Experimental Study of Oriented Strand Board Ignition by Radiant Heat Fluxes

Abstract

:1. Introduction

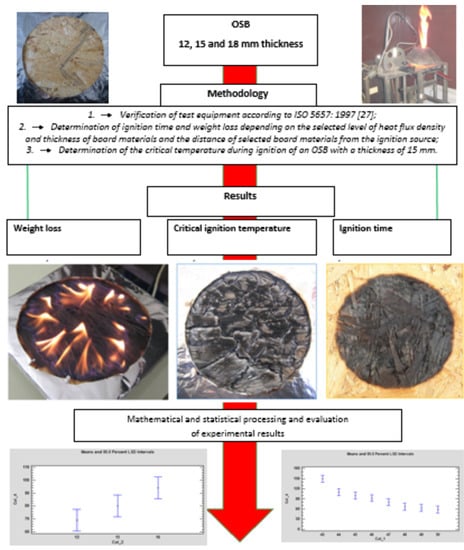

2. Materials and Methods

2.1. Experimental Samples

2.2. Experimental Procedures

- Verification of test equipment; a small burner flame was not used as the secondary ignition source.

- Determination of ignition time and weight loss depending on the selected level of heat flux density and thickness of board materials and on the distance of selected board materials from the ignition source.

- Determination of the critical temperature during ignition of an OSB with a thickness of 15 mm.

