Emergence of Polymeric Material Utilising Sustainable Radiation Curable Palm Oil-Based Products for Advanced Technology Applications

Abstract

1. Introduction

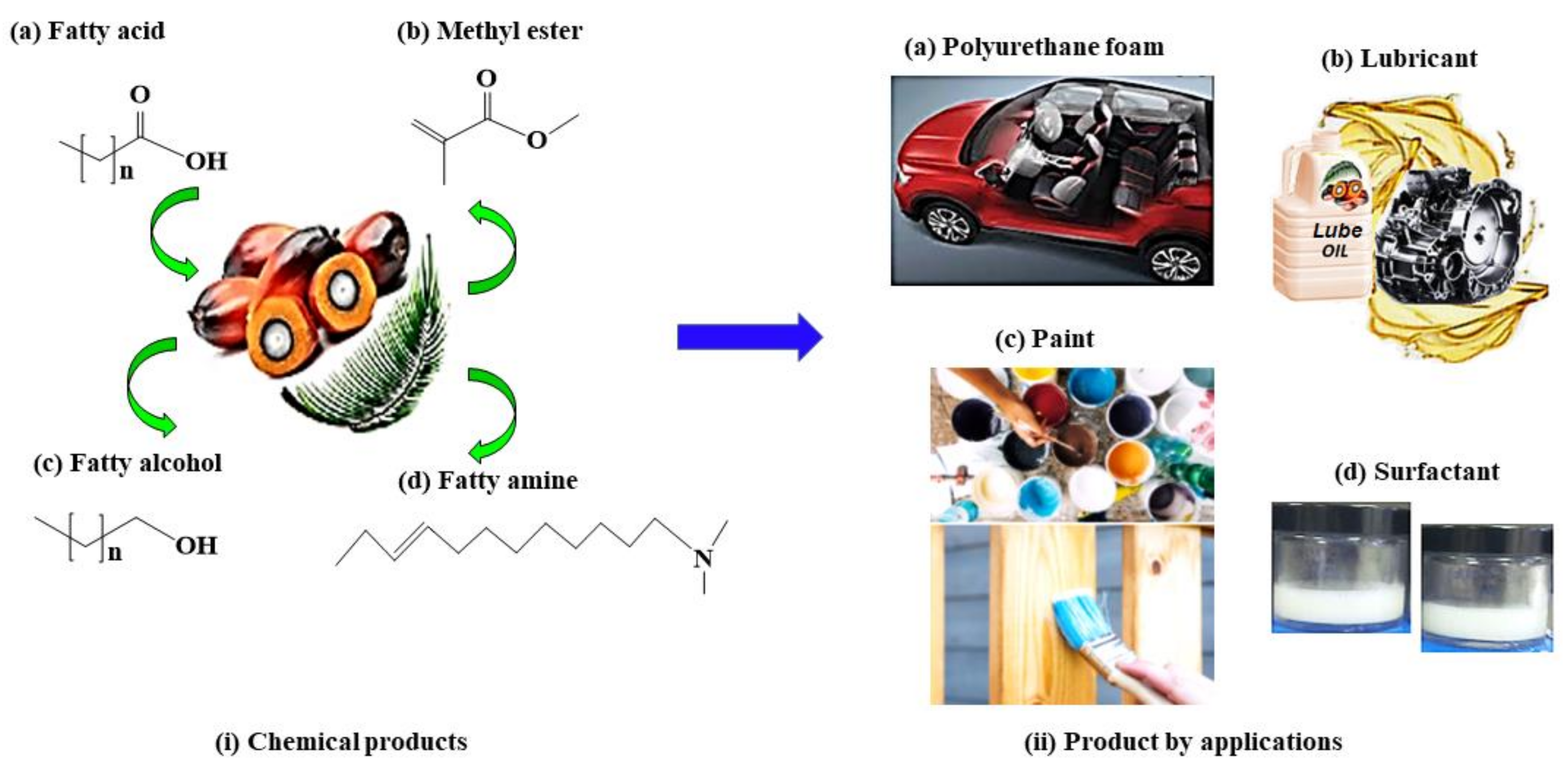

2. Fundamentals of Radiation Processing in Polymeric Biomaterial Design

3. Radiation Curable Palm Oil-Based Materials

4. Current Application of Radiation Curable Palm Oil-Based Polymeric Materials

4.1. Surface Coating

4.2. Drug Delivery Systems

4.3. Scaffolds

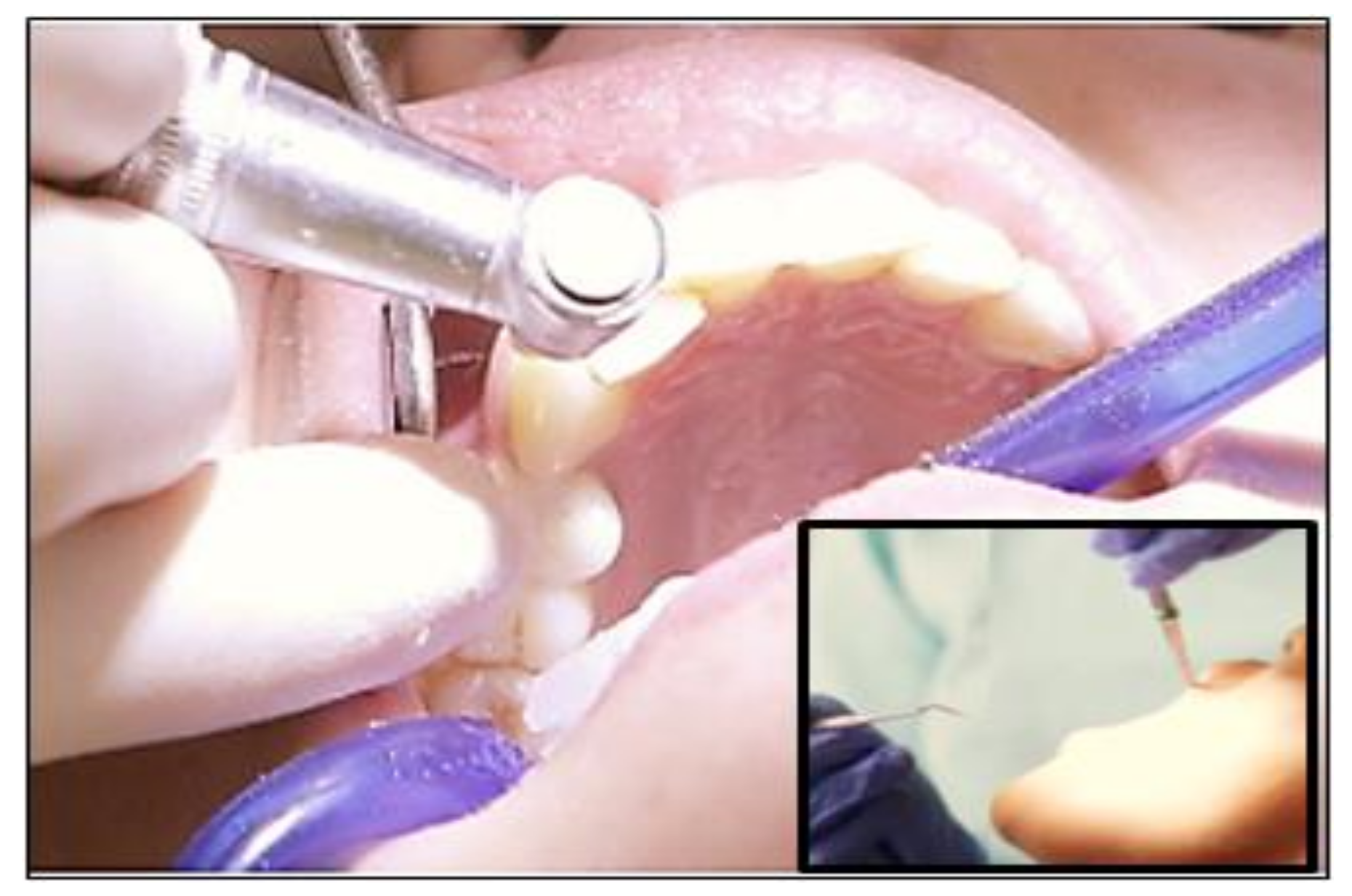

4.4. Dentistry

5. Emerging Applications of Radiation Processing for Modification of Palm Oil-Based Polymeric Biomaterials for Potential Use in Biomedical Application

5.1. Medical Surface Coating

5.2. Medical Light Curing Adhesives

5.3. Nanoscale Radionuclides and Radiolabelled Nanomaterial

5.4. Three-Dimensional (3D) Scaffold for Tissue Engineering Application

6. Way Forward

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salleh, M.Z.; Tajau, R.; Mudri, N.H. The Evolution of Palm Oil Acrylates within 20 Years in Nuclear Malaysia; INIS-MY–2017-072; IAEA: Vienna, Austria, 2016; pp. 1–6. [Google Scholar]

- Hanzah, N.A.; Tuan Ismail, T.N.M.; Adnan, S.; Mohd Noor, N.; Sattar, M.N.; Mohd Zan, A.; Poo Palam, K.D.; Abu Bakar, Z.; Zolkarnain, N.; Hoong, S.S.; et al. Development of Palm oil-based polyols and polyurethane products in MPOB. Palm Oil Dev. 2019, 71, 13–17. [Google Scholar]

- Cheong, M.Y.; Zafarizal Aldrin, A.H. Potential of palm oil as a renewable material for radiation curable coating. Palm Oil Dev. 2018, 68, 14–17. [Google Scholar]

- Mohan, S.; Oluwafemi, O.S.; Kalarikkal, N.; Thomas, S.; Songca, S.P. Biopolymers-Application in Nanoscience and Nanotechnology. In Recent Advances in Biopolymers; Perveen, F.K., Ed.; Intech Open: London, UK, 2016. [Google Scholar]

