Copper-Polyurethane Composite Materials: Particle Size Effect on the Physical-Chemical and Antibacterial Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Copper-Polyurethane Composite Materials

2.3. Characterization of Copper-Polyurethane Composite Materials

2.3.1. Evaluation of the Processability of Composite Materials by Torque Rheometry and the Melt Flow Index (MFI)

2.3.2. Thermal Stability

2.3.3. Scanning Electron Microscopy (SEM)

2.4. Antibacterial Properties

2.4.1. Bacterial Strains

2.4.2. Death Kinetics

2.4.3. Statistical Analysis

2.5. Cu2+ Migration

2.6. Tensile Properties

3. Results and Discussion

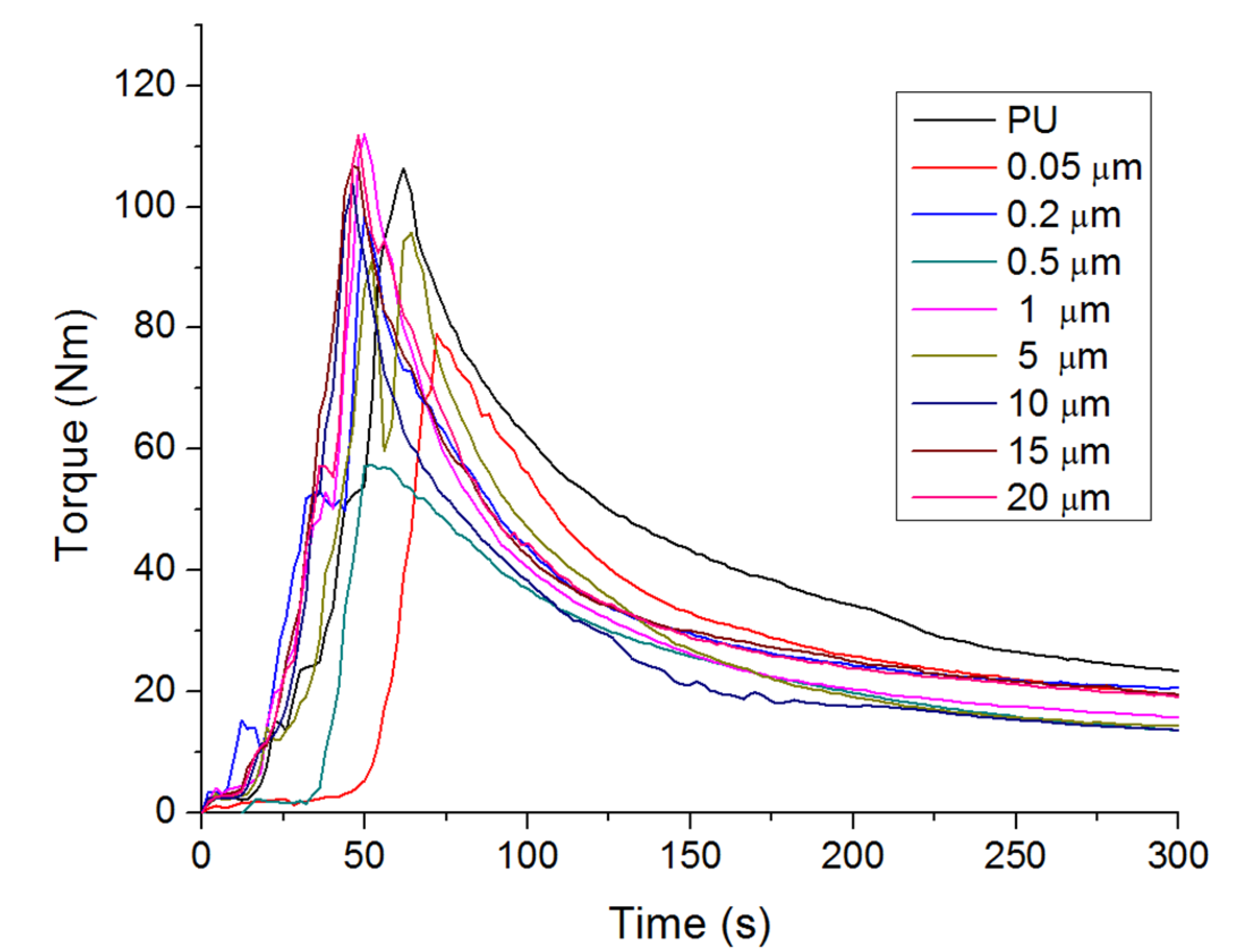

3.1. Processability Evaluation of Composite Materials by Torque Rheometry and the Melt Flow Index (MFI)

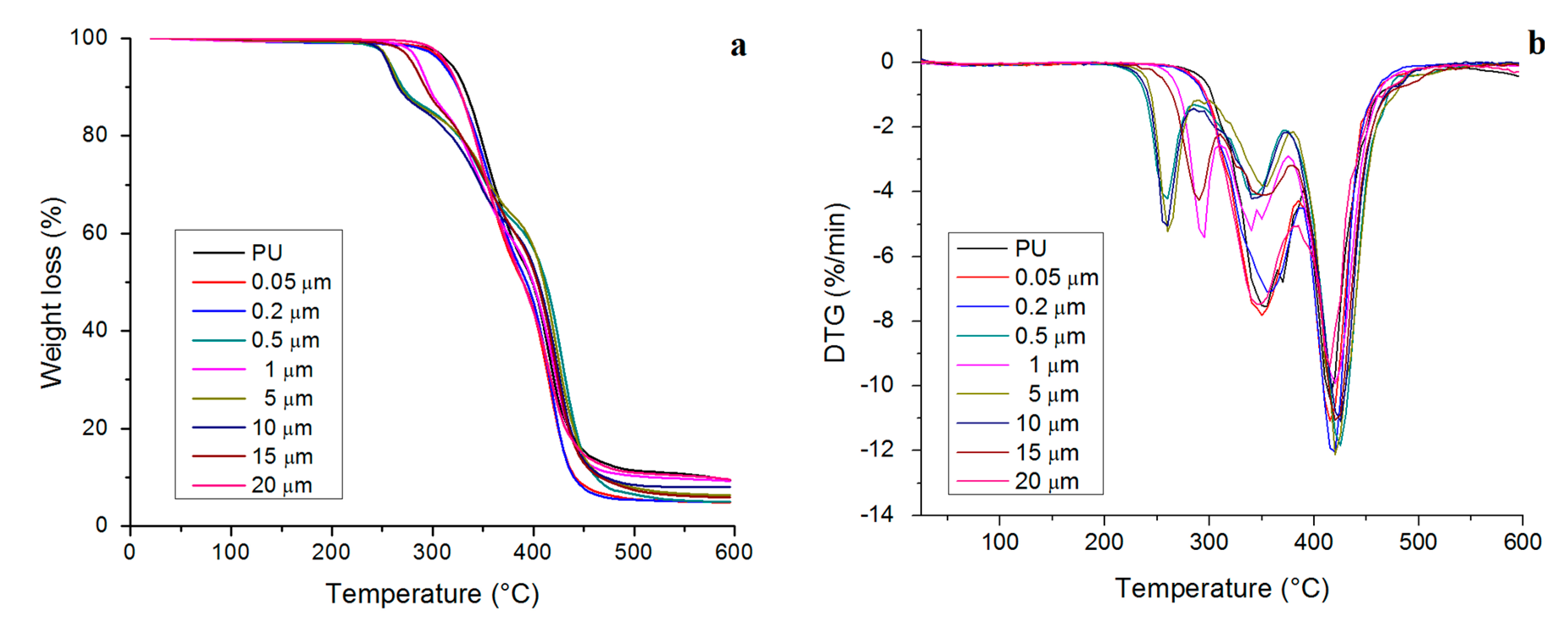

3.2. Thermal Stability

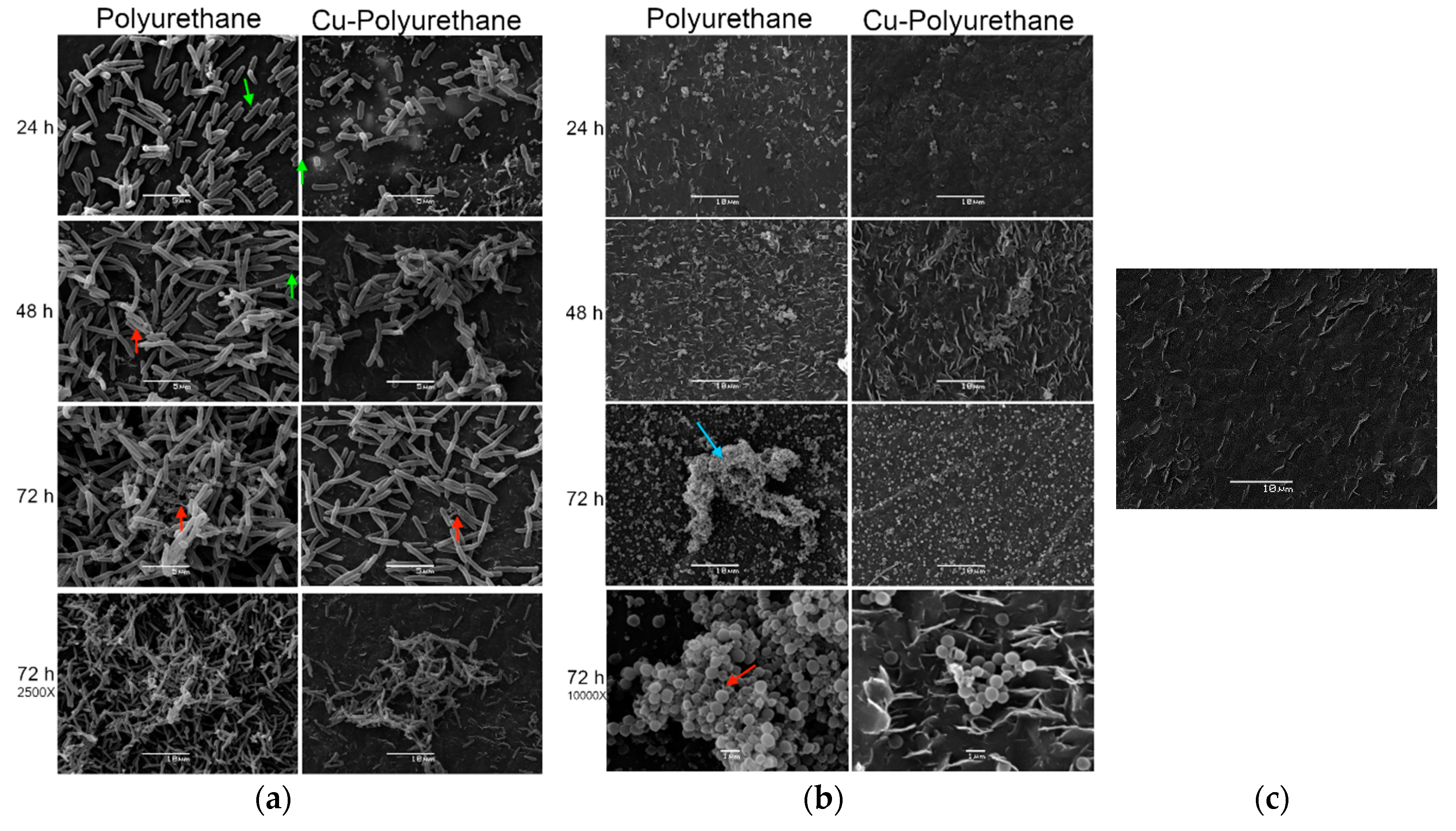

3.3. Scanning Electron Microscopy