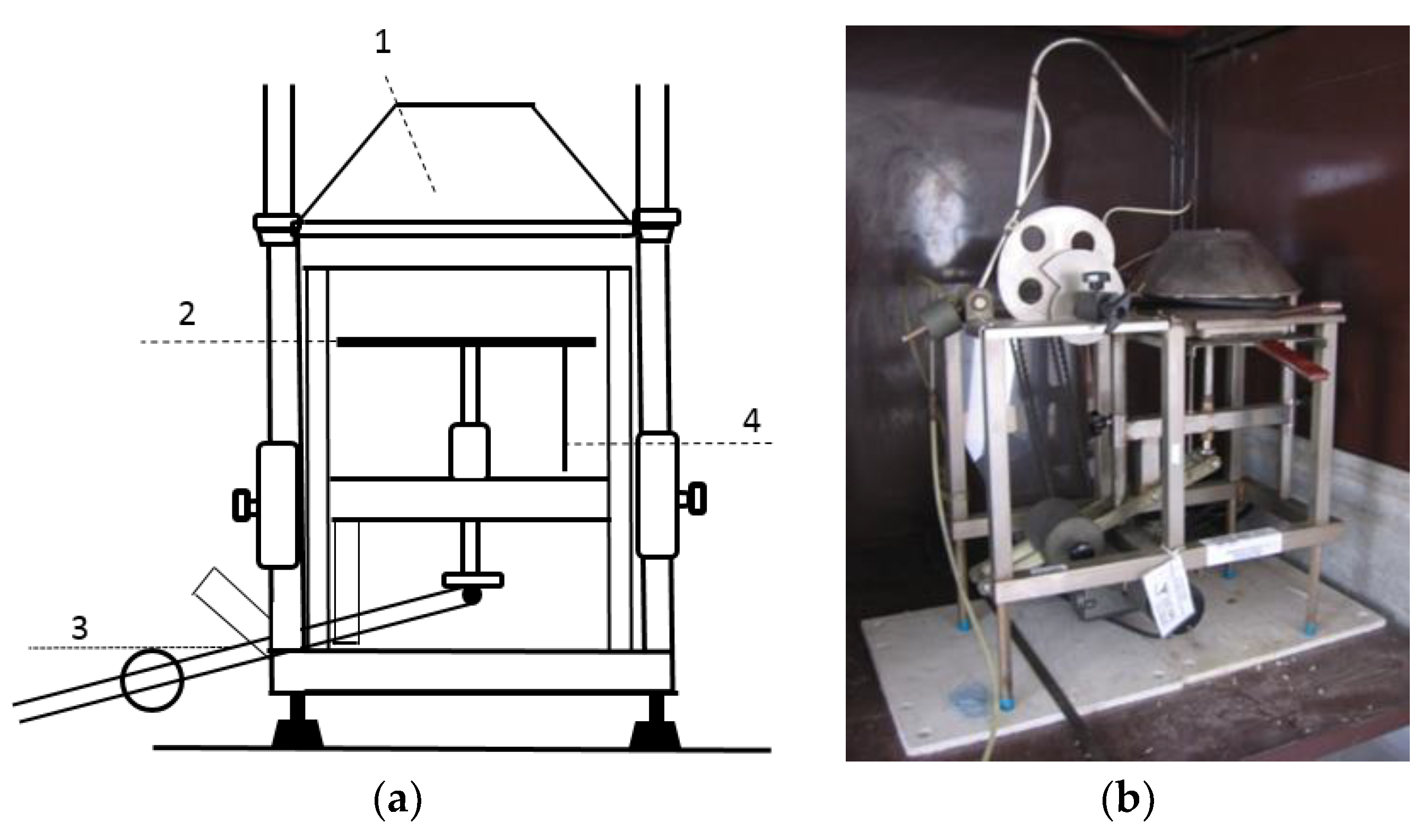

2.2.1. Verification of Test Equipment

2.2.2. Methodology for Determining Ignition Time and Weight Loss

- the thickness of the board material; and

- the density of the radiant heat flux.

