Enhanced Heat Dissipation Performance of Automotive LED Lamps Using Graphene Coatings

Abstract

:1. Introduction

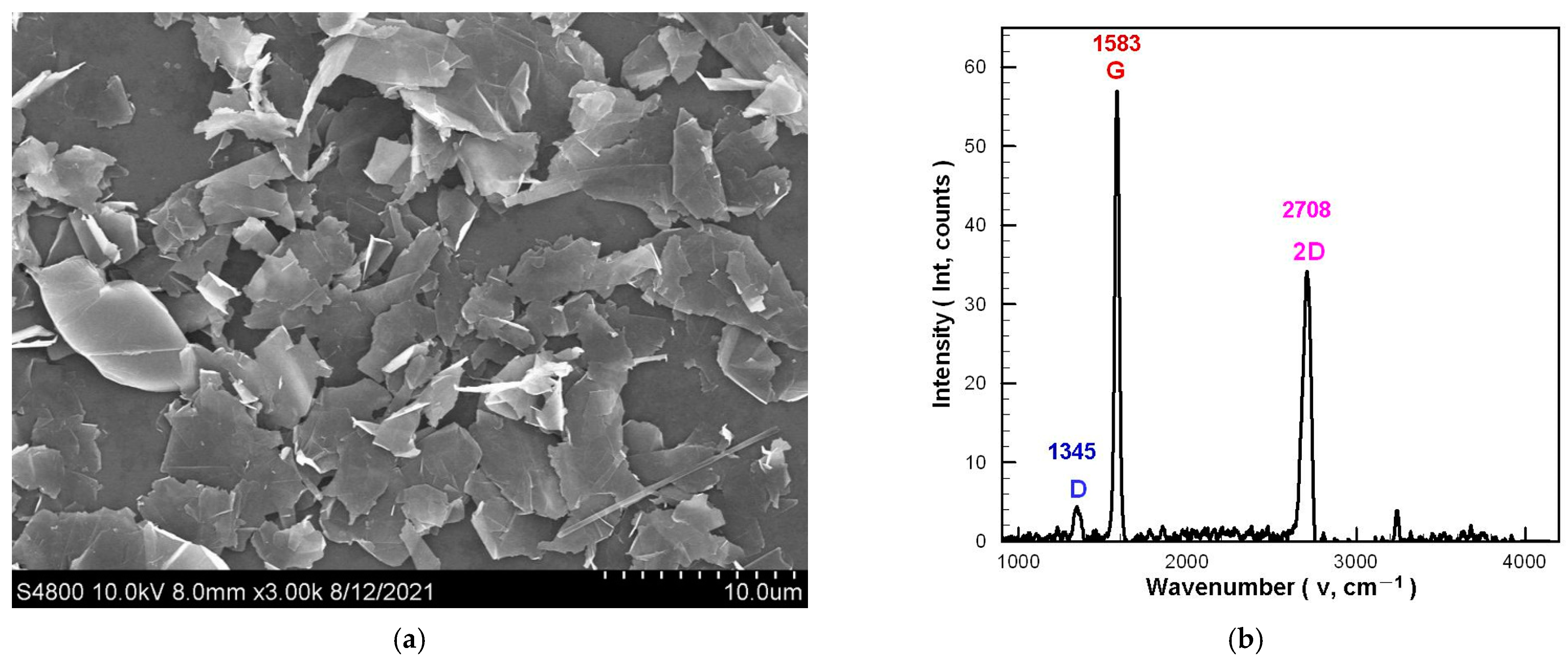

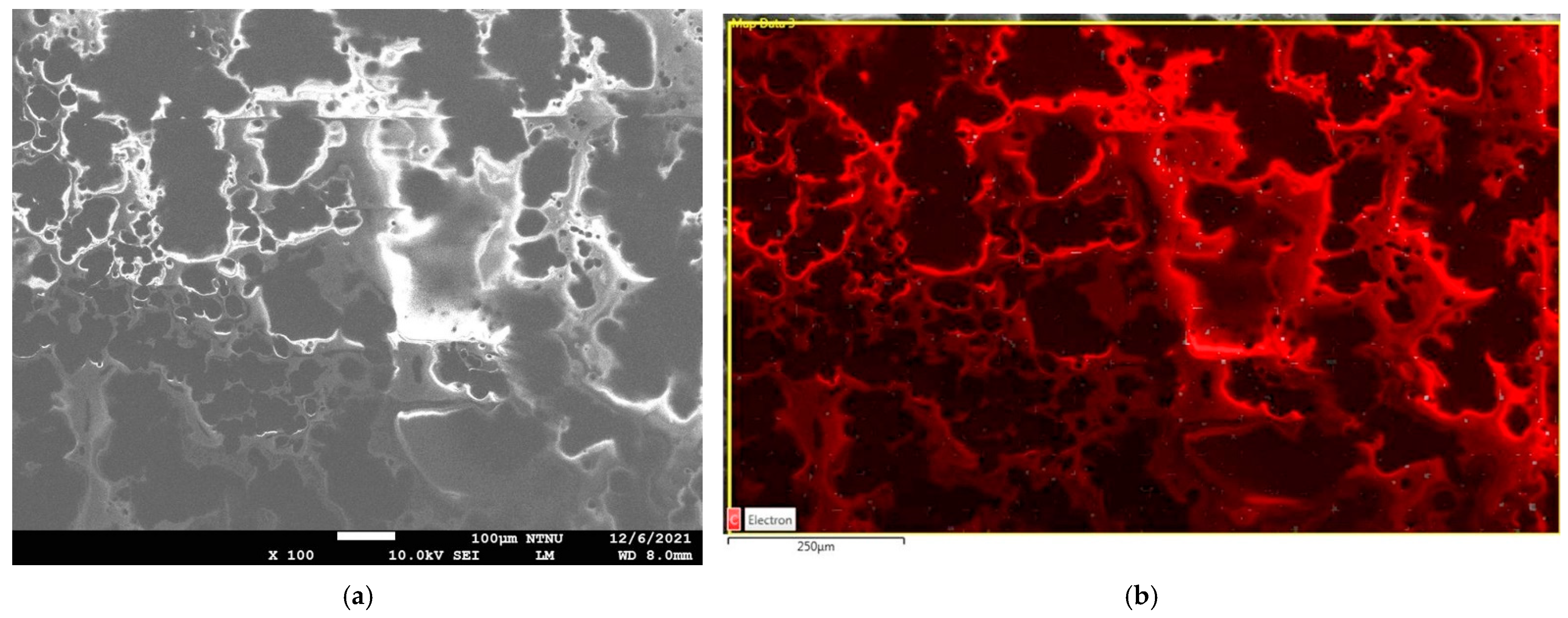

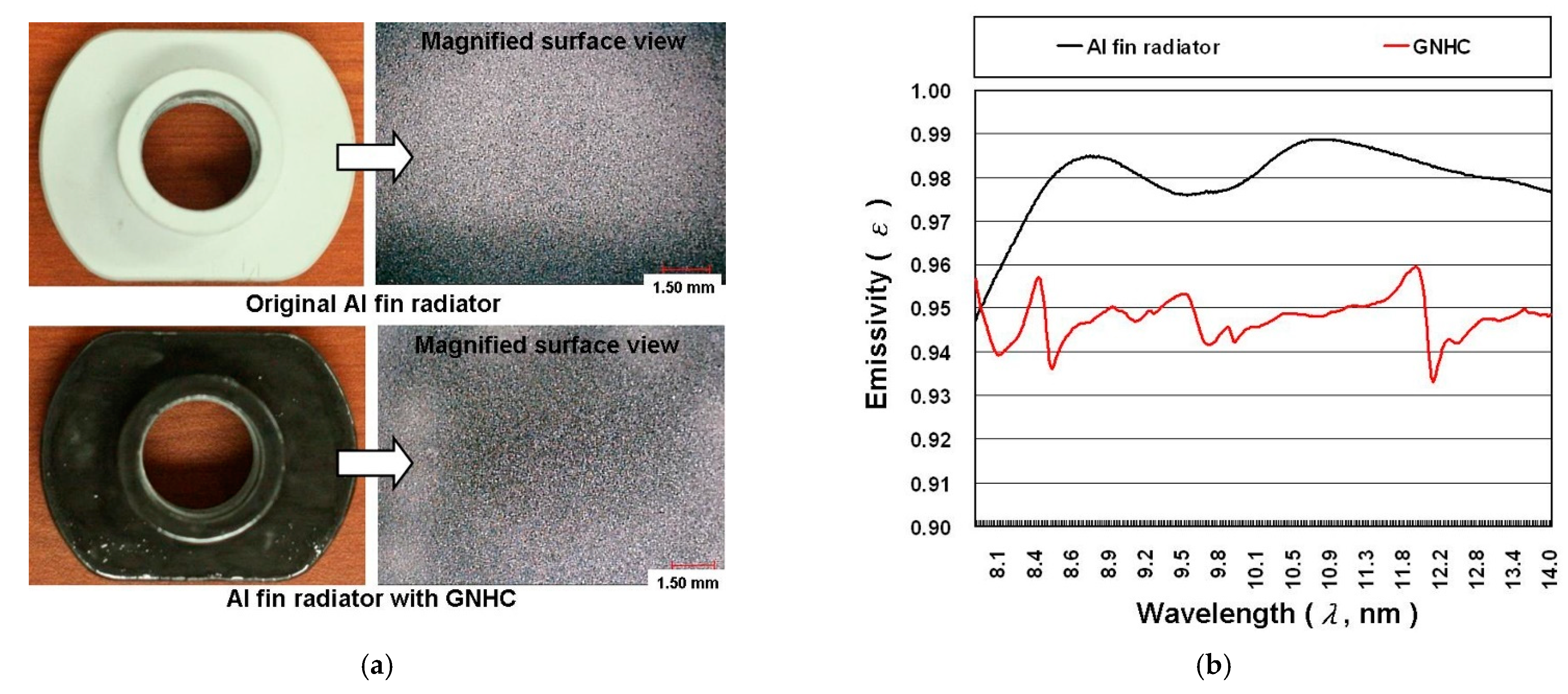

2. Preparation of GNHC

