Effect of Corrosion and Post-Weld Treatment on the Fatigue Behavior of Multipass Robot GMAW Welds of S700MC Steel

Abstract

:1. Introduction

2. Materials and Methods

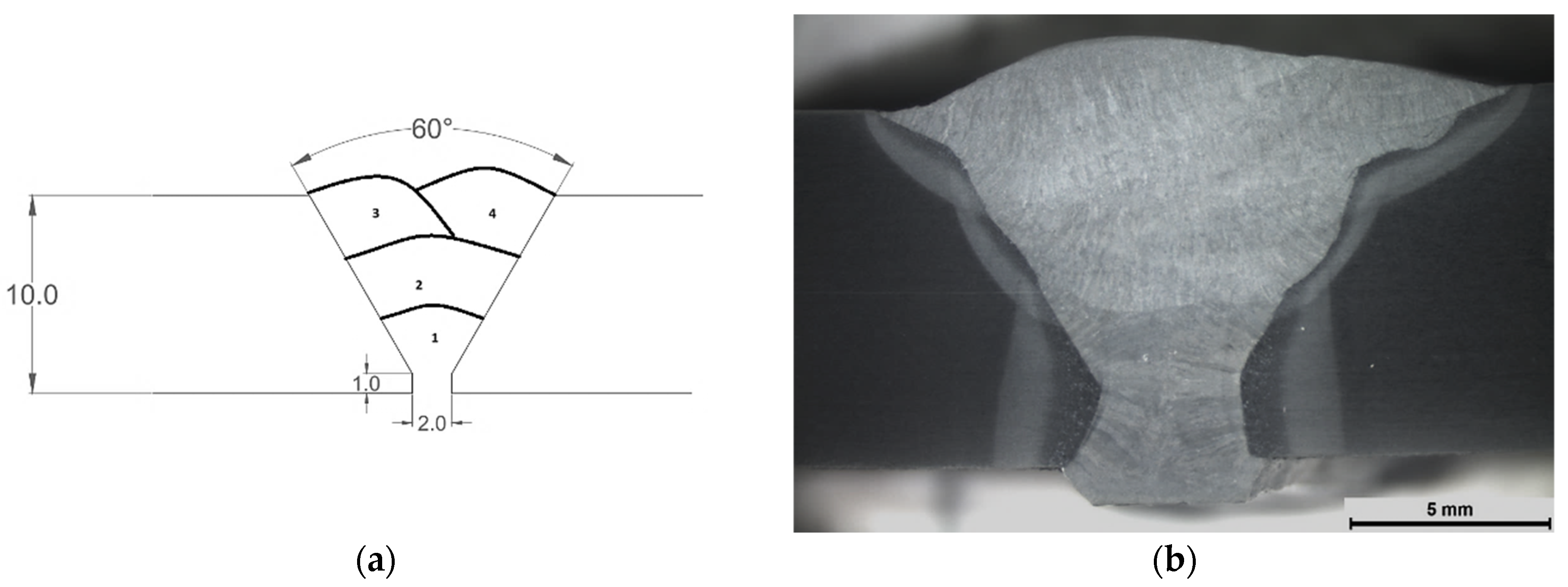

2.1. Materials and Welding Procedure

2.2. Metallographic Observations

2.3. Corrosion Tests

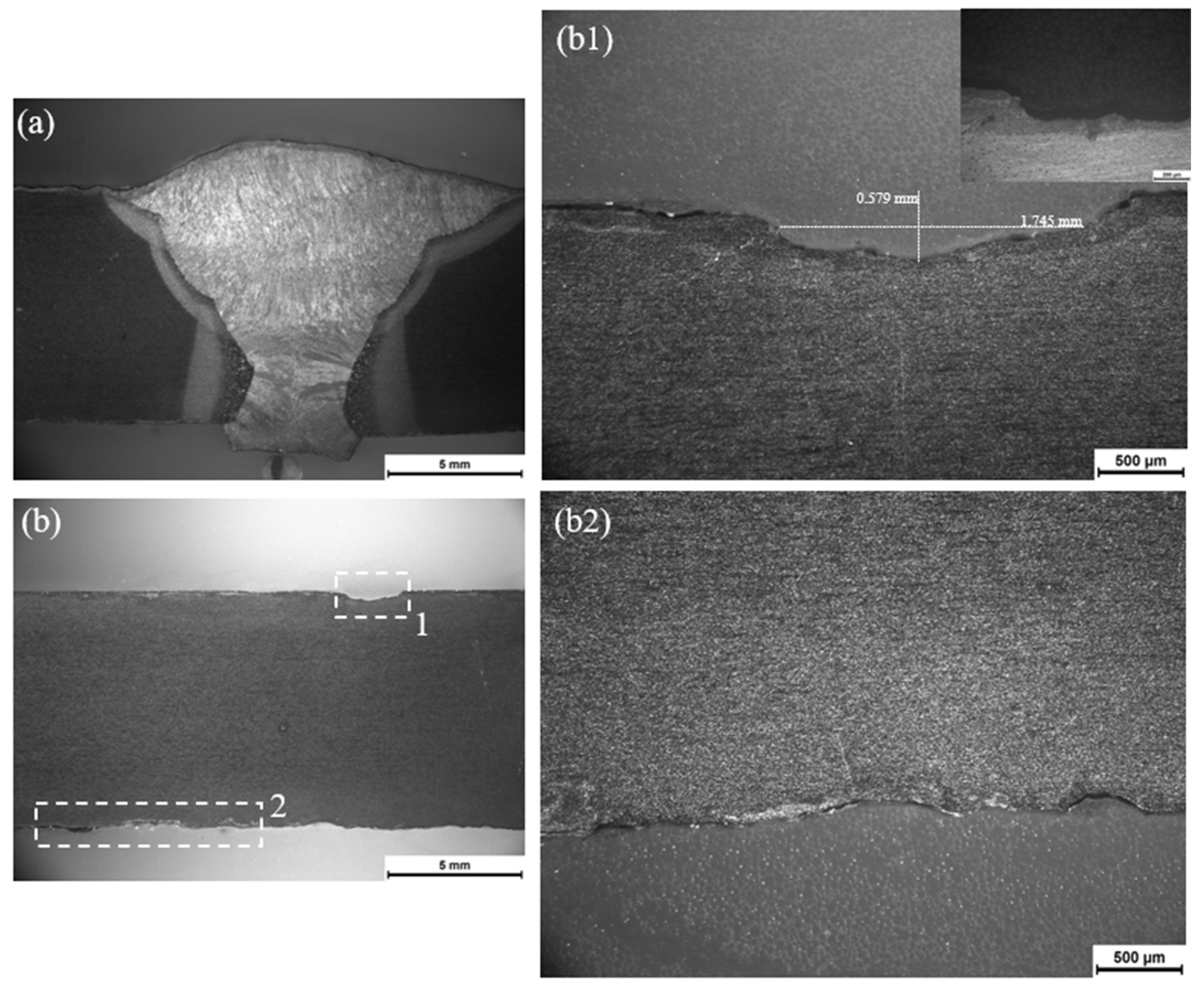

2.4. HFMI Treatment Procedure

2.5. Tensile and Fatigue Tests

2.6. Characterization of Fractured Surfaces

3. Results and Discussion

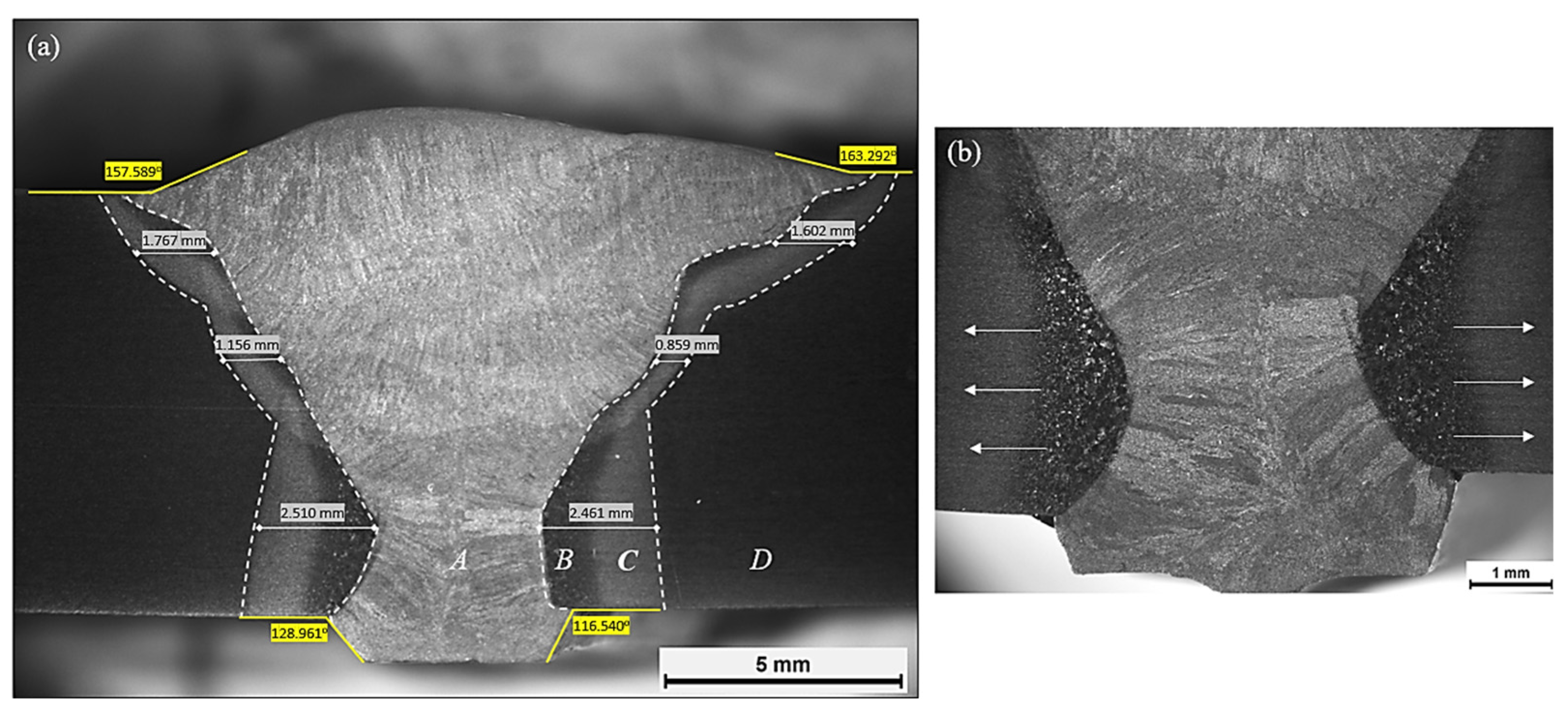

3.1. Macrostructural Examination

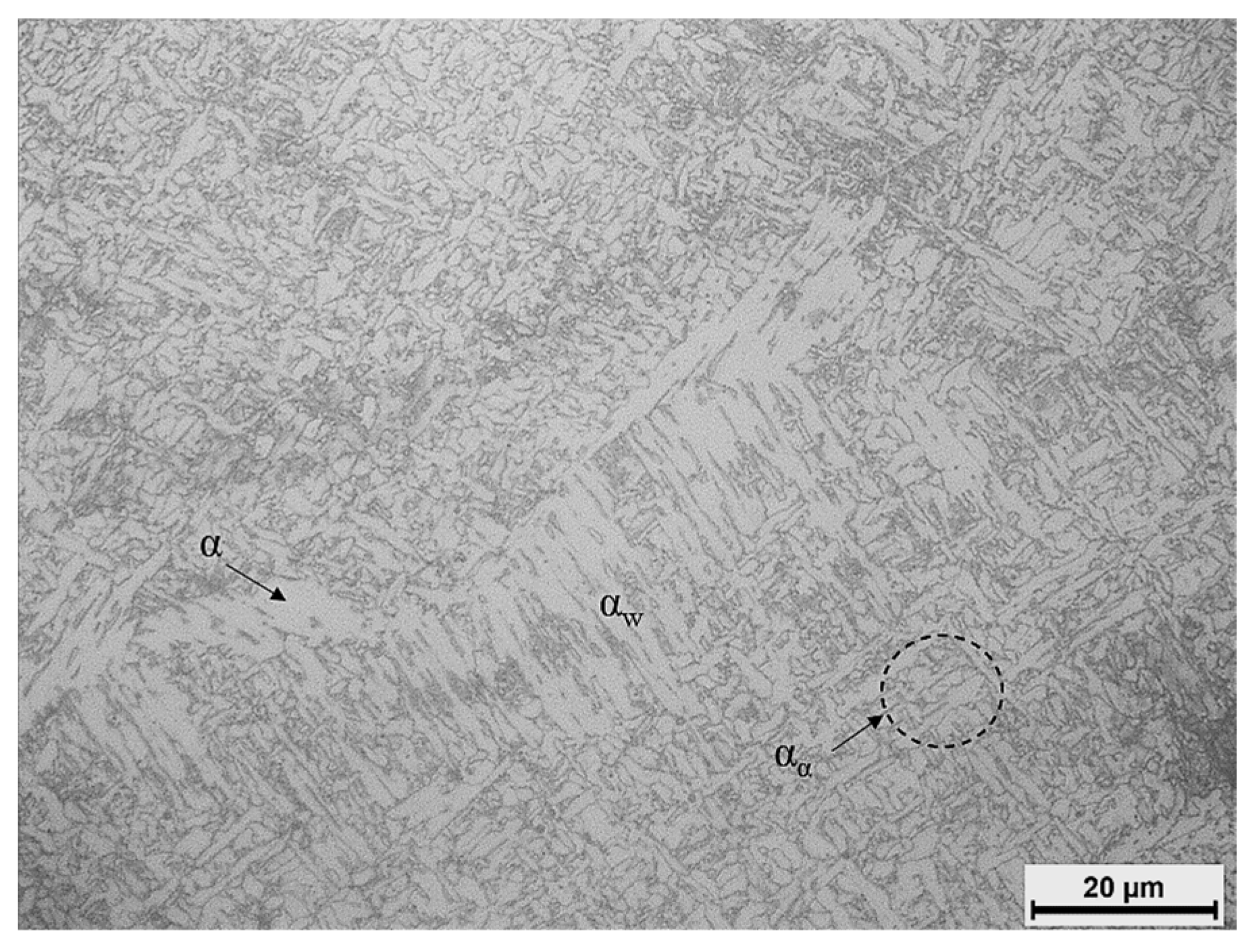

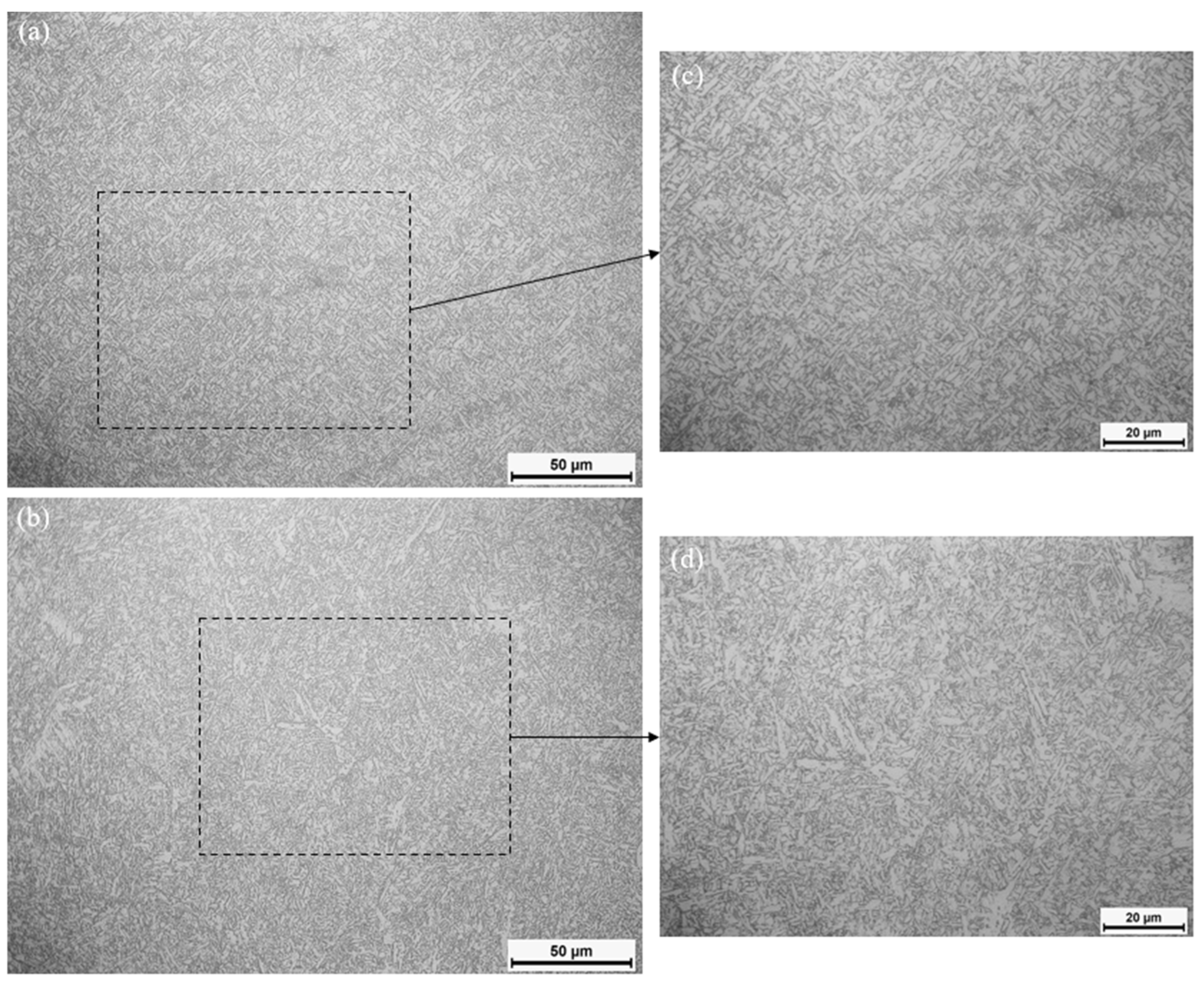

3.2. Microstructural Examination

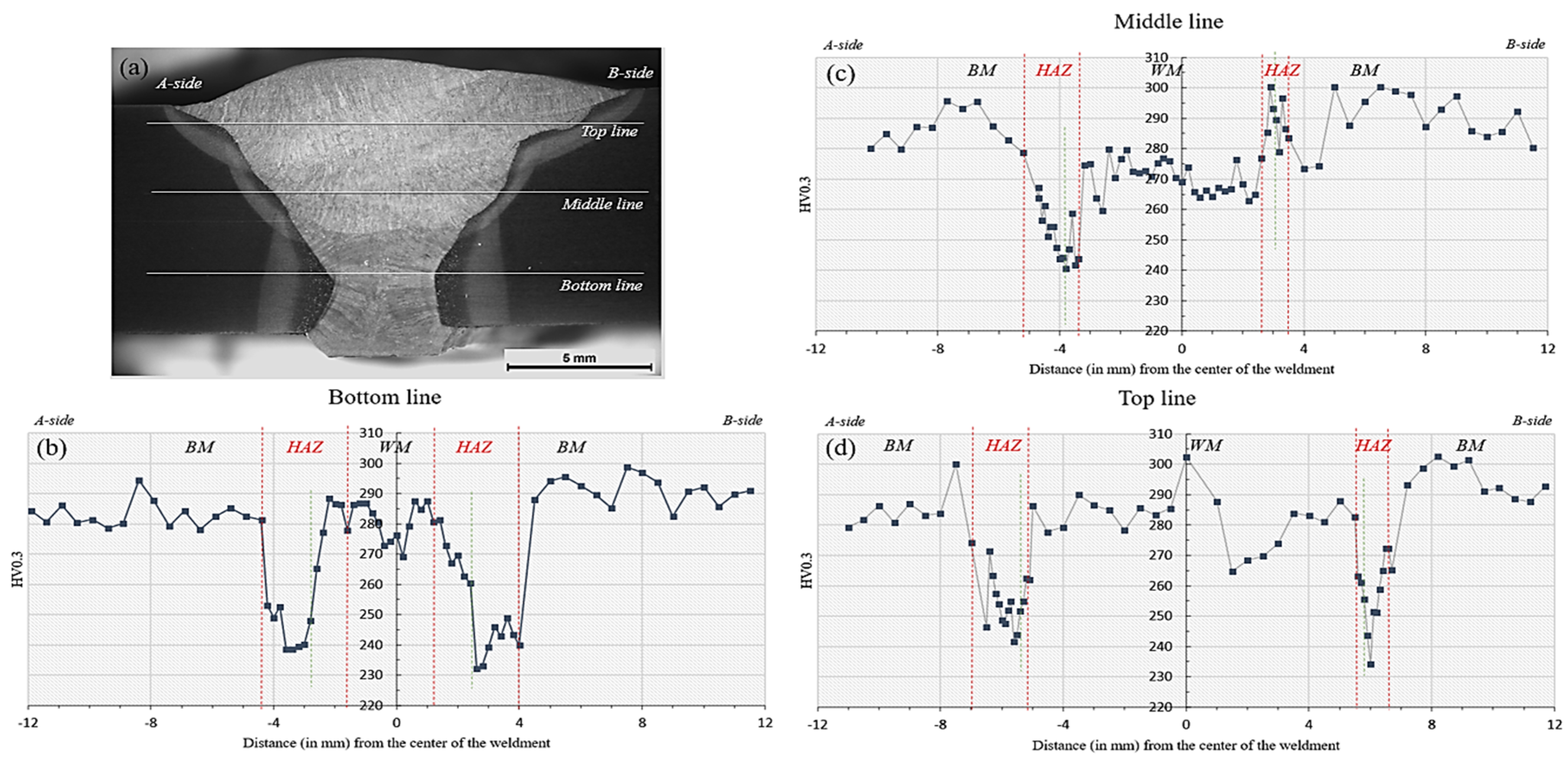

3.3. Mechanical Property Evaluation

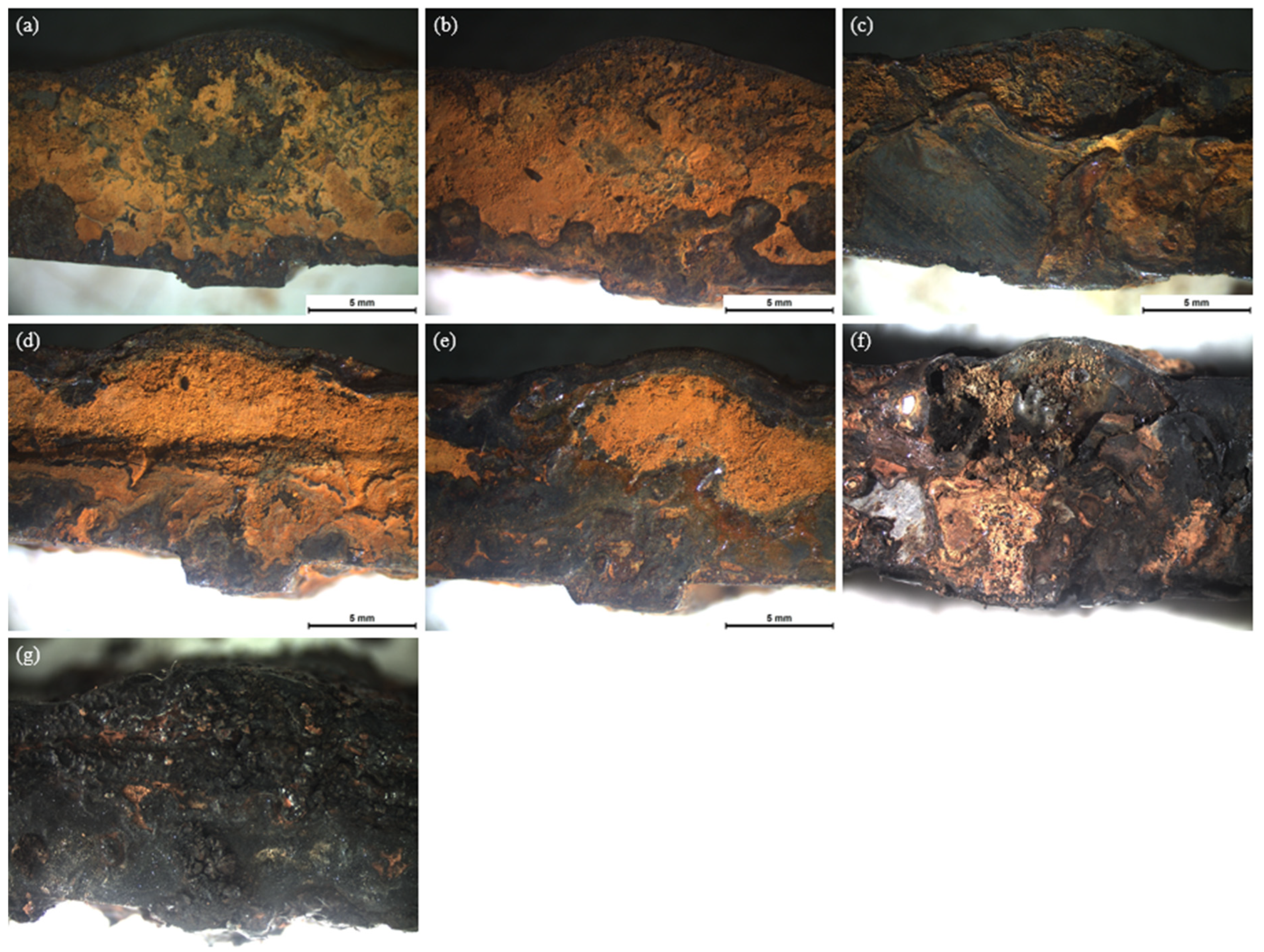

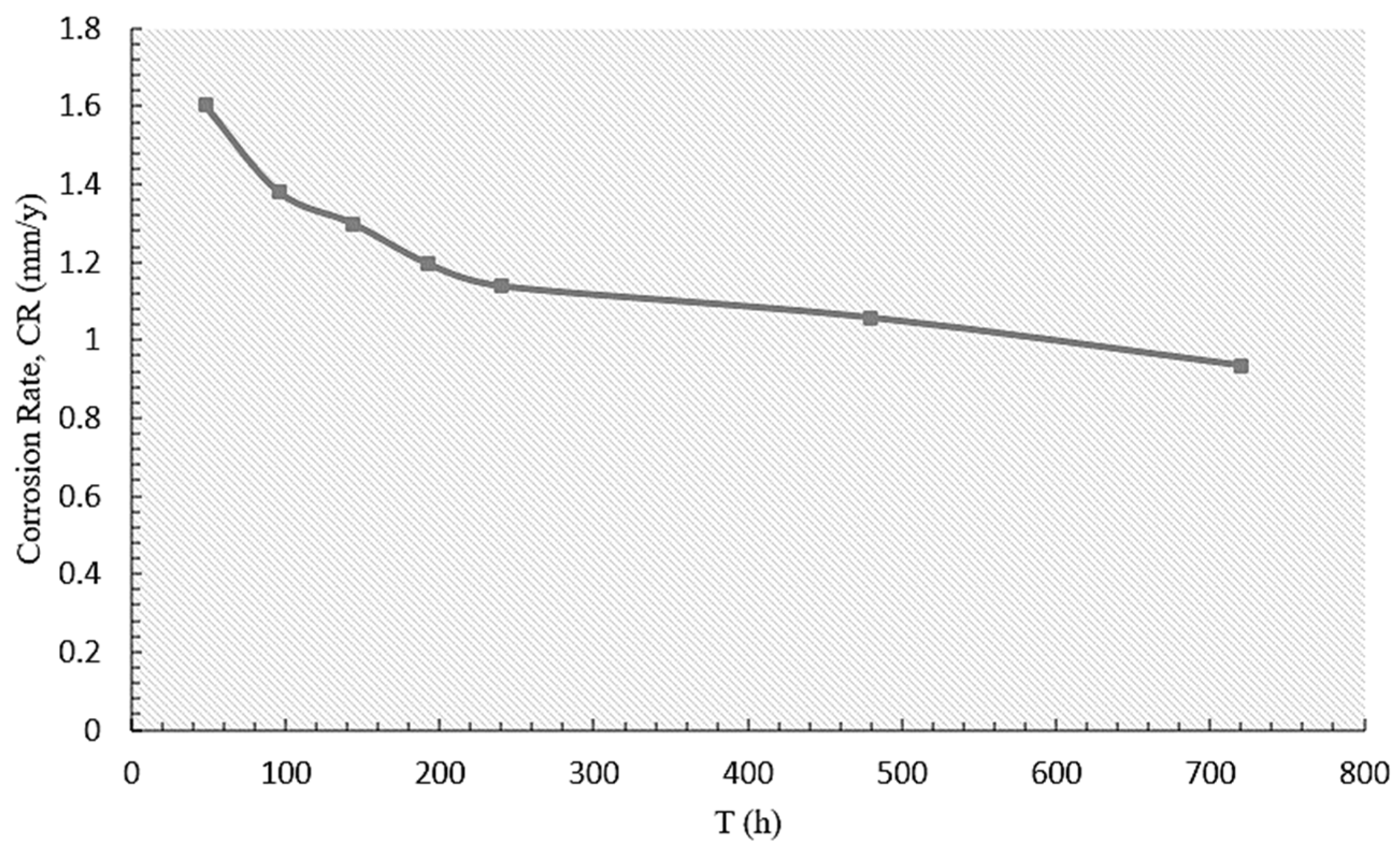

3.4. Corrosion Testing Evaluation

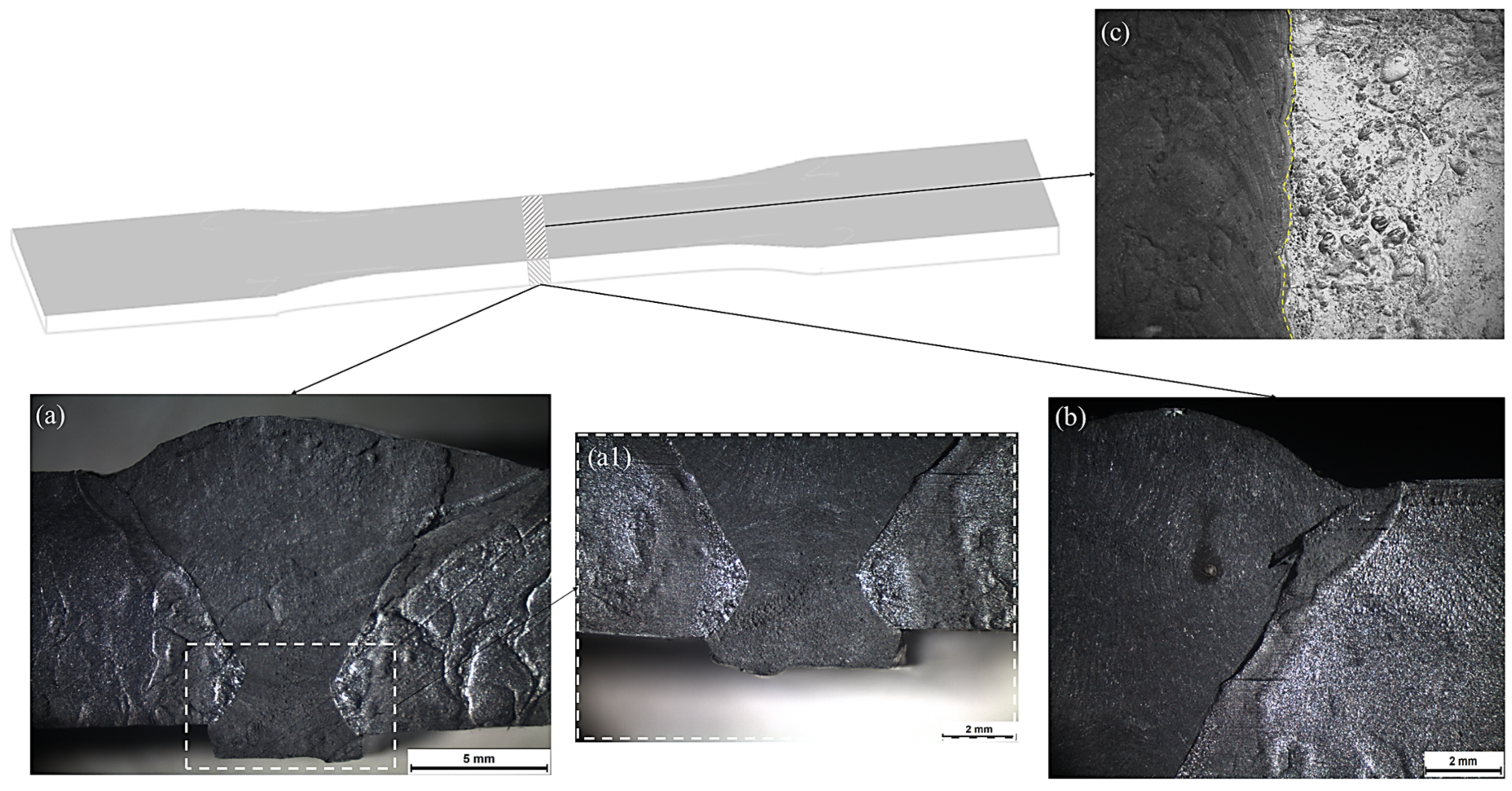

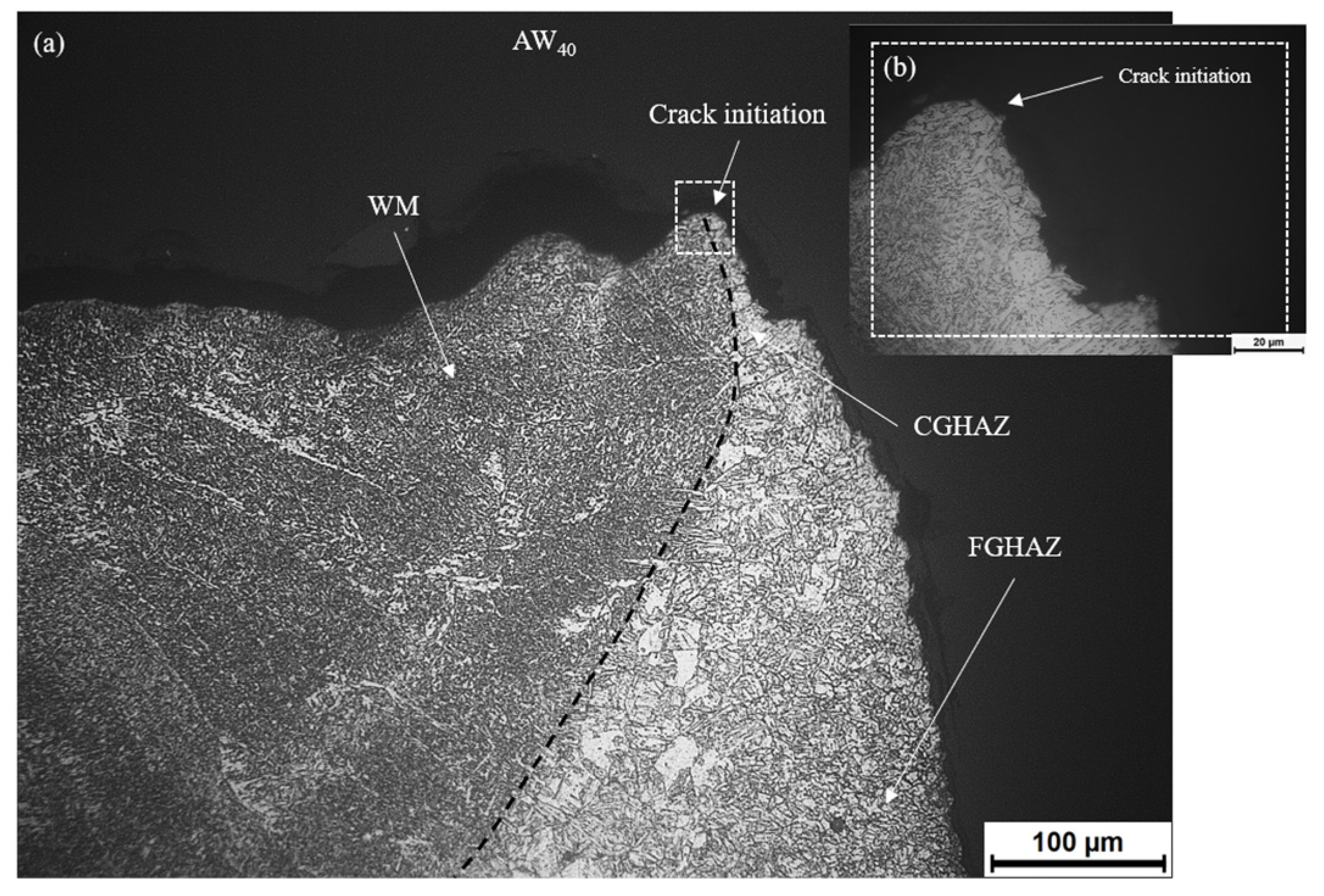

3.5. Fatigue Test Evaluation

4. Conclusions

- The macroscopic examination of the weldments verified the absence of metallurgical defects, while the intensity of surface imperfections and imperfections in joint geometry results in a level C quality assessment.