2.2.3. Determination of the Critical Ignition Temperature

2.2.4. Statistical Processing of Data and Evaluation of Results

3. Results and Discussion

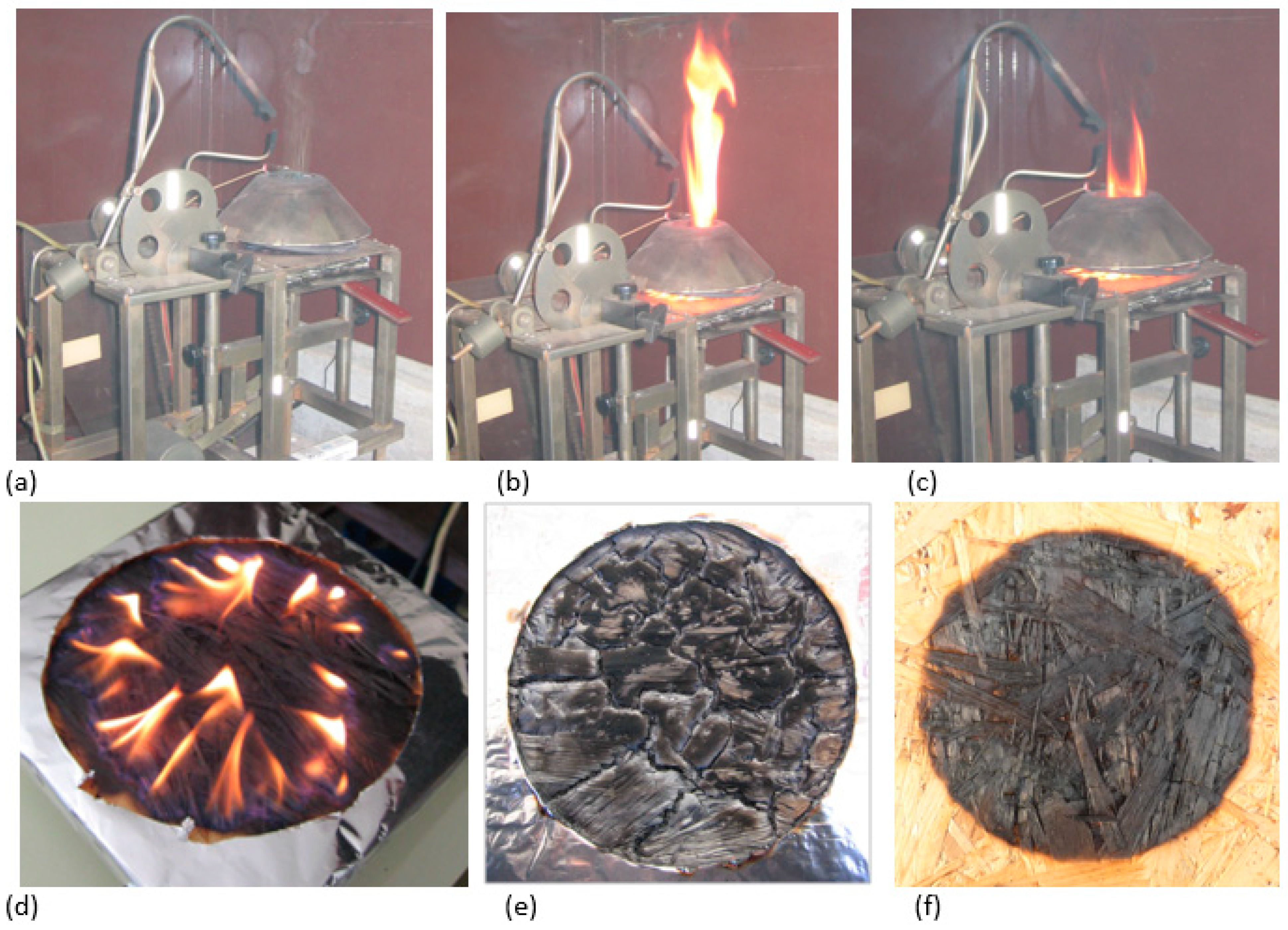

3.1. Determination of Ignition Temperature and Weight Loss

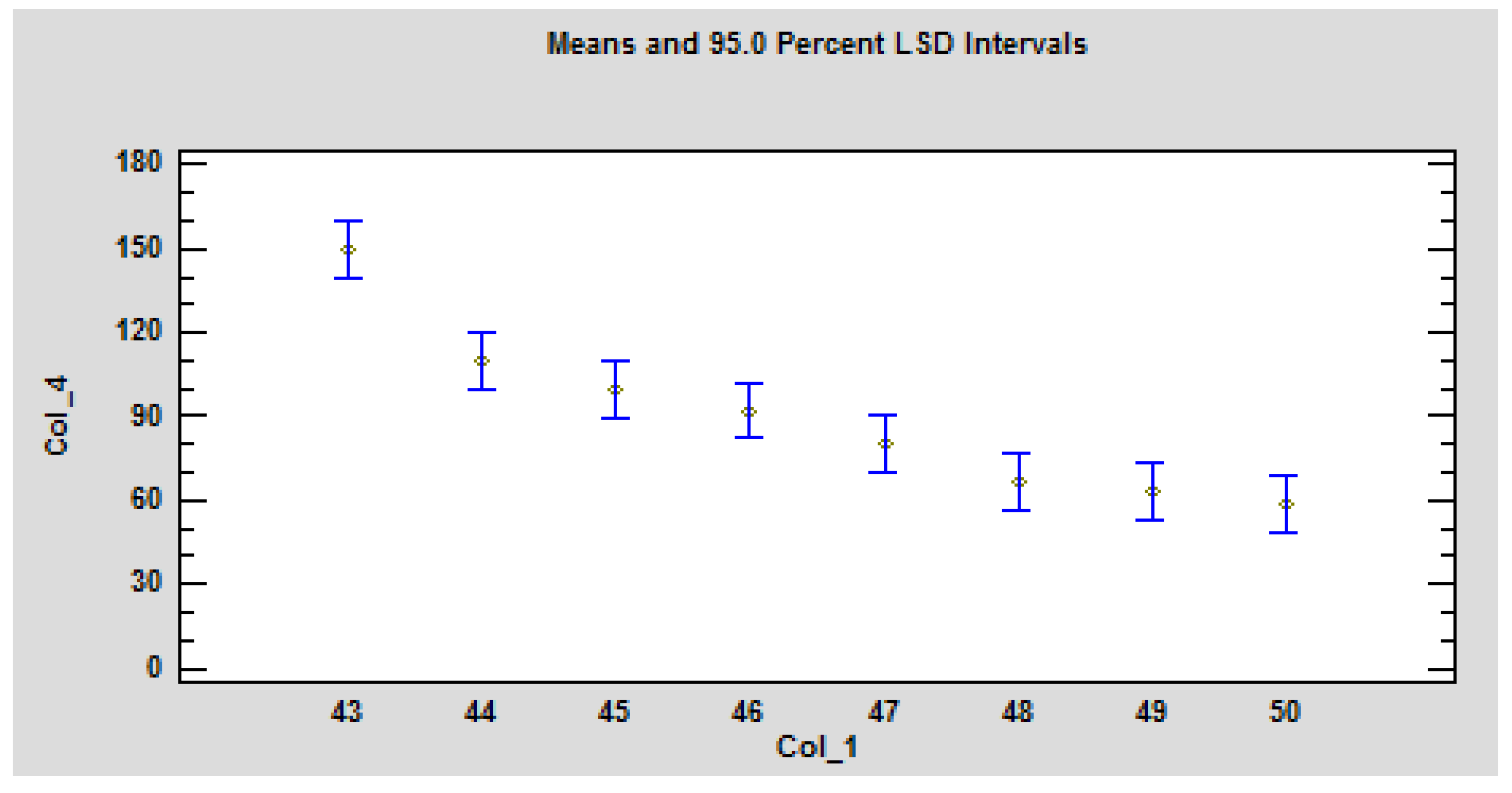

3.2. Determination of Critical Ignition Temperature

4. Conclusions

- As the heat flux density increased, the ignition time decreased in all thicknesses of analysed OSB.

- The ignition time increased with increasing thickness of the OSB, and the weight loss decreased with increasing thickness of the OSB at a constant heat flux.