- Palanisamy, C.P.; Cui, B.; Zhang, H.; Jayaraman, S.; Muthukaliannan, G.K. A Comprehensive Review on Corn Starch-Based Nanomaterials: Properties, simulations, and applications. Polymers 2020, 12, 2161. [Google Scholar] [CrossRef]

- Samrot, A.V.; Tan, C.S.; Bisyarah, U.; Mirarmandi, A.; Faradjeva, E.; Abu bakar, A.; Alia, H.H.; Angalene, J.L.A.; Kumar, S.S. Production, characterization and application of nanocarriers made of polysaccharides, proteins, bio-polyesters and other biopolymers: A review. Int. J. Biol. Macromol. 2020, 165, 3088–3105. [Google Scholar] [CrossRef]

- Han, Y.; Duan, Q.; Li, Y.; Tian, J. Preparation and characterization of chitosan-based nanoparticles as protein delivery system. Adv. Polym. Technol. 2018, 37, 1–7. [Google Scholar] [CrossRef]

- Wurm, F.R.; Weiss, C.K. Nanoparticles from renewable polymers. Front. Chem. 2014, 2, 49. [Google Scholar] [CrossRef] [PubMed]

- Ab Latif, F.E.; Zainal Abidin, Z.; Cardona, F.; Awang Biak, D.R.; Abdan, K.; Mohd Tahir, P.; Liew, K.E. Bio-resin production through ethylene unsaturated carbon using vegetable oils. Processes 2020, 8, 48. [Google Scholar] [CrossRef]

- Mustapha, R.; Rahmat, A.R.; Abdul Majid, R.; Mustapha, S.N.H. Vegetable oil-based epoxy resins and their composites with bio-based hardener: A short review. Polym. Plast. Technol. Mater. 2019, 58, 1311–1326. [Google Scholar] [CrossRef]

- Gan, Y.; Jiang, X. Photo-cured materials from vegetable oils. In Green Materials from Plant Oils; Liu, Z., Kraus, G., Eds.; Royal Society of Chemistry: Cambridge, UK, 2014; Volume RSC Green Chemistry; pp. 1–27. [Google Scholar]

