The Impact of Rheology on Viscous Oil Displacement by Polymers Analyzed by Pore-Scale Network Modelling

Abstract

1. Introduction

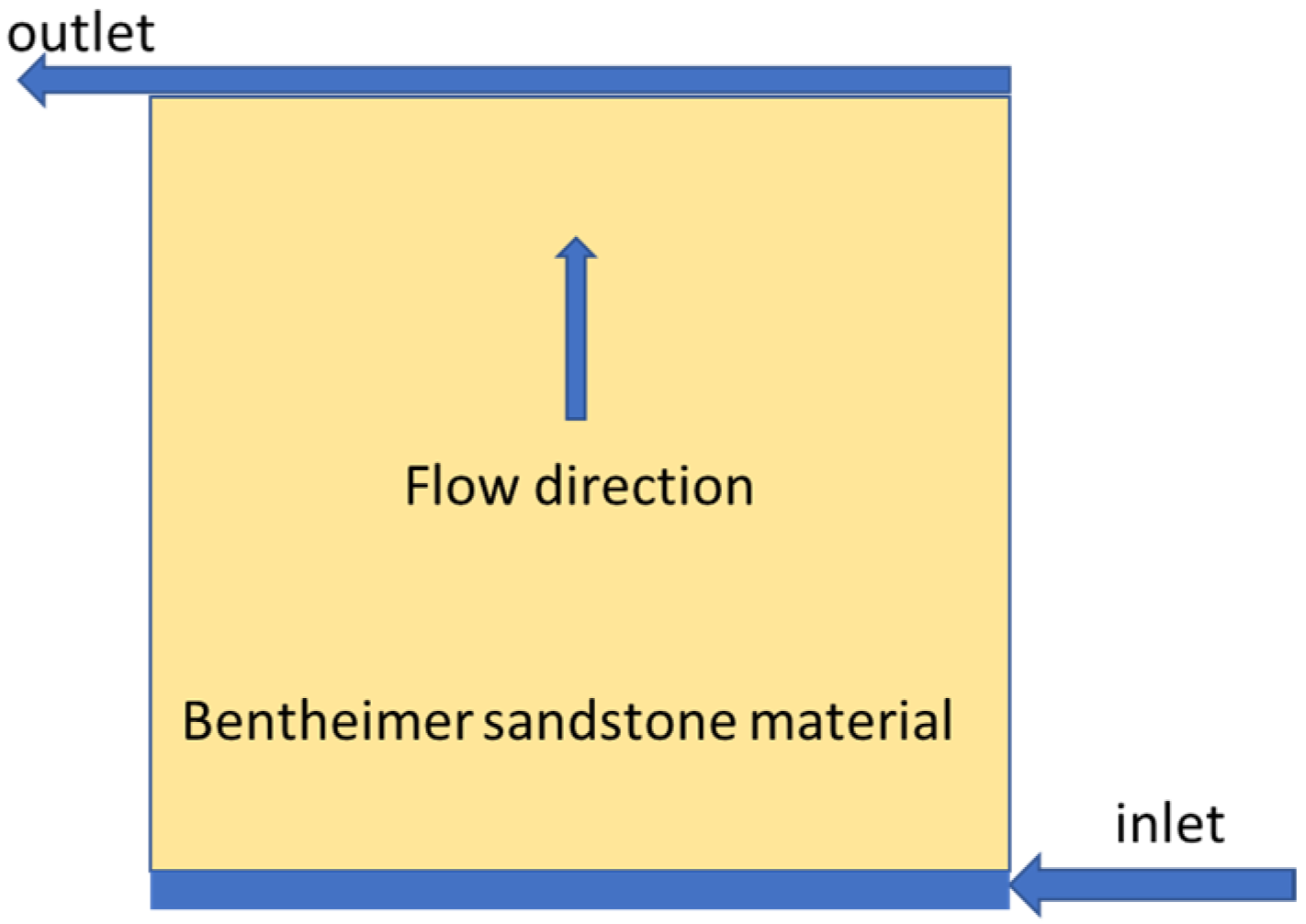

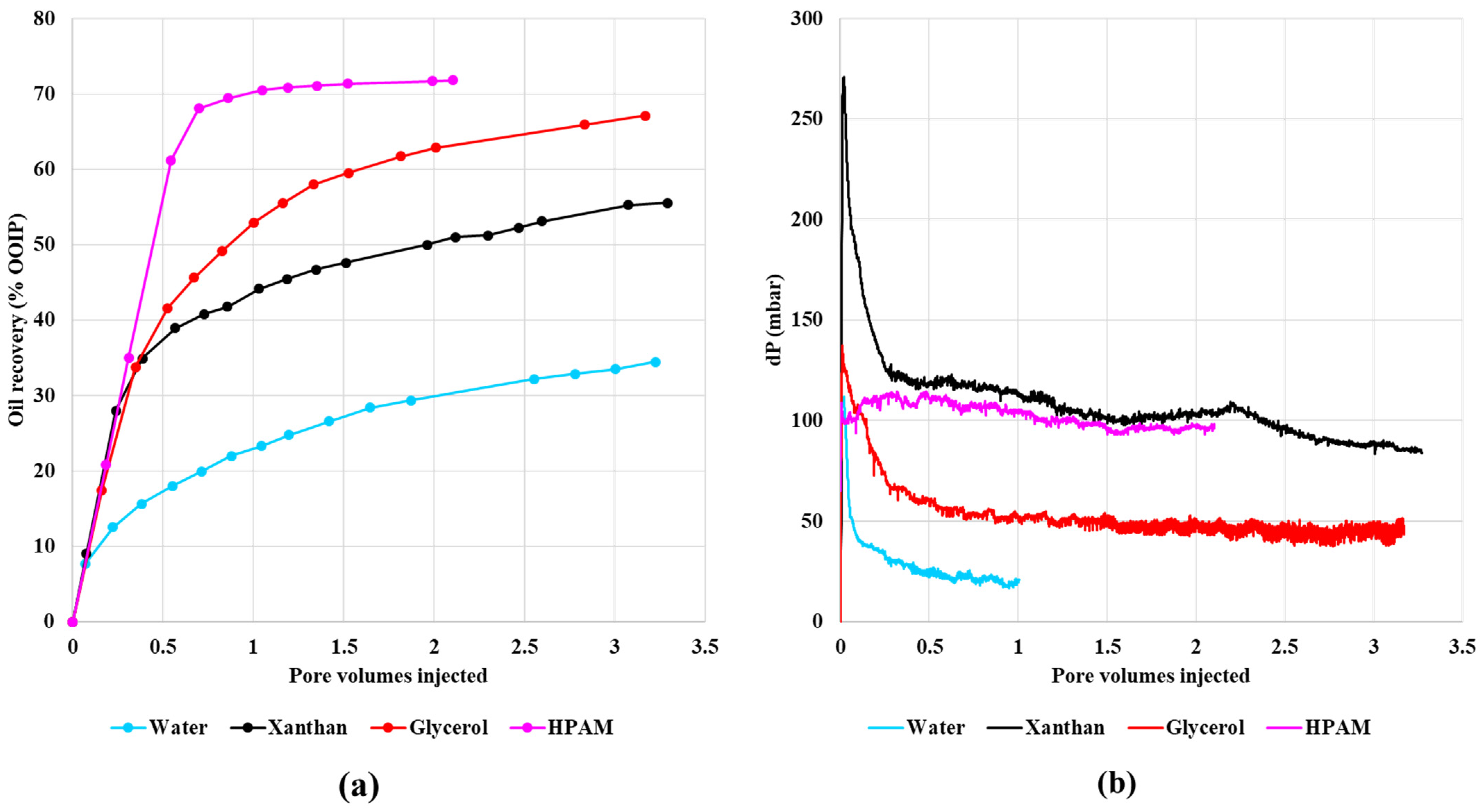

2. Experimental Data Used from Literature

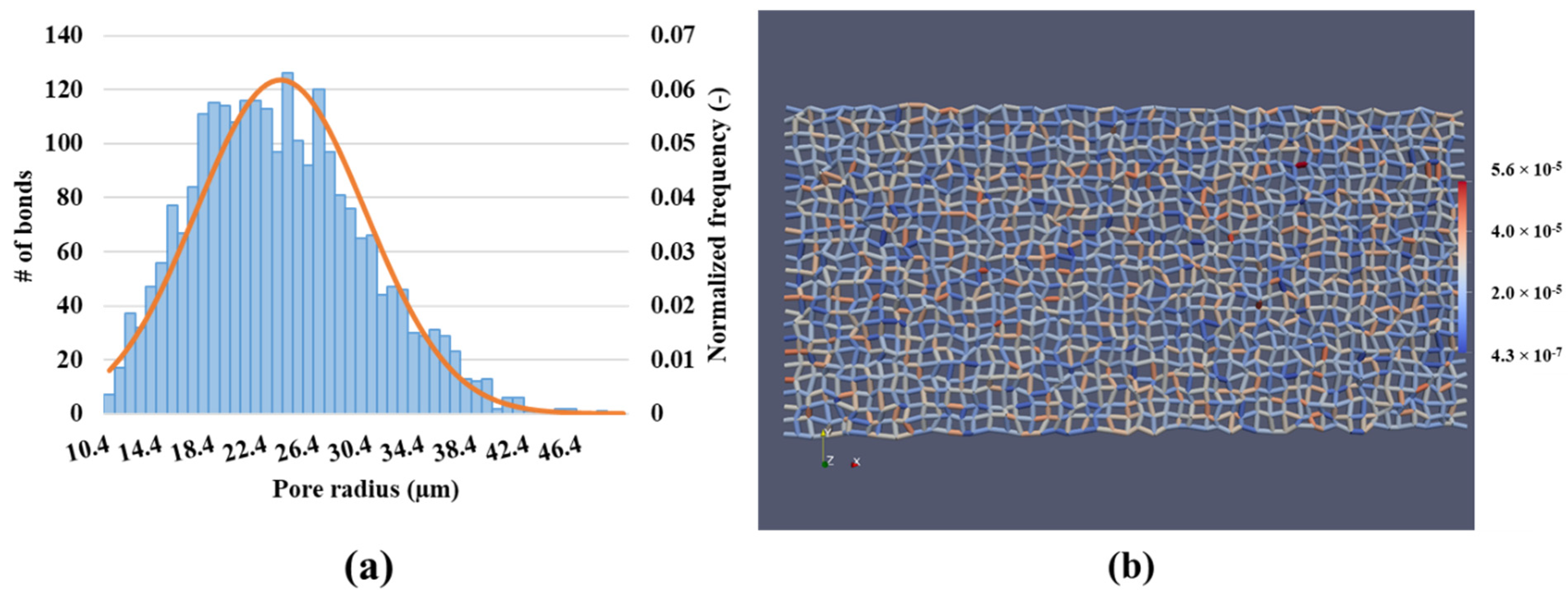

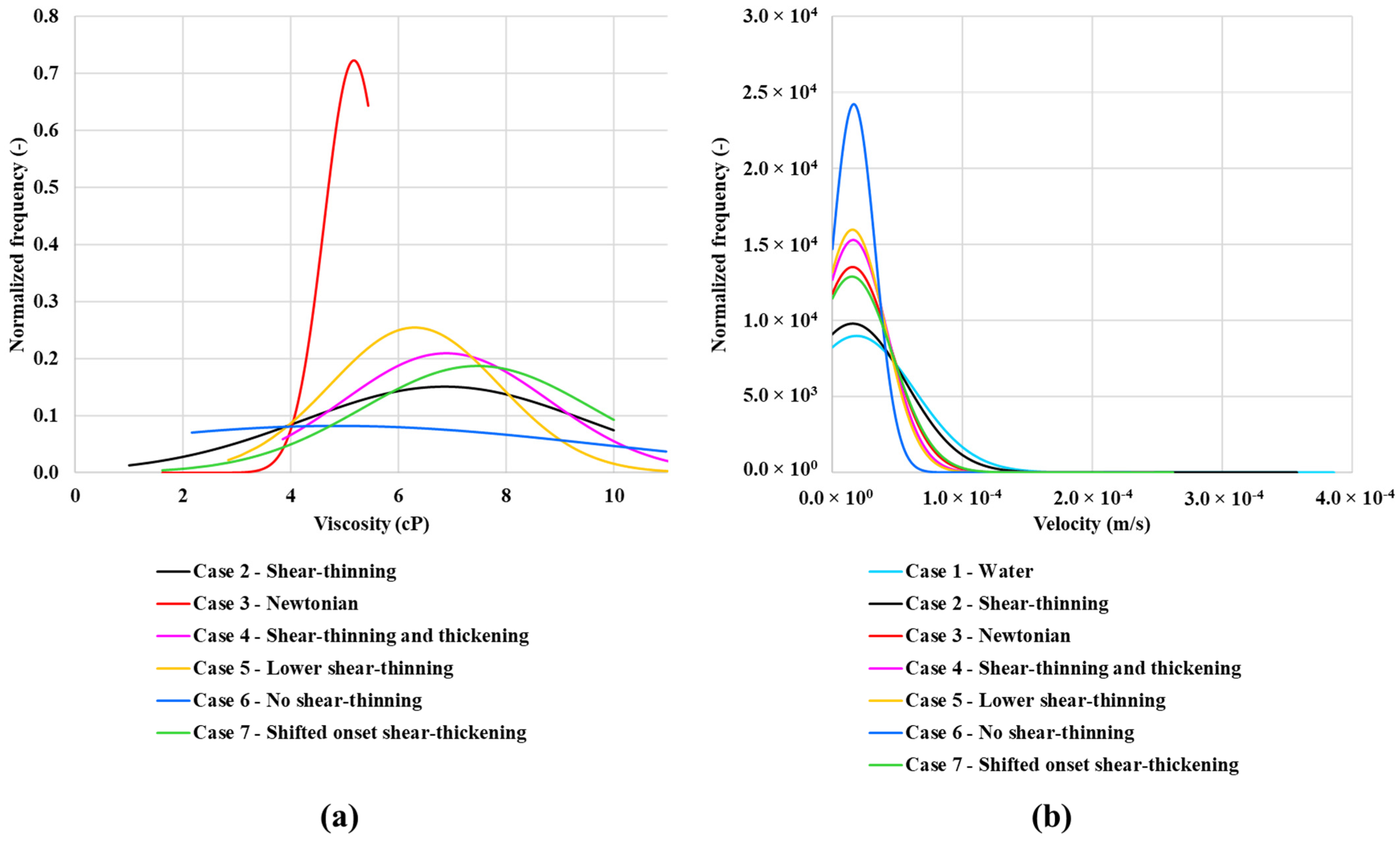

3. Dynamic Pore Network Model (DPNM) Simulation

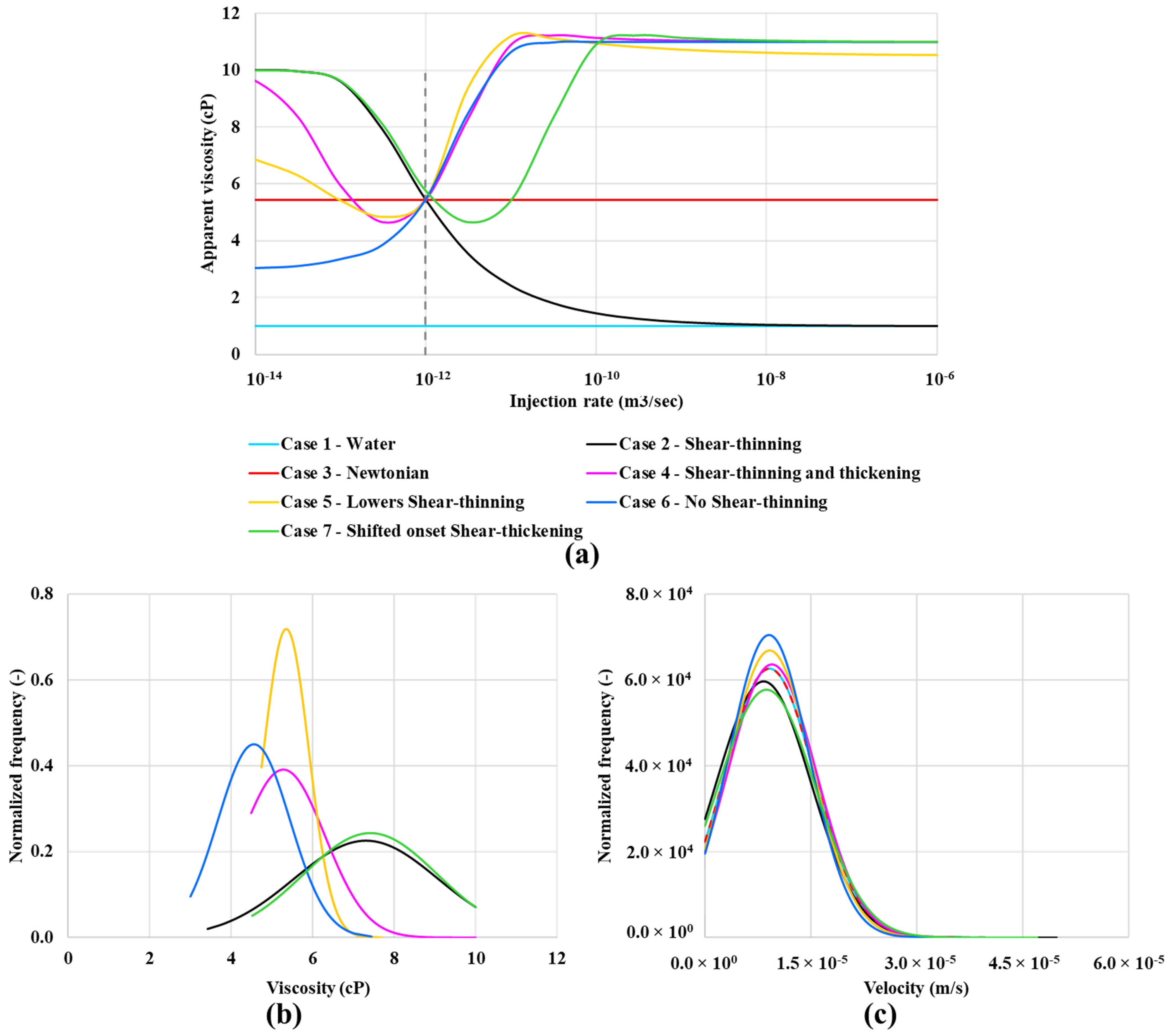

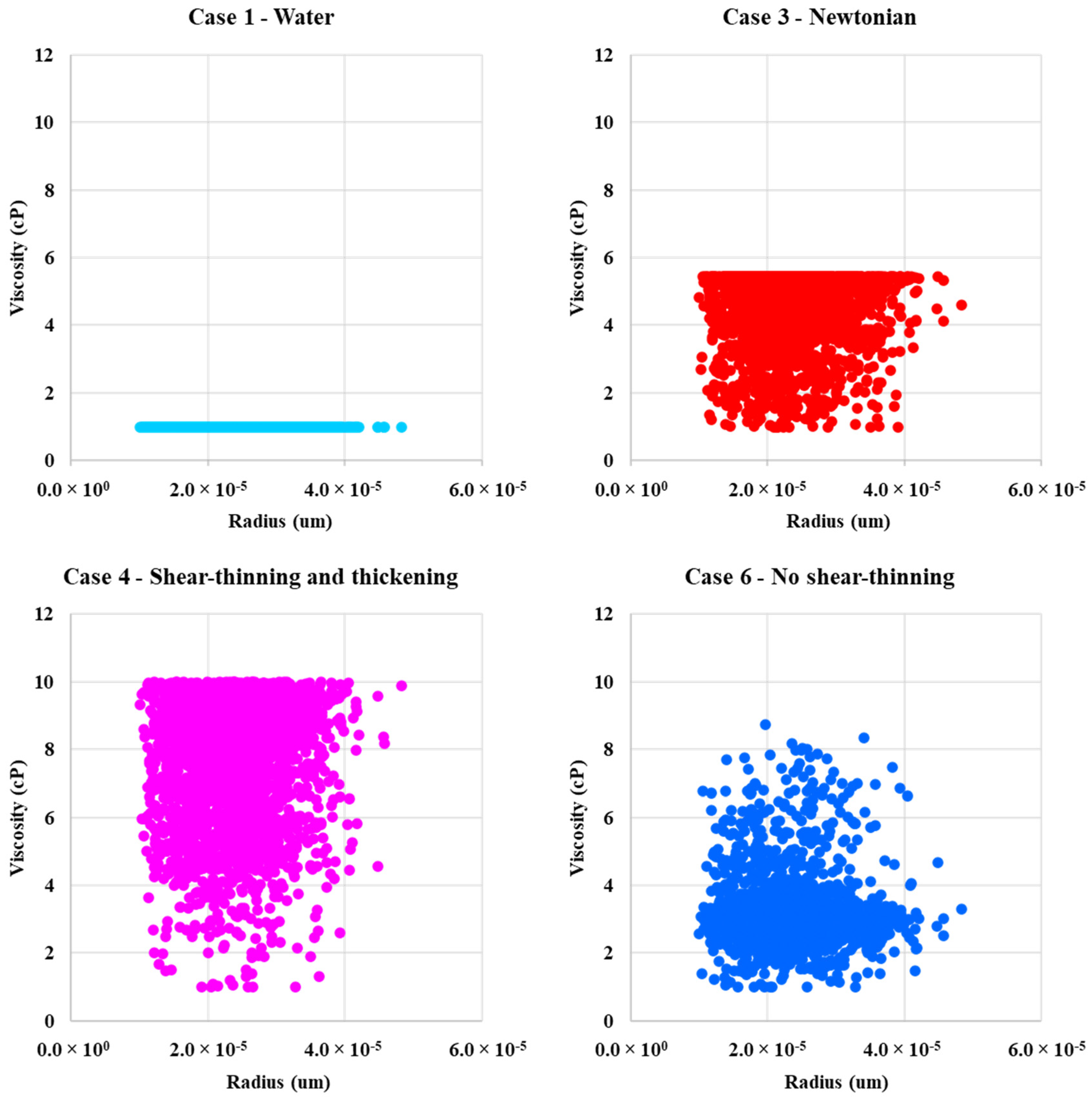

