The Influence of Deformation under Tension on Some Mechanical and Tribological Properties of High-Density Polyethylene

Abstract

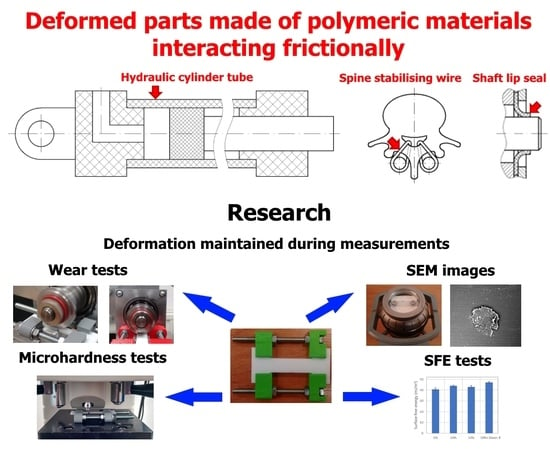

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Maintenance of Deformation

2.3. Deformation Measurement

2.4. Measurement of Wear

2.5. Microhardness

2.6. Surface Free Energy

2.7. Observation of the Surface by Means of SEM

2.8. Statistical Analysis of the Results

3. Results

3.1. Impact of Deformation Direction on PE-HD Wear

3.1.1. Impact of 24-Hour Maintenance of Tension on Wear

3.2. Impact of Deformation on Microhardness

3.3. Effect of Deformation on the Surface Free Energy of PE-HD

3.4. Microscopic Observations of the Sample Surface After Friction

4. Discussion

4.1. Correlation between Wear, Microhardness, and Surface Free Energy Test Results

4.2. Defects due to Tension vs Wear

4.3. Analysis of Microscopic Images

4.4. Further Research

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stryczek, J.; Banaś, M.; Krawczyk, J.; Marciniak, L.; Stryczek, P. The Fluid Power Elements and Systems Made of Plastics. Procedia Eng. 2017, 176, 600–609. [Google Scholar] [CrossRef]

- Brończyk, A.; Kowalewski, P. The influence of tension force of polymer fibres on friction. Tribologia 2015, 46, 9–16. [Google Scholar]

- Liu, H.; Wang, J.; Jiang, P.; Yan, F. Hydrostatic pressure-dependent wear behavior of thermoplastic polymers in deep sea. Polym. Adv. Technol. 2018, 29, 2410–2415. [Google Scholar] [CrossRef]

- Bekhet, N. Tribological behaviour of drawn polypropylene. Wear 1999, 236, 55–61. [Google Scholar] [CrossRef]

- Liu, X.J.; Liu, X.X.; Li, T.S.; Lv, R.G.; Liu, X.; Li, T.; Lv, R. Study on Tribological Properties of Polytetrafluoroethylene Drawn Uniaxially at Different Temperature. Macromol. Mater. Eng. 2005, 290, 172–178. [Google Scholar] [CrossRef]

- Voss, H.; Magill, J.H.; Friedrich, K. On the wear behavior of doubly-oriented polymers. I. Nylon 6. J. Appl. Polym. Sci. 1987, 33, 1745–1761. [Google Scholar] [CrossRef]

- Vinogradov, G.V.; Bartenev, G.M.; El’Kin, I.A.; Yanovsky, Y.G.; Nikolayev, V.N.; Frenkin, I.E. Friction properties of oriented crystalline polymers. J. Phys. D Appl. Phys. 1969, 2, 1687–1692. [Google Scholar] [CrossRef]

- Bielyj, B.A. Wlijanie Struktury Polimerow na Prociessy Trienija. In Trienie Polimerov; Nauka: Moskwa, Russia, 1972. [Google Scholar]

- Yamaguchi, Y. Friction. In Tribology of Plastic Materials Their Characteristics and Applications to Sliding Components; Elsevier: Tokyo, Japan, 1990. [Google Scholar]

- Cayer-Barrioz, J.; Mazuyer, D.; Kapsa, P.; Chateauminois, A.; Robert, G. Abrasive wear micromechanisms of oriented polymers. Polymers 2004, 45, 2729–2736. [Google Scholar] [CrossRef]

- Sui, H.; Pohl, H.; Schomburg, U.; Upper, G.; Heine, S. Wear and friction of PTFE seals. Wear 1999, 224, 175–182. [Google Scholar] [CrossRef]