- Mohd Noor, M.A.; Tuan Ismail, T.N.M.; Ghazali, R. Bio-based content of oligomers derived from palm oil: Sample combustion and liquid scintillation counting technique. Malays. J. Anal. Sci. 2020, 24, 906–917. [Google Scholar]

- Hassana, N.; Idris, A.; Akhtarb, J. Overview on bio-refinery concept in Malaysia: Potential high value-added products from palm oil biomass. J. Kejuruter. 2019, 2, 113–124. [Google Scholar]

- Idriss, M.; Hodroj, M.H.; Fakhoury, R.; Rizk, S. Beta-Tocotrienol Exhibits More Cytotoxic Effects than Gamma-Tocotrienol on Breast Cancer Cells by Promoting Apoptosis via a P53-Independent PI3-Kinase Dependent Pathway. Biomolecules 2020, 10, 577. [Google Scholar] [CrossRef] [PubMed]

- Tomeo, A.C.; Geller, M.; Watkins, T.R.; Gapor, A.; Bierenbaum, M.L. Antioxidant effects of tocotrienols in patients with hyperlipidemia and carotid stenosis. Lipids 1995, 30, 1179–1183. [Google Scholar] [CrossRef]

- Pignitter, M.; Hernler, N.; Zaunschirm, M.; Kienesberger, J.; Somoza, M.M.; Kraemer, K.; Somoza, V. Evaluation of Palm Oil as a Suitable Vegetable Oil for Vitamin A Fortification Programs. Nutrients 2016, 8, 378. [Google Scholar] [CrossRef] [PubMed]

- Ashfaq, A.; Clochard, M.C.; Coqueret, X.; Dispenza, C.; Driscoll, M.S.; Ulanski, P.; Al-Sheikhly, A. Polymerization Reactions and Modifications of Polymers by Ionizing Radiation. Polymers 2020, 12, 2877. [Google Scholar] [CrossRef] [PubMed]

- Freitas, L.F.D.; Varca, G.H.C.; Batista, J.G.D.S.; Lugão, A.B. An Overview of the Synthesis of Gold Nanoparticles Using Radiation Technologies. Nanomaterials 2018, 8, 939. [Google Scholar] [CrossRef] [PubMed]

- Gerasimov, G.Y. Radiation methods in nanotechnology. J. Eng. Phys. Thermophys. 2011, 84, 947–963. [Google Scholar] [CrossRef]

- Tajau, R.; Hashim, K.; Sharif, J.; Ratnam, C.T. Teknologi Pemprosesan Sinaran Mengion (Ionizing Radiation Processing Technology); Dewan Bahasa dan Pustaka: Kuala Lumpur, Malaysia, 2017. [Google Scholar]

- Sun, Y.; Chmielewski, A.G. Applications of Ionizing Radiation in Materials Processing; Institute of Nuclear Chemistry and Technology: Warszawa, Poland, 2017; Volume 1, pp. 1–244. [Google Scholar]

- Quinn, J.F.; Davis, T.P.; Barner, L.; Barner-Kowollik, C. The application of ionizing radiation in reversible addition refragmentation chain transfer (RAFT) polymerization: Renaissance of a key synthetic and kinetic tool. Polymer 2007, 48, 6467–6480. [Google Scholar] [CrossRef]

- Chmielewska, D. Radiation methods and uses in nanotechnology. In Applications of Ionizing Radiation in Materials Processing; Sun, Y., Chmielewski, A.G., Eds.; Institute of Nuclear Chemistry and Technology: Warszawa, Poland, 2017; Volume 1, pp. 395–414. [Google Scholar]

- IAEA. Uses of Ionizing Radiation for Tangible Cultural Heritage Conservation; International Atomic Energy Agency: Vienna, Austria, 2017; pp. 1–264. [Google Scholar]

- Adlienė, D. Basic radiation physics and sources of radiation. In Applications of Ionizing Radiation in Materials Processing; Sun, Y., Chmielewski, A.G., Eds.; Institute of Nuclear Chemistry and Technology: Warszawa, Poland, 2017; Volume 1, pp. 7–31. [Google Scholar]

- Vasile, C.; Butnaru, E. Radiation chemistry of organic solids. In Applications of Ionizing Radiation in Materials Processing; Sun, Y., Chmielewski, A.G., Eds.; Institute of Nuclear Chemistry and Technology: Warszawa, Poland, 2017; Volume 1, pp. 117–141. [Google Scholar]

- Rosiak, J.M.; Ulanski, P. Synthesis of hydrogels by irradiation of polymers in aqueous solution. Radiat. Phys. Chem. 1999, 55, 139–151. [Google Scholar] [CrossRef]

- Ulanski, P.; Janik, I.; Rosiak, J.M. Radiation formation of polymeric nanogels. Radiat. Phys. Chem. 1998, 52, 289–294. [Google Scholar] [CrossRef]

- Abdulkarim, M.F.; Abdullah, G.Z.; Sakeena, M.H.F.; Chitneni, M.; Yam, M.F.; Mahdi, E.S.; Salman, I.M.; Ameer, O.Z.; Sattar, M.A.; Basri, M.; et al. Study of pseudoternary phase diagram behaviour and the effect of several tweens and spans on palm oil esters characteristics. Int. J. Drug Deliv. 2011, 3, 95–100. [Google Scholar] [CrossRef]

- Amir Reza, S.; Suraya, A.R.; Azmi, Z. Synthesis of gold nanoparticles dispersed in palm oil using laser ablation technique. J. Nanomater. 2017, 1–5. [Google Scholar] [CrossRef]

- Syafinaz, Z.; Mahiran, B.; Hamidon, B.; Ahmad Fuad, S.; Siti Salwa, A.G.; Roghayeh, A.K.; Emilia, A.M. Formulation optimization of a palm-based nanoemulsion system containing levodopa. Int. J. Mol. Sci. 2012, 13, 13049–13064. [Google Scholar]

- Tajau, R.; Rohani, R.; Wan Isahak, W.N.R.; Salleh, M.Z. Palm oil-based precursors for development of polymeric delivery system. Malays. J. Anal. Sci. 2017, 21, 496–511. [Google Scholar]

- Agensi Nuklear Malaysia. EPOLA; Trade Mark 2016074912; Intellectual Property Corporation of Malaysia (MyIPO): Kuala Lumpur, Malaysia, 2016.

