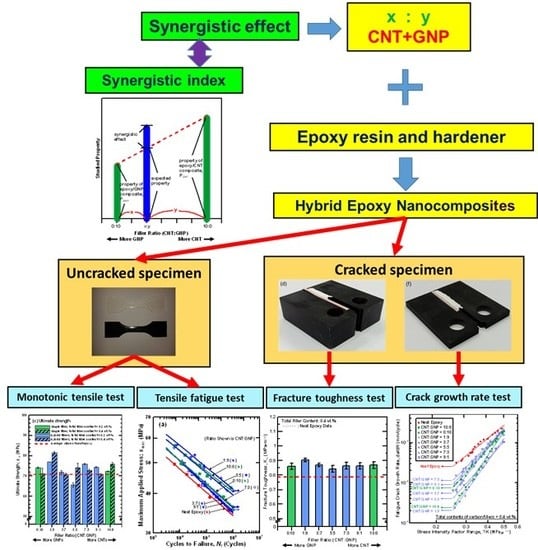

Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Monotonic and Fatigue Properties of Uncracked and Cracked Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation of Specimens

2.2. Tests of Mechanical Properties

3. Results and Discussion

3.1. Monotonic Tensile Tests

3.2. Tensile Fatigue Tests

3.3. Mode I Fracture Toughness Tests

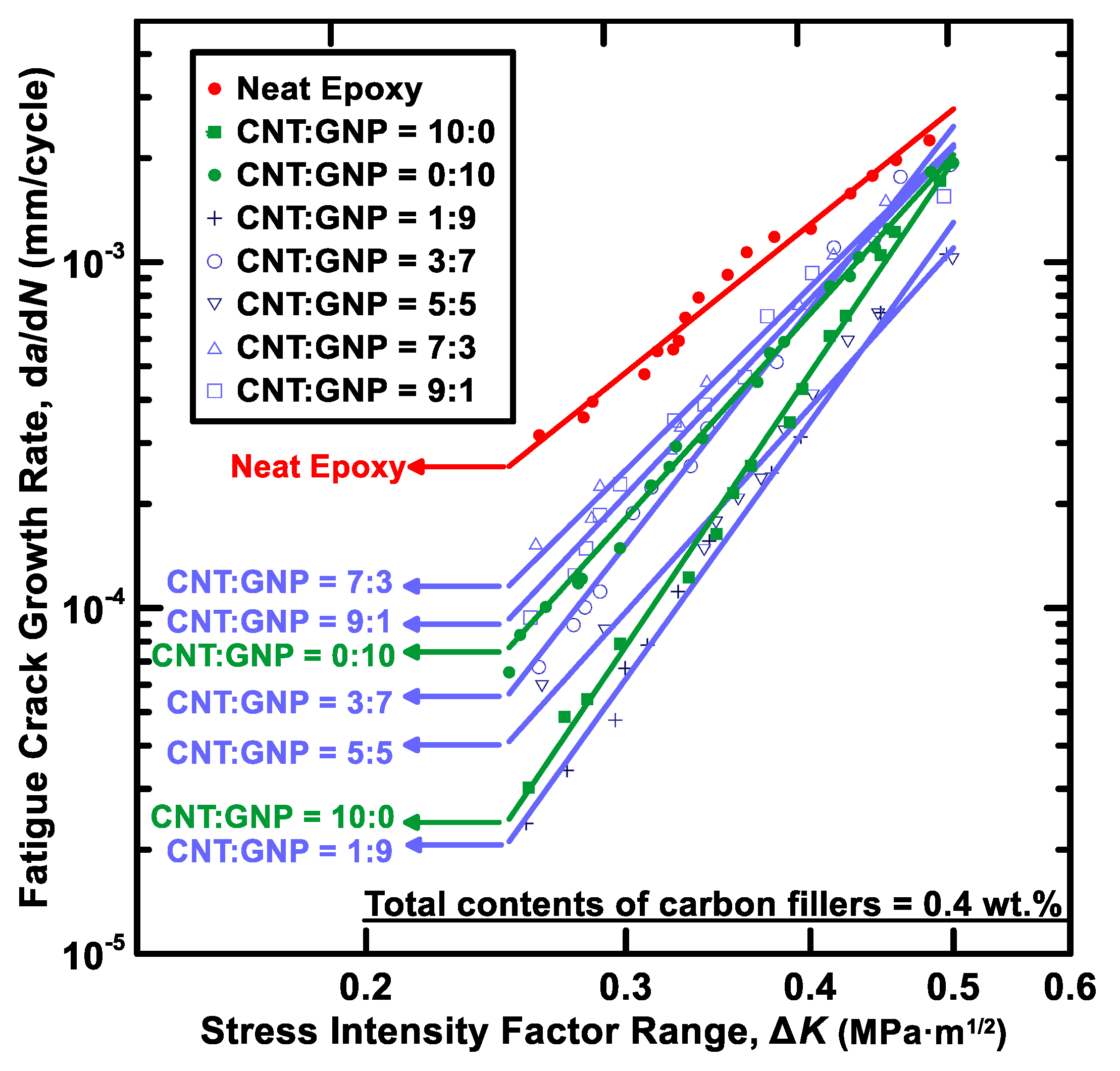

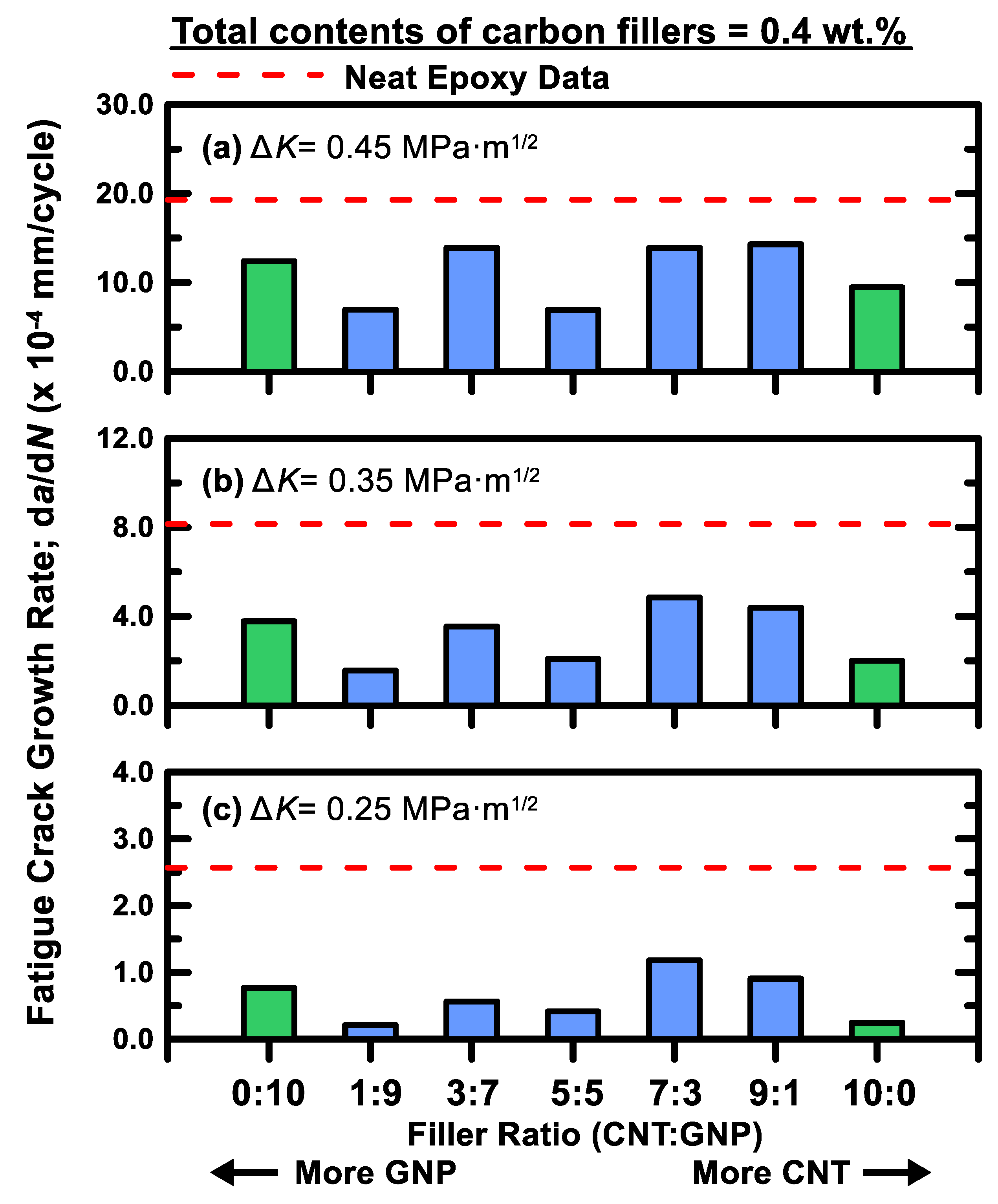

3.4. Fatigue Crack Growth Rate Tests

3.5. Facture Surfaces Study

4. Conclusions and Recommendations

Author Contributions

Funding

Conflicts of Interest

References

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A-Appl. S. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Li, B.; Zhong, W.H. Review on polymer/graphite nanoplatelet nanocomposites. J. Mater. Sci. 2011, 46, 5595–5614. [Google Scholar] [CrossRef]

- Atif, R.; Shyha, I.; Inam, F. Mechanical, thermal, and electrical properties of graphene-epoxy nanocomposites—A review. Polymers 2016, 8, 281. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review of the mechanical and thermal properties of graphene and its hybrid polymer nanocomposites for structural applications. J. Mater. Sci. 2019, 54, 5992–6026. [Google Scholar] [CrossRef]

- Shukla, M.K.; Sharma, K. Effect of carbon nanofillers on the mechanical and interfacial properties of epoxy based nanocomposites: A review. Polym. Sci. Ser. B 2019, 61, 439–460. [Google Scholar] [CrossRef]

- Li, J.; Wong, P.S.; Kim, J.K. Hybrid nanocomposites containing carbon nanotubes and graphite nanoplatelets. Mater. Sci. Eng. A 2008, 483, 660–663. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Sun, L.L.; Caceres, S.; Li, B.; Wood, W.; Perugini, A.; Maguire, R.G.; Zhong, W.H. Dynamic synergy of graphitic nanoplatelets and multi-walled carbon nanotubes in polyetherimide nanocomposites. Nanotechnology 2010, 21, 105702. [Google Scholar] [CrossRef]

- Yang, S.Y.; Lin, W.N.; Huang, Y.L.; Tien, H.W.; Wang, J.Y.; Ma, C.C.; Li, S.M.; Wang, Y.S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Ren, P.G.; Di, Y.Y.; Zhang, Q.; Li, L.; Pang, H.; Li, Z.M. Composites of ultrahigh-molecular-weight polyethylene