- Choi, H.J.; Park, C.W.; Lee, J.C.; Kim, J.G.; Choi, S.D. Analysis on the mechanical characteristics of PTFE oil seal for the rear part in the automotive engine. Int. J. Precis. Eng. Manuf. 2011, 12, 485–490. [Google Scholar] [CrossRef]

- Kletschkowski, T.; Schomburg, U.; Bertram, A. Computational analysis of PTFE shaft seals. Comput. Mater. Sci. 2005, 32, 392–399. [Google Scholar] [CrossRef]

- Li, W.; Mays, S.; Lam, D. Material and finite element analysis of poly(tetrafluoroethylene) rotary seals. Plast. Rubber Compos. 2002, 31, 359–363. [Google Scholar] [CrossRef]

- Buciumeanu, M.; Crudu, I.; Palaghian, L.; Miranda, A.; Silva, F.; Miranda, A.; Silva, F. Influence of an additional elastic stress on dry wear behaviour in reciprocating tests. Tribol. Int. 2009, 42, 1101–1107. [Google Scholar] [CrossRef]

- Kujawa, M.; Wieleba, W. The influence of a constant state of deformation on the friction coefficient in selected thermoplastics (polymer–steel pair). Tribologia 2017, 274, 39–45. [Google Scholar] [CrossRef]

- Kujawa, M. The influence of deformation under tension on hardness, friction and wear in selected thermoplastics. Eng. Mech. 2018, 24, 453–456. [Google Scholar]

- Bartenev, G.M.; Lavrentev, V.V. Wear of Polymers. In Friction and Wear of Polymers; Bartenev, G.M., Lavrentev, V.V., Payne, D.B., Lee, L.H., Ludema, K.C., Eds.; Elsevier: Amsterdam, The Netherlands, 1981; Volume 6, pp. 202–260. [Google Scholar]

- Myshkin, N.K.; Kovalev, A.V. Adhesion and Friction of Polymers. In Polymer Tribology; Imperial College Press: London, UK, 2009; pp. 3–37. ISBN 9781848162044. [Google Scholar]

- Tervoort, T.A.; Visjager, J.; Smith, P. On abrasive wear of polyethylene. Macromolecules 2002, 35, 8467–8471. [Google Scholar] [CrossRef]

- Flores, A.; Ania, F.; Baltá-Calleja, F.J. From the glassy state to ordered polymer structures: A microhardness study. Polimers 2009, 50, 729–746. [Google Scholar] [CrossRef] [Green Version]

- Bartczak, Z. Deformation of semicrystalline polymers—The contribution of crystalline and amorphous phases. Polimers 2017, 62, 787–799. [Google Scholar] [CrossRef]

- Pawlak, A. Cavitation during deformation of polymers on the example of polypropylene. J. Appl. Polym. Sci. 2012, 125, 4177–4187. [Google Scholar] [CrossRef]

- Pawlak, A.; Galeski, A. Plastic Deformation of Crystalline Polymers: The Role of Cavitation and Crystal Plasticity. Macromolecules 2005, 38, 9688–9697. [Google Scholar] [CrossRef]

- Narisawa, I.; Ishikawa, M. Crazing in Semicrystalline Thermoplastics. In Crazing Polymers; Springer: Berlin/Heidelberg, Germany, 2006; Volume 2, pp. 353–391. [Google Scholar]

- Pawlak, A. Cavitation during tensile deformation of high-density polyethylene. Polymer 2007, 48, 1397–1409. [Google Scholar] [CrossRef]

- Kujawa, M. The influence of uniaxial compression on the friction coefficient (polymer–steel pair), wear, and hardness in selected thermoplastics. Tribologia 2018, 279, 77–82. [Google Scholar] [CrossRef]

| ε | 0% | 2% | 5% | 20% | 50% |

|---|---|---|---|---|---|

| V (mm3) | 0.25 ± 0.02 | 0.37 ± 0.09 | 0.79 ± 0.16 | 1.61 ± 0.18 | 1.20 ± 0.08 |

