Changes in the Structure and Digestibility of Wrinkled Pea Starch with Malic Acid Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Starch Isolation and Synthesis of Malate Derivatives of Wrinkled Pea Starch

2.3. Scanning Electron Microscopy (SEM)

2.4. Polarized Light Microscopy

2.5. Determination of Degree of Substitution (DS)

2.6. Swelling Power and Starch Solubility

2.7. Fourier-Transform Infrared Spectroscopy (FTIR)

2.8. Nuclear Magnetic Resonance Spectroscopy (NMR)

2.9. In Vitro Digestion with Pancreatin and Amyloglucosidase

2.10. Statistical Analysis

3. Results and Discussion

3.1. Granule Structure and DS of Starch Samples

3.2. Swelling Power and Starch Solubility

3.3. FTIR of Starch Samples

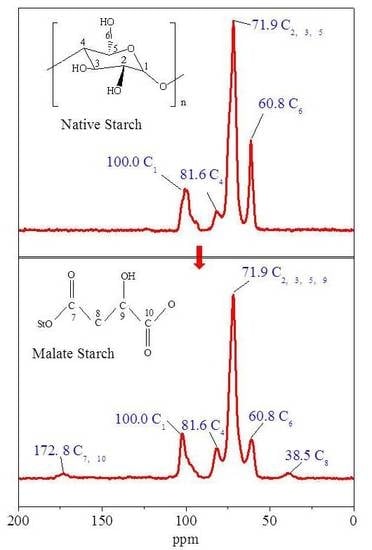

3.4. 13C CP/MAS NMR of Starch Samples

3.5. The Sample Contents of the Three Nutritional Components

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, G.Y.; Sofyan, M.; Hamaker, B.R. Slowly digestible state of starch: Mechanism of slow digestion property of gelatinized maize starch. J. Agric. Food Chem. 2008, 56, 4695–4702. [Google Scholar] [CrossRef] [PubMed]

- Englyst, H.N.; Kingman, S.M.; Cummings, J.H. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1992, 46, S33–S50. [Google Scholar]

- Lehmann, U.; Robin, F. Slowly digestible starch–its structure and health implications: A review. Trends Food Sci. Technol. 2007, 18, 346–355. [Google Scholar] [CrossRef]

- Kapelko-Zeberska, M.; Zieba, T.; Spychaj, R.; Gryszkin, A. Selected rheological properties of RS3/4 type resistant starch. Pol. J. Food Nutr. Sci. 2017, 67, 293–299. [Google Scholar] [CrossRef]

- Okumus, B.N.; Tacer-Caba, Z.; Kahraman, K.; Nilufer-Erdil, D. Resistant starch type V formation in brown lentil (Lens culinaris Medikus) starch with different lipids/fatty acids. Food Chem. 2018, 240, 550–558. [Google Scholar] [CrossRef]

- Trinh, K.S.; Le, H.D. Tapioca resistant starch production and its structure properties under annealing and plasma treatments. Carpathian J. Food Sci. Technol. 2017, 9, 36–42. [Google Scholar]

- Wang, H.; Wang, Z.; Li, X.; Chen, L.; Zhang, B. Multi-scale structure, pasting and digestibility of heat moisture treated red adzuki bean starch. Int. J. Biol. Macromol. 2017, 102, 162–169. [Google Scholar] [CrossRef] [PubMed]

- Mei, J.-Q.; Zhou, D.-N.; Jin, Z.-Y.; Xu, X.-M.; Chen, H.-Q. Effects of citric acid esterification on digestibility, structural and physicochemical properties of cassava starch. Food Chem. 2015, 187, 378–384. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Shi, Y.-C.; Rong, L.; Hsiao, B.S. Debranching and crystallization of waxy maize starch in relation to enzyme digestibility. Carbohydr. Polym. 2010, 81, 385–393. [Google Scholar] [CrossRef]

- Zeng, F.; Ma, F.; Gao, Q.; Yu, S.; Kong, F.; Zhu, S. Debranching and temperature-cycled crystallization of waxy rice starch and their digestibility. Carbohydr. Polym. 2014, 113, 91–96. [Google Scholar] [CrossRef]

- Van Hung, P.; Vien, N.L.; Phi, N.T.L. Resistant starch improvement of rice starches under a combination of acid and heat-moisture treatments. Food Chem. 2015, 19, 67–73. [Google Scholar]

- Xia, H.; Li, Y.; Gao, Q. Preparation and properties of RS4 citrate sweet potato starch by heat-moisture treatment. Food Hydrocoll. 2016, 55, 172–178. [Google Scholar] [CrossRef]

- Van Hung, P.; Huong, N.T.M.; Phi, N.T.L.; Tien, N.N.T. Physicochemical characteristics and in vitro digestibility of potato and cassava starches under organic acid and heat-moisture treatments. Int. J. Biol. Macromol. 2017, 95, 299–305. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.J.; Liu, Q. Development and physicochemical characterization of new resistant citrate starch from different corn starches. Starch 2004, 56, 364–370. [Google Scholar] [CrossRef]