- Regardless of the number of welding passes, the microstructure of WM was composed of an acicular ferritic matrix along with grain boundary and Widmanstätten ferrite. Increasing the number of passes led to an increase in grain boundary ferrite at the expense of acicular ferrite, due to the slower cooling rate. CGHAZ mainly consisted of bainite and proeutectoid ferrite, while the FGHAZ microstructure resembled that of the BM; however, the development of high temperatures during welding eliminated the rolling texture inherent to the latter.

- Microhardness evaluation confirmed a softening effect within the HAZ. Tensile testing revealed no degradation in the overall mechanical properties of the weldments. Notably, failure consistently occurred within the BM region, rather than the HAZ, in a failure mode often observed for hot-rolled steels, indicating a good weld quality.

- Short-term exposure of the welded joints to salt fog resulted in the formation of corrosion pits, primarily on the BM surface. Although prolonged exposure resulted in an increase in both the number and size of the pits on the BM, as well as the presence of microscopic pits on the WM and HAZ surface, the corrosion rate decreased with longer exposure times due to the formation of a protective layer.

- Fatigue cracks of the as-welded and pre-corroded specimens were initiated on the face side of the CGHAZ, mainly influenced by the geometry of the weldment and the presence of coarse-grained bainitic matrix. Although pre-corrosion generally reduces the fatigue strength of the welded joints, this is not the case for all specimens, indicating that corrosion may be a less significant factor in determining the specimens’ behavior under cyclic loading for the exposure times employed in this study. Instead, the impact of angular deformation, which induces additional bending stresses during cyclic loading, should also be considered.

- Regarding the HFMI treatment, a significant improvement in fatigue life under constant amplitude loading was observed. Plastic deformation caused an increase in microhardness near the surface of the specimens. Beyond a depth of 0.1 mm from the surface, the extent of this increase was reduced.