Water Absorption Kinetics in Natural Rubber Composites Reinforced with Natural Fibers Processed by Electron Beam Irradiation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Experimental Installation and Samples Irradiation

2.4. Laboratory Tests—Water Absorption Tests and Measurements

3. Results and Discussion

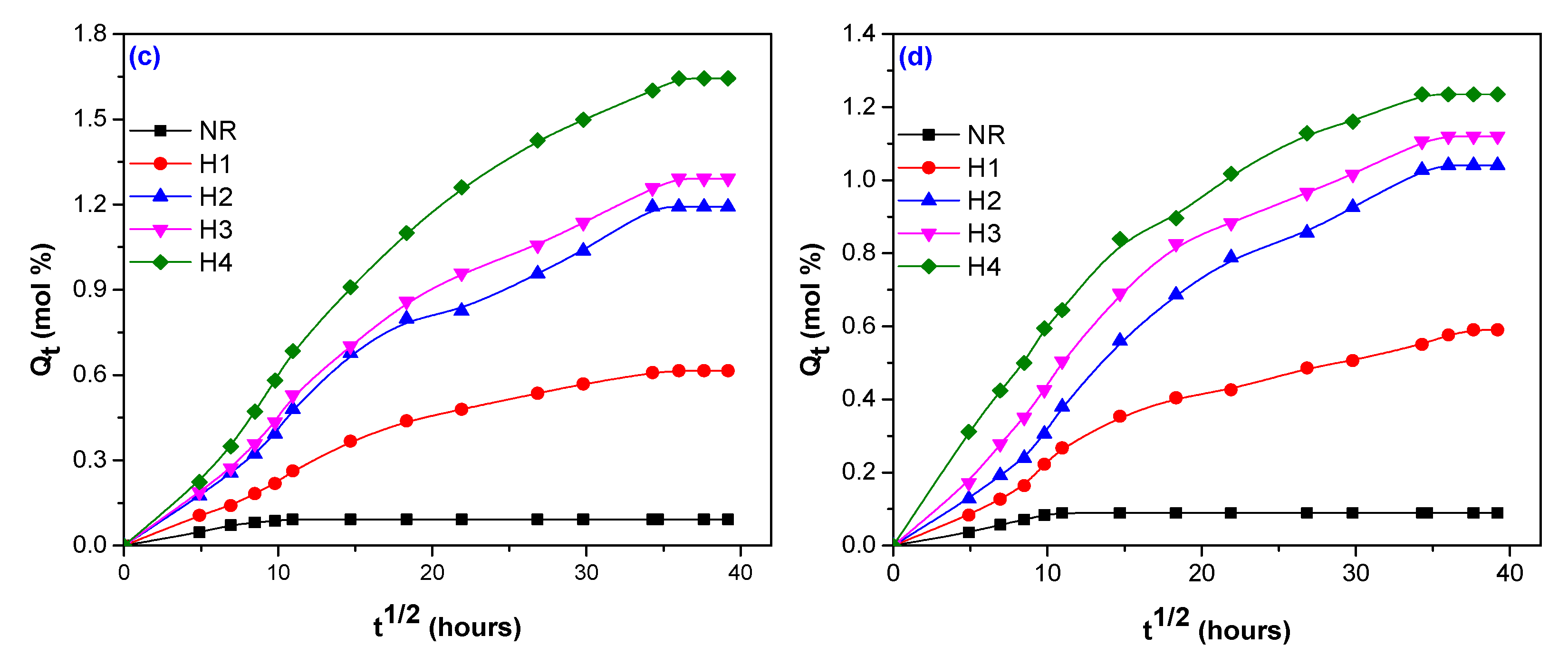

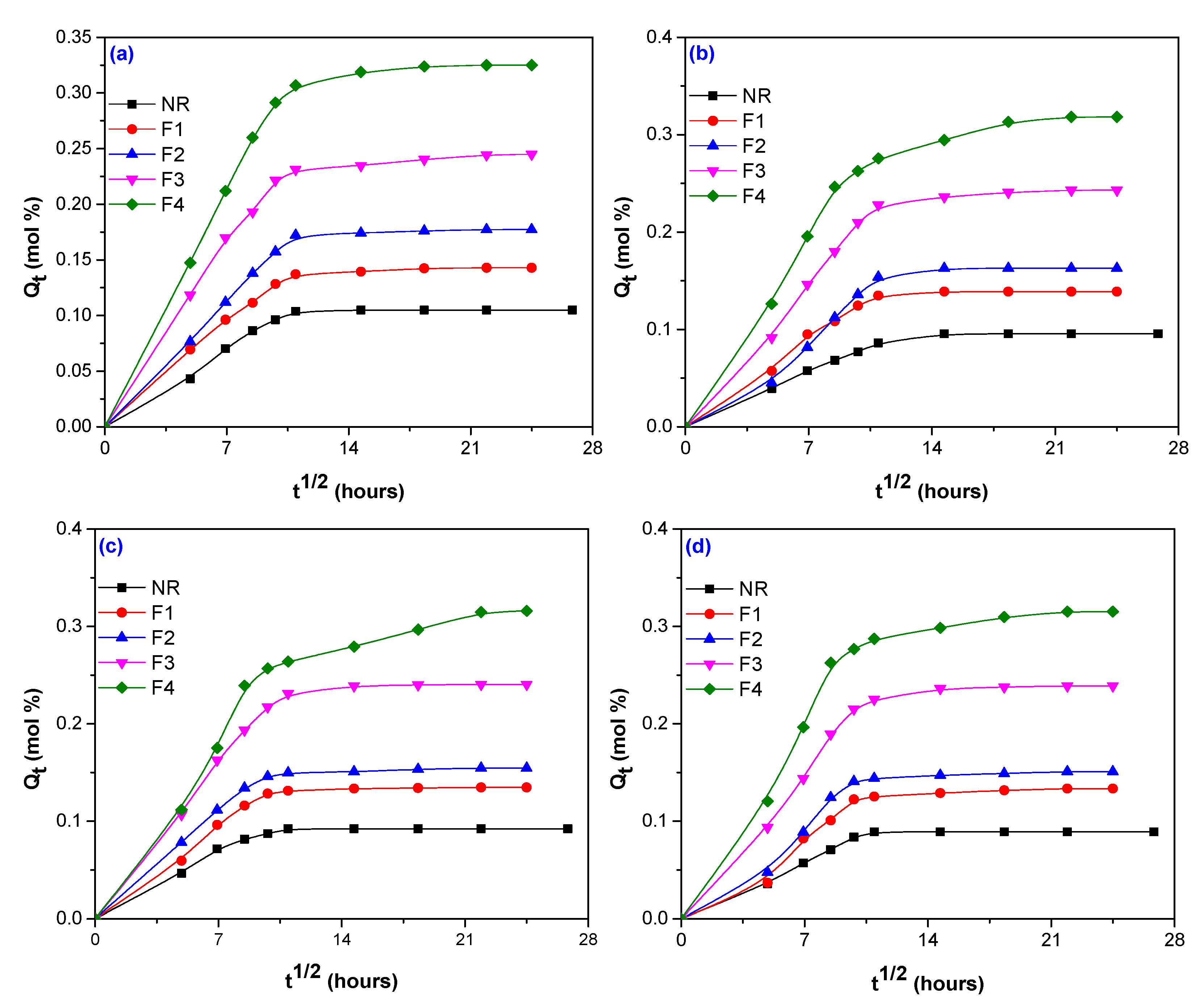

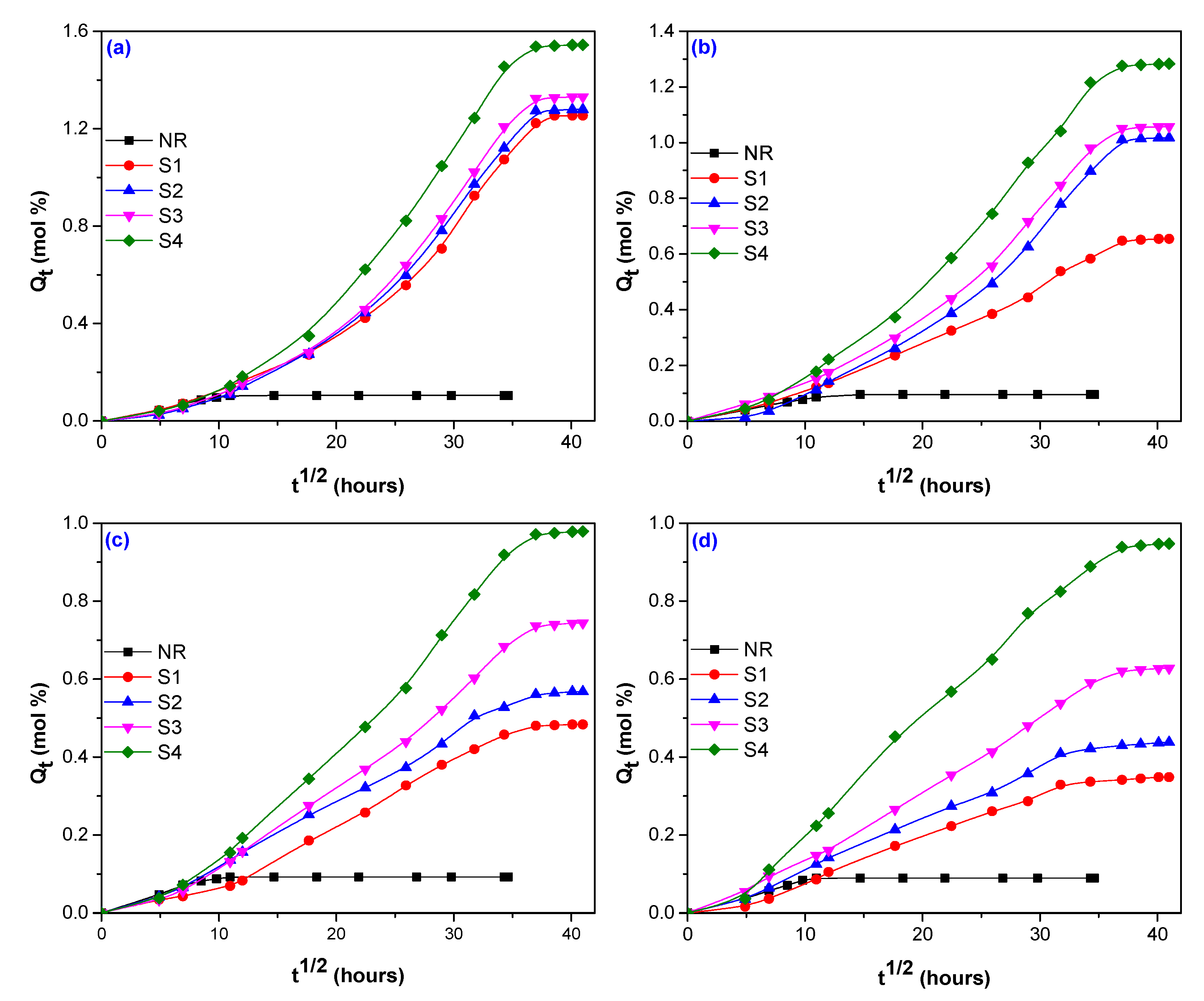

3.1. Water Absorption Behavior

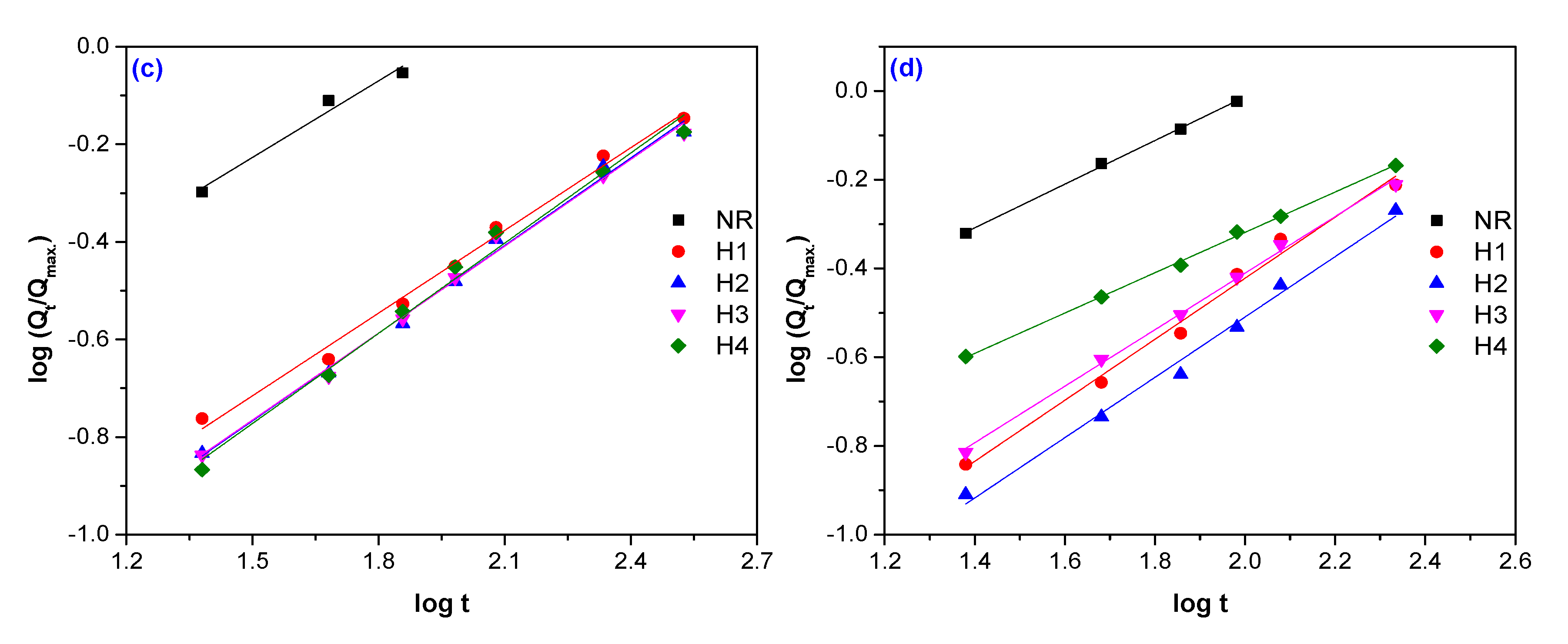