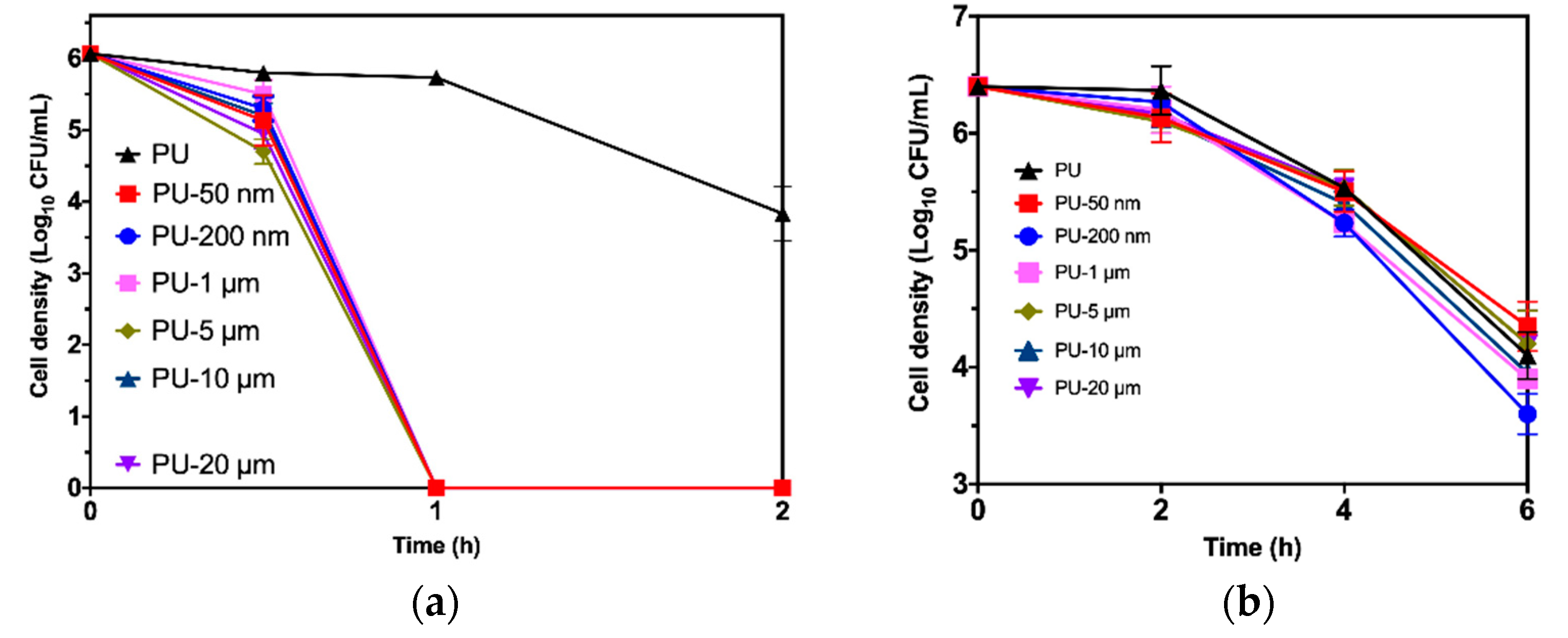

3.4. Antibacterial Properties

3.4.1. Biofilm Formation

3.4.2. Death Kinetics

3.5. Cu2+ Migration

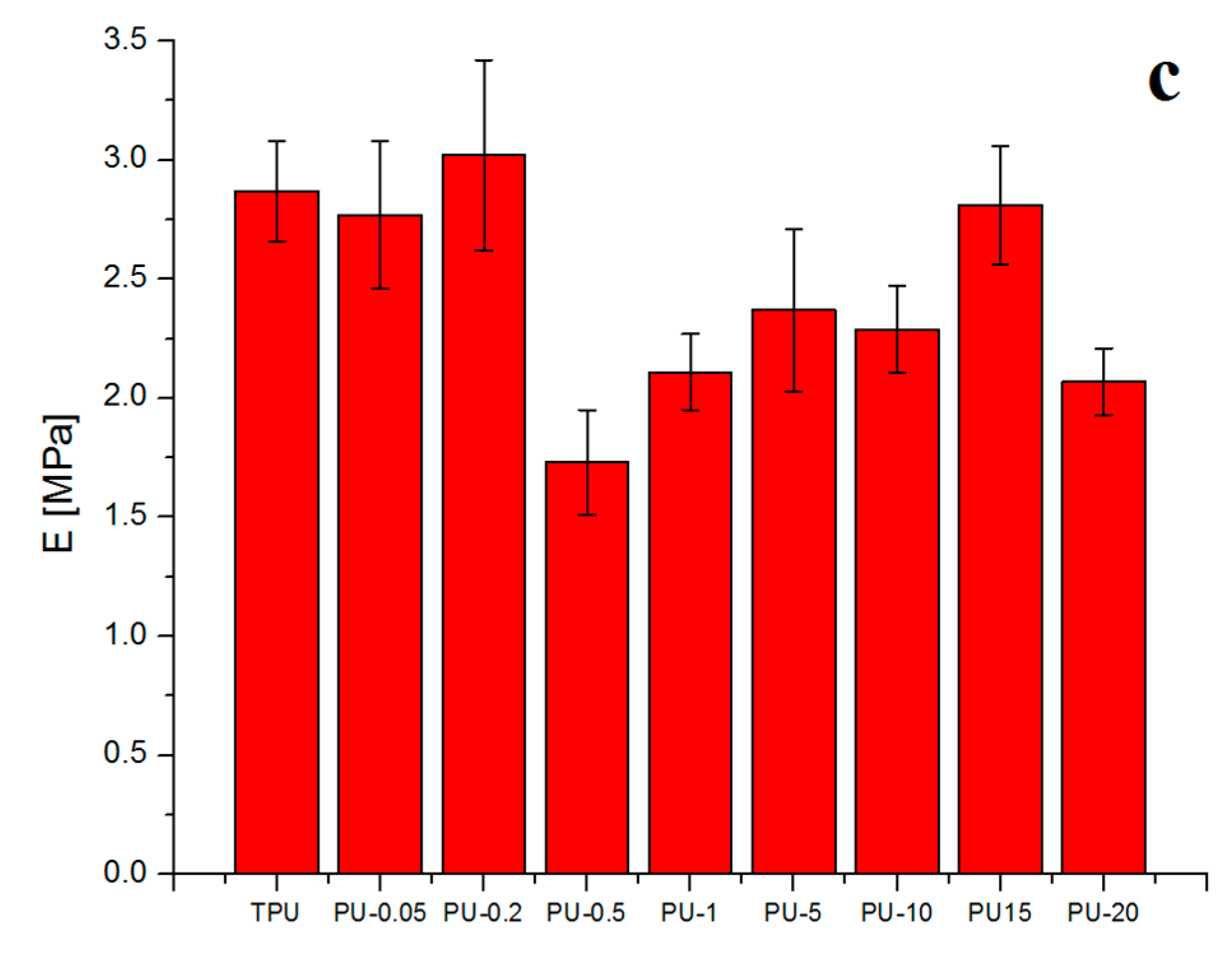

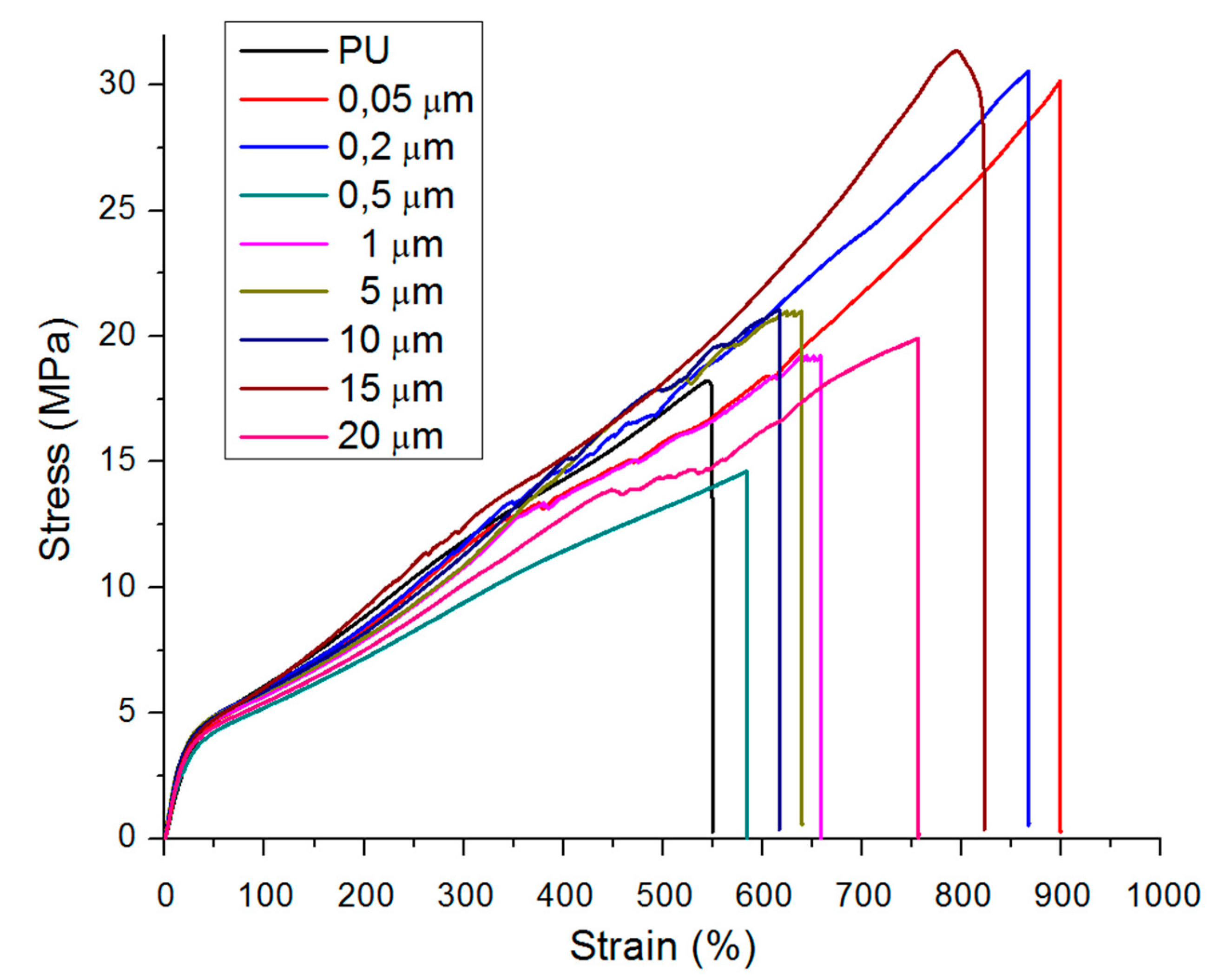

3.6. Tensile Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nasrollahzadeh, M.; Sajadi, M.; Atarod, M.; Sajjadi, M.; Issaabadi, Z. An Introduction to Green Nanotechnology. In Interface Science and Technology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 28, pp. 231–316. [Google Scholar]

- Jain, P.; Pradeep, T. Potential of silver nanoparticle-coated polyurethane foam as an antibacterial water filter. Biotechnol. Bioeng. 2005, 90, 59–63. [Google Scholar] [CrossRef] [PubMed]

- Guzmán, M.G.; Dille, J.; Godet, S. Synthesis of silver nanoparticles by chemical reduction method and their antibacterial activity. Int. J. Chem. Biol. Eng. 2009, 3, 104–111. [Google Scholar]