- Tajau, R.; Rohani, R.; Salleh, M.Z. Physicochemical and thermal properties of acrylated palm olein as promising biopolymer. J. Polym. Environ. 2020, 28, 2734–2748. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Tajau, R.; Mohd Dahlan, K.Z.; Salleh, M.Z.; Che Ismail, R. Synthesis and Production of Palm Oil Based Urethane Acrylates (Pobua) for Use in Uv/Eb Curing of Coating Adhesives and Printing Inks; Malaysia Patent No. MY-176255-A; Intellectual Property Corporation of Malaysia (MyIPO): Kuala Lumpur, Malaysia, 2020.

- Tajau, R.; Ibrahim, M.I.; Mohd Yunus, N.; Mahmood, M.H.; Salleh, M.Z.; Nik Salleh, N.G. Development of palm oil-based UV-curable epoxy acrylate and urethane acrylate resins for wood coating application. In Proceedings of the International Conference on Nuclear Science Technology and Engineering 2013 (iNuSTEC2013), Kuala Lumpur, Malaysia, 30 September–2 October 2014; pp. 164–169. [Google Scholar]

- Teo, K.T.; Aziz, H.; Gan, S.N. UV-curable urethane acrylate resin from palm fatty acid distillate. Polymer 2018, 10, 1374. [Google Scholar] [CrossRef]

- Nik Salleh, N.G.; Salleh, M.Z.; Tajau, R.; Alias, M.S.; Harun, M.H.; Mudri, N.H.; Abdul Halim, K.A.; Muhammad Faisal, S.; Che Ismail, R. Radiation Curable Resin for Overprint Varnish; Malaysia Filing Patent No. PI 2016704912; Intellectual Property Corporation of Malaysia (MyIPO): Kuala Lumpur, Malaysia, 2016.

- Mahmood, M.H.; Abdullah, Z.; Sakurai, Y.; Mohd Dahlan, K.Z. Effects of monomers on the properties of palm-oil-based radiation curable pressure sensitive adhesives (PSA)—A prepolymer method. Radiat. Phys. Chem. 2001, 60, 129–137. [Google Scholar] [CrossRef]

- Salleh, M.Z.; Badri, K.; Tajau, R.; Nik Salleh, N.G. The production of green polymer-Hyperbranced curable palm oil oleic acid. Adv. Mateials Res. 2014, 1024, 197–200. [Google Scholar] [CrossRef]

- Mudri, N.H.; Nik Salleh, N.G.; Salleh, M.Z.; Alias, M.S.; Tajau, R.; Che Ismail, R.; Abdurrahaman, N. Development of UV Curable Overprint Varnishes (OPV) Formulation from Epoxidized Palm Olein Acrylated (EPOLA). In Proceedings of the Seminar R&D Nuklear Malaysia 2016 Kajang, Selangor, Malaysia, 14–16 October 2014. [Google Scholar]

- Asraf, M.S.; Ahmad, M.; Ibrahim, N.A.; Mohd Dahlan, K.Z.; Tajau, R.; Mahmood, M.H.; Wan Yunus, W.M.Z. Synthesis of radiation curable palm oil-based epoxy acrylate: NMR and FTIR spectroscopic investigations. Molecules 2015, 20, 14191–14211. [Google Scholar]

- Nurliyana, A.R.; Khairiah, B.; Nik Ghazali, N.S. UV-curable acrylated coating from epoxidized palm oil. Aip Conf. Proc. 2014, 1614, 439–445. [Google Scholar]

- Tajau, R.; Mahmood, M.H.; Salleh, M.Z.; Mohd Dahlan, K.Z.; Che Ismail, R.; Muhammad Faisal, S.; Sheikh Abdul Rahman, S.M.Z. Production of uv-curable palm oil resins/oligomers using laboratory scale and pilot scale systems. Sains Malays. 2013, 42, 459–467. [Google Scholar]

- Mohd Azam, A.; Ooi, T.L.; Salmiah, A.; Umaru, S.I.; Mohd Ishak, Z.A. New UV-Curable Acrylated Polyester Prepolymers from Palm Oil Based Products; INIS-MY-034; International Atomic Energy Agency: Vienna, Austria, 1999; pp. 383–390. [Google Scholar]

- Kosheela Devi, P.P.; Hazimah, A.H.; Tuan Noor Maznee, T.I.; Yeong, S.K.; Hoong, S.S.; Kushairi, A.; Choo, Y.M. Optimisation on synthesis of acrylated epoxidised palm olein using response surface methodology. J. Oil Palm Res. 2015, 27, 366–376. [Google Scholar]

- Mek Zah, S.; Khairiah, H.B.; Mohd Hilmi, M.; Sahrim, A. Synthesis of UV-curable hyperbranched urethane acrylate from palm oil oleic acid. J. Nucl. Relat. Technol. 2010, 7, 38–48. [Google Scholar]

- Salleh, M.Z.; Badri, K.; Ahmad, S.; Mahmood, M.H.; Tajau, R.; Nik Salleh, N.G.; Latif, M.L. Properties of radiation curable hyperbranched polyurethane acrylate from palm oil oleic acid. Nucl. Sci. Tech. 2013, 24, 1–6. [Google Scholar]

- Hazimah, A.H.; Kosheela Devi, P.P.; Tuan Noor Maznee, T.I.; Mohd Norhisham, S.; Hoong, S.S.; Yeong, S.K.; Salmiah, A.; Ooi, T.L. Palm-based polyols and polyurethanes: Two decades of expriences. Oil Palm Bull. 2011, 63, 33–42. [Google Scholar]

- Ooi, T.L.; Salmiah, A.; Hazimah, A.H.; Chong, Y.J. An overview of R&D in palm oil-based polyols and polyurethanes in MPOB. Palm Oil Dev. 2006, 44, 1–7. [Google Scholar]

