3D-MID Technology for Surface Modification of Polymer-Based Composites: A Comprehensive Review

Abstract

:1. Introduction

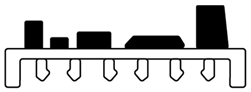

2. Single-Shot Injection Molding

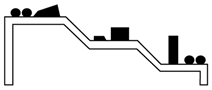

3. Two-Shot Injection Molding

4. Material Properties and Characteristics for MID Substrate

- -

- Assembly temperature

- -

- Rheological properties

- -

- Degradation

- -

- Shrinkage and tolerances

- -

- Anisotropy properties

- -

- Tensile and flexural properties

- -

- Metallization capability

- -

- Electrical properties

- -

- Environmental concerns

- -

- Cost

- -

- Materials have to be meaningful

- -

- Materials have to be comparable

- -

- Materials should be rationally measurable

5. Thermoplastics for MID

5.1. Polypropylene (PP)

5.2. Syndiotactic Polystyrene (sPS)

5.3. Polyphenyl Ether (PPE)

5.4. Polycarbonate (PC)

5.5. Polybutylene Terephthalate (PBT)

5.6. Acrylonitrile Butadiene Styrene (ABS)

5.7. Polyamides (PA)

5.8. Polyphenylene Sulfide (PPS)

5.9. Liquid Crystal Polymer (LCPs)

5.10. Polyetherimide (PEI)

5.11. Polyethersulfone (PES)

6. Modified Thermoplastics for MID

7. Radiation of Cross-Linked Thermoplastics

8. Thermoplastics Composites

- -

- Maximization of filling

- -

- Filler shape and size

- -

- Filler mixtures

- -

- Additivity

9. LDS Materials for MID

10. Thermoset Plastic for MID

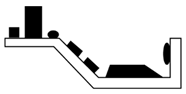

11. Laser-Assisted Metallization for Polymer Materials

12. Influence of Laser Irradiation on Polymer

13. The Absorption Coefficient for Laser Radiation

14. Photochemical and Photothermal Ablation

15. Selection Criteria of Laser for Polymers

- -

- Gas laser (excimer laser, nitrogen or carbon dioxide laser)

- -

- Solid-state lasers (neodymium, Nd:YAG laser)

- -

- Dye laser

16. Metallization

- -

- Dipping in a metal paint

- -

- Sputtering

- -

- Vapour deposition technique

- -

- Electro plating

- -

- Electroless plating

17. Electro and Electroless Plating

18. Electroless Plating Procedure

- (i)

- Cleaning step:

- (ii)

- Etching steps:

- (iii)

- Neutralization steps:

- (iv)

- Activation steps:

- (v)

- Acceleration steps:

- (vi)

- Deposition or plating steps:

19. Future Recommendation

20. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Tg | Glass transition temperature [°C] |

| α | Laser absorption coefficient |

| αeff | Effective coefficient of laser absorption |

| n | Reflective index |

| R | Coefficient of reflection |

| Rp | Polarization resistance [Ω/cm2] |

| κ | Extinction coefficient |

| λ | Light wavelength [nm] |

| I | Laser radiation intensity [W/sr] |

| I0 | Intensity of incident laser radiation [W/sr] |

| i | Plating process rate [s] |

| Eth | Ablation threshold [J/cm2] |

| Ej | Energy per laser pulse [J/cm2] |

| Ea | Activation energy for ablation [J/cm2] |

| φ | Quantum yield of bond breaking (0 to 1) |

| hν | Photon energy [eV] |

| TD | Threshold ablation temperature [°K] |

| TR | Initial temperature [°K] |

| Cw | Specific heat of polymeric materials [J/kg·K] |

| L | Ablation depth [mm] |

| Lchem | Photochemical ablation depth [mm] |

| Ltherm | Photothermal ablation depth [mm] |

| ba, bc | Tafel equation coefficients |

| v | Dependence of deposition rate [dm2/L] |

References

- Islam, A.; Hansen, H.N.; Tang, P.T.; Sun, J. Process Chains for the Manufacturing of Molded Interconnect Devices. Int. J. Adv. Manuf. Technol. 2009, 42, 831–841. [Google Scholar] [CrossRef]

- Feldmann, K.; Brand, A. Analytical and Experimental Research on Assembly Systems for Molded Interconnection Devices (3D-MID). CIRP Ann. 1994, 43, 15–18. [Google Scholar] [CrossRef]

- Amend, P.; Pscherer, C.; Rechtenwald, T.; Frick, T.; Schmidt, M. A Fast and Flexible Method for Manufacturing 3D Molded Interconnect Devices by the Use of a Rapid Prototyping Technology. Phys. Procedia 2010, 5, 561–572. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, B.; Hirsch, S.; Leneke, T. A Multilayer Process for the Connection of Fine-pitch-devices on Molded Interconnect Devices (MIDs). Circuit World 2009, 35, 23–29. [Google Scholar] [CrossRef]

- Three-Dimensional Molded Interconnect Devices (3D-MID): Materials, Manufacturing, Assembly and Applications for Injection Molded Circuit Carriers; Franke, J. (Ed.) Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2014. [Google Scholar] [CrossRef]

- Rong, C.; Tao, X.; Lu, C.; Hu, Z.; Huang, X.; Zeng, Y.; Liu, M. Analysis and Optimized Design of Metamaterials for Mid-Range Wireless Power Transfer Using a Class-E RF Power Amplifier. Appl. Sci. 2019, 9, 26. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Gao, Z.; Xue, H.; Zhang, L.; He, M.; Yang, Z.; Singh, R.; Chong, Y.; Zhang, B.; Chen, H. Realization of a Three-Dimensional Photonic Topological Insulator. Nature 2019, 565, 622. [Google Scholar] [CrossRef]

- Yu, X.; Wang, D.; Zhao, Z. Research Progress of Semi-Physical Verification Technology Based on Photoelectric Sensing. In Semi-physical Verification Technology for Dynamic Performance of Internet of Things System; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–43. [Google Scholar]

- Ushimaru, Y.; Takahashi, T.; Souma, Y.; Yanagimoto, Y.; Nagase, H.; Tanaka, K.; Miyazaki, Y.; Makino, T.; Kurokawa, Y.; Yamasaki, M.; et al. Innovation in Surgery/Operating Room Driven by Internet of Things on Medical Devices. Surg. Endosc. 2019. [Google Scholar] [CrossRef]

- Venkatraman, P.; Sureka, C.S. An In-Vitro Study for Early Detection and to Distinguish Breast and Lung Malignancies Using the Pcb Technology Based Nanodosimeter. Sci. Rep. 2019, 9, 380. [Google Scholar] [CrossRef] [Green Version]

- Choi, D.S.; Zhang, Z.; Pachauri, N. Nanoengineered Material Applications in Electronics, Biology, and Energy Harnessing. Microelectron. Nanoelectron. Mater. Devices Manuf. 2012, 350–369. [Google Scholar]

- Ahmad, S. Organic Semiconductors for Device Applications: Current Trends and Future Prospects. J. Polym. Eng. 2014, 34, 279–338. [Google Scholar] [CrossRef]

- Nadeem, A.; Hussain, M.A.; Owais, O.; Salam, A.; Iqbal, S.; Ahsan, K. Application Specific Study, Analysis and Classification of Body Area Wireless Sensor Network Applications. Comput. Netw. 2015, 83, 363–380. [Google Scholar] [CrossRef]

- Becker, K.; Braun, T.; Neumann, A.; Ostmann, A.; Koch, M.; Bader, V.; Aschenbrenner, R.; Reichl, H. Duromer MID Technology for System-in-Package Generation. IEEE Trans. Electron. Packag. Manuf. 2005, 28, 291–296. [Google Scholar] [CrossRef]

- Schneider, M. Radio Frequency Identification (RFID) Technology and its Applications in the Commercial Construction Industry. Professur Informatik im Bauwesen. Available online: https://www.db-thueringen.de/receive/dbt_mods_00035602 (accessed on 27 May 2020).

- Huang, Y.; Wu, H.; Xiao, L.; Duan, Y.; Zhu, H.; Bian, J.; Ye, D.; Yin, Z. Assembly and Applications of 3D Conformal Electronics on Curvilinear Surfaces. Mater. Horiz. 2019. [Google Scholar] [CrossRef]

- Chtioui, I.; Bossuyt, F.; Vanfleteren, J.; Bedoui, M.H. 2.5/3D Dynamically Stretchable and Permanently Shaped Electronic Circuits. Microsyst. Technol. 2018, 24, 831–853. [Google Scholar] [CrossRef]

- Kurnosenko, A.E.; Arabov, D.I. Optimization of Electronic Components Mounting Sequence for 3D MID Assembly Process. KnE Eng. 2018, 3, 311–321. [Google Scholar] [CrossRef] [Green Version]

- Tacken, R.; De Zwart, R.; Bolt, P. New Methods for Selective Metallization of 3-D Polymer Microparts. Available online: http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.515.1814 (accessed on 27 May 2020).

- Shaw, M.; Zhan, H.; Elmi, M.; Pawar, V.; Essmann, C.; Srinivasan, M.A. Three-Dimensional Behavioural Phenotyping of Freely Moving C. Elegans Using Quantitative Light Field Microscopy. PLoS ONE 2018, 13, e0200108. [Google Scholar] [CrossRef] [Green Version]

- Peng, H.; Wang, K.; Huang, Z. An Injection Molding Method to Prepare Chitosan-Zinc Composite Material for Novel Biodegradable Flexible Implant Devices. Mater. Manuf. Process. 2019, 34, 256–261. [Google Scholar] [CrossRef]

- Oh, J.W.; Park, J.M.; Shin, D.S.; Noh, J.; Park, S.J. Comparative Study of Nanoparticle Effects on Feedstock Behavior for Injection Molding. Mater. Manuf. Process. 2019, 34, 414–421. [Google Scholar] [CrossRef]

- Azad, R.; Shahrajabian, H. Experimental Study of Warpage and Shrinkage in Injection Molding of HDPE/RPET/Wood Composites with Multiobjective Optimization. Mater. Manuf. Process. 2019, 34, 274–282. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, F.; Wu, X.; Zhou, C.; Zhao, H.; Li, L.; Tang, Y. Precise WEDM of Micro-Textured Mould for Micro-Injection Molding of Hydrophobic Polymer Surface. Mater. Manuf. Process. 2019, 34, 1342–1351. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I. Processing of PLA/Sisal Fiber Biocomposites Using Direct-and Extrusion-Injection Molding. Mater. Manuf. Process. 2017, 32, 468–474. [Google Scholar] [CrossRef]

- Liparoti, S.; Sorrentino, A.; Titomanlio, G. Temperature and Pressure Evolution in Fast Heat Cycle Injection Molding. Mater. Manuf. Process. 2019, 34, 422–430. [Google Scholar] [CrossRef]

- Tian, Y.-C.; Gao, F. Injection Velocity Control of Thermoplastic Injection Molding via a Double Controller Scheme. Ind. Eng. Chem. Res. 1999, 38, 3396–3406. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.; Lee, J.; Ryu, S.; Kim, J. Laser Direct Structuring and Electroless Plating Applicable Super-Engineering Plastic PPS Based Thermal Conductive Composite with Particle Surface Modification. RSC Adv. 2018, 8, 9933–9940. [Google Scholar] [CrossRef] [Green Version]

- Balzereit, S.; Proes, F.; Altstädt, V.; Emmelmann, C. Properties of Copper Modified Polyamide 12-Powders and Their Potential for the Use as Laser Direct Structurable Electronic Circuit Carriers. Addit. Manuf. 2018, 23, 347–354. [Google Scholar] [CrossRef]

- Mahanty, S.; Gouthama. Surface Nanostructuring of TIMETAL 834 Using Excimer Laser Treatment. Surf. Eng. 2016, 32, 916–922. [Google Scholar] [CrossRef]

- Bachy, B.; Süß-Wolf, R.; Wang, L.; Fu, Z.; Travitzky, N.; Greil, P.; Franke, J. Novel Ceramic-Based Material for the Applications of Molded Interconnect Devices (3D-MID) Based on Laser Direct Structuring. Adv. Eng. Mater. 2018, 20, 1700824. [Google Scholar] [CrossRef]

- Petit, E. Laser Processing of Metallic and Intermetallic Surfaces. Mater. Manuf. Process 1993, 8, 299–314. [Google Scholar] [CrossRef]

