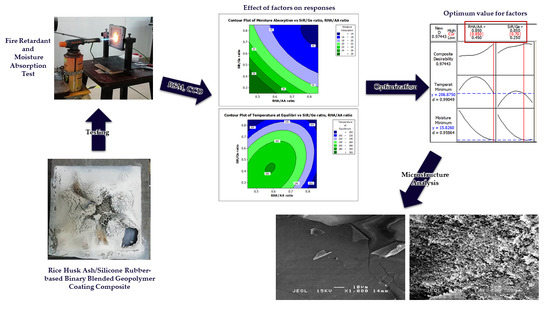

Rice Husk Ash/Silicone Rubber-Based Binary Blended Geopolymer Coating Composite: Fire Retardant, Moisture Absorption, Optimize Composition, and Microstructural Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Factors and Levels of the Design of Experiment (DOE)

2.2. Design of Experiment

2.3. Raw Materials and Sample Preparation

2.4. Fire Retardant Test

2.5. Moisture Absorption Test

2.6. Microstructure of Rice Husk Ash

3. Results and Discussion

3.1. Statistical Analysis of Temperature at Equilibrium and Moisture Absorption Properties

3.2. Effect of Factors on Moisture Absorption and Temperature at Equilibrium

3.3. Optimization of the Responses

3.4. Experimental Validation

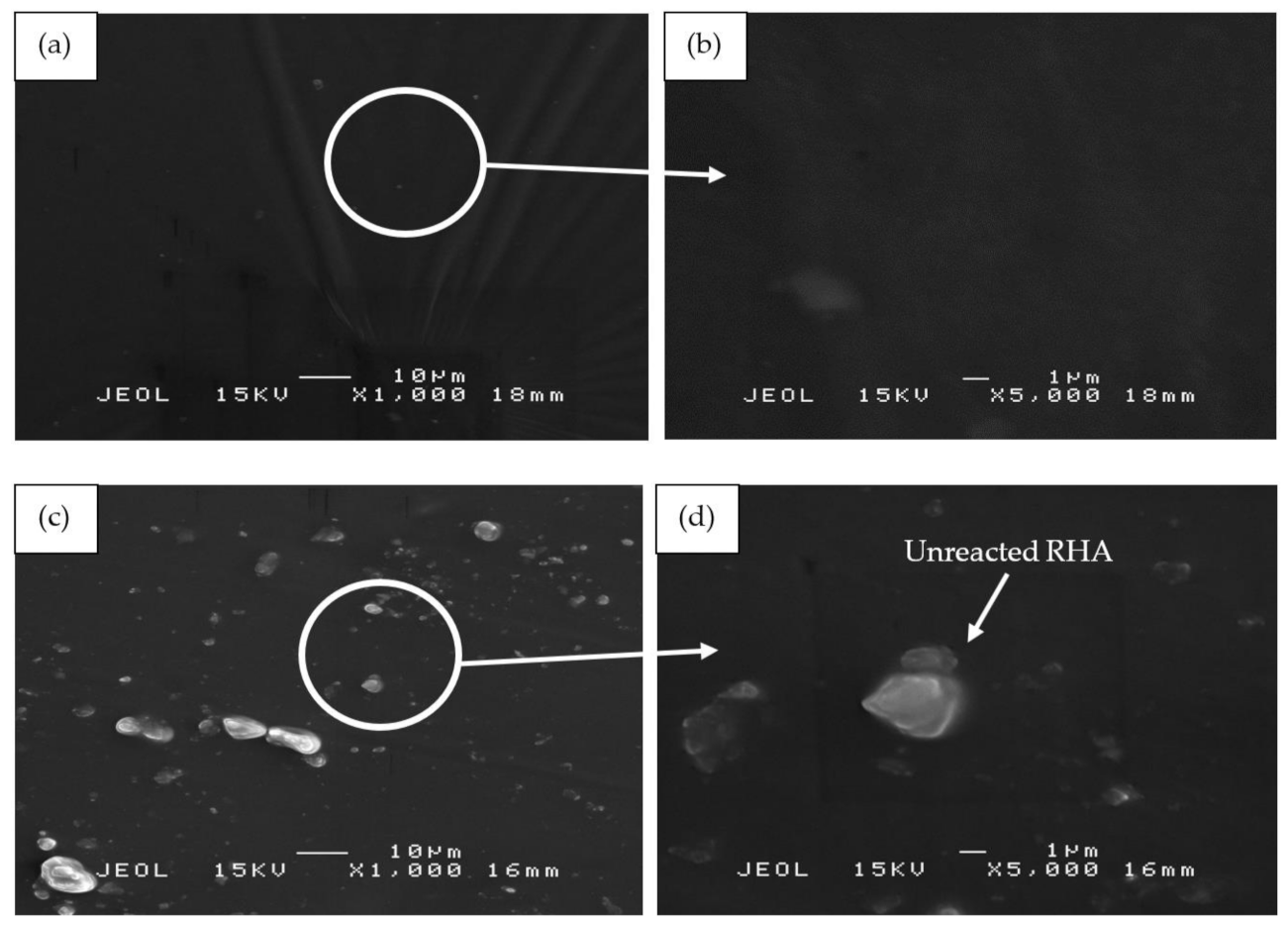

3.5. Microstructure Analysis of RHA/SiR-Based Binary Blended Geopolymer Coating Composite

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajamoorthy, Y.; Munusamy, S. Rice industry in Malaysia: Challenges, policies and implications. Procedia Econ. Financ. 2015, 31, 861–867. [Google Scholar] [CrossRef]

- Chuayjuljit, S.; Eiumnoh, S.; Potiyaraj, P. Using silica from rice husk as a reinforcing filler in natural rubber. J. Sci. Res. Chula. Univ. 2001, 26, 127–138. [Google Scholar]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete. Constr. Build. Mater. 2010, 24, 2145–2150. [Google Scholar] [CrossRef]

