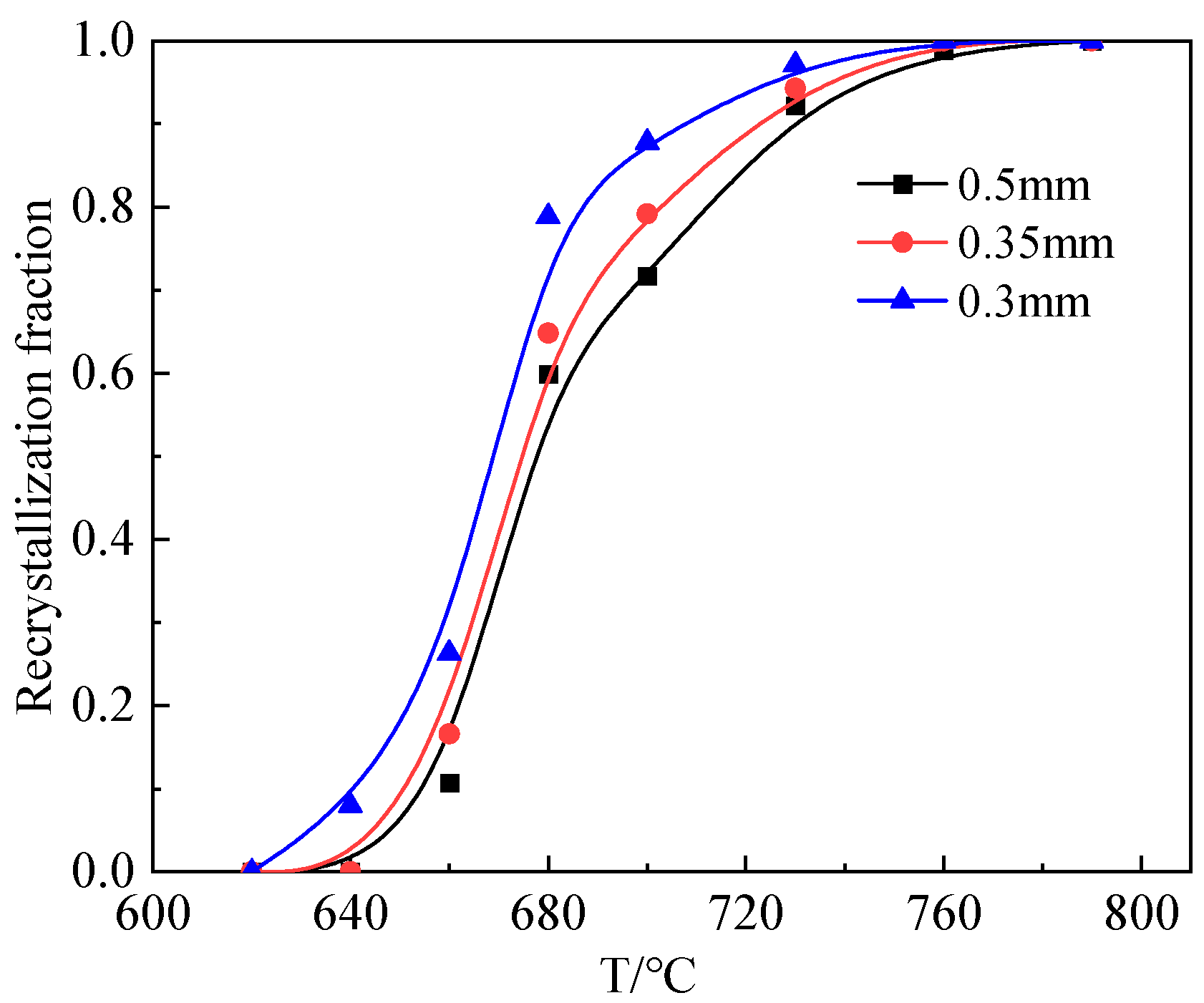

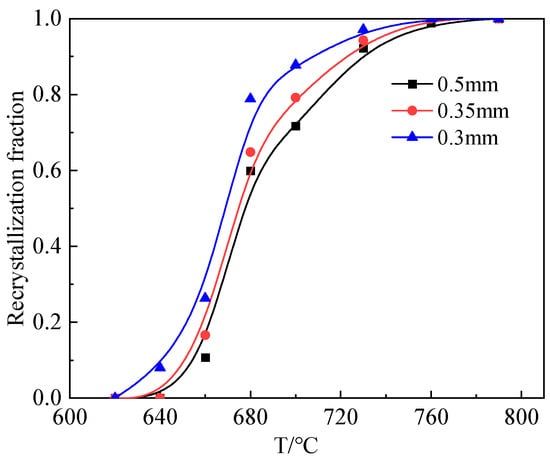

The purpose of annealing non-oriented silicon steel is to complete the recrystallization and grain growth in a short time at a high temperature, and the annealing time is limited. The recrystallization fraction of the microstructure at the same annealing time (3 min) and different annealing temperatures (600~800 °C) was estimated by Image-Pro software [24] as shown in Figure 8. With the increase in the cold rolling reduction, the dislocation density and energy storage increase, and the corresponding recrystallization starting temperature decreases. At the same annealing temperature, the recrystallization fraction increases with the increase in cold rolling reduction.

Figure 8.

Recrystallization fraction of cold rolled sheets with thickness of 0.5 mm, 0.35 mm and 0.3 mm at different annealing temperatures.