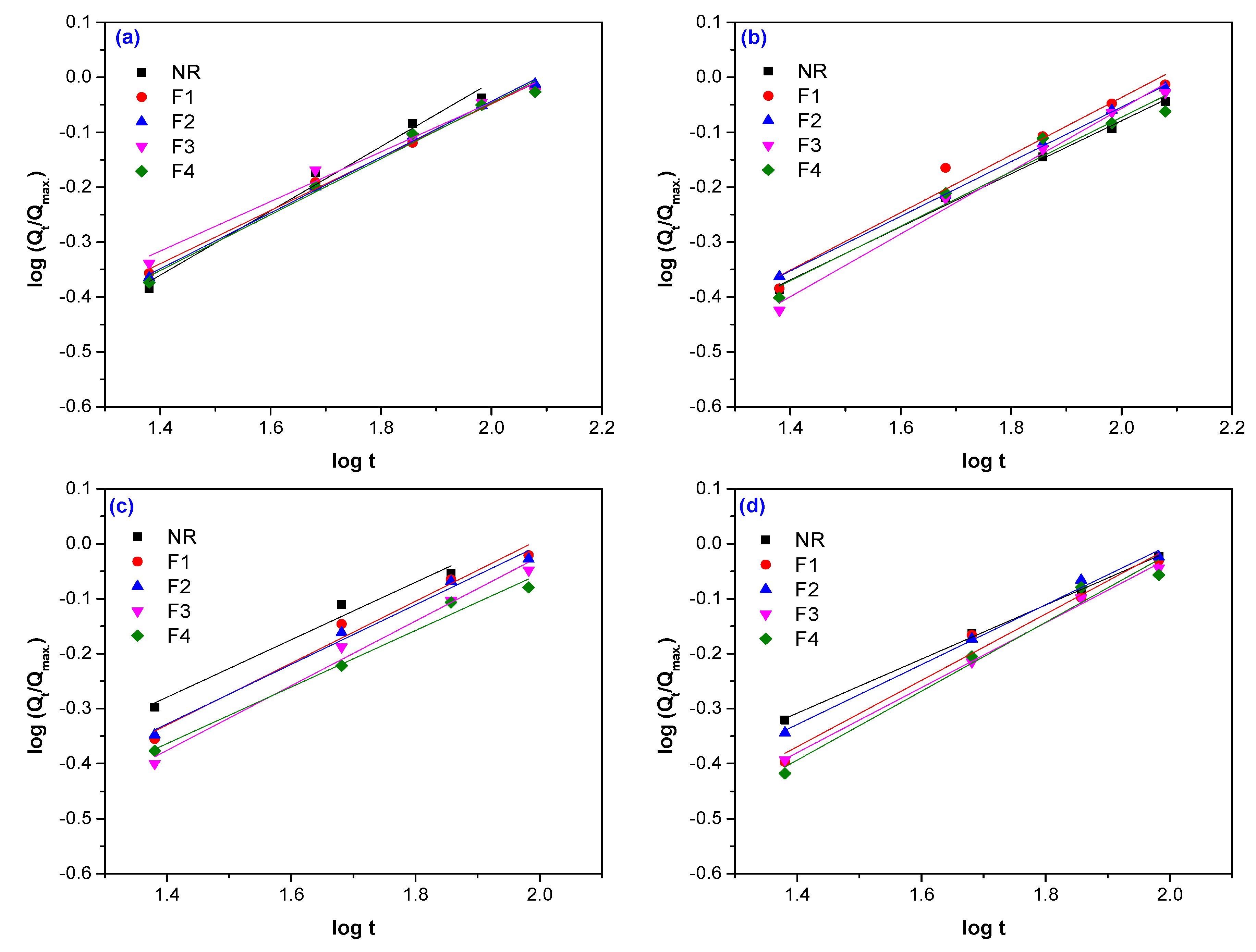

3.2. Mechanism of Water Transport

3.3. Transport Coefficients

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stelescu, M.D. Characteristics of silicone rubber blends. Leather Footwear J. 2010, 10, 51–58. [Google Scholar]