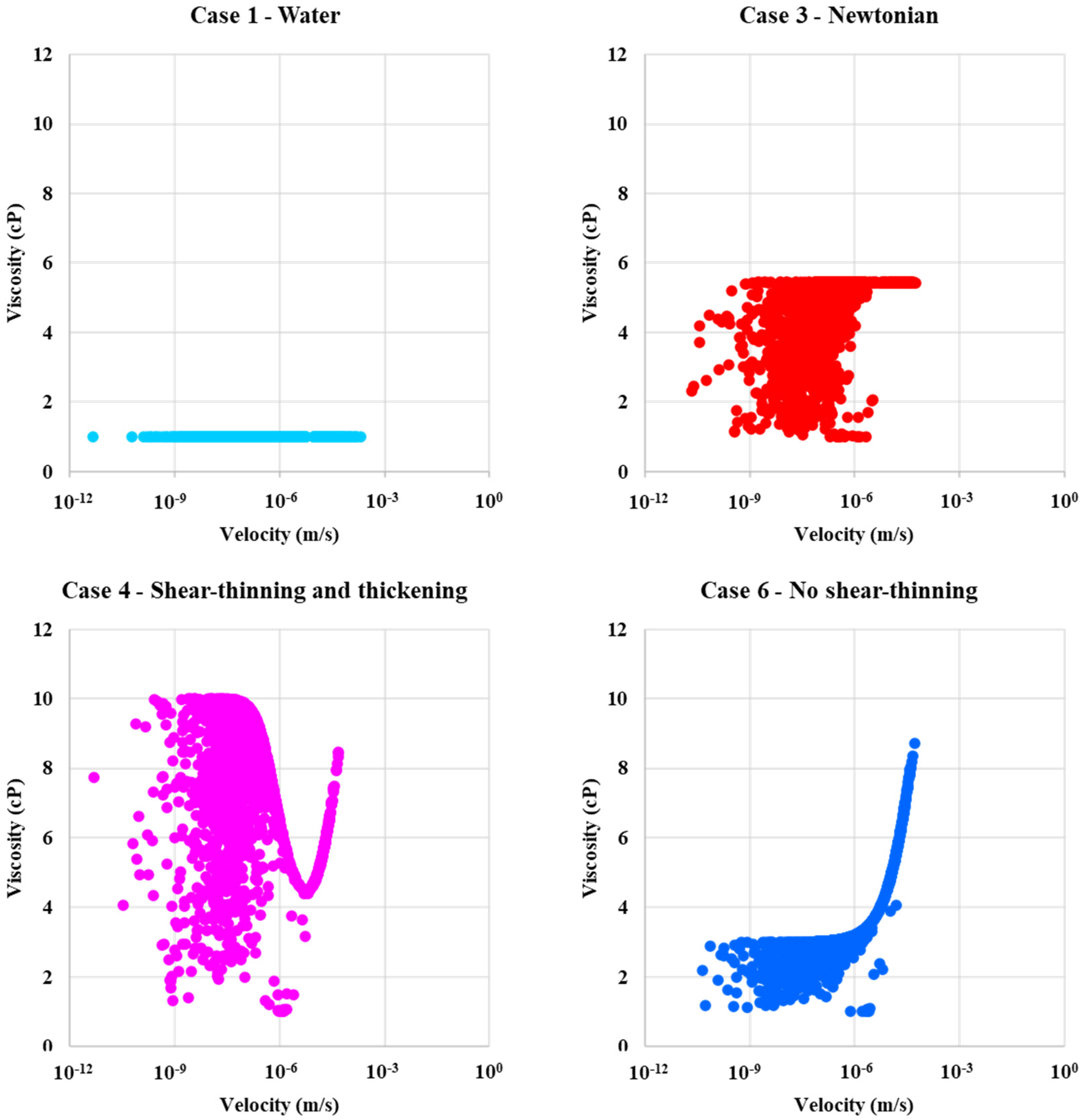

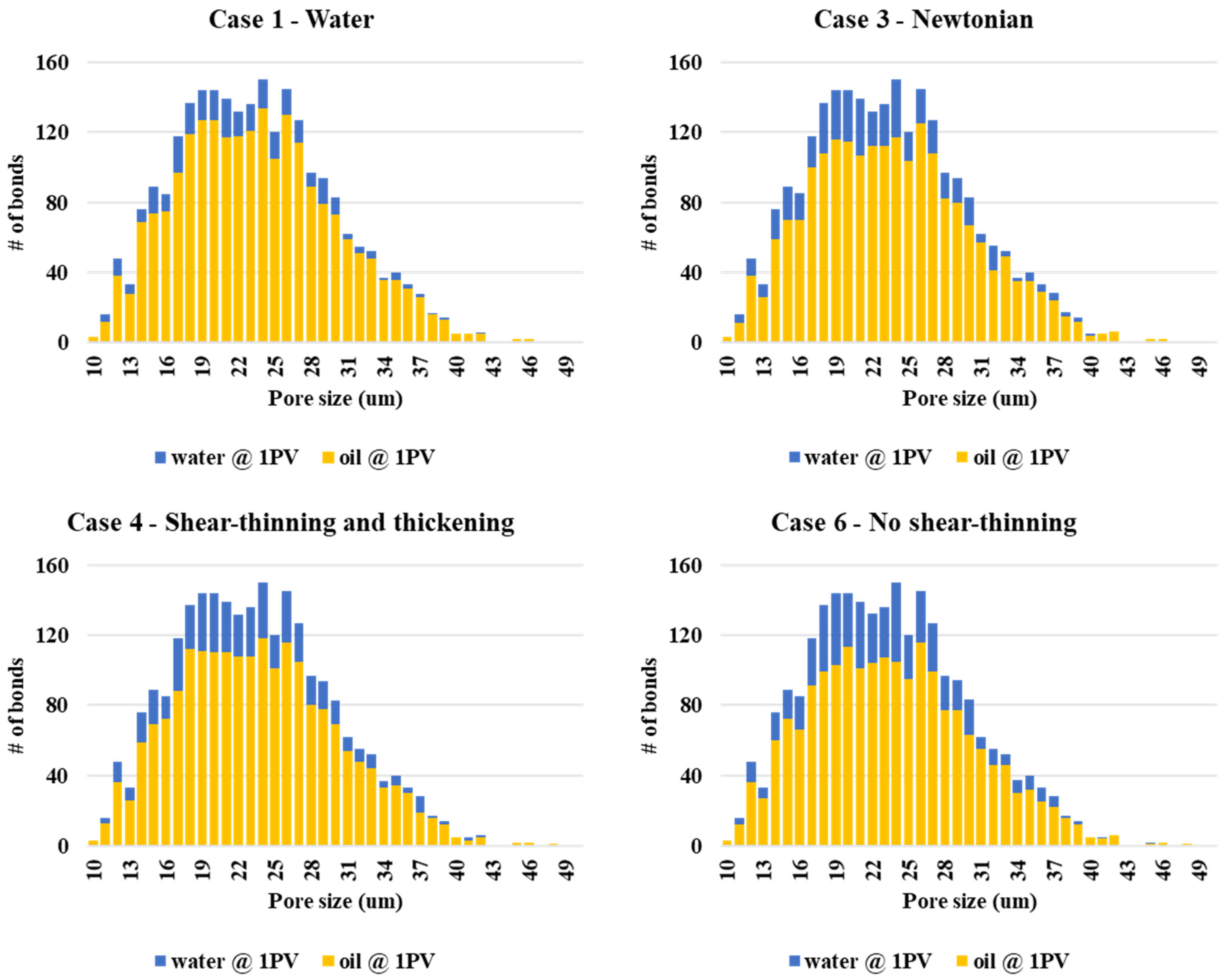

- Case 1—Water flood,

- Case 2—Shear-thinning only (no shear thickening region),

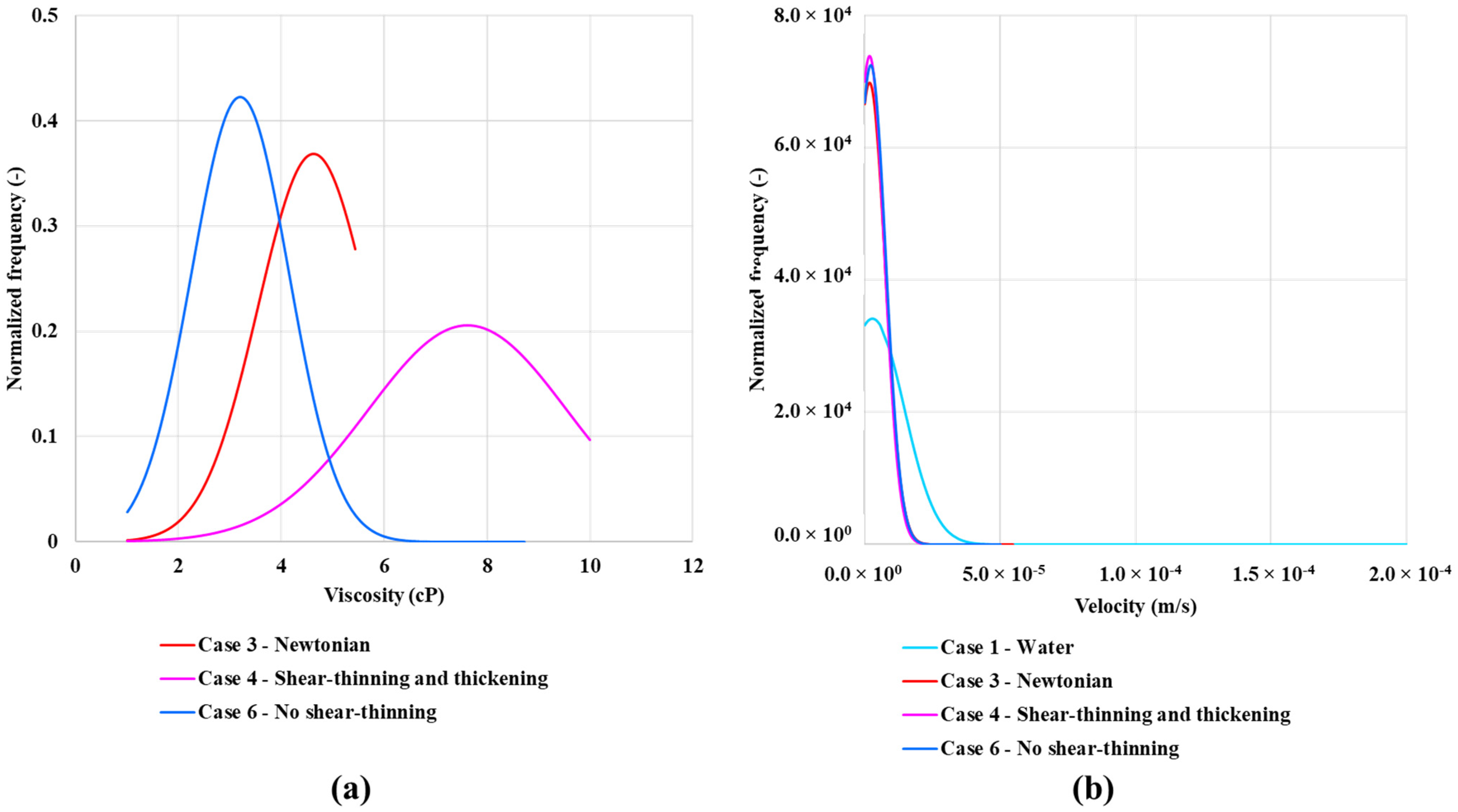

- Case 3—Newtonian “polymer” with a fixed viscosity (~ 5.5 cP in this Case) equivalent to the in-situ effective viscosity of the other polymers at the base Case flow rate (Q = 1 × 10−12 m3/s),

- Case 4—Shear-thinning and thickening polymer (most like an HPAM),

- Case 5—Lower shear-thinning, like case 4 but a lower Newtonian plateau at a low shear rate but the same shear-thickening region as case 4,

- Case 6—No shear-thinning—case with a lower viscosity Newtonian plateau going into the shear-thickening region without showing any shear-thinning,

- Case 7—Shifted onset shear-thickening—the same curve as Case 4 (shear-thinning/thickening) but moved to the right, as shown in Figure 4a.

