Usage of Near-Infrared Spectroscopy for Inline Monitoring the Degree of Curing in RTM Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

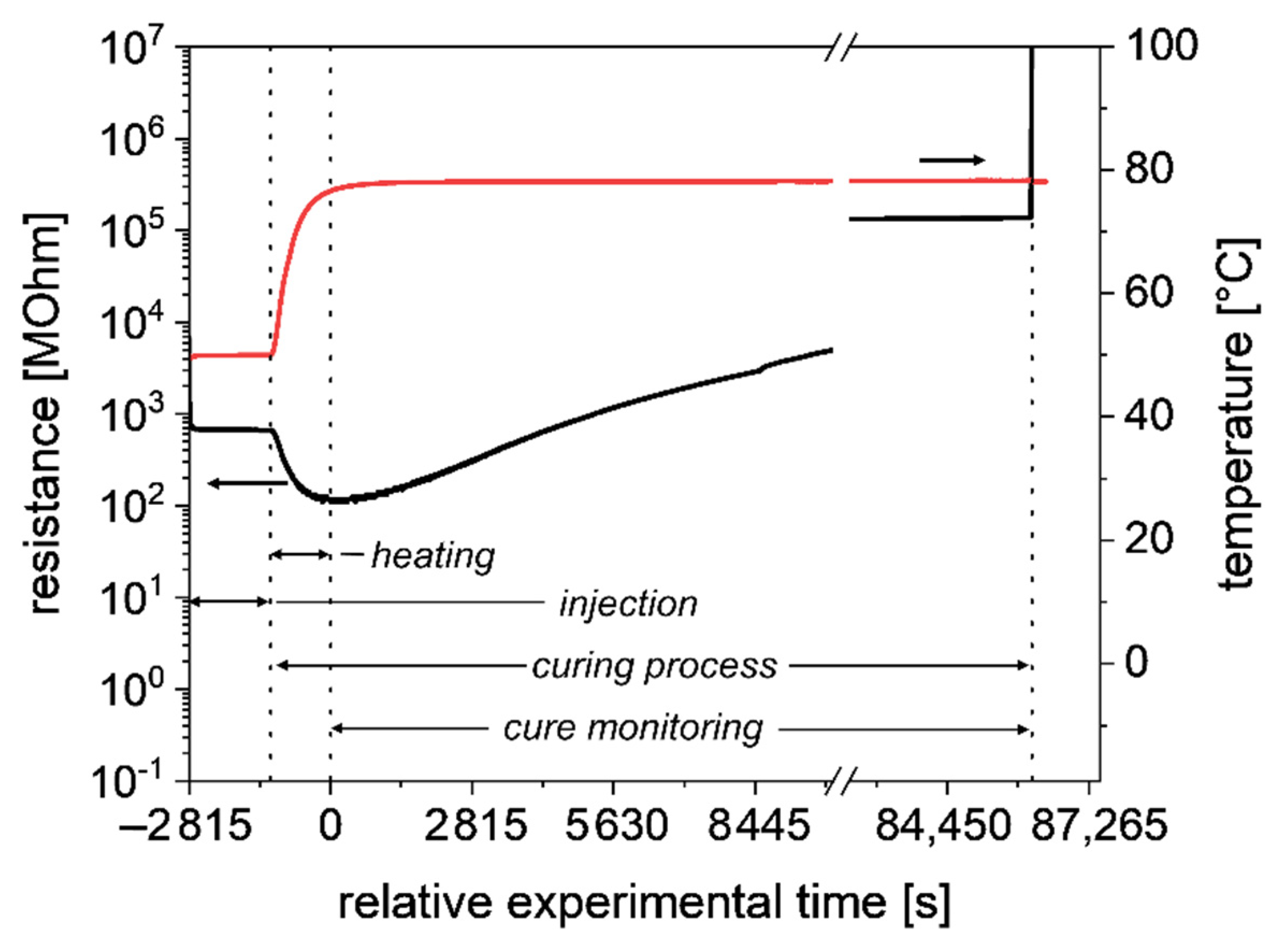

2.2. RTM Process

2.3. Inline Measurements

2.4. DSC Measurements

2.5. Data Analysis

3. Results

3.1. Reference Measurements

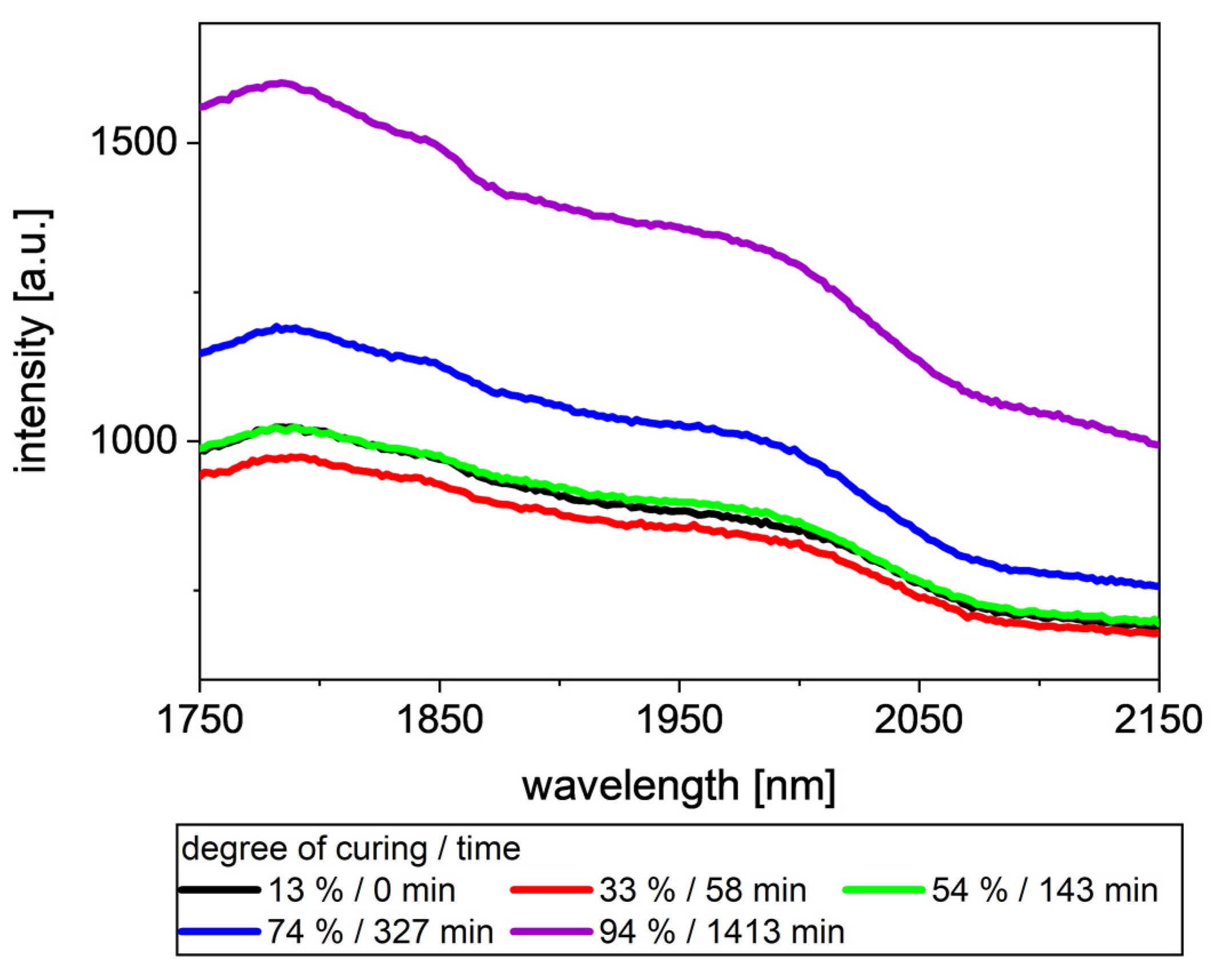

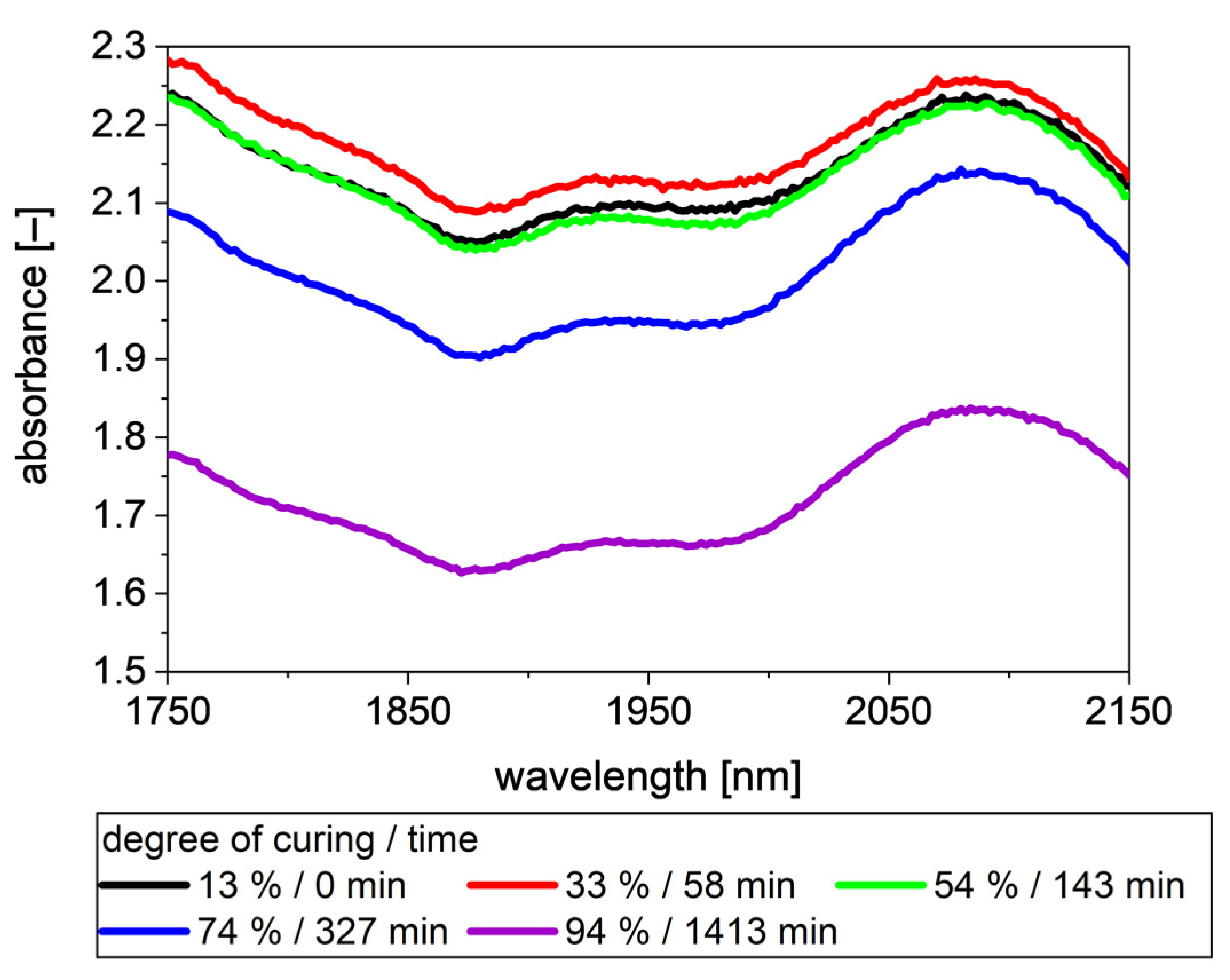

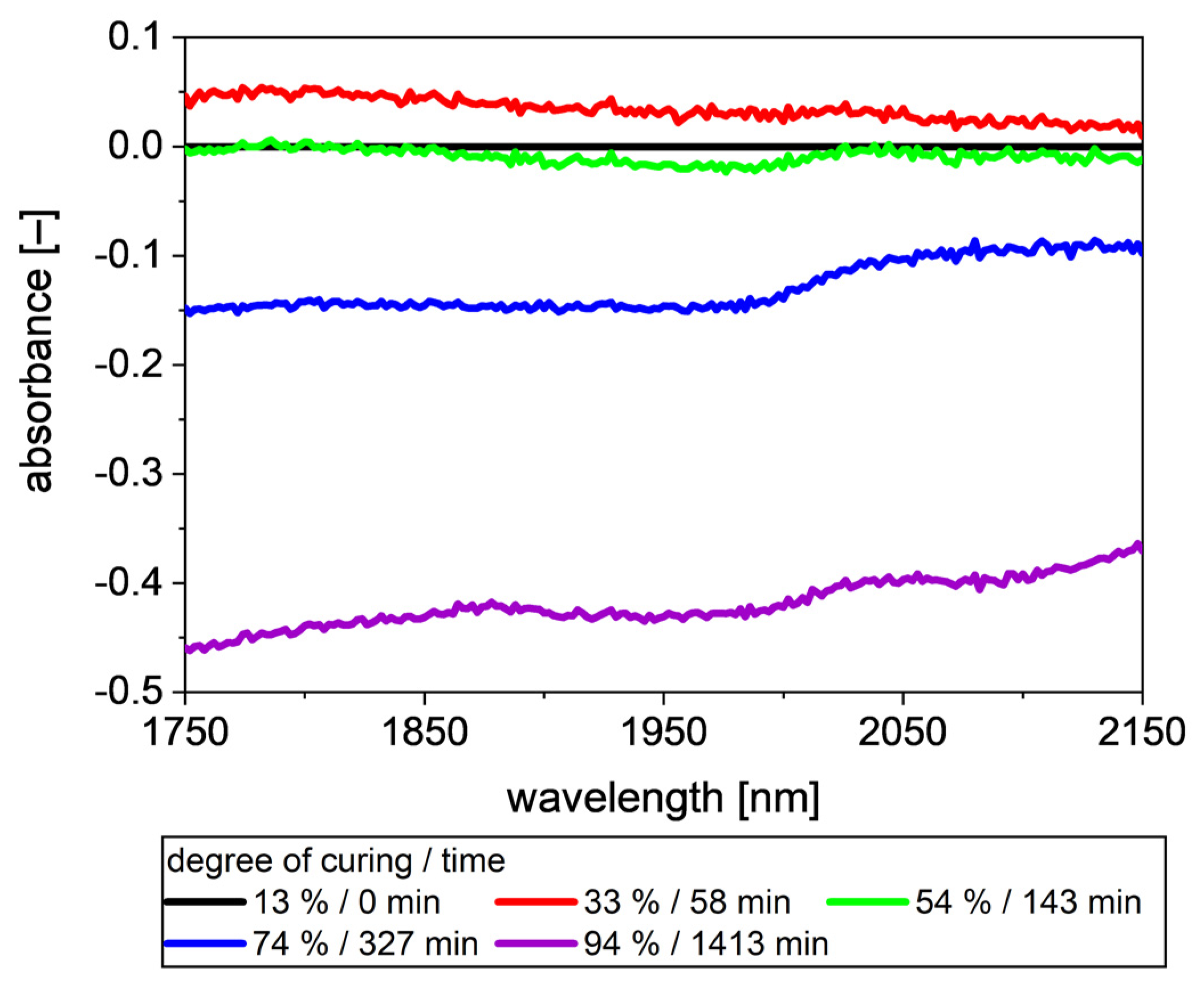

3.2. NIR Data

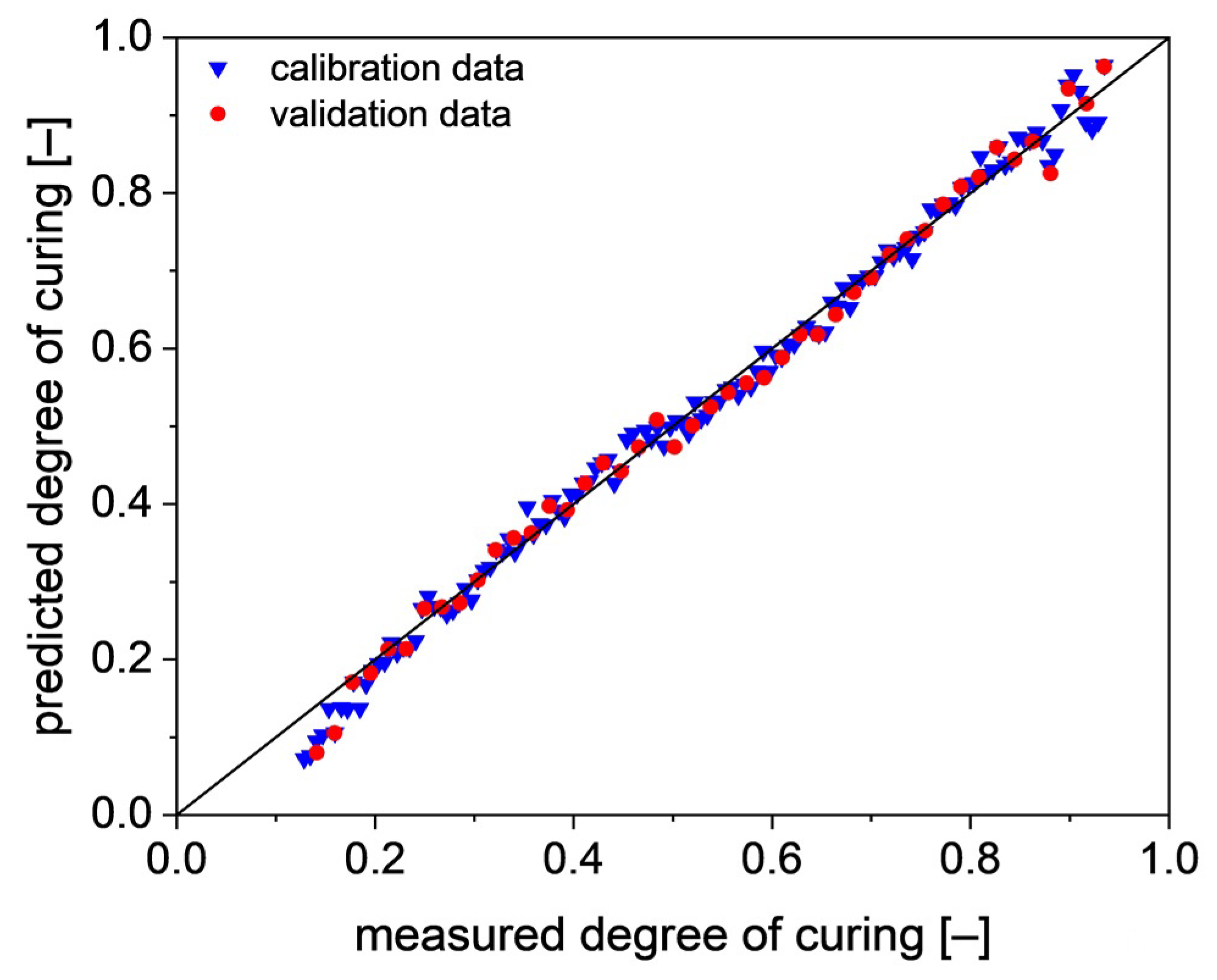