- Muthadhi, A.; Kothandaraman, S. Experimental investigations of performance characteristics of rice husk ash–blended concrete. J. Mater. Civ. Eng. 2013, 25, 1115–1118. [Google Scholar] [CrossRef]

- Aguirre-Guerrero, A.M.; Robayo-Salazar, R.A.; de Gutiérrez, R.M. A novel geopolymer application: Coatings to protect reinforced concrete against corrosion. Appl. Clay Sci. 2017, 135, 437–446. [Google Scholar] [CrossRef]

- Mohd Basri, M.S.; Mustapha, F.; Mazlan, N.; Ishak, M.R. Fire Retardant performance of rice husk ash-based geopolymer coated mild steel-A factorial design and microstructure analysis. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2016; pp. 48–54. [Google Scholar]

- Saharudin, K.A.; Sreekantan, S.; Basiron, N.; Chun, L.K.; Kumaravel, V.; Abdullah, T.K.; Ahmad, Z.A. Improved super-hydrophobicity of eco-friendly coating from palm oil fuel ash (POFA) waste. Surf. Coat. Technol. 2018, 337, 126–135. [Google Scholar] [CrossRef]

- Gulicovski, J.; Nenadović, S.; Kljajević, L.; Mirković, M.; Nišavić, M.; Kragović, M.; Stojmenović, M. Geopolymer/CeO2 as solid electrolyte for IT-SOFC. Polymers 2020, 12, 248. [Google Scholar] [CrossRef]

- Temuujin, J.; Minjigmaa, A.; Rickard, W.; Lee, M.; Williams, I.; Van Riessen, A. Preparation of metakaolin based geopolymer coatings on metal substrates as thermal barriers. Appl. Clay Sci. 2009, 46, 265–270. [Google Scholar] [CrossRef]

