Silicon Solar Cells: Trends, Manufacturing Challenges, and AI Perspectives

Abstract

1. Introduction

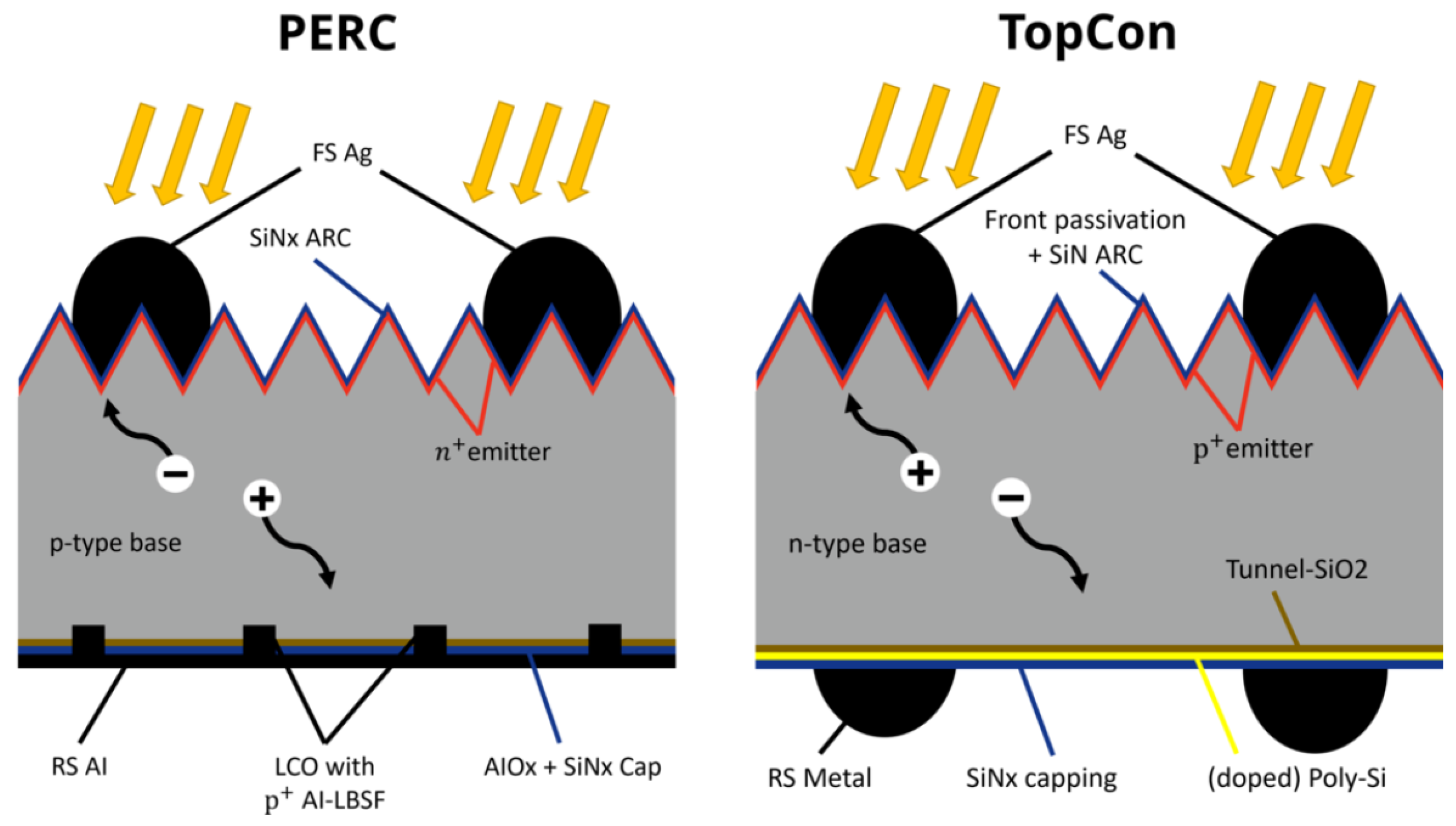

2. PV Solar Industry and Trends

3. Silicon Ingot Production for Solar Cells: Current State and Challenges

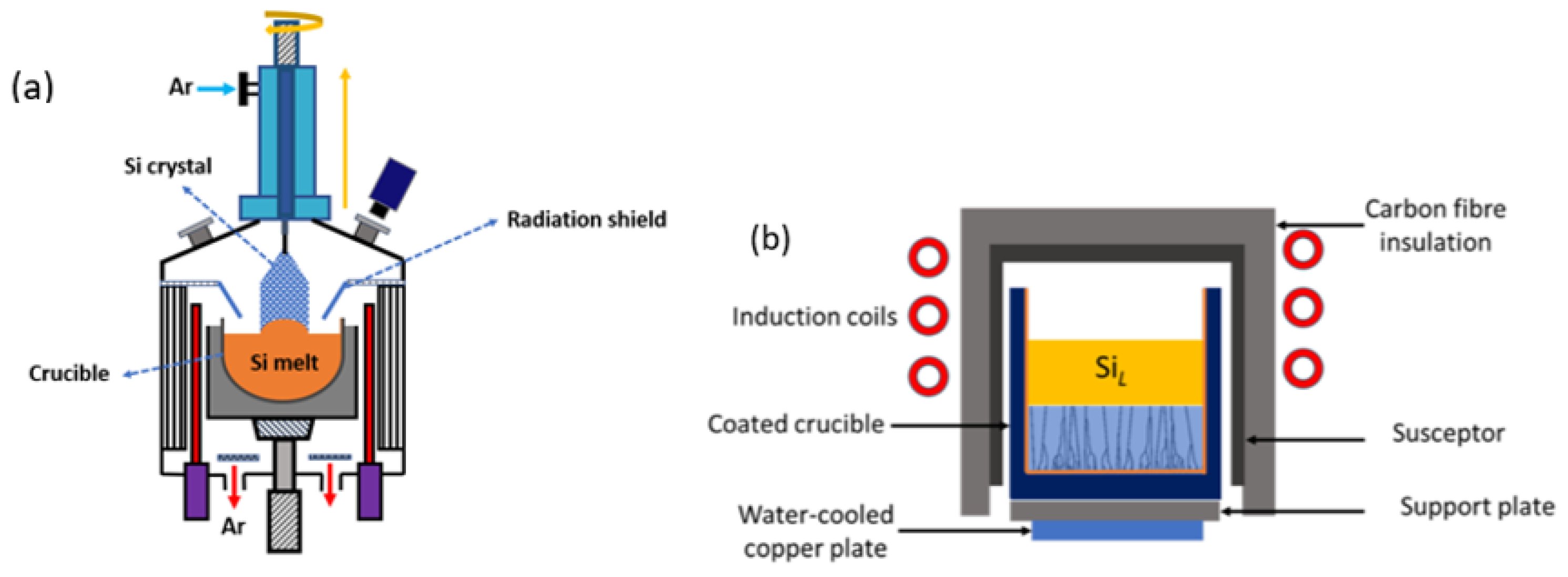

3.1. Czochralski vs. Directional Solidification

3.2. Major Challenges of Cz Silicon Production

3.2.1. Structure Loss

3.2.2. High Demand

3.2.3. Cost and Efficiency

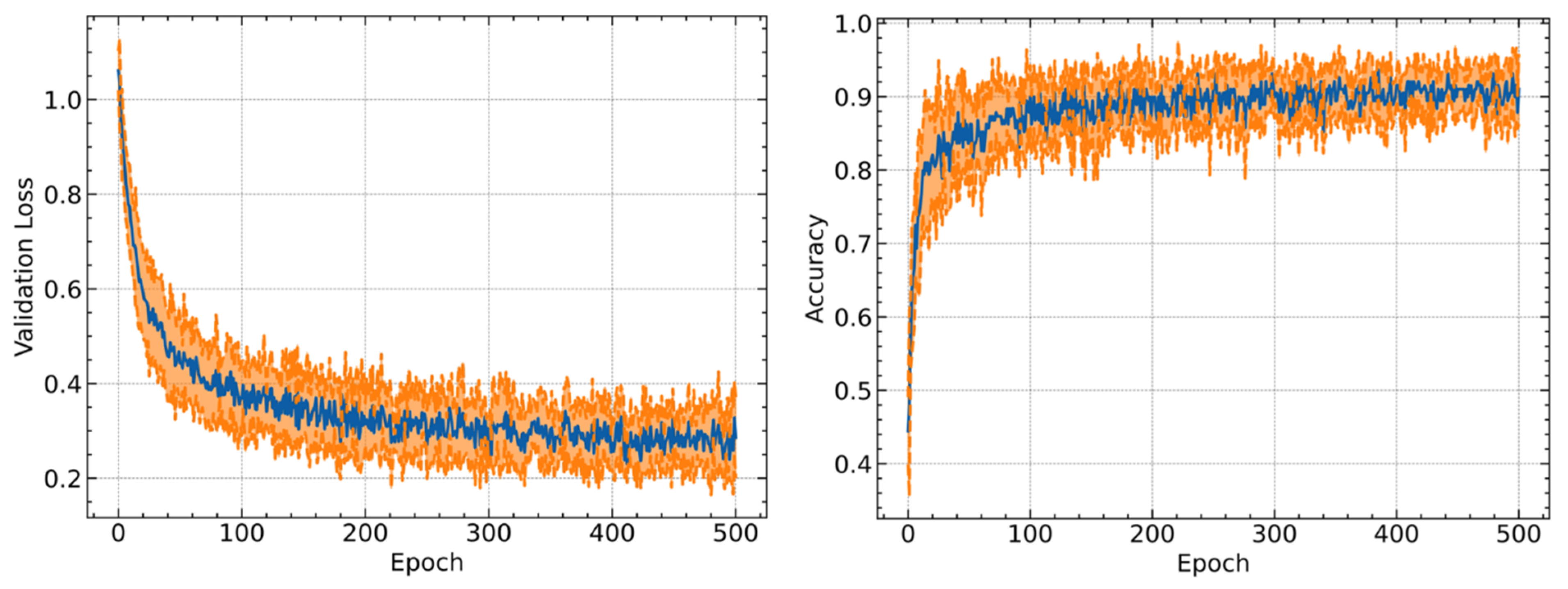

4. The Role of AI and How It Can Help to Solve Some of the PV Challenges

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fraunhofer Institute for Solar Energy Systems, ISE. Photovoltaics Report; ISE: Freiburg, Germany, 2023. [Google Scholar]

- Fernández, L. Cumulative Installed Solar Pv Capacity Worldwide from 2000 to 2022. Available online: https://www.statista.com/statistics/280220/global-cumulative-installed-solar-pv-capacity/ (accessed on 20 December 2023).

- Shockley, W.; Queisser, H.J. Detailed Balance Limit of Efficiency of p-n Junction Solar Cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Hinken, D.; Rauer, M.; Hao, X. Solar cell efficiency tables (Version 60). Prog. Photovolt. Res. Appl. 2022, 30, 687–701. [Google Scholar] [CrossRef]

- Woditsch, P.; Koch, W. Solar grade silicon feedstock supply for PV industry. Sol. Energy Mater. Sol. Cells 2002, 72, 11–26. [Google Scholar] [CrossRef]