4. Results and Discussion

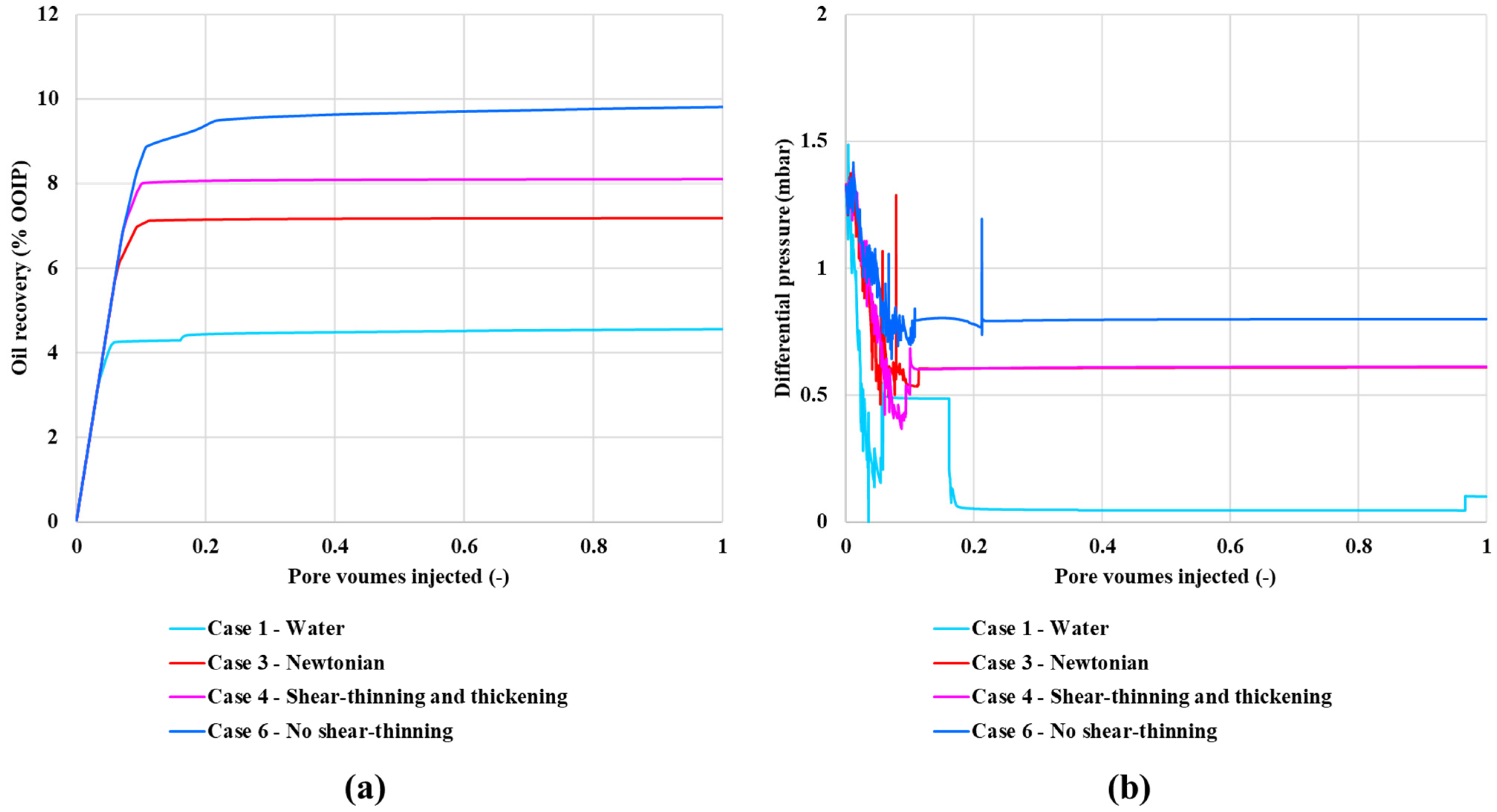

4.1. Base Case Dynamic Network Simulations

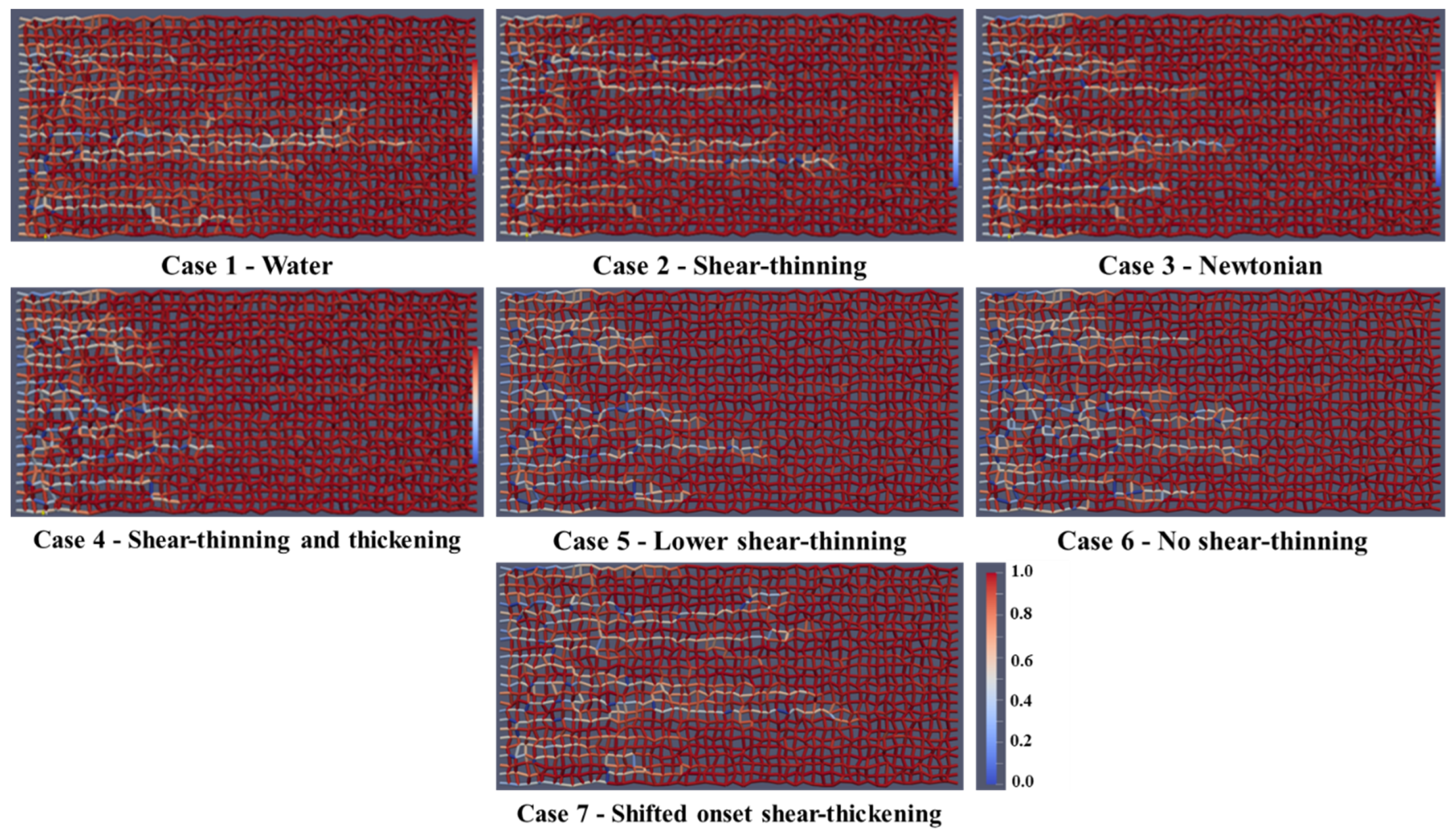

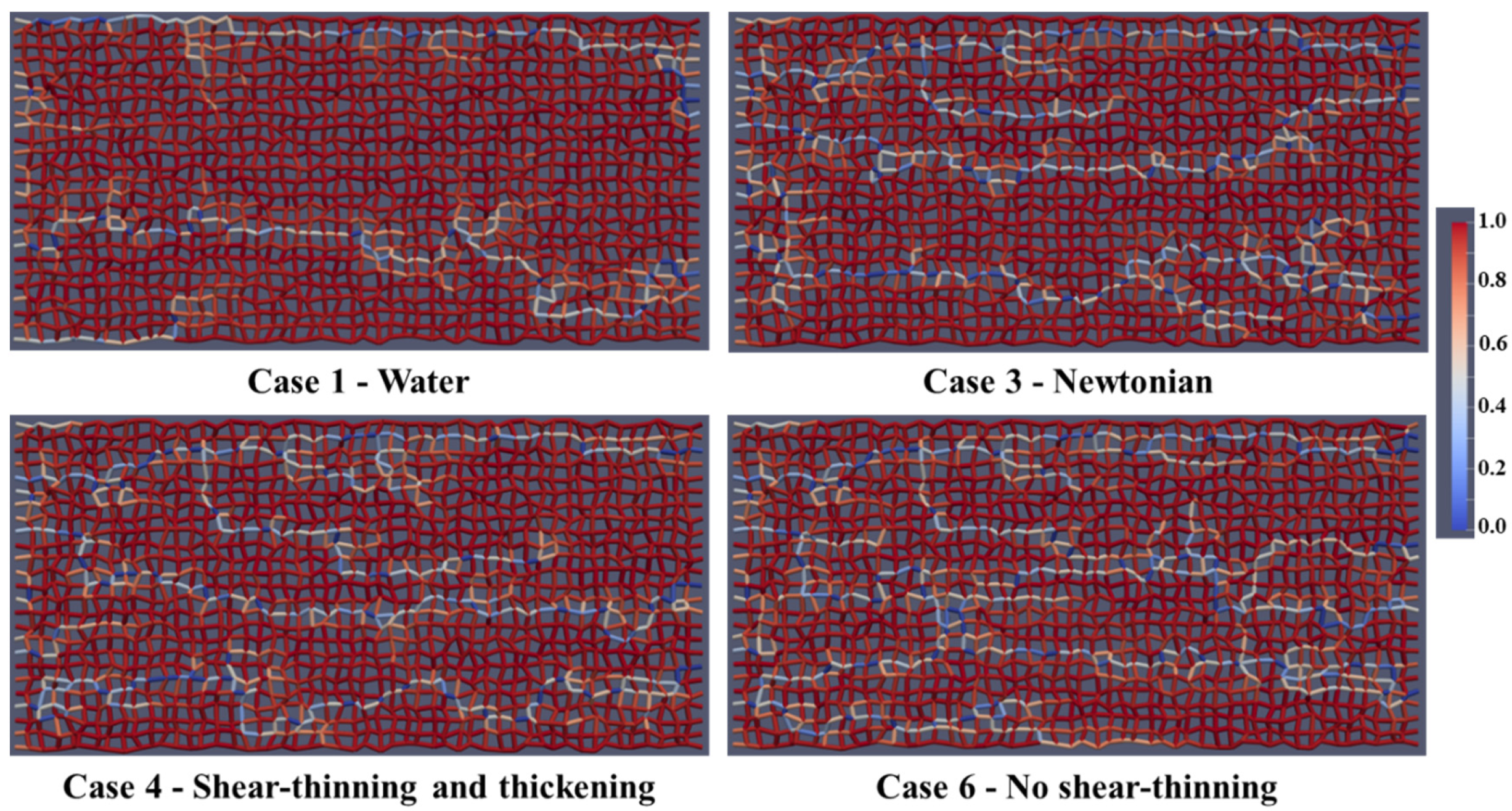

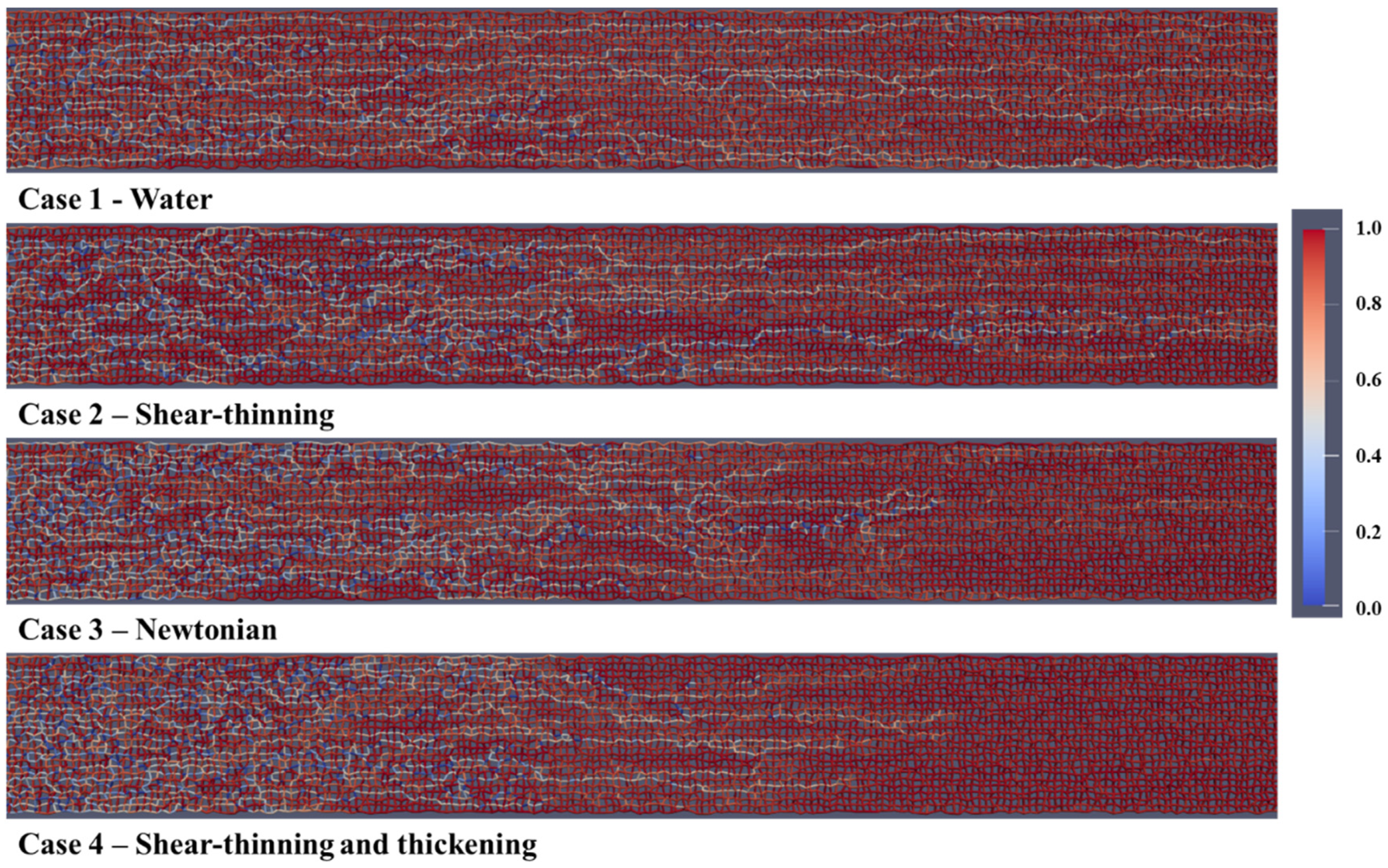

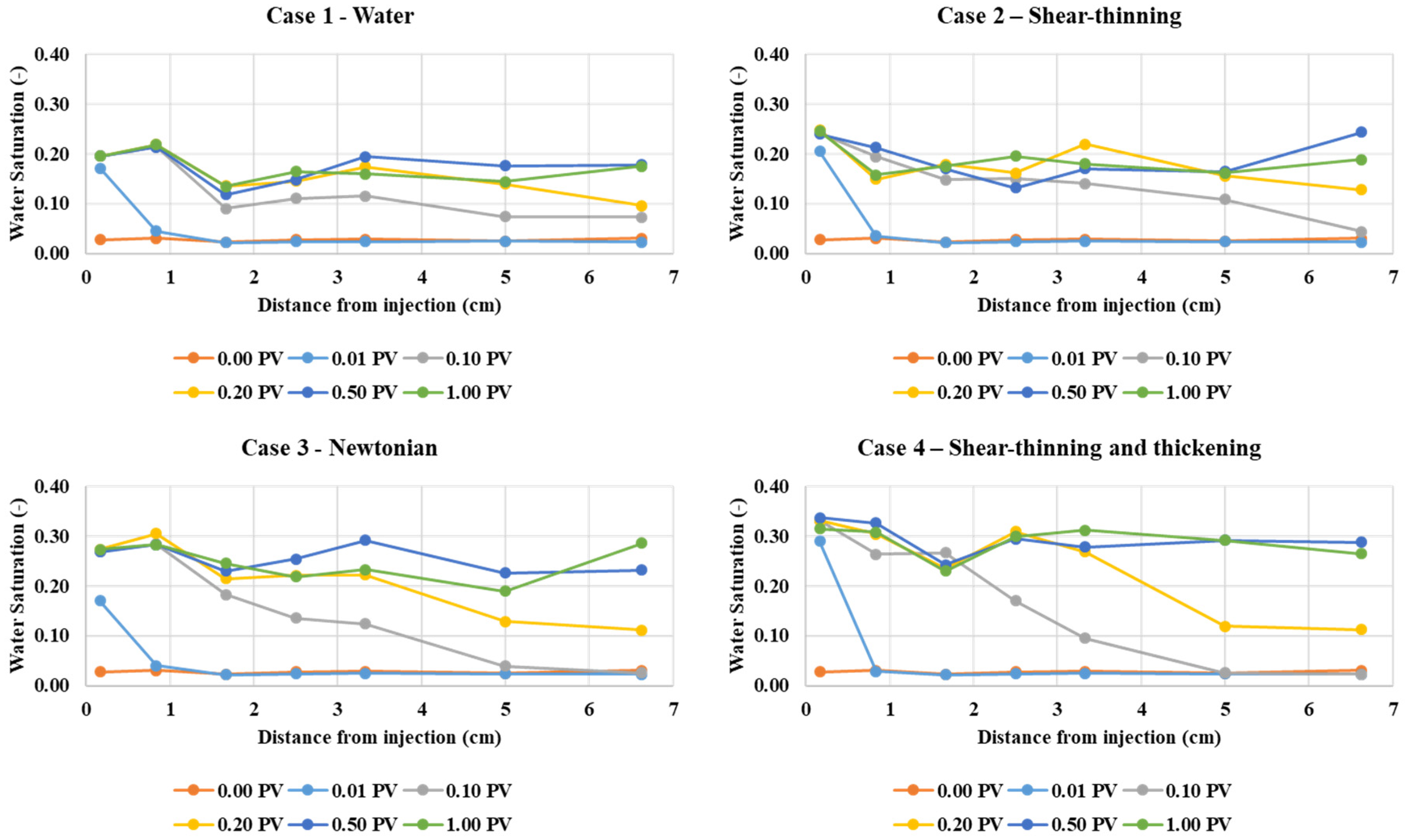

4.2. Fluid Displacement Patterns

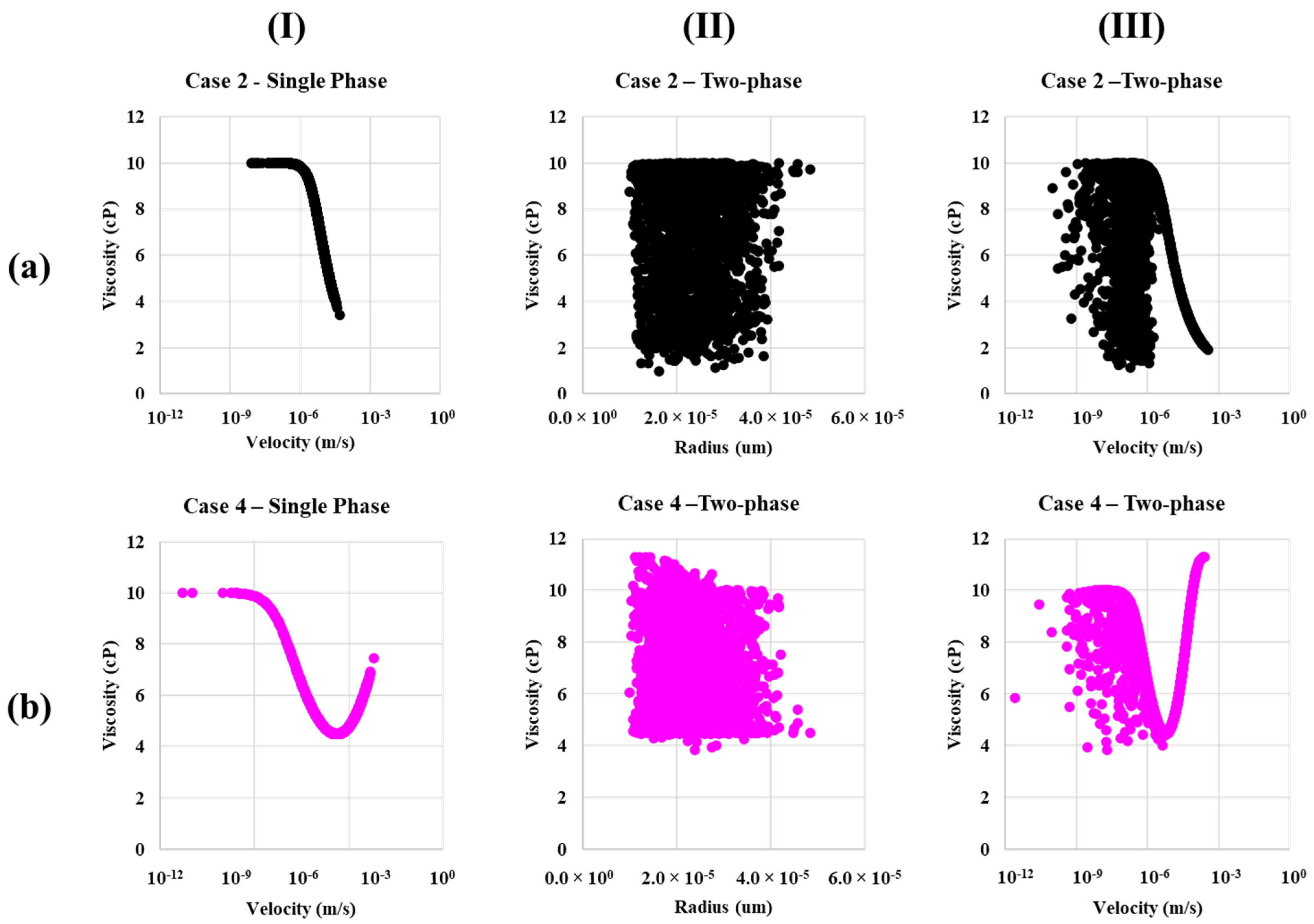

4.3. In-Situ Viscosity Distribution

4.4. In-Situ Velocity Distributions

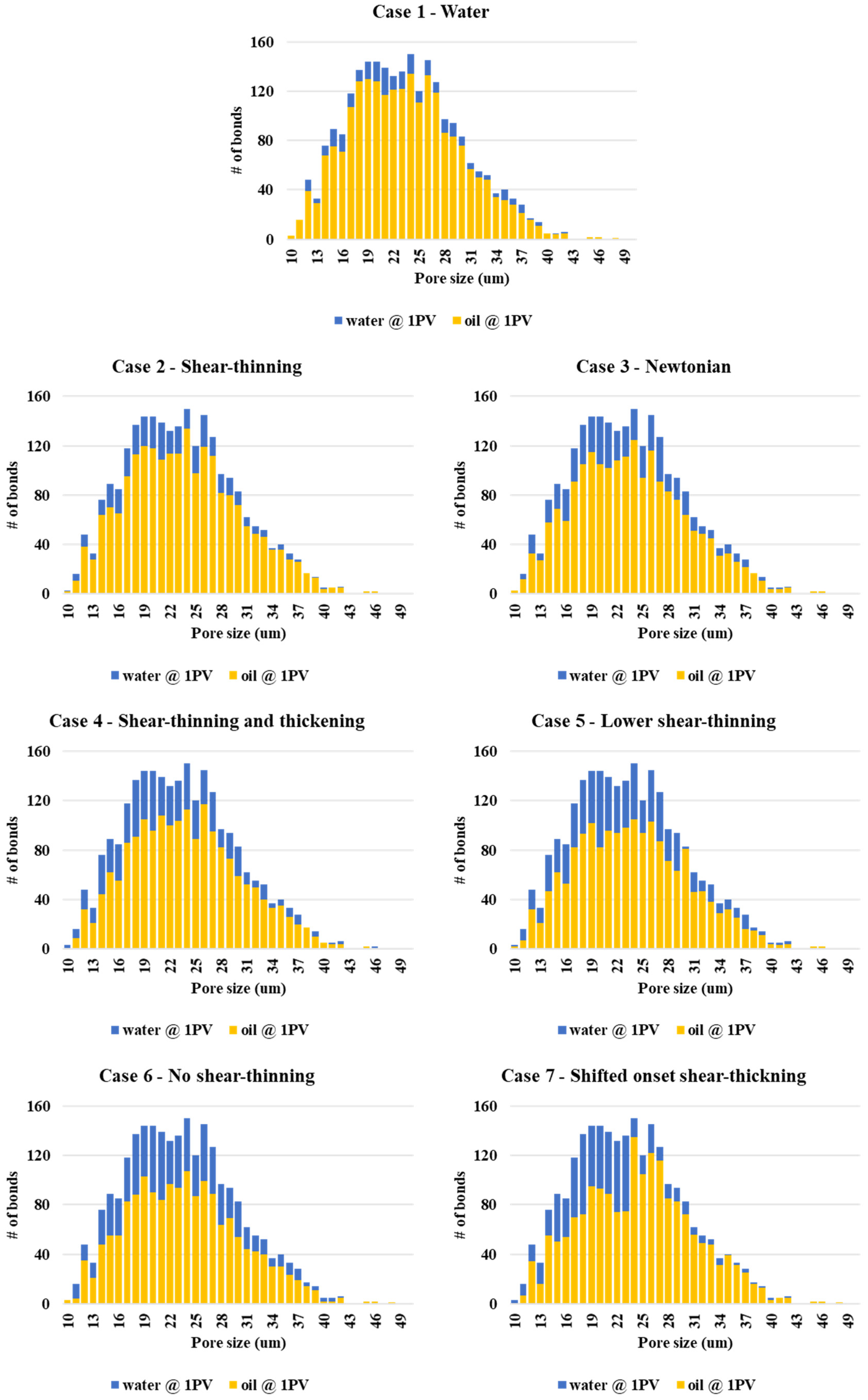

4.5. Pore Occupancy Statistics—Base Case Simulations

4.6. Lower Flow Rate Results—Recoveries

4.7. Lower Flow Rate Results—Fluid Distributions

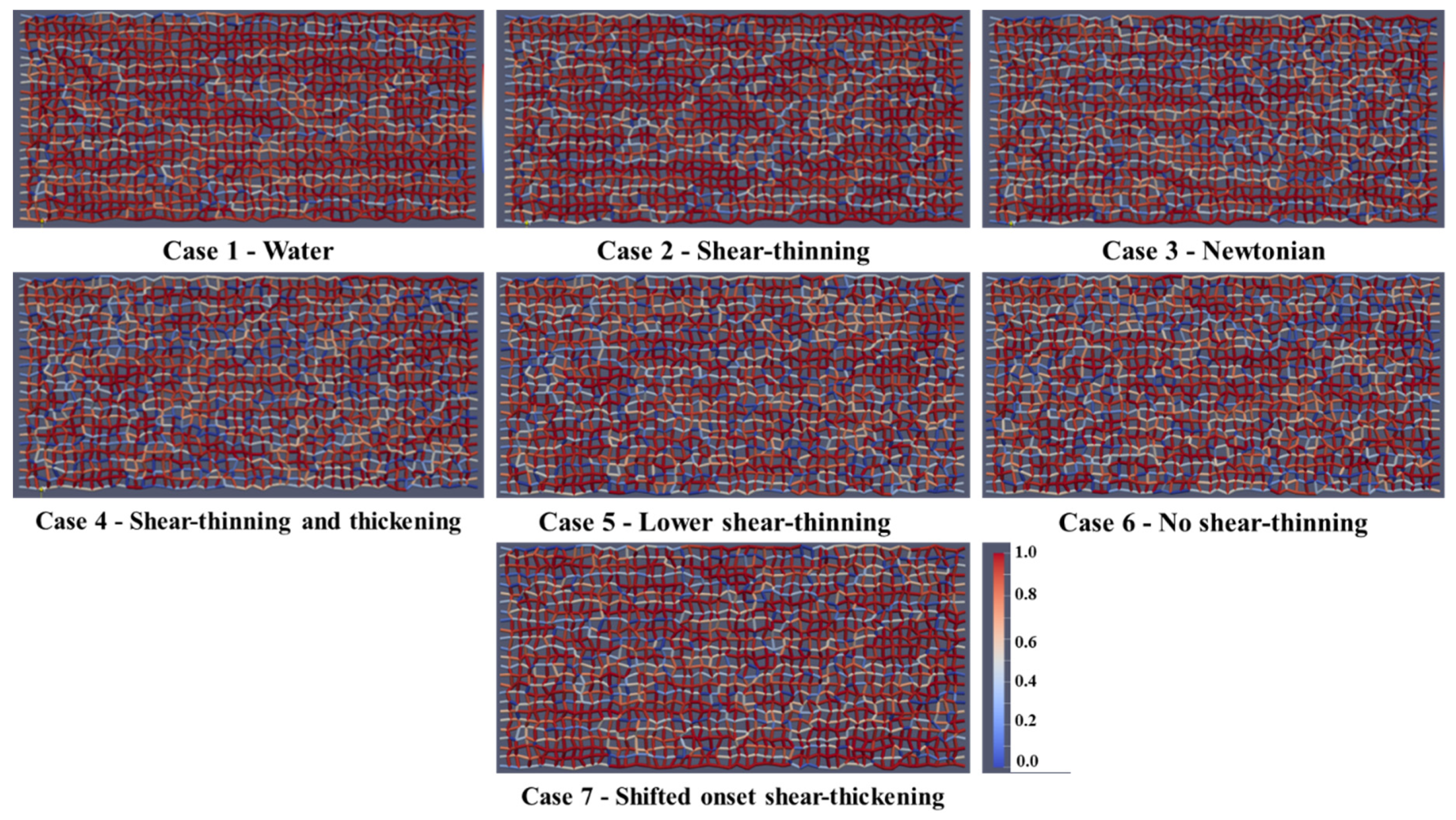

4.8. Lower Flow Rate Results—Fluid and Velocity/Viscosity Distributions

4.9. Lower Flow Rate Results—Phase Occupancy Statistics

4.10. Longer Model Results

5. Summary and Conclusions

- In the dynamic viscous oil network displacement simulations, all polymers (shear-thinning, shear-thinning/thickening, and Newtonian) gave improvements in oil recovery compared with the (lower viscosity) waterflood. The viscosification of the polymer was adjusted in the model until they had the same in-situ effective viscosity (at Sw =1). Simulations predicted that the oil