3.3. PLS Model for the Degree of Curing

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ehrenstein, G.W. Faserverbund-Kunststoffe: Werkstoffe-Verarbeitung-Eigenschaften; 2. völlig überarbeitete Auflage; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2006; ISBN 3-446-22716-4. [Google Scholar]

- Struzziero, G.; Skordos, A.A. Multi-objective optimization of Resin Infusion. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 17–28. [Google Scholar] [CrossRef]

- Konstantopoulos, S.; Hueber, C.; Antoniadis, I.; Summerscales, J.; Schledjewski, R. Liquid composite molding reproducibility in real-world production of fiber reinforced polymeric composites: A review of challenges and solutions. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 85–99. [Google Scholar] [CrossRef]

- Konstantopoulos, S.; Fauster, E.; Schledjewski, R. Monitoring the production of FRP composites: A review of in-line sensing methods. Express Polym. Lett. 2014, 8, 823–840. [Google Scholar] [CrossRef]

- Burns, D.A.; Ciurczak, E.W. Handbook of Near-Infrared Analysis, 3rd ed.; Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-0-8493-7393-0. [Google Scholar]

- Jiang, B.; Huang, Y.D. Quality inspection of laid fabric epoxy resins prepreg by near infrared spectroscopy. Compos. Part A Appl. Sci. Manuf. 2008, 39, 712–717. [Google Scholar] [CrossRef]

- Li, W.; Huang, Y.D.; Liu, L.; Bo, J. On-line Monitoring of Resin Content and volatile content in Carbon/Phenolic Resin Prepreg Cloth by Near-Infrared-Spectroscopy. Polym. Polym. Compos. 2006, 14, 537–543. [Google Scholar] [CrossRef]

- Li, W.; Huang, Y.D.; Liu, L.; Jiang, B. The application of near infrared spectroscopy in the quality control analysis of glass/phenolic resin prepreg. J. Mater. Sci 2006, 41, 7183–7189. [Google Scholar] [CrossRef]

- Roggo, Y.; Chalus, P.; Maurer, L.; Lema-Martinez, C.; Edmond, A.; Jent, N. A review of near infrared spectroscopy and chemometrics in pharmaceutical technologies. J. Pharm. Biomed. Anal. 2007, 44, 683–700. [Google Scholar] [CrossRef] [PubMed]