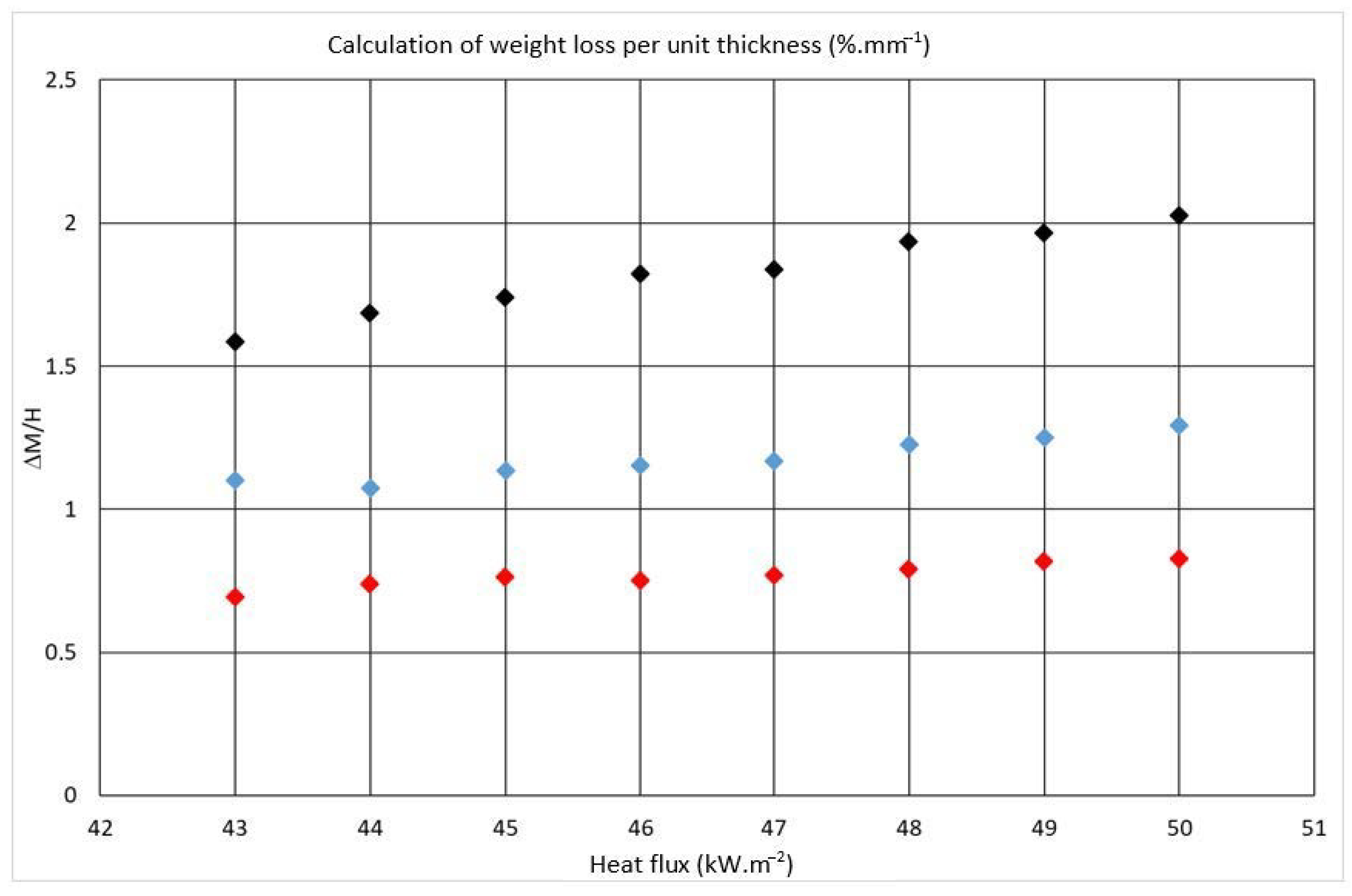

- With increasing board thickness, the weight loss decreased. The largest average weight loss of 24.31% was recorded in a 12 mm OSB that was exposed to a radiant heat flux of 50 kW.m−2; the lowest average weight loss of 12.44% was recorded in a sample of 18 mm OSB that was exposed to a radiant heat flux of 43 kW.m−2.

- The ignition time is significantly dependent on the thickness of the OSB sample and on the value of the heat flux. As the heat flux increases, the ignition time shortens; as the thickness of the OSB increases, the ignition time extends. The largest weight loss of 27.22% was recorded in an OSB with a thickness of 12 mm and a density in the range of 500 to 550 kg.m−3, which was exposed to a radiant heat flux of 50 kW.m−2. The lowest weight loss of 11.91% was found in an OSB with a thickness of 18 mm and a density in the range of 550–600 kg.m−3, which was exposed to a radiant heat flux of 43 kW.m−2.

- The weight loss is not significantly dependent on the ignition time and the thickness of the OSB.

- Critical temperature of an OSB with a thickness of 15 mm that was exposed to heat flux densities of 44 kW.m−2 and 46 kW.m−2 had a linear character; at the heat flux densities of 48 kW.m−2 and 50 kW.m−2, it had an initially linear course, but due to ignition, a sharp rise in temperature was noted at the upper surface of the sample. The sharp rise in temperature was caused by two effects. The first effect was a higher heat flux from the cone calorimeter to the surface of the tested sample, and the second effect was a higher reverse heat radiation from flares.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mantanis, G.I.; Athanassiadou, E.T.; Barbu, M.C.; Wijnendaele, K. Adhesive systems used in the European particleboard, MDF and OSB industries. Wood Mater. Sci. Eng. 2017, 13, 104–116. [Google Scholar] [CrossRef]

- Bušterová, M.; Tureková, I.; Martinka, J.; Harangózo, J. The Influence of Heat Flux on the Ignition of OSB Boards. Spektrum 2011, 11, 5–7. (In Slovak) [Google Scholar]

- Gaff, M.; Kacik, F.; Gasparik, M. The effect of synthetic and natural fire-retardants on burning and chemical characteristics of thermally modified teak (Tectona grandis L. f.) wood. Constr. Build. Mater. 2019, 200, 551–558. [Google Scholar] [CrossRef]

- Notice of Special Conditions for the Award of a National Eco-Label, Product Group wood-based panels. Available online: https://www.minzp.sk/files/eu/oznamenie_dosky-baze-dreva_2-17.pdf (accessed on 9 March 2017). (In Slovak).

