Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber

Abstract

:1. Introduction

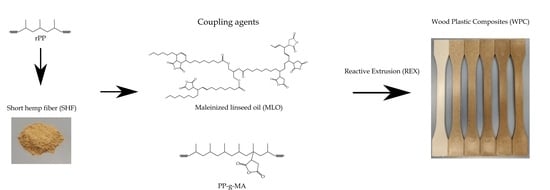

2. Materials and Methods

2.1. Materials

2.2. Manufacturing of the Recycled Polypropylene Sample and the rPP/Hemp Fiber Composites

2.3. Mechanical Properties

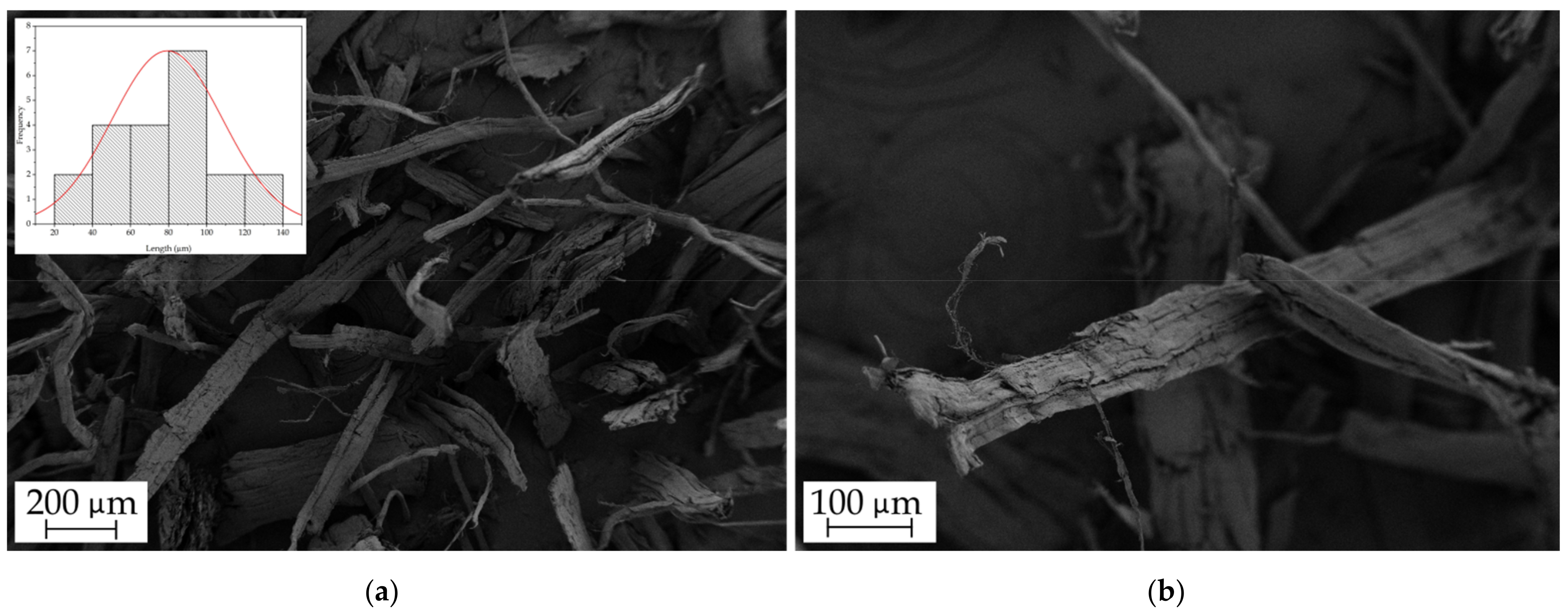

2.4. Morphological Characterization

2.5. Thermal Properties

2.6. Thermomechanical Properties

2.7. Color Measurements

2.8. Water Absorption Analysis

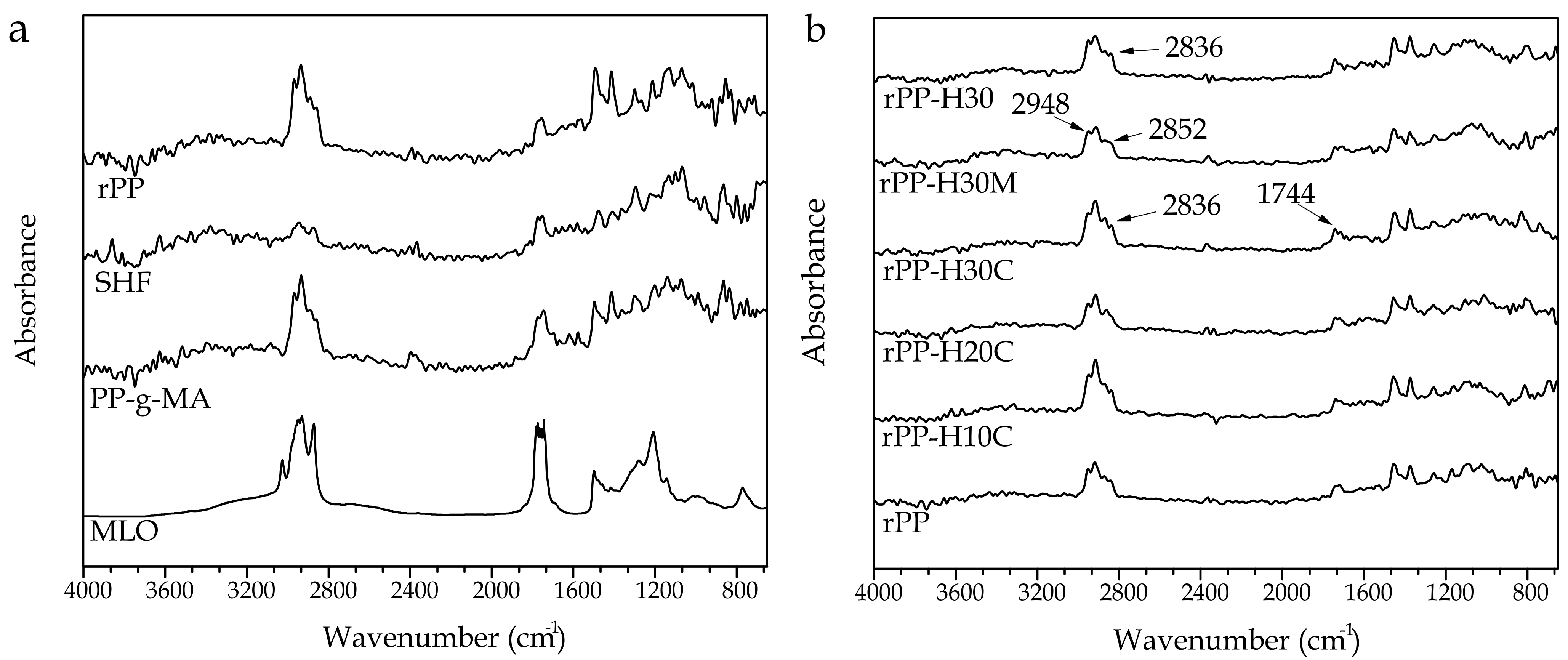

2.9. Chemical Structure and Infrared Spectroscopy

3. Results

3.1. Mechanical Properties of the Recycled Polypropylene Sample and the rPP/Hemp Fiber Composites

3.2. Morphological Characterization of the Recycled Polypropylene Sample and the rPP/Hemp Fiber Composites

3.3. Thermal Properties of the Recycled Polypropylene Sample and the rPP/Hemp Fiber Composites

3.4. Thermomechanical Properties of the Recycled Polypropylene Sample and the rPP/Hemp Fiber Composites

3.5. Water Uptake Properties of the Recycled Polypropylene Sample and the rPP/Hemp Fiber Composites

3.6. Colorimetry Properties of rPP/Hemp Fiber Composites

3.7. Chemical Structure and Infrared Spectroscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- La Mantia, F.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Schwarzkopf, M.J.; Burnard, M.D. Wood-plastic composites—Performance and environmental impacts. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts; Springer: Singapore, 2016; pp. 19–43. [Google Scholar]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural fibre composites and their applications: A review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef] [Green Version]

- Rohit, K.; Dixit, S. A review-future aspect of natural fiber reinforced composite. Polym. Renew. Resour. 2016, 7, 43–59. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Fombuena, V.; MD, S. Study of the properties of thermoset materials derived from epoxidized soybean oil and protein fillers. J. Am. Oil Chem. Soc. 2013, 90, 449–457. [Google Scholar] [CrossRef] [Green Version]