- Yuge, N.; Sakaguchi, Y.; Terashima, H.; Aratani, F. Purification of silicon by directional solidification. Nippon. Kinzoku Gakkaishi/J. Jpn. Inst. Met. 1997, 61, 1094–1100. [Google Scholar] [CrossRef][Green Version]

- Yuge, N.; Hanazawa, K.; Hiwasa, S.; Kato, Y. Removal of Metal Impurities in Molten Silicon by Directional Solidification with Electron Beam Heating. J. Jpn. Inst. Met. 2003, 67, 575–582. [Google Scholar] [CrossRef][Green Version]

- Liu, T.; Dong, Z.; Zhao, Y.; Wang, J.; Chen, T.; Xie, H.; Li, J.; Ni, H.; Huo, D. Purification of metallurgical silicon through directional solidification in a large cold crucible. J. Cryst. Growth 2012, 355, 145–150. [Google Scholar] [CrossRef]

- Martorano, M.A.; Neto, J.B.F.; Oliveira, T.S.; Tsubaki, T.O. Refining of metallurgical silicon by directional solidification. Mater. Sci. Eng. B 2011, 176, 217–226. [Google Scholar] [CrossRef]

- Jiang, D.; Ren, S.; Shi, S.; Dong, W.; Qiu, J.; Tan, Y.; Li, J. Phosphorus Removal from Silicon by Vacuum Refiningand Directional Solidification. J. Electron. Mater. 2014, 43, 314–319. [Google Scholar] [CrossRef]

- Qiu, S.; Wen, S.; Fang, M.; Zhang, L.; Gan, C.; Jiang, D.; Tan, Y.; Li, J.; Luo, X. Process parameters influence on the growth rate during silicon purification by vacuum directional solidification. Vacuum 2016, 125, 40–47. [Google Scholar] [CrossRef]

- Pizzini, S. Towards solar grade silicon: Challenges and benefits for low cost photovoltaics. Sol. Energy Mater. Sol. Cells 2010, 94, 1528–1533. [Google Scholar] [CrossRef]