- CEN Standard EN 300: 2007. Oriented Strand Boards (OSB). Definitions, Classification and Specifications; European Committe for Standartion: Brussels, Belgium, 2007. [Google Scholar]

- Lunguleasa, A.; Dumitrascu, A.E.; Ciobanu, V.D. Comparative Studies on Two Types of OSB Boards Obtained from Mixed Resinous and Fast-growing Hard Wood. Appl. Sci. 2020, 10, 6634. [Google Scholar] [CrossRef]

- Li, W.; Chen, C.; Shi, J.; Mei, C.; Kibleur, P.; Van Acker, J.; Van den Bulcke, J. Understanding the mechanical performance of OSB in compression tests. Constr. Build. Mater. 2020, 260, 119837. [Google Scholar] [CrossRef]

- Igaz, R.; Krišťák, L.; Ružiak, I.; Gajtanska, M.; Kučerka, M. Thermophysical Properties of OSB Boards versus Equilibrium Moisture Content. BioResources 2017, 12, 8106–8118. [Google Scholar]

- Tudor, E.M.; Dettendorfer, A.; Kain, G.; Barbu, M.C.; Réh, R.; Krišťák, L. Sound-Absorption Coefficient of Bark-Based Insulation Panels. Polymers 2020, 12, 1012. [Google Scholar] [CrossRef]

- Michalovič, R. Fire assesment of different floor materials. In Proceedings of the 19th International Scientific Conference Crisis Management in a Specific Environment, Faculty of Security Engineering, Žilina, Slovakia, 21–22 May 2014; University of Žilina: Žilina, Slovakia, 2014; pp. 497–504. (In Slovak). [Google Scholar]

- Štefka, V. Composite Wood Materials. Part 2: Technology of Agglomerated Materials, 1st ed.; Technical University in Zvolen: Zvolen, Slovakia, 2005; 205p. (In Slovak) [Google Scholar]

- Očkajová, A.; Kučerka, M. Materials and Technology 1, 1st ed.; Woodtechnology Monography; Belanium–Matej Bel University: Banská Bystrica, Slovakia, 2011; 115p. [Google Scholar]

- SterlingOSB Material Safety Data Sheet. (esi.info). Available online: 10366_1506070430142.pdf (accessed on 1 June 2017).

- Vandličková, M.; Marková, I.; Makovická Osvaldová, L.; Gašpercová, S.; Svetlík, J.; Vraniak, J. Tropical Wood Dusts—Granulometry, Morfology and Ignition Temperature. Appl. Sci. 2020, 10, 7608. [Google Scholar] [CrossRef]

- Marková, I.; Ladomerský, J.; Hroncová, E.; Mračková, E. Thermal parameters of beech wood dust. BioResources 2018, 13, 3098–3109. [Google Scholar] [CrossRef]

- Makovická Osvaldová, L.; Gašpercová, G. The evaluation of flammability properties regarding testing methods. Civ. Environ. Eng. Sci. Tech. J. 2015, 11, 142–146. (In Slovak) [Google Scholar]

- Lowden, L.A.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Sinha, A.; Nairn, J.A.; Gupta, R. Thermal degradation of bending strenght of plywood and oriented strand board: A kinetics approach. Wood Sci. Technol. 2011, 45, 315–330. [Google Scholar] [CrossRef]

- CEN Standard EN ISO 13943: 2018. Fire safety. Vocabulary; European Committe for Standartion: Brussels, Belgium, 2018. [Google Scholar]

- ISO 3261: :1975 Fire tests — Vocabulary; International Organization for Standardization: Geneva, Switzerland, 1975.

- Rantuch, P.; Kacíková, D.; Martinka, J.; Balog, K. The Influence of Heat Flux Density on the Thermal Decomposition of OSB. Acta Fac. Xylologiae Zvolen Publica Slovaca 2005, 57, 125–134. [Google Scholar]

- Babrauskas, V. Ignition of wood: A Review of the State of the Art; Interscience Communications Ltd.: London, UK, 2001; pp. 71–88. [Google Scholar]

- Babrauskas, V. Ignition Handbook, 1st ed.; Fire Science Publishers: Issaquah, WA, USA, 2003. [Google Scholar]

- ISO 5657:1997 Reaction to Fire Tests—Ignitability of Building Products using a Radiant Heat Source; International Organization for Standardization: Geneva, Switzerland, 1997.

- CEN Standard EN 323:1993—Wood-Based Panels—Determination of Density; European Committe for Standartion: Brussels, Belgium, 1993.