- Garcia, D.; Balart, R.; Sanchez, L.; Lopez, J. Compatibility of recycled PVC/ABS blends. Effect of previous degradation. Polym. Eng. Sci. 2007, 47, 789–796. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jimenez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crop. Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Pawlak, F.; Aldas, M.; Parres, F.; Lopez-Martinez, J.; Patricia Arrieta, M. Silane-Functionalized Sheep Wool Fibers from Dairy Industry Waste for the Development of Plasticized PLA Composites with Maleinized Linseed Oil for Injection-Molded Parts. Polymers 2020, 12, 2523. [Google Scholar] [CrossRef]

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Huda, M.; Drzal, L.; Ray, D.; Mohanty, A.; Mishra, M. Natural-fiber composites in the automotive sector. In Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008; pp. 221–268. [Google Scholar]

- Luzi, F.; Fortunati, E.; Puglia, D.; Lavorgna, M.; Santulli, C.; Kenny, J.M.; Torre, L. Optimized extraction of cellulose nanocrystals from pristine and carded hemp fibres. Ind. Crop. Prod. 2014, 56, 175–186. [Google Scholar] [CrossRef]

- Plastic Europe. Plastics—The Facts 2020. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 8 March 2021).

- Drzyzga, O.; Prieto, A. Plastic waste management, a matter for the ‘community’. Microb. Biotechnol. 2019, 12, 66. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Jia, S.; Du, S.; Wang, Y.; Lv, L.; Zhang, J. Improved properties of recycled polypropylene by introducing the long chain branched structure through reactive extrusion. Waste Manag. 2018, 76, 172–179. [Google Scholar] [CrossRef]

- Matias, Á.A.; Lima, M.S.; Pereira, J.; Pereira, P.; Barros, R.; Coelho, J.F.; Serra, A.C. Use of recycled polypropylene/poly (ethylene terephthalate) blends to manufacture water pipes: An industrial scale study. Waste Manag. 2020, 101, 250–258. [Google Scholar] [CrossRef]

- Gu, F.; Guo, J.; Zhang, W.; Summers, P.A.; Hall, P. From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. Sci. Total Environ. 2017, 601, 1192–1207. [Google Scholar] [CrossRef]

- Suaria, G.; Achtypi, A.; Perold, V.; Lee, J.R.; Pierucci, A.; Bornman, T.G.; Aliani, S.; Ryan, P.G. Microfibers in oceanic surface waters: A global characterization. Sci. Adv. 2020, 6, eaay8493. [Google Scholar] [CrossRef]

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current developments: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Collister, T.; Combe, M.; Sivakugan, N.; Deng, Z. Post-cracking performance of recycled polypropylene fibre in concrete. Constr. Build. Mater. 2015, 101, 1069–1077. [Google Scholar] [CrossRef]

- Najafi, S.K. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef]

- Arrieta, M.; Fortunati, E.; Burgos, N.; Peltzer, M.A.; López, J.; Peponi, L. Nanocellulose-based polymeric blends for food packaging applications. In Multifunctional Polymeric Nanocomposites Based on Cellulosic Reinforcements; Puglia, D., Fortunati, E., Kenny, J.M., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 205–252. [Google Scholar]

- Lee, S.-H.; Wang, S. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. Part A Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Yatigala, N.S.; Bajwa, D.S.; Bajwa, S.G. Compatibilization improves physico-mechanical properties of biodegradable biobased polymer composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 315–325. [Google Scholar] [CrossRef]

- Han, H.; Gong, X.; Zhou, M.; Wu, Y. A Study About Water/Alkali Treatments of Hemp Fiber on Ultraviolet Ageing of the Reinforced Polypropylene Composites. J. Polym. Environ. 2020, 28, 2572–2583. [Google Scholar] [CrossRef]

- Rachini, A.; Mougin, G.; Delalande, S.; Charmeau, J.Y.; Barres, C.; Fleury, E. Hemp fibers/polypropylene composites by reactive compounding: Improvement of physical properties promoted by selective coupling chemistry. Polym. Degrad. Stab. 2012, 97, 1988–1995. [Google Scholar] [CrossRef]

- Wang, X.; Yu, Z.; McDonald, A.G. Effect of different reinforcing fillers on properties, interfacial compatibility and weatherability of wood-plastic composites. J. Bionic Eng. 2019, 16, 337–353. [Google Scholar] [CrossRef]