- Biondi, L.; Perry, M.; Vlachakis, C.; Wu, Z.; Hamilton, A.; McAlorum, J. Ambient cured fly ash geopolymer coatings for concrete. Materials 2019, 12, 923. [Google Scholar] [CrossRef]

- Prusty, J.K.; Pradhan, B. Multi-response optimization using Taguchi-Grey relational analysis for composition of fly ash-ground granulated blast furnace slag based geopolymer concrete. Constr. Build. Mater. 2020, 241, 118049. [Google Scholar] [CrossRef]

- Abdul Rashid, M.K.; Ramli Sulong, N.H.; Alengaram, U.J. Fire resistance performance of composite coating with geopolymer-based bio-fillers for lightweight panel application. J. Appl. Polym. Sci. 2020, 137, 49558. [Google Scholar] [CrossRef]

- Basri, M.S.M.; Mazlan, N.; Mustapha, F.; Ishak, M.R. Correlation between compressive strength and fire resistant performance of rice husk ash-based geopolymer binder for panel applications. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; p. 01025. [Google Scholar]

- Maulana, A.I.; Wardani, N.K.; Syamsidar, D. Development of hybrid composite rice husk ash (RHA)–geopolymer for bricks bearing buildings. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; p. 01009. [Google Scholar]

- Villaquirán-Caicedo, M.; De Gutiérrez, R.M.; Gallego, N. A novel MK-based geopolymer composite activated with rice husk ash and KOH: Performance at high temperature. Mater. Construcción 2017, 67, 117. [Google Scholar] [CrossRef]

- Ramasamy, V.-W. Compressive strength and durability properties of rice husk ash concrete. KSCE J. Civ. Eng. 2012, 16, 93–102. [Google Scholar] [CrossRef]

- Buyondo, K.A.; Olupot, P.W.; Kirabira, J.B.; Yusuf, A.A. Optimization of production parameters for rice husk ash-based geopolymer cement using response surface methodology. Case Stud. Constr. Mater. 2020, 13, e00461. [Google Scholar] [CrossRef]

- Liang, G.; Zhu, H.; Zhang, Z.; Wu, Q.; Du, J. Investigation of the waterproof property of alkali-activated metakaolin geopolymer added with rice husk ash. J. Clean. Prod. 2019, 230, 603–612. [Google Scholar] [CrossRef]

- Zhu, H.; Liang, G.; Xu, J.; Wu, Q.; Zhai, M. Influence of rice husk ash on the waterproof properties of ultrafine fly ash based geopolymer. Constr. Build. Mater. 2019, 208, 394–401. [Google Scholar] [CrossRef]

- Mansaray, K.; Ghaly, A. Thermal degradation of rice husks in nitrogen atmosphere. Bioresour. Technol. 1998, 65, 13–20. [Google Scholar] [CrossRef]

- Akinwumi, I.I.; Awoyera, P.; Olofinnade, O.; Busari, A.; Okotie, M. Rice husk as a concrete constituent: Workability, water absorption and strength of the concrete. Asian J. Civ. Eng. 2016, 17, 887–898. [Google Scholar]

- Hua, J.; Zhao, Z.M.; Yu, W.; Wei, B.Z. Hydroscopic and mechanical properties performance analysis of rice husk powder/PLA composites. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; pp. 1231–1235. [Google Scholar]

- Ismail, H.; Hong, H.; Ping, C.; Khalil, H.A. Polypropylene/silica/rice husk ash hybrid composites: A study on the mechanical, water absorption and morphological properties. J. Thermoplast. Compos. Mater. 2003, 16, 121–137. [Google Scholar] [CrossRef]

- Marques, B.; Tadeu, A.; António, J.; Almeida, J.; de Brito, J. Mechanical, thermal and acoustic behaviour of polymer-based composite materials produced with rice husk and expanded cork by-products. Constr. Build. Mater. 2020, 239, 117851. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P. A review on silicone rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, K. Inspection and Monitoring Technologies of Transmission Lines with Remote Sensing; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Kamarudin, N.; Abd Razak, J.; Norddin, N.; Mohamad, N.; Tee, L.K.; Chew, T.; Saad, N.M. Hardness and Water Absorption Properties of Silicone Rubber Based Composites for High Voltage Insulator Applications. Symp. Intell. Manuf. Mechatron. 2019, 343–352. [Google Scholar]