with graphene sheets and/or MWCNTs with segregated network structure: Preparation and properties. Macromol. Mater. Eng. 2012, 297, 437–443. [Google Scholar] [CrossRef]

- Chatterjee, S.; Nafezarefi, F.; Tai, N.; Schlagenhauf, L.; Nüesch, F.; Chu, B. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon 2012, 50, 5380–5386. [Google Scholar] [CrossRef]

- Das, A.; Kasaliwal, G.R.; Jurk, R.; Boldt, R.; Fischer, D.; Stöckelhuber, K.W.; Heinrich, G. Rubber composites based on graphene nanoplatelets, expanded graphite, carbon nanotubes and their combination: A comparative study. Compos. Sci. Technol. 2012, 72, 1961–1967. [Google Scholar] [CrossRef]

- Li, W.; Dichiara, A.; Bai, J. Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos. Sci. Technol. 2013, 74, 221–227. [Google Scholar] [CrossRef]

- Zhang, S.; Yin, S.; Rong, C.; Huo, P.; Jiang, Z.; Wang, G. Synergistic effects of functionalized graphene and functionalized multi-walled carbon nanotubes on the electrical and mechanical properties of poly(ether sulfone) composites. Eur. Polym. J. 2013, 49, 3125–3134. [Google Scholar] [CrossRef]