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhadeshia, H.; Honeycombe, R. Steels: Microstructure and Properties, 4th ed.; Butterworth-Heinmann: Oxford, UK, 2017. [Google Scholar]

- Kim, N.J. The Physical Metallurgy of HSLA Linepipe Steels—A Review. J. Met. 1983, 35, 21–27. [Google Scholar] [CrossRef]

- Porter, L.; Repas, P. The Evolution of HSLA Steels. J. Met. 1982, 34, 14–21. [Google Scholar] [CrossRef]

- Skobir, D.A. High strength low-alloy (HSLA) steels. Mater. Technol. 2011, 45, 295–301. [Google Scholar]

- Lahtinen, T.; Vilaça, P.; Infante, V. Fatigue behavior of MAG welds of thermo-mechanically processed 700MC ultra high strength steel. Int. J. Fatigue 2019, 126, 62–71. [Google Scholar] [CrossRef]

- Costa, J.D.M.; Ferreira, J.A.M.; Abreu, L.P.M. Fatigue behaviour of butt welded joints in a high strength steel. Procedia Eng. 2010, 2, 697–705. [Google Scholar] [CrossRef]

- Guo, W.; Li, L.; Crowther, D.; Dong, S.; Francis, J.A.; Thompson, A. Laser welding of high strength steels (S960 and S700) with medium thickness. J. Laser Appl. 2016, 28, 022425. [Google Scholar] [CrossRef]