- Pei, S.; Han, Y.; Guo, Y.; Liu, J.; Ding, J.; Li, Y.; Zhou, H.; Zhao, T. Thermal and water absorption properties of cyanate ester resins modified by fluoride-containing and silicone-containing components. Polym. Adv. Technol. 2020, 31, 1245–1255. [Google Scholar] [CrossRef]

- Mohd Basri, M.S.; Mustapha, F.; Mazlan, N.; Ishak, M.R. Optimization of Adhesion Strength and Microstructure Properties by Using Response Surface Methodology in Enhancing the Rice Husk Ash-Based Geopolymer Composite Coating. Polymers 2020, 12, 2709. [Google Scholar] [CrossRef]

- Aqlibous, A.; Tretsiakova-McNally, S.; Fateh, T. Waterborne intumescent coatings containing industrial and bio-fillers for fire protection of timber materials. Polymers 2020, 12, 757. [Google Scholar] [CrossRef]

- Yu, K.; Yuan, T.; Zhang, S.; Bao, C. Hypergravity-Induced Accumulation: A New, Efficient, and Simple Strategy to Improve the Thermal Conductivity of Boron Nitride Filled Polymer Composites. Polymers 2021, 13, 459. [Google Scholar] [CrossRef]

- Song, J.; Huang, Z.; Qin, Y.; Wang, H.; Shi, M. Effects of Zirconium Silicide on the Vulcanization, Mechanical and Ablation Resistance Properties of Ceramifiable Silicone Rubber Composites. Polymers 2020, 12, 496. [Google Scholar] [CrossRef] [PubMed]

- Ricciardi, P.; Belloni, E.; Merli, F.; Buratti, C. Sustainable Panels Made with Industrial and Agricultural Waste: Thermal and Environmental Critical Analysis of the Experimental Results. Appl. Sci. 2021, 11, 494. [Google Scholar] [CrossRef]

- Czitrom, V. One-factor-at-a-time versus designed experiments. Am. Stat. 1999, 53, 126–131. [Google Scholar]

- Box, G.E.; Wilson, K.B. On the experimental attainment of optimum conditions. In Breakthroughs in Statistics; Springer: Berlin, Germany, 1992; pp. 270–310. [Google Scholar]

- Czyrski, A.; Jarzębski, H. Response Surface Methodology as a Useful Tool for Evaluation of the Recovery of the Fluoroquinolones from Plasma—The Study on Applicability of Box-Behnken Design, Central Composite Design and Doehlert Design. Processes 2020, 8, 473. [Google Scholar] [CrossRef]

- Flaifel, M.H. An Approach Towards Optimization Appraisal of Thermal Conductivity of Magnetic Thermoplastic Elastomeric Nanocomposites Using Response Surface Methodology. Polymers 2020, 12, 2030. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Roslan, S.A.; Sapuan, S.; Rasid, Z.A.; Mohd Nor, A.F.; Md Daud, M.Y.; Dolah, R.; Mohamed Yusoff, M.Z. Mercerization Optimization of Bamboo (Bambusa vulgaris) Fiber-Reinforced Epoxy Composite Structures Using a Box–Behnken Design. Polymers 2020, 12, 1367. [Google Scholar] [CrossRef]

- Azeem, B.; KuShaari, K.; Naqvi, M.; Kok Keong, L.; Almesfer, M.K.; Al-Qodah, Z.; Naqvi, S.R.; Elboughdiri, N. Production and Characterization of Controlled Release Urea Using Biopolymer and Geopolymer as Coating Materials. Polymers 2020, 12, 400. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, F.; Dong, L.; Li, Z.; Chen, L.; He, X.; Gong, J.; Zhang, J.; Li, Q. Design and optimization of flexible polypyrrole/bacterial cellulose conductive nanocomposites using response surface methodology. Polymers 2019, 11, 960. [Google Scholar] [CrossRef]