- Sharifah Nafisah, S.I.; Ahmad Faiza, M.; Rahmah, M. Synthesis and properties of acrylated epoxidized palm oil for UV cured coatings. Solid State Sci. Technol. 2017, 25, 86–95. [Google Scholar]

- Tugiman, N.; Rahmat, A.R.; Jamaluddin, J.; Wan Tajulruddin, W.N.; Mustapha, R. Preliminary study on degree of conversion of uv curablemaleinated acrylated epoxidised palm oil pressure sensitive adhesives synthesised with isobornyl methacrylate monomer via FTIR-ATR analysis. Chem. Eng. Trans. 2017, 56, 223–228. [Google Scholar]

- Onn, M.; Mohd, A.F.; Yhaya, M.F. The effect of reactives diluents to the physical properties of acrylated palm oil based polyurethane coatings. In Proceedings of the MATEC Web of Conferences, Melaka, Malaysia, 1–2 December 2015; pp. 1–7. [Google Scholar]

- Said, H.M.; Nik Salleh, N.G.; Alias, M.S.; El-Naggar, A.W.M. Synthesis and characterization of hard materials based on radiation cured bio-polymer and nanoparticles. J. Radiat. Res. Appl. Sci. 2013, 6, 71–78. [Google Scholar] [CrossRef][Green Version]

- Cheong, M.Y.; Ooi, T.L.; Ahmad, S.; Wan Yunus, W.M.Z.; Kuang, D. Synthesis and characterization of palm-based resin for UV coating. J. Appl. Polym. Sci. 2009, 111, 2353–2361. [Google Scholar] [CrossRef]

- Ulanski, P.; Rosiak, J.M. Polymeric nano/microgels. In Encyclopedia of Nanoscience and Nanotechnology; Nalwa, H.S., Ed.; American Scientific Publishers: Los Angeles, CA, USA, 2004; Volume 10, pp. 1–26. [Google Scholar]

- Dispenza, C.; Alessi, S.; Spadaro, G. Radiation processing of polymers in aqueous media. In Applications of Ionizing Radiation in Materials Processing; Sun, Y., Chmielewski, A.G., Eds.; Institute of Nuclear Chemistry and Technology: Warszawa, Poland, 2017; Volume 2, pp. 291–326. [Google Scholar]

- Hamzah, Y.; Wan Yunus, W.M.Z.; Mat Isa, N.; Tajau, R.; Hashim, K.; Mohd Dahlan, K.Z. Synthesis of polyethylene glycol diacrylate nanogel using irradiation of inverse micelles technique. E-Polymer 2012, 12, 1–6. [Google Scholar] [CrossRef]

- Noordin, M.I.; Yong, C.L.; Mofat, I.; Zainuddin, Z.; Arya, A.; Nyamathulla, S. Evaluation of palm oil-based paracetamol suppositories by differential scanning calorimetry. Trop. J. Pharm. Res. 2014, 13, 23–29. [Google Scholar] [CrossRef][Green Version]

- Basheer, H.S.; Mohamed Ibrahim, N.; Ghareeb, M.M. Characterization of microemulsions prepared using isopropyl palmitate with various surfactants and cosurfactants. Trop. J. Pharm. Res. 2013, 12, 305–310. [Google Scholar]

- Pradhan, S.; Sagiri, S.S.; Singh, V.K.; Pal, K.; Ray, S.S.; Pradhan, D.K. Palm oil-based organogels and microemulsions for delivery of antimicrobial drugs. J. Appl. Polym. Sci. 2014, 131, 39979. [Google Scholar] [CrossRef]

- Baran, N.; Singh, V.K.; Pal, K.; Anis, A.; Pradhan, D.K.; Pramanika, K. Development and characterization of soy lecithin and palm oil-based organogels. Polym. Plast. Technol. Eng. 2014, 53, 865–879. [Google Scholar] [CrossRef]

- Sakeena, M.H.; Muthanna, F.A.; Ghassan, Z.A.; Kanakal, M.M.; Elrashid, S.M.; Munavvar, A.S.; Azmin, M.N. Formulation and in vitro evaluation of ketoprofen in palm oil esters nanoemulsion for topical delivery. J. Oleo Sci. 2010, 59, 223–228. [Google Scholar] [CrossRef] [PubMed]

- Musthanna, F.A.; Ghassan Zuhair, A.; Mallikarjun, C.; Elrashid Saleh, M.; Mun, F.Y.; Ahmed, F.; Ibrahim, M.S.; Omar Ziad, A.; Mohanad, N.S.; Munawar Zubaid, A.; et al. Formulation and characterization of palm oil esters based nanocream for topical delivery of piroxicam. Int. J. Drug Deliv. 2010, 2, 287–298. [Google Scholar]

- Cook, R.O.; Pannu, R.K.; Kellaway, I.W. Novel sustained release microspheres for pulmonary drug delivery. J. Control. Release 2005, 104, 79–90. [Google Scholar] [CrossRef] [PubMed]

- Tajau, R.; Mohd Dahlan, K.Z.; Mahmood, M.H.; Wan Yunus, W.M.Z.; Hashim, K. Radiation induced formation of acrylated palm oil (APO) nanoparticles using cetyltrimethylammonium bromide microemulsion system. J. Adv. Mater. Res. 2012, 364, 278–282. [Google Scholar] [CrossRef]

- Abbasalipourkabir, R.; Salehzadeh, A.; Abdullah, R. Characterization and stability of nanostructured lipid carriers as drug delivery system. Pak. J. Biol. Sci. 2012, 15, 141–146. [Google Scholar] [CrossRef][Green Version]

- Rodrigues, M.; Peirico, N.; Matos, H.; Azevedo, E.G.; Lobato, M.R.; Almeida, A.J. Microcomposites theophylline/hydrogenated palm oil from a PGSS process for controlled drug delivery systems. J. Supercrit. Fluids 2004, 29, 175–184. [Google Scholar] [CrossRef]