- Li, X.; Wu, J.; Xu, M.; Ma, W. Separation and purification of silicon from cutting kerf-loss slurry waste by electromagnetic and slag treatment technology. J. Clean. Prod. 2019, 211, 695–703. [Google Scholar] [CrossRef]

- Ning, S.; Shuo, D. Thin Film Deposition Technologies and Application in Photovoltaics. In Thin Films; Dongfang, Y., Ed.; IntechOpen: Rijeka, Croatia, 2022. [Google Scholar]

- Zhao, Y.; Procel, P.; Han, C.; Cao, L.; Yang, G.; Özkol, E.; Alcañiz, A.; Kovačević, K.; Limodio, G.; Santbergen, R.; et al. Strategies for realizing high-efficiency silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 2023, 258, 112413. [Google Scholar] [CrossRef]

- Mandelkorn, J.; Lamneck, J.H. Simplified fabrication of back surface electric field silicon cells and novel characteristics of such cells. Sol. Cells 1990, 29, 121–130. [Google Scholar] [CrossRef][Green Version]

- Kim, K.H.; Park, C.S.; Lee, J.D.; Lim, J.Y.; Yeon, J.M.; Kim, I.H.; Lee, E.J.; Cho, Y.H. Record high efficiency of screen-printed silicon aluminum back surface field solar cell: 20.29%. Jpn. J. Appl. Phys. 2017, 56, 08MB25. [Google Scholar] [CrossRef]

- Blakers, A.W.; Wang, A.; Milne, A.M.; Zhao, J.; Green, M.A. 22.8% efficient silicon solar cell. Appl. Phys. Lett. 1989, 55, 1363–1365. [Google Scholar] [CrossRef]

- International Technology Roadmap for Photovoltaic (ITRPV); VDMA: Frankfurt am Main, Germany, 2022.