- Tabaraki, R.; Nateghi, A. Optimization of ultrasonic-assisted extraction of natural antioxidants from rice bran using response surface methodology. Ultrason. Sonochem. 2011, 18, 1279–1286. [Google Scholar] [CrossRef]

- Shinohara, Y.; Kohyama, N. Quantitative analysis of tridymite and cristobalite crystallized in rice husk ash by heating. Ind. Health 2004, 42, 277–285. [Google Scholar] [CrossRef]

- Singh, B. Rice husk ash. In Waste and Supplementary Cementitious Materials in Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 417–460. [Google Scholar]

- UL1709. Standard for Rapid Rise Fire Tests of Protection Materials for Structural Steel; Underwriters Laboratory Inc.: Northbrook, IL, USA, 1994. [Google Scholar]

- ASTM D5229M-92. Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar] [CrossRef]

- Fan, Y.; Gomez, A.; Ferraro, S.; Pinto, B.; Muliana, A.; Saponara, V.L. Diffusion of water in glass fiber reinforced polymer composites at different temperatures. J. Compos. Mater. 2019, 53, 1097–1110. [Google Scholar] [CrossRef]

- Hamilton, D.; Ghert, M.; Simpson, A. Interpreting Regression Models in Clinical Outcome Studies; The British Editorial Society of Bone and Joint Surgery London: London, UK, 2015. [Google Scholar]

- Li, Q.; Pham, H. A testing-coverage software reliability model considering fault removal efficiency and error generation. PLoS ONE 2017, 12, e0181524. [Google Scholar] [CrossRef]

- Nasruddin, N.; Mazlan, N.; Basri, M.M.; Ariff, A.M.; Nasir, N.M. Thermogravimetric analysis on rice husk ashes-based geopolymer paste. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012014. [Google Scholar]

- Cheng Yong, H.; Liew, Y.M.; Al Bakri Abdullah, M.M.; Hussin, K. Fire resistant properties of geopolymers: A review. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2015; pp. 39–43. [Google Scholar]

- Kiaei, M.; Amiri, H.; Samariha, A.; Amani, N. Effect of nanosilica on thermal, flammability, and morphological properties of WF/RPS-based nanocomposites. Cerne 2018, 24, 59–66. [Google Scholar] [CrossRef]

- Xu, W.; Lo, T.Y.; Memon, S.A. Microstructure and reactivity of rich husk ash. Constr. Build. Mater. 2012, 29, 541–547. [Google Scholar] [CrossRef]

- Timpe, D. Silicone rubber flame resistance. Rubber Plast. News 2007, 1–6. [Google Scholar]

- Khan, H.; Amin, M.; Ali, M.; Iqbal, M.; Yasin, M. Effect of micro/nano-SiO2 on mechanical, thermal, and electrical properties of silicone rubber, epoxy, and EPDM composites for outdoor electrical insulations. Turk. J. Electr. Eng. Comput. Sci. 2017, 25, 1426–1435. [Google Scholar] [CrossRef]

- Kong, S.; Mariatti, M.; Busfield, J. Effects of types of fillers and filler loading on the properties of silicone rubber composites. J. Reinf. Plast. Compos. 2011, 30, 1087–1096. [Google Scholar] [CrossRef]

- Parida, U.; Bastia, T.; Kar, B. A Study on the Water Absorption Efficiency of Porous Silica Gel Prepared from Rice Husk Ash. Asian J. Water Environ. Pollut. 2017, 14, 83–86. [Google Scholar] [CrossRef]