- Becerra, A.; Rodríguez-Llamazares, S.; Carrasco, C.; Díaz-Visurraga, J.; Riffo, C.; Mondaca, M.A. Preparation of poly(vinyl chloride)/copper nanocomposite films with reduced bacterial adhesion. High Perform. Polym. 2012, 25, 51–60. [Google Scholar] [CrossRef]

- Suntharalingam, P.; Cvitkovitch, D.G. Quorum sensing in streptococcal biofilm formation. Trends Microbiol. 2005, 13, 3–6. [Google Scholar] [CrossRef] [PubMed]

- Schopf, S.; Wanner, G.; Rachel, R.; Wirth, R. An archaeal bi-species biofilm formed by Pyrococcus furiosus and Methanopyrus kandleri. Arch. Microbiol. 2008, 190, 371–377. [Google Scholar] [CrossRef]

- Koerdt, A.; Gödeke, J.; Berger, J.; Thormann, K.M.; Albers, S.-V. Crenarchaeal Biofilm Formation under Extreme Conditions. PLoS ONE 2010, 5, e14104. [Google Scholar] [CrossRef]

- Savelyev, Y.; Gonchar, A.; Movchan, B.; Gornostay, A.; Vozianov, S.; Rudenko, A.; Rozhnova, R.; Travinskaya, T.V. Antibacterial polyurethane materials with silver and copper nanoparticles. Mater. Today Proc. 2017, 4, 87–94. [Google Scholar] [CrossRef]