- Zhao, J.; Wang, A.; Green, M.A. 24% efficient PERL structure silicon solar cells. In Proceedings of the IEEE Conference on Photovoltaic Specialists, Kissimmee, FL, USA, 21–25 May 1990; Volume 331, pp. 333–335. [Google Scholar]

- Zhao, J.; Wang, A.; Green, M.A. 24·5% Efficiency silicon PERT cells on MCZ substrates and 24·7% efficiency PERL cells on FZ substrates. Prog. Photovolt. Res. Appl. 1999, 7, 471–474. [Google Scholar] [CrossRef]

- JinkoSolar’s High-efficiency N-Type Monocrystalline Silicon Solar Cell Sets Our New Record with Maximum Conversion Efficiency of 26.4%. Available online: https://www.jinkosolar.com/en/site/newsdetail/1827 (accessed on 10 January 2024).

- The Complete Guide to TOPCon Technology. Available online: https://www.eco-greenenergy.com/the-complete-guide-to-topcon-technology/ (accessed on 23 December 2023).

- Tanaka, M.; Taguchi, M.; Matsuyama, T.; Sawada, T.; Tsuda, S.; Nakano, S.; Hanafusa, H.; Kuwano, Y. Development of New a-Si/c-Si Heterojunction Solar Cells: ACJ-HIT (Artificially Constructed Junction-Heterojunction with Intrinsic Thin-Layer). Jpn. J. Appl. Phys. 1992, 31, 3518. [Google Scholar] [CrossRef]

- Wright, M.; Stefani, B.V.; Soeriyadi, A.; Basnet, R.; Sun, C.; Weigand, W.; Yu, Z.; Holman, Z.; Macdonald, D.; Hallam, B. Progress with Defect Engineering in Silicon Heterojunction Solar Cells. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2021, 15, 2100170. [Google Scholar] [CrossRef]

- Jiang, K.; Liu, W.; Yang, Y.; Yan, Z.; Huang, S.; Li, Z.; Li, X.; Zhang, L.; Liu, Z. Functions of oxygen atoms in hydrogenated amorphous silicon oxide layers for rear-emitter silicon heterojunction solar cells. J. Mater. Sci. Mater. Electron. 2022, 33, 416–426. [Google Scholar] [CrossRef]

- Lin, H.; Yang, M.; Ru, X.; Wang, G.; Yin, S.; Peng, F.; Hong, C.; Qu, M.; Lu, J.; Fang, L.; et al. Silicon heterojunction solar cells with up to 26.81% efficiency achieved by electrically optimized nanocrystalline-silicon hole contact layers. Nat. Energy 2023, 8, 789–799. [Google Scholar] [CrossRef]

- Dupré, O.; Vaillon, R.; Green, M.A. Thermal Behavior of Photovoltaic Devices; Springer: Cham, Germany, 2017. [Google Scholar]

- Garcia, A.S.; Kristensen, S.T.; Strandberg, R. Analytical Modeling of the Temperature Sensitivity of the Maximum Power Point of Solar Cells. IEEE J. Photovolt. 2022, 12, 1237–1242. [Google Scholar] [CrossRef]

- Stefaan, D.W.; Kondo, M. Boron-Doped a-Si:H/C-Si Interface Passivation: Degradation Mechanism. Appl. Phys. Lett. 2007, 91, 112109. [Google Scholar] [CrossRef]

- Hallam, B.; Chen, D.; Shi, J.; Einhaus, R.; Holman, Z.C.; Wenham, S. Pre-Fabrication Gettering and Hydrogenation Treatments for Silicon Heterojunction Solar Cells: A Possible Path to >700 mV Open-Circuit Voltages Using Low-Lifetime Commercial-Grade p-Type Czochralski Silicon. Sol. RRL 2018, 2, 1700221. [Google Scholar] [CrossRef]

- Vicari Stefani, B.; Weigand, W.; Wright, M.; Soeriyadi, A.; Yu, Z.; Kim, M.; Chen, D.; Holman, Z.; Hallam, B. P-type Upgraded Metallurgical-Grade Multicrystalline Silicon Heterojunction Solar Cells with Open-Circuit Voltages over 690 mV. Phys. Status Solidi A 2019, 216, 1900319. [Google Scholar] [CrossRef]

- Chen, D.; Kim, M.; Shi, J.; Vicari Stefani, B.; Yu, Z.; Liu, S.; Einhaus, R.; Wenham, S.; Holman, Z.; Hallam, B. Defect engineering of p-type silicon heterojunction solar cells fabricated using commercial-grade low-lifetime silicon wafers. Prog. Photovolt. Res. Appl. 2021, 29, 1165–1179. [Google Scholar] [CrossRef]