- Wei, X.; Ming, F.; Li, D.; Chen, L.; Liu, Y. Influence of water content on mechanical strength and microstructure of alkali-activated fly ash/GGBFS mortars cured at cold and polar regions. Materials 2020, 13, 138. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Deng, C.; Cao, J.-Y.; Wang, Y.-Z. An efficient flame retardant for silicone rubber: Preparation and application. Polym. Degrad. Stab. 2015, 121, 42–50. [Google Scholar] [CrossRef]

- Vickers, L.; Van Riessen, A.; Rickard, W.D. Fire-Resistant Geopolymers: Role of Fibres and Fillers to Enhance Thermal Properties; Springer: Berlin, Germany, 2015. [Google Scholar]

- Ou, H.; Sahli, M.; Barriere, T.; Gelin, J.-C. Determination of the activation energy of silicone rubbers using different kinetic analysis methods. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2016; p. 16007. [Google Scholar]

- Lv, L.; Schlangen, E.; Xing, F. Self-sealing cementitious materials by using water-swelling rubber particles. Materials 2017, 10, 979. [Google Scholar] [CrossRef]

- Li, Z.; Liang, W.; Shan, Y.; Wang, X.; Yang, K.; Cui, Y. Study of flame-retarded silicone rubber with ceramifiable property. Fire Mater. 2020, 44, 487–496. [Google Scholar] [CrossRef]

- Wang, L.; Guo, Y.; Chen, Y.; Chen, T.; Zhu, S.; Zhang, T.; Liu, S. Enhanced Mechanical and Water Absorption Properties of Rice Husk-Derived Nano-SiO2 Reinforced PHBV Composites. Polymers 2018, 10, 1022. [Google Scholar] [CrossRef]

- Zhang, P.; Wittmann, F.; Haist, M.; Müller, H.; Vontobel, P.; Zhao, T. Water penetration into micro-cracks in reinforced concrete. Restor. Build. Monum. 2014, 20, 85–94. [Google Scholar]

