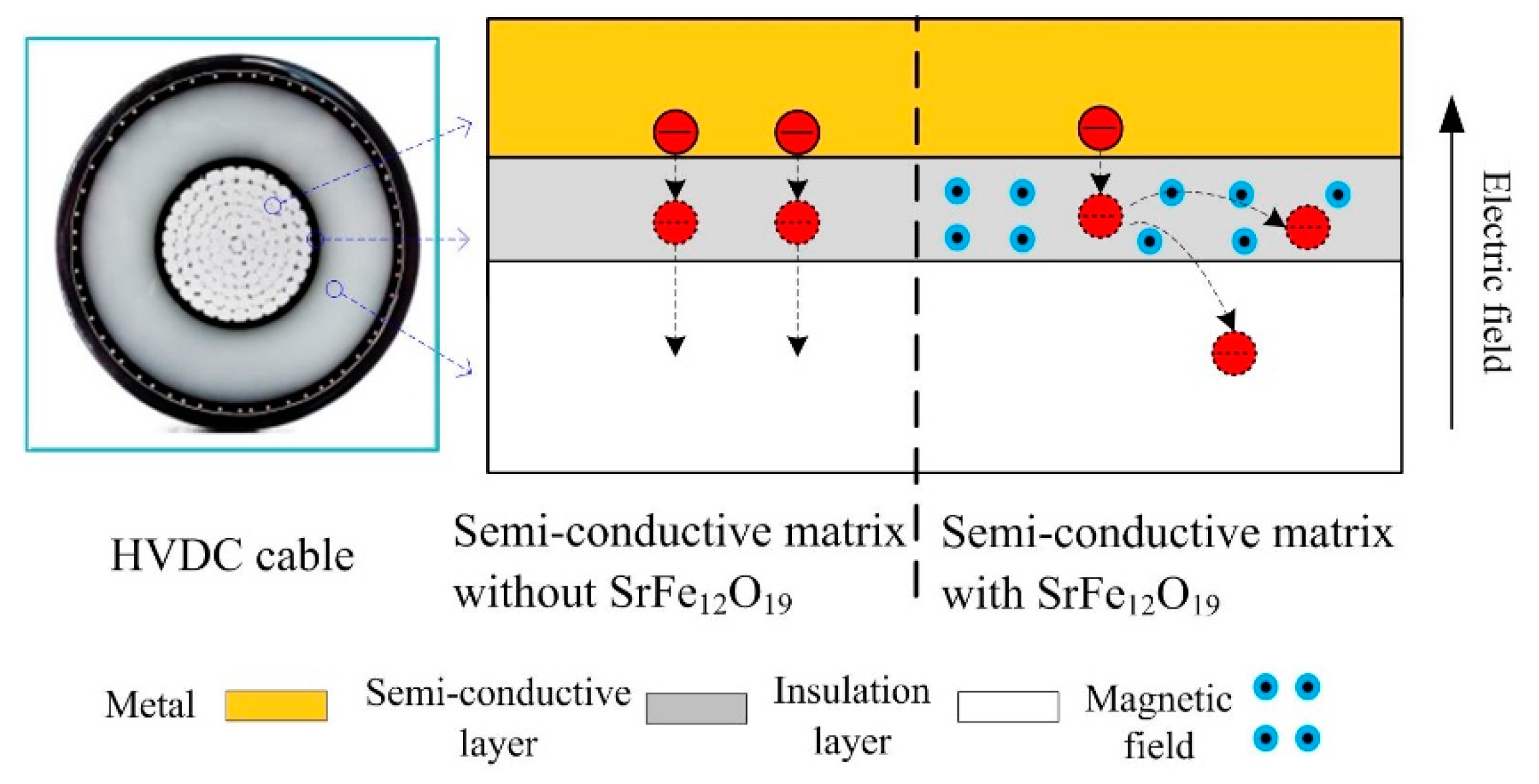

Effect of Semi-Conductive Layer Modified by Magnetic Particle SrFe12O19 on Charge Injection Characteristics of HVDC Cable

