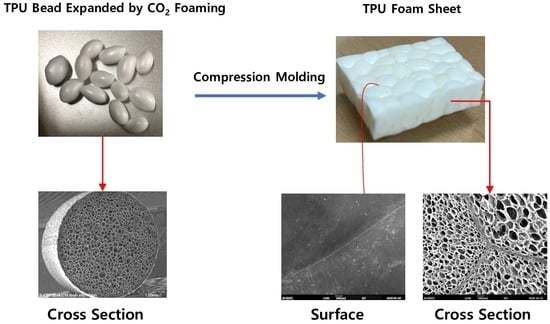

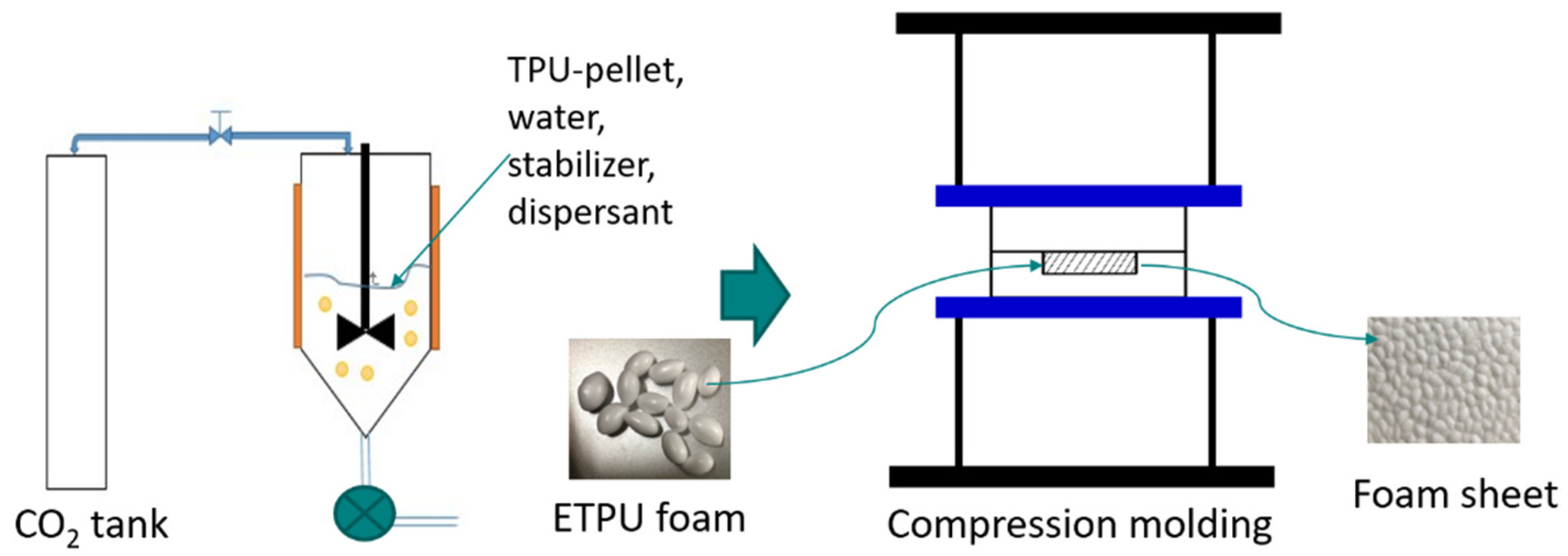

Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mills, N.J. Chapter 1–Introduction to polymer foam microstructure. In Polymer Foams Handbook: Engineering and Biomechanics Application and Design Guide, 1st ed.; Butterworth-Heinemannn Ltd.: Oxford, UK, 2007; pp. 1–18. [Google Scholar]

- Han, X.M.; Zeng, C.C.; Lee, L.J.; Koelling, K.W.; Tomasko, D.L. Extrusion of Polystyrene Nanocomposite Foams With Supercritical CO2. Poly. Eng. Sci. 2003, 43, 1261–1275. [Google Scholar] [CrossRef]

- Hayashi, H.; Mori, T.; Okamoto, M.; Yamasaki, S.; Hayami, H. Polyethylene ionomer-based nano-composite foams prepared by a batch process and MuCell® injection molding. Mater. Sci. Eng. C 2010, 30, 62–70. [Google Scholar] [CrossRef]