- Stelescu, M.D.; Manaila, E.; Craciun, G. Vulcanization of ethylene-propylene–terpolymer-based rubber mixtures by radiation processing. J. Appl. Polym. Sci. 2012, 128, 2325–2336. [Google Scholar] [CrossRef]

- Ikarashi, Y.; Toyoda, K.; Ohasawa, N.; Uchima, T.; Tsuchiya, T.; Kaniwa, M.A.; Sato, M.; Takahashi, M.; Nakamura, A. Comparative studies by cell culture and in vivo implantation test on the toxicity of natural rubber latex materials. J. Biomed. Mater. Res. 1992, 26, 339–356. [Google Scholar] [CrossRef] [PubMed]

- Kruzelak, J.; Sykora, R.; Hudec, I. Peroxide vulcanization of natural rubber. Part I: Effect of temperature and peroxide concentration. J. Polym. Eng. 2014, 34, 617–624. [Google Scholar] [CrossRef]

- Babu, R.R.; Singha, N.K.; Naskar, K. Dynamically vulcanized blends of polypropylene and ethylene-octene copolymer: Comparison of different peroxides on mechanical, thermal, and morphological characteristics. J. Appl. Polym. Sci. 2009, 113, 1836–1852. [Google Scholar] [CrossRef]

- Craciun, G.; Manaila, E.; Stelescu, M.D. New Elastomeric Materials Based on Natural Rubber Obtained by Electron Beam Irradiation for Food and Pharmaceutical Use. Materials 2016, 9, 999. [Google Scholar] [CrossRef]

- Jansomboon, W.; Loykulnant, S.; Kongkachuichay, P.; Dittanet, P.; Prapainainar, P. Electron beam radiation curing of natural rubber filled with silica-graphene mixture prepared by latex mixing. Ind. Crop. Prod. 2019, 141, 111789. [Google Scholar] [CrossRef]

- Rattanasom, N.; Saowapark, T.; Deeprasertkul, C. Reinforcement of natural rubber with silica/carbon black hybrid filler. Polym. Test. 2007, 26, 369–377. [Google Scholar] [CrossRef]

- IARC Monographs on the Evaluation of Carcinogenic Risks to Humans: Silica, Some Silicates, Coal Dust and Para-Aramid Fibrils; World Health Organization: Lyon, France, 1997; Volume 68. Available online: http://monographs.iarc.fr/ENG/Monographs/vol68/index.php (accessed on 18 September 2014).

- Beliczky, L.S.; Fajen, J. Rubber industry. In Encyclopaedia of Occupational Health and Safety, 4th ed.; Stellman, J.M., Ed.; International Labor Office: Geneva, Switzerland, 1998; 80.1; Available online: https://www.iloencyclopaedia.org/contents/part-xii-57503/rubber-industry (accessed on 22 October 2014).

- Upadhyaya, P.; Garg, M.; Kumar, V.; Nema, A.K. The Effect of Water Absorption on Mechanical Properties of Wood Flour/Wheat Husk Polypropylene Hybrid Composites. Mater. Sci. Appl. 2012, 3, 317–325. [Google Scholar] [CrossRef][Green Version]

- Sanjeevamurthy, G.C.; Srinivas, G.R. Sisal/Coconut Coir Natural Fibers–Epoxy Composites: Water Absorption and Mechanical Properties. Int. J. Eng. Innov. Technol. (IJEIT) 2012, 2, 166–170. [Google Scholar]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Ngo, T.-D. Chapter 7: Natural Fibers for Sustainable Bio-Composites. In Natural and Artificial Fiber-Reinforced Composites as Renewable Sources; Günay, E., Ed.; IntechOpen: London, UK, 2018; pp. 107–126. [Google Scholar]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic treatment of natural fibers and their composites. A review. J. Ind. Text. 2018, 47, 2153–2183. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Tech. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Jacob, M.; Varughese, K.T.; Thomas, S. Water Sorption Studies of Hybrid Biofiber-Reinforced Natural Rubber Biocomposites. Biomacromolecules 2005, 6, 2969–2979. [Google Scholar] [CrossRef] [PubMed]

- Ehi, I.P.; Bidemi, J.K.; Yahaya, L.E. Kinetic Studies on Water Absorption properties of Cocoa-pod Epoxy Composites. Iran. J. Energy Environ. 2016, 7, 48–51. [Google Scholar]

- Kushwaha, P.K.; Kumar, R. Studies on water absorption of bamboo-epoxy composites: Effect of silane treatment of mercerized bamboo. J. Appl. Polym. Sci. 2010, 115, 1846–1852. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part. A. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Karmaker, A.C. Effect of water absorption on dimensional stability and impact energy of jute fibre reinforced polypropylene. J. Mater. Sci. Lett. 1997, 16, 462–464. [Google Scholar] [CrossRef]

- Zhou, J.; Lucas, J.P. The effects of a water environment on anomalous absorption behavior in graphite/epoxy composites. Compos. Sci. Technol. 1995, 53, 57–64. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Effects of environmental aging on the mechanical properties of bamboo–glass fiber reinforced polymer matrix hybrid composites. Compos. Part. A 2002, 33, 43–52. [Google Scholar] [CrossRef]

- Militky, J.; Jabbar, A. Comparative evaluation of fiber treatments on the creep behavior of jute/green epoxy composites. Compos. Part. B. 2015, 80, 361–368. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Joseph, S.; Jacob, M.; Thomas, S. Oil palm fibre reinforced phenol formaldehyde composites: Influence of fibre surface modifications on the mechanical performance. Appl. Compos. Mater. 2000, 7, 295–329. [Google Scholar] [CrossRef]