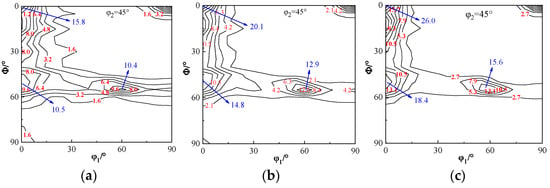

4.2. Texture Evolution during Recrystallization Process

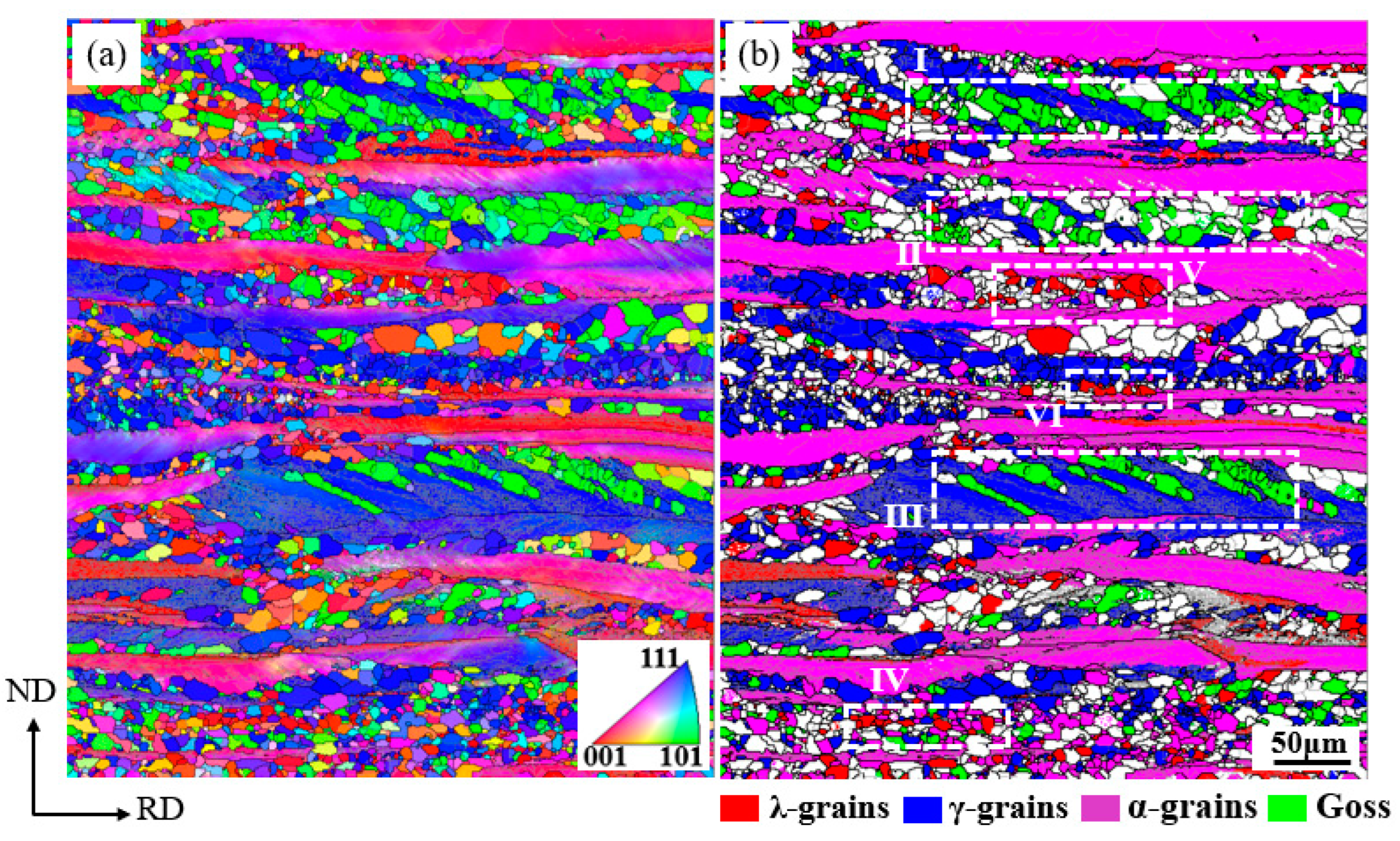

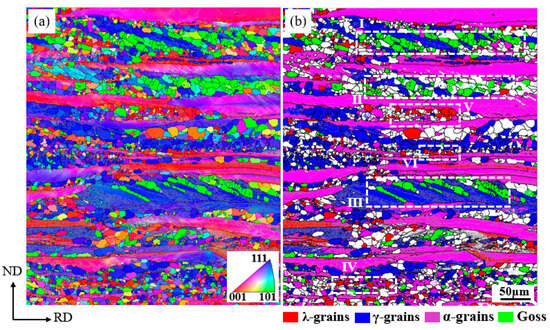

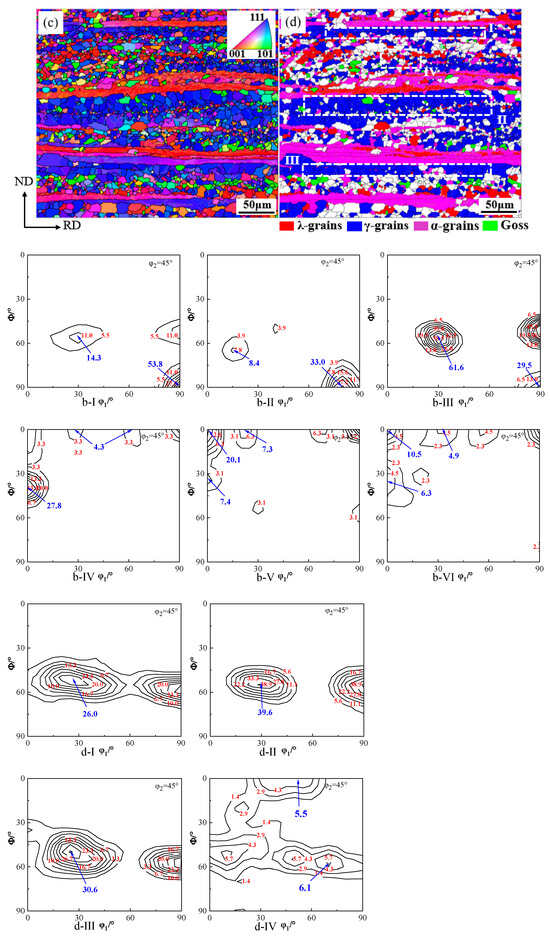

Due to the difference of microstructure and energy storage of deformed microstructure in cold rolled bands with different reduction rates, the order of deformation storage energy of grains with different orientations is: {001}<{112}<{111}<{110} [17,25], and the recrystallization rate is different during annealing. Goss and γ fiber texture storage can form recrystallized grains first, while the α fiber texture is a stable rolling texture, which is difficult to recrystallize. In order to clarify the texture transformation relationship during the recrystallization process of cold rolled bands with different reduction rates, the grain orientation images at different recrystallization stages were studied using the EBSD technique. By comparing the 680 °C for 3 min partial recrystallization annealing of the cold rolled sheets with thicknesses of 0.5 and 0.3 mm, the nucleation position and texture transformation of the recrystallized grains in the initial stage of recrystallization were analyzed. Figure 9 shows the texture characteristics at the initial stage of recrystallization and the macroscopic texture in some areas. At the early stage of the recrystallization of the cold rolled band (0.5 mm) with a reduction rate of 78%, the energy storage of the shear band of the coarse γ fiber texture is high. As a preferential nucleation site, the Goss grains will nucleate in the deformed {111}<112> shear band (I–III areas in Figure 9b). The grain boundary region of the deformed α-grains can form some new λ-grains by strain-induced grain boundary migration. For example, the {100}<012> and {100}<001> oriented new grains in the region of IV~VI nucleate near the {112}<110> and {100}<110> deformation bands [26].

Figure 9.

Recrystallization texture and ODF section (φ2 = 45°) of cold rolled sheet after annealing at 680 °C for 3 min. (a,b) 0.5 mm; (c,d) 0.30 mm; (b) I–VI and (d) I–IV: The specific recrystallization textures of the micro regions.

With the increase in the rolling reduction, the nucleation position of the recrystallized grains changed greatly. When the rolling reduction rate is 87%, a large number of initial recrystallized grains mainly nucleate at the deformation band and grain boundary [27]. As shown in Figure 9d-I~III, the γ texture grains tend to nucleate along the deformed γ texture grain boundary and inside, and the recrystallized grains are mainly {111}<112> and a small amount of {111}<110> texture grains. The {100}<001> and {114}<481> grains nucleate at the γ-fiber texture grain boundaries (such as the d-IV region). A small amount of the Goss grains nucleated at the residual {111}<112> shear band.