- Gomez-Monterde, J.; Hain, J.; Sanchez-Soto, M.; Maspoch, M.L. Microcellular injection moulding: A comparison between MuCell process and the novel micro-foaming technology IQ Foam. J. Mater. Process. Technol. 2019, 268, 162–170. [Google Scholar] [CrossRef]

- Raps, D.; Hossieny, N.; Park, C.B.; Altstadt, V. Past and present developments in polymer bead foams and bead foaming technology. Polymer 2015, 56, 5–19. [Google Scholar] [CrossRef]

- Nofar, M.; Ameli, A.; Park, C.B. A novel technology to manufacture biodegradable polylactide bead foam products. Mater. Des. 2015, 83, 413–421. [Google Scholar] [CrossRef]

- Kang, D.H.; Oh, S.S.; Kim, H.I. Improvement of Physical Properties of Polypropylene Chemical Foam by Glass Fiber Reinforcement. Polym. Korea 2019, 43, 589–594. [Google Scholar] [CrossRef]

- Li, Q.; Matuana, L.M. Foam extrusion of high density polyethylene/wood-flour composites using chemical foaming agents. J. Appl. Polym. Sci. 2003, 28, 3139–3150. [Google Scholar] [CrossRef]

- Shin, J.H.; Lee, H.K.; Song, K.B.; Lee, K.H. Characterization of Poly(lactic acid) Foams Prepared with Supercritical Carbon Dioxode. Polym. Korea 2013, 37, 685–693. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Usda, Y.; Suganaga, H.; Haruki, M.; Kihara, S.; Takishima, S. Pressure drop threshold in the foaming of low density polyethylene, polystyrene, and polypropylene using CO2 and N2 as foaming agents. J. Supercrit. Fluid. 2015, 103, 38–47. [Google Scholar] [CrossRef]

- He, J.; Gao, Q.; Song, X.; Bu, X.; He, J. Effect of foaming agent on physical and mechanical properties of alkali-activated slag foamed concrete. Constr. Build. Mater. 2019, 226, 280–287. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, K.; Hu, S.F.; Liu, Q.T.; Zhao, X.; Liu, Y. Improved cell morphology and reduced shrinkage ratio of ETPU beads by reactive blending. Polym. Test. 2017, 63, 38–46. [Google Scholar] [CrossRef]

- Standau, T.; Hadelt, B.; Schreier, P.; Altstadt, V. Development a Bead Foam from an Engineering Polymer with Addition of Chain Extender: Expanded Polybutylene Terephthalate. Ind. Eng. Chem. Res. 2018, 57, 17170–17176. [Google Scholar] [CrossRef]

- Shen, J.; Cao, X.; Lee, L.J. Synthesis and foaming of water expandable polystyrene-clay nanocomposites. Polymer 2006, 47, 6303–6310. [Google Scholar] [CrossRef]

- Wali, K.F.; Bhavnani, H.; Overfelt, R.A.; Sheldon, D.S.; Williams, K. Investigation of the Performance of an Expandable Polystyrene Injector for Use on the Lost-Foam Casting Process. Metall. Mater. Trans. B 2003, 34, 843–851. [Google Scholar] [CrossRef]

- Ruiz, J.A.R.; Vincent, M.; Agassant, J.F.; Sadik, T.; Caroline, P. Polymer foaming with chemical blowing agents: Experiment and modeling. Polym. Eng. Sci. 2015, 55, 2018–2029. [Google Scholar] [CrossRef]

- Hossieny, N.J.; Barzegari, M.R.; Nofar, M.; Mahmood, S.H.; Park, C.B. Crystallization of hard segment domains with the presence of butane for microcellular thermoplastic polyurethane foams. Polymer 2014, 55, 651–662. [Google Scholar] [CrossRef]

- Guo, Y.; Hossieny, N.; Chu, R.K.M.; Park, C.B.; Zhou, N. Critical processing parameters for foamed bead manufacturing in a lab-scale autoclave system. Chem. Eng. J. 2013, 214, 180–188. [Google Scholar] [CrossRef]

- Naduib, H.E.; Park, C.B.; Reichelt, N. Fundamental Foaming Mechanisms Governing the Volume Expansion of Extruded Polypropylene Foams. J. Appl. Polym. Sci. 2004, 91, 2661–2668. [Google Scholar]