| Kw () | 0.25 ± 0.02 | 0.38 ± 0.09 | 0.80 ± 0.16 | 1.64 ± 0.18 | 1.22 ± 0.08 |

| ΔKw | - | +51% | +220% | +554% | +386% |

| ε | 0% | 2% | 5% | 20% | 50% |

|---|---|---|---|---|---|

| V (mm3) | 0.25 ±0.02 | 0.35 ±0.02 | 0.40 ±0.01 | 0.96 ±0.13 | 0.78 ±0.12 |

| Kw () | 0.25 ±0.02 | 0.35 ±0.02 | 0.41 0.01 | 0.98 ±0.13 | 0.79 ±0.12 |

| ΔKw | - | +41% | +62% | +289% | +216% |

| ε | 0% | 20% | 20% + 24 h |

|---|---|---|---|

| V (mm3) | 0.25 ± 0.02 | 1.61 ± 0.18 | 2.42 ± 0.20 |

| Kw () | 0.25 ± 0.02 | 1.64 ± 0.18 | 2.46 ± 0.21 |

| ΔKw | - | +554% | +879% |

| Direction of Indenter | ε = 0% | ε = 2% | ε = 5% | ε = 20% | ε = 50% | |

|---|---|---|---|---|---|---|

| Parallel | HK 0.01 | 5.14 ± 0.12 | 4.27 ± 0.15 | 4.01 ± 0.17 | 3.31 ± 0.16 | 3.15 ± 0.22 |

| ΔHK 0.01 | - | −17% | −22% | −35% | −38% | |

| Perpendicular | HK 0.01 | 4.72 ± 0.18 | 4.05 ± 0.14 | 3.69 ± 0.09 | 3.09 ± 0.18 | 3.10 ± 0.21 |

| ΔHK 0.01 | - | −14% | −22% | −35% | −34% |

| ε | 0% | 20% | 20% + 24 h |

|---|---|---|---|

| HK 0.01 | 6.3 ± 0.45 | 4.02 ± 0.18 | 4.85 ± 0.30 |

| ΔHK 0.01 | - | −36% | −23% |

| ε | 0% | 20% | 50% | 50% + 30 min |

|---|---|---|---|---|

| SFE (mJ/m2) | 40.7 ± 1.4 | 44.0 ± 0.6 | 42.9 ± 1.2 | 47.1 ± 0.8 |

| ΔSFE | - | +8% | +6% | +16% |

| ε | 0% | 2% | 5% | 20% | 50% |

|---|---|---|---|---|---|

| Kw () | 0.25 ± 0.02 | 0.38 ± 0.09 | 0.80 ± 0.16 | 1.64 ± 0.18 | 1.22 ± 0.08 |

| ΔKw | - | +51% | +220% | +554% | +386% |

| HK 0.01 | 5.14 ± 0.12 | 4.27 ± 0.15 | 4.01 ± 0.17 | 3.31 ± 0.16 | 3.15 ± 0.22 |

| ΔHK 0.01 | - | −17% | −22% | −35% | −38% |

| SFE (mJ/m2) | 40.7 ± 1.4 | X | X | 44.0 ± 0.6 | 42.9 ± 1.2 |

| ΔSFE | - | X | X | +8% | +6% |

| ε | 0% | 20% | 20% + 24 h |

|---|---|---|---|

| Kw () | 0.25 ± 0.02 | 1.64 ± 0.18 | 2.46 ± 0.21 |

| ΔKw | - | +554% | +879% |

| HK 0.01 | 6.3 ± 0.45 | 4.02 ± 0.18 | 4.85 ± 0.30 |

| ΔHK 0.01 | - | −36% | −23% |

| ε | 0% | 50% | 50% + 30 min |

| SFE (mJ/m2) | 40.7 ± 1.4 | 42.9 ± 1.2 | 47.1 ± 0.8 |

| ΔSFE | - | +6% | +16% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kujawa, M.; Kowalewski, P.; Wieleba, W. The Influence of Deformation under Tension on Some Mechanical and Tribological Properties of High-Density Polyethylene. Polymers 2019, 11, 1429. https://doi.org/10.3390/polym11091429

Kujawa M, Kowalewski P, Wieleba W. The Influence of Deformation under Tension on Some Mechanical and Tribological Properties of High-Density Polyethylene. Polymers. 2019; 11(9):1429. https://doi.org/10.3390/polym11091429

Chicago/Turabian StyleKujawa, Maciej, Piotr Kowalewski, and Wojciech Wieleba. 2019. "The Influence of Deformation under Tension on Some Mechanical and Tribological Properties of High-Density Polyethylene" Polymers 11, no. 9: 1429. https://doi.org/10.3390/polym11091429

APA StyleKujawa, M., Kowalewski, P., & Wieleba, W. (2019). The Influence of Deformation under Tension on Some Mechanical and Tribological Properties of High-Density Polyethylene. Polymers, 11(9), 1429. https://doi.org/10.3390/polym11091429