- Tatavarti, A.S.; Fahmy, R.; Hussain, A.S.; Marnane, W.; Bensly, D.; Hollenbeck, G.; Hoag, S.W. Assessment of NIR spectroscopy for nondestructive analysis of physical and chemical attributes of sulfamethazine bolus dosage forms. AAPS Pharmscitech 2005, 6, E91–E99. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sarraguça, M.C.; Lopes, J.A. Quality control of pharmaceuticals with NIR: From lab to process line. Vib. Spectrosc. 2009, 49, 204–210. [Google Scholar] [CrossRef]

- Saad, A.G.; Jaiswal, P.; Jha, S.N. Non-destructive quality evaluation of intact tomato using VIS-NIR spectroscopy. Int. J. Adv. Res. 2014, 12, 632–639. [Google Scholar]

- dos Santos, C.; Lopo, M.; Páscoa, R.; Lopes, J. A review on the applications of portable near-infrared spectrometers in the agro-food industry. Appl. Spectrosc. 2013, 67, 1215–1233. [Google Scholar] [CrossRef] [PubMed]

- Janisse, A.P.; Wiggins, J.S. Real-time quantification of network growth of epoxy/diamine thermosets as a function of cure protocol. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Sales, R.C.M.; Diniz, M.F.; Dutra, R.C.L.; Thim, G.P.; Dibbern-Brunelli, D. Study of curing process of glass fiber and epoxy resin composite by FT-NIR, photoacoustic spectroscopy and luminescence spectroscopy. J. Mater. Sci. 2011, 46, 1814–1823. [Google Scholar] [CrossRef]

- Jiang, B.; He, S.; Huang, Y.D.; Pan, H.T. Investigation of the Kinetics of Curing Reaction for the Resin Matrix Polymer Composite Based on Near-Infrared Spectroscopy. Appl. Spectrosc. Rev. 2015, 50, 627–640. [Google Scholar] [CrossRef]

- Jiang, B.; Huang, Y. Near Infrared Spectroscopy for On-line Monitoring of Alkali- Free Cloth /Phenolic Resin Prepreg During Manufacture. IJMS 2007, 8, 541–552. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Gao, W.J.; Chen, P.; Sun, B.L. Near-Infrared Spectroscopy and Principal Components Regression for the Quality Analysis of Glass/Epoxy Prepreg. Polym. Polym. Compos. 2011, 19, 15–20. [Google Scholar] [CrossRef]

- Yu, Y.; Su, H.; Gan, W. Effects of Storage Aging on the Properties of Epoxy Prepregs. Ind. Eng. Chem. Res. 2009, 48, 4340–4345. [Google Scholar] [CrossRef]

- Wang, Q.; Storm, B.K.; Houmøller, L.P. Study of the isothermal curing of an epoxy prepreg by near-infrared spectroscopy. J. Appl. Polym. Sci. 2003, 87, 2295–2305. [Google Scholar] [CrossRef] [Green Version]

- Salzmann, M.; Schledjewski, R. Controlling moisture content of natural fibres in RTM-process. Key Eng. Mater. 2019, 610–614. [Google Scholar] [CrossRef]

- Si-Ware Systems. Neospectra Datasheet. 2019. Available online: https://662292468.r.worldcdn.net/wp-content/uploads/2019/09/NeoSpectra-SWS62231-Datasheet.v2-2.5-22-19.pdf (accessed on 28 October 2019).

- Anusic, A.; Blößl, Y.; Oreski, G.; Resch-Fauster, K. High-performance thermoset with 100 % bio-based carbon content. Polym. Degrad. Stab. 2020, 181, 109284. [Google Scholar] [CrossRef]

- Schledjewski, R.; Lloret Pertegas, S.; Blößl, Y.; Anusic, A.; Resch-Fauster, K.; Mahendran, A.R.; Wuzella, G. High Performance Green Composites for Green Technologies. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch SZ, Switzerland, 2017; pp. 271–277. [Google Scholar]

- Erdmann, M.; Trappe, V.; Sturm, H.; Braun, U.; Duemichen, E. Cure conversion of structural epoxies by cure state analysis and in situ cure kinetics using nondestructive NIR spectroscopy. Thermochim. Acta 2017, 650, 8–17. [Google Scholar] [CrossRef]