- Jyothi, A.N.; Moorthy, S.N.; Sreekumar, J.N.; Rajasekharan, K.N. Studies on the properties of citrate derivatives of cassava (Manihot esculenta Crantz) starch synthesized by microwave technique. J. Sci. Food Agric. 2007, 87, 871–879. [Google Scholar] [CrossRef]

- Kim, H.-S.; Min, S.C. Effects of microwave-discharged cold plasma on synthesis and characteristics of citrate derivatives of corn starch granules. Food Sci. Biotechnol. 2017, 26, 697–706. [Google Scholar] [CrossRef]

- Raghunathan, R.; Hoover, R.; Waduge, R.; Liu, Q.; Warkentin, T.D. Impact of molecular structure on the physicochemical properties of starches isolated from different field pea (Pisum sativum L.) cultivars grown in Saskatchewan, Canada. Food Chem. 2017, 221, 1514–1521. [Google Scholar] [CrossRef]

- Chung, H.-J.; Liu, Q. Physicochemical properties and in vitro digestibility of flour and starch from pea (Pisum sativum L.) cultivars. Int. J. Biol. Macromol. 2012, 50, 131–137. [Google Scholar] [CrossRef]

- Shi, M.M.; Wang, K.; Yu, S.J.; Gilbert, R.G.; Gao, Q.Y. Structural characterizations and in vitro digestibility of acid-treated wrinkled and smooth pea starch (Pisum sativum L.). Starch 2016, 68, 762–770. [Google Scholar] [CrossRef]

- Shi, M.M.; Zhang, Z.H.; Yu, S.J.; Wang, K.; Gilbert, R.G.; Gao, Q.Y. Pea starch (Pisum sativum L.) with slow digestion property produced using beta-amylase and transglucosidase. Food Chem. 2014, 164, 317–323. [Google Scholar] [CrossRef]

- Wang, S.J.; Copeland, L. Effect of alkali treatment on structure and function of pea starch granules. Food Chem. 2012, 135, 1635–1642. [Google Scholar] [CrossRef]

- Hosseinpourpia, R.; Echart, A.S.; Adamopoulos, S.; Gabilondo, N.; Eceiza, A. Modification of pea starch and dextrin polymers with isocyanate functional groups. Polymers 2018, 10, 939. [Google Scholar] [CrossRef]

- Beta, T.; Corke, H.; Rooney, L.W.; Taylor, J. Starch properties as affected by sorghum grain chemistry. J. Sci. Food Agric. 2001, 81, 245–251. [Google Scholar] [CrossRef]

- Klaushofer, H.; Berghofer, E.; Steyrer, W. Starch citrates-Production and technical application properties. Starch 1978, 30, 47–51. [Google Scholar] [CrossRef]

- Kweon, D.K.; Choi, J.K.; Kim, E.K.; Lim, S.T. Adsorption of divalent metal ions by succinylated and oxidized corn starches. Carbohydr. Polym. 2001, 46, 171–177. [Google Scholar] [CrossRef]

- Li, S.; Ward, R.; Gao, Q. Effect of heat-moisture treatment on the formation and physicochemical properties of resistant starch from mung bean (Phaseolus radiatus) starch. Food Hydrocoll. 2011, 25, 1702–1709. [Google Scholar] [CrossRef]

- Ye, F.; Miao, M.; Huang, C.; Lu, K.; Jiang, B.; Zhang, T. Elucidation of substituted ester group position in octenylsuccinic anhydride modified sgary maize soluble starch. J. Agric. Food Chem. 2014, 62, 11696–11705. [Google Scholar] [CrossRef]

- Miao, M.; Zhang, T.; Jiang, B. Characterisations of kabuli and desi chickpea starches cultivated in China. Food Chem. 2009, 113, 1025–1032. [Google Scholar] [CrossRef]

- Xing, Q.H.; Hou, C.L.; Zhang, Z.M.; Han, K.; Yan, Q.Z.; Luo, J. Comparative study on the physicochemical properties of pea, chickpea, and wheat starch gels in the presence of sweeteners. Starch 2017, 69, 10. [Google Scholar] [CrossRef]

- Xing, J.J.; Li, D.; Wang, L.J.; Adhikari, B. Multiple endothermic transitions of acid hydrolyzed and heat-moisture treated corn starch. LWT Food Sci. Technol. 2017, 81, 195–201. [Google Scholar] [CrossRef]