Abstract

:1. Introduction

2. Sample Preparation and Characterization

2.1. Sample Preparation

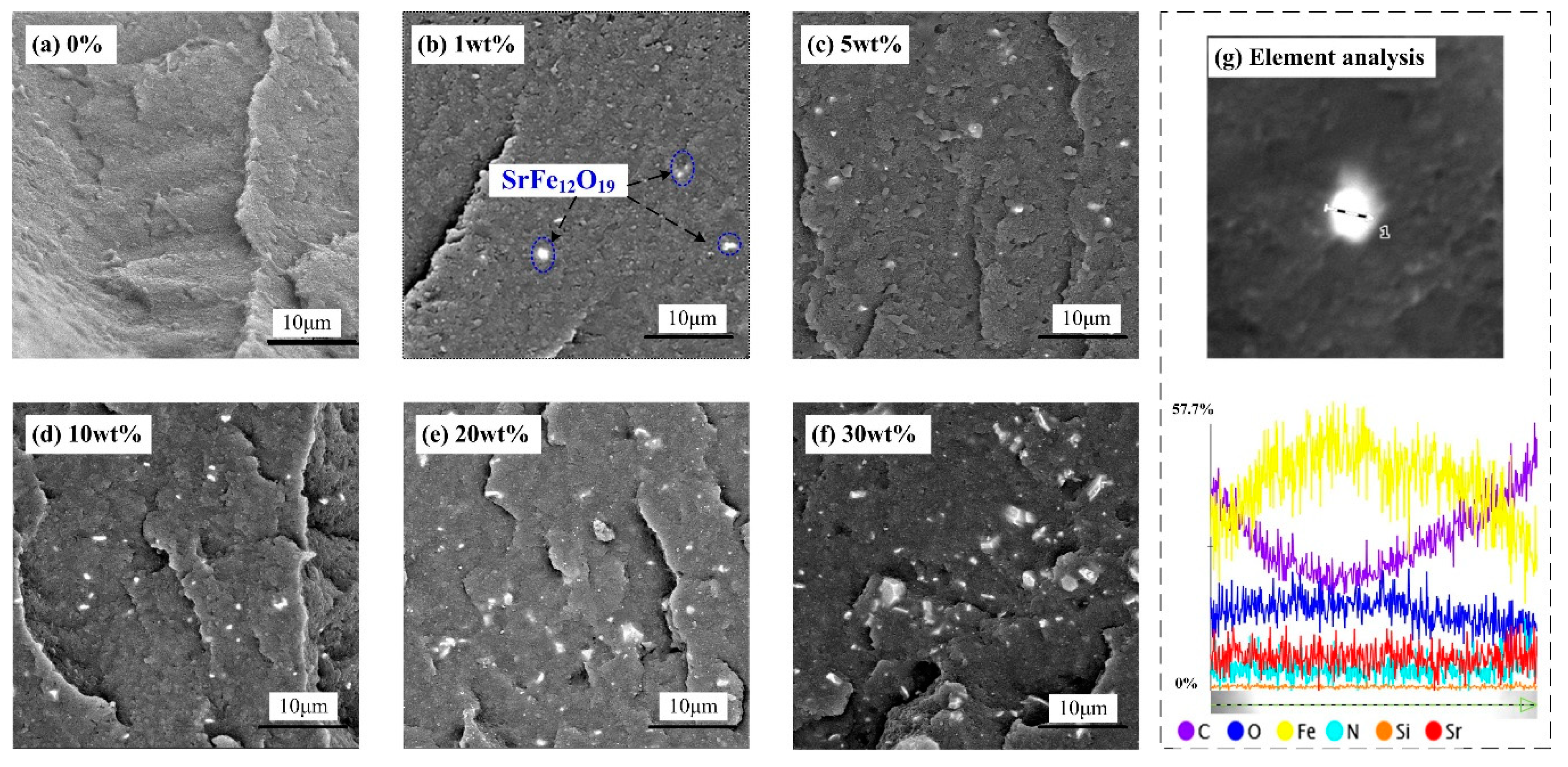

2.2. Characterization of SrFe12O19/Semi-Conductive Composites

2.2.1. Micromorphology

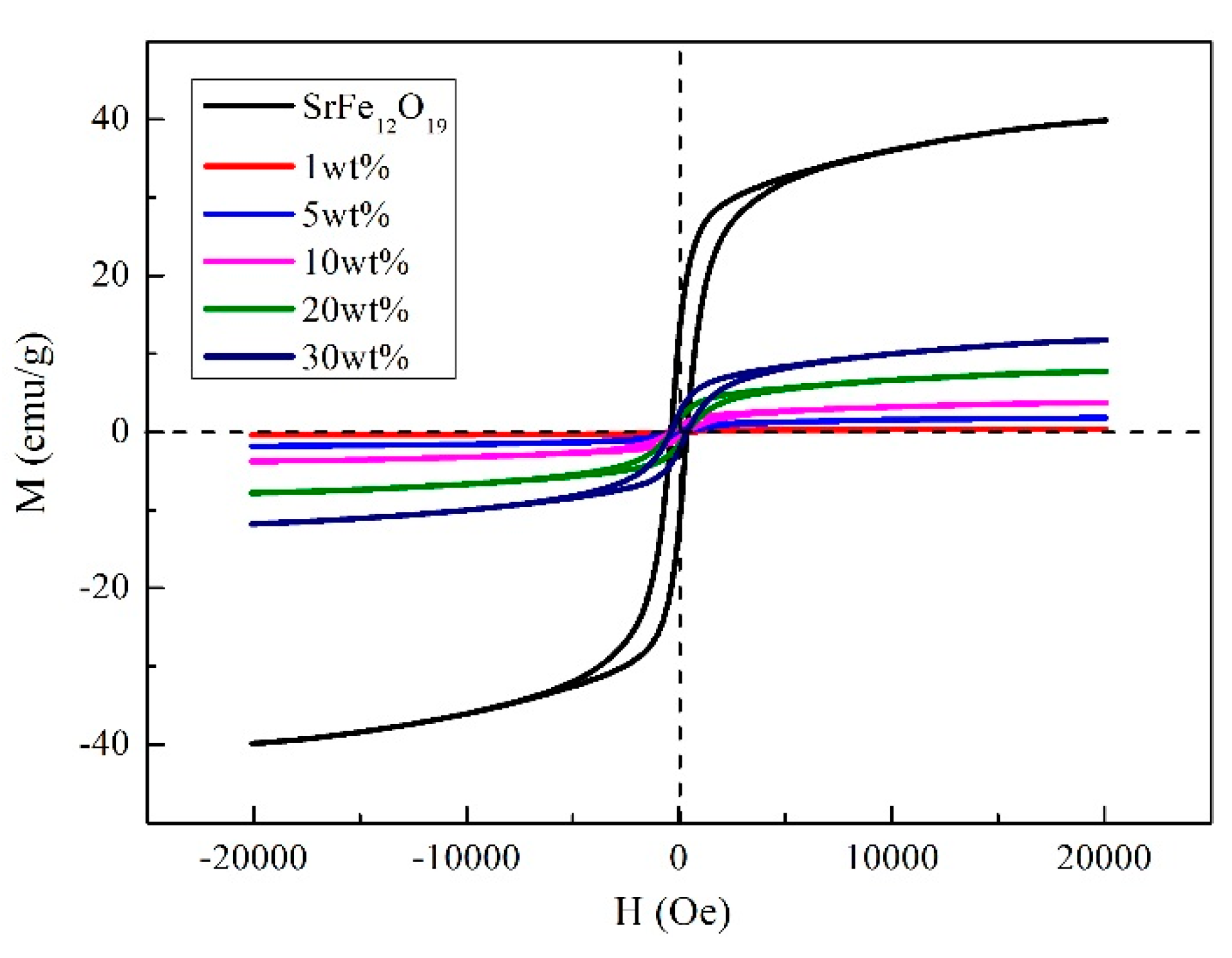

2.2.2. Hysteresis Loop of SrFe12O19/Semi-Conductive Composites