- Kromer, R.; Danlos, Y.; Aubignat, E.; Verdy, C.; Costil, S. Coating Deposition and Adhesion Enhancements by Laser Surface Texturing—Metallic Particles on Different Classes of Substrates in Cold Spraying Process. Mater. Manuf. Process. 2017, 32, 1642–1652. [Google Scholar] [CrossRef]

- Cheng, C.-W.; Chen, J.-S.; Chen, H.-H. Patterning of Crystalline ITO Using Infrared Nanosecond Fiber Laser Pulses. Mater. Manuf. Process. 2010, 25, 684–688. [Google Scholar] [CrossRef]

- Nattapat, M.; Marimuthu, S.; Kamara, A.; Esfahani, M.N. Laser Surface Modification of Carbon Fiber Reinforced Composites. Mater. Manuf. Process. 2015, 30, 1450–1456. [Google Scholar] [CrossRef] [Green Version]

- Fang, S.; Pérez, V.; Salán, N.; Baehre, D.; Llanes, L. Surface Patterning of Cemented Carbides by Means of Nanosecond Laser. Mater. Manuf. Process. 2020, 35, 123–129. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Guo, W.; Kar, A. Characteristics of Laser-Fabricated Metal Structures. Mater. Manuf. Process. 1998, 13, 537–554. [Google Scholar] [CrossRef]

- Armeyev, V.Y.; Chapliev, N.; Chistyakov, I.; Konov, V.; Ralchenko, V.; Strelnitsky, V.; Volkov, V.Y. Direct Laser Writing of Microstructures in Diamond-like Carbon Films. Mater. Manuf. Process. 1993, 8, 9–17. [Google Scholar] [CrossRef]

- Roslizar, A.; Dottermusch, S.; Vüllers, F.; Kavalenka, M.N.; Guttmann, M.; Schneider, M.; Paetzold, U.W.; Hölscher, H.; Richards, B.S.; Klampaftis, E. Self-Cleaning Performance of Superhydrophobic Hot-Embossed Fluoropolymer Films for Photovoltaic Modules. Sol. Energy Mater. Sol. Cells 2019, 189, 188–196. [Google Scholar] [CrossRef]

- Gao, X.; Huang, Y.; He, X.; Fan, X.; Liu, Y.; Xu, H.; Wu, D.; Wan, C. Mechanically Enhanced Electrical Conductivity of Polydimethylsiloxane-Based Composites by a Hot Embossing Process. Polymers 2019, 11, 56. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Xie, J.; Li, W.; Lu, K. Study on Non-Isothermal Hot-Embossing of Polymer Micro-Prism Array with Efficiency and Accuracy. J. Mater. Process. Technol. 2019, 266, 675–686. [Google Scholar] [CrossRef]

- Li, J.; Zhou, Y.; Yang, J.; Ye, R.; Gao, J.; Ren, L.; Liu, B.; Liang, L.; Jiang, L. Fabrication of Gradient Porous Microneedle Array by Modified Hot Embossing for Transdermal Drug Delivery. Mater. Sci. Eng. C 2019, 96, 576–582. [Google Scholar] [CrossRef]

- Yi, P.; Deng, Y.; Shu, Y.; Peng, L. Experimental Studies on a Novel Roll-to-Roll Powder Hot Embossing for Large-Area Fabrication of Micropyramid Arrays on Polymers. J. Micromech. Microeng. 2018, 28, 085007. [Google Scholar] [CrossRef]

- Lin, T.-Y.; Do, T.; Kwon, P.; Lillehoj, P.B. 3D Printed Metal Molds for Hot Embossing Plastic Microfluidic Devices. Lab. Chip 2017, 17, 241–247. [Google Scholar] [CrossRef] [Green Version]

- Çoğun, F.; Yıldırım, E.; Sahir Arikan, M. Investigation on Replication of Microfluidic Channels by Hot Embossing. Mater. Manuf. Process. 2017, 32, 1838–1844. [Google Scholar] [CrossRef]

- Ong, N.S.; Koh, Y.H. Experimental Investigation into Micro Injection Molding of Plastic Parts. Mater. Manuf. Process. 2005, 20, 245–253. [Google Scholar] [CrossRef]

- Chen, C.-C.; Su, P.-L.; Chiou, C.-B.; Chiang, K.-T. Experimental Investigation of Designed Parameters on Dimension Shrinkage of Injection Molded Thin-Wall Part by Integrated Response Surface Methodology and Genetic Algorithm: A Case Study. Mater. Manuf. Process. 2011, 26, 534–540. [Google Scholar] [CrossRef]

- Ali, M.; Ahmad, F. Influence of Powder Loading on Rheology and Injection Molding of Fe-50Ni Feedstocks. Mater. Manuf. Process. 2020, 35, 579–589. [Google Scholar] [CrossRef]

- Ong, N.S.; Zhang, H.; Woo, W.H. Plastic Injection Molding of High-Aspect Ratio Micro-Rods. Mater. Manuf. Process. 2006, 21, 824–831. [Google Scholar] [CrossRef]

- Islam, A.; Hansen, H.; Tang, P.; Jørgensen, M.; Ørts, S. Two Component Injection Molding for MID Fabrication. Laser 2009, 2, 3. [Google Scholar]

- Tenteris-Noebe, A. Review of: “Introduction to Plastics and Composites Mechanical Properties and Engineering Applications” Edited by Edward Miller. Mater. Manuf. Process. 1996, 11, 891–892. [Google Scholar] [CrossRef]

- Wissbrock, H.; Naundorf, G. A Fundamentally New Mechanism for Additive Metallization of Polymeric Substrates in Ultra Fine Line Technology Illustrated for 3D-MIDs. Galvanotechnik 2000, 91, 2449–2451. [Google Scholar]

- Hoerber, J.; Glasschroeder, J.; Pfeffer, M.; Schilp, J.; Zaeh, M.; Franke, J. Approaches for Additive Manufacturing of 3D Electronic Applications. Procedia CIRP 2014, 17, 806–811. [Google Scholar] [CrossRef] [Green Version]

- Lomakin, K.; Pavlenko, T.; Ankenbrand, M.; Sippel, M.; Ringel, J.; Scheetz, M.; Klemm, T.; Gräf, D.; Helmreich, K.; Franke, J.; et al. Evaluation and Characterization of 3-D Printed Pyramid Horn Antennas Utilizing Different Deposition Techniques for Conductive Material. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 1998–2006. [Google Scholar] [CrossRef]

- Shin, I.J.; Park, M.S. Direct Conductive Patterning on 3D Printed Structure Using Laser. Phys. Status Solidi A 2018, 215, 1700597. [Google Scholar] [CrossRef]

- Berkelmann, L.; Martinelli, T.; Friedrich, A.; Manteuffel, D. Design and Integration of a Wearable Antenna System for On and Off-Body Communication Based on 3D-MID Technology. In Proceedings of the 12th European Conference on Antennas and Propagation (EuCAP 2018), London, UK, 9–13 April 2018. [Google Scholar] [CrossRef]

- Yoshida, Y.; Wada, H.; Izumi, K.; Tokito, S. Three-Dimensional Interconnect Layers Inkjet Printed on Plastic Substrates Using Continuous-Wave Xenon Light Sintering. Jpn. J. Appl. Phys. 2018, 58, 016507. [Google Scholar] [CrossRef]

- Lu, B.; Lan, H.; Liu, H. Additive Manufacturing Frontier: 3D Printing Electronics. Opto-Electron. Adv. 2018, 01, 170004. [Google Scholar] [CrossRef]

- Kilian, A.; Weinzierl, J.; Schmidt, L. Investigation of the Hot Embossing Technology for Low-Cost Antennas Printed on Polymer Substrates. In Proceedings of the 2008 38th European Microwave Conference, Amsterdam, The Netherlands, 27–31 October 2008; pp. 1–4. [Google Scholar] [CrossRef]

- Battermann, A.; Gunther, B.; Schafer, H. UV-Curable Conductive Adhesives for 3-D MID Application. In Proceedings of the First International IEEE Conference on Polymers and Adhesives in Microelectronics and Photonics. Incorporating POLY, PEP Adhesives in Electronics. Proceedings (Cat. No.01TH8592), Potsdam, Germany, 21–24 October 2001; pp. 181–184. [Google Scholar] [CrossRef]

- Lu, Y.; Yun, H.-Y.; Vatani, M.; Kim, H.-C.; Choi, J.-W. Direct-Print/Cure as a Molded Interconnect Device (MID) Process for Fabrication of Automobile Cruise Controllers. J. Mech. Sci. Technol. 2015, 29, 5377–5385. [Google Scholar] [CrossRef]

- Polzinger, B.; Matic, V.; Liedtke, L.; Keck, J.; Hera, D.; Günther, T.; Eberhardt, W.; Kück, H. Printing of Functional Structures on Molded 3D Devices. Available online: www.scientific.net/AMR.1038.37 (accessed on 21 April 2019).

- Petrovskaya, T.; Toropkov, N.; Mironov, E.; Azarmi, F. 3D Printed Biocompatible Polylactide-Hydroxyapatite Based Material for Bone Implants. Mater. Manuf. Process. 2018, 33, 1899–1904. [Google Scholar] [CrossRef]

- Goud, V.; Ramasamy, A.; Das, A.; Kalyanasundaram, D. Box-Behnken Technique Based Multi-Parametric Optimization of Electrostatic Spray Coating in the Manufacturing of Thermoplastic Composites. Mater. Manuf. Process. 2019, 34, 1638–1645. [Google Scholar] [CrossRef]

- Tamrin, K.; Nukman, Y.; Sheikh, N. Laser Spot Welding of Thermoplastic and Ceramic: An Experimental Investigation. Mater. Manuf. Process. 2015, 30, 1138–1145. [Google Scholar] [CrossRef]

- Jakus, A.E. Chapter 1—An Introduction to 3D Printing—Past, Present, and Future Promise. In 3D Printing in Orthopaedic Surgery; Dipaola, M., Wodajo, F.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–15. [Google Scholar] [CrossRef]

- Hüske, M.; Kickelhain, J.; Müller, J.; Eßer, G. Laser supported activation and additive metallization of thermoplastics for 3D-MIDs. In Proceedings of the 3rd LANE, Erlangen, Germany, 28–31 August 2001. [Google Scholar]

- Vanfleteren, J.; Chtioui, I.; Plovie, B.; Yang, Y.; Bossuyt, F.; Vervust, T.; Dunphy, S.; Vandecasteele, B. Arbitrarily Shaped 2.5D Circuits Using Stretchable Interconnections and Embedding in Thermoplastic Polymers. Procedia Technol. 2014, 15, 208–215. [Google Scholar] [CrossRef]

- Vanfleteren, J.; Bossuyt, F.; Plovie, B. A New Technology for Rigid 3D Free-Form Electronics Based on the Thermoplastic Deformation of Flat Standard PCB Type Circuits. In Proceedings of the 2016 12th International Congress Molded Interconnect Devices (MID), Wurzburg, Germany, 28–29 September 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Chinnadurai, T.; Arungalai Vendan, S.; Rusu, C.; Scutelnicu, E. Experimental Investigations on the Polypropylene Behavior during Ultrasonic Welding. Mater. Manuf. Process. 2018, 33, 718–726. [Google Scholar] [CrossRef]

- Srinivasan, T.; Palanikumar, K.; Rajagopal, K.; Latha, B. Optimization of Delamination Factor in Drilling GFR–Polypropylene Composites. Mater. Manuf. Process. 2017, 32, 226–233. [Google Scholar] [CrossRef]

- Li, T.-T.; Chen, A.-P.; Hwang, P.-W.; Pan, Y.-J.; Hsing, W.-H.; Lou, C.-W.; Chen, Y.-S.; Lin, J.-H. Synergistic Effects of Micro-/Nano-Fillers on Conductive and Electromagnetic Shielding Properties of Polypropylene Nanocomposites. Mater. Manuf. Process. 2018, 33, 149–155. [Google Scholar] [CrossRef]

- Mudhukrishnan, M.; Hariharan, P.; Palanikumar, K.; Latha, B. Tool Materials Influence on Surface Roughness and Oversize in Machining Glass Fiber Reinforced Polypropylene (GFR-PP) Composites. Mater. Manuf. Process. 2017, 32, 988–997. [Google Scholar] [CrossRef]