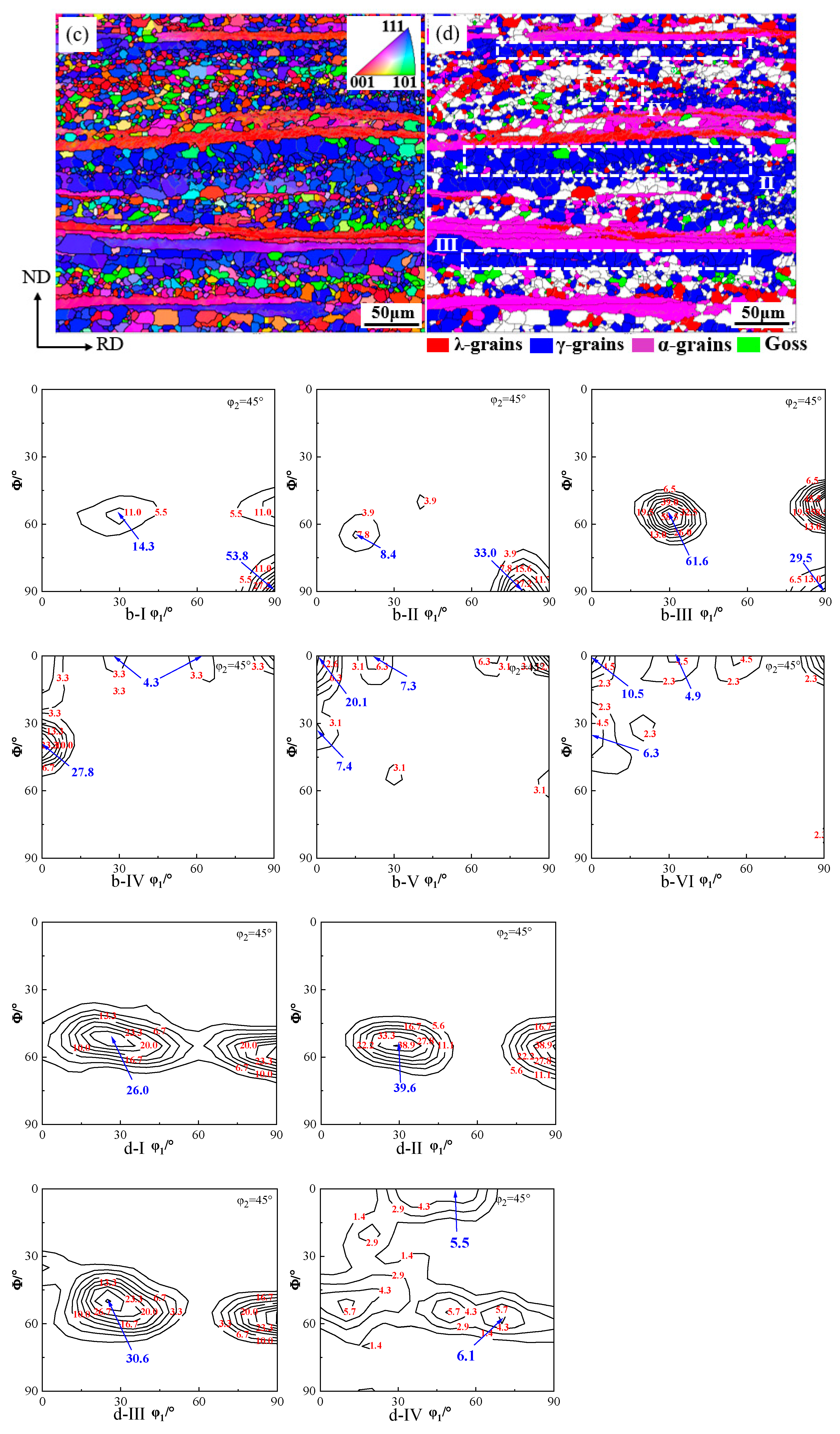

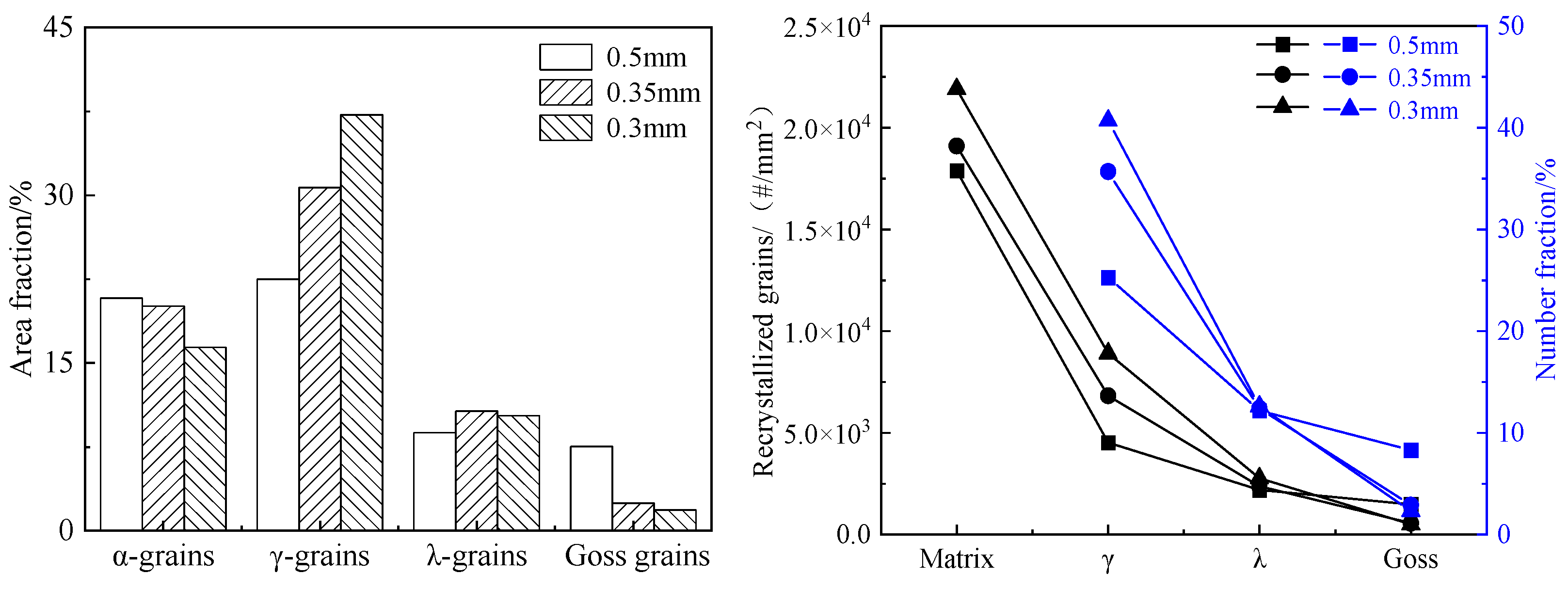

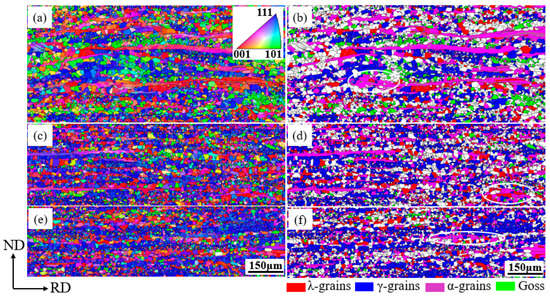

Figure 10 shows the grain orientation and specific texture orientation of the partially recrystallized annealed band, with clustered recrystallized Goss grains found at the shear band position. The γ-grains have the advantage of a preferential recrystallization, with a relatively high proportion of recrystallization. The remaining deformation matrix is mainly composed of a α fiber texture. The area fractions of λ, α, γ fiber and Goss texture and recrystallized grains in annealed sheets of 0.5, 0.35 and 0.3 mm are quantitatively counted as shown in Figure 11. With the increase in the cold rolling reduction rate, the content of the Goss and α fiber texture in the corresponding annealed sheets decreases, while the content of the γ fiber texture increases significantly, from 22.5% to 37.2%.

Figure 10.

Grain orientation and special texture orientation diagram of partial recrystallization of annealed sheet. (a,b) 0.5 mm; (c,d) 0.35 mm; (e,f) 0.3 mm.

Figure 11.

Partial recrystallization of annealed sheets mainly oriented grains and texture content.

With the increase in the cold rolling reduction rate, the energy storage of cold rolled sheet increases, and the temperature at the beginning of the recrystallization will decrease, which is beneficial to increase the nucleation rate of the recrystallization. The decrease in the number of shear bands in the plate leads to a reduction in the nucleation position of the Goss grains during the recrystallization process. In the early stage of recrystallization, the recrystallized γ-grains tend to nucleate at the deformed γ-grains and grain boundaries, and then aggregate and grow to occupy a numerical advantage. The high energy storage and quantity advantages provide favorable conditions for these recrystallized γ-grains to engulf adjacent deformed λ and α grains. The nucleation quantity of recrystallized λ grains at the grain boundaries of the deformed α and γ-grains is small and dispersed. However, the stored energy of the deformed α and λ grains is low, and recrystallization is not easy to occur. In the later stage of recrystallization, partial recrystallization also occurs in the α-deformed grains, and the size of the recrystallized α-grains is generally larger than that of the matrix grains, as shown in Figure 11. Compared with the recrystallization of annealed sheets with thicknesses of 0.5, 0.35 and 0.3 mm, the number of recrystallized grains increased from 1.79 × 104 to 2.19 × 104/mm2, the number of γ-oriented recrystallized grains increased from 4.52 × 103 to 8.91 × 103/mm2, and the Goss recrystallized grains decreased from 1478.2 to 504.6/mm2 due to the increase in the proportion of the grain boundaries and the decrease in the number of shear bands in the cold rolled sheet.