- Szycher, M. (Ed.) Structure–Property Relations in Polyurethanes. In Szycher’s Handbook of Polyurethanes; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Fluckiger, U.; Ulrich, M.; Steinhuber, A.; Döring, G.; Mack, D.; Landmann, R.; Goerke, C.; Wolz, C. Biofilm Formation, icaADBC Transcription, and Polysaccharide Intercellular Adhesin Synthesis by Staphylococci in a Device-Related Infection Model. Infect. Immun. 2005, 73, 1811–1819. [Google Scholar] [CrossRef]

- Lim, E.S.; Koo, O.K.; Kim, M.-J.; Kim, J.S. Bio-enzymes for inhibition and elimination of Escherichia coli O157:H7 biofilm and their synergistic effect with sodium hypochlorite. Sci. Rep. 2019, 9, 9920. [Google Scholar] [CrossRef]

- Maria, S.; Galani, I.; Plachouras, D.; Panagea, T.; Armaganidis, A.; Petrikkos, G.; Giamarellou, H. Antimicrobial activity of copper surfaces against carbapenemase-producing contemporary Gram-negative clinical isolates. J. Antimicrob. Chemother. 2012, 68, 852–857. [Google Scholar] [CrossRef]

- Galani, I.; Priniotakis, G.; Chronis, I.; Tzerachoglou, A.; Plachouras, D.; Chatzikonstantinou, M.; Westbroek, P.; Souli, M. Copper-coated textiles: Armor against MDR nosocomial pathogens. Diagn. Microbiol. Infect. Dis. 2016, 85, 205–209. [Google Scholar] [CrossRef]

- Różańska, A.; Chmielarczyk, A.; Romaniszyn, D.; Majka, G.; Bulanda, M. Antimicrobial effect of copper alloys on Acinetobacter species isolated from infections and hospital environment. Antimicrob. Resist. Infect. Control 2018, 7, 10. [Google Scholar] [CrossRef] [PubMed]

- Su, B.; Zhou, Y.-G.; Wu, H.-H. Influence of mechanical properties of polypropylene/low-density polyethylene nanocomposites. Nanomater. Nanotechnol. 2017, 7, 1–11. [Google Scholar] [CrossRef]