- Long, X.; He, L.; Zhang, Y.; Yu, S.; Ge, M. Surface Modification of Polypropylene Non-Woven Fabric for Improving Its Hydrophilicity. Surf. Eng. 2018, 34, 818–824. [Google Scholar] [CrossRef]

- Huang, P.; Wu, M.; Pang, Y.; Shen, B.; Wu, F.; Lan, X.; Luo, H.; Zheng, W. Ultrastrong, Flexible and Lightweight Anisotropic Polypropylene Foams with Superior Flame Retardancy. Compos. Part Appl. Sci. Manuf. 2019, 116, 180–186. [Google Scholar] [CrossRef]

- Davis, A.M.; Hanzly, L.E.; DeButts, B.L.; Barone, J.R. Characterization of Dimensional Stability in Flax Fiber Reinforced Polypropylene Composites. Polym. Compos. 2019, 40, 132–140. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Guo, X.; Peng, Y.; Cao, J. Water Absorption and Mold Susceptibility of Wood Flour/Polypropylene Composites Modified with Silane-Wax Emulsions. Polym. Compos. 2019, 40, 141–148. [Google Scholar] [CrossRef] [Green Version]

- Kaymakci, A.; Birinci, E.; Ayrilmis, N. Surface Characteristics of Wood Polypropylene Nanocomposites Reinforced with Multi-Walled Carbon Nanotubes. Compos. Part B Eng. 2019, 157, 43–46. [Google Scholar] [CrossRef]

- Dai, Z.; Su, J.; Zhu, X.; Xu, K.; Zhu, J.; Huang, C.; Ke, Q. Multifunctional Polyethylene (PE)/Polypropylene (PP) Bicomponent Fiber Filter with Anchored Nanocrystalline MnO2 for Effective Air Purification. J. Mater. Chem. A 2018, 6, 14856–14866. [Google Scholar] [CrossRef]

- López Nava, J.; Méndez González, J.; Ruelas Chacón, X.; Nájera Luna, J. Assessment of Edible Fungi and Films Bio-Based Material Simulating Expanded Polystyrene. Mater. Manuf. Process. 2016, 31, 1085–1090. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, L.; Wang, D. Preparation and Hydrophobic Behaviours of Polystyrene Composite Coating. Surf. Eng. 2016, 32, 95–101. [Google Scholar] [CrossRef]

- Kausar, A.; Wajid-Ullah; Muhammad, B.; Siddiq, M. Influence of Processing Technique on the Physical Properties of Modified Polystyrene/Exfoliated Graphite Nanocomposites. Mater. Manuf. Process. 2015, 30, 346–355. [Google Scholar] [CrossRef]

- Sato, S.; Yamamoto, Y.; Kaneko, F. Cocrystal Formation between Syndiotactic Polystyrene and Polyethylene Glycol from Binary Solute Solutions. Chem. Lett. 2019, 48, 177–180. [Google Scholar] [CrossRef]

- Abdeldaym, A.; Elhady, M.A. Investigation of the Effect of Aluminum Oxide Nanoparticle Additives and Gamma Irradiation on the Thermal Behavior of Syndiotactic Polystyrene. Polym. Compos. 2019, 40, 3588–3600. [Google Scholar] [CrossRef]

- Chen, P.-H.; Lan, Y.-K.; Lin, S.-J.; Tsai, J.-C.; Jeng, U.-S.; Su, A.-C. Crystallization of α versus β Phases in Syndiotactic Poly(Styrene-Stat-3-Methylstyrene) and Poly(Styrene-Stat-4-Methylstyrene). ACS Appl. Polym. Mater. 2019, 1, 251–258. [Google Scholar] [CrossRef]

- Naga, N.; Sakurai, T.; Hashimoto, T.; Noguchi, K. Crystalline Structure and Phase Transition of Syndiotactic Styrene-based Copolymers. Polym. Int. 2019, 68, 71–78. [Google Scholar] [CrossRef]

- Liu, C.; Kremer, K.; Bereau, T. Polymorphism of Syndiotactic Polystyrene Crystals from Multiscale Simulations. Adv. Theory Simul. 2018, 1, 1800024. [Google Scholar] [CrossRef]

- Shi, Z.; Guo, F.; Li, Y.; Hou, Z. Synthesis of Amino-Containing Syndiotactic Polystyrene as Efficient Polymer Support for Palladium Nanoparticles. J. Polym. Sci. Part Polym. Chem. 2015, 53, 5–9. [Google Scholar] [CrossRef]

- Itagaki, H.; Sano, T.; Okabe, T.; Sano, S.; Ebihara, H.; Tomono, F.; Dohra, H. Polymerization of Aniline in Tubular Cavities of the Crystalline Phase of Syndiotactic Polystyrene: Proposal of a Preparation Method of Sophisticated Polymer Composites. ACS Macro Lett. 2017, 6, 1099–1103. [Google Scholar] [CrossRef]

- Li, Y.; Huang, X.; Zeng, L.; Li, R.; Tian, H.; Fu, X.; Wang, Y.; Zhong, W.-H. A Review of the Electrical and Mechanical Properties of Carbon Nanofiller-Reinforced Polymer Composites. J. Mater. Sci. 2019, 54, 1036–1076. [Google Scholar] [CrossRef]

- Bin Rusayyis, M.A.; Schiraldi, D.A.; Maia, J. Property/Morphology Relationships in SEBS-Compatibilized HDPE/Poly(Phenylene Ether) Blends. Macromolecules 2018, 51, 6513–6523. [Google Scholar] [CrossRef]

- Wang, J.; Tsou, A.H.; Passino, H.L.; Favis, B.D. PPE-g-HDPE in High-Performance Poly(p-Phenylene Ether)/Polyethylene Blends: Synthesis and Compatibilization Effects. Polymer 2018, 138, 92–102. [Google Scholar] [CrossRef]

- Jasinska-Walc, L.; Bouyahyi, M.; Lorenc, P.; Heeneman, A.L.; Duchateau, R.; Różański, A.; Bernaerts, K.V. Synthesis of Isotactic Polypropylene-Block-Polystyrene Block Copolymers as Compatibilizers for Isotactic Polypropylene/Polyphenylene Oxide Blends. Polymer 2018, 147, 121–132. [Google Scholar] [CrossRef]

- Wang, Y.; Tao, Y.; Zhou, J.; Sun, J.; Fang, Q. Biobased Anethole-Functionalized Poly(Phenylene Oxides): New Low Dielectric Materials with High Tg and Good Dimensional Stability. ACS Sustain. Chem. Eng. 2018, 6, 9277–9282. [Google Scholar] [CrossRef]

- Seike, Y.; Okude, Y.; Iwakura, I.; Chiba, I.; Ikeno, T.; Yamada, T. Synthesis of Polyphenylene Ether Derivatives: Estimation of Their Dielectric Constants. Macromol. Chem. Phys. 2003, 204, 1876–1881. [Google Scholar] [CrossRef]

- Stack, S.; O’Donoghue, O.; Birkinshaw, C. The Thermal Stability and Thermal Degradation of Blends of Syndiotactic Polystyrene and Polyphenylene Ether. Polym. Degrad. Stab. 2003, 79, 29–36. [Google Scholar] [CrossRef]

- Hou, H.; Vacandio, F.; Vona, M.L.D.; Knauth, P. Sulfonated Polyphenyl Ether by Electropolymerization. Electrochim. Acta 2012, 81, 58–63. [Google Scholar] [CrossRef]

- Nunoshige, J.; Akahoshi, H.; Shibasaki, Y.; Ueda, M. Efficient Oxidative Coupling Polymerization for Synthesis of Thermosetting Poly(Phenylene Ether) Copolymer with a Low Dielectric Loss. J. Polym. Sci. Part Polym. Chem. 2008, 46, 5278–5282. [Google Scholar] [CrossRef]

- Kim, I.G.; Hong, S.Y.; Park, B.O.; Choi, H.J.; Lee, J.H. Polyphenylene Ether/Glycol Modified Polyethylene Terephthalate Blends and Their Physical Characteristics. J. Macromol. Sci. Part B 2012, 51, 798–806. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Boccarusso, L.; Langella, A. Influence of Cold-Rolling on Incremental Sheet Forming of Polycarbonate. Mater. Manuf. Process. 2020, 35, 328–336. [Google Scholar] [CrossRef]

- Małachowska, A.; Winnicki, M.; Stachowicz, M.; Korzeniowski, M. Metallisation of Polycarbonates Using a Low Pressure Cold Spray Method. Surf. Eng. 2018, 34, 251–258. [Google Scholar] [CrossRef]

- Sabry, R.S.; Al-Mosawi, M.I. Novel Approach to Fabricate a Stable Superhydrophobic Polycarbonate. Surf. Eng. 2018, 34, 151–157. [Google Scholar] [CrossRef]

- Ul Haq, A.; Boyd, A.; Acheson, J.; McLaughlin, J.; Meenan, B.J. Corona Discharge-Induced Functional Surfaces of Polycarbonate and Cyclic Olefins Substrates. Surf. Coat. Technol. 2019, 362, 185–190. [Google Scholar] [CrossRef]

- Hazer, S.; Coban, M.; Aytac, A. Effects of Ammonium Polyphosphate and Triphenyl Phosphate on the Flame Retardancy, Thermal, and Mechanical Properties of Glass Fiber–Reinforced PLA/PC Composites. Fire Mater. 2019, 43, 277–282. [Google Scholar] [CrossRef]

- Zimmerer, C.; Matulaitiene, I.; Niaura, G.; Reuter, U.; Janke, A.; Boldt, R.; Sablinskas, V.; Steiner, G. Nondestructive Characterization of the Polycarbonate—Octadecylamine Interface by Surface Enhanced Raman Spectroscopy. Polym. Test. 2019, 73, 152–158. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rubio-de-Hita, P. Influence of Polycarbonate Waste on Gypsum Composites: Mechanical and Environmental Study. J. Clean. Prod. 2019, 218, 21–37. [Google Scholar] [CrossRef]

- Abenojar, J.; Torregrosa-Coque, R.; Martínez, M.A.; Martín-Martínez, J.M. Surface Modifications of Polycarbonate (PC) and Acrylonitrile Butadiene Styrene (ABS) Copolymer by Treatment with Atmospheric Plasma. Surf. Coat. Technol. 2009, 203, 2173–2180. [Google Scholar] [CrossRef]

- Aquino, F.W.B.; Paranhos, C.M.; Pereira-Filho, E.R. Method for the Production of Acrylonitrile–Butadiene–Styrene (ABS) and Polycarbonate (PC)/ABS Standards for Direct Sb Determination in Plastics from e-Waste Using Laser-Induced Breakdown Spectroscopy. J. Anal. At. Spectrom. 2016, 31, 1228–1233. [Google Scholar] [CrossRef]

- Xiao, C.; Leng, X.; Zhang, X.; Zheng, K.; Tian, X. Improved Thermal Properties by Controlling Selective Distribution of AlN and MWCNT in Immiscible Polycarbonate (PC)/Polyamide 66 (PA66) Composites. Compos. Part Appl. Sci. Manuf. 2018, 110, 133–141. [Google Scholar] [CrossRef]

- Standau, T.; Hädelt, B.; Fafara, M.; Altstädt, V. Development of a Bead Foam Based on the Engineering Polymer Polybutylene Terephthalate. AIP Conf. Proc. 2019, 2055, 060004. [Google Scholar] [CrossRef]

- Gemmeke, N.; Feldmann, M.; Heim, H.-P. Processing and Characterization of Engineering Biocomposites Based on Polybutylenterephthalat (PBT) and Polytrimethylentherephthalat (PTT) with Regenerated Cellulose Fibers Modified with Maleic Anhydride Grafted Polyethylene as a Processing Agent. Compos. Part Appl. Sci. Manuf. 2019, 118, 327–335. [Google Scholar] [CrossRef]

- Kchaou, M.; Torres, E.; Ylla, N.; Colella, M.; Da Cruz-Boisson, F.; Cassagnau, P.; Espuche, E.; Bounor-Legaré, V. Enhanced Hydrophobicity and Reduced Water Transport Properties in Alkylalkoxysilane Modified Poly(Butylene Terephthalate) Using Reactive Extrusion. Mater. Chem. Phys. 2019, 223, 597–606. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, X.; Xu, T.; Salem, D.R.; Fong, H. Hybrid Multi-Scale Thermoplastic Composites Reinforced with Interleaved Nanofiber Mats Using in-Situ Polymerization of Cyclic Butylene Terephthalate. Compos. Commun. 2019, 12, 91–97. [Google Scholar] [CrossRef]