- Pradhan, B.; Srivastava, S.K. Synergistic effect of three-dimensional multi-walled carbon nanotube–graphene nanofiller in enhancing the mechanical and thermal properties of high-performance silicone rubber. Polym. Int. 2014, 63, 1219–1228. [Google Scholar] [CrossRef]

- Montes, S.; Carrasco, P.M.; Ruiz, V.; Cabañero, G.; Grande, H.J.; Labidi, J.; Odriozola, I. Synergistic reinforcement of poly(vinyl alcohol) nanocomposites with cellulose nanocrystal-stabilized graphene. Compos. Sci. Technol. 2015, 117, 26–31. [Google Scholar] [CrossRef]

- Li, C.; Li, Y.; She, X.; Vongsvivut, J.; Li, J.; She, F.; Gao, W.; Kong, L. Reinforcement and deformation behaviors of polyvinyl alcohol/graphene/montmorillonite clay composites. Compos. Sci. Technol. 2015, 118, 1–8. [Google Scholar] [CrossRef]

- Cui, X.; Ding, P.; Zhuang, N.; Shi, L.; Song, N.; Tang, S. Thermal conductive and mechanical properties of polymeric composites based on solution-exfoliated boron nitride and graphene nanosheets: A morphology-promoted synergistic effect. ACS Appl. Mater. Interfaces 2015, 7, 19068–19075. [Google Scholar] [CrossRef]

- Al-Saleh, M.H. Electrical and mechanical properties of graphene/carbon nanotube hybrid nanocomposites. Synth. Met. 2015, 209, 41–46. [Google Scholar] [CrossRef]

- Moosa, A.A.; Sa, A.R.; Ibrahim, M.N. Mechanical and electrical properties of graphene nanoplates and carbon nanotubes hybrid epoxy nanocomposites. Am. J. Mater. Sci. 2016, 6, 157–165. [Google Scholar]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Enhancement of fracture toughness, mechanical and thermal properties of rubber/epoxy composites by incorporation of graphene nanoplatelets. Compos. Part A-Appl. S. Manuf. 2016, 87, 10–22. [Google Scholar] [CrossRef]

- Ghaleb, Z.; Mariatti, M.; Ariff, Z. Synergy effects of graphene and multiwalled carbon nanotubes hybrid system on properties of epoxy nanocomposites. J. Reinf. Plast. Compos. 2017, 36, 685–695. [Google Scholar] [CrossRef]

- Wang, J.; Jin, X.; Wu, H.; Guo, S. Polyimide reinforced with hybrid graphene oxide@ carbon nanotube: Toward high strength, toughness, electrical conductivity. Carbon 2017, 123, 502–513. [Google Scholar] [CrossRef]

- Sahu, S.K.; Badgayan, N.D.; Samanta, S.; Sreekanth, P.R. Quasistatic and dynamic nanomechanical properties of HDPE reinforced with 0/1/2 dimensional carbon nanofillers based hybrid nanocomposite using nanoindentation. Mater. Chem. Phys. 2018, 203, 173–184. [Google Scholar] [CrossRef]

- Ribeiro, H.; Trigueiro, J.P.; Owuor, P.S.; Machado, L.D.; Woellner, C.F.; Pedrotti, J.J.; Jaques, Y.M.; Kosolwattana, S.; Chipara, A.; Silva, W.M.; et al. Hybrid 2D nanostructures for mechanical reinforcement and thermal conductivity enhancement in polymer composites. Compos. Sci. Technol. 2018, 159, 103–110. [Google Scholar] [CrossRef]

- Min, C.; Liu, D.; Shen, C.; Zhang, Q.; Song, H.; Li, S.; Shen, X.; Zhu, M.; Zhang, K. Unique synergistic effects of graphene oxide and carbon nanotube hybrids on the tribological properties of polyimide nanocomposites. Tribol. Int. 2018, 117, 217–224. [Google Scholar] [CrossRef]

- Shukla, M.K.; Sharma, K. Effect of functionalized graphene/CNT ratio on the synergetic enhancement of mechanical and thermal properties of epoxy hybrid composite. Mater. Res. Express 2019, 6, 085318. [Google Scholar] [CrossRef]