recovery performance was highest for the more complex polymer solutions including both shear-thinning/thickening behavior (i.e., HPAM-like). This, in turn, was predicted to better than the Newtonian (glycerol) “polymer”, and this was predicted to be better than for the purely shear-thinning polymer (i.e., xanthan-like polymer). This is in exact agreement with the literature experimental observations.

- The reason for this behavior in the DPNM simulations has been established by performing a detailed analysis of the flow field and its effect on the local pore viscosities for the various rheologies. The pore network model shows that the shear-thinning polymer experience higher flow velocity. Thus, lower viscosity approaches water viscosity at higher flow rates. As a result, a more severe and inefficient finger pattern is observed for a shear-thinning polymer (xanthan) compared to combined shear-thinning and thickening, in our DPNM simulations.

- In the most efficient oil recovery case for the shear-thinning/thickening (HPAM like) polymer, it was shown that this rheology results in more pore-scale fluid diversion, leading to more stable fluid displacement fronts and more efficient oil displacement.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Model Description

Appendix A.1. The Dynamic Imbibition Pore Network Model for EOR

- Choose arbitrary and () and calculate

- Choose Pin = Pout and calculate

- Based on the calculated and in the above two steps, calculate using Equations (A4) and (A5).

- Update pressure at the inlet using the following equation (A6).

- Repeat the above four steps until a satisfactory accuracy between a predefined injection rate () and is obtained.

Appendix A.2. Modifying the Dynamic Imbibition Model to Include Polymer Displacements

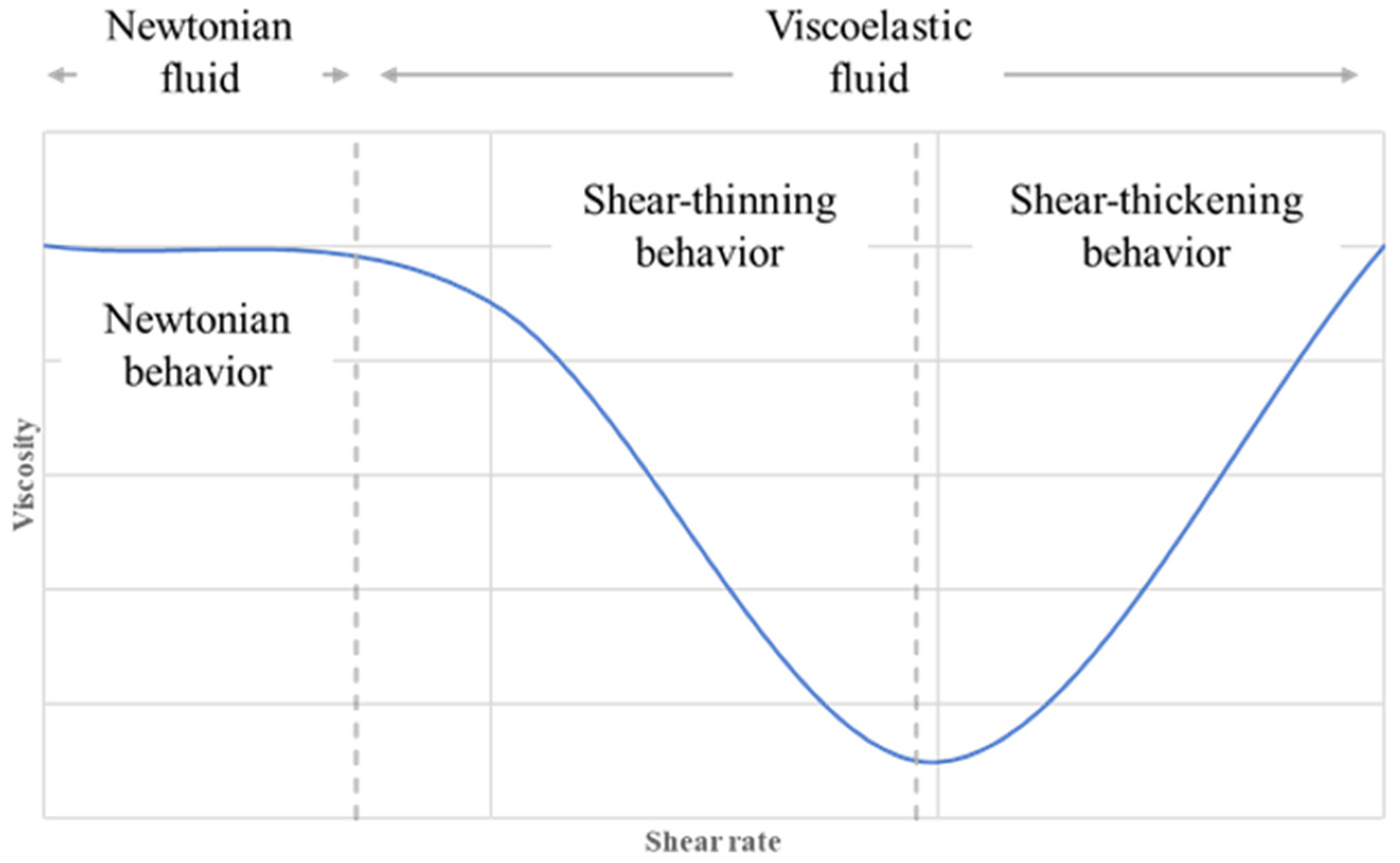

- (a)

- Newtonian behavior: Polymer viscosity depends on polymer concentration but is independent of a shear rate (flow rate).

- (b)

- Shear thinning behavior: Polymer viscosity decreases as the shear rate increases.

- (c)

- Shear thickening: polymer viscosity increases as the shear rate increases.

- (d)

- Combination of all or some of the previously mentioned behaviors.

References

- Sorbie, K.S. Polymer-Improved Oil Recovery; Springer: Blackie, AB, Canada, 1991; ISBN 978-0-8493-7137-0. [Google Scholar]