- De Almeida, A.; Nébouy, M.; Baeza, G.P. Bimodal Crystallization Kinetics of PBT/PTHF Segmented Block Copolymers: Impact of the Chain Rigidity. Macromolecules 2019, 52, 1227–1240. [Google Scholar] [CrossRef]

- Slot, H.M.; IJzerman, R.M.; le Feber, M.; Nord-Varhaug, K.; van der Heide, E. Rain Erosion Resistance of Injection Moulded and Compression Moulded Polybutylene Terephthalate PBT. Wear 2018, 414–415, 234–242. [Google Scholar] [CrossRef]

- Dechet, M.A.; Gómez Bonilla, J.S.; Lanzl, L.; Drummer, D.; Bück, A.; Schmidt, J.; Peukert, W. Spherical Polybutylene Terephthalate (PBT)—Polycarbonate (PC) Blend Particles by Mechanical Alloying and Thermal Rounding. Polymers 2018, 10, 1373. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rosenboom, J.-G.; De Lorenzi, L.; Storti, G.; Morbidelli, M. Reaction Kinetics and Simulations of Ring-Opening Polymerization for the Synthesis of Polybutylene Terephthalate. Polymer 2018, 146, 120–132. [Google Scholar] [CrossRef] [Green Version]

- Chiou, K.-C.; Chang, F.-C. Reactive Compatibilization of Polyamide-6 (PA 6)/Polybutylene Terephthalate (PBT) Blends by a Multifunctional Epoxy Resin. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 23–33. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Effect of Polybutylene Terephthalate (PBT) on Impact Property Improvement of Hybrid Kenaf/Glass Epoxy Composite. Mater. Lett. 2012, 67, 5–7. [Google Scholar] [CrossRef]

- Kuram, E.; Timur, G.; Ozcelik, B.; Yilmaz, F. Influences of Injection Conditions on Strength Properties of Recycled and Virgin PBT/PC/ABS. Mater. Manuf. Process. 2014, 29, 1260–1268. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Ray, S.; Archer, R.; Arif, K.M. Preparation and Characterization of Thermally Stable ABS/HDPE Blend for Fused Filament Fabrication. Mater. Manuf. Process. 2020, 35, 230–240. [Google Scholar] [CrossRef]

- Li, J.; Li, C.; Liao, Q.; Xu, Z. Environmentally-Friendly Technology for Rapid on-Line Recycling of Acrylonitrile-Butadiene-Styrene, Polystyrene and Polypropylene Using near-Infrared Spectroscopy. J. Clean. Prod. 2019, 213, 838–844. [Google Scholar] [CrossRef]

- Selvamani, S.K.; Samykano, M.; Subramaniam, S.R.; Ngui, W.K.; Kadirgama, K.; Sudhakar, K.; Idris, M.S. Preliminary Investigation of Acrylonitrile Butadiene Styrene (ABS) Properties. AIP Conf. Proc. 2019, 2059, 020040. [Google Scholar] [CrossRef] [Green Version]

- Huang, B.; Meng, S.; He, H.; Jia, Y.; Xu, Y.; Huang, H. Study of Processing Parameters in Fused Deposition Modeling Based on Mechanical Properties of Acrylonitrile-Butadiene-Styrene Filament. Polym. Eng. Sci. 2019, 59, 120–128. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, Y.; Wang, W.; Lv, L.; Li, C.; Zhang, J. Recycled Polycarbonate/Acrylonitrile–Butadiene–Styrene Reinforced and Toughened through Chemical Compatibilization. J. Appl. Polym. Sci. 2019, 136, 47537. [Google Scholar] [CrossRef]

- Jung, D.-J.; Cheon, J.; Na, S.-J. Effect of Surface Pre-Oxidation on Laser Assisted Joining of Acrylonitrile Butadiene Styrene (ABS) and Zinc-Coated Steel. Mater. Des. 2016, 99, 1–9. [Google Scholar] [CrossRef]

- Jyoti, J.; Basu, S.; Singh, B.P.; Dhakate, S.R. Superior Mechanical and Electrical Properties of Multiwall Carbon Nanotube Reinforced Acrylonitrile Butadiene Styrene High Performance Composites. Compos. Part B Eng. 2015, 83, 58–65. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Song, J.; He, M.; Song, J.; Xia, K. Recycling of Acrylonitrile–Butadiene–Styrene (ABS) Copolymers from Waste Electrical and Electronic Equipment (WEEE), through Using an Epoxy-Based Chain Extender. Polym. Degrad. Stab. 2015, 112, 167–174. [Google Scholar] [CrossRef]

- Li, Y.; Wu, X.; Song, J.; Li, J.; Shao, Q.; Cao, N.; Lu, N.; Guo, Z. Reparation of Recycled Acrylonitrile- Butadiene-Styrene by Pyromellitic Dianhydride: Reparation Performance Evaluation and Property Analysis. Polymer 2017, 124, 41–47. [Google Scholar] [CrossRef]

- Wang, N.; Liu, Y.; Liu, Y.; Wang, Q. A Shear Pan Mill for Preparation of Ultrafine Polyamide 66 Powder Using Sodium Sulfate Ionic Crystals as Grinding Aid. Mater. Manuf. Process. 2017, 32, 115–120. [Google Scholar] [CrossRef]

- Negi, S.; Sharma, R.K. Influence of Processing Variables on Dynamic Mechanical Response of Laser-Sintered Glass-Filled Polyamide. Mater. Manuf. Process. 2015, 30, 1431–1441. [Google Scholar] [CrossRef]

- Rytlewski, P. Influence of Glass Fibre Content on Catalytic and Adhesion Properties of Laser Irradiated Polyamide Composites. Surf. Eng. 2013, 29, 713–719. [Google Scholar] [CrossRef]

- Zheng, R.; Zhang, X.; Zhang, Z.; Niu, H.; Wang, C.; Wang, W. Preparation and Multifunction of Electrochromic Polyamides Containing Flexible Backbone Chains with Electrochemical, Fluorescence and Memory Properties. Appl. Surf. Sci. 2019, 478, 906–915. [Google Scholar] [CrossRef]

- Krause, B.; Kroschwald, L.; Pötschke, P. The Influence of the Blend Ratio in PA6/PA66/MWCNT Blend Composites on the Electrical and Thermal Properties. Polymers 2019, 11, 122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zou, G.; Wang, P.; Feng, W.; Ren, Z.; Ji, J. Bio-Based Transparent Polyamide 10T/10I/1012 with High Performance. J. Appl. Polym. Sci. 2019, 136, 47305. [Google Scholar] [CrossRef]

- Nagel, K.; Spange, S. Polyamide/Silica Hybrid Materials by Anionic Melt Polymerization of Lactam-Substituted Silane Monomers with ε-Caprolactam. Eur. Polym. J. 2019, 113, 385–394. [Google Scholar] [CrossRef]

- Winnacker, M.; Rieger, B. Biobased Polyamides: Recent Advances in Basic and Applied Research. Macromol. Rapid Commun. 2016, 37, 1391–1413. [Google Scholar] [CrossRef] [PubMed]

- Battegazzore, D.; Salvetti, O.; Frache, A.; Peduto, N.; De Sio, A.; Marino, F. Thermo-Mechanical Properties Enhancement of Bio-Polyamides (PA10.10 and PA6.10) by Using Rice Husk Ash and Nanoclay. Compos. Part Appl. Sci. Manuf. 2016, 81, 193–201. [Google Scholar] [CrossRef]

- Van Velthoven, J.L.J.; Gootjes, L.; Noordover, B.A.J.; Meuldijk, J. Bio-Based, Amorphous Polyamides with Tunable Thermal Properties. Eur. Polym. J. 2015, 66, 57–66. [Google Scholar] [CrossRef]

- Wu, J.; Mizuno, Y.; Nakamura, K. Enhancement in Mechanical Quality Factors of Poly Phenylene Sulfide under High-Amplitude Ultrasonic Vibration through Thermal Annealing. Ultrasonics 2019, 91, 52–61. [Google Scholar] [CrossRef]

- Zhao, L.; Huang, Z.; Xiong, S.; Peng, J.; Sun, J.; Yin, X.; Guo, G.; Xiong, B.; Song, X.; Huang, L.; et al. Polyphenylene Sulfide Composite Laminate from Flexible Nonwovens and Carbon Fiber Fabrics Prepared by Thermal Lamination and Thermal Treatment. Polym. Bull. 2019. [Google Scholar] [CrossRef]

- Huang, H.; Li, Y.; Zhao, L.; Yu, Y.; Xu, J.; Yin, X.; Chen, S.; Wu, J.; Yue, H.; Wang, H.; et al. A Facile Fabrication of Chitosan Modified PPS-Based Microfiber Membrane for Effective Antibacterial Activity and Oil-in-Water Emulsion Separation. Cellulose 2019, 26, 2599–2611. [Google Scholar] [CrossRef]

- Xing, J.; Ni, Q.-Q.; Deng, B.; Liu, Q. Morphology and Properties of Polyphenylene Sulfide (PPS)/Polyvinylidene Fluoride (PVDF) Polymer Alloys by Melt Blending. Compos. Sci. Technol. 2016, 134, 184–190. [Google Scholar] [CrossRef]

- Gu, J.; Guo, Y.; Yang, X.; Liang, C.; Geng, W.; Tang, L.; Li, N.; Zhang, Q. Synergistic Improvement of Thermal Conductivities of Polyphenylene Sulfide Composites Filled with Boron Nitride Hybrid Fillers. Compos. Part Appl. Sci. Manuf. 2017, 95, 267–273. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Q.; Li, Y.; Zhou, S.; Zou, H.; Liang, M. Enhanced Mechanical and Tribological Properties in Polyphenylene Sulfide/Polytetrafluoroethylene Composites Reinforced by Short Carbon Fiber. Compos. Part B Eng. 2016, 91, 579–588. [Google Scholar] [CrossRef]

- Huang, H.; Liu, M.; Li, Y.; Yu, Y.; Yin, X.; Wu, J.; Chen, S.; Xu, J.; Wang, L.; Wang, H. Polyphenylene Sulfide Microfiber Membrane with Superhydrophobicity and Superoleophilicity for Oil/Water Separation. J. Mater. Sci. 2018, 53, 13243–13252. [Google Scholar] [CrossRef]

- Chen, D.; Kang, Z.; Hirahara, H.; Aisawa, S.; Li, W. Adsorption Behaviors of Deposition-Targeted Metallic Ions onto Thiol-Containing Silane Modified Liquid Crystal Polymer Surfaces. Appl. Surf. Sci. 2019, 479, 368–374. [Google Scholar] [CrossRef]

- Li, X.; Ma, S.; Hu, J.; Ni, Y.; Lin, Z.; Yu, H. Photo-Activated Bimorph Composites of Kapton and Liquid-Crystalline Polymer towards Biomimetic Circadian Rhythms of Albizia Julibrissin Leaves. J. Mater. Chem. C 2019, 7, 622–629. [Google Scholar] [CrossRef]

- Gantenbein, S.; Masania, K.; Woigk, W.; Sesseg, J.P.W.; Tervoort, T.A.; Studart, A.R. Three-Dimensional Printing of Hierarchical Liquid-Crystal-Polymer Structures. Nature 2018, 561, 226. [Google Scholar] [CrossRef]

- Xu, F.; Xin, Y.; Li, T. Friction-Induced Surface Textures of Liquid Crystalline Polymer Evaluated by Atomic Force Microscopy, Spectroscopy and Nanoindentation. Polym. Test. 2018, 68, 146–152. [Google Scholar] [CrossRef]

- Fan, W.; Tong, X.; Li, G.; Zhao, Y. Photoresponsive Liquid Crystalline Polymer Single-Chain Nanoparticles. Polym. Chem. 2017, 8, 3523–3529. [Google Scholar] [CrossRef]

- Li, C.; Yun, J.-H.; Kim, H.; Cho, M. Light Propagation and Photoactuation in Densely Cross-Linked Azobenzene-Functionalized Liquid-Crystalline Polymers: Contribution of Host and Concerted Isomerism. Macromolecules 2016, 49, 6012–6020. [Google Scholar] [CrossRef]