- Anusic, A.; Resch-Fauster, K.; Mahendran, A.R.; Wuzella, G. Anhydride Cured Bio-Based Epoxy Resin: Effect of Moisture on Thermal and Mechanical Properties. Macromol. Mater. Eng. 2019, 304, 1900031. [Google Scholar] [CrossRef] [Green Version]

- Kessler, W. Multivariate Datenanalyse für die Pharma-, Bio- und Prozessanalytik: Ein Lehrbuch; 1. Aufl.; 1. Nachdr; WILEY-VCH: Weinheim, Germany, 2008; ISBN 978-3-527-31262-7. [Google Scholar]

- Hueber, C.; Konstantopoulos, S.; Hergan, P.; Höfler, J.; Horejsi, K.; Schledjewski, R. Influence of Cure Monitoring on the Curing Cycle Influence of Cure Monitoring on the Curing Cycle Time and the Associated Economic Impact. J. Mineral. Metal. Mater. Eng. 2017, 3, 58–63. [Google Scholar]

- Bellamy, L.J.; Nordon, A.; Littlejohn, D. Effects of particle size and cohesive properties on mixing studied by non-contact NIR. Int. J. Pharm. 2008, 361, 87–91. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Lyon, B.G.; Windham, W.R.; Realini, C.E.; Pringle, T.D.D.; Duckett, S. Prediction of color, texture, and sensory characteristics of beef steaks by visible and near infrared reflectance spectroscopy. A feasibility study. Meat Sci. 2003, 65, 1107–1115. [Google Scholar] [CrossRef]

- Witschnigg, A. Charakterisierung von Kunststoffen in Hinblick auf Inline Qualitätskontrolle in Extrusionsprozessen Mittels Nahinfrarotspektroskopie. Ph.D. Thesis, Monantuniveristät Leoben, Leoben, Austria, 2014. [Google Scholar]

| Sample Number | Resin State | Sample Preparation |

|---|---|---|

| 1 | Uncured | None |

| 2 | Partially cured | Heating from 50 °C to 80 °C within 20 min |

| 3 | Cured | Cured at 80 °C for 24 h |

| Abbreviation PLS Model | Reference Spectrum | No. of LVs | R2 | ||

|---|---|---|---|---|---|

| UR | Uncured Resin | 2 | 0.992 | 0.024 | 0.022 |

| PTFE-A | PTFE | 2 | 0.776 | 0.108 | 0.111 |

| PTFE-B | PTFE | 4 | 0.989 | 0.024 | 0.027 |

| Abbreviation PLS Model | Processing | No. of LVs | R2 | ||

|---|---|---|---|---|---|

| UR | None | 2 | 0.992 | 0.024 | 0.022 |

| UR-1 | Mean Center | 3 | 0.994 | 0.018 | 0.019 |

| UR-2 | 1st Deriv | 3 | 0.976 | 0.038 | 0.037 |

| UR-3 | MSC | 2 | 0.088 | 0.25 | 0.23 |

| UR-4 | Smoothing (SavGol) | 2 | 0.986 | 0.038 | 0.036 |

| Abbreviation PLS Model | Preprocessing | No. of LVs | R2 | ||

|---|---|---|---|---|---|

| PTFE-B | None | 4 | 0.989 | 0.029 | 0.027 |

| PTFE-1 | Mean Center | 3 | 0.995 | 0.018 | 0.019 |

| PTFE-2 | 1st Deriv | 4 | 0.967 | 0.046 | 0.043 |

| PTFE-3 | MSC | 3 | 0.991 | 0.026 | 0.024 |

| PTFE-4 | Smoothing (SavGol) | 4 | 0.989 | 0.026 | 0.027 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salzmann, M.; Blößl, Y.; Todorovic, A.; Schledjewski, R. Usage of Near-Infrared Spectroscopy for Inline Monitoring the Degree of Curing in RTM Processes. Polymers 2021, 13, 3145. https://doi.org/10.3390/polym13183145

Salzmann M, Blößl Y, Todorovic A, Schledjewski R. Usage of Near-Infrared Spectroscopy for Inline Monitoring the Degree of Curing in RTM Processes. Polymers. 2021; 13(18):3145. https://doi.org/10.3390/polym13183145

Chicago/Turabian StyleSalzmann, Moritz, Yannick Blößl, Andrea Todorovic, and Ralf Schledjewski. 2021. "Usage of Near-Infrared Spectroscopy for Inline Monitoring the Degree of Curing in RTM Processes" Polymers 13, no. 18: 3145. https://doi.org/10.3390/polym13183145