- Delamaide, E.; Zaitoun, A.; Renard, G.; Tabary, R. Pelican Lake Field: First Successful Application of Polymer Flooding In a Heavy-Oil Reservoir. SPE Reserv. Eval. Eng. 2014, 17, 340–354. [Google Scholar] [CrossRef]

- Bondino, I.; Nguyen, R.; Hamon, G.; Ormehaug, P.A.; Skauge, A.; Jouenne, S. Tertiary Polymer Flooding in Extra-Heavy Oil: An Investigation Using 1D and 2D Experiments, Core Scale Simulation and Pore-Scale Network Models. In Proceedings of the International Symposium of the Society of Core An-alysts, Austin, TX, USA, 18–21 September 2011. [Google Scholar]

- Fabbri, C.; Cottin, C.; Jimenez, J.; Nguyen, M.; Hourcq, S.; Bourgeois, M.; Hamon, G. Secondary and Tertiary Polymer Flooding in Extra-Heavy Oil: Reservoir Conditions Measurements-Performance Comparison. In Proceedings of the IPTC 2014: International Petroleum Technology Conference, Doha, Qatar, 19–22 January 2014. [Google Scholar]

- Fabbri, C.; de Loubens, R.; Skauge, A.; Ormehaug, P.A.; Vik, B.; Bourgeois, M.; Morel, D.; Hamon, G. Comparison of History-Matched Water Flood, Tertiary Polymer Flood Relative Permeabilities and Evidence of Hysteresis During Tertiary Polymer Flood in Very Viscous Oils. In Proceedings of the SPE Asia Pacific Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 12 August 2015. [Google Scholar]