- Wang, E.; Dong, Y.; Islam, M.Z.; Yu, L.; Liu, F.; Chen, S.; Qi, X.; Zhu, Y.; Fu, Y.; Xu, Z.; et al. Effect of graphene oxide-carbon nanotube hybrid filler on the mechanical property and thermal response speed of shape memory epoxy composites. Compos. Sci. Technol. 2019, 169, 209–216. [Google Scholar] [CrossRef]

- Ren, Y.; Li, F.; Cheng, H.M.; Liao, K. Tension–tension fatigue behavior of unidirectional single-walled carbon nanotube reinforced epoxy composite. Carbon 2003, 41, 2177–2179. [Google Scholar] [CrossRef]

- Zhang, W.; Picu, R.C.; Koratkar, N. Suppression of fatigue crack growth in carbon nanotube composites. Appl. Phys. Lett. 2007, 91, 193109. [Google Scholar] [CrossRef] [Green Version]

- Yu, N.; Zhang, Z.H.; He, S.Y. Fracture toughness and fatigue life of MWCNT/epoxy composites. Mater. Sci. Eng. A 2008, 494, 380–384. [Google Scholar] [CrossRef]

- Bortz, D.R.; Merino, C.; Martin-Gullon, I. Carbon nanofibers enhance the fracture toughness and fatigue performance of a structural epoxy system. Compos. Sci. Technol. 2011, 71, 31–38. [Google Scholar] [CrossRef] [Green Version]

- Loos, M.R.; Yang, J.; Feke, D.L.; Manas-Zloczower, I. Enhanced fatigue life of carbon nanotube-reinforced epoxy composites. Polym. Eng. Sci. 2012, 52, 1882–1887. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Yavari, F.; Rafiee, J.; Koratkar, N. Fullerene–epoxy nanocomposites-enhanced mechanical properties at low nanofiller loading. J. Nanopart. Res. 2011, 13, 733–737. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Srivastava, I.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Fracture and fatigue in graphene nanocomposites. Small 2010, 6, 179–183. [Google Scholar] [CrossRef] [PubMed]

- Ladani, R.B.; Bhasin, M.; Wu, S.; Ravindran, A.R.; Ghorbani, K.; Zhang, J.; Kinloch, A.J.; Mouritz, A.P.; Wang, C.H. Fracture and fatigue behaviour of epoxy nanocomposites containing 1-D and 2-D nanoscale carbon fillers. Eng. Fract. Mech. 2018, 203, 102–114. [Google Scholar] [CrossRef]

- Ismail, H.; Ramly, A.F.; Othman, N. The effect of carbon black/multiwall carbon nanotube hybrid fillers on the properties of natural rubber nanocomposites. Polym.-Plast. Technol. 2011, 50, 1660–1666. [Google Scholar] [CrossRef]

- Dong, B.; Liu, C.; Lu, Y.; Wu, Y. Synergistic effects of carbon nanotubes and carbon black on the fracture and fatigue resistance of natural rubber composites. J. Appl. Polym. Sci. 2015, 132, 42075. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Esmkhani, M.; Haghighatkhah, A.R.; Zhao, Z. Flexural fatigue behavior of synthesized graphene/carbon-nanofiber/epoxy hybrid nanocomposites. Mater. Design 2014, 62, 401–408. [Google Scholar] [CrossRef]

- ASTM International. Standard Test. Method for Tensile Properties of Plastics; D638-14; ASTM International: West Conshohocken, PA, USA, 2014; Available online: https://www.astm.org/Standards/D638.htm (accessed on 15 July 2020).

- ASTM International. Standard Test. Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials; D5045-14; ASTM International: West Conshohocken, PA, USA, 2014; Available online: https://www.astm.org/Standards/D5045.htm (accessed on 15 July 2020).

- ASTM International. Standard Test. Method for Measurement of Fatigue Crack Growth Rates; E647-15e1; ASTM International: West Conshohocken, PA, USA, 2015; Available online: https://www.astm.org/Standards/E647.htm (accessed on 15 July 2020).