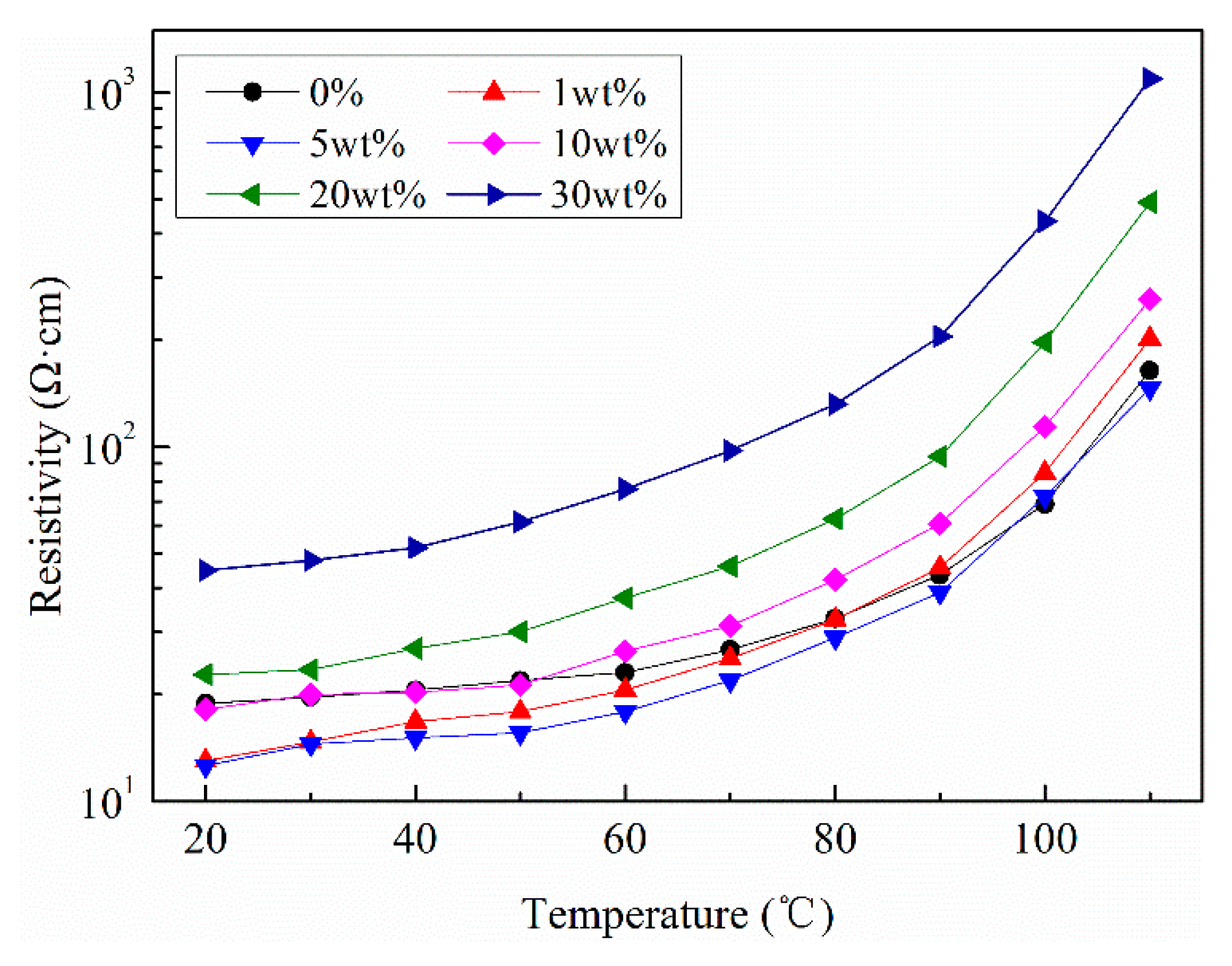

2.2.3. Resistivity of SrFe12O19/Semi-Conductive Composites

3. Experimental Results and Analysis

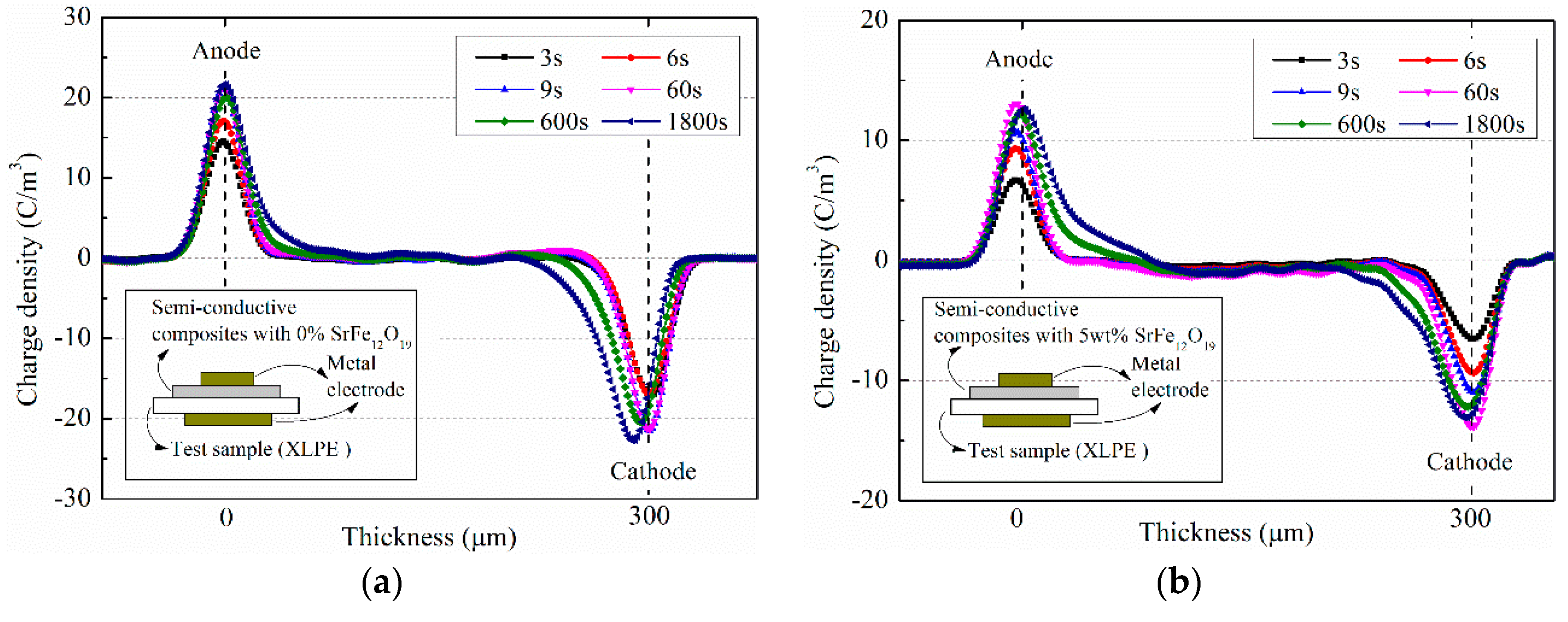

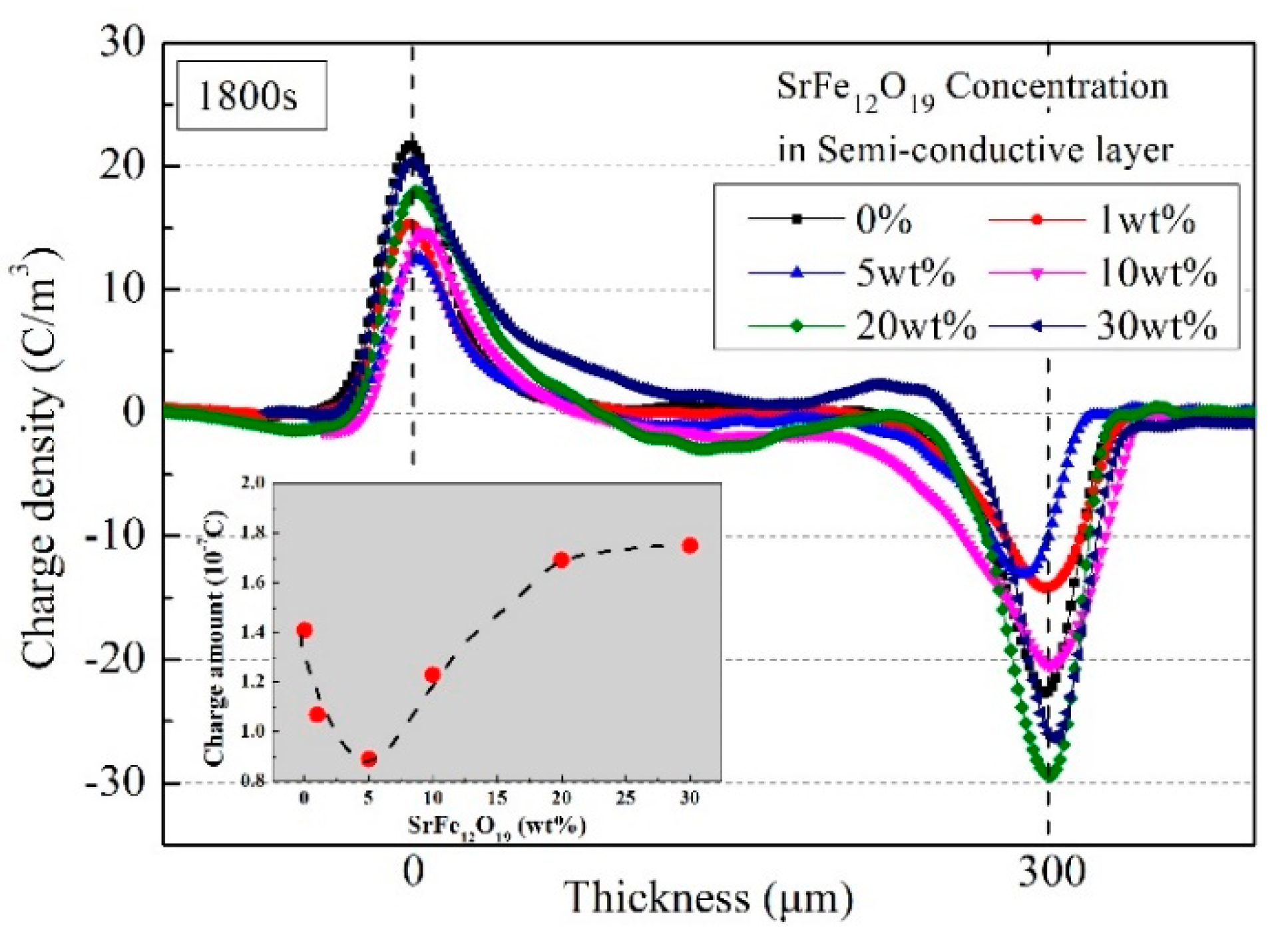

3.1. Space Charge Characteristics