- Cochrane, R. Phase transformations in microalloyed high strength low alloy (HSLA) steels. In Part II: Phase Transformations in High Strength Steels; Woodhead Publishing: Sawston, UK, 2012; Volume 2, pp. 153–212. [Google Scholar]

- Rashid, M. High-Strength, Low-Alloy Steels. Science 1980, 208, 862–869. [Google Scholar] [CrossRef] [PubMed]

- Mohrbacher, H. Mohrbacher, H. Mo and Nb Alloying in Plate Steels for High-Performance Applications. In 2011 International Symposium on the Recent Developments in Plate Steels; Association for Iron & Steel Technology: Warrendale, PA, USA, 2011; pp. 169–179. [Google Scholar]

- DeArdo, A.J. Multi-phase microstructures and their properties in high strength low carbon steels. ISIJ Int. 1995, 35, 946–954. [Google Scholar] [CrossRef]

- Shao, Y.; Liu, C.; Yan, Z.; Li, H.; Liu, Y. Formation mechanism and control methods of acicular ferrite in HSLA steels: A review. J. Mater. Sci. Technol. 2018, 34, 737–744. [Google Scholar] [CrossRef]

- Jorge, J.C.F.; de Souza, L.F.G.; Mendes, M.C.; Bott, M.C.; Araújo, L.S.; Santos, V.R.D.; Rebello, J.M.A.; Evans, G.M. Microstructure characterization and its relationship with impact toughness of C–Mn and high strength low alloy steel weld metals—A Review. J. Mater. Res. Technol. 2021, 10, 471–501. [Google Scholar] [CrossRef]

- Vimalraj, C.; Kah, P.; Layus, P.; Belinga, E.M.; Parshin, S. High-strength steel S960QC welded with rare earth nanoparticle coated filler wire. Int. J. Adv. Manuf. Technol. 2018, 102, 105–119. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- Tümer, M.; Schneider-Bröskamp, G.; Enzinger, N. Fusion welding of ultra-high strength structural steels—A review. J. Manuf. Process. 2022, 82, 203–229. [Google Scholar] [CrossRef]

- Hochhauser, F.; Ernst, W.; Rauch, R.; Vallant, R.; Enzinger, N. Influence of the soft zone on the strength of welded modern HSLA Steels. Weld. World 2012, 56, 77–85. [Google Scholar] [CrossRef]

- Amraei, M.; Ahola, A.; Afkhami, S.; Björk, T.; Heidarpour, A.; Zhao, X.-L. Effects of heat input on the mechanical properties of butt-welded high and ultra-high strength steels. Eng. Struct. 2019, 198, 109460. [Google Scholar] [CrossRef]