- CEN Standard EN 13501-2: 2018. Fire Classification of Construction Products and Building Elements. Part 1: Classification using Data from Reaction to Fire Tests; European Committe for Standartion: Brussels, Belgium, 2018. [Google Scholar]

- ASTM E84. Standard Test Method for Surface Burning Characteristics of Building Materials; ASTM: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Ayrilmis, N.; Kartal, S.; Laufenberg, T.; Winandy, J.; White, R. Physical and mechanical properties and fire, decay, and termite resistance of treated oriented strandboard. For. Prod. J. 2005, 55, 74. [Google Scholar]

- Östman, B.A.L.; Mikkola, E. European classes for the reaction to fire performance of wood products. Holz als Roh-und Werkst. 2006, 64, 327–337. [Google Scholar] [CrossRef]

- Rantuch, P.; Hladová, M.; Martinka, J.; Kobetičová, H. Comparison of Ignition Parameters of Oven-Dried and Non-Dried OSB. Fire Prot. Saf. Sci. J. 2019, 13, 63–79. (In Slovak) [Google Scholar]

- Simms, D.L.; Law, M. The ignition of wet and dry wood by radiation. Combust. Flame 1967, 11, 377–388. [Google Scholar] [CrossRef]

- Mitterová, I.; Garaj, J. The Effect of the Retardation Treatment on the Mass Loss of the Thermally Loaded Spruce Wood and OSB Board. Fire Prot. Saf. Sci. J. 2019, 13, 51–55. (In Slovak) [Google Scholar]

- Osvaldova, L.M.; Gaspercova, S.; Mitrenga, P. The influence of density of test speciemens on the quality assessment of retarding effects of fire retardants. Wood Res. 2016, 61, 35–42. [Google Scholar]

- Osvaldova, L.M.; Osvald, A. Flame retardation of wood. 4th International Conference on Manufacturing Science and Engineering (ICMSE 2013), Dalian, China, 30–31 March 2013. Adv. Mater. Res. 2013, 690–693, 1331–1334. [Google Scholar]

- Bušterová, M. Effect of Heat Flux on the Ignition of Selected Board Materials; Faculty of Materials Science and Technology in Trnava, Slovak University of Technology in Bratislava: Bratislava, Slovakia, 2011; 149p. [Google Scholar]

- Sultan, M.A. Fire Resistance of Exterior Wall Assemblies for Housing and Small Buildings. Fire Technol. 2020. [Google Scholar] [CrossRef]

- Manzello, S.L.; Suzuki, S.; Nii, D. Full-Scale Experimental Investigation to Quantify Building Component Ignition Vulnerability from Mulch Beds Attacked by Firebrand Showers. Fire Technol. 2017, 53, 535–551. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koo, E.; Pagni, P.J.; Weise, D.R.; Woycheese, J.P. Firebrands and spotting ignition in large-scale fires. Int. J. Wildland Fire 2011, 19, 818–843. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Notes | Values |

|---|---|---|

| Density (kg.m−3) | 630 ± 10% | |

| Humidity (%) | 5 ± 12% | |

| Bending Strength (N.mm−2) | Main Axis | 20 |

| Secondary Axis | 10 | |

| Modulus of Elasticity (N.mm−2) | Main Axis | 3500 |

| Secondary Axis | 1400 | |

| Swelling (%) | 15 | |

| Thermal Conductivity (W.m−2.K−1) | 0.13 | |

| Formaldehyde Content (mg.100 g−1) | 8 | |

| Flame Spread Index 1 | 83.3 | |

| Reaction to Fire | Thickness 9 mm 2 | D-s2, d2 |

| Thickness 18 mm 3 | D-s1, d0 | |

| Class of Fire Reaction [26] | E—Eoderately Flammable |

| Density of Radiant Heat Flux (kW.m−2) | Corresponding Temperature (°C) 1 | Thickness (mm) | Ignition Time (s) | Weight Loss (%) |