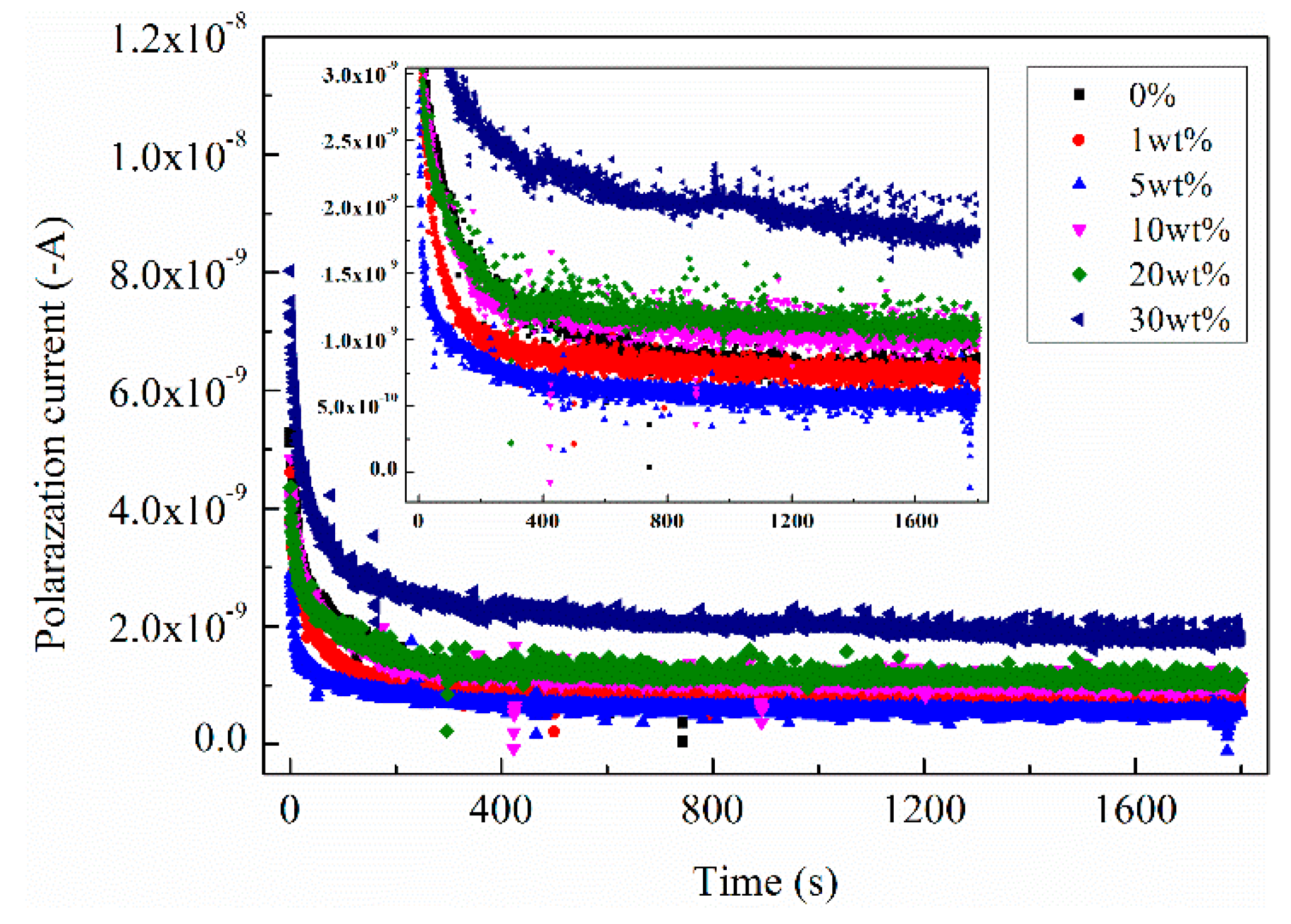

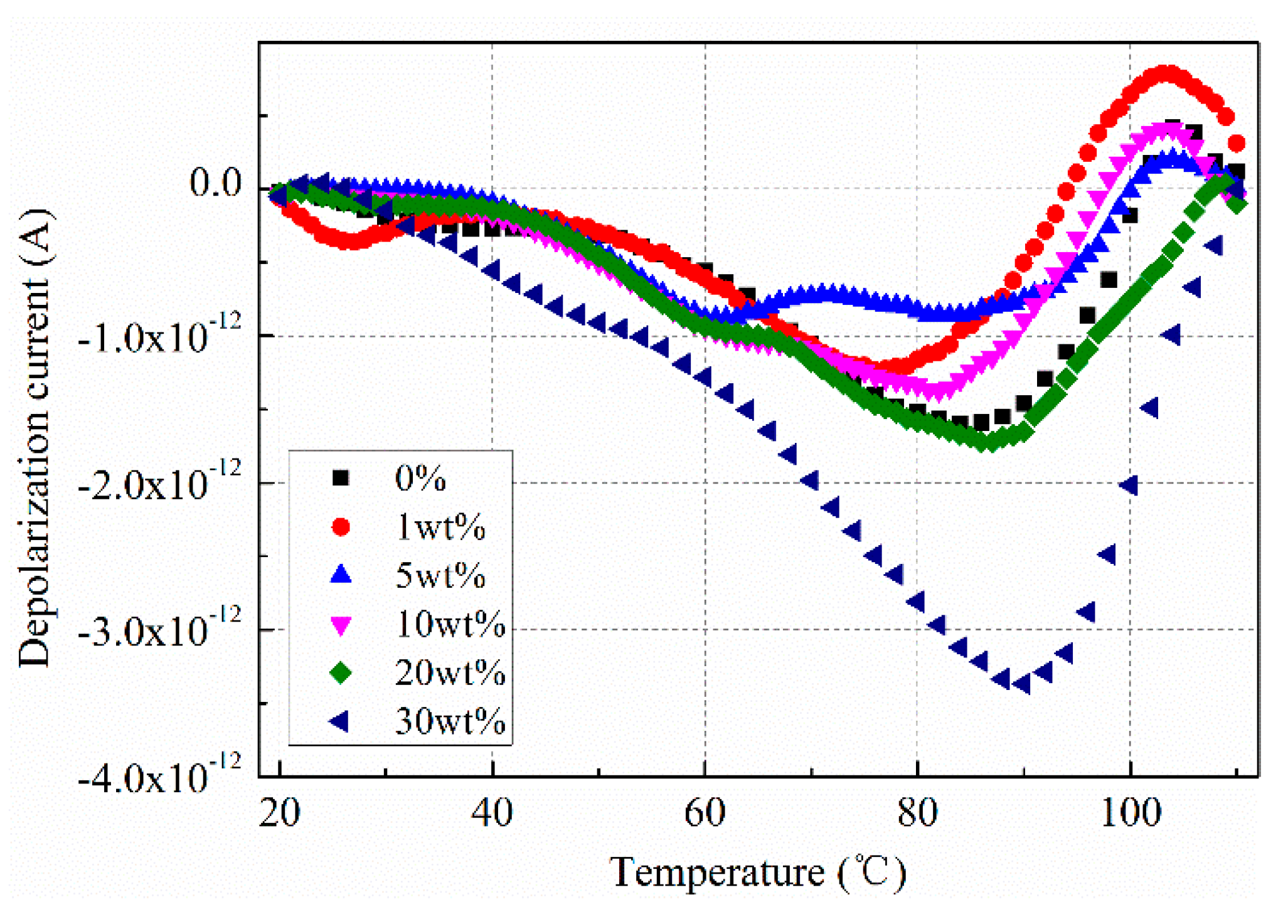

3.2. Polarization and Depolarization Current Characteristics

4. Discussion

5. Conclusions

- (1)

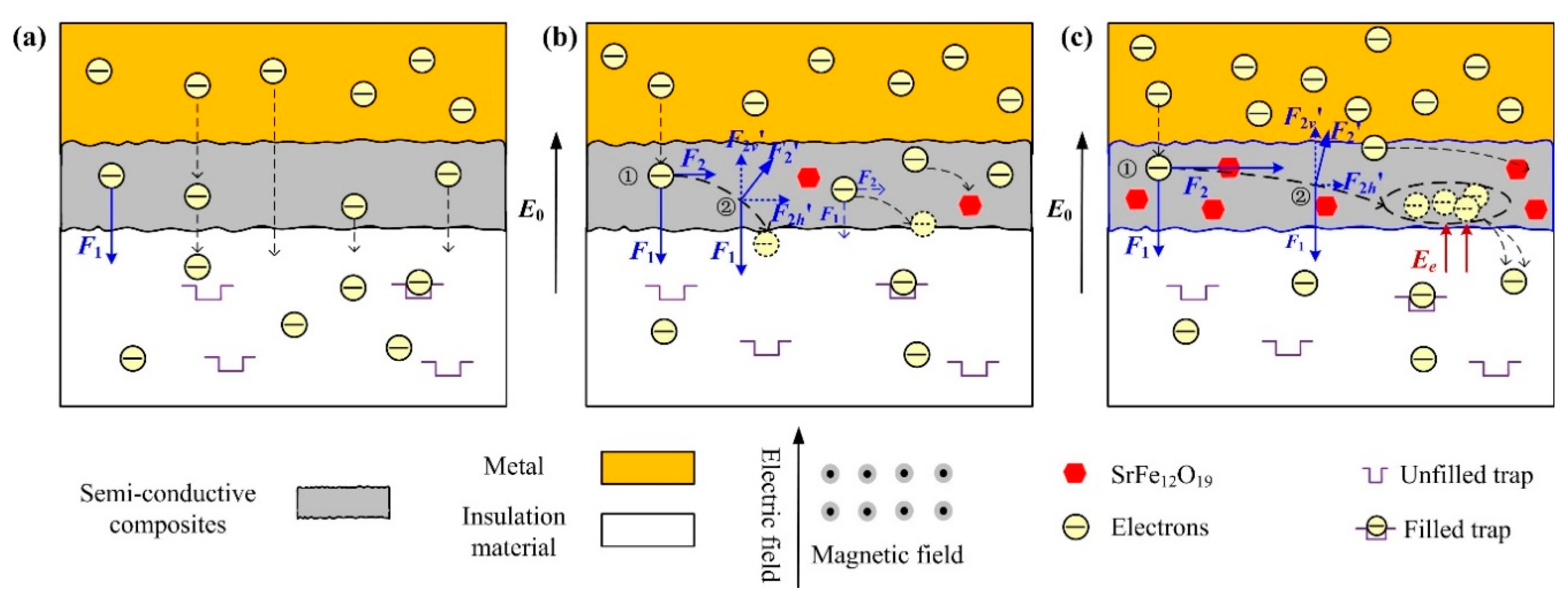

- When SrFe12O19 content is low (1 wt.% and 5 wt.%), the experimental results show that the charges in the insulation sample are significantly inhibited. For SrFe12O19 content with 5 wt.%, the insulation sample has the smallest charge amount, 0.89 × 10−7 C, decreasing by 37%, and the steady-state current is 6.01 × 10−10 A, decreasing by 22%. This is because the moving charges will be affected by the horizontal Lorentz force, leading to the deflection of the charge migration path in SrFe12O19/semi-conductive composites. In addition, the moving charges are subjected to the electric field force in the vertical direction, and only some of the electrons enter the insulation sample.