- Moravec, J.; Sobotka, J.; Solfronk, P.; Thakral, R. Heat Input Influence on the Fatigue Life of Welds from Steel S460MC. Metals 2020, 10, 1288. [Google Scholar] [CrossRef]

- Steimbreger, C.; Gubeljak, N.; Vuherer, T.; Enzinger, N.; Ernst, W.; Chapetti, M. Effect of welding processes on the fatigue behaviour of ultra-high strength steel butt-welded joints. Eng. Fract. Mech. 2022, 275, 108845. [Google Scholar] [CrossRef]

- Pollard, B.; Cover, R.J. Fatigue of Steel Weldments. Weld. Res. Suppl. 1972, 544–554. [Google Scholar]

- Pantelis, D.I.; Tsiourva, T.E. Corrosion of weldments. In Trends in Oil and Gas Corrosion Research and Technologies; Woodhead Publishing: Sawston, UK, 2017; pp. 249–270. [Google Scholar]

- Guo, Y.-B.; Li, C.; Liu, Y.-C.; Yu, L.-M.; Ma, Z.-Q.; Liu, C.-X.; Li, H.-J. Effect of microstructure variation on the corrosion behavior of high-strength low-alloy steel in 3.5wt% NaCl solution. Int. J. Miner. Metall. Mater. 2015, 22, 604–612. [Google Scholar] [CrossRef]

- ASM International. Corrosion of Weldments, Davis, J.R., Ed.; ASM International: Materials Park, OH, USA, 2006. [Google Scholar]

- Gkatzogiannis, S.; Weinert, J.; Engelhardt, I.; Khoedel, P.; Ummenhofer, T. Corrosion fatigue behaviour of HFMI-treated butt welds. Int. J. Fatigue 2021, 145, 106079. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Jr, F.V.L.; Metzger, M.M. Corrosion fatigue of an HSLA steel. Fatigue Fract. Eng. Mater. Struct. 1992, 12, 625–642. [Google Scholar] [CrossRef]

- Knysh, V.; Solovei, S.; Motrunich, S.; Lyudmila, N.; Yildirim, H.C. Influence of the accelarated corrosion exposure on the fatigue behaviour of welded joints treated by high frequency mechanical impact. Int. J. Fatigue 2021, 149, 106272. [Google Scholar] [CrossRef]

- Gkatzogiannis, S.; Weinert, J.; Engelhardt, I.; Knoedel, P.; Ummenhofer, T. Correlation of laboratory and real marine corrosion for the investigation of corrosion fatigue behaviour of steel components. Int. J. Fatigue 2019, 126, 90–102. [Google Scholar] [CrossRef]

- Marquis, G.B.; Barsoum, Z. A Guideline for Fatigue Stength Improvement of High Strength Steel Welded Structures Using High Frequency Mechanical Impact Treatment. Procedia Eng. 2013, 66, 98–107. [Google Scholar] [CrossRef]

- Leitner, M.; Simunek, D.; Shah, S.F.; Stoschka, M. Numerical fatigue assessment of welded and HFMI-treated joints by notch stress/strain and fracture mechanical approaches. Adv. Eng. Softw. 2018, 120, 96–106. [Google Scholar] [CrossRef]

- Weich, I.; Ummenhofer, T.; Nitschke-Pagel, T.; Dilger, K.; Eslami, H. Fatigue Behaviour of Welded High-Strength Steels after High Frequency Mechanical Post-Weld Treatments. Weld. World 2009, 53, R322–R332. [Google Scholar] [CrossRef]

- Yıldırım, H.C.; Marquis, G.; Sonsino, C.M. Lightweight Potential of Welded High-Strength Steel Joints from S700 under Constant and Variable Amplitude Loading by HighFrequency Mechanical Impact (HFMI) Treatment. Procedia Eng. 2015, 101, 467–475. [Google Scholar] [CrossRef]

- Moravec, J.; Sobotka, J.; Novakova, I.; Bukovska, S. Assessment the Partial Welding Influences on Fatigue Life of S700MC Steel Fillet Welds. Metals 2021, 11, 334. [Google Scholar] [CrossRef]

- Nový, F.; Petrů, M.; Trško, L.; Jambor, M.; Bokůvka, O.; Lago, J. Fatigue properties of welded strenx 700 MC HSLA Steel after Ultrasonic Impact Treatment Application. Mater. Today Proc. 2020, 32, 174–178. [Google Scholar] [CrossRef]

- OK Aristorod 69. Available online: https://esab.com (accessed on 2 December 2023).

- DOCOL ® The Automotive Steel, “Docol S700MC,” 2021. Available online: https://www.ssab.com (accessed on 25 November 2023).

- EN 1011-1; Welding—Recommendations for Welding of Metallic Materials, Part 1: General Guidance for arc Welding. European Committee for Standardization: Brussels, Belgium, 2009.

- Daskalopoulos, N. Optimization of Robot Welding GMAW Procedure of S700MC Steel on a Heat Input Basis; National Technical University of Athens: Athens, Greece, 2022. (In Greek) [Google Scholar]

- EN ISO 5817; Welding—Fusion-Welded Joints in Steel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections. European Committee for Standardization: Brussels, Belgium, 2007.

- EN ISO 6520-1; Welding and Allied Processes—Classification of Geometric Imperfections in Metallic Materials—Part 1: Fusion Welding. European Committee for Standardization: Brussels, Belgium, 2007.

- ISO 6507-1; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2018.

- Kumar, V.; Tiwari, S.K.; Sharma, N. Mechanical and surface characterization of interstitial-free steel corroded under wet-dry salt spray and immersion conditions: A comparative study. Mater. Corros. 2023, 74, 1289–1300. [Google Scholar] [CrossRef]

- ASTM B117; Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International: West Conshohocken, PA, USA, 2011.

- EN ISO 7539-1; Corrosion of Metals and Alloys—Stress Corrosion Testing—Part 1: General Guidance on Testing Procedures. European Committee for Standardization: Brussels, Belgium, 2012.

- EN ISO 6892-1; Metallic Materials—Tensile testing—Part 1: Method of Test at Room Temperature. European Committee of Standardization: Brussels, Belgium, 2019.

- ASTM E468; Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM E 8M-04; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM E466-96; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 1996.

- Bukovská, Š.; Moravec, J.; Solfronk, P.; Pekárek, M. Assessment of the Effect of Residual Stresses Arising in the HAZ of Welds on the Fatigue Life of S700MC Steel. Metals 2022, 12, 1890. [Google Scholar] [CrossRef]

- Baptista, R.; Santos, T.; Marques, J.; Guedes, M.; Infante, V. Fatigue behavior and microstructural characterization of a high strength. Int. J. Fatigue 2018, 117, 1–8. [Google Scholar] [CrossRef]

- Wang, P.; Gomes, F.M.; Warchomicka, F.G.; Ernst, W.; Vallant, R.; Poletti, M.C.; Enzinger, N. The effect of thermomechanical welding on the microstructure and mechanical properties of S700MC steel welds. Weld. World 2024, 68, 1053–1069. [Google Scholar] [CrossRef] [PubMed]

- Szymczak, T.; Makowska, K.; Kowalewski, Z.L. Influence of the Welding Process on the Mechanical Characteristics and Fracture of the S700MC High Strength Steel under Various Types of Loading. Materials 2020, 13, 5249. [Google Scholar] [CrossRef] [PubMed]