- Zhang, X.; Liu, T.; Sreekumar, T.V.; Kumar, S.; Moore, V.C.; Hauge, R.H.; Smalley, R.E. Poly(vinylalcohol)/SWNT Composite Film. Nano Lett. 2003, 3, 1285–1288. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Q.; Chen, D. Enhanced mechanical properties of graphene-based poly(vinyl alcohol) composites. Macromolecules 2010, 43, 2357–2363. [Google Scholar] [CrossRef]

- Bannantine, J.A.; Comer, J.J.; Handrock, J.L. Fundamentals of Metal Fatigue Analysis, 1st ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 1990; pp. 3–4. [Google Scholar]

- Szeluga, U.; Kumanek, B.; Trzebicka, B. Synergy in hybrid polymer/nanocarbon composites. A review. Compos. Part A-Appl. S. Manuf. 2015, 73, 204–231. [Google Scholar] [CrossRef]

- Bortz, D.R.; Heras, E.G.; Martin-Gullon, I. Impressive Fatigue Life and Fracture Toughness Improvements in Graphene Oxide/Epoxy Composites. Macromolecules 2013, 45, 238–245. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Park, Y.T.; Qian, Y.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy toughening with low graphene loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Cha, J.; Kim, J.; Ryu, S.; Hong, S.H. Comparison to mechanical properties of epoxy nanocomposites reinforced by functionalized carbon nanotubes and graphene nanoplatelets. Compos. Part. B-Eng. 2019, 162, 283–288. [Google Scholar] [CrossRef]

- Kumar, A.; Li, S.; Roy, S.; King, J.A.; Odegard, G.M. Fracture properties of nanographene reinforced EPON 862 thermoset polymer system. Compos. Sci. Technol. 2015, 114, 87–93. [Google Scholar] [CrossRef]

- Moosa, A.A.; Kubba, F.; Raad, M.; Ramazani, A. Mechanical and thermal properties of graphene nanoplates and functionalized carbon-nanotubes hybrid epoxy nanocomposites. Am. J. Mater. Sci. 2016, 6, 125–134. [Google Scholar]

| Filler Ratio | Monotonic Tensile Properties | |||

|---|---|---|---|---|

| MWCNT:GNP | Tensile Modulus, E (MPa) | Yield Strength, σy (MPa) | Ultimate Strength, σult (MPa) | Percent Elongation, εf (%) |

| Neat epoxy | 3554.7 ± 70.5 | 52.8 ± 2.7 | 70.8 ± 0.1 | 8.2 ± 0.54 |

| Total filler content = 0.2 wt % | ||||

| 0:10 | 3722.4 ± 28.1 (+4.7) 1 | 53.3 ± 1.6 (+0.9) | 74.2 ± 0.3 (+4.8) | 4.4 ± 0.89 (−46.3) |

| 1:9 | 3738.2 ± 43.9 (+5.2) | 53.3 ± 0.2 (+0.9) | 77.0 ± 0.04 (+8.8) | 6.9 ± 0.27 (−15.9) |

| 3:7 | 3474.7 ± 59.2 (−2.2) | 51.0 ± 0.9 (−3.41) | 71.8 ± 1.0 (+1.4) | 5.8 ± 0.43 (−29.3) |

| 5:5 | 3326.1 ± 32.7 (−6.4) | 44.3 ± 1.8 (−16.1) | 65.5 ± 1.1 (−7.5) | 5.8 ± 0.18 (−29.3) |

| 7:3 | 3521.0 ± 38.2 (−0.9) | 51.8 ± 0.8 (−1.9) | 75.9 ± 0.3 (+7.2) | 6.8 ± 0.32 (−17.1) |

| 9:1 | 3511.4 ± 106.1 (−1.2) | 52.9 ± 1.6 (+0.2) | 74.4 ± 0.4 (+5.1) | 6.5 ± 0.78 (−20.7) |

| 10:0 | 3654.5 ± 37.6 (+2.8) | 54.8 ± 3.7 (+3.8) | 72.4 ± 0.1 (+2.3) | 6.9 ± 0.12 (−15.9) |

| Total filler content = 0.4 wt % | ||||

| 0:10 | 3407.2 ± 42.2 (−4.1) | 52.8 ± 3.8 (+0/.0) | 71.1 ± 2.7 (+0.4) | 6.2 ± 0.73 (−24.4) |