- Gunning, M.A.; Geever, L.M.; Killion, J.A.; Lyons, J.G.; Higginbotham, C.L. Effect of compatibilizer content on the mechanical properties of bioplastic composites via hot melt extrusion. Polym. Plast. Technol. Eng. 2014, 53, 1223–1235. [Google Scholar] [CrossRef]

- Islam, M.R.; Beg, M.D.; Gupta, A. Characterization of laccase-treated kenaf fibre reinforced recycled polypropylene composites. BioResources 2013, 8, 3753–3770. [Google Scholar] [CrossRef] [Green Version]

- Srebrenkoska, V.; Gaceva, G.B.; Avella, M.; Errico, M.E.; Gentile, G. Recycling of polypropylene-based eco-composites. Polym. Int. 2008, 57, 1252–1257. [Google Scholar] [CrossRef] [Green Version]

- Kord, B. Influence of nanoparticle on hygroscopic thickness swelling rate of composites from hemp fiber and recycled plastic. Sci. Eng. Compos. Mater. 2013, 20, 1–6. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crop. Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Ferri, J.; Garcia-Garcia, D.; Sánchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (MLO) on mechanical performance of poly (lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef]

- Joseph, P.; Joseph, K.; Thomas, S.; Pillai, C.; Prasad, V.; Groeninckx, G.; Sarkissova, M. The thermal and crystallisation studies of short sisal fibre reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 253–266. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, B.-H.; Choi, S.-W.; Kim, S.; Kim, H.-J. The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1473–1482. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. Part B Eng. 2017, 114, 15–22. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Garcia, D.; Fenollar, O.; Fombuena, V.; Lopez-Martinez, J.; Balart, R. Improvement of Mechanical Ductile Properties of Poly (3-hydroxybutyrate) by Using Vegetable Oil Derivatives. Macromol. Mater. Eng. 2017, 302, 1600330. [Google Scholar] [CrossRef]

- Liminana, P.; Quiles-Carrillo, L.; Boronat, T.; Balart, R.; Montanes, N. The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly (Butylene Succinate (PBS) Matrix Compatibilized with Maleinized Linseed Oil (MLO). Materials 2018, 11, 2179. [Google Scholar] [CrossRef] [Green Version]

- Essabir, H.; Raji, M.; Laaziz, S.A.; Rodrique, D.; Bouhfid, R. Thermo-mechanical performances of polypropylene biocomposites based on untreated, treated and compatibilized spent coffee grounds. Compos. Part B Eng. 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Ivorra-Martinez, J.; Manuel-Mañogil, J.; Boronat, T.; Sanchez-Nacher, L.; Balart, R.; Quiles-Carrillo, L. Development and Characterization of Sustainable Composites from Bacterial Polyester Poly (3-Hydroxybutyrate-co-3-hydroxyhexanoate) and Almond Shell Flour by Reactive Extrusion with Oligomers of Lactic Acid. Polymers 2020, 12, 1097. [Google Scholar] [CrossRef]

- Lu, N.; Oza, S. A comparative study of the mechanical properties of hemp fiber with virgin and recycled high density polyethylene matrix. Compos. Part B Eng. 2013, 45, 1651–1656. [Google Scholar] [CrossRef]

- Song, Y.S.; Lee, J.T.; Ji, D.S.; Kim, M.W.; Lee, S.H.; Youn, J.R. Viscoelastic and thermal behavior of woven hemp fiber reinforced poly(lactic acid) composites. Compos. Part B Eng. 2012, 43, 856–860. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Duart, S.; Montanes, N.; Torres-Giner, S.; Balart, R. Enhancement of the mechanical and thermal properties of injection-molded polylactide parts by the addition of acrylated epoxidized soybean oil. Mater. Des. 2018, 140, 54–63. [Google Scholar] [CrossRef]

- Maslinda, A.; Majid, M.A.; Ridzuan, M.; Afendi, M.; Gibson, A. Effect of water absorption on the mechanical properties of hybrid interwoven cellulosic-cellulosic fibre reinforced epoxy composites. Compos. Struct. 2017, 167, 227–237. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Boronat, T.; Montanes, N.; Balart, R.; Torres-Giner, S. Injection-molded parts of fully bio-based polyamide 1010 strengthened with waste derived slate fibers pretreated with glycidyl-and amino-silane coupling agents. Polym. Test. 2019, 77, 105875. [Google Scholar] [CrossRef]