- Martí, A.; Araújo, G.L. Limiting efficiencies for photovoltaic energy conversion in multigap systems. Sol. Energy Mater. Sol. Cells 1996, 43, 203–222. [Google Scholar] [CrossRef]

- Hirst, L.C.; Ekins-Daukes, N.J. Fundamental losses in solar cells. Prog. Photovolt. Res. Appl. 2011, 19, 286–293. [Google Scholar] [CrossRef]

- Best Research-Cell Efficiency Chart. NREL Laboratory Cell Efficiency: 2023. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 10 January 2024).

- Li, X.; Xu, Q.; Yan, L.; Ren, C.; Shi, B.; Wang, P.; Mazumdar, S.; Hou, G.; Zhao, Y.; Zhang, X. Silicon heterojunction-based tandem solar cells: Past, status, and future prospects. Nanophotonics 2020, 10, 2001–2022. [Google Scholar] [CrossRef]

- Jacak, J.E.; Jacak, W.A. Routes for Metallization of Perovskite Solar Cells. Materials 2022, 15, 2254. [Google Scholar] [CrossRef]

- Jacak, W.A. Quantum Nano-Plasmonics; Cambridge University Press: Cambridge, UK, 2020. [Google Scholar]

- Divya, A.; Adish, T.; Kaustubh, P.; Zade, P.S. Review on recycling of solar modules/panels. Sol. Energy Mater. Sol. Cells 2023, 253, 112151. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Tao, M.; Fthenakis, V.; Ebin, B.; Steenari, B.-M.; Butler, E.; Sinha, P.; Corkish, R.; Wambach, K.; Simon, E.S. Major challenges and opportunities in silicon solar module recycling. Prog. Photovolt. Res. Appl. 2020, 28, 1077–1088. [Google Scholar] [CrossRef]

- Tao, J.; Yu, S. Review on feasible recycling pathways and technologies of solar photovoltaic modules. Sol. Energy Mater. Sol. Cells 2015, 141, 108–124. [Google Scholar] [CrossRef]

- Doi, T.; Igari, S.; Tsuda, I. Development of a recyclable PV-module-expansion to multi-cells modules. In Proceedings of the Conference Record of the Thirty-First IEEE Photovoltaic Specialists Conference, Lake Buena Vista, FL, USA, 3–7 January 2005; pp. 1773–1776. [Google Scholar]

- Jung, B.; Park, J.; Seo, D.; Park, N. Sustainable System for Raw-Metal Recovery from Crystalline Silicon Solar Panels: From Noble-Metal Extraction to Lead Removal. ACS Sustain. Chem. Eng. 2016, 4, 4079–4083. [Google Scholar] [CrossRef]

- Huang, W.-H.; Shin, W.J.; Wang, L.; Sun, W.-C.; Tao, M. Strategy and technology to recycle wafer-silicon solar modules. Sol. Energy 2017, 144, 22–31. [Google Scholar] [CrossRef]

- Manni, M.; Aghaei, M.; Sizkouhi, A.M.M.; Kumar, R.R.R.; Stølen, R.; Steen-Hansen, A.E.; Di Sabatino, M.; Moazami, A.; Völler, S.; Jelle, B.P.; et al. Solar Energy in the Built Environment. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Yu, X.; Yang, D. Growth of Crystalline Silicon for Solar Cells: Czochralski Si. In Handbook of Photovoltaic Silicon; Yang, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 129–174. [Google Scholar]

- Ganesh, R.B.; Ryningen, B.; Syvertsen, M.; Øvrelid, E.; Saha, I.; Tathgar, H.; Rajeswaran, G. Growth and characterization of multicrystalline silicon ingots by directional solidification for solar cell applications. Energy Procedia 2011, 8, 371–376. [Google Scholar] [CrossRef][Green Version]

- Saito, T.; Shimura, A.; Ichikawa, S. A new directional solidification technique for polycrystalline solar grade silicon. In Proceedings of the 15th Photovoltaic Specialists Conference, Kissimmee, FL, USA, 12–15 May 1981. [Google Scholar]

- Dash, W.C. Growth of Silicon Crystals Free from Dislocations. J. Appl. Phys. 2004, 30, 459–474. [Google Scholar] [CrossRef]

- Goetzberger, A.; Hebling, C.; Schock, H.-W. Photovoltaic materials, history, status and outlook. Mater. Sci. Eng. R Rep. 2003, 40, 1–46. [Google Scholar] [CrossRef]

- Hendawi, R. Reusable Crucible Materials and Coatings for Photovoltaic Silicon Applications. PhD Thesis, NTNU, Trondheim, Norway, 2021. [Google Scholar]