| 1:9 | 3868.7 ± 58.8 (+8.8) | 55.7 ± 1.6 (+5.5) | 81.6 ± 0.6 (+15.3) | 7.1 ± 0.44 (−13.4) |

| 3:7 | 3420.8 ± 57.6 (−3.8) | 47.3 ± 2.2 (−10.4) | 70.8 ± 0.6 (+0.0) | 7.8 ± 0.27 (−4.9) |

| 5:5 | 3590.6 ± 40.1 (+1.0) | 55.0 ± 0.4 (+2.0) | 74.2 ± 2.1 (+4.8) | 6.6 ± 0.18 (−19.5) |

| 7:3 | 3463.6 ± 9.7 (−2.6) | 49.9 ± 1.7 (−5.5) | 72.7 ± 0.6 (+2.7) | 7.9 ± 0.24 (−3.7) |

| 9:1 | 3465.7 ± 53.7 (−2.5) | 46.7 ± 0.9 (−11.6) | 71.0 ± 0.2 (+0.3) | 7.8 ± 0.39 (−4.9) |

| 10:0 | 3835.0 ± 16.1 (+7.9) | 54.2 ± 2.7 (+2.7) | 75.8 ± 1.1 (+7.1) | 7.9 ± 0.16 (−3.7) |

| Filler Ratio | 1:9 | 3:7 | 5:5 | 7:3 | 9:1 | |

|---|---|---|---|---|---|---|

| Studied | ||||||

| Properties | ||||||

| Monotonic tensile properties1 | ||||||

| Tensile modulus | 0.6/12.1 | −6.1/−3.2 | −9.8/−0.8 | −4.2/−6.6 | −4.1/−8.6 | |

| Yield strength | −0.3/5.2 | −5.1/−11.1 | −18.0/2.8 | −4.7/−7.2 | −3.2/−13.6 | |

| Ultimate strength | 4.0/14.0 | −2.5/−2.4 | −10.6/1.0 | 4.0/−2.3 | 2.5/−5.7 | |

| Percent elongation | 48.4/11.5 | 12.6/16.2 | 2.7/−6.4 | 10.6/6.9 | −2.3/0.9 | |

| Fatigue strength corresponding to | ||||||

| 104 cycles | 10.5 | −2.8 | −6.8 | −5.4 | −6.8 | |

| 105 cycles | 11.4 | −4.7 | −6.9 | −6.8 | −10.3 | |

| 106 cycles | 11.8 | −6.5 | −7.0 | −8.2 | −13.7 | |

| Mode I fracture toughness | 4.9 | 0.9 | −2.4 | −0.3 | −0.6 | |

| MWCNTs | GNPs | Epoxy Matrix | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| lCNT (nm) | dCNT (nm) | (g/cm3) | ECNT (MPa) | lGNP (nm) | tGNP (nm) | (g/cm3) | EGNP (TPa) | (g/cm3) | EM (MPa) | ||

| 15,000 | 30 | 0.29 | 60,000 | 4000 | 5 | 1.39 | 1.0 | 1.14 | 3554 | ||

| Filler Ratio (MWCNT:GNP) | Loading Level r (%) | Max. Applied Stress (MPa) | Fatigue Life Nf (cycles) | Fatigue Life Curves | |||

|---|---|---|---|---|---|---|---|

| Fatigue Strength a | Fatigue Exponent b | Coef. of Determination R2 | Pseudo Fatigue Limit, (MPa) | ||||