| Factors | Levels | Total Number of Experimental Runs | |

|---|---|---|---|

| Full Factorial Design | RSM | ||

| 4 | 5 | 625 (54) | 31 |

| 5 | 5 | 3125 (55) | 54 |

| 6 | 5 | 15,625 (56) | 90 |

| 7 | 5 | 78,125 (57) | 160 |

| Factor | Unit | Notation | Levels | ||||

|---|---|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | |||

| RHA/AA ratio | - | V1 | 0.45 | 0.55 | 0.65 | 0.75 | 0.85 |

| SiR/Ge ratio | - | V2 | 0.25 | 0.40 | 0.55 | 0.70 | 0.85 |

| Sample | Coded Factor | Uncoded Factor | ||

|---|---|---|---|---|

| V1 | V2 | V1 | V2 | |

| S1 | 2 | 0 | 0.85 | 0.55 |

| S2 | 0 | −2 | 0.65 | 0.25 |

| S3 | 0 | 0 | 0.65 | 0.55 |

| S4 | 1 | −1 | 0.75 | 0.40 |

| S5 | 0 | 0 | 0.65 | 0.55 |

| S6 | 0 | 0 | 0.65 | 0.55 |

| S7 | 0 | 0 | 0.65 | 0.55 |

| S8 | −2 | 0 | 0.45 | 0.55 |

| S9 | 0 | 0 | 0.65 | 0.55 |

| S10 | 0 | −2 | 0.65 | 0.25 |

| S11 | 0 | 0 | 0.65 | 0.55 |

| S12 | 2 | 0 | 0.85 | 0.55 |

| S13 | −2 | 0 | 0.45 | 0.55 |

| S14 | 0 | 0 | 0.65 | 0.55 |

| S15 | 1 | 1 | 0.75 | 0.70 |

| S16 | −1 | 1 | 0.55 | 0.70 |

| S17 | 0 | 2 | 0.65 | 0.85 |

| S18 | 1 | 1 | 0.75 | 0.70 |

| S19 | −1 | 1 | 0.55 | 0.70 |

| S20 | 0 | 0 | 0.65 | 0.55 |

| S21 | −1 | −1 | 0.55 | 0.40 |

| S22 | 1 | −1 | 0.75 | 0.40 |

| S23 | 0 | 2 | 0.65 | 0.85 |

| S24 | −1 | −1 | 0.55 | 0.40 |

| Properties | RHA |

|---|---|

| Particles Size | <125 µm |

| Colour | Light grey |

| Structure | Power form |

| Odour | Non |

| Sample | RHA/AA Ratio (V1) | SiR/Ge Ratio (V2) | RHA/AA Ratio (V1) | SiR/Ge Ratio (V2) | Moisture Absorption (%) | Temperature at Equilibrium (°C) |