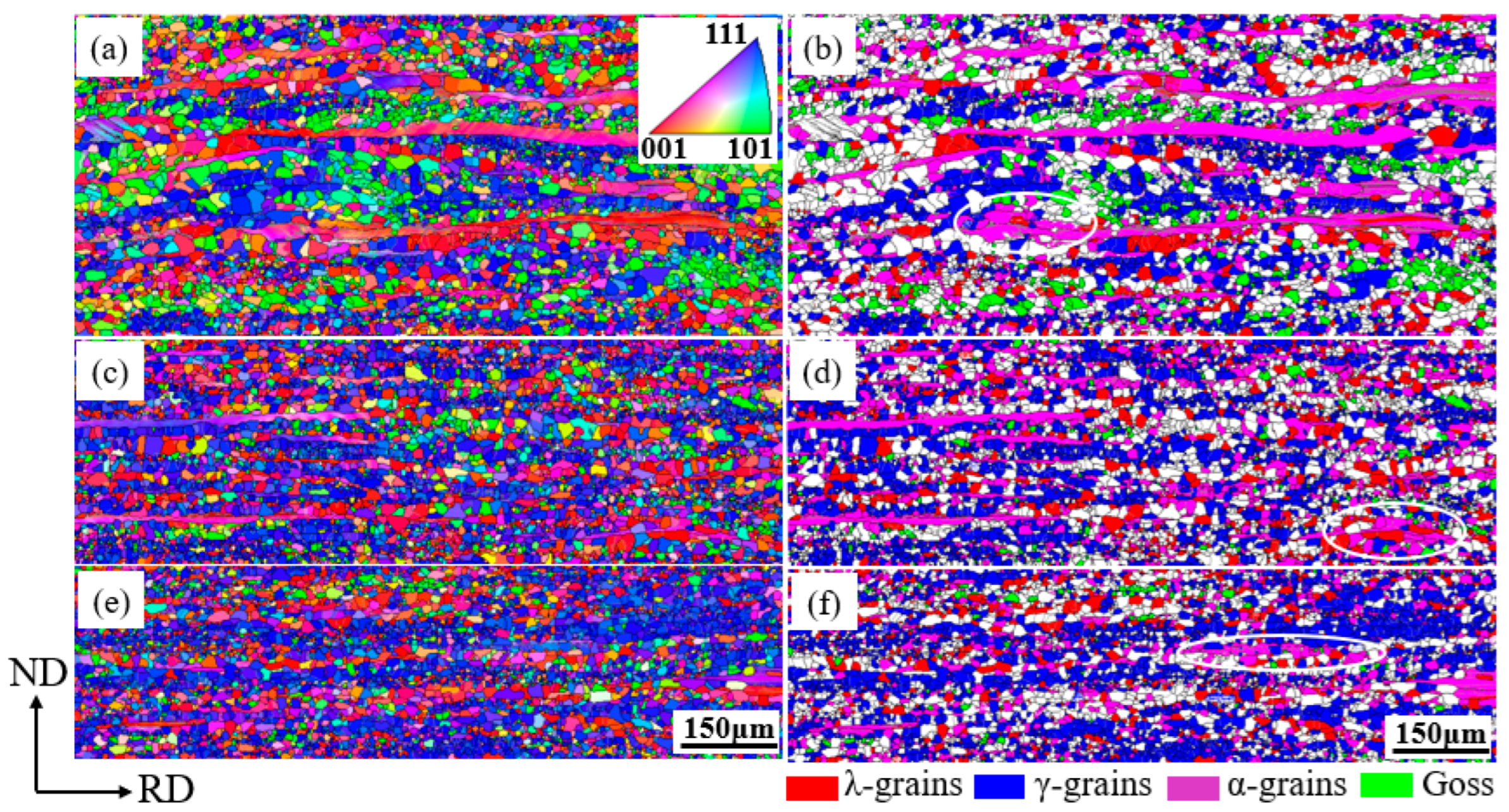

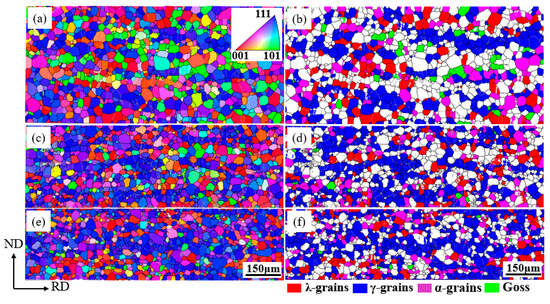

When the annealing temperature is raised to 820 °C, the annealed sheet is completely recrystallized, and the grain orientation, and the grain orientation, distribution, and content of the special texture of the annealed plate are shown in Figure 12 and Figure 13. The increase in annealing temperature leads to an increase in recrystallization activation energy (recrystallization driving force), resulting in the recrystallization of some α-deformed structure with lower energy storage. On the other hand, the migration speed of the grain boundaries increases, and the recrystallized grains grow. The recrystallized grains consume the adjacent deformed structure during the growth process, until the deformed structure in the plate is completely replaced by the recrystallized grains. With the increase in the cold rolling reduction rate, the recrystallized γ-grains have a numerical advantage and are more likely to come into contact with the deformed α-grains, providing more opportunities for the γ-grains to engulf adjacent deformed α-grains and grow. The area fraction of the recrystallized γ fibers texture increases significantly.