| 0:00 (Neat Epoxy) | 70 | 49.56 | 6,203 | 94.64 | −0.0741 | 0.996 | 34 |

| 65 | 46.02 | 17,995 | |||||

| 60 | 42.48 | 50,281 | |||||

| 55 | 38.94 | 134,088 | |||||

| 50 | 35.4 | 639,238 | |||||

| 0:10 | 70 | 49.77 | 10,921 | 101.21 | −0.0743 | 0.977 | 36.26 |

| 65 | 46.22 | 54,603 | |||||

| 60 | 42.66 | 109,242 | |||||

| 55 | 39.11 | 432,690 | |||||

| 50 | 35.55 | >1,000,000 | |||||

| 1:9 | 70 | 57.12 | 7,741 | 107.98 | −0.0697 | 0.989 | 41.22 |

| 65 | 53.04 | 36,070 | |||||

| 60 | 48.96 | 82,263 | |||||

| 55 | 44.88 | 340,644 | |||||

| 50 | 40.8 | >1,000,000 | |||||

| 3:7 | 70 | 49.56 | 13,240 | 106.04 | −0.0801 | 0.998 | 35.07 |

| 65 | 46.02 | 37,232 | |||||

| 60 | 42.48 | 84,852 | |||||

| 55 | 38.94 | 254,360 | |||||

| 50 | 35.4 | 924,930 | |||||

| 5:5 | 75 | 55.65 | 6,136 | 94.24 | −0.0703 | 0.979 | 35.68 |

| 70 | 51.94 | 25,820 | |||||

| 65 | 48.23 | 79,835 | |||||

| 60 | 44.52 | 145,844 | |||||

| 55 | 40.81 | 581,860 | |||||

| 7:3 | 70 | 50.89 | 11,950 | 101.14 | −0.0748 | 0.986 | 35.99 |

| 65 | 47.26 | 21,436 | |||||

| 60 | 44.82 | 86,999 | |||||

| 55 | 39.99 | 189,423 | |||||

| 50 | 36.35 | >1,000,000 | |||||

| 9:1 | 70 | 49.7 | 14,842 | 109.37 | −0.0834 | 0.995 | 34.55 |

| 65 | 46.15 | 28,631 | |||||

| 60 | 42.6 | 72,395 | |||||

| 55 | 39.05 | 226,105 | |||||

| 50 | 35.5 | 779,772 | |||||

| 10:0 | 75 | 56.85 | 6,700 | 100.57 | −0.0659 | 0.978 | 40.46 |

| 70 | 53.06 | 15,662 | |||||

| 65 | 49.27 | 56,860 | |||||

| 60 | 45.48 | 105,850 | |||||

| 55 | 41.69 | 792,079 | |||||

| MWCNT: GNP | 0:0 (Neat Epoxy) | 0:10 | 1:9 | 3:7 | 5:5 | 7:3 | 9:1 | 10:0 |

|---|---|---|---|---|---|---|---|---|

| Fracture toughness 1 KIC | 0.289 ± 0.018 | 0.861 ± 0.021 (+9.2) | 0.904 ± 0.013 (+14.7) | 0.871 ± 0.012 (+1.4) | 0.843 ± 0.024 (+7.9) | 0.863 ± 0.023 (+9.5) | 0.862 ± 0.022 (+9.4) | 0.868 ± 0.022 (+10.1) |

| Filler Ratio MWCNT:GNP | 0:0 (Neat Epoxy) | 0:10 | 1:9 | 3:7 | 5:5 | 7:3 | 9:1 | 10:0 |

|---|---|---|---|---|---|---|---|---|

| Coefficient, C | 0.0299 | 0.0543 | 0.0809 | 0.1079 | 0.0316 | 0.0399 | 0.0605 | 0.1325 |

| Exponent, m | 3.432 | 4.732 | 5.956 | 5.450 | 4.789 | 4.202 | 4.691 | 6.189 |

| Coef. of determination, R2 | 0.982 | 0.943 | 0.993 | 0.988 | 0.984 | 0.990 | 0.987 | 0.994 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jen, Y.-M.; Huang, J.-C.; Zheng, K.-Y. Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Monotonic and Fatigue Properties of Uncracked and Cracked Epoxy Composites. Polymers 2020, 12, 1895. https://doi.org/10.3390/polym12091895

Jen Y-M, Huang J-C, Zheng K-Y. Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Monotonic and Fatigue Properties of Uncracked and Cracked Epoxy Composites. Polymers. 2020; 12(9):1895. https://doi.org/10.3390/polym12091895

Chicago/Turabian StyleJen, Yi-Ming, Jui-Cheng Huang, and Kun-Yang Zheng. 2020. "Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Monotonic and Fatigue Properties of Uncracked and Cracked Epoxy Composites" Polymers 12, no. 9: 1895. https://doi.org/10.3390/polym12091895