|---|---|---|---|---|

| 43 | 700 | 12 | 107.4 ± 32.927 | 19.018 ± 0.742 |

| 15 | 172.8 ± 68.271 | 16.528 ± 1.103 | ||

| 18 | 170.0 ± 19.279 | 12.436 ± 0.402 | ||

| 44 | 710 | 12 | 80.80 ± 14.372 | 20.188 ± 1.210 |

| 15 | 108.0 ± 31.093 | 16.092 ± 0.885 | ||

| 18 | 140.0 ± 31.698 | 13.256 ± 0.745 | ||

| 45 | 720 | 12 | 86.4 ± 10.442 | 20.87 ± 0.889 |

| 15 | 100.2 ± 21.673 | 17.026 ± 0.541 | ||

| 18 | 111.2 ± 24.235 | 13.716 ± 0.303 | ||

| 46 | 724 | 12 | 84.4 ± 9.002 | 21.868 ± 0.879 |

| 15 | 93.4 ± 21.767 | 17.272 ± 0.647 | ||

| 18 | 98.8 ± 12.592 | 13.504 ± 0.228 | ||

| 47 | 727 | 12 | 67.08 ± 5.403 | 22.026 ± 0.908 |

| 15 | 71.0 ± 8.671 | 17.5 ± 0.455 | ||

| 18 | 103.6 ± 18.391 | 13.818 ± 0.266 | ||

| 48 | 730 | 12 | 58.60 ± 5.953 | 23.206 ± 0.505 |

| 15 | 63.40 ± 7.116 | 18.366 ± 0.910 | ||

| 18 | 77.60 ± 25.881 | 14.222 ± 0.826 | ||

| 49 | 735 | 12 | 62.20 ± 3.2497 | 23.578 ± 0.858 |

| 15 | 63.20 ± 3.187 | 18.764 ± 0.571 | ||

| 18 | 65.0 ± 11.436 | 14.678 ± 0.899 | ||

| 50 | 742 | 12 | 56.80 ± 2.039 | 24.302 ± 0.814 |

| 15 | 59.40 ± 5.607 | 19.402 ± 0.586 | ||

| 18 | 60.20 ± 5.741 | 14.846 ± 1.033 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | P-Value |

|---|---|---|---|---|---|

| Between Groups | 12,608.1 | 2 | 6304.03 | 4.31 | 0.0156 |

| Within Groups | 170,953 | 117 | 1461.13 | ||

| Total (Corr.) | 183,561 | 119 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | P-Value |

|---|---|---|---|---|---|

| Between Groups | 96,009.1 | 7 | 13,715.6 | 17.55 | 0.000 |

| Within Groups | 87,551.5 | 112 | 781.71 | ||

| Total (Corr.) | 183,561 | 119 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | P-Value |

|---|---|---|---|---|---|

| Between Groups | 5.11703E7 | 7 | 7.31005E6 | 2.05 | 0.0554 |

| Within Groups | 4.00277E8 | 112 | 3.5739E6 | ||

| Total (Corr.) | 4.51448E8 | 119 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | P-Value |

|---|---|---|---|---|---|

| Between Groups | 5.78793E6 | 2 | 2.89396E6 | 0.76 | 0.4701 |

| Within Groups | 4.4566E8 | 117 | 3.80906E6 | ||

| Total (Corr.) | 4.51448E8 | 119 |

| Heat Flux (kW.m−2) | Time to Ignition (°C) | Temperature (°C) | |

|---|---|---|---|

| Direct Side of Heat | Opposite Side | ||

| 44 | 142 | 287 | 34 |

| 46 | 70 | 358 | 25 |

| 48 | 64 | 252 | 26 |

| 50 | 58 | 319 | 27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tureková, I.; Marková, I.; Ivanovičová, M.; Harangózo, J. Experimental Study of Oriented Strand Board Ignition by Radiant Heat Fluxes. Polymers 2021, 13, 709. https://doi.org/10.3390/polym13050709

Tureková I, Marková I, Ivanovičová M, Harangózo J. Experimental Study of Oriented Strand Board Ignition by Radiant Heat Fluxes. Polymers. 2021; 13(5):709. https://doi.org/10.3390/polym13050709

Chicago/Turabian StyleTureková, Ivana, Iveta Marková, Martina Ivanovičová, and Jozef Harangózo. 2021. "Experimental Study of Oriented Strand Board Ignition by Radiant Heat Fluxes" Polymers 13, no. 5: 709. https://doi.org/10.3390/polym13050709

APA StyleTureková, I., Marková, I., Ivanovičová, M., & Harangózo, J. (2021). Experimental Study of Oriented Strand Board Ignition by Radiant Heat Fluxes. Polymers, 13(5), 709. https://doi.org/10.3390/polym13050709