- Xiang, Z.; Chen, S.; Luo, Y.; Li, P.; Zhang, H. Influence of the Side-Chain Structure and Molecular Weight on the Re-Entrant Behaviors of Mesogen-Jacketed Liquid Crystalline Polymers. RSC Adv. 2016, 6, 78516–78527. [Google Scholar] [CrossRef]

- Guo, D.; Khan, A.U.; Liu, T.; Zhou, Z.; Liu, G. Sub-10 Nm Domains in High-Performance Polyetherimides. Polym. Chem. 2019, 10, 379–385. [Google Scholar] [CrossRef]

- Vega, J.; Andrio, A.; Lemus, A.A.; Díaz, J.A.I.; del Castillo, L.F.; Gavara, R.; Compañ, V. Modification of Polyetherimide Membranes with ZIFs Fillers for CO2 Separation. Sep. Purif. Technol. 2019, 212, 474–482. [Google Scholar] [CrossRef]

- Cacciotti, I.; Rinaldi, M.; Fabbrizi, J.; Nanni, F. Innovative Polyetherimide and Diatomite Based Composites: Influence of the Diatomite Kind and Treatment. J. Mater. Res. Technol. 2019. [Google Scholar] [CrossRef]

- Liu, J.; Su, J.; Li, R.; Zhao, L.; Lu, Y.; Liu, X. Characterization of Cavities in Polyetherimide and the Influence on Insulation Performance of Ultra-High Voltage Pulse. Mater. Lett. 2019, 240, 153–156. [Google Scholar] [CrossRef]

- Jiao, Y.; Shi, H.; Tang, J.; Li, F.; Wang, S. Improvement of Radio Frequency (RF) Heating Uniformity on Low Moisture Foods with Polyetherimide (PEI) Blocks. Food Res. Int. 2015, 74, 106–114. [Google Scholar] [CrossRef]

- Karisma, D.; Febrianto, G.; Mangindaan, D. Polyetherimide Thin Film Composite (PEI-TFC) Membranes for Nanofiltration Treatment of Dyes Wastewater. IOP Conf. Ser. Earth Environ. Sci. 2018, 195, 012057. [Google Scholar] [CrossRef]

- Blanco, I.; Cicala, G.; Ognibene, G.; Rapisarda, M.; Recca, A. Thermal Properties of Polyetherimide/Polycarbonate Blends for Advanced Applications. Polym. Degrad. Stab. 2018, 154, 234–238. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, H.; Liu, Z.; Zhang, X.; Zhang, W.; Chen, X.; Zhu, Y. Durable Fluorine-Free Superhydrophobic Polyethersulfone (PES) Composite Coating with Uniquely Weathering Stability, Anti-Corrosion and Wear-Resistance. Prog. Org. Coat. 2019, 127, 16–26. [Google Scholar] [CrossRef]

- Zangeneh, H.; Zinatizadeh, A.A.; Zinadini, S.; Feyzi, M.; Bahnemann, D.W. Preparation and Characterization of a Novel Photocatalytic Self-Cleaning PES Nanofiltration Membrane by Embedding a Visible-Driven Photocatalyst Boron Doped-TiO2SiO2/CoFe2O4 Nanoparticles. Sep. Purif. Technol. 2019, 209, 764–775. [Google Scholar] [CrossRef]

- Ballout, W.; Van Velthem, P.; Magnin, D.; Henry, E.; Sclavons, M.; Pardoen, T.; Bailly, C. Specific Influence of Polyethersulfone Functionalization on the Delamination Toughness of Modified Carbon Fiber Reinforced Polymer Processed by Resin Transfer Molding. Polym. Eng. Sci. 2019, 59, 996–1009. [Google Scholar] [CrossRef]

- Khorshidi, B.; Hosseini, S.A.; Ma, G.; McGregor, M.; Sadrzadeh, M. Novel Nanocomposite Polyethersulfone- Antimony Tin Oxide Membrane with Enhanced Thermal, Electrical and Antifouling Properties. Polymer 2019, 163, 48–56. [Google Scholar] [CrossRef]

- Lin, J.; Ye, W.; Zhong, K.; Shen, J.; Jullok, N.; Sotto, A.; Van der Bruggen, B. Enhancement of Polyethersulfone (PES) Membrane Doped by Monodisperse Stöber Silica for Water Treatment. Chem. Eng. Process. Process Intensif. 2016, 107, 194–205. [Google Scholar] [CrossRef]

- Rajabi, H.; Ghaemi, N.; Madaeni, S.S.; Daraei, P.; Astinchap, B.; Zinadini, S.; Razavizadeh, S.H. Nano-ZnO Embedded Mixed Matrix Polyethersulfone (PES) Membrane: Influence of Nanofiller Shape on Characterization and Fouling Resistance. Appl. Surf. Sci. 2015, 349, 66–77. [Google Scholar] [CrossRef]

- Nasrollahi, N.; Vatanpour, V.; Aber, S.; Mahmoodi, N.M. Preparation and Characterization of a Novel Polyethersulfone (PES) Ultrafiltration Membrane Modified with a CuO/ZnO Nanocomposite to Improve Permeability and Antifouling Properties. Sep. Purif. Technol. 2018, 192, 369–382. [Google Scholar] [CrossRef]

- Chen, D.; Pi, C.; Chen, M.; He, L.; Xia, F.; Peng, S. Amplitude-Dependent Damping Properties of Ramie Fiber-Reinforced Thermoplastic Composites with Varying Fiber Content. Polym. Compos. 2019, 40, 2681–2689. [Google Scholar] [CrossRef]

- Baena, J.; Jiménez, G.; López-Ruiz, E.; Antich, C.; Griñán-Lisón, C.; Perán, M.; Gálvez-Martín, P.; Marchal, J. Volume-by-Volume Bioprinting of Chondrocytes-Alginate Bioinks in High Temperature Thermoplastic Scaffolds for Cartilage Regeneration. Exp. Biol. Med. 2019, 244, 13–21. [Google Scholar] [CrossRef]

- Mamalis, D.; Obande, W.; Koutsos, V.; Blackford, J.R.; Ó Brádaigh, C.M.; Ray, D. Novel Thermoplastic Fibre-Metal Laminates Manufactured by Vacuum Resin Infusion: The Effect of Surface Treatments on Interfacial Bonding. Mater. Des. 2019, 162, 331–344. [Google Scholar] [CrossRef]

- Jose, A.J.; Alagar, M.; Thomas, P.S. Preparation and Characterization of Organoclay Filled Polysulfone Nanocomposites. Mater. Manuf. Process. 2012, 27, 247–254. [Google Scholar] [CrossRef]

- Barbe, A.; Bökamp, K.; Kummerlöwe, C.; Sollmann, H.; Vennemann, N.; Vinzelberg, S. Investigation of Modified SEBS-Based Thermoplastic Elastomers by Temperature Scanning Stress Relaxation Measurements. Polym. Eng. Sci. 2005, 45, 1498–1507. [Google Scholar] [CrossRef]

- Kashi, S.; Hadigheh, S.A.; Varley, R. Microwave Attenuation of Graphene Modified Thermoplastic Poly(Butylene Adipate-Co-Terephthalate) Nanocomposites. Polymers 2018, 10, 582. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peters, E.N. 1—Engineering Thermoplastics—Materials, Properties, Trends. In Applied Plastics Engineering Handbook, 2nd ed.; Kutz, M., Ed.; Plastics Design Library; William Andrew Publishing: Norwich, NY, USA, 2017; pp. 3–26. [Google Scholar] [CrossRef]

- Rao, Y.S.; Mohan, N.S.; Shetty, N.; Shivamurthy, B. Drilling and Structural Property Study of Multi-Layered Fiber and Fabric Reinforced Polymer Composite-a Review. Mater. Manuf. Process. 2019, 34, 1549–1579. [Google Scholar] [CrossRef]

- Natarajan, S. Fundamental Principles of Polymeric Materials by Christopher S. Brazel and Stephen L. Rosen. Mater. Manufact. Process. 2015, 30. [Google Scholar] [CrossRef]

- Li, R.; Wu, G.; Hao, Y.; Peng, J.; Zhai, M. Chapter Five - Radiation Degradation or Modification of Poly(Tetrafluoroethylene) and Natural Polymers. In Radiation Technology for Advanced Materials; Wu, G., Zhai, M., Wang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 141–182. [Google Scholar] [CrossRef]

- Ghazali, Z.; Johnson, A.F.; Dahlan, K.Z. Radiation Crosslinked Thermoplastics Natural Rubber (TPNR) Foams. Radiat. Phys. Chem. 1999, 55, 73–79. [Google Scholar] [CrossRef]

- Voit, W.; Ware, T.; Gall, K. Radiation Crosslinked Shape-Memory Polymers. Polymer 2010, 51, 3551–3559. [Google Scholar] [CrossRef]

- Gehring, J.; Zyball, A. Radiation Crosslinking of Polymers-Status, Current Issues, Trends and Challenges. Radiat. Phys. Chem. 1995, 46, 931–936. [Google Scholar] [CrossRef]

- Shi, X.; Wang, X.; Fu, C.; Ran, X. Dual-Shape Memory Effect in Radiation Crosslinked Thermoplastic Blends: Fabrication, Optimization and Mechanisms. RSC Adv. 2015, 5, 61601–61611. [Google Scholar] [CrossRef]

- Leisen, C.; Seefried, A.; Drummer, D. Post-Crosslinking Behavior of Radiation Crosslinked Polyamide 66 during Vibration Welding. Polym. Eng. Sci. 2016, 56, 735–742. [Google Scholar] [CrossRef]

- Mohsin, M.A.A.; Iannucci, L.; Greenhalgh, E.S. Fibre-Volume-Fraction Measurement of Carbon Fibre Reinforced Thermoplastic Composites Using Thermogravimetric Analysis. Heliyon 2019, 5, e01132. [Google Scholar] [CrossRef] [Green Version]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling Glass Fiber Thermoplastic Composites from Wind Turbine Blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Gaugler, M.; Luedtke, J.; Grigsby, W.J.; Krause, A. A New Methodology for Rapidly Assessing Interfacial Bonding within Fibre-Reinforced Thermoplastic Composites. Int. J. Adhes. Adhes. 2019, 89, 66–71. [Google Scholar] [CrossRef]

- Arhant, M.; Briançon, C.; Burtin, C.; Davies, P. Carbon/Polyamide 6 Thermoplastic Composite Cylinders for Deep Sea Applications. Compos. Struct. 2019, 212, 535–546. [Google Scholar] [CrossRef] [Green Version]

- Unal, H.; Mimaroglu, A. Comparison of Tribological Performance of Some Neat Polymer and Polymers Composites. Surf. Eng. 2013, 29, 455–461. [Google Scholar] [CrossRef]

- Kumar, S.; Chauhan, S.; Rakesh, P.; Singh, I.; Davim, J. Drilling of Glass Fiber/Vinyl Ester Composites with Fillers. Mater. Manuf. Process. 2012, 27, 314–319. [Google Scholar] [CrossRef]

- Perisic, S.D.; Radovic, I.; Petrovic, M.; Marinkovic, A.; Stojanovic, D.; Uskokovic, P.; Radojevic, V. Processing of Hybrid Wood Plastic Composite Reinforced with Short PET Fibers. Mater. Manuf. Process. 2018, 33, 572–579. [Google Scholar] [CrossRef]

- Singh, K.; Nanda, T.; Mehta, R. Processing of Polyethylene Terephthalate Fiber Reinforcement to Improve Compatibility with Constituents of GFRP Nanocomposites. Mater. Manuf. Process. 2018, 33, 165–173. [Google Scholar] [CrossRef]

- Jiang, M.; Li, H.; Fang, D.; Liu, L.; Tai, Q.; Li, L.; Dong, L.; Xie, H.; Xiong, C. Structure–Property Relationship in Injection-Molded Polypropylene/Clay Composite Foams. Mater. Manuf. Process. 2014, 29, 160–165. [Google Scholar] [CrossRef]

- Kaci, S.; Rahmoune, R.; Kezzoula, F.; Boudiaf, Y.; Keffous, A.; Manseri, A.; Menari, H.; Cheraga, H.; Guerbous, L.; Belkacem, Y.; et al. Impact of Porous SiC-Doped PVA Based LDS Layer on Electrical Parameters of Si Solar Cells. Opt. Mater. 2018, 80, 225–232. [Google Scholar] [CrossRef]