- Ricks, R.A.; Howell, P.R.; Barritte, G.S. The nature of acicular ferrite in HSLA steel weld metals. J. Materals Sci. 1982, 17, 732–740. [Google Scholar] [CrossRef]

- Lan, L.; Kong, X.; Qiu, C.; Zhao, D. Influence of microstructural aspects on impact toughness of multi-pass submerged arc welded HSLA steel joints. Mater. Des. 2016, 90, 488–498. [Google Scholar] [CrossRef]

- Duprez, L.; Leunis, E.; Güngör, Ö.E.; Claessens, S. Hydrogen embrittlement of high strength, low alloy (HSLA) steels and their welds. In Gaseous Hydrogen Embrittlement of Materials in Energy Technologies; Woodhead Publishing: Sawston, UK, 2016; Volume 2, pp. 562–591. [Google Scholar]

- Nový, F.; Medvecká, D.; Trško, L.; Bokůvka, O.; Drímalová, P. Effect of Welding Methods on the Mechanical Properties of Domex 700MC Steel. Mater. Res. Proc. 2023, 34, 1–5. [Google Scholar]

- Harati, E.; Svensson, L.-E.; Karlsson, L.; Widmark, M. Effect of High Frequency Mechanical Impact treatment on fatigue strength of welded 1300 MPa yield strength steel. Int. J. Fatigue 2016, 92, 96–106. [Google Scholar] [CrossRef]

- Kopas, P.; Sága, M.; Jambor, M.; Nový, F.; Trško, L.; Jakubovičová, L. Comparison of the mechanical properties and microstructural evolution in the HAZ of HSLA DOMEX 700MC welded by gas metal arc welding and electron beam welding. MATEC Web Conf. 2018, 244, 01009. [Google Scholar] [CrossRef]

- Mičian, M.; Frátrik, M.; Brůna, M. Softening effect in the heat affected zone of laser welded joints of high strength low alloyed steels. Weld. World 2024, 68, 1497–1514. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, J.; Xu, Y.; Liu, Z. Effects of Cr, Ni and Cu on the Corrosion Behavior of Low Carbon Microallying Steel in a Cl- Containing Environment. J. Mater. Sci. Technol. 2013, 29, 168–174. [Google Scholar] [CrossRef]

- Guo, J.; Yang, S.; Shang, C.; Wang, Y.; He, X. Influence of carbon content and microstructure on corrosion behaviour of low alloy steels in a Cl- containing environment. Corros. Sci. 2008, 51, 242–251. [Google Scholar] [CrossRef]

- Melchers, R.E. A review of Trends for Corrosion Loss and Pit Depth in Longer-Term Exposures. Corros. Mater. Degrad. 2018, 1, 42–58. [Google Scholar] [CrossRef]

- Fontana, M.G. Corrosion Engineering, 3rd ed.; McGraw-Hill: New York, NY, USA, 1987. [Google Scholar]

- Hobbacher, A. Recommendations for Fatigue Design of Welded Joints and Components, 2nd ed.; IIW Collection; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Ummenhofer, T.; Gkatzogiannis, S.; Weidner, P. Einfluss der Korrosion auf die Ermüdungsfestigkeit von Konstruktionen des Stahlwasserbaus. In Proceedings of the Kolloquium Korrosionsschutz und Tragfähigkeit bestehender Stahlwasserbauverschlüsse, Karlsruhe, Germany, 8–9 February 2017. [Google Scholar]

- Alipooramirabad, H.; Ghomashchi, R.; Paradowska, A.; Reid, M. Residual stress-microstructure-mechanical property interrelationships in multipass HSLA steel welds. J. Mater. Process. Technol. 2016, 231, 456–467. [Google Scholar] [CrossRef]

- Lago, J.; Trško, L.; Jambor, M.; Nový, F.; Bokůvka, O.; Mičian, M.; Pastorek, F. Fatigue life improvement of the high strength steel welded joints by ultrasonic impact peening. Metals 2019, 9, 619. [Google Scholar] [CrossRef]

- Bakkar, M.A.; Kanrar, B.; Das, D. Low Cycle Fatigue Behavior of a Microalloyed Steel. In Processing and Characterization of Materials; Springer: Singapore, 2021. [Google Scholar]

- Tomar, B. Fatigue Analyses of GMAW Welds of Thermo-Mechanically Processed 700MC Ultra High Strentgh Steel. Int. J. Res. Eng. Sci. Manag. 2020, 3, 220–225. [Google Scholar]

| wt. % | C | Si | Mn | P | S | Al | Nb * | V * | Ti * | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S700MC | max 0.12 | max 0.21 | max 2.1 | max 0.02 | max 0.01 | min 0.015 | max 0.09 | max 0.2 | max 0.15 | - | - | - |

| Filler Metal | 0.089 | 0.53 | 1.54 | - | - | - | - | - | - | 1.23 | 0.26 | 0.24 |

| No. of Pass | Current (A) | Voltage (V) | Type of Current | Travel Speed (cm/min) | Heat Input (kJ/mm) |

|---|---|---|---|---|---|

| 1–4 | 180 | 30 | DC | 35 | 0.7405 |

| Travel Speed | Distance | Speed | Intensity | Air Pressure | Depth of the Treatment |

|---|---|---|---|---|---|

| Toe: 64.5 s Root: 63.5 s | 35 cm | 5.5 mm/s | 2 Revolutions | 7 Bars | 0.20–0.25 mm |

| AW85 | AW40 | AW30a | AW30b | AW25 | AW20 | |

| Δσ (MPa) Nf (Cycles) | 535.5 | 252 | 189 | 189 | 157.5 | 126 |

| 8842 | 156,997 | 705,017 | 402,051 | 773,958 | 1,559,422 | |

| C85 | C50 | C40 | C30a | C30b | ||

| 535.5 | 315 | 252 | 189 | 189 | ||

| 16,871 | 82,508 | 150,054 | 4,307,762 | 263,365 | ||

| HFMI 40 | HFMI30a | HFMI30b | HFMI25 | C20 | ||

| 252 | 189 | 189 | 157.5 | 126 | ||

| 263,741 | 548,013 | 589,611 | 1,162,114 | 3,292,732 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spyropoulou, S.; Christofilis, E.; Zervaki, A.D. Effect of Corrosion and Post-Weld Treatment on the Fatigue Behavior of Multipass Robot GMAW Welds of S700MC Steel. Crystals 2024, 14, 609. https://doi.org/10.3390/cryst14070609

Spyropoulou S, Christofilis E, Zervaki AD. Effect of Corrosion and Post-Weld Treatment on the Fatigue Behavior of Multipass Robot GMAW Welds of S700MC Steel. Crystals. 2024; 14(7):609. https://doi.org/10.3390/cryst14070609

Chicago/Turabian StyleSpyropoulou, Stefania, Emmanouil Christofilis, and Anna D. Zervaki. 2024. "Effect of Corrosion and Post-Weld Treatment on the Fatigue Behavior of Multipass Robot GMAW Welds of S700MC Steel" Crystals 14, no. 7: 609. https://doi.org/10.3390/cryst14070609

APA StyleSpyropoulou, S., Christofilis, E., & Zervaki, A. D. (2024). Effect of Corrosion and Post-Weld Treatment on the Fatigue Behavior of Multipass Robot GMAW Welds of S700MC Steel. Crystals, 14(7), 609. https://doi.org/10.3390/cryst14070609