- Levitt, D.; Jouenne, S.; Bondino, I.; Santanach-Carreras, E.; Bourrel, M. Polymer Flooding of Heavy Oil Under Adverse Mobility Conditions. In Proceedings of the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 2–4 July 2013. [Google Scholar]

- Skauge, A.; Ormehaug, P.; Vik, B.; Fabbri, C.; Bondino, I.; Hamon, G. Polymer Flood Design for Displacement of Heavy Oil Analysed by 2D-imaging. In Proceedings of the IOR 2013-17th European Symposium on Improved Oil Recovery, St. Petersburg, Russia, 16–18 April 2013. [Google Scholar]

- Skauge, A.; Ormehaug, P.A.; Gurholt, T.; Vik, B.; Bondino, I.; Hamon, G. 2-D Visualisation of Unstable Waterflood and Polymer Flood for Displacement of Heavy Oil. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar]

- Skauge, A.; Salmo, I. Relative Permeability Functions for Tertiary Polymer Flooding. In Proceedings of the IOR 2015-18th European Symposium on Improved Oil Recovery, Dresden, Germany, 14–16 April 2015. [Google Scholar]

- Skauge, T.; Vik, B.F.; Ormehaug, P.A.; Jatten, B.K.; Kippe, V.; Skjevrak, I.; Standnes, D.C.; Uleberg, K.; Skauge, A. Polymer Flood at Adverse Mobility Ratio in 2D Flow by X-ray Visualization. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014. [Google Scholar]

- Wassmuth, F.; Green, K.; Arnold, W.; Cameron, N. Polymer Flood Application to Improve Heavy Oil Recovery at East Bodo. J. Can. Pet. Technol. 2009, 48, 55–61. [Google Scholar] [CrossRef]

- Wassmuth, F.; Green, K.; Hodgins, L.; Turta, A. Polymer Flood Technology for Heavy Oil Recovery. In Proceedings of the Canadian International Petroleum Conference, Calgary, Alberta, 12–14 June 2007. [Google Scholar]

- Salmo, I.C.; Pettersen, Ø.; Skauge, A. Polymer Flooding at an Adverse Mobility Ratio: Acceleration of Oil Production by Crossflow into Water Channels. Energy Fuels 2017, 31, 5948–5958. [Google Scholar] [CrossRef]

- Sorbie, K.; Skauge, A. Mobilization of By-Passed Oil by Viscous Crossflow in EOR Processes. In Proceedings of the IOR 2019—20th European Symposium on Improved Oil Recovery, Pau, France, 8–11 April 2019. [Google Scholar]

- Bird, R.B.; Armstrong, R.C.; Hassager, O. Dynamics of Polymeric Liquids, Volume 1: Fluid Mechanics; John Wiley and Sons Inc.: New York, NY, USA, 1987. [Google Scholar]

- Skauge, A.; Zamani, N.; Jacobsen, J.G.; Shiran, B.S.; Al-Shakry, B.; Skauge, T. Polymer Flow in Porous Media: Relevance to Enhanced Oil Recovery. Colloids Interfaces 2018, 2, 27. [Google Scholar] [CrossRef]

- Seright, R.S.; Seheult, J.M.; Talashek, T. Injectivity Characteristics of EOR Polymers. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Standnes, D.C.; Skjevrak, I. Literature review of implemented polymer field projects. J. Pet. Sci. Eng. 2014, 122, 761–775. [Google Scholar] [CrossRef]

- Seright, R.S.; Wang, D.; Lerner, N.; Nguyen, A.; Sabid, J.; Tochor, R. Can 25-cp Polymer Solution Efficiently Displace 1,600-cp Oil During Polymer Flooding? SPE J. 2018, 23, 2260–2278. [Google Scholar] [CrossRef]

- Vermolen, E.; van Haasterecht, M.; Masalmeh, S.K. A Systematic Study of the Polymer Visco-Elastic Effect on Residual Oil Saturation by Core Flooding. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014. [Google Scholar]

- Vik, B.; Kedir, A.; Kippe, V.; Sandengen, K.; Skauge, T.; Solbakken, J.; Zhu, D. Viscous Oil Recovery by Polymer Injection; Impact of In-Situ Polymer Rheology on Water Front Stabilization. In Proceedings of the SPE Europec featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018. [Google Scholar]

- Wang, D.; Xia, H.; Yang, S.; Wang, G. The influence of visco-elasticity on micro forces and displacement efficiency in pores, cores and in the field. In Proceedings of the SPE EOR Conference at Oil & Gas West Asia, Muscat, Oman, 11–13 April 2010. [Google Scholar]

- Clarke, A.; Howe, A.M.; Mitchell, J.; Staniland, J.; Hawkes, L.A. How Viscoelastic-Polymer Flooding Enhances Displacement Efficiency. SPE J. 2016, 21, 0675–0687. [Google Scholar] [CrossRef]

- De, S.; Krishnan, P.; Van Der Schaaf, J.; Kuipers, J.A.M.; Peters, E.A.J.F.; Padding, J.T. Viscoelastic effects on residual oil distribution in flows through pillared mi-crochannels. J. Colloid Interface Sci. 2018, 510, 262–271. [Google Scholar] [CrossRef]

- Urbissinova, T.S.; Trivedi, J.J.; Kuru, E. Effect of Elasticity During Viscoelastic Polymer Flooding: A Possible Mechanism of Increasing the Sweep Efficiency. J. Can. Pet. Technol. 2010, 49, 49–56. [Google Scholar] [CrossRef]

- Afsharpoor, A.; Balhoff, M.T. Static and Dynamic CFD Modeling of Viscoelastic Polymer: Trapped Oil Displacement and Deformation at the Pore-Level. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Bai, Y.; Zhang, X.; Zhao, G. Theoretical analysis of microscopic oil displacement mechanism by viscoelastic polymer solution. Theor. Appl. Mech. Lett. 2011, 1, 022004. [Google Scholar] [CrossRef]

- Xia, H.; Wang, D.; Wang, G.; Ma, W.-G.; Deng, H.W.; Liu, J. Mechanism of the Effect of Micro-Forces on Residual Oil in Chemical Flooding. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Zamani, N.; Salmo, I.C.; Sorbie, K.; Skauge, A. Numerical Study of Polymer Flow in Porous Media using Dynamic Pore Network Modelling. In Proceedings of the IOR 2019—20th European Symposium on Improved Oil Recovery, Pau, France, 8–11 April 2019. [Google Scholar]

- Li, J.; McDougall, S.; Sorbie, K. Dynamic pore-scale network model (PNM) of water imbibition in porous media. Adv. Water Resour. 2017, 107, 191–211. [Google Scholar] [CrossRef]

- Li, J. A Pore-Scale Network Modelling Study to Explain the Observed Differences between Steady-State and Unsteady-State Relative Permeabilities. Ph.D. Thesis, Heriot-Watt University, Edinburgh, UK, 2016. [Google Scholar]

- Salmo, I.C.; Zamani, N.; Skauge, T.; Sorbie, K.; Skauge, A. Use of Dynamic Pore Network Modeling to Improve Our Understanding of Experimental Observations in Viscous Oil Displacement by Polymers. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 31 August–4 September 2020. [Google Scholar]

- Aker, E.; Måløy, K.J.; Hansen, A.; Batrouni, G. A Two-Dimensional Network Simulator for Two-Phase Flow in Porous Media. Transp. Porous Media 1998, 32, 163–186. [Google Scholar] [CrossRef]

- Zamani, N.; Bondino, I.; Kaufmann, R.; Skauge, A. Computation of polymer in-situ rheology using direct numerical simulation. J. Pet. Sci. Eng. 2017, 159, 92–102. [Google Scholar] [CrossRef]

| Unit | Water | Xanthan | Glycerol | HPAM | |

|---|---|---|---|---|---|

| Viscous Behavior | - | Newtonian | Shear-thinning | Newtonian | Shear-thinning and thickening |

| Dimensions | cm × cm × cm | 30 × 30 × 1.99 | 30 × 30 × 2.00 | 30 × 30 × 1.97 | 30 × 30 × 2.16 |

| Porosity | % | 25.9 | 24.8 | 24.3 | 22.2 |

| Absolute Permeability | mD | 1706 | 1554 | 1783 | 2510 |

| Swi | fraction | 0.11 | 0.14 | 0.07 | 0.11 |

| Oil Viscosity | cP (mPas) | 478 | 487 | 433 | 467 |

| Injection Rate: Q = 0.05 mL/min | |||||

| Water Breakthrough | PV inj. | 0.09 | 0.24 | 0.17 | 0.55 |

| Total Recovery | % OOIP | 31 | 56 | 67 | 72 |

| dP @ end | mbar | 21 | 87 | 45 | 96 |

| Parameter | Unit | Value |

|---|---|---|

| Network size | - | 50 × 25 × 1 |

| Coordination number | - | 4 |

| Pore size distribution model | µm | = 18, = 9 |

| Minimum inscribed radius | µm | 10 |

| Maximum inscribed radius | µm | 50 |

| Permeability | mD | 2069 |

| Distortion factor | - | 0.3 |

| Average pore length | µm | 333 |

| Pore half angles | - | 30, 30, 30 |

| Wettability | - | Water wet |

| Water/oil contact angle | Degree | 0 |

| Interfacial tension | N/m | 0.0004 |

| Swi | - | 0 |

| Injection rate | m3/s | 1 × 10−12 |

| Capillary No. (waterflood) | - | 3.28 × 10−6 |

| Oil viscosity | cP (mPas) | 466 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salmo, I.C.; Sorbie, K.S.; Skauge, A. The Impact of Rheology on Viscous Oil Displacement by Polymers Analyzed by Pore-Scale Network Modelling. Polymers 2021, 13, 1259. https://doi.org/10.3390/polym13081259

Salmo IC, Sorbie KS, Skauge A. The Impact of Rheology on Viscous Oil Displacement by Polymers Analyzed by Pore-Scale Network Modelling. Polymers. 2021; 13(8):1259. https://doi.org/10.3390/polym13081259

Chicago/Turabian StyleSalmo, Iselin C., Ken S. Sorbie, and Arne Skauge. 2021. "The Impact of Rheology on Viscous Oil Displacement by Polymers Analyzed by Pore-Scale Network Modelling" Polymers 13, no. 8: 1259. https://doi.org/10.3390/polym13081259

APA StyleSalmo, I. C., Sorbie, K. S., & Skauge, A. (2021). The Impact of Rheology on Viscous Oil Displacement by Polymers Analyzed by Pore-Scale Network Modelling. Polymers, 13(8), 1259. https://doi.org/10.3390/polym13081259