- Luyt, A.; Dramićanin, M.; Antić, Ž.; Djoković, V. Morphology, mechanical and thermal properties of composites of polypropylene and nanostructured wollastonite filler. Polym. Test. 2009, 28, 348–356. [Google Scholar] [CrossRef]

- Dolores Samper, M.; Bertomeu, D.; Patricia Arrieta, M.; Miguel Ferri, J.; Lopez-Martinez, J. Interference of Biodegradable Plastics in the Polypropylene Recycling Process. Materials 2018, 11, 1886. [Google Scholar] [CrossRef] [Green Version]

- Orue, A.; Eceiza, A.; Arbelaiz, A. Pretreatments of natural fibers for polymer composite materials. In Lignocellulosic Composite Materials; Springer: Berlin/Heidelberg, Germany, 2018; pp. 137–175. [Google Scholar]

- Agüero, Á.; Garcia-Sanoguera, D.; Lascano, D.; Rojas-Lema, S.; Ivorra-Martinez, J.; Fenollar, O.; Torres-Giner, S. Evaluation of different compatibilization strategies to improve the performance of injection-molded green composite pieces made of polylactide reinforced with short flaxseed fibers. Polymers 2020, 12, 821. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Luo, X.; Lin, X. Preparation and characterization of hollow glass microsphere reinforced poly (butylene succinate) composites. Mater. Des. 2013, 46, 902–909. [Google Scholar] [CrossRef]

- Pracella, M.; Chionna, D.; Anguillesi, I.; Kulinski, Z.; Piorkowska, E. Functionalization, compatibilization and properties of polypropylene composites with hemp fibres. Compos. Sci. Technol. 2006, 66, 2218–2230. [Google Scholar] [CrossRef]

- García-García, D.; Carbonell, A.; Samper, M.; García-Sanoguera, D.; Balart, R. Green composites based on polypropylene matrix and hydrophobized spend coffee ground (SCG) powder. Compos. Part B Eng. 2015, 78, 256–265. [Google Scholar] [CrossRef]

- Badji, C.; Beigbeder, J.; Garay, H.; Bergeret, A.; Bénézet, J.-C.; Desauziers, V. Natural weathering of hemp fibers reinforced polypropylene biocomposites: Relationships between visual and surface aspects, mechanical properties and microstructure based on statistical approach. Compos. Sci. Technol. 2018, 167, 440–447. [Google Scholar] [CrossRef] [Green Version]

- Gadioli, R.; Morais, J.A.; Waldman, W.R.; De Paoli, M.-A. The role of lignin in polypropylene composites with semi-bleached cellulose fibers: Mechanical properties and its activity as antioxidant. Polym. Degrad. Stab. 2014, 108, 23–34. [Google Scholar] [CrossRef]

- Gonzalez, L.; Agüero, A.; Quiles-Carrillo, L.; Lascano, D.; Montanes, N. Optimization of the loading of an environmentally friendly compatibilizer derived from linseed oil in poly(lactic acid)/diatomaceous earth composites. Materials 2019, 12, 1627. [Google Scholar] [CrossRef] [Green Version]

- Rayon, E.; Ferrandiz, S.; Isabel Rico, M.; Lopez, J.; Arrieta, M.P. Microstructure, Mechanical, and Thermogravimetric Characterization of Cellulosic By-Products Obtained from Biomass Seeds. Int. J. Food Prop. 2015, 18, 1211–1222. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Rachini, A.; Le Troedec, M.; Peyratout, C.; Smith, A. Comparison of the thermal degradation of natural, alkali-treated and silane-treated hemp fibers under air and an inert atmosphere. J. Appl. Polym. Sci. 2009, 112, 226–234. [Google Scholar] [CrossRef]

- Hussain, S.; Anjum, F.; Butt, M.; Sheikh, M. Chemical composition and functional properties of flaxseed (Linum usitatissimum) flour. Sarhad J. Agric 2008, 24, 649–653. [Google Scholar]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Suardana, N.; Piao, Y.; Lim, J.K. Mechanical properties of hemp fibers and hemp/pp composites: Effects of chemical surface treatment. Mater. Phys. Mech. 2011, 11, 1–8. [Google Scholar]