- Xian, W.; Song, L.; Liu, B.; Ding, H.; Li, Z.; Cheng, M.; Ma, L. Rheological and mechanical properties of thermoplastic polyurethane elastomer derived from CO2 copolymer diol. J. Appl. Polym. Sci. 2017, 135, 45974. [Google Scholar] [CrossRef]

- Li, D.; Zhou, M.; Xie, L.; Yu, X.; Yu, Y.; Ai, H.; Tang, S. Synergism of pentaerythritol-zinc with β-diketone and calcium stearate in poly(vinyl chloride) thermal stability. Polym. J. 2012, 45, 775–782. [Google Scholar] [CrossRef]

- Shahbazi, K.; Aghjeh, M.K.R.; Abbasi, F.; Meran, M.; Mazidi, M.M. Rheology, morphology and tensile properties of reactive compatibilized polyethylene/polystyrene blends via Friedel–Crafts alkylation reaction. Polym. Bull. 2012, 69, 241–259. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Yu, C.; Wu, B.; Wang, Y.; Li, W. A novel method for the determination of steady-state torque of polymer melts by HAAKE MiniLab. Polym. Test. 2014, 33, 138–144. [Google Scholar] [CrossRef]

- Miranda, C.; Rodríguez-Llamazares, S.; Castaño, J.; Mondaca, M.A. Cu nanoparticles/PVC Composites: Thermal, Rheological, and Antibacterial Properties. Adv. Polym. Technol. 2016, 37, 937–942. [Google Scholar] [CrossRef]

- Rylski, A.; Siczek, K. The Effect of Addition of Nanoparticles, Especially ZrO2-Based, on Tribological Behavior of Lubricants. Lubricants 2020, 8, 23. [Google Scholar] [CrossRef]

- Macocinschi, D.; Filip, D.; Zaltariov, M.F.; Varganici, C.-D. Thermal and hydrolytic stability of silver nanoparticle polyurethane biocomposites for medical applications. Polym. Degrad. Stab. 2015, 121, 238–246. [Google Scholar] [CrossRef]

- Fang, Y.; Li, J.; Du, X.; Du, Z.; Cheng, X.; Wang, H. Thermal- and mechanical-responsive polyurethane elastomers with self-healing, mechanical-reinforced, and thermal-stable capabilities. Polym. 2018, 158, 166–175. [Google Scholar] [CrossRef]

- Burgaz, E.; Kendirlioglu, C. Thermomechanical behavior and thermal stability of polyurethane rigid nanocomposite foams containing binary nanoparticle mixtures. Polym. Test. 2019, 77, 105930. [Google Scholar] [CrossRef]

- Yonezawa, T.; Tsukamoto, H.; Nguyen, M.T. Particle size tuning in scalable synthesis of anti-oxidized copper fine particles by polypeptide molecular weights. Adv. Powder Technol. 2017, 28, 1966–1971. [Google Scholar] [CrossRef]

- Fang, C.; Zhou, X.; Yu, Q.; Liu, S.; Guo, D.-G.; Yu, R.; Hu, J. Synthesis and characterization of low crystalline waterborne polyurethane for potential application in water-based ink binder. Prog. Org. Coat. 2014, 77, 61–71. [Google Scholar] [CrossRef]

- Lei, W.; Fang, C.; Zhou, X.; Cheng, Y.; Yang, R.; Liu, D. Morphology and thermal properties of polyurethane elastomer based on representative structural chain extenders. Thermochim. Acta 2017, 653, 116–125. [Google Scholar] [CrossRef]

- Król, B.; Pielichowska, K.; Król, P.; Kędzierski, M. Polyurethane cationomer films as ecological membranes for building industry. Prog. Org. Coat. 2019, 130, 83–92. [Google Scholar] [CrossRef]

- Shih, H.-Y.; Lin, Y.E. Efficacy of Copper-Silver Ionization in Controlling Biofilm- and Plankton-Associated Waterborne Pathogens. Appl. Environ. Microbiol. 2010, 76, 2032–2035. [Google Scholar] [CrossRef][Green Version]

- Gugala, N.; Lemire, J.A.; Turner, R.J. The efficacy of different anti-microbial metals at preventing the formation of, and eradicating bacterial biofilms of pathogenic indicator strains. J. Antibiot. 2017, 70, 775–780. [Google Scholar] [CrossRef]

- Vaidya, M.Y.; McBain, A.J.; Butler, J.A.; Banks, C.E.; Whitehead, K.A. Antimicrobial Efficacy and Synergy of Metal Ions against Enterococcus faecium, Klebsiella pneumoniae and Acinetobacter baumannii in Planktonic and Biofilm Phenotypes. Sci. Rep. 2017, 7, 5911. [Google Scholar] [CrossRef]

- Sengan, M.; Subramaniyan, S.B.; Prakash, S.A.; Kamlekar, R.K.; Anbazhagan, V.; Megarajan, S.; Anbazhagan, V. Effective elimination of biofilm formed with waterborne pathogens using copper nanoparticles. Microb. Pathog. 2019, 127, 341–346. [Google Scholar] [CrossRef] [PubMed]

- Miao, L.; Wang, P.; Hou, J.; Yao, Y.; Liu, Z.; Liu, S. Low concentrations of copper oxide nanoparticles alter microbial community structure and function of sediment biofilms. Sci. Total Environ. 2019, 653, 705–713. [Google Scholar] [CrossRef] [PubMed]