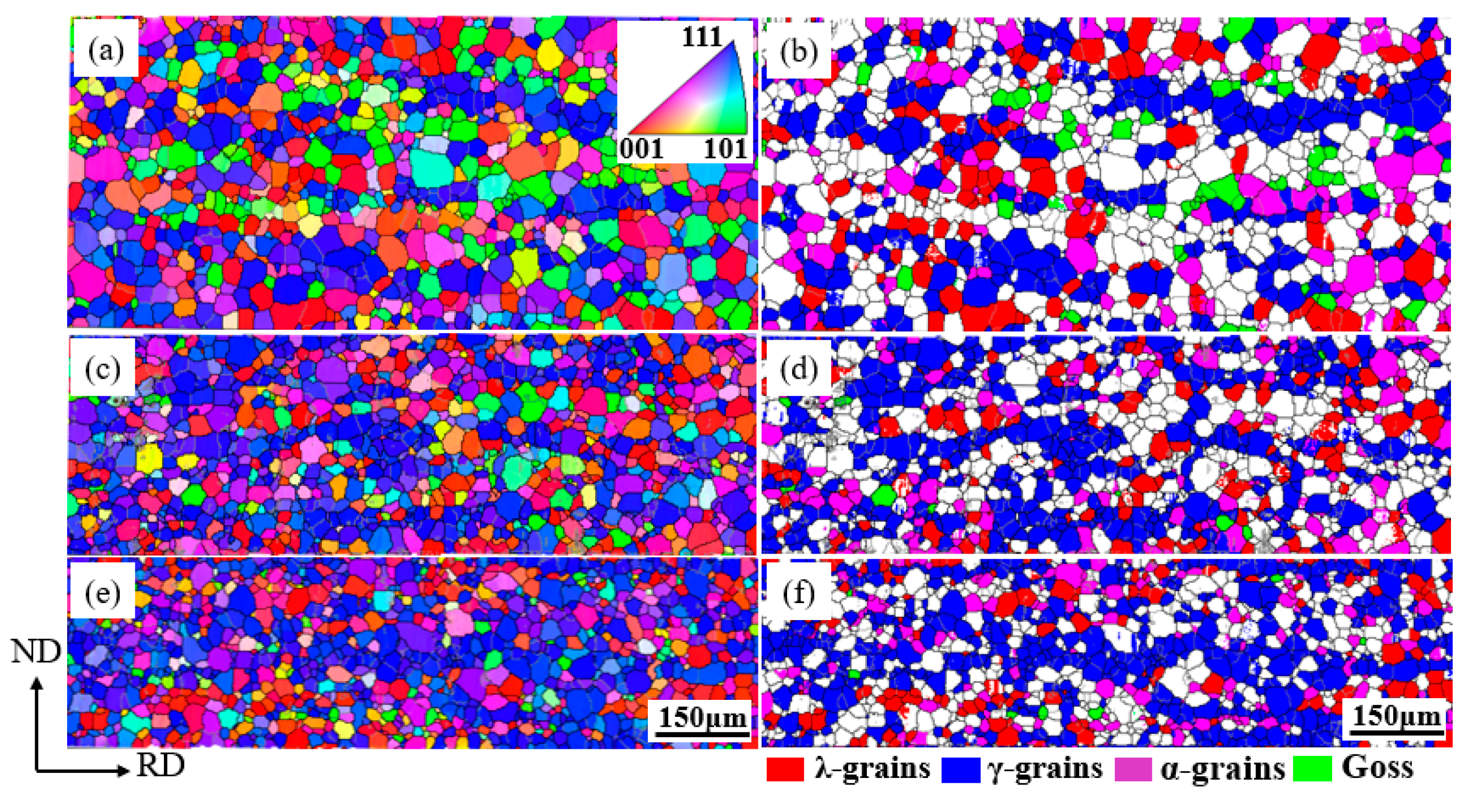

Figure 12.

Grain orientation and special texture distribution diagram of annealed sheet when recrystallization is completed. (a,b) 0.5 mm; (c,d) 0.35 mm; (e,f) 0.3 mm.

Figure 13.

The main oriented grains and texture content of the annealed sheet as the recrystallization is completed.

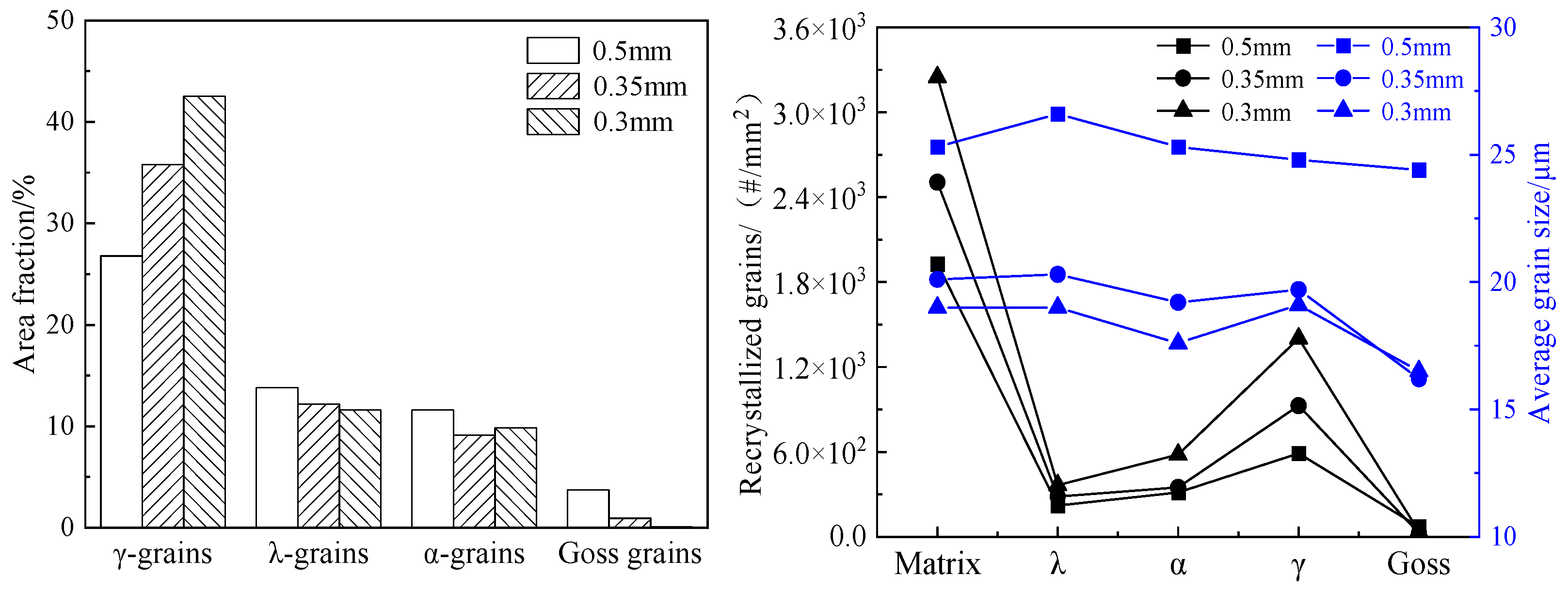

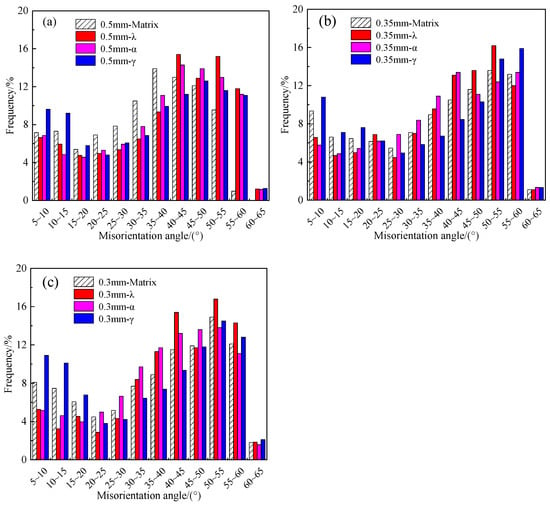

The growth of the recrystallized grains in the annealed sheet depends on the misorientation distribution of adjacent grains. Generally, low-angle grain boundaries with misorientation less than 15° relative to the adjacent grains are considered to have a lower grain boundary mobility, while the high-angle grain boundaries with a misorientation between 15° and 40° have a higher grain boundary mobility [28]. Figure 14 shows the statistical results of the orientation deviation angles of the matrix and the main oriented grains of the fully recrystallized annealed bands with thicknesses of 0.5, 0.35 and 0.3 mm, respectively. Compared to the matrix grains, the frequency of low angle grain boundaries between adjacent grains of the γ grains is higher, while that of the λ-grains is lower.

Figure 14.

Distribution of orientation deviation between main oriented grains and adjacent grains in annealed sheet. (a) 0.5 mm; (b) 0.35 mm; (c) 0.3 mm.

With the increase in the cold rolling reduction rate, the high angle grain boundary with the orientation difference of 15~40° in the annealed band decreases from 36.1 to 32.3%, and the trend of grain growth decreases. Under the annealing process of annealing at 820 °C for 3 min, the grain size of the annealed band decreases, and the frequency of low-angle grain boundaries with an orientation difference less than 15° between the adjacent grains of γ-grains increases from 17.9 to 21.0%, and the high-angle grain boundaries with an orientation difference between 15° and 40° increase from 31.3 to 28.6%, while the frequency of low-angle grain boundaries with an orientation difference of less than 15° between adjacent grains of λ-grains increases from 12.6 to 8.5%. With the increase in the cold rolling reduction rate, the λ-grains in the fully recrystallized annealed sheet have the advantage of high mobility and grow upwards, while the γ-grains have the advantage of quantity but only have a low grain boundary mobility and are not easy to grow upwards. With the increase in the annealing temperature, the grains in the annealed sheet grow further, the content of the λ fibers texture increases and the content of the γ fibers texture decreases.