- Ji, W.; Wang, D.; Guo, J.; Fei, B.; Gu, X.; Li, H.; Sun, J.; Zhang, S. The preparation of starch derivatives reacted with urea-phosphoric acid and effect on fire performance of expandable polystyrene foams. Carbohydr. Polymers 2020, 233, 115841. [Google Scholar]

- Nofar, M.; Guo, Y.; Park, C.B. Double Crystal Melting Peak Generation for Expanded Polypropylene Bead Foam Manufacturing. Ind. Eng. Chem. Res. 2013, 52, 2297–2303. [Google Scholar] [CrossRef]

- Sulong, N.H.R.; Mustapa, S.A.S.; Rashid, M.K.A. Application of expanded polystyrene (EPS) in buildings and constructions: A review. J. Appl. Polym. Sci. 2019, 136, 47529–47539. [Google Scholar] [CrossRef] [Green Version]

- Guo, P.; Xu, Y.; Lu, M.; Zhang, S. Expanded Linear Low- Density Polyethylene Beads: Fabrication, Melt Strength, and Foam Morphology. Ind. Eng. Chem. Res. 2016, 55, 8104–8113. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Wang, C.; Park, C.B. Ultra-lightweight, super thermal-insulation and strong PP/CNT microcellular foams. Compos. Sci. Technol. 2020, 191, 108084–108095. [Google Scholar] [CrossRef]

- Srivastava, V.; Srivastava, R. A Review on Manufacturing, Properties and Application of Expanded Polypropylene. MIT. Int. J. Mech. Eng. 2014, 4, 22–28. [Google Scholar]

- Ge, C.B.; Wang, S.P.; Zheng, W.G.; Zhai, W.T. Preparation of Microcellular Thermoplastic Polyurethane (TPU) Foam and Its Tensile Property. Polym. Eng. Sci. 2018, 58, E158–E166. [Google Scholar] [CrossRef]

- Jiang, X.; Zhao, L.; Feng, L.; Chen, C. Microcellular Thermoplastic Polyurethanes and their flexible properties prepared by mold foaming process with supercritical CO2. J. Cell. Plast. 2019, 55, 615–631. [Google Scholar] [CrossRef]

- Zhai, W.T.; Kim, Y.W.; Jung, D.W.; Park, C.B. Steam-Chest Molding of Expanded Polypropylene Foams. 2. Mechanism of Interbead Bonding. Ind. Eng. Chem. Res. 2011, 50, 5523–5531. [Google Scholar] [CrossRef]

- Hossieny, N.; Ameli, A.; Park, C.B. Characterization of Expanded Polypropylene Bead Foams with Modified Steam-Chest Molding. Ind. Eng. Chem. Res. 2013, 52, 8236–8247. [Google Scholar] [CrossRef]

- Ge, C.B.; Een, Q.; Wang, S.P.; Zheng, W.G.; Zhai, W.T.; Park, C.B. Steam-chest molding of expanded thermoplastic polyurethane bead foams and their mechanical properties. Chem. Eng. Sci. 2017, 174, 337–346. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, G.J.; Wang, M.H. Investigation of the effect of foaming process parameters on expanded thermoplastic polyurethane bead foams properties using response surface methodology. J. Appl. Polym. Sci. 2018, 135, 46327–46337. [Google Scholar] [CrossRef]

- Okolieocha, C.; Raps, D.; Subramanianm, K.; Altstadt, V. Microcellular to nanocellular polymer foams: Progress (2004–2015) and future directions-A review. Eur. Polym. J. 2015, 73, 500–519. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Lee, S.-J.; Yoo, Y.H.; Park, K.-H.; Kang, H.-J. Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming. Polymers 2021, 13, 656. https://doi.org/10.3390/polym13040656

Zhang T, Lee S-J, Yoo YH, Park K-H, Kang H-J. Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming. Polymers. 2021; 13(4):656. https://doi.org/10.3390/polym13040656

Chicago/Turabian StyleZhang, Tao, Seung-Jun Lee, Yong Hwan Yoo, Kyu-Hwan Park, and Ho-Jong Kang. 2021. "Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming" Polymers 13, no. 4: 656. https://doi.org/10.3390/polym13040656

APA StyleZhang, T., Lee, S.-J., Yoo, Y. H., Park, K.-H., & Kang, H.-J. (2021). Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming. Polymers, 13(4), 656. https://doi.org/10.3390/polym13040656