- Sicairos-Ruelas, E.E.; Gerba, C.P.; Bright, K.R. Efficacy of copper and silver as residual disinfectants in drinking water. J. Environ. Sci. Health Part A 2019, 54, 146–155. [Google Scholar] [CrossRef] [PubMed]

- Lei, J.; Yao, G.; Sun, Z.; Wang, B.; Yu, C.; Zheng, S. Fabrication of a novel antibacterial TPU nanofiber membrane containing Cu-loaded zeolite and its antibacterial activity toward Escherichia coli. J. Mater. Sci. 2019, 54, 11682–11693. [Google Scholar] [CrossRef]

- Mokhtari, S.; Skelly, K.D.; Krull, E.A.; Coughlan, A.; Mellott, N.P.; Gong, Y.; Borges, R.; Wren, A.W. Copper-containing glass polyalkenoate cements based on SiO2–ZnO–CaO–SrO–P2O5 glasses: Glass characterization, physical and antibacterial properties. J. Mater. Sci. 2017, 52, 8886–8903. [Google Scholar] [CrossRef]

- Makwana, D.; Castaño, J.; Somani, R.S.; Bajaj, H.C. Characterization of Agar-CMC/Ag-MMT nanocomposite and evaluation of antibacterial and mechanical properties for packaging applications. Arab. J. Chem. 2020, 13, 3092–3099. [Google Scholar] [CrossRef]

- Patel, R.H.; Patel, K.S. Synthesis and characterization of flame retardant hyperbranched polyurethanes for nano-composite and nano-coating applications. Prog. Org. Coat. 2015, 88, 283–292. [Google Scholar] [CrossRef]

- Acuña, D.C. Study of the Effect of Gold Nanoparticles on the Mechanical Properties of Polyurethane. Thesis Phisic Engeneering, 2017. Available online: https://fisica.usach.cl/sites/fisica/files/acuna_conejeros_daniela_del_carmen.pdf (accessed on 29 July 2020).

- Mrówczyński, S.; Rybczyński, M.; Włodarczyk, Z. Transverse momentum versus multiplicity fluctuations in high-energy nuclear collisions. Phys. Rev. C 2004, 70, 054906. [Google Scholar] [CrossRef]

- Rybczyński, M.; Włodarczyk, Z. Non-monotonic behavior of multiplicity fluctuations. J. Phys. Conf. Ser. 2005, 5, 238–245. [Google Scholar] [CrossRef]

- Rybczynski, M.; the NA49 Collaboration; Alt, C.; Anticic, T.; Baatar, B.; Barna, D.; Bartkle, J.; Betev, L.; Bialkowska, H.; Billmeier, A.; et al. Multiplicity fluctuations in nuclear collisions at 158A GeV. J. Phys. Conf. Ser. 2005, 5, 74–85. [Google Scholar] [CrossRef]

- Zuo, P.; Benevides, R.; Laribi, M.-A.; Fitoussi, J.; Shirinbayan, M.; Bakir, F.; Tcharkhtchi, A. Multi-scale analysis of the effect of loading conditions on monotonic and fatigue behavior of a glass fiber reinforced polyphenylene sulfide (PPS) composite. Compos. Part B Eng. 2018, 145, 173–181. [Google Scholar] [CrossRef]

- Di Landro, L.A.; Capone, C.; Inzoli, F.; Malacari, P.E. Coextruded PVC tubes for biomedical application. J. Vinyl Addit. Technol. 2005, 11, 111–118. [Google Scholar] [CrossRef]

- Thein-Han, W.W.; Shah, J.; Misra, R. Superior In Vitro biological response and mechanical properties of an implantable nanostructured biomaterial: Nanohydroxyapatite–silicone rubber composite. Acta Biomater. 2009, 5, 2668–2679. [Google Scholar] [CrossRef] [PubMed]

| Sample Code | Poliurethane (wt%) | Copper Particle Size (µm) | Torque Max (Nm) | Torque Steady State (Nm) | MFI (g/10 min) |

|---|---|---|---|---|---|

| PU | 100 | 0 | 106.9 ± 3.0 | 24.1 ± 0.32 | 4.1 ± 0.26 |

| PU-0.05 | 99 | 0.05 | 101.7 ± 2.3 | 12.9 ± 0.31 | 9.1 ± 0.28 |

| PU-0.2 | 99 | 0.2 | 99.6 ± 4.4 | 12.2 ± 0.15 | 8.2 ± 0.39 |

| PU 0.5 | 99 | 0.5 | 100.8 ± 0.34 | 11.0 ± 0.23 | 6.7 ± 0.65 |

| PU-1 | 99 | 1 | 111.0 ± 5.3 | 15.7 ± 0.10 | 6.8 ± 0.33 |

| PU-5 | 99 | 5 | 111.2 ± 2.1 | 15.3 ± 0.19 | 7.7 ± 0.25 |

| PU-10 | 99 | 10 | 108.8 ± 5.0 | 14.6 ± 0.07 | 11.0 ± 0.28 |

| PU-15 | 99 | 15 | 113.5 ± 3.8 | 17.9 ± 0.26 | 8.1 ± 0.31 |

| PU-20 | 99 | 20 | 111.8 ± 6.9 | 16.4 ± 0.08 | 8.2 ± 1.5 |

| Initial Decomposition | Second Step Decomposition | Third Step Decomposition | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample Code | T(max) (°C) | Loss Weight (%) | Degrad. Rate (%/min) | T(max) (°C) | Loss Weight (%) | Degrad. Rate (%/min) | T(max) (°C) | Loss Weight (%) | Degrad. Rate (%/min) | Residual (%) |