- Bahareh, S.; Mohamed Ibrahim, N.; Shaharuddin, M.; Rosnani, H.; Afendi, D.; Javar, H.A. Development and characterization of liposomal doxorubicin hydrochloride with palm oil. Biomed Res. Int. 2014, 2014, 765426. [Google Scholar]

- Bahareh, S.; Mohamed Ibrahim, N.; Shaharuddin, M.; Rosnani, H.; Afendi, D.; Javar, H.A. Degradation study of liposome drug delivery prepared with palm oil; Using 1H NMR. Int. J. Pharm. Sci. Res. 2015, 6, 2741–2747. [Google Scholar]

- Reza, Z.; Azmi, Z.; Hossein, A.A.; Amir Reza, S.; Mohd Adzir, M. Fabrication of silver nanoparticles dispersed in palm oil using laser ablation. Int. J. Mol. Sci. 2010, 11, 4764–4770. [Google Scholar]

- Tajau, R.; Mohd Dahlan, K.Z.; Mahmood, M.H.; Salleh, M.Z. A Composition Susceptible to Irradiation for Use as a Compound Carrier; Malaysia Patent No. MY-182996-A; Intellectual Property Corporation of Malaysia (MyIPO): Kuala Lumpur, Malaysia, 2021.

- Sadrolhosseini, A.R.; Mahdi, M.A.; Alizadeh, F.; Rashid, S.A. Laser Ablation Technique for Synthesis of Metal Nanoparticle in Liquid, Laser Technology and its Applications. In Laser Technology and its Applications; Ma, Y., Ed.; IntechOpen: London, UK, 2019; pp. 63–84. [Google Scholar]

- Tajau, R.; Rohani, R.; Abdul Hamid, S.S.; Adam, Z.; Mohd Janib, S.N.; Salleh, M.Z. Surface functionalisation of poly-APO-b-polyol ester cross-linked copolymers as core-shell nanoparticles for targeted breast cancer therapy. Sci. Rep. 2020, 10, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Caykara, T. Polymer Brushes by surface-mediated raft polymerization for biological function. In Polymer and Biopolymer Brushes: For Materials Science and Biotechnology; Azzaroni, O., Szleife, I., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2017; Volume 1, pp. 97–122. [Google Scholar]

- Zengin, A.; Yildirim, E.; Tamer, U.; Caykara, T. Molecularly imprinted superparamagnetic iron oxide nanoparticles for rapid enrichment and separation of cholesterol. Analyst 2013, 138, 7238–7245. [Google Scholar] [CrossRef] [PubMed]

- Karmakar, P.D.; Seesala, V.S.; Pal, A.; Dhara, S.; Chatterjee, S.; Pal, S. Synthesis of raft-mediated amphiphilic graft copolymeric micelle using dextran and poly (oleic acid) toward oral delivery of nifedipine. J. Polym. Sci. Part. A Polym. Chem. 2018, 56, 2354–2363. [Google Scholar] [CrossRef]

- Shaikh, N.; Payghan, S.A.; Desouza, J.I. Formulation of gastroretentive drug delivery system (floating tablets) of nifedipine. Int. J. Pharm. Sci. Res. 2011, 2, 2929–2933. [Google Scholar]

- Talib, M. Formulation of photopolymer resin prepared from acrylated palm oil resin for tissue engineering application. In Proceedings of the IAEA Fourth Research Coordinating Meeting of the IAEA Coordinate Research Project (F23030-E31007) on Instructive Surfaces and Scaffolds for Tissue Engineering Using Radiation Technology, Sao Paulo, Brazil, 8–12 April 2019. [Google Scholar]

- Tajau, R.; Talib, M. Biobahan (Biomaterial). In Teknologi Pemprosesan Sinaran Mengion (Ionizing Radiation Processing Technology); Tajau, R., Hashim, K., Sharif, J., Ratnam, C.T., Eds.; Dewan Bahasa Dan Pustaka: Kuala Lumpur, Malaysia, 2017; pp. 199–222. [Google Scholar]

- Serrano-Aroca, A.; Deb, S. Acrylic-based hydrogels as advanced biomaterials. In Acrylate Polymers for Advanced Applications; Serrano-Aroca, A., Ed.; Intechopen: London, UK, 2020. [Google Scholar]

- Jabbari, E.; Nozari, S. Swelling behavior of acrylic acid hydrogels prepared by γ-radiation crosslinking of polyacrylic acid in aqueous solution. Eur. Polym. J. 2000, 36, 2685–2692. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Kim, S.; Lee, Y.; Le, E.K. Synthesis and characteristics of interpenetrating polymer network hydrogel composed of chitosan and poly(acrylic acid). Polymer 1998, 73, 113–120. [Google Scholar] [CrossRef]

- Fabbri, P.; Valentini, L.; Bittolo Bon, S.; Foix, D.; Pasquali, L.; Montecchi, M.; Sangermano, M. In-situ graphene oxide reduction during UV-photopolymerization of graphene oxide/acrylic resins mixtures. Polymer 2012, 53, 6039–6044. [Google Scholar] [CrossRef]

- Rao, U.; Sridhar, R.; Sehgal, P.K. Biosynthesis and biocompatibility of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) produced by Cupriavidus necator from spent palm oil. Biochem. Eng. J. 2010, 49, 13–20. [Google Scholar] [CrossRef]

- Kamilah, H.; Al-Gheethi, A.; Yang, T.A.; Sudesh, K. The use of palm oil-based waste cooking oil to enhance the production of polyhydroxybutyrate [P(3HB)] by cupriavidus necator H16 strain. Arab. J. Sci. Eng. 2019, 44, 673–674. [Google Scholar] [CrossRef]

- Ardelean, L.C.; Bortun, C.M.; Podariu, A.C.; Rusu, L.C. Acrylates and their alternatives in dental applications. In Acrylic Polymers in Healthcare; Reddy, B.S.R., Ed.; Intechopen: London, UK, 2017. [Google Scholar]

- Tyliszczak, B.; Drabczyk, A.; Kudłacik-Kramarczyk, S. Acrylates in Dental Applications. In Acrylic Polymers in Healthcare; Reddy, B.S.R., Ed.; Intechopen: London, UK, 2017. [Google Scholar]