- Yuan, S.; Hu, D.; Yu, X.; Zhang, F.; Luo, H.; He, L.; Yang, D. Controllable Nitrogen Doping in Multicrystalline Silicon by Casting Under Low Cost Ambient Nitrogen. Silicon 2018, 10, 1717–1722. [Google Scholar] [CrossRef]

- Qi, X.; Xue, Y.; Su, W.; Ma, W.; Liu, L. Effect of Argon Flow on Oxygen and Carbon Coupled Transport in an Industrial Directional Solidification Furnace for Crystalline Silicon Ingots. Crystals 2021, 11, 421. [Google Scholar] [CrossRef]

- Hendawi, R.; Ciftja, A.; Arnberg, L.; Di Sabatino, M. Kinetics of silicon nitride coatings degradation and its influence on liquid infiltration in PV silicon crystallization processes. Sol. Energy Mater. Sol. Cells 2021, 230, 111190. [Google Scholar] [CrossRef]

- Hendawi, R.; Arnberg, L.; Di Sabatino, M. Effect of gas atmospheres on the interactions between liquid silicon and coated graphite substrates. Sol. Energy Mater. Sol. Cells 2022, 235, 111452. [Google Scholar] [CrossRef]

- Bellmann, M.P.; Meese, E.A.; Arnberg, L. Effect of accelerated crucible rotation on the segregation of impurities in vertical Bridgman growth of multi-crystalline silicon. J. Cryst. Growth 2011, 318, 239–243. [Google Scholar] [CrossRef]

- Bellmann, M.P.; Meese, E.A. Effect of steady crucible rotation on the segregation of impurities in vertical Bridgman growth of multi-crystalline silicon. J. Cryst. Growth 2011, 333, 1–6. [Google Scholar] [CrossRef]

- Pätzold, O.; Grants, I.; Wunderwald, U.; Jenkner, K.; Cröll, A.; Gerbeth, G. Vertical gradient freeze growth of GaAs with a rotating magnetic field. J. Cryst. Growth 2002, 245, 237–246. [Google Scholar] [CrossRef]

- Kiessling, F.M.; Büllesfeld, F.; Dropka, N.; Frank-Rotsch, C.; Müller, M.; Rudolph, P. Characterization of mc-Si directionally solidified in travelling magnetic fields. J. Cryst. Growth 2012, 360, 81–86. [Google Scholar] [CrossRef]

- Schmid, E.; Poklad, A.; Heinze, V.; Meier, D.; Pätzold, O.; Stelter, M. Growth of multicrystalline silicon in a cone-shaped crucible. J. Cryst. Growth 2015, 416, 1–7. [Google Scholar] [CrossRef]

- Reimann, C.; Trempa, M.; Lehmann, T.; Rosshirt, K.; Stenzenberger, J.; Friedrich, J.; Hesse, K.; Dornberger, E. Influence of different seed materials on multi-crystalline silicon ingot properties. J. Cryst. Growth 2016, 434, 88–95. [Google Scholar] [CrossRef]

- Schwanke, S.; Trempa, M.; Reimann, C.; Kuczynski, M.; Schroll, G.; Sans, J.; Friedrich, J. Production of high performance multi-crystalline silicon ingots for PV application by using contamination-free SixNy seed particles. J. Cryst. Growth 2019, 522, 151–159. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, H.; Yuan, S.; Wu, Y.; Zhang, X.; You, D.; Wang, L.; Yu, X.; Wan, Y.; Yang, D. Multicrystalline silicon assisted by polycrystalline silicon slabs as seeds. Sol. Energy Mater. Sol. Cells 2018, 179, 312–318. [Google Scholar] [CrossRef]

- Coletti, G.; Kvande, R.; Mihailetchi, V.D.; Geerligs, L.J.; Arnberg, L.; Øvrelid, E.J. Effect of iron in silicon feedstock on p- and n-type multicrystalline silicon solar cells. J. Appl. Phys. 2008, 104, 104913. [Google Scholar] [CrossRef]

- Li, T.F.; Yeh, K.M.; Hsu, W.C.; Lan, C.W. High-quality multi-crystalline silicon (mc-Si) grown by directional solidification using notched crucibles. J. Cryst. Growth 2011, 318, 219–223. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, D.; Zhong, D.; Huang, C.; Yuan, S.; You, D.; Zhang, X.; Wan, Y. The effect of diffusion barrier on minority carrier lifetime improvement of seed assisted cast silicon ingot. J. Cryst. Growth 2020, 541, 125684. [Google Scholar] [CrossRef]

- Trempa, M.; Sturm, F.; Kranert, C.; Schwanke, S.; Reimann, C.; Friedrich, J.; Schenk, C. Impact of different SiO2 diffusion barrier layers on lifetime distribution in multi-crystalline silicon ingots. J. Cryst. Growth 2020, 532, 125378. [Google Scholar] [CrossRef]

- Lei, Q.; He, L.; Ao, P.; Li, X.; Liu, S.; Zhang, X.; Liao, L.; Zhou, L. Study on reducing the contamination of metal impurities for casting silicon ingots by using non-oxide crucible barrier layer. Sol. Energy Mater. Sol. Cells 2021, 231, 111132. [Google Scholar] [CrossRef]