- Yuan, B.; Chen, G.; Zou, Y.; Shang, S.; Sun, Y.; Yu, B.; He, S.; Chen, X. Alumina nanoflake-coated graphene nanohybrid as a novel flame retardant filler for polypropylene. Polym. Adv. Technol. 2019, 30, 2153–2158. [Google Scholar] [CrossRef]

- Oza, S.; Wang, R.; Lu, N. Thermal and mechanical properties of recycled high density polyethylene/hemp fiber composites. Int. J. Appl. Sci. Technol. 2011, 1, 31–36. [Google Scholar]

- Amash, A.; Zugenmaier, P. Thermal and dynamic mechanical investigations on fiber-reinforced polypropylene composites. J. Appl. Polym. Sci. 1997, 63, 1143–1154. [Google Scholar] [CrossRef]

- Etaati, A.; Pather, S.; Fang, Z.; Wang, H. The study of fibre/matrix bond strength in short hemp polypropylene composites from dynamic mechanical analysis. Compos. Part B Eng. 2014, 62, 19–28. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Chemical modification of flax reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 442–448. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Effect of plasticizer type and concentration on tensile, thermal and barrier properties of biodegradable films based on sugar palm (Arenga pinnata) starch. Polymers 2015, 7, 1106–1124. [Google Scholar] [CrossRef]

- Pawlak, F.; Aldas, M.; López-Martínez, J.; Samper, M.D. Effect of different compatibilizers on injection-molded green fiber-reinforced polymers based on poly (lactic acid)-maleinized linseed oil system and sheep wool. Polymers 2019, 11, 1514. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.R.; Rivai, M.; Gupta, A.; Beg, M.D.H. Characterization of ultrasound-treated oil palm empty fruit bunch-glass fiber-recycled polypropylene hybrid composites. J. Polym. Eng. 2015, 35, 135–143. [Google Scholar] [CrossRef]

- Ferrero, B.; Boronat, T.; Moriana, R.; Fenollar, O.; Balart, R. Green composites based on wheat gluten matrix and posidonia oceanica waste fibers as reinforcements. Polym. Compos. 2013, 34, 1663–1669. [Google Scholar] [CrossRef]

- Lascano, D.; Garcia-Garcia, D.; Rojas-Lema, S.; Quiles-Carrillo, L.; Balart, R.; Boronat, T. Manufacturing and characterization of green composites with partially biobased epoxy resin and flaxseed flour wastes. Appl. Sci. 2020, 10, 3688. [Google Scholar] [CrossRef]

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A fractal model for capillary flow through a single tortuous capillary with roughened surfaces in fibrous porous media. Fractals 2021, 29, 2150017. [Google Scholar] [CrossRef]

- Ashori, A.; Sheshmani, S. Hybrid composites made from recycled materials: Moisture absorption and thickness swelling behavior. Bioresour. Technol. 2010, 101, 4717–4720. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Barcík, Š.; Gašparík, M.; Razumov, E.Y. Effect of temperature on the color changes of wood during thermal modification. Cellul. Chem. Technol. 2015, 49, 789–798. [Google Scholar]

- Ostafi, M.-F.; Dinulică, F.; Nicolescu, V.-N. Physical properties and structural features of common walnut (Juglans regia L.) wood: A case-study/Physikalische Eigenschaften und strukturelle Charakteristika des Holzes der Walnuß (Juglans regia L.): Eine Fallstudie. Die Bodenkult. J. Land Manag. Food Environ. 2016, 67, 105–120. [Google Scholar] [CrossRef] [Green Version]

- Luís, R.C.G.; Nisgoski, S.; Klitzke, R.J. Effect of steaming on the colorimetric properties of Eucalyptus saligna wood. Floresta Ambiente 2018, 25, e00101414. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Ke, K.; Yang, M.-B.; Yang, W. Recent progress on chemical modification of cellulose for high mechanical-performance Poly(lactic acid)/Cellulose composite: A short review. Compos. Commun. 2020, 23, 100548. [Google Scholar] [CrossRef]

- Sclavons, M.; Franquinet, P.; Carlier, V.; Verfaillie, G.; Fallais, I.; Legras, R.; Laurent, M.; Thyrion, F. Quantification of the maleic anhydride grafted onto polypropylene by chemical and viscosimetric titrations, and FTIR spectroscopy. Polymer 2000, 41, 1989–1999. [Google Scholar] [CrossRef]