- Varatharajan, V.; Hoover, R.; Li, J.; Vasanthan, T.; Nantanga, K.K.M.; Seetharaman, K.; Liu, Q.; Donner, E.; Jaiswal, S.; Chibbar, R.N. Impact of structural changes due to heat-moisture treatment at different temperatures on the susceptibility of normal and waxy potato starches towards hydrolysis by porcine pancreatic alpha amylase. Food Res. Int. 2011, 44, 2594–2606. [Google Scholar] [CrossRef]

- Zeng, S.; Wu, X.; Lin, S.; Zeng, H.; Lu, X.; Zhang, Y.; Zheng, B. Structural characteristics and physicochemical properties of lotus seed resistant starch prepared by different methods. Food Chem. 2015, 186, 213–222. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Kim, H.S. Influence of semi-dry heating reaction conditions on resistant starch contents and pasting viscosities of starch citrates. Food Eng. Prog. 2015, 19, 313–319. [Google Scholar] [CrossRef]

- Guo, Z.B.; Zeng, S.X.; Zhang, Y.; Lu, X.; Tian, Y.T.; Zheng, B.D. The effects of ultra-high pressure on the structural, rheological and retrogradation properties of lotus seed starch. Food Hydrocoll. 2015, 44, 285–291. [Google Scholar] [CrossRef]

- Heinze, T.; Talaba, P.; Heinze, U. Starch derivatives of high degree of functionalization. 1. Effective, homogeneous synthesis of p-toluenesulfonyl (tosyl) starch with a new functionalization pattern. Carbohydr. Polym. 2000, 42, 411–420. [Google Scholar] [CrossRef]

- Kochkar, H.; Morawietz, M.; Hölderich, W. Oxidation of potato starch with NO2: Characterization of the carboxylic acid salts. Appl. Catal. A Gen. 2001, 210, 325–328. [Google Scholar] [CrossRef]

- Zou, W.; Yu, L.; Liu, X.; Chen, L.; Zhang, X.; Qiao, D.; Zhang, R. Effects of amylose/amylopectin ratio on starch-based superabsorbent polymers. Carbohydr. Polym. 2012, 87, 1583–1588. [Google Scholar] [CrossRef]

- Zhu, F. NMR spectroscopy of starch systems. Food Hydrocoll. 2017, 63, 611–624. [Google Scholar] [CrossRef]

- Kapelko-Zeberska, M.; Buksa, K.; Szumny, A.; Zieba, T.; Gryszkin, A. Analysis of molecular structure of starch citrate obtained by a well-stablished method. LWT Food Sci. Technol. 2016, 69, 334–341. [Google Scholar] [CrossRef]

- Vu, T.-H.; Bean, S.; Hsieh, C.-F.; Shi, Y.-C. Changes in protein and starch digestibility in sorghum flour during heat-moisture treatments. J. Sci. Food Agric. 2017, 97, 4770–4779. [Google Scholar] [CrossRef]

| Starch Sample | Uncooked | Cooked | ||||

|---|---|---|---|---|---|---|

| RDS (%) | SDS (%) | RS (%) | RDS (%) | SDS (%) | RS (%) | |

| Native pea starch | 7.91 ± 0.53 a | 7.40 ± 0.28 a | 84.69 ± 0.81 d | 88.99 ± 2.01 c | 6.94 ± 0.66 a | 4.07 ± 2.67 a |

| Malate starch | 13.90 ± 0.20 b | 14.87 ± 0.55 b | 71.23 ± 0.75 c | 14.52 ± 0.61 a | 12.45 ± 0.21 b | 73.03 ± 0.82 d |

| HMT-malate starch | 13.37 ± 0.43 b | 16.33 ± 0.14 c | 70.30 ± 0.57 b | 13.85 ± 1.33 a | 15.43 ± 0.71 c | 70.72 ± 2.04 c |

| Malate-HMT starch | 36.44 ± 0.52 c | 22.78 ± 0.33 d | 40.78 ± 0.19 a | 38.83 ± 0.46 b | 20.34 ± 0.40 d | 40.83 ± 0.06 b |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Gao, Q.; Liu, Y. Changes in the Structure and Digestibility of Wrinkled Pea Starch with Malic Acid Treatment. Polymers 2018, 10, 1359. https://doi.org/10.3390/polym10121359

Shi M, Gao Q, Liu Y. Changes in the Structure and Digestibility of Wrinkled Pea Starch with Malic Acid Treatment. Polymers. 2018; 10(12):1359. https://doi.org/10.3390/polym10121359

Chicago/Turabian StyleShi, Miaomiao, Qunyu Gao, and Yanqi Liu. 2018. "Changes in the Structure and Digestibility of Wrinkled Pea Starch with Malic Acid Treatment" Polymers 10, no. 12: 1359. https://doi.org/10.3390/polym10121359

APA StyleShi, M., Gao, Q., & Liu, Y. (2018). Changes in the Structure and Digestibility of Wrinkled Pea Starch with Malic Acid Treatment. Polymers, 10(12), 1359. https://doi.org/10.3390/polym10121359