| PU | 354.2 | 25.4 | 7.1 | 418.2 | 65.2 | 14.4 | 9.4 | |||

| PU-0.05 | 366.2 | 27.3 | 6.7 | 421.5 | 64.2 | 12.5 | 8.5 | |||

| PU-0.2 | 366.5 | 29.8 | 6.7 | 421.8 | 63.7 | 13.0 | 6.5 | |||

| PU-0.5 | 362.9 | 8.9 | 5.9 | 374.5 | 33.5 | 3.4 | 426.5 | 50.1 | 11.8 | 7.5 |

| PU-1 | 296.1 | 7.9 | 4.1 | 358.9 | 28.6 | 4.1 | 424.4 | 55.5 | 12.0 | 8.0 |

| PU-5 | 258.2 | 6.7 | 3.7 | 346.6 | 24.9 | 3.7 | 428.5 | 53.8 | 12.8 | 8.0 |

| PU-10 | 258.8 | 6.6 | 4.4 | 344.8 | 23.6 | 3.2 | 430.6 | 59.2 | 13.1 | 10.6 |

| PU-15 | 338.9 | 15.9 | 6.5 | 361.9 | 31.1 | 3.2 | 420.3 | 42.4 | 12.2 | 10.6 |

| PU-20 | 313.8 | 10.8 | 6.3 | 359.3 | 30.1 | 4.1 | 422.1 | 48.9 | 10.9 | 10.2 |

| Cu2+ Concentration (µg/L) Deionized Water | Cu2+ Concentration (µg/L) Physiological Serum | |||

|---|---|---|---|---|

| Time (Days) | PU | 1% Cu | PU | 1% Cu |

| 0 | <0.02 | <0.02 | <0.02 | <0.02 |

| 0.05 | <0.02 | <0.02 | <0.02 | 0.06 |

| 0.25 | <0.02 | <0.02 | <0.02 | 0.39 |

| 1 | <0.02 | 0.24 | <0.02 | 1.51 |

| 2 | <0.02 | 0.27 | <0.02 | 2.43 |

| 3 | <0.02 | 0.33 | <0.02 | 2.95 |

| 7 | <0.02 | 0.70 | <0.02 | 3.83 |

| 14 | <0.02 | 1.26 | <0.02 | 5.44 |

| 21 | <0.02 | 1.40 | <0.02 | 5.94 |

| Sample Code | E (MPa) | sM (MPa) | EB (%) | Integral Value (KJ/m3) * |

|---|---|---|---|---|

| PU | 2.5 ± 0.2 | 16.8 ± 1.8 | 512.7 ± 63.4 | 2264.9 |

| PU-0.05 | 2.9 ± 0.2 | 30.1 ± 3.5 | 900.2 ± 69.4 | 4092.4 |

| PU-0.2 | 3.0 ± 0.3 | 30.5 ± 2.5 | 874.4 ± 67.2 | 4107.1 |

| PU 0.5 | 1.7 ± 0.2 | 13.6 ± 2.2 | 589.4 ± 65.1 | 1831.2 |

| PU-1 | 2.1 ± 0.1 | 19.6 ± 0.5 | 679.8 ± 54.5 | 2233.6 |

| PU-5 | 2.4 ± 0.3 | 19.1 ± 2.4 | 664.7 ± 54.7 | 2563.2 |

| PU-10 | 2.3 ± 0.2 | 19.4 ± 1.7 | 620.4 ± 42.6 | 2613.8 |

| PU-15 | 2.2 ± 0.3 | 29.88 ± 3.4 | 859.9 ± 45.4 | 4006.2 |

| PU-20 | 2.1 ± 0.1 | 20.0 ± 1.9 | 754.4 ± 50.5 | 2561.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miranda, C.; Castaño, J.; Valdebenito-Rolack, E.; Sanhueza, F.; Toro, R.; Bello-Toledo, H.; Uarac, P.; Saez, L. Copper-Polyurethane Composite Materials: Particle Size Effect on the Physical-Chemical and Antibacterial Properties. Polymers 2020, 12, 1934. https://doi.org/10.3390/polym12091934

Miranda C, Castaño J, Valdebenito-Rolack E, Sanhueza F, Toro R, Bello-Toledo H, Uarac P, Saez L. Copper-Polyurethane Composite Materials: Particle Size Effect on the Physical-Chemical and Antibacterial Properties. Polymers. 2020; 12(9):1934. https://doi.org/10.3390/polym12091934

Chicago/Turabian StyleMiranda, Cristian, Johanna Castaño, Emky Valdebenito-Rolack, Felipe Sanhueza, Rody Toro, Helia Bello-Toledo, Patricio Uarac, and Luciano Saez. 2020. "Copper-Polyurethane Composite Materials: Particle Size Effect on the Physical-Chemical and Antibacterial Properties" Polymers 12, no. 9: 1934. https://doi.org/10.3390/polym12091934

APA StyleMiranda, C., Castaño, J., Valdebenito-Rolack, E., Sanhueza, F., Toro, R., Bello-Toledo, H., Uarac, P., & Saez, L. (2020). Copper-Polyurethane Composite Materials: Particle Size Effect on the Physical-Chemical and Antibacterial Properties. Polymers, 12(9), 1934. https://doi.org/10.3390/polym12091934