- Wolny, F.; Krause, A.; Müller, M.; Fischer, G.; Neuhaus, H. Reduced metal contamination from crucible and coating using a silicon nitride based diffusion barrier for the growth of cast quasi-single crystalline silicon ingots. J. Cryst. Growth 2019, 514, 49–53. [Google Scholar] [CrossRef]

- Hendawi, R.; Arnberg, L.; Di Sabatino, M. Crucibles and Coatings for Silicon Melting and Crystallization: An In-Depth Review of Key Considerations. Prog. Mater. Sci. 2023; in press. [Google Scholar]

- Hendawi, R.; Arnberg, L.; Di Sabatino, M. Novel coatings for graphite materials in PV silicon applications: A study of the surface wettability and interface interactions. Sol. Energy Mater. Sol. Cells 2022, 234, 111422. [Google Scholar] [CrossRef]

- Yang, Y.M.; Yu, A.; Hsu, B.; Hsu, W.C.; Yang, A.; Lan, C.W. Development of high-performance multicrystalline silicon for photovoltaic industry. Prog. Photovolt. Res. Appl. 2015, 23, 340–351. [Google Scholar] [CrossRef]

- Stokkan, G.; Hu, Y.; Mjøs, Ø.; Juel, M. Study of evolution of dislocation clusters in high performance multicrystalline silicon. Sol. Energy Mater. Sol. Cells 2014, 130, 679–685. [Google Scholar] [CrossRef]

- Stoddard, N.; Wu, B.; Witting, I.; Wagener, M.C.; Park, Y.; Rozgonyi, G.A.; Clark, R. Casting Single Crystal Silicon: Novel Defect Profiles from BP Solar’s Mono2 TM Wafers. Solid State Phenom. 2008, 131–133, 1–8. [Google Scholar]

- Guerrero, I.; Parra, V.; Carballo, T.; Black, A.; Miranda, M.; Cancillo, D.; Moralejo, B.; Jiménez, J.; Lelièvre, J.-F.; del Cañizo, C. About the origin of low wafer performance and crystal defect generation on seed-cast growth of industrial mono-like silicon ingots. Prog. Photovolt. Res. Appl. 2014, 22, 923–932. [Google Scholar] [CrossRef]

- Song, L.; Yu, X. Defect engineering in cast mono-like silicon: A review. Prog. Photovolt. Res. Appl. 2021, 29, 294–314. [Google Scholar] [CrossRef]

- Takahashi, I.; Joonwichien, S.; Iwata, T.; Usami, N. Seed manipulation for artificially controlled defect technique in new growth method for quasi-monocrystalline Si ingot based on casting. Appl. Phys. Express 2015, 8, 105501. [Google Scholar] [CrossRef]

- He, L.; Yuan, S.; Xu, Y.; Lei, Q.; Mao, W.; Luo, H.; He, X.; Li, X.; Wang, L.; Yang, D.; et al. Evaluation of large-scale recycled seed for cast monocrystalline silicon: Defect multiplication mechanisms and feasibility. Sol. Energy Mater. Sol. Cells 2021, 230, 111266. [Google Scholar] [CrossRef]

- Ballif, C.; Haug, F.-J.; Boccard, M.; Verlinden, P.J.; Hahn, G. Status and perspectives of crystalline silicon photovoltaics in research and industry. Nat. Rev. Mater. 2022, 7, 597–616. [Google Scholar] [CrossRef]

- Lanterne, A.; Gaspar, G.; Hu, Y.; Øvrelid, E.; Sabatino, M.D. Investigation of different cases of dislocation generation during industrial Cz silicon pulling. Phys. Status Solidi C 2016, 13, 827–832. [Google Scholar] [CrossRef]

- Hendawi, R.; Di Sabatino, M. Analyzing structure loss in Czochralski silicon growth: Root causes investigation through surface examination. J. Cryst. Growth 2024, 629, 127564. [Google Scholar] [CrossRef]

- Lanterne, A.; Gaspar, G.; Hu, Y.; Øvrelid, E.; Di Sabatino, M. Characterization of the loss of the dislocation-free growth during Czochralski silicon pulling. J. Cryst. Growth 2017, 458, 120–128. [Google Scholar] [CrossRef]

- Sortland, Ø.S.; Øvrelid, E.J.; M’Hamdi, M.; Di Sabatino, M. Investigation of pinholes in Czochralski silicon ingots in relation to structure loss. J. Cryst. Growth 2019, 510, 1–6. [Google Scholar] [CrossRef]

- Sortland, Ø.S.; Jomâa, M.; M’Hamdi, M.; Øvrelid, E.J.; Di Sabatino, M. Statistical analysis of structure loss in Czochralski silicon growth. AIP Conf. Proc. 2019, 2147, 100002. [Google Scholar]

- World Energy Outlook; IRENA: Masdar City, United Arab Emirates, 2022.