|---|---|---|---|---|---|---|

| S1 | 2 | 0 | 0.85 | 0.55 | 16.8 | 214 |

| S2 | 0 | −2 | 0.65 | 0.25 | 24.6 | 243 |

| S3 | 0 | 0 | 0.65 | 0.55 | 18.4 | 288 |

| S4 | 1 | −1 | 0.75 | 0.40 | 20.3 | 252 |

| S5 | 0 | 0 | 0.65 | 0.55 | 18.5 | 283 |

| S6 | 0 | 0 | 0.65 | 0.55 | 18.6 | 280 |

| S7 | 0 | 0 | 0.65 | 0.55 | 18.8 | 270 |

| S8 | −2 | 0 | 0.45 | 0.55 | 24.7 | 247 |

| S9 | 0 | 0 | 0.65 | 0.55 | 18.8 | 268 |

| S10 | 0 | −2 | 0.65 | 0.25 | 24.3 | 256 |

| S11 | 0 | 0 | 0.65 | 0.55 | 19.1 | 264 |

| S12 | 2 | 0 | 0.85 | 0.55 | 17.3 | 212 |

| S13 | −2 | 0 | 0.45 | 0.55 | 22.5 | 244 |

| S14 | 0 | 0 | 0.65 | 0.55 | 19.2 | 260 |

| S15 | 1 | 1 | 0.75 | 0.70 | 15.4 | 230 |

| S16 | −1 | 1 | 0.55 | 0.70 | 19.7 | 242 |

| S17 | 0 | 2 | 0.65 | 0.85 | 17.0 | 208 |

| S18 | 1 | 1 | 0.75 | 0.70 | 16.0 | 243 |

| S19 | −1 | 1 | 0.55 | 0.70 | 20.2 | 246 |

| S20 | 0 | 0 | 0.65 | 0.55 | 19.5 | 257 |

| S21 | −1 | −1 | 0.55 | 0.40 | 25.2 | 285 |

| S22 | 1 | −1 | 0.75 | 0.40 | 19.1 | 261 |

| S23 | 0 | 2 | 0.65 | 0.85 | 17.0 | 229 |

| S24 | −1 | −1 | 0.55 | 0.40 | 25.7 | 298 |

| Term | Notation | Coefficient | Standard Error of Coefficient | p |

|---|---|---|---|---|

| Constant | 273.146 | 3.460 | 0.000 | |

| RHA/AA ratio | V1 | −8.958 | 2.188 | 0.001 |

| SiR/Ge ratio | V2 | −10.792 | 2.188 | 0.000 |

| RHA/AA ratio* RHA/AA ratio | V1* V1 | −10.500 | 1.641 | 0.000 |

| SiR/Ge ratio* SiR/Ge ratio | V2* V2 | −9.313 | 1.641 | 0.000 |

| RHA/AA ratio* SiR/Ge ratio | V1* V2 | 6.875 | 3.790 | 0.086 |

| R2 = 0.8467 R2 (adj) = 0.8041 | ||||

| Term | Notation | Coefficient | Standard Error of Coefficient | p |

|---|---|---|---|---|

| Constant | 19.031 | 0.257 | 0.000 | |

| RHA/AA ratio | V1 | −1.925 | 0.163 | 0.000 |

| SiR/Ge ratio | V2 | −2.033 | 0.163 | 0.000 |

| RHA/AA ratio* RHA/AA ratio | V1* V1 | 0.365 | 0.122 | 0.008 |

| SiR/Ge ratio* SiR/Ge ratio | V2* V2 | 0.465 | 0.122 | 0.001 |

| RHA/AA ratio* SiR/Ge ratio | V1* V2 | 0.375 | 0.282 | 0.201 |

| R2 = 0.9459 R2 (adj) = 0.9309 | ||||

| Sample | Temperature at Equilibrium (°C) | Moisture Absorption (%) | ||||

|---|---|---|---|---|---|---|

| Experimental Value | Predicted Value | Error (%) | Experimental Value | Predicted Value | Error (%) | |

| SV1 | 248 | 206.9 | 19.86 | 15.73 | 15.8 | 0.44 |

| SV2 | 211 | 206.9 | 1.98 | 15.43 | 15.8 | 2.34 |

| SV3 | 237 | 206.9 | 14.55 | 15.62 | 15.8 | 1.14 |

| Error | 12.13 | Error | 1.31 | |||

| Before and after Fire Retardant Test | |||

| Performance | Sample Number | RHA/AA Ratio | SiR/Ge Ratio |

| Good | S17 | 0.65 | 0.85 |

| Moderate | S18 | 0.75 | 0.70 |

| Poor | S21 | 0.55 | 0.40 |

| Before Moisture Absorption Test | |||

| Performance | Sample Number | RHA/AA Ratio | SiR/Ge Ratio |

| Good | S1 | 0.85 | 0.55 |

| Moderate | S14 | 0.65 | 0.55 |

| Poor | S21 | 0.55 | 0.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Basri, M.S.; Yek, T.H.; A. Talib, R.; Mohamed Amin Tawakkal, I.S.; Kamarudin, S.H.; Mazlan, N.; Maidin, N.A.; Ab Rahman, M.H. Rice Husk Ash/Silicone Rubber-Based Binary Blended Geopolymer Coating Composite: Fire Retardant, Moisture Absorption, Optimize Composition, and Microstructural Analysis. Polymers 2021, 13, 985. https://doi.org/10.3390/polym13060985

Mohd Basri MS, Yek TH, A. Talib R, Mohamed Amin Tawakkal IS, Kamarudin SH, Mazlan N, Maidin NA, Ab Rahman MH. Rice Husk Ash/Silicone Rubber-Based Binary Blended Geopolymer Coating Composite: Fire Retardant, Moisture Absorption, Optimize Composition, and Microstructural Analysis. Polymers. 2021; 13(6):985. https://doi.org/10.3390/polym13060985

Chicago/Turabian StyleMohd Basri, Mohd Salahuddin, Tee Hui Yek, Rosnita A. Talib, Intan Syafinaz Mohamed Amin Tawakkal, Siti Hasnah Kamarudin, Norkhairunnisa Mazlan, Nurul Ain Maidin, and Mohd Hidayat Ab Rahman. 2021. "Rice Husk Ash/Silicone Rubber-Based Binary Blended Geopolymer Coating Composite: Fire Retardant, Moisture Absorption, Optimize Composition, and Microstructural Analysis" Polymers 13, no. 6: 985. https://doi.org/10.3390/polym13060985

APA StyleMohd Basri, M. S., Yek, T. H., A. Talib, R., Mohamed Amin Tawakkal, I. S., Kamarudin, S. H., Mazlan, N., Maidin, N. A., & Ab Rahman, M. H. (2021). Rice Husk Ash/Silicone Rubber-Based Binary Blended Geopolymer Coating Composite: Fire Retardant, Moisture Absorption, Optimize Composition, and Microstructural Analysis. Polymers, 13(6), 985. https://doi.org/10.3390/polym13060985