- Zhang, Q.; Zheng, R.; Ding, J.; Wei, W. Excellent Luminous Efficiency and High Thermal Stability of Glass-in-LuAG Ceramic for Laser-Diode-Pumped Green-Emitting Phosphor. Opt. Lett. 2018, 43, 3566–3569. [Google Scholar] [CrossRef]

- Hardy, M.T.; Feezell, D.F.; DenBaars, S.P.; Nakamura, S. Group III-Nitride Lasers: A Materials Perspective. Mater. Today 2011, 14, 408–415. [Google Scholar] [CrossRef]

- Nakamura, S. Materials Issues for InGaN-Based Lasers. J. Electron. Mater. 1998, 27, 160–165. [Google Scholar] [CrossRef]

- Sanner, N.; Huot, N.; Audouard, E.; Larat, C.; Huignard, J.-P. Direct Ultrafast Laser Micro-Structuring of Materials Using Programmable Beam Shaping. Opt. Lasers Eng. 2007, 45, 737–741. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Malinauskas, M.; Schlie, S.; Chichkov, B.; Gittard, S.; Narayan, R.; Löbler, M.; Sternberg, K.; Schmitz, K.-P.; Haverich, A. Three-Dimensional Laser Micro- and Nano-Structuring of Acrylated Poly(Ethylene Glycol) Materials and Evaluation of Their Cytoxicity for Tissue Engineering Applications. Acta Biomater. 2011, 7, 967–974. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Faraz, A.; Heymann, T.; Biermann, D. Experimental Investigations on Drilling GFRP Epoxy Composite Laminates Using Specialized and Conventional Uncoated Cemented Carbide Drills. Mater. Manuf. Process. 2011, 26, 609–617. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, L.; Chen, M.; Ren, F. Experimental Study on Mechanical Drilling of Carbon/Epoxy Composite-Ti6Al4V Stacks. Mater. Manuf. Process. 2019, 34, 715–725. [Google Scholar] [CrossRef]

- Li, C.; Dong, H.; Zhang, W. Low-Temperature Plasma Treatment of Carbon Fibre/Epoxy Resin Composite. Surf. Eng. 2018, 34, 870–876. [Google Scholar] [CrossRef]

- Garg, M.; Sharma, S.; Mehta, R. Processing of Functionalized and Pristine Carbon Nanotube Epoxy Composites with Silane-Treated Glass Fiber. Mater. Manuf. Process. 2016, 31, 2044–2056. [Google Scholar] [CrossRef]

- Poorzeinolabedin, M.; Golzar, M. Improving the Woven Glass/Epoxy Composite for Automobile Exterior Body Cover. Mater. Manuf. Process. 2011, 26, 562–566. [Google Scholar] [CrossRef]

- Kordass, T.; Bachy, B.; Weisser, M.; Franke, J. Laser-Assisted Selective Activation of Injection Molded Chip Packaging Devices with Thermoset Substrate Materials for Intelligent Connectivity Systems in Automobiles. Procedia CIRP 2017, 63, 101–106. [Google Scholar] [CrossRef]

- Nishida, H.; Carvelli, V.; Fujii, T.; Okubo, K. Thermoplastic vs. Thermoset Epoxy Carbon Textile Composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012043. [Google Scholar] [CrossRef]

- Jony, B.; Thapa, M.; Mulani, S.B.; Roy, S. Repeatable Self-Healing of Thermosetting Fiber Reinforced Polymer Composites with Thermoplastic Healant. Smart Mater. Struct. 2019, 28, 025037. [Google Scholar] [CrossRef]

- Sobkowicz-Kline, M.; Budhlall, B.M.; Mead, J.L. Synthetic Resins and Plastics. In Handbook of Industrial Chemistry and Biotechnology; Kent, J.A., Bommaraju, T.V., Barnicki, S.D., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 1397–1462. [Google Scholar] [CrossRef]

- Xia, Y. Hole Accumulation Effect on Laser-Assisted Field Evaporation of Insulators. Ultramicroscopy 2019, 196, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Baranauskaite, V.E.; Novomlinskii, M.O.; Tumkin, I.I.; Khairullina, E.M.; Mereshchenko, A.S.; Balova, I.A.; Panov, M.S.; Kochemirovsky, V.A. In Situ Laser-Induced Synthesis of Gas Sensing Microcomposites Based on Molybdenum and Its Oxides. Compos. Part B Eng. 2019, 157, 322–330. [Google Scholar] [CrossRef]

- Xu, J.; Li, X.; Zhong, Y.; Qi, J.; Wang, Z.; Chai, Z.; Li, W.; Jing, C.; Cheng, Y. Glass-Channel Molding Assisted 3D Printing of Metallic Microstructures Enabled by Femtosecond Laser Internal Processing and Microfluidic Electroless Plating. Adv. Mater. Technol. 2018, 3, 1800372. [Google Scholar] [CrossRef]

- Ratautas, K.; Jagminienė, A.; Stankevičienė, I.; Norkus, E.; Račiukaitis, G. Laser Assisted Fabrication of Copper Traces on Dielectrics by Electroless Plating. Procedia CIRP 2018, 74, 367–370. [Google Scholar] [CrossRef]

- Ninz, P.; Kern, F.; Ermantraut, E.; Müller, H.; Eberhardt, W.; Zimmermann, A.; Gadow, R. Doping of Alumina Substrates for Laser Induced Selective Metallization. Procedia CIRP 2018, 68, 772–777. [Google Scholar] [CrossRef]

- Waugh, D.; Lawrence, J. CO2 Laser Surface Patterning of Nylon 6, 6 and Subsequent Effects on Wettability Characteristics and Apatite Response. Surf. Eng. 2011, 27, 724–728. [Google Scholar] [CrossRef]

- Bellmann, M.; Gerhard, C.; Haese, C.; Wieneke, S.; Viöl, W. DBD Plasma Improved Spot Repair of Automotive Polymer Surfaces. Surf. Eng. 2012, 28, 754–758. [Google Scholar] [CrossRef]

- Ahmed, N.; Darwish, S.; Alahmari, A.M. Laser Ablation and Laser-Hybrid Ablation Processes: A Review. Mater. Manuf. Process. 2016, 31, 1121–1142. [Google Scholar] [CrossRef]

- Sathiyamurthy, R.; Duraiselvam, M. Selective Laser Ablation of CFRP Composite to Enhance Adhesion Bonding. Mater. Manuf. Process. 2019, 34, 1296–1305. [Google Scholar] [CrossRef]

- Mittal, K.L.; Bahners, T. Laser Surface Modification and Adhesion; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Konieczkowska, J.; Schab-Balcerzak, E.; Libera, M.; Mihaila, I.; Sava, I. Surface Relief Gratings in Azopolyimides Induced by Pulsed Laser Irradiation. Eur. Polym. J. 2019, 110, 85–89. [Google Scholar] [CrossRef]

- Ponnamma, D.; Sivakumar, V.; Popelka, A.; Hussein, Y.H.A.; Al Ali Al-Maadeed, M. Laser Induced Periodic Surface Structures on Nano Metal Oxide Filled Polyvinylidene Fluoride Nanocomposites. Optik 2019, 176, 372–383. [Google Scholar] [CrossRef]

- Arai, S.; Tsunoda, S.; Yamaguchi, A.; Ougizawa, T. Effect of Anisotropy in the Build Direction and Laser-Scanning Conditions on Characterization of Short-Glass-Fiber-Reinforced PBT for Laser Sintering. Opt. Laser Technol. 2019, 113, 345–356. [Google Scholar] [CrossRef]

- Curylofo-Zotti, F.A.; Scheffel, D.L.S.; Macedo, A.P.; de Souza-Gabriel, A.E.; Hebling, J.; Corona, S.A.M. Effect of Er:YAG Laser Irradiation and Chitosan Biomodification on the Stability of Resin/Demineralized Bovine Dentin Bond. J. Mech. Behav. Biomed. Mater. 2019, 91, 220–228. [Google Scholar] [CrossRef]

- Liu, H.; Tang, Y.; Xie, Y.; Lu, L.; Wan, Z.; Tang, W.; Yang, L.; Yang, D. Effect of Pulsed Nd:YAG Laser Processing Parameters on Surface Properties of Polyimide Films. Surf. Coat. Technol. 2019, 361, 102–111. [Google Scholar] [CrossRef]

- Sionkowska, A.; Wisniewski, M.; Kaczmarek, H.; Skopinska, J.; Chevallier, P.; Mantovani, D.; Lazare, S.; Tokarev, V. The Influence of UV Irradiation on Surface Composition of Collagen/PVP Blended Films. Appl. Surf. Sci. 2006, 253, 1970–1977. [Google Scholar] [CrossRef]

- Serafetinides, A.A.; Makropoulou, M.I.; Skordoulis, C.D.; Kar, A.K. Ultra-Short Pulsed Laser Ablation of Polymers. Appl. Surf. Sci. 2001, 180, 42–56. [Google Scholar] [CrossRef]

- Rebollar, E.; Hernández, M.; Sanz, M.; Pérez, S.; Ezquerra, T.A.; Castillejo, M. Laser-Induced Surface Structures on Gold-Coated Polymers: Influence of Morphology on Surface-Enhanced Raman Scattering Enhancement. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef] [Green Version]

- Michaljaničová, I.; Slepička, P.; Heitz, J.; Barb, R.A.; Sajdl, P.; Švorčík, V. Comparison of KrF and ArF Excimer Laser Treatment of Biopolymer Surface. Appl. Surf. Sci. 2015, 339, 144–150. [Google Scholar] [CrossRef]

- Li, T.; Hou, Z.; Fu, Y.; Yu, J.; Gu, W.; Wang, Z. Correction of Self-Absorption Effect in Calibration-Free Laser-Induced Breakdown Spectroscopy (CF-LIBS) with Blackbody Radiation Reference. Anal. Chim. Acta 2019, 1058, 39–47. [Google Scholar] [CrossRef]

- Shukla, P.; Lawrence, J. Distribution of Temperature during Fibre Laser Radiation and Effects Thereon Phase Transformation of ZrO2 Engineering Ceramic. Surf. Eng. 2011, 27, 742–748. [Google Scholar] [CrossRef]

- Yilbas, B. Laser Ablation of Phosphor Bronze for Superhydrophobic Surface. Surf. Eng. 2016, 32, 885–892. [Google Scholar] [CrossRef]

- Yilbas, B.; Arif, A.; Karatas, C. Laser Treatment of Silicon at Nitrogen Ambient: Thermal Stress Analysis. Surf. Eng. 2011, 27, 436–444. [Google Scholar] [CrossRef]

- Tyurin, A.; Nagavkin, S.; Malikov, A.; Orishich, A. Microstructure of WC–Co Hard Alloy Surface after Laser Treatment. Surf. Eng. 2015, 31, 74–77. [Google Scholar] [CrossRef]

- Hashim, M.; Sarath Raghavendra Babu, K.; Duraiselvam, M.; Natu, H.; Muthupandi, V.; Sivaprasad, K.; Rajith, K. Tribological Studies on Laser Surface Melted Hastelloy C-276. Surf. Eng. 2013, 29, 531–535. [Google Scholar] [CrossRef]

- Peng, W.Y.; Cassady, S.J.; Strand, C.L.; Goldenstein, C.S.; Spearrin, R.M.; Brophy, C.M.; Jeffries, J.B.; Hanson, R.K. Single-Ended Mid-Infrared Laser-Absorption Sensor for Time-Resolved Measurements of Water Concentration and Temperature within the Annulus of a Rotating Detonation Engine. Proc. Combust. Inst. 2019, 37, 1435–1443. [Google Scholar] [CrossRef]

- Jansen, E.D.; van Leeuwen, T.G.; Motamedi, M.; Borst, C.; Welch, A.J. Temperature Dependence of the Absorption Coefficient of Water for Midinfrared Laser Radiation. Lasers Surg. Med. 1994, 14, 258–268. [Google Scholar] [CrossRef]

- Meier, M.; Romano, V.; Feurer, T. Material Processing with Pulsed Radially and Azimuthally Polarized Laser Radiation. Appl. Phys. A 2007, 86, 329–334. [Google Scholar] [CrossRef] [Green Version]

- Frenz, M.; Pratisto, H.; Konz, F.; Jansen, E.D.; Welch, A.J.; Weber, H.P. Comparison of the Effects of Absorption Coefficient and Pulse Duration of 2.12-/Spl Mu/m and 2.79-/Spl Mu/m Radiation on Laser Ablation of Tissue. IEEE J. Quantum Electron. 1996, 32, 2025–2036. [Google Scholar] [CrossRef]