- Wang, B.; Sain, M.; Oksman, K. Study of structural morphology of hemp fiber from the micro to the nanoscale. Appl. Compos. Mater. 2007, 14, 89–103. [Google Scholar] [CrossRef]

- Sain, M.; Bhatnagar, A. Manufacturing of Nanofibrils from Natural Fibres, Agro Based Fibres and Root Fibres. CA Patent CA2437616A1, 4 August 2003. [Google Scholar]

- Ardejani, F.D.; Badii, K.; Limaee, N.Y.; Shafaei, S.Z.; Mirhabibi, A. Adsorption of Direct Red 80 dye from aqueous solution onto almond shells: Effect of pH, initial concentration and shell type. J. Hazard. Mater. 2008, 151, 730–737. [Google Scholar] [CrossRef]

- Jorda-Reolid, M.; Gomez-Caturla, J.; Ivorra-Martinez, J.; Stefani, P.M.; Rojas-Lema, S.; Quiles-Carrillo, L. Upgrading Argan Shell Wastes in Wood Plastic Composites with Biobased Polyethylene Matrix and Different Compatibilizers. Polymers 2021, 13, 922. [Google Scholar] [CrossRef]

- Dominici, F.; García García, D.; Fombuena, V.; Luzi, F.; Puglia, D.; Torre, L.; Balart, R. Bio-polyethylene-based composites reinforced with alkali and palmitoyl chloride-treated coffee silverskin. Molecules 2019, 24, 3113. [Google Scholar] [CrossRef] [Green Version]

| Code | rPP (wt%) | SHF (wt%) | PP-g-MA (phr) | MLO (phr) |

|---|---|---|---|---|

| rPP | 100 | - | - | - |

| rPP-H10-C | 90 | 10 | 2.5 | - |

| rPP-H20-C | 80 | 20 | 5.0 | - |

| rPP-H30-C | 70 | 30 | 7.5 | - |

| rPP-H30 | 70 | 30 | - | - |

| rPP-H30-M | 70 | 30 | - | 7.5 |

| Code | Et (MPa) | σmax (MPa) | εb (%) | Shore D Hardness | Impact Strength (kJ m−2) |