- Rokaya, D.; Srimaneepong, V.; Sapkota, J.; Qin, J.; Siraleartmukul, K.; Siriwongrungson, V. Polymeric materials and films in dentistry: An overview. J. Adv. Res. 2018, 14, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Ionta, F.Q.; Alencar, C.R.B.; Val, P.P.; Boteon, A.P.; Jordão, M.C.; Honório, H.M.; Buzalaf, M.A.R.; Rios, D. Effect of vegetable oils applied over acquired enamel pellicle on initial erosion. J. Appl. Oral Sci. 2017, 25, 420–426. [Google Scholar] [CrossRef]

- Gan, S.N.; Kasim, N.H.B.A.; Alsanabana, F.; Radzi, Z.B.; Yahya, N.A.B. Polyurethane Oligomers for Use in Restorative Dentistry. U.S. Patent No. 8,703,897, 22 April 2014. [Google Scholar]

- Sharma, K.K.; Singh, U.S.; Sharma, P.; Kumar, A.; Sharma, L. Seed treatments for sustainable agriculture-A review. J. Appl. Nat. Sci. 2015, 7, 521–539. [Google Scholar] [CrossRef]

- Ryan, J.W.; Juen, D.R. Crosslinked Silicone Coatings for Botanical Seeds. U.S. Patent No. 4,753,035, 28 June 1988. [Google Scholar]

- Fierascu, R.C.; Doni, M.; Fierascu, I. Selected aspects regarding the restoration/conservation of traditional wood and masonry building materials: A short overview of the last decade findings. Appl. Sci. 2020, 10, 1164. [Google Scholar] [CrossRef]

- Cao, Y.; Salvini, A.; Camaiti, M. Current status and future prospects of applying bioinspired superhydrophobic materials for conservation of stone artworks. Coatings 2020, 10, 353. [Google Scholar] [CrossRef]

- Mohd Nor, H.; Mahmood, M.H.; Kifli, H.; Abdul Rahman, M. The use of epoxidised palm oil products for the synthesis of radiation curable resins: Several factors affecting the synthesis of epoxidised RBD palm olein acrylate (EPOLA). Elaeis 1992, 4, 60–64. [Google Scholar]

- Mahmood, M.H.; Tajau, R.; Salleh, M.Z.; Che Ismail, R. Method for Manufacturing Palm Oil Based Hydroxyl Containing Products for Use in Making Polyurethane Materials; Malaysia Patent No. MY-142814-A; Intellectual Property Corporation of Malaysia (MyIPO): Kuala Lumpur, Malaysia, 2011.

- Sangermano, M.; Malucelli, G.; Amerio, E.; Priola, A.; Billi, E.; Rizza, G. Photopolymerization of epoxy coatings containing silica nanoparticles. Prog. Org. Coat. 2005, 54, 134–138. [Google Scholar] [CrossRef]

- Alias, M.S.; Nik Salleh, N.G.; Salleh, M.Z.; Harun, M.H.; Tajau, R.; Abdul Halim, K.A.; Mudri, N.H. The influence of zirconium acrylate on curable palm oil resin as coating material by using UV technique. In Proceedings of the Seminar R&D Nuklear Malaysia 2016, Malaysia Nuclear Agency, Kajang, Selangor, Malaysia, 7–9 November 2016. [Google Scholar]

- Mahmood, M.H.; Mohd Nor, H.; Abd Raof, K.H.; Roslan, I.; Mohd Rosli, M.R.; Shariff, S.M.; Abdullah, Z. Development of pressure sensitive adhesives from palm oil acrylated resins by irradiation—A preliminary study. J. Sains Nukl. Malays. 1995, 13, 61–68. [Google Scholar]

- Ng, W.S.; Lee, C.S.; Chuah, C.H.; Cheng, S.F. Preparation and modification of water-blown porous biodegradable polyurethane foams with palm oil-based polyester polyol. Ind. Crop. Prod. 2017, 97, 65–78. [Google Scholar] [CrossRef]

- Ng, W.S.; Choy, S.L.; Cheng, S.F.; Cheng, H.C.; Shew, F.W. Biocompatible polyurethane scaffolds prepared from glycerol monostearate-derived polyester polyol. J. Polym. Environ. 2018, 26, 2881–2900. [Google Scholar] [CrossRef]

- Yeoh, F.H.; Lee, C.S.; Kang, Y.B.; Wong, S.F.; Cheng, S.F.; Ng, W.S. Production of biodegradable palm oil-based polyurethane as potential biomaterial for biomedical applications. Polymer 2020, 112, 1842. [Google Scholar] [CrossRef]

- Yusup, E.; Mahzan, S.; Mohammad, B.; Wan Daud, W.R. A Novel Approach for Bone Scaffold from Oil Palm Empty Fruit Bunch-Cellulose Phosphate/Glass Material. Adv. Mater. Res. 2013, 748, 180–183. [Google Scholar] [CrossRef]

- Zubairi, S.I.; Mantalaris, A.; Bismarck, A.; Aizad, S. Polyhydroxyalkanoates (PHAs) for tissue engineering applications: Biotransformation of palm oil mill effluent (POME) to value-added polymers. J. Teknol. 2016, 78, 13–29. [Google Scholar] [CrossRef][Green Version]

| Type of Palm Oil-Based Products | APO [34] | Polyol Ester [32] |

|---|---|---|

| Acid value (mg KOH/g oil) | 8.37 | 39.74 |

| Saponification value (mg KOH/g oil) | 221.89 | 297.00 |

| Hydroxyl value (mg KOH/g oil) | 46.41 | 182.51 |

| Ester value | 209.14 | 257.26 |

| Viscosity (cps) | 1774.67 | 1006.33 |

| Molecular weight (Daltons) | 1750.04 | 5004.00 |

| Colour | Brownish | Dark |

| Developed Products | Thermal and Mechanical Properties | References |

|---|---|---|

| Acrylated resin from epoxidized oil (EPOLA®-based products) | Adhesion: 1.15 MPa Pencil hardness: H-2H | [51] |