- Angelsky, O.V.; Bekshaev, A.Y.; Maksimyak, P.P.; Maksimyak, A.P.; Hanson, S.G.; Kontush, S.M. Controllable Generation and Manipulation of Micro-Bubbles in Water with Absorptive Colloid Particles by CW Laser Radiation. Opt. Express 2017, 25, 5232–5243. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torrisi, L.; Calcagno, L.; Giulietti, D.; Cutroneo, M.; Zimbone, M.; Skala, J. Laser Irradiations of Advanced Targets Promoting Absorption Resonance for Ion Acceleration in TNSA Regime. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 355, 221–226. [Google Scholar] [CrossRef]

- Sun, S.; Chen, J.; Jiang, K.; Tang, Z.; Wang, Y.; Li, Z.; Liu, C.; Wu, A.; Lin, H. Ce6-Modified Carbon Dots for Multimodal-Imaging-Guided and Single-NIR-Laser-Triggered Photothermal/Photodynamic Synergistic Cancer Therapy by Reduced Irradiation Power. ACS Appl. Mater. Interfaces 2019, 11, 5791–5803. [Google Scholar] [CrossRef] [PubMed]

- Du, Q.; Chen, T.; Liu, J.; Zeng, X. Surface Microstructure and Chemistry of Polyimide by Single Pulse Ablation of Picosecond Laser. Appl. Surf. Sci. 2018, 434, 588–595. [Google Scholar] [CrossRef]

- Neelgund, G.M.; Oki, A. Photothermal Effect of Ag Nanoparticles Deposited over Poly(Amidoamine) Grafted Carbon Nanotubes. J. Photochem. Photobiol. Chem. 2018, 364, 309–315. [Google Scholar] [CrossRef]

- Hatanaka, K.; Kawao, M.; Tsuboi, Y.; Fukumura, H.; Masuhara, H. Switching from Photochemical to Photothermal Mechanism in Laser Ablation of Benzene Solutions. J. Appl. Phys. 1997, 82, 5799–5806. [Google Scholar] [CrossRef]

- Melancon, M.P.; Lu, W.; Yang, Z.; Zhang, R.; Cheng, Z.; Elliot, A.M.; Stafford, J.; Olson, T.; Zhang, J.Z.; Li, C. In Vitro and in Vivo Targeting of Hollow Gold Nanoshells Directed at Epidermal Growth Factor Receptor for Photothermal Ablation Therapy. Mol. Cancer Ther. 2008, 7, 1730–1739. [Google Scholar] [CrossRef] [Green Version]

- Yingling, Y.G.; Garrison, B.J. Photochemical Induced Effects in Material Ejection in Laser Ablation. Chem. Phys. Lett. 2002, 364, 237–243. [Google Scholar] [CrossRef]

- Sato, H.; Nishio, S. Polymer Laser Photochemistry, Ablation, Reconstruction, and Polymerization. J. Photochem. Photobiol. C Photochem. Rev. 2001, 2, 139–152. [Google Scholar] [CrossRef]

- Abdelaziem, A.; El-Khatib, K.M.; Hafez, M.A.; Badr, Y. Effect of Annealing on La0.8Sr0.2MnO3 Thin Films Prepared by Pulsed Laser Deposition. Spectrochim. Acta A. Mol. Biomol. Spectrosc. 2019, 211, 100–107. [Google Scholar] [CrossRef]

- Davari, S.A.; Gottfried, J.L.; Liu, C.; Ribeiro, E.L.; Duscher, G.; Mukherjee, D. Graphitic Coated Al Nanoparticles Manufactured as Superior Energetic Materials via Laser Ablation Synthesis in Organic Solvents. Appl. Surf. Sci. 2019, 473, 156–163. [Google Scholar] [CrossRef]

- Van Geenen, F.A.M.G.; Franssen, M.C.R.; Miikkulainen, V.; Ritala, M.; Zuilhof, H.; Kostiainen, R.; Nielen, M.W.F. TiO2 Photocatalyzed Oxidation of Drugs Studied by Laser Ablation Electrospray Ionization Mass Spectrometry. J. Am. Soc. Mass Spectrom. 2019, 30, 639–646. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Censabella, M.; Torrisi, V.; Boninelli, S.; Bongiorno, C.; Grimaldi, M.G.; Ruffino, F. Laser Ablation Synthesis of Mono- and Bimetallic Pt and Pd Nanoparticles and Fabrication of Pt-Pd/Graphene Nanocomposites. Appl. Surf. Sci. 2019, 475, 494–503. [Google Scholar] [CrossRef]

- Sinha, S.K. Effect of Temperature on Structural, Optical and Electrical Properties of Pulsed-Laser Deposited W-Doped V2O5 Thin Films. Superlattices Microstruct. 2019, 125, 88–94. [Google Scholar] [CrossRef]

- Mikhailov, V.A.; Liko, I.; Mize, T.H.; Bush, M.F.; Benesch, J.L.P.; Robinson, C.V. Infrared Laser Activation of Soluble and Membrane Protein Assemblies in the Gas Phase. Anal. Chem. 2016, 88, 7060–7067. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Simonds, B.; Nomoto, K.; Puthen Veettil, B.; Lin, Z.; Perez Wurfl, I.; Conibeer, G. Pulsed KrF Excimer Laser Dopant Activation in Nanocrystal Silicon in a Silicon Dioxide Matrix. Appl. Phys. Lett. 2016, 108, 083103. [Google Scholar] [CrossRef]

- Ahluwalia, J.; Avram, M.M.; Ortiz, A.E. Outcomes of Long-Pulsed 1064 Nm Nd:YAG Laser Treatment of Basal Cell Carcinoma: A Retrospective Review. Lasers Surg. Med. 2019, 51, 34–39. [Google Scholar] [CrossRef] [Green Version]

- Abedi, H.R.; Hoseinpour Gollo, M. An Experimental Study of the Effects of Surface Roughness and Coating of Cr2O3 Layer on the Laser-Forming Process. Opt. Laser Technol. 2019, 109, 336–347. [Google Scholar] [CrossRef]

- Hopkins, P.E.; Serrano, J.R.; Phinney, L.M.; Kearney, S.P.; Grasser, T.W.; Harris, C.T. Criteria for Cross-Plane Dominated Thermal Transport in Multilayer Thin Film Systems During Modulated Laser Heating. J. Heat Transf. 2010, 132, 081302–081310. [Google Scholar] [CrossRef]

- Eltas, S.D.; Gursel, M.; Eltas, A.; Alptekin, N.O.; Ataoglu, T. Evaluation of Long-Term Effects of Diode Laser Application in Periodontal Treatment of Poorly Controlled Type 2 Diabetic Patients with Chronic Periodontitis. Int. J. Dent. Hyg. 2019, 17, 292–299. [Google Scholar] [CrossRef]

- Bernhardt, A.F.; Rasmussen, P. Design Criteria and Operating Characteristics of a Single-Mode Pulsed Dye Laser. Appl. Phys. B 1981, 26, 141–146. [Google Scholar] [CrossRef]

- Brenier, A.; Boulon, G. New Criteria to Choose the Best Yb3+-Doped Laser Crystals. EPL Europhys. Lett. 2001, 55, 647. [Google Scholar] [CrossRef]

- Gaddam, S.; Mathur, S.C.; Singh, M.; Arora, J.; Wani, S.B.; Gupta, N.; Overhiser, A.; Rastogi, A.; Singh, V.; Desai, N. Erratum: Novel Probe-Based Confocal Laser Endomicroscopy Criteria and Interobserver Agreement for the Detection of Dysplasia in Barrett’s Esophagus. Am. J. Gastroenterol. 2013, 108, 460. [Google Scholar] [CrossRef]

- Malafeyev, O.A.; Neverova, E.G.; Nemnyugin, S.A.; Alferov, G.V. Multi-Criteria Model of Laser Radiation Control. In Proceedings of the 2014 2nd 2014 2nd International Conference on Emission Electronics (ICEE), St. Petersburg, Russia, 30 June–4 July 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Kudtarkar, K.; Iglesias, P.; Smith, T.W.; Schertzer, M.J. Effect of Metallization on the Electromechanical Properties of Microfluidically Synthesized Hydrogel Beads. J. Fluids Eng. 2018, 141, 031303–031306. [Google Scholar] [CrossRef]

- Valov, I.; Waser, R.; Jameson, J.R.; Kozicki, M.N. Electrochemical Metallization Memories—Fundamentals, Applications, Prospects. Nanotechnology 2011, 22, 254003. [Google Scholar] [CrossRef]

- Le, X.T.; Poirier, J.-S.; Michel, S. Completely Aqueous Route for Metallization of Structural Polymeric Materials in Micro-Electro-Mechanical Systems. Appl. Surf. Sci. 2019, 478, 717–724. [Google Scholar] [CrossRef]

- Zhao, J.; An, T.; Fang, C.; Bie, X.; Qin, F.; Chen, P.; Dai, Y. A Study on the Effect of Microstructure Evolution of the Aluminum Metallization Layer on Its Electrical Performance during Power Cycling. IEEE Trans. Power Electron. 2019. [Google Scholar] [CrossRef]

- Murarka, S.P.; Hymes, S.W. Copper Metallization for ULSL and Beyond. Crit. Rev. Solid State Mater. Sci. 1995, 20, 87–124. [Google Scholar] [CrossRef]

- Shacham-Diamand, Y.; Lopatin, S. Integrated Electroless Metallization for ULSI. Electrochim. Acta 1999, 44, 3639–3649. [Google Scholar] [CrossRef]

- Rekha, S.; Jeeva, P.; Karthikeyan, S.; Srinivasan, K.; Ramkumar, D.; Arivazhagan, N.; Narayanan, S. Metallization of Iron Powders by Autocatalytic Copper Plating Process. Mater. Manuf. Process. 2013, 28, 905–909. [Google Scholar] [CrossRef]

- Nelyub, V.; Tarasov, V. Ion-Beam Processing of Metallized Carbon Fiber-Reinforced Plastics. Mater. Manuf. Process. 2020, 35. [Google Scholar] [CrossRef]

- Pujari, M.; Agarwal, A.; Uppaluri, R.; Verma, A. Combinatorial Electroless Plating Characteristics for Dense Pd–PSS Composite Membrane Fabrication. Mater. Manuf. Process. 2016, 31, 6–11. [Google Scholar] [CrossRef]

- Pujari, M.; Agarwal, A.; Uppaluri, R.; Verma, A. Effect of Pd Concentration on Electroless Dense Pd-PSS Membrane Fabrication. Surf. Eng. 2015, 31, 209–213. [Google Scholar] [CrossRef]

- Pujari, M.; Agarwal, A.; Uppaluri, R.; Verma, A. Efficacy of Novel Electroless Plating Process for Dense Pd/Cr2O3/PSS Membrane Fabrication. Mater. Manuf. Process. 2016, 31, 1–5. [Google Scholar] [CrossRef]

- Agarwal, A.; Pujari, M.; Uppaluri, R.; Verma, A. Efficacy of Palladium Solution Concentration on Electroless Fabrication of Dense Metal Ceramic Composite Membranes Coupled with Surfactant and Sonication. Mater. Manuf. Process. 2016, 31, 18–23. [Google Scholar] [CrossRef]

- Zhang, Y.; Zong, B.; Jin, J.; Cao, X. Electroless Copper Plating on Particulate Reinforcements and Effects on Mechanical Properties of SiCp/Fe Composite. Surf. Eng. 2015, 31, 232–239. [Google Scholar] [CrossRef]

- Lu, Z.-L.; Wang, Z.-C.; Luo, L.-M.; Huang, X.-M.; Tan, X.-Y.; Chen, J.-B.; Cheng, J.; Wu, Y.-C. Electroless Plating of Copper on Al2O3 and Its Heat Treatment Behaviour. Surf. Eng. 2015, 31, 240–244. [Google Scholar] [CrossRef]

- Vaškelis, A.; Norkus, H.J.; Rozovskis, G.; Vinkevičius, H.J. New Methods of Electroless Plating and Direct Electroplating of Plastics. Trans. IMF 1997, 75, 1–3. [Google Scholar] [CrossRef]

- Dos Santos, F.S.; Martins, L.F.O.; D’Ajello, P.C.T.; Pasa, A.A.; Hasenack, C.M. Electroless and Electro-Plating of Cu on Si. Microelectron. Eng. 1997, 33, 59–64. [Google Scholar] [CrossRef]