|---|---|---|---|---|---|

| rPP | 933 ± 45 | 21.2 ± 0.8 | 100.0 ± 11.0 | 70.3 ± 0.6 | 2.2 ± 0.1 |

| rPP-H10-C | 1617 ± 19 | 24.2 ± 0.7 | 6.7 ± 0.6 | 70.7 ± 0.5 | 2.0 ± 0.2 |

| rPP-H20-C | 2172 ± 62 | 26.6 ± 0.3 | 5.3 ± 0.6 | 72.7 ± 0.6 | 2.4 ± 0.2 |

| rPP-H30-C | 2977 ± 53 | 28.9 ± 0.5 | 5.1 ± 0.5 | 76.0 ± 1.0 | 3.2 ± 0.2 |

| rPP-H30 | 2339 ± 90 | 22.4 ± 0.8 | 4.9 ± 0.7 | 72.8 ± 0.8 | 2.7 ± 0.3 |

| rPP-H30-M | 1884 ± 47 | 17.7 ± 0.2 | 8.1 ± 0.4 | 69.3 ± 0.6 | 3.7 ± 0.3 |

| Code | Tc (°C) | Tm (°C) | ΔHm (J g−1) | χc_max (%) |

|---|---|---|---|---|

| rPP | 118.6 ± 0.6 | 163.7 ± 0.6 | 94.2 ± 0.4 | 68.3 ± 0.3 |

| rPP-H10-C | 117.9 ± 0.9 | 164.0 ± 0.6 | 85.2 ± 0.5 | 70.3 ± 0.5 |

| rPP-H20-C | 117.4 ± 0.8 | 163.1 ± 0.5 | 78.7 ± 0.5 | 74.9 ± 0.7 |

| rPP-H30-C | 116.8 ± 0.6 | 164.2 ± 0.4 | 66.6 ± 0.7 | 74.1 ± 0.4 |

| rPP-H30 | 118.7 ± 0.4 | 165.0 ± 0.7 | 61.5 ± 0.6 | 63.7 ± 0.4 |

| rPP-H30-M | 115.7 ± 0.7 | 163.9 ± 0.6 | 64.3 ± 0.5 | 71.8 ± 0.5 |

| Code | T5% (°C) | Tdeg_max (°C) | Residual Mass (%) |

|---|---|---|---|

| rPP | 352.3 ± 2.1 | 448.8 ± 2.3 | 6.8 ± 0.5 |

| rPP-H10-C | 323.8 ± 1.2 | 422.0 ± 1.4 | 7.2 ± 0.3 |

| rPP-H20-C | 292.4 ± 1.5 | 416.3 ± 1.6 | 8.2 ± 0.7 |

| rPP-H30-C | 270.3 ± 2.0 | 390.8 ± 1.3 | 11.1 ± 0.6 |

| rPP-H30 | 262.3 ± 1.8 | 382.2 ± 1.7 | 10.1 ± 0.5 |

| rPP-H30-M | 261.7 ± 1.4 | 422.8 ± 2.2 | 11.3 ± 0.6 |

| SHF | 191.2 ± 1.6 | 345.9 ± 1.9 | 24.8 ± 0.4 |

| Code | DMTA | |||

|---|---|---|---|---|

| E’ at −125 °C (MPa) | E’ at 25 °C (MPa) | E’ at 100 °C (MPa) | Tg (°C) | |

| rPP | 2117.6 ± 50.2 | 951.5 ± 20.2 | 228.2 ± 18.2 | 13.6 ± 1.1 |

| rPP-H10-C | 1804.3 ± 42.4 | 894.6 ± 10.5 | 256.4 ± 16.4 | 14.9 ± 0.7 |

| rPP-H20-C | 2392.6 ± 33.7 | 1216.9 ± 25.2 | 417.3 ± 11.3 | 15.3 ± 0.6 |

| rPP-H30-C | 2695.3 ± 61.1 | 1428.7 ± 12.3 | 520.0 ± 17.4 | 13.6 ± 0.6 |

| rPP-H30 | 2693.5 ± 64.4 | 1463.4 ± 30.2 | 573.0 ± 20.3 | 15.2 ± 0.9 |

| rPP-H30-M | 2818.4 ± 44.6 | 1239.4 ± 28.7 | 360.0 ± 13.1 | 7.6 ± 0.8 |

| Code | L* | a* | b* | |

|---|---|---|---|---|

| rPP | 87.5 ± 0.4 | −0.2 ± 0.1 | 0.6 ± 0.2 | - |

| rPP-H10-C | 68.8 ± 0.6 | 4.6 ± 0.5 | 13.4 ± 0.5 | 23.7 ± 0.6 |

| rPP-H20-C | 63.8 ± 0.3 | 5.4 ± 0.1 | 17.6 ± 0.1 | 30.1 ± 0.1 |

| rPP-H30-C | 55.0 ± 0.2 | 6.2 ± 0.5 | 15.5 ± 0.5 | 36.8 ± 0.2 |

| rPP-H30 | 56.9 ± 0.5 | 61 ± 0.4 | 17.7 ± 0.6 | 36.1 ± 0.2 |

| rPP-H30-M | 55.3 ± 0.4 | 6.7 ± 0.2 | 19.0 ± 0.4 | 38.2 ± 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burgada, F.; Fages, E.; Quiles-Carrillo, L.; Lascano, D.; Ivorra-Martinez, J.; Arrieta, M.P.; Fenollar, O. Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber. Polymers 2021, 13, 1248. https://doi.org/10.3390/polym13081248

Burgada F, Fages E, Quiles-Carrillo L, Lascano D, Ivorra-Martinez J, Arrieta MP, Fenollar O. Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber. Polymers. 2021; 13(8):1248. https://doi.org/10.3390/polym13081248

Chicago/Turabian StyleBurgada, Francisco, Eduardo Fages, Luis Quiles-Carrillo, Diego Lascano, Juan Ivorra-Martinez, Marina P. Arrieta, and Octavio Fenollar. 2021. "Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber" Polymers 13, no. 8: 1248. https://doi.org/10.3390/polym13081248

APA StyleBurgada, F., Fages, E., Quiles-Carrillo, L., Lascano, D., Ivorra-Martinez, J., Arrieta, M. P., & Fenollar, O. (2021). Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber. Polymers, 13(8), 1248. https://doi.org/10.3390/polym13081248