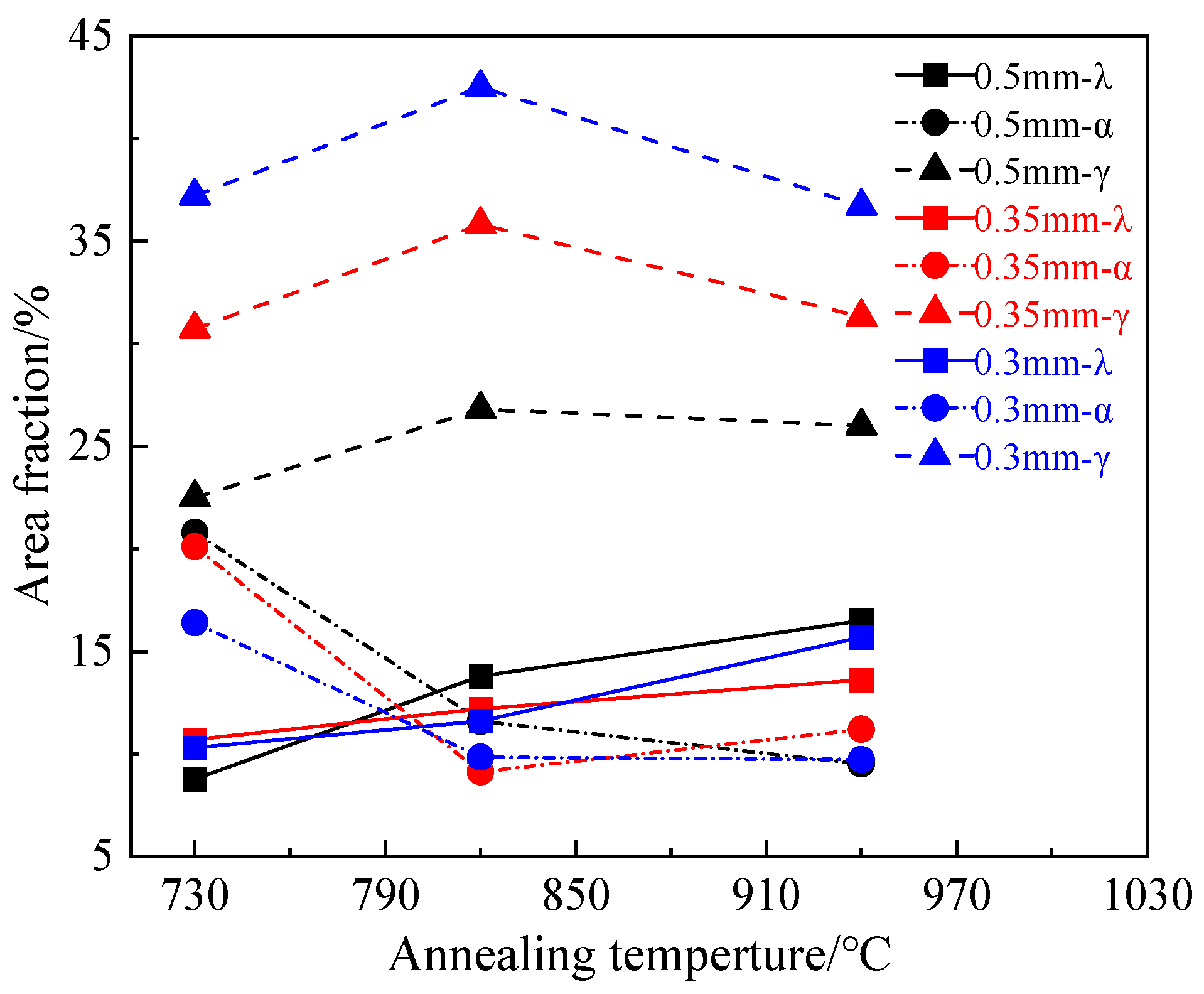

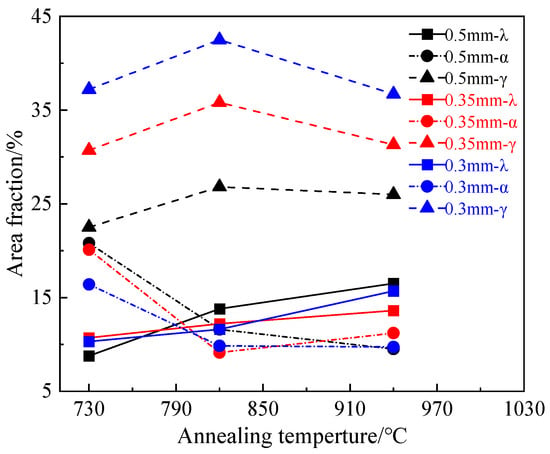

Figure 15 shows the changes in the content of λ, α and γ fibers textures in the annealed bands at annealing temperatures of 730, 820 and 940 °C, respectively. During the recrystallization process, the content of the α fibers texture in the annealed sheet decreases, and the content of the λ and γ fibers texture increases. Because of the high energy storage of deformed γ-grains and the grain boundary is the main position of γ recrystallization nucleation. With the increase in the cold rolling reduction, the γ fibers texture nucleated at the grain boundary has an obvious competitive advantage in the recrystallization process, and the γ texture is the dominant texture and the corresponding content increases. In the process of the grain growth of the annealed band, although λ-grains grow with the advantage of high mobility, there is no quantitative advantage, and the increase in the texture content is small.

Figure 15.

Variation of area fraction of specific oriented grains in annealed sheets at different annealing temperatures.

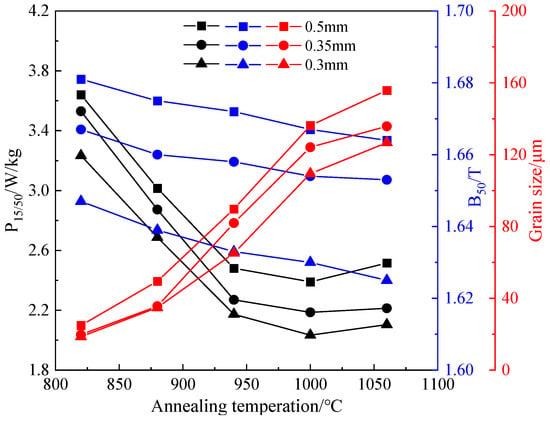

4.3. Effect of Microstructure and Texture on Magnetic Properties

The main influencing factors of magnetic induction intensity (B50) of non-oriented silicon steel are chemical composition and crystal texture. In addition, the thickness of the finished sheet and grain size have a great influence on the core loss (P1.5/50) of silicon steel. The λ fibers texture with two easy magnetization directions in the rolling plane is the ideal crystal texture of non-oriented silicon steel, while the γ fibers texture without easy magnetization direction in the rolling plane is the most unfavorable texture component for the magnetization of non-oriented silicon steel [29]. With the increase in the cold rolling reduction, the unfavorable γ texture content in the annealed sheet increases, and the corresponding magnetic induction intensity B50 decreases.