- (2)

- When SrFe12O19 content exceeds 10 wt.%, the charge suppression effect is not obvious and even leads to the increase of charge amount in the insulation sample, owing to the secondary injection of charges. For high doping content, a large Lorentz force will be generated in the SrFe12O19/semi-conductive composites, and most moving charges will deflect towards the horizontal direction and cannot directly access the insulation sample, resulting in a large number of charges accumulating in the SrFe12O19/semi-conductive composites. Consequently, the interface electric field between the semi-conductive layer and the insulation sample was enhanced, leading to the secondary injection of charges.

Author Contributions

Funding

Conflicts of Interest

References

- Mazzanti, A.G.; Marzinotto, M. Extruded Cables for High-Voltage Direct-Current Transmission: Advances in Research and Development; John Wiley & Sons, Inc.: Piscataway, NJ, USA, 2013. [Google Scholar]

- Pleşa, I.; Noţingher, P.V.; Schlögl, S.; Sumereder, C.; Muhr, M. Properties of polymer composites used in high-voltage applications. Polymers 2016, 8, 173. [Google Scholar] [CrossRef] [PubMed]

- Chao, Z.; Mizutani, T.; Kaneko, K.; Tatsuo, M.; Mitsugu, I. Space charge behaviors of low-density polyethylene blended with polypropylene copolymer. Polymer 2002, 43, 2261–2266. [Google Scholar]

- Hoang, A.; Pallon, L.; Liu, D.; Serdyuk, Y.; Gubanski, S. Charge transport in LDPE nanocomposites Part I—experimental approach. Polymers 2016, 8, 87. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wang, J.; Han, W.; Wei, Y.; Li, S. Influence of temperature on charge accumulation in low-density polyethylene based on depolarization current and space charge decay. Polymers 2019, 11, 587. [Google Scholar] [CrossRef] [PubMed]

- Rogti, F.; Mekhaldi, A.; Laurent, C. Space charge behavior at physical interfaces in cross-linked polyethylene under DC field. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1478–1485. [Google Scholar] [CrossRef]

- Wei, Y.; Liu, M.; Han, W.; Li, G.; Hao, C.; Lei, Q. Charge injection characteristics of semi-conductive composites with carbon black-polymer for HVDC cable. Polymers 2019, 11, 1134. [Google Scholar] [CrossRef]

- Tanaka, T.; Okamoto, T.; Hozumi, N.; Suzuki, K. Interfacial improvement of XLPE cable insulation at reduced thickness. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 345–350. [Google Scholar] [CrossRef]

- Zhang, Z.; Assala, P.D.S.; Wu, L.H. Residual life assessment of 110 kV XLPE cable. Electr. Power Syst. Res. 2018, 163, 572–580. [Google Scholar] [CrossRef]

- Okamoto, T.; Ishida, M.; Hozumi, N. Dielectric breakdown strength affected by the lamellar configuration in XLPE insulation at a semiconducting interface. IEEE Trans. Dielectr. Electr. Insul. 1989, 24, 599–607. [Google Scholar] [CrossRef]

- Li, L.; Han, B.; Song, W.; Wang, X.; Lei, Q. The effect of the semiconductive screen on space charge suppression in cross-Linked polyethylene. Chin. Phys. Lett. 2014, 31, 112–115. [Google Scholar] [CrossRef]

- Vissouvanadin, B.; Roy, S.L.; Teyssedre, G.; Laurent, C.; Denizet, I.; Mammeri, M.; Poisson, B. Impact of concentration gradient of polarizable species on the electric field distribution in polymeric insulating material for HVDC cable. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 833–839. [Google Scholar] [CrossRef]

- Carstensen, P.; Farkas, A.A.; Campus, A.; Nilsson, U.H. The effect of the thermal history on the space charge accumulation in HVDC crosslinked polyethylene cables. In Proceedings of the 2005 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Nashville, TN, USA, 16–19 October 2005; pp. 381–388. [Google Scholar]

- Takada, T.; Hayase, Y.; Tanaka, Y.; Okamoto, T. Space charge trapping in electrical potential well caused by permanent and induced dipoles for LDPE/MgO nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 152–160. [Google Scholar] [CrossRef]

- Nelson, J.K.; Fothergill, J.C. Internal charge behaviour of nanocomposites. Nanotechnology 2004, 15, 586–595. [Google Scholar] [CrossRef] [Green Version]

- Lewis, T.J. Charge transport in polyethylene nanodielectrics. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 479–502. [Google Scholar] [CrossRef]

- Lau, K.Y.; Vaughan, A.S.; Chen, G.; Hosier, I.L.; Holt, A.F.; Ching, K.Y. On the space charge and DC breakdown behavior of Polyethylene/Silica nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 340–351. [Google Scholar] [CrossRef]

- Lau, K.; Vaughan, A.; Chen, G. Nanodielectrics: Opportunities and challenges. IEEE Trans. Dielectr. Electr. Insul. 2015, 31, 45–54. [Google Scholar] [CrossRef]

- Hozumi, N.; Suzuki, H.; Okamoto, T.; Watanabe, K.; Watanabe, A. Direct observation of time-dependent space charge profiles in XLPE cable under high electric fields. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 1068–1076. [Google Scholar] [CrossRef]

- Wang, W.; Min, D.; Li, S. Understanding the conduction and breakdown properties of polyethylene nanodielectrics: Effect of deep traps. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 564–572. [Google Scholar] [CrossRef]