- Warden, G.K.; Juel, M.; Gaweł, B.A.; Di Sabatino, M. Recent developments on manufacturing and characterization of fused quartz crucibles for monocrystalline silicon for photovoltaic applications. Open Ceram. 2023, 13, 100321. [Google Scholar] [CrossRef]

- Peng, L.; Qin, S.; Gu, X. Effects of melting parameters and quartz purity on silica glass crucible produced by arc method. Eng. Res. Express 2020, 2, 015046. [Google Scholar] [CrossRef]

- Forster, M.; Fourmond, E.; Einhaus, R.; Lauvray, H.; Kraiem, J.; Lemiti, M. Ga co-doping in Cz-grown silicon ingots to overcome limitations of B and P compensated silicon feedstock for PV applications. Phys. Status Solidi C 2011, 8, 678–681. [Google Scholar] [CrossRef]

- Schubert, M.C.; Schindler, F.; Benick, J.; Riepe, S.; Krenckel, P.; Richter, A.; Müller, R.; Hammann, B.; Nold, S. The potential of cast silicon. Sol. Energy Mater. Sol. Cells 2021, 219, 110789. [Google Scholar] [CrossRef]

- Sanchez Garcia, A.; Hendawi, R.; Di Sabatino, M. Machine learning methods for structure loss classification in Czochralski silicon ingots. Submitt. Cryst. Growth Des. 2023; in press. [Google Scholar]

- Buratti, Y.; Eijkens, C.; Hameiri, Z. Optimization of Solar Cell Production Lines Using Neural Networks and Genetic Algorithms. ACS Appl. Energy Mater. 2020, 3, 10317–10322. [Google Scholar] [CrossRef]

- Roy, R.K. Design of Experiments Using The Taguchi Approach: 16 Steps to Product and Process Improvement; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Haug, H.; Greulich, J. PC1Dmod 6.2–Improved Simulation of c-Si Devices with Updates on Device Physics and User Interface. Energy Procedia 2016, 92, 60–68. [Google Scholar] [CrossRef]

- Su, B.; Chen, H.; Chen, P.; Bian, G.; Liu, K.; Liu, W. Deep Learning-Based Solar-Cell Manufacturing Defect Detection With Complementary Attention Network. IEEE Trans. Ind. Inform. 2021, 17, 4084–4095. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, L.; Polosukhin, I. Attention Is All You Need. arXiv 2023, arXiv:1706.03762. [Google Scholar]

- Chen, F.C.; Jahanshahi, M.R. NB-CNN: Deep Learning-Based Crack Detection Using Convolutional Neural Network and Naïve Bayes Data Fusion. IEEE Trans. Ind. Electron. 2018, 65, 4392–4400. [Google Scholar] [CrossRef]

- Deitsch, S.; Christlein, V.; Berger, S.; Buerhop-Lutz, C.; Maier, A.; Gallwitz, F.; Riess, C. Automatic classification of defective photovoltaic module cells in electroluminescence images. Sol. Energy 2019, 185, 455–468. [Google Scholar] [CrossRef]

- Han, H.; Gao, C.; Zhao, Y.; Liao, S.; Tang, L.; Li, X. Polycrystalline silicon wafer defect segmentation based on deep convolutional neural networks. Pattern Recognit. Lett. 2020, 130, 234–241. [Google Scholar] [CrossRef]

- Buratti, Y.; Abdullah-Vetter, Z.; Sowmya, A.; Trupke, T.; Hameiri, Z. A Deep Learning Approach for Loss-Analysis from Luminescence Images. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021. [Google Scholar]

- Buratti, Y.; Sowmya, A.; Evans, R.; Trupke, T.; Hameiri, Z. Half and full solar cell efficiency binning by deep learning on electroluminescence images. Prog. Photovolt. Res. Appl. 2022, 30, 276–287. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Sabatino, M.; Hendawi, R.; Garcia, A.S. Silicon Solar Cells: Trends, Manufacturing Challenges, and AI Perspectives. Crystals 2024, 14, 167. https://doi.org/10.3390/cryst14020167

Di Sabatino M, Hendawi R, Garcia AS. Silicon Solar Cells: Trends, Manufacturing Challenges, and AI Perspectives. Crystals. 2024; 14(2):167. https://doi.org/10.3390/cryst14020167

Chicago/Turabian StyleDi Sabatino, Marisa, Rania Hendawi, and Alfredo Sanchez Garcia. 2024. "Silicon Solar Cells: Trends, Manufacturing Challenges, and AI Perspectives" Crystals 14, no. 2: 167. https://doi.org/10.3390/cryst14020167

APA StyleDi Sabatino, M., Hendawi, R., & Garcia, A. S. (2024). Silicon Solar Cells: Trends, Manufacturing Challenges, and AI Perspectives. Crystals, 14(2), 167. https://doi.org/10.3390/cryst14020167