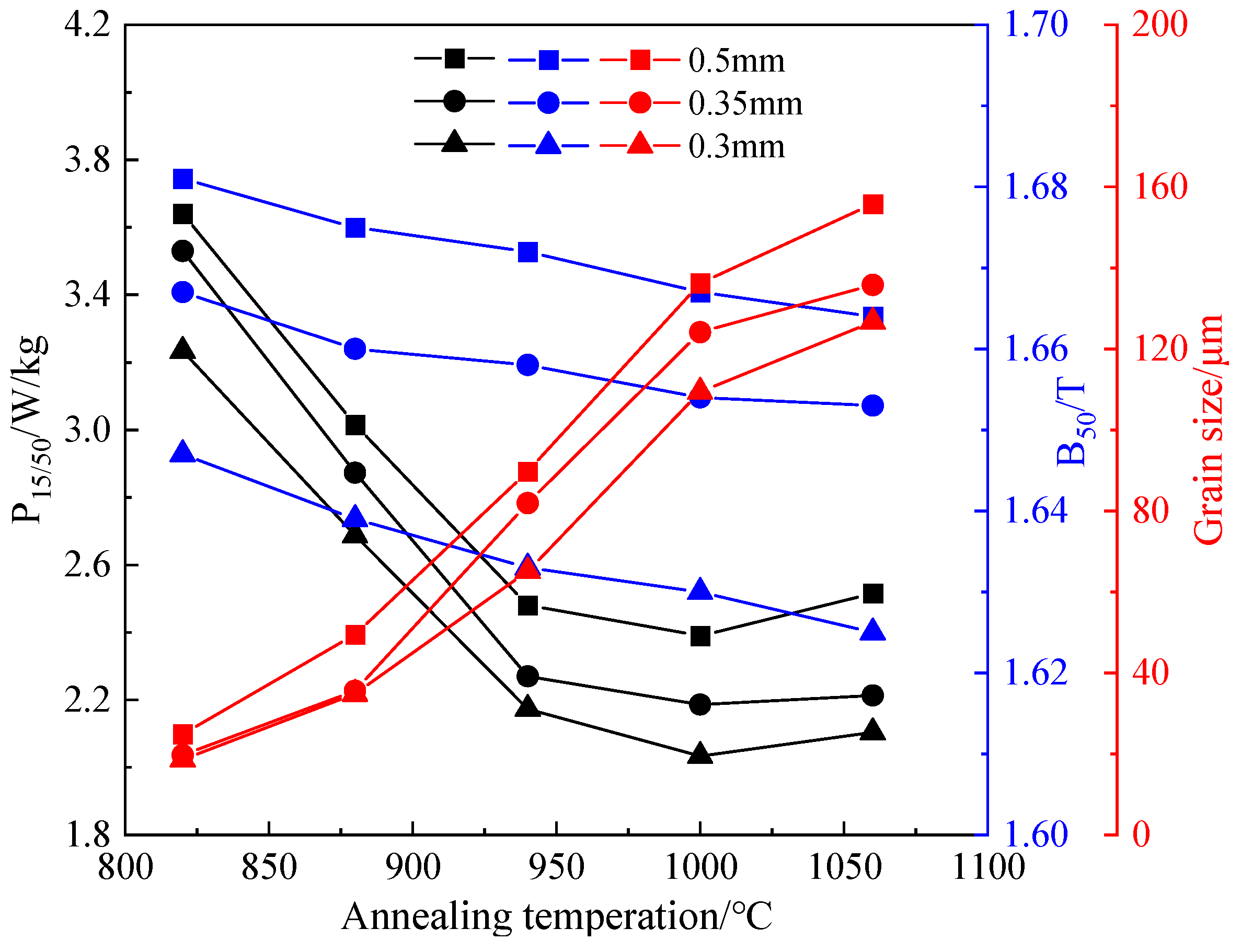

The iron loss (Pt) of non-oriented silicon steel is mainly determined by hysteresis loss (Ph) and eddy current loss (Pe). Among them, the empirical formula of Ph and the classical formula of Pe of thin band material derived from Maxwell’s equation show that: under the same frequency test of the same material, the Ph is proportional to the maximum magnetic induction intensity, and the Pe is proportional to the square of the maximum magnetic induction intensity and the material thickness [9,30]. As the thickness of the annealed sheet decreases, the Pe decreases significantly. Thinning material thickness is an effective measure to reduce core loss. With the increase in the annealing temperature, the average grain size of the annealed band increases, the proportion of grain boundary decreases, and the Ph decreases. As the average size increases, the magnetic domain size increases, and the Pe increases. There is a suitable critical size to make Pt the lowest [19,31]. From the relationship between the grain size and magnetic properties (P1.5/50 and B50) of the annealed sheets at different annealing temperatures in Figure 16, when the annealing temperature is 1000 °C, the grain sizes of the annealed bands with thicknesses of 0.5, 0.35 and 0.3 mm are 136.2, 124.1 and 109.4 μm, respectively, the core loss is the lowest. In the smaller grain size range, the iron loss is dominated by hysteresis loss. As the grain size increases, the eddy current loss increases and becomes the main part of the iron loss.

Figure 16.

Grain size and magnetic properties of annealed sheets at different annealing temperatures.

5. Conclusions

(1) The microstructure of cold rolled band is mainly composed of deformed grains elongated along the rolling direction and shear bands with 20~35° to the rolling surface. With the increase in the cold rolling reduction rate, the width of the deformation band becomes narrower, the proportion of grain boundaries increases and the number of intragranular shear bands decreases. The cold rolled band is a strong α fiber texture and a weak γ fiber texture, and the annealed band is mainly a γ fiber texture. With the increase in the cold rolling reduction rate, the intensity of the α and γ fiber texture in the cold rolled sheet increases.

(2) In the early stage of recrystallization, the shear band of the coarse γ fiber texture has a high energy storage and preferential nucleation, and Goss grains will nucleate in the deformed {111}<112> shear band. The λ-grains can nucleate at the grain boundaries of the deformed α-grains. With the increase in the rolling reduction, a large number of initial recrystallized grains mainly nucleate at the deformation band and grain boundary, mainly recrystallized γ-grains.

(3) During the recrystallization process, the content of α fibers texture in the annealed sheet decreases, and the content of the λ and γ fibers texture increases. With the increase in the cold rolling reduction, the γ-grains nucleated at grain boundaries have obvious competitive advantages and become the dominant texture. In the process of grain growth, the λ-grains have a higher mobility and grow upwards. Due to the lack of a quantitative advantage, the increase in the texture content is small.

(4) With the increase in the cold rolling reduction rate, the unfavorable γ texture content in the annealed sheet increases, and the magnetic induction intensity B50 decreases. Thickness reduction can significantly reduce Pe and reduce core loss. In the smaller grain size range, the iron loss is dominated by the Ph. As the grain size increases, the Pe increases and becomes the main part of the iron loss. There is a critical size that makes the Pt the lowest.

Author Contributions

Conceptualization, F.G. and Y.N.; methodology, F.G.; software, J.Q.; validation, F.G., B.F. and J.Q.; formal analysis, F.G.; investigation, F.G.; resources, S.Q.; data curation, Y.N., J.Q. and S.Q.; writing—original draft preparation, F.G.; writing—review and editing, Y.N. and J.Q.; visualization, F.G. and B.F.; supervision, J.Q.; project administration, J.Q. and S.Q.; funding acquisition, S.Q. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the support from the Jiangxi Province Major Scientific and Technological Research and Development Special Funding Project (20213AAE01009) and the Jiangxi Provincial Key Laboratory of High-Performance Steel and Iron Alloy Materials (No. 2024SSY05042).

Data Availability Statement

Data available in a publicly accessible repository.

Acknowledgments

This work was supported by Xinyu Iron and Steel Group Co., Ltd., whose support is gratefully appreciated.