- Shacham-Diamand, Y.; Osaka, T.; Okinaka, Y.; Sugiyama, A.; Dubin, V. 30years of Electroless Plating for Semiconductor and Polymer Micro-Systems. Microelectron. Eng. 2015, 132, 35–45. [Google Scholar] [CrossRef] [Green Version]

- Genova, V.; Paglia, L.; Marra, F.; Bartuli, C.; Pulci, G. Pure Thick Nickel Coating Obtained by Electroless Plating: Surface Characterization and Wetting Properties. Surf. Coat. Technol. 2019, 357, 595–603. [Google Scholar] [CrossRef]

- Nagireddi, S.; Golder, A.K.; Uppaluri, R. Role of EDTA on the Pd(II) Adsorption Characteristics of Chitosan Cross-Linked 3-Amino-1,2,4-Triazole-5-Thiol Derivative from Synthetic Electroless Plating Solutions. Int. J. Biol. Macromol. 2019, 127, 320–329. [Google Scholar] [CrossRef]

- Alique, D.; Martinez-Diaz, D.; Sanz, R.; Calles, J.A. Review of Supported Pd-Based Membranes Preparation by Electroless Plating for Ultra-Pure Hydrogen Production. Membranes 2018, 8, 5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zoppas, F.M.; Marchesini, F.A.; Devard, A.; Bernardes, A.M.; Miró, E.E. Controlled Deposition of Pd and In on Carbon Fibers by Sequential Electroless Plating for the Catalytic Reduction of Nitrate in Water. Catal. Commun. 2016, 78, 59–63. [Google Scholar] [CrossRef]

- Jones, C.G.; Mills, B.E.; Nishimoto, R.K.; Robinson, D.B. Electroless Deposition of Palladium on Macroscopic 3D-Printed Polymers with Dense Microlattice Architectures for Development of Multifunctional Composite Materials. J. Electrochem. Soc. 2017, 164, D867–D874. [Google Scholar] [CrossRef]

- Tang, J.; Ou, Q.; Zhou, H.; Qi, L.; Man, S. Seed-Mediated Electroless Deposition of Gold Nanoparticles for Highly Uniform and Efficient SERS Enhancement. Nanomaterials 2019, 9, 185. [Google Scholar] [CrossRef] [Green Version]

- Atli, A.; Simon, S.; Aires, F.J.C.S.; Cardenas, L.; Ehret, E.; Lourdin, P. A New Strategy to Activate Liquid Crystal Polymer Samples for Electroless Copper Deposition. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Muench, F.; Solomonov, A.; Bendikov, T.; Molina-Luna, L.; Rubinstein, I.; Vaskevich, A. Empowering Electroless Plating to Produce Silver Nanoparticle Films for DNA Biosensing Using Localized Surface Plasmon Resonance Spectroscopy. ACS Appl. Bio Mater. 2019, 2, 856–864. [Google Scholar] [CrossRef]

- Aixiang, Z.; Weihao, X.; Jian, X. Electroless Ni-P Coating of Cenospheres Using Silver Nitrate Activator. Surf. Coat. Technol. 2005, 197, 142–147. [Google Scholar] [CrossRef]

- Horkans, J.; Kim, J.; McGrath, C.; Romankiw, L.T. A TEM Study of the Effect of Accelerators on Pd-Sn Colloidal Catalysts and on the Initiation of Electroless Cu Deposition on Epoxy. J. Electrochem. Soc. 1987, 134, 300–304. [Google Scholar] [CrossRef]

- Ghosh, S. Electroless Copper Deposition: A Critical Review. Thin Solid Films 2019, 669, 641–658. [Google Scholar] [CrossRef]

- Xiang, S.; Li, W.; Qian, Z.; Zhu, L.; Liu, H. The Effect of 2-Mercaptobenzothiazole on Laser-Assisted Electroless Copper Plating. RSC Adv. 2016, 6, 38647–38652. [Google Scholar] [CrossRef]

- Shi, S.; Wang, L.; Wang, A.; Huang, R.; Ding, L.; Su, R.; Qi, W.; He, Z. Bioinspired Fabrication of Optical Fiber SPR Sensors for Immunoassays Using Polydopamine-Accelerated Electroless Plating. J. Mater. Chem. C 2016, 4, 7554–7562. [Google Scholar] [CrossRef]

- Qi, K.; Xie, Y.; Wang, R.; Liu, S.; Zhao, Z. Electroless Plating Ni-P Cocatalyst Decorated g-C3N4 with Enhanced Photocatalytic Water Splitting for H2 Generation. Appl. Surf. Sci. 2019, 466, 847–853. [Google Scholar] [CrossRef]

- Simpson, D.E.; Johnson, C.A.; Roy, D. Pulsed Galvanostatic Electrodeposition of Copper on Cobalt Using a PH-Neutral Plating Bath and Electroless Seeds. J. Electrochem. Soc. 2019, 166, D3142–D3154. [Google Scholar] [CrossRef]

- Cheng, J.; Gan, X.; Chen, S.; Lai, Y.; Xiong, H.; Zhou, K. Properties and Microstructure of Copper/Nickel-Iron-Coated Graphite Composites Prepared by Electroless Plating and Spark Plasma Sintering. Powder Technol. 2019, 343, 705–713. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Salgueiriño-Maceira, V.; Liz-Marzán, L.M. Deposition of Silver Nanoparticles on Silica Spheres by Pretreatment Steps in Electroless Plating. Chem. Mater. 2001, 13, 1630–1633. [Google Scholar] [CrossRef]

- Hanna, F.; Hamid, Z.A.; Aal, A.A. Controlling Factors Affecting the Stability and Rate of Electroless Copper Plating. Mater. Lett. 2004, 58, 104–109. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Tadaki, Y.; Nagao, D.; Konno, M. Deposition of Gold Nanoparticles on Silica Spheres by Electroless Metal Plating Technique. J. Colloid Interface Sci. 2005, 283, 601–604. [Google Scholar] [CrossRef]

- Stanley, M.L.; Henne, P.; Yang, B.W.; De Brigard, F. Resistance to Position Change, Motivated Reasoning, and Polarization. Polit. Behav. 2019. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.M.; An, H.; Yoon, K.J.; Kim, B.-K.; Lee, H.-W.; Son, J.-W.; Kim, H.; Shin, D.; Ji, H.-I.; Lee, J.-H. Electrochemical Analysis of High-Performance Protonic Ceramic Fuel Cells Based on a Columnar-Structured Thin Electrolyte. Appl. Energy 2019, 233–234, 29–36. [Google Scholar] [CrossRef]

- Subardi, A.; Liao, K.-Y.; Fu, Y.-P. Oxygen Transport, Thermal and Electrochemical Properties of NdBa0.5Sr0.5Co2O5+δ Cathode for SOFCs. J. Eur. Ceram. Soc. 2019, 39, 30–40. [Google Scholar] [CrossRef]

- Abdel-Gawad, S.A.; Shoeib, M.A. Corrosion Studies and Microstructure of Mg−Zn−Ca Alloys for Biomedical Applications. Surf. Interfaces 2019, 14, 108–116. [Google Scholar] [CrossRef]

- Brown, D.; Darr, D.; Morse, J.; Laskowski, B.; Betti, R. Experimental Validation of a Micro-Sized Polarization Resistance Corrosion Sensor for Structural Health Management Applications. In Proceedings of the 6th EuropeanWorkshop onStructural Health Monitoring, Dresden, Germany, 3–6 July 2012. [Google Scholar]

- Montero, M.A.; Marozzi, C.A.; Gennero de Chialvo, M.R.; Chialvo, A.C. A Simple Method to Establish the Relationship between the Equilibrium Polarization Resistance and the Elementary Kinetic Parameters of an Electrocatalysed Reaction. Electrocatalysis 2018, 9, 409–415. [Google Scholar] [CrossRef]

- Huan, D.; Wang, W.; Xie, Y.; Shi, N.; Wan, Y.; Xia, C.; Peng, R.; Lu, Y. Investigation of Real Polarization Resistance for Electrode Performance in Proton-Conducting Electrolysis Cells. J. Mater. Chem. A 2018, 6, 18508–18517. [Google Scholar] [CrossRef]

- Samson, G.; Deby, F.; Garciaz, J.-L.; Perrin, J.-L. Alternative Methodology for Linear Polarization Resistance Assessment of Reinforced Concrete Structure. MATEC Web Conf. 2018, 199, 06009. [Google Scholar] [CrossRef] [Green Version]

- Setevich, C.; Prado, F.; Caneiro, A. Study of the Electrode Polarization Resistance of Cobaltites with High Ba Content as Cathode for IT-SOFC. J. Electrochem. Soc. 2017, 164, F759–F767. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, J.; Wang, T.; Chen, G.; Wu, K.; Cheng, Y. Decreasing the Polarization Resistance of LaSrCoO4 Cathode by Fe Substitution for Ba(Zr0.1Ce0.7Y0.2)O3 Based Protonic Ceramic Fuel Cells. J. Alloys Compd. 2016, 689, 581–586. [Google Scholar] [CrossRef]

- Iatalese, M.; Coluccio, M.L.; Onesto, V.; Amato, F.; Fabrizio, E.D.; Gentile, F. Relating the Rate of Growth of Metal Nanoparticles to Cluster Size Distribution in Electroless Deposition. Nanoscale Adv. 2019, 1, 228–240. [Google Scholar] [CrossRef] [Green Version]

- Li, J.-M.; Hu, C.-C.; Wu, T.-H.; Hsu, Y.-J. Electroless Deposition of RuO 2 -Based Nanoparticles for Energy Conversion Applications. RSC Adv. 2019, 9, 4239–4245. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Gawad, S.A.; Sadik, M.A.; Shoeib, M.A. Preparation and Properties of a Novel Nano Ni-B-Sn by Electroless Deposition on 7075-T6 Aluminum Alloy for Aerospace Application. J. Alloys Compd. 2019, 785, 1284–1292. [Google Scholar] [CrossRef]

- Xu, M.L.; Kang, S.M.; Chen, T.T. Coating Properties of Electroless Ni-P Plating on Magnesium Alloy with Cerium Chloride. Metalurgija 2019, 58, 106–108. [Google Scholar]

- Porter, L.A.; Choi, H.C.; Ribbe, A.E.; Buriak, J.M. Controlled Electroless Deposition of Noble Metal Nanoparticle Films on Germanium Surfaces. Nano Lett. 2002, 2, 1067–1071. [Google Scholar] [CrossRef] [Green Version]

- Eom, K.; Cho, K.; Kwon, H. Effects of Electroless Deposition Conditions on Microstructures of Cobalt–Phosphorous Catalysts and Their Hydrogen Generation Properties in Alkaline Sodium Borohydride Solution. J. Power Sources 2008, 180, 484–490. [Google Scholar] [CrossRef]

- Touir, R.; Larhzil, H.; EbnTouhami, M.; Cherkaoui, M.; Chassaing, E. Electroless Deposition of Copper in Acidic Solutions Using Hypophosphite Reducing Agent. J. Appl. Electrochem. 2006, 36, 69–75. [Google Scholar] [CrossRef]

- Zhang, W.X.; Huang, N.; He, J.G.; Jiang, Z.H.; Jiang, Q.; Lian, J.S. Electroless Deposition of Ni–W–P Coating on AZ91D Magnesium Alloy. Appl. Surf. Sci. 2007, 253, 5116–5121. [Google Scholar] [CrossRef]

- Ohno, I. Electrochemistry of Electroless Plating. Mater. Sci. Eng. A 1991, 146, 33–49. [Google Scholar] [CrossRef]

| The conventional planar process surface (2D) |

| The planar process surface with 3D element on the process side (2½D) |

| The planar process surface with 3D element on the opposite process side (2½D) |

| The multi parallel plane process surfaces (2½D) |

| The multi process surfaces with different angles (2D x n) |

| The regular cylindrical process surfaces (3D) |

| The freeform process surfaces (3D) |

| Thermal properties | - Heat distortion resistance - Thermal expansion - Melting and crystallization |

| Mechanical properties | - Strength and yield strength - Fracture elongation - Stiffness (E modulus) |

| Electrical properties | - Dielectricity - Electrical puncture resistance |

| Workability properties | - Flowability - Shrinkage - Distortion |