| UV curable PSA of maleinated acrylated epoxidized palm oil (EPOLA®-based products) | Good and high adhesion properties | [52] |

| UV-curable polyurethane coating (EPOLA®-based products) | Adhesion: 0.5–1.5 MPa Pencil hardness: B and 2B Volatile organic compound: 5–15% | [53] |

| UV radiation-curable acrylic resin (EPOLA®-based products) | Degradation: 250–550 °C Pendulum hardness: 60% Tensile strength: 5.2–6.2 MPa | [42] |

| UV-curable acrylated coating (EPOLA®-based products) | Pendulum hardness: 55–75% | [43] |

| UV radiation-curable polyurethane resin (Polyol-based products) | Degradation: 200–455 °C Pencil hardness: B-2H | [48] |

| UV/EB-curable acrylated coating (EPOLA®-based products) | Scratch resistance: 0.1–0.9 N Pendulum hardness: 5–50% Pencil hardness: B-6H | [54] |

| UV curable acrylated polyol ester prepolymer (EPOLA®-based products) | Pendulum hardness: 49.4% | [55] |

| Product Development | Methods | Properties | Potential Application | References |

|---|---|---|---|---|

| Palm oil-based paracetamol suppositories | Double casting | More than 95% drug release | Oral delivery | [59] |

| Transparent microemulsion from palm oil-derived isopropyl palmitate (IPP) with Tween 80 and 1- butanol | Microemulsion | Particle size <150 nm pH: 6.76 to 7.80 Charge: −32 to −75 mV Storage stability for 4 weeks. | Transdermal and Topical | [60] |

| Palm oil based-organogels and microemulsions from palm oil, span 80/tween 80 mixture (organogel) and water | Microemulsion | Highly haemo-compatible Non-irritant | Topical delivery | [61] |

| Palm oil and soy oil-based organogels | Microemulsion | Good spreadability and vscosity profile highly biocompatible | Topical delivery | [62] |

| Palm Oil Esters (POEs)-based nanoemulsions | Microemulsion | Less than 500 nm | Topical delivery | [63] |

| Palm oil esters (POEs)-based nano-cream | Microemulsion | Less than 130 nm −20 mV Stable | Topical delivery | [64] |

| Microspheres encapsulating terbutaline sulphate nanoparticles using hydrogenated palm oil | Emulsion | 3.9 um | Pulmonary delivery | [65] |

| Palm oil-based nanoparticle | Microemulsion and ionizing radiation | Particle size: 70–220 nm | Preliminary study for oral delivery | [66] |

| Solid lipid nanoparticle (SLN) using varieties of emulsifier of palm oil (S154) and lecithin (Lipoid 100) | High pressure homogenization (HPH) | Particle size: 140–300 nm Zeta potential of about −13 and −20 mV uniform size distribution | Colloidal drug delivery | [67] |

| Microcomposites theophylline/hydrogenated palm oil | Particles from gas saturated solutions (PGSS) | Mean particle size: 2.5–3.0 um Contain initially from 0.5 to 3.5% (weight) of theophylline uniform size distribution | Controlled drug delivery systems | [68] |

| Palm oil-based Liposomal Dox (Doxorubicin hydrochloride) | Freeze-thaw |

| Breast cancer delivery | [69] |

| Palm oil-based liposome | Thin film hydration |

| Drug delivery device | [70] |

| Palm-oil-based Liposomal Dox (Doxorubicin hydrochloride) | Freeze-thaw | Distribution sizes of 438 and 453 nm Zeta potential of about −31 and −32 mV Stability | Breast cancer delivery | [71] |

| Palm oil-based liposome | Thin film hydration | Mean particle size: 340–450 nm Zeta potential: −26 to −33 mV Stable Biodegradability | Drug delivery device | [72] |

| Silver nanoparticles | Laser ablation | 2.5–2 nm | Nanocomposite fabrications and antibacterial | [71] |

| Gold nanoparticles | Laser ablation | 8–20 nm | Drug delivery device | [30] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tajau, R.; Rohani, R.; Alias, M.S.; Mudri, N.H.; Abdul Halim, K.A.; Harun, M.H.; Mat Isa, N.; Che Ismail, R.; Muhammad Faisal, S.; Talib, M.; et al. Emergence of Polymeric Material Utilising Sustainable Radiation Curable Palm Oil-Based Products for Advanced Technology Applications. Polymers 2021, 13, 1865. https://doi.org/10.3390/polym13111865

Tajau R, Rohani R, Alias MS, Mudri NH, Abdul Halim KA, Harun MH, Mat Isa N, Che Ismail R, Muhammad Faisal S, Talib M, et al. Emergence of Polymeric Material Utilising Sustainable Radiation Curable Palm Oil-Based Products for Advanced Technology Applications. Polymers. 2021; 13(11):1865. https://doi.org/10.3390/polym13111865

Chicago/Turabian StyleTajau, Rida, Rosiah Rohani, Mohd Sofian Alias, Nurul Huda Mudri, Khairul Azhar Abdul Halim, Mohd Hamzah Harun, Naurah Mat Isa, Rosley Che Ismail, Sharilla Muhammad Faisal, Marina Talib, and et al. 2021. "Emergence of Polymeric Material Utilising Sustainable Radiation Curable Palm Oil-Based Products for Advanced Technology Applications" Polymers 13, no. 11: 1865. https://doi.org/10.3390/polym13111865

APA StyleTajau, R., Rohani, R., Alias, M. S., Mudri, N. H., Abdul Halim, K. A., Harun, M. H., Mat Isa, N., Che Ismail, R., Muhammad Faisal, S., Talib, M., Rawi Mohamed Zin, M., Izni Yusoff, I., Khairul Zaman, N., & Asyila Ilias, I. (2021). Emergence of Polymeric Material Utilising Sustainable Radiation Curable Palm Oil-Based Products for Advanced Technology Applications. Polymers, 13(11), 1865. https://doi.org/10.3390/polym13111865