Conflicts of Interest

Authors J.Q. and S.Q. were employed by Iron and Steel Research Institute Co., Ltd., and Author B.F. were employed by Xinyu Iron and Steel Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Oda, Y.; Kohno, M.; Honda, A. Recent development of non-oriented electrical steel sheet for automobile electrical devices. J. Magn. Magn. Mater. 2008, 320, 2430–2435. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, H.X.; Zhang, W.K.; Wang, S.J.; Sun, Y.; Wang, Y.D. Texture evolution and properties of cold rolled non-oriented silicon steel with high reduction rate. China Metall. 2022, 32, 64–70. [Google Scholar]

- Cheng, C.Y.; Zhong, B.L.; Ni, Z.X.; Jing, W.Q.; Zhang, S.Q.; Liu, J. Research progress on the control of force and magnetic properties of high-strength non-oriented silicon steel for driving motors of new energy vehicles. J. Eng. Sci. 2023, 45, 1482–1492. [Google Scholar]

- Zhu, C.Y.; Bao, Y.K.; Wang, Y.; Ma, J.H.; Li, G.Q. Research progress on application status and performance control of non-oriented silicon steel for drive motor of new energy vehicles. Mater. Rep. 2021, 35, 23089–23096. [Google Scholar]

- Bian, X.H.; Zeng, Y.P.; Nan, D.; Wu, M. The effect of copper precipitates on the recrystallization textures and magnetic properties of non-oriented electrical steels. J. Alloys Compd. 2014, 588, 108–113. [Google Scholar] [CrossRef]

- Fan, L.F.; Qin, M.M.; Yue, E.B.; Xiao, L.J.; He, J.Z. Technical challenges of new energy vehicles to non-oriented silicon steel. Mater. Rep. 2021, 35, 15183–15188. [Google Scholar]

- De Campos, M.F.; Yonamine, T.; Fukuhara, M.; Landgraf, F.J.G.; Achete, C.A.; Missell, F.P. Effect of frequency on the iron losses of 0.5% and 1.5% Si non-oriented electrical steels. IEEE Trans. Magn. 2006, 42, 2812–2814. [Google Scholar] [CrossRef]

- Gong, J.; Luo, H.W. Research and progress of high strength non-oriented silicon steel sheet for new energy vehicle drive motor. J. Mater. Eng. 2015, 43, 102–112. [Google Scholar]

- He, Z.Z.; Zhao, Y.; Luo, H.W. Electrical Steel; Metallurgical Industry Press: Beijing, China, 2012. [Google Scholar]

- Chu, S.J.; Shen, K.Y.; Sha, Y.H.; Chen, X. Orientation dependence of deformation energy storage and its effect on recrystallization texture of non-oriented silicon steel. J. Mater. Eng. 2019, 47, 147–153. [Google Scholar]

- Shan, N.; Sha, Y.H.; Zhang, F.; Liu, J.L.; Zuo, L. Recrystallization texture transition in Fe-2.1 Wt Pct Si steel by different cold rolling reduction. Metall. Mater. Trans. A 2016, 47, 5777–5782. [Google Scholar] [CrossRef]

- Yang, H.P.; Sha, Y.H.; Zhang, F.; Zuo, L. Recrystallization texture evolution of cold rolled non-oriented silicon steel with large reduction. J. Northeast. Univ. Nat. Sci. Edit. 2013, 34, 658–662. [Google Scholar]

- Wu, S.; Jia, J.; Song, X.L.; Cheng, C.Y.; Wu, J.; Liu, J. Effect of cold rolling reduction rate on deformation microstructure and magnetic properties of high strength non-oriented electrical steel. J. Mater. Eng. 2024, 52, 158–165. [Google Scholar]

- Jiao, H.T.; Xu, Y.B.; Xiong, W.; Zhang, Y.X.; Cao, G.M.; Li, C.G.; Niu, J.; Misra, R.D.K. High-permeability and thin-gauge non-oriented electrical steel through twin-roll strip casting. Mater. Design. 2017, 136, 23–33. [Google Scholar] [CrossRef]

- Hawezy, D.; Birosca, S. Disparity in recrystallization of α-& γ-fibers and its impact on Cube texture formation in non-oriented electrical steel. Acta Mater. 2021, 216, 117141. [Google Scholar]

- Sha, Y.H.; Sun, C.; Zhang, F.; Patel, D.; Chen, X.; Kalidindi, S.R.; Zuo, L. Strong cube recrystallization texture in silicon steel by twin-roll casting process. Acta Mater. 2014, 76, 106–117. [Google Scholar] [CrossRef]

- Park, J.T.; Szpunar, J.A. Evolution of recrystallization texture in non-oriented electrical steels. Acta Mater. 2003, 51, 3037–3051. [Google Scholar] [CrossRef]

- Sun, C.; Sha, Y.H.; Zhang, F.; Zuo, L. Effect of cold rolling reduction rate on deformation and recrystallization texture of twin-roll casting silicon steel. J. Northeast. Univ. Nat. Sci. Edit. 2016, 37, 1311–1316. [Google Scholar]

- Li, Z.H.; Xie, S.K.; Wang, G.D.; Liu, H.T. Dependence of recrystallization behavior and magnetic properties on grain size prior to cold rolling in high silicon non-oriented electrical steel. J. Alloys Compd. 2021, 888, 161576. [Google Scholar] [CrossRef]

- Qin, J.; Yang, J.F.; Zhang, Y.H.; Zhou, Q.Y.; Cao, Y.Y. Strong {100}<012>-{411}<148> recrystallization textures in heavily hot-rolled non-oriented electrical steels. Mater. Lett. 2020, 259, 126844. [Google Scholar]

- Xu, H.J.; Xu, Y.B.; He, Y.L.; Jiao, H.T.; Yue, S.; Li, J.P. A quasi in-situ EBSD study of the nucleation and growth of Goss grains during primary and secondary recrystallization of a strip-cast Fe-6.5 wt% Si alloy. J. Alloys Compd. 2021, 861, 158550. [Google Scholar] [CrossRef]

- Wang, S.J.; Li, M.; Wang, H.X.; Xu, C.X.; Lin, Y.; Wei, H.; Zhang, W.K.; Qiu, S.Y.; Wang, Y.D. Effect of grain size before cold rolling on microstructure, texture and magnetic properties of ultra-thin low-Si non-oriented silicon steel. JOM 2023, 75, 1824–1838. [Google Scholar] [CrossRef]

- Lee, H.H.; Jung, J.; Yoon, J.I.; Kim, J.K.; Kim, H.S. Modelling the evolution of recrystallization texture for a non-grain oriented electrical steel. Comp. Mater. Sci. 2018, 149, 57–64. [Google Scholar] [CrossRef]

- Yu, L.; Luo, H.W. Effect of partial recrystallization annealing on magnetic and mechanical properties of non-oriented silicon steel. Acta Metall. Sin. 2020, 56, 291–300. [Google Scholar]

- Shan, N.; Liu, J.L.; Sha, Y.H.; Zhang, F.; Zuo, L. Development of through-thickness Cube recrystallization texture in non-oriented electrical steels by optimizing nucleation environment. Metall. Mate. Trans. A 2019, 50, 2486–2494. [Google Scholar] [CrossRef]

- Dillamore, I.L.; Morris, P.L.; Smith, C.J.E.; Hutchinson, W.B. Transition bands and recrystallization in metals. Proc. R. Soc. Lond. A Math. Phy. Eng. Sci. 1972, 329, 405–420. [Google Scholar]

- Kestens, L.; Jacobs, S. Texture control during the manufacturing of non-oriented electrical steels. Texture Stress Microstruct. 2008, 2008, 173083. [Google Scholar] [CrossRef]

- Suehiro, R.; Hayakawa, Y.; Takamiya, T. Effect of Sn addition on evolution of primary recrystallization texture in 3% Si steel. ISIJ Int. 2019, 59, 351–358. [Google Scholar] [CrossRef]

- Sidor, J.J.; Verbeken, K.; Gomes, E.; Schneider, J.; Calvillo, P.R.; Kestens, L.A.I. Through process texture evolution and magnetic properties of high Si non-oriented electrical steels. Mater. Charact. 2012, 71, 49–57. [Google Scholar] [CrossRef]

- Qin, J.; Yang, P.; Mao, W.M.; Ye, F. Effect of texture and grain size on the magnetic flux density and core loss of cold-rolled high silicon steel sheets. J. Magn. Magn. Mater. 2015, 393, 537–543. [Google Scholar] [CrossRef]

- Lee, K.M.; Park, S.Y.; Huh, M.Y.; Kim, J.S.; Engler, O. Effect of texture and grain size on magnetic flux density and core loss in non-oriented electrical steel containing 3.15% Si. J. Magn. Magn. Mater. 2014, 354, 324–332. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).