- Wang, S. DC Insulation Performance of XLPE and Its Nano-Composites. Ph.D. Thesis, Xi’an Jiaotong University, Xi’an, China, 2017. [Google Scholar]

- Matsui, K.; Tanaka, Y.; Takada, T.; Fukao, T.; Fukunaga, K.; Maeno, T.; Alison, J.M. Space charge behavior in low density polyethylene at pre-breakdown. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 406–415. [Google Scholar] [CrossRef]

- Wang, X.; Lv, Z.; Wu, K.; Chen, X.; Tu, D.; Dissado, L.A. Study of the factors that suppress space charge accumulation in LDPE nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1670–1679. [Google Scholar] [CrossRef]

- Delpino, S.; Fabiani, D.; Montanari, G.C.; Laurent, C.; Teyssedre, G.; Morshuis, P.H.F.; Bodega, R.; Dissado, L.A. Polymeric HVDC cable design and space charge accumulation. Part 2: Insulation interfaces. IEEE Electr. Insul. Mag. 2008, 24, 14–24. [Google Scholar] [CrossRef]

- Fabiani, D.; Montanari, G.C.; Laurent, C.; Teyssedre, G.; Morshuis, P.H.F.; Bodega, R.; Dissado, L.A. Polymeric HVDC cable design and space charge accumulation. Part 1: Insulation/semicon interface. IEEE Electr. Insul. Mag. 2007, 23, 11–19. [Google Scholar] [CrossRef]

- Roy, M.; Nelson, J.K.; Maccrone, R.K.; Schadler, L.S.; Reed, C.W.; Keefe, R.; Zenger, W. Polymer nanocomposite dielectrics-the role of the interface. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 629–643. [Google Scholar] [CrossRef]

- Li, Z.; Du, B.; Han, C.; Xu, H. Trap modulated charge carrier transport in polyethylene/graphene nanocomposites. Sci. Rep. 2017, 7, 4015. [Google Scholar] [CrossRef]

- Nilsson, U.H.; Boström, J.-O. Influence of the semi-conductive material on space charge build-up in extruded HVDC cables. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–4. [Google Scholar]

- Van der Born, D.; Tsekmes, A.; Person, T.J. Evaluation of space charge accumulation processes in small size polymeric cable models. In Proceedings of the 2012 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Montreal, QC, Canada, 14–17 October 2012; pp. 669–672. [Google Scholar]

- Han, S.J.; Wasserman, S.H. Agglomeration and percolation network behavior of semi-conductive polymer composites with carbon nanotubes. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–4. [Google Scholar]

- Zhang, Z.; Niu, F.; An, Z.; Zheng, F.; Ma, P.; Lei, Q. Space charge injection in LDPE by semi-conductive electrode with different carbon black filling rates. High Volt. Eng. 2011, 37, 1904–1909. [Google Scholar]

- Zhou, Z. Ferrite Magnetic Material. Science Press: Beijing, China, 1981. [Google Scholar]

- Chen, T. Study on Polyamide 6/Strontium Ferrite Composites. Master’s Thesis, South China University of Technology, Guangzhou, China, 2012. [Google Scholar]

- Korshak, Y.V.; Medvedeva, T.V.; Ovchinnikov, A.A.; Spector, V.N. Organic polymer ferromagnet. Am. Inst. Phys. 1987, 43, 399–402. [Google Scholar] [CrossRef]

- Wen, D.; Wan, Y. Technology of Preparing Isotropical Polymer-NdFeB Magnetic Composite. Actamateriae Compos. Sin. 1997, 14, 6–9. [Google Scholar]

- Lv, G. Influence of the Properties of the Compounding Technology on Plastics Magnet. China Synth. Resin Plast. 1990, 2, 33–36. [Google Scholar]

- Shashanka, H.M.; Anantharamaiah, P.N.; Joy, P.A. Magnetic parameters of SrFe12O19 sintered from a mixture of nanocrystalline and micron-sized powders. Ceram. Int. 2019, 45, 13592–13596. [Google Scholar] [CrossRef]

- Chen, G.; Li, S.T.; Zhong, L.S. Space charge in nanodielectrics and its impact on electrical performance. In Proceedings of the IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 36–39. [Google Scholar]

- Li, G.; Zhou, X.; Hao, C.; Lei, Q.; Wei, Y. Temperature and electric field dependence of charge conduction and accumulation in XLPE based on polarization and depolarization current. AIP Adv. 2019, 9, 015109. [Google Scholar] [CrossRef] [Green Version]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Y.; Liu, M.; Wang, J.; Li, G.; Hao, C.; Lei, Q. Effect of Semi-Conductive Layer Modified by Magnetic Particle SrFe12O19 on Charge Injection Characteristics of HVDC Cable. Polymers 2019, 11, 1309. https://doi.org/10.3390/polym11081309

Wei Y, Liu M, Wang J, Li G, Hao C, Lei Q. Effect of Semi-Conductive Layer Modified by Magnetic Particle SrFe12O19 on Charge Injection Characteristics of HVDC Cable. Polymers. 2019; 11(8):1309. https://doi.org/10.3390/polym11081309

Chicago/Turabian StyleWei, Yanhui, Mingyue Liu, Jiaxing Wang, Guochang Li, Chuncheng Hao, and Qingquan Lei. 2019. "Effect of Semi-Conductive Layer Modified by Magnetic Particle SrFe12O19 on Charge Injection Characteristics of HVDC Cable" Polymers 11, no. 8: 1309. https://doi.org/10.3390/polym11081309

APA StyleWei, Y., Liu, M., Wang, J., Li, G., Hao, C., & Lei, Q. (2019). Effect of Semi-Conductive Layer Modified by Magnetic Particle SrFe12O19 on Charge Injection Characteristics of HVDC Cable. Polymers, 11(8), 1309. https://doi.org/10.3390/polym11081309