- Uehara, T.; Sakata, I. Effect of corona discharge treatment on cellulose prepared from beech wood. J. Appl. Polym. Sci. 1990, 41, 1695–1706. [Google Scholar] [CrossRef]

- Sakata, I.; Morita, M.; Furuichi, H.; Hawaguchi, Y. Improvement of plybond strength of paperboard by corona treatment. J. Appl. Polym. Sci. 1991, 42, 2099–2104. [Google Scholar] [CrossRef]

- Podgorski, L.; Roux, M. Wood modification to improve the durability of coatings. Surf. Coat. Int. 1999, 12, 590–596. [Google Scholar] [CrossRef]

- Maldas, D.; Kokta, B.V.; Daneault, C. Influence of coupling agents and treatments on the mechanical properties of cellulose fiber–polystyrene composites. J. Appl. Polym. Sci. 1989, 37, 751–775. [Google Scholar] [CrossRef]

- Henniges, U.; Hasani, M.; Potthast, A.; Westman, G.; Rosenau, T. Electron Beam Irradiation of Cellulosic Materials-Opportunities and Limitations. Materials 2013, 6, 1584–1598. [Google Scholar] [CrossRef]

- Kim, H.G.; Lee, U.S.; Kwac, L.K.; Lee, S.O.; Kim, Y.-S.; Shin, H.K. Electron Beam Irradiation Isolates Cellulose Nanofiber from Korea “Tall Goldenrod” Invasive Alien Plant Pulp. Nanomaterials 2019, 9, 1358. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Y.; Liu, J.; Shen, Z.; Liang, J.; Wang, X. Rapid and Continuous Preparation of Polyacrylonitrile-Based Carbon Fibers with Electron-Beam Irradiation Pretreatment. Materials 2018, 11, 1270. [Google Scholar] [CrossRef]

- Forster, A.L.; Tsinas, Z.; Al-Sheikhly, M. Effect of Irradiation and Detection of Long-Lived Polyenyl Radicals in Highly Crystalline Ultra-High Molar Mass Polyethylene (UHMMPE) Fibers. Polymers 2019, 11, 924. [Google Scholar] [CrossRef]

- Cicala, G.; Cristaldi, G.; Recca, G.; Latteri, A. (2010). Composites Based on Natural Fibre Fabrics. In Woven Fabric Engineering; Dobnik Dubrovski, P., Ed.; Sciyo InTech Europe: Rijeka, Croatia, 2010; pp. 317–342. ISBN 978-953-307-194-7. Available online: http://www.libvolume8.xyz/textile/btech/semester7/fibrereinforcedtextiles/studyofmajornaturalfibres/studyofmajornaturalfibrestutorial1.pdf (accessed on 22 October 2020).

- Williams, G.I.; Wool, R.P. Composites from Natural Fibers and Soy Oil Resins. Appl. Compos. Mater. 2000, 7, 421–432. [Google Scholar] [CrossRef]

- Bogoeva-Gaceva, G.; Avella, M.; Malinconico, M.; Buzarovska, A.; Grozdanov, A.; Gentile, G.; Errico, M.E. Natural Fiber Eco-Composites. Polym. Compos. 2007, 28, 98–107. [Google Scholar] [CrossRef]

- Nanda, S.; Mohanty, P.; Pant, K.K.; Naik, S.; Kozinski, J.A.; Dalai, A.K. Characterization of North American Lignocellulosic Biomass and Biochars in Terms of their Candidacy for Alternate Renewable Fuels. Bioenerg. Res. 2013, 6, 663–677. [Google Scholar] [CrossRef]

- Nhuchhen, D.R.; Basu, P.; Acharya, B. A Comprehensive Review on Biomass Torrefaction. Int. J. Renew. Energy Biofuels 2014, 2014, 56. [Google Scholar] [CrossRef]

- Menon, V.; Rao, M. Trends in bioconversion of lignocellulose: Biofuels, platform chemicals & biorefinery concept. Prog. Energ. Combust. 2012, 38, 522–550. [Google Scholar]

- Manaila, E.; Stelescu, M.D.; Craciun, G.; Surdu, L. Effects of benzoyl peroxide on some properties of composites based on hemp and natural rubber. Polym. Bull. 2014, 71, 2001–2022. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Manaila, E.; Craciun, G.; Dumitrascu, M. New green polymeric composites based on hemp and natural rubber processed by electron beam irradiation. Sci. World J. 2014, 2014, 684047. [Google Scholar] [CrossRef]

- Craciun, G.; Manaila, E.; Stelescu, M.D.; Vasilescu, A.M. Characteristics of Wood Sawdust/Natural Rubber Composites Processed by Electron Beam Irradiation. Mater. Plast. 2015, 52, 234–238. [Google Scholar]

- Manaila, E.; Stelescu, M.D.; Craciun, G.; Ighigeanu, D. Wood Sawdust/Natural Rubber Ecocomposites Cross-Linked by Electron Beam Irradiation. Materials 2016, 9, 503. [Google Scholar] [CrossRef] [PubMed]

- Manaila, E.; Craciun, G.; Stelescu, M.D.; Dinca, C.L.; Surdu, L.; Gurau, D. Polymeric composites based on flax wastes and natural rubber. Ind. Textila 2014, 65, 53–60. [Google Scholar]

- Al-Maharma, A.Y.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. Possibilities to improve the properties of natural fiber reinforced plastics by fiber modification–Jute polypropylene composites. Appl. Compos. Mater. 2000, 7, 373–385. [Google Scholar] [CrossRef]

- Lau, K.-T.; Hung, P.-Y.; Zhu, M.-H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part B 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Fernandes, R.L.; De Moura, M.F.S.F.; Moreira, R.D.F. Effect of moisture on pure mode I and II fracture behaviour of composite bonded joints. Int. J. Adhes. Adhes. 2016, 68, 30–38. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Chi Truong, T.; Vangrimde, B.; Verpoest, I. Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Compos. Part A 2006, 37, 1368–1376. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, K.U.; Joseph, R. Swelling behaviour of isora/natural rubber composites in oils used in Automobiles. B Mater. Sci. 2006, 29, 91–99. [Google Scholar] [CrossRef]

- Viet Cao, X.; Ismail, H.; Rashid, A.A.; Takeichi, T.; Vo-Huu, T. Mechanical properties and water absorption of kenaf powder filled recycled high density polyethylene/natural rubber biocomposites using MAPE as a compatibilizer. Bioresources 2011, 6, 3260–3271. [Google Scholar]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of Chemical Modifications of the Pineapple Leaf Fiber Surfaces on the Interfacial and Mechanical Properties of Laminated Biocomposites. Compos. Interface. 2008, 15, 169–191. [Google Scholar] [CrossRef]

- Bouchard, J.; Methot, M.; Jordan, B. The effects of ionizing radiation on the cellulose of wood-free paper. Cellulose 2006, 13, 601–610. [Google Scholar] [CrossRef]

- Desmet, G. Functionalization of Cotton-Cellulose via High Energy Irradiation Initiated Grafting and Cyclodextrin Immobilization. Master’s Thesis, Department of Textiles, Faculty of Engineering University of Ghent, Ghent, Belgium, 2010. [Google Scholar]

- Wencka, M.; Wichlacz, K.; Kasprzyk, H.; Lijewski, S.; Hoffmann, S.K. Free radicals and their electron spin relaxation in cellobiose. X-band and W-band ESR and electron spin echo studies. Cellulose 2007, 14, 183–194. [Google Scholar] [CrossRef]

- Wach, R.A.; Mitomo, H.; Yoshii, F. ESR investigation on gamma-irradiated methylcellulose and hydroxyethylcellulose in dry state and in aqueous solution. J. Radioanal. Nucl. Chem. 2004, 261, 113–118. [Google Scholar] [CrossRef]

- Alberti, A.; Bertini, S.; Gastaldi, G.; Iannaccone, N.; Macciantelli, D.; Torri, G.; Vismara, E. Electron beam irradiated textile cellulose fibres: ESR studies and derivatisation with glycidyl methacrylate (GMA). Eur. Polym. J. 2005, 41, 1787–1797. [Google Scholar] [CrossRef]

- Ahmad, I.; Lane, C.E.; Mohd, D.H.; Abdullah, I. Electron-beam-irradiated rice husk powder as reinforcing filler in natural rubber/high-density polyethylene (NR/HDPE) composites. Compos. Part B 2012, 43, 3069–3075. [Google Scholar] [CrossRef]

- Iskandar, S. Graft Copolymerization of Methyl Methacrylate Monomer onto Starch and Natural Rubber Latex Initiated by Gamma Irradiation. Atom. Indones. 2011, 37, 24–28. [Google Scholar] [CrossRef]

- Ajith Kumar, K.A.; Sreekala, M.S.; Arun, S. Studies on Properties of Bio-Composites from Ecoflex/Ramie Fabric-Mechanical and Barrier Properties. J. Biomater. Nanobiotechnol. 2012, 3, 396–404. [Google Scholar] [CrossRef]

- Sambhudevan, S.; Shankar, B.; Appukuttan, S.; Joseph, K. Evaluation of kinetics and transport mechanism of solvents through natural rubber composites containing organically modified gadolinium oxide. Plast. Rubber Compos. 2016, 45, 216–223. [Google Scholar] [CrossRef]

- Anil Kumar, S.; Kumaran, M.G.; Thomas, S. Sorption and diffusion of arenes through poly (ethylene-co-vinyl acetate) membranes. J. Mater. Sci. 2006, 41, 4892–4900. [Google Scholar] [CrossRef]

- Aminabhavi, T.M.; Phayde, H.T.S. Molecular-transport characteristics of santoprene thermoplastic rubber in the presence of aliphatic alkanes over the temperature interval of 25-degrees-c to 70-degrees-c. Polymer 1995, 36, 1023–1033. [Google Scholar] [CrossRef]

- Aminabhavi, T.M.; Khinnavar, R.S. Diffusion and sorption of organic liquids through polymer membranes: 10. polyurethane, nitrile-butadiene rubber and epichlorohydrin versus aliphatic-alcohols (C1–C5). Polymer 1993, 34, 1006–1008. [Google Scholar] [CrossRef]

- Anil Kumar, P.V.; Varughese, K.T.; Thomas, S. Molecular Transport of Aromatic Hydrocarbons through Ethylene Propylene Diene Terpolymer. Polym. Polym. Compos. 2002, 10, 553–565. [Google Scholar]

- Harogoppad, S.B.; Aminabhavi, T.M. Diffusion and sorption of organic liquids through polymer membranes. 5. Neoprene, styrene-butadiene-rubber, ethylene-propylene-diene terpolymer, and natural rubber versus hydrocarbons (C8–C16). Macromolecules 1991, 24, 2598–2605. [Google Scholar] [CrossRef]

- Mathew, A.P.; Pakirisamy, S.; Kumaran, M.G.; Thomas, S. Transport of styrene monomer through natural-rubber. Polymer 1995, 36, 4935–4942. [Google Scholar] [CrossRef]

- Crank, J.A. Theoretical investigation of the influence of molecular relaxation and internal stress on diffusion in polymers. J. Polym. Sci. 1953, 11, 151–168. [Google Scholar] [CrossRef]

- Büyükkaya, K. Kinetics of long-term water absorption behavior of different oeganic waste dust/polymethylmethacrylate composites. J. Chem. Technol. Metall. 2019, 54, 339–347. [Google Scholar]

- Muñoz, E.; García-Manrique, J.A. Water Absorption Behaviour and Its Effect on the Mechanical Properties of Flax Fibre Reinforced Bioepoxy Composites. J. Polym. Sci. 2015, 2015. [Google Scholar] [CrossRef]

- Bismarck, A.; Aranberri-Askargorta, I.; Springer, J.; Lampke, T.; Wielage, B.; Stamboulis, A.; Shenderovich, I.; Limbach, H.H. Surface characterization of flax, hemp and cellulose fibers; surface properties and the water uptake behavior. Polym Compos. 2004, 23, 872–894. [Google Scholar] [CrossRef]

- Marom, G. The role of water transport in composite materials. In Polymer Permeability, 1st ed.; Comyn, J., Ed.; Springer: Dordrecht, The Netherlands, 1985; pp. 341–374. [Google Scholar]

| Material | Function | Properties |

|---|---|---|

| natural rubber of Crep 1X type | matrix | Mooney viscosity is 74 ML1+4 at 100 °C, 0.32 wt.% volatile materials, 0.38 wt.% nitrogen, 0.22 wt.% ash, 0.021 wt.% impurities |

| irganox 1010 | antioxidant | melting point of 40 °C, 1.15 g/mL density (at 40 °C), 98% active ingredient |

| polyethylene glycol PEG 4000 | lubricant and plasticizer | 1.128 g/cm3 density, 4–8 °C melting point range |

| hemp fiber | filler | thread length of max 3 mm; composition: 70.2–74.4 wt.% cellulose, 17.9–22.4 wt.% hemicellulose, 3.7–5.7 wt.% lignin, 0.8 wt.% wax, 10.8 wt.% water, 7.0 wt.% others [35,36,37]. |

| flax wastes | filler | thread length of max 3 mm; composition: 71–75 wt.% cellulose, 18.6–20.6 wt.% hemicellulose, 2.2 wt.% lignin, 1.7 wt.% wax, 10.0 wt.% water, 6.0 wt.% others [35,36,37]. |

| wood sawdust | filler | ground of max mesh 250–270; composition: 38–51 wt.% cellulose, 17–38 wt.% hemicellulose, 21–31 wt.% lignin, 1.5 wt.% wax, 6.7 wt.% water, 3.0 wt.% others [38,39,40]. |

| Ingredients | Loading (phr) |

|---|---|

| Natural rubber | 100 |

| PEG 4000 | 3 |

| Irganox 1010 | 1 |

| Filler (hemp, flax and wood sawdust) | 0–20 |

| Natural Rubber without Filler Addition | NR | ||

|---|---|---|---|

| Filler Amount (phr) | Hemp | Flax | Sawdust |

| 5 | H1 | F1 | S1 |

| 10 | H2 | F2 | S2 |

| 15 | H3 | F3 | S3 |

| 20 | H4 | F4 | S4 |

| Filler Amount (phr) | Irradiation Doses | ||||

|---|---|---|---|---|---|

| 75 kGy | 150 kGy | 300 kGy | 600 kGy | ||

| NR | no | 0.105 | 0.095 | 0.092 | 0.089 |

| NR/ Hemp | 5 | 1.004 | 1.313 | 1.725 | 2.085 |

| 10 | 0.658 | 1.197 | 1.297 | 1.666 | |

| 15 | 0.615 | 1.192 | 1.292 | 1.644 | |

| 20 | 0.590 | 1.041 | 1.120 | 1.235 | |

| NR/ Flax | 5 | 0.143 | 0.177 | 0.245 | 0.325 |

| 10 | 0.139 | 0.163 | 0.243 | 0.318 | |

| 15 | 0.135 | 0.155 | 0.241 | 0.316 | |

| 20 | 0.133 | 0.151 | 0.239 | 0.315 | |

| NR/ Sawdust | 5 | 1.254 | 1.279 | 1.331 | 1.545 |

| 10 | 0.654 | 1.017 | 1.058 | 1.283 | |

| 15 | 0.484 | 0.568 | 0.744 | 0.979 | |

| 20 | 0.348 | 0.438 | 0.628 | 0.947 | |

| Filler (phr) | Irradiation Doses | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 75 kGy | 150 kGy | 300 kGy | 600 kGy | ||||||

| n | k × 102 | n | k × 102 | n | k × 102 | n | k × 102 | ||

| NR | no | 0.586 | 6.60 | 0.483 | 9.03 | 0.523 | 9.73 | 0.492 | 10.06 |

| NR/ Hemp | 5 | 0.614 | 1.23 | 0.699 | 1.21 | 0.565 | 2.74 | 0.688 | 1.59 |

| 10 | 0.630 | 1.27 | 0.616 | 1.80 | 0.599 | 2.16 | 0.680 | 1.35 | |

| 15 | 0.638 | 1.31 | 0.652 | 1.36 | 0.593 | 2.21 | 0.637 | 2.07 | |

| 20 | 0.722 | 0.81 | 0.738 | 0.95 | 0.616 | 2.01 | 0.454 | 5.92 | |

| NR/ Flax | 5 | 0.485 | 9.58 | 0.524 | 8.24 | 0.563 | 7.61 | 0.604 | 6.10 |

| 10 | 0.508 | 8.70 | 0.497 | 8.94 | 0.542 | 8.18 | 0.545 | 8.10 | |

| 15 | 0.451 | 11.26 | 0.571 | 6.33 | 0.589 | 6.31 | 0.591 | 6.20 | |

| 20 | 0.509 | 8.63 | 0.496 | 8.61 | 0.515 | 8.24 | 0.627 | 5.35 | |

| NR/ Sawdust | 5 | 0.809 | 0.24 | 0.681 | 0.72 | 0.730 | 0.55 | 0.752 | 0.56 |

| 10 | 0.982 | 0.08 | 1.048 | 0.06 | 0.654 | 0.96 | 0.618 | 1.32 | |

| 15 | 0.951 | 0.10 | 0.720 | 0.51 | 0.768 | 0.41 | 0.599 | 1.35 | |

| 20 | 0.945 | 0.11 | 0.849 | 0.23 | 0.806 | 0.32 | 0.755 | 0.53 | |

| Filler (phr) | Irradiation Doses | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 75 kGy | 150 kGy | 300 kGy | 600 kGy | ||||||||||

| D × 109 | Φ | D* × 109 | D × 109 | Φ | D* × 109 | D × 109 | Φ | D* × 109 | D × 109 | Φ | D* × 109 | ||

| NR | no | 9.41 | 0.983 | 9.80 | 6.03 | 0.984 | 6.27 | 5.51 | 0.985 | 5.72 | 7.99 | 0.983 | 8.32 |

| NR/ Hemp | 5 | 2.34 | 0.857 | 3.36 | 2.32 | 0.902 | 2.95 | 2.41 | 0.907 | 2.81 | 2.08 | 0.911 | 2.58 |

| 10 | 2.47 | 0.820 | 3.92 | 2.43 | 0.833 | 3.73 | 2.36 | 0.834 | 3.61 | 2.11 | 0.851 | 3.08 | |

| 15 | 2.48 | 0.772 | 4.32 | 2.44 | 0.818 | 3.90 | 2.37 | 0.819 | 3.78 | 2.36 | 0.839 | 3.56 | |

| 20 | 2.98 | 0.733 | 6.16 | 2.56 | 0.775 | 4.64 | 2.44 | 0.777 | 4.39 | 2.37 | 0.823 | 3.70 | |

| NR/ Flax | 5 | 10.24 | 0.976 | 10.84 | 9.93 | 0.977 | 10.51 | 9.86 | 0.977 | 10.40 | 9.91 | 0.977 | 10.46 |

| 10 | 10.71 | 0.970 | 11.49 | 9.76 | 0.965 | 10.62 | 9.48 | 0.974 | 10.09 | 9.63 | 0.974 | 10.23 | |

| 15 | 9.05 | 0.958 | 10.01 | 8.26 | 0.958 | 9.12 | 7.62 | 0.959 | 8.39 | 7.06 | 0.959 | 7.79 | |

| 20 | 10.58 | 0.945 | 12.08 | 8.21 | 0.946 | 9.35 | 7.26 | 0.946 | 8.27 | 6.38 | 0.946 | 7.26 | |

| NR/ Sawdust | 5 | 0.427 | 0.830 | 0.661 | 0.402 | 0.903 | 0.510 | 0.201 | 0.927 | 0.240 | 1.20 | 0.946 | 1.37 |

| 10 | 0.445 | 0.823 | 0.701 | 0.417 | 0.854 | 0.602 | 0.653 | 0.913 | 0.807 | 1.12 | 0.932 | 1.33 | |

| 15 | 0.483 | 0.816 | 0.777 | 0.441 | 0.848 | 0.647 | 0.642 | 0.888 | 0.848 | 0.719 | 0.904 | 0.911 | |

| 20 | 0.509 | 0.789 | 0.884 | 0.493 | 0.818 | 0.787 | 0.627 | 0.855 | 0.903 | 0.801 | 0.859 | 1.14 | |

| Filler (phr) | Irradiation Doses | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 75 kGy | 150 kGy | 300 kGy | 600 kGy | ||||||

| P × 1010 | S | P × 1010 | S | P × 1010 | S | P × 1010 | S | ||

| NR | no | 1.85 | 0.019 | 1.08 | 0.017 | 0.95 | 0.017 | 1.53 | 0.018 |

| NR/ Hemp | 5 | 6.07 | 0.181 | 3.49 | 0.119 | 3.12 | 0.111 | 2.74 | 0.106 |

| 10 | 9.28 | 0.237 | 8.05 | 0.216 | 7.75 | 0.215 | 5.70 | 0.188 | |

| 15 | 14.08 | 0.311 | 9.11 | 0.234 | 8.81 | 0.233 | 7.18 | 0.202 | |

| 20 | 23.15 | 0.376 | 13.92 | 0.301 | 13.03 | 0.296 | 8.29 | 0.222 | |

| NR/ Flax | 5 | 2.79 | 0.026 | 2.62 | 0.025 | 2.53 | 0.024 | 2.53 | 0.024 |

| 10 | 3.67 | 0.032 | 3.93 | 0.038 | 2.84 | 0.028 | 2.78 | 0.027 | |

| 15 | 4.41 | 0.044 | 3.99 | 0.044 | 3.64 | 0.043 | 3.35 | 0.043 | |

| 20 | 7.08 | 0.059 | 5.36 | 0.057 | 4.71 | 0.057 | 4.12 | 0.057 | |

| NR/ Sawdust | 5 | 1.49 | 0.226 | 0.61 | 0.118 | 0.21 | 0.087 | 0.86 | 0.063 |

| 10 | 1.62 | 0.230 | 1.11 | 0.183 | 0.83 | 0.102 | 1.04 | 0.079 | |

| 15 | 1.86 | 0.240 | 1.23 | 0.191 | 1.14 | 0.134 | 1.03 | 0.113 | |

| 20 | 2.46 | 0.278 | 1.82 | 0.231 | 1.59 | 0.176 | 1.95 | 0.171 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manaila, E.; Craciun, G.; Ighigeanu, D. Water Absorption Kinetics in Natural Rubber Composites Reinforced with Natural Fibers Processed by Electron Beam Irradiation. Polymers 2020, 12, 2437. https://doi.org/10.3390/polym12112437

Manaila E, Craciun G, Ighigeanu D. Water Absorption Kinetics in Natural Rubber Composites Reinforced with Natural Fibers Processed by Electron Beam Irradiation. Polymers. 2020; 12(11):2437. https://doi.org/10.3390/polym12112437

Chicago/Turabian StyleManaila, Elena, Gabriela Craciun, and Daniel Ighigeanu. 2020. "Water Absorption Kinetics in Natural Rubber Composites Reinforced with Natural Fibers Processed by Electron Beam Irradiation" Polymers 12, no. 11: 2437. https://doi.org/10.3390/polym12112437

APA StyleManaila, E., Craciun, G., & Ighigeanu, D. (2020). Water Absorption Kinetics in Natural Rubber Composites Reinforced with Natural Fibers Processed by Electron Beam Irradiation. Polymers, 12(11), 2437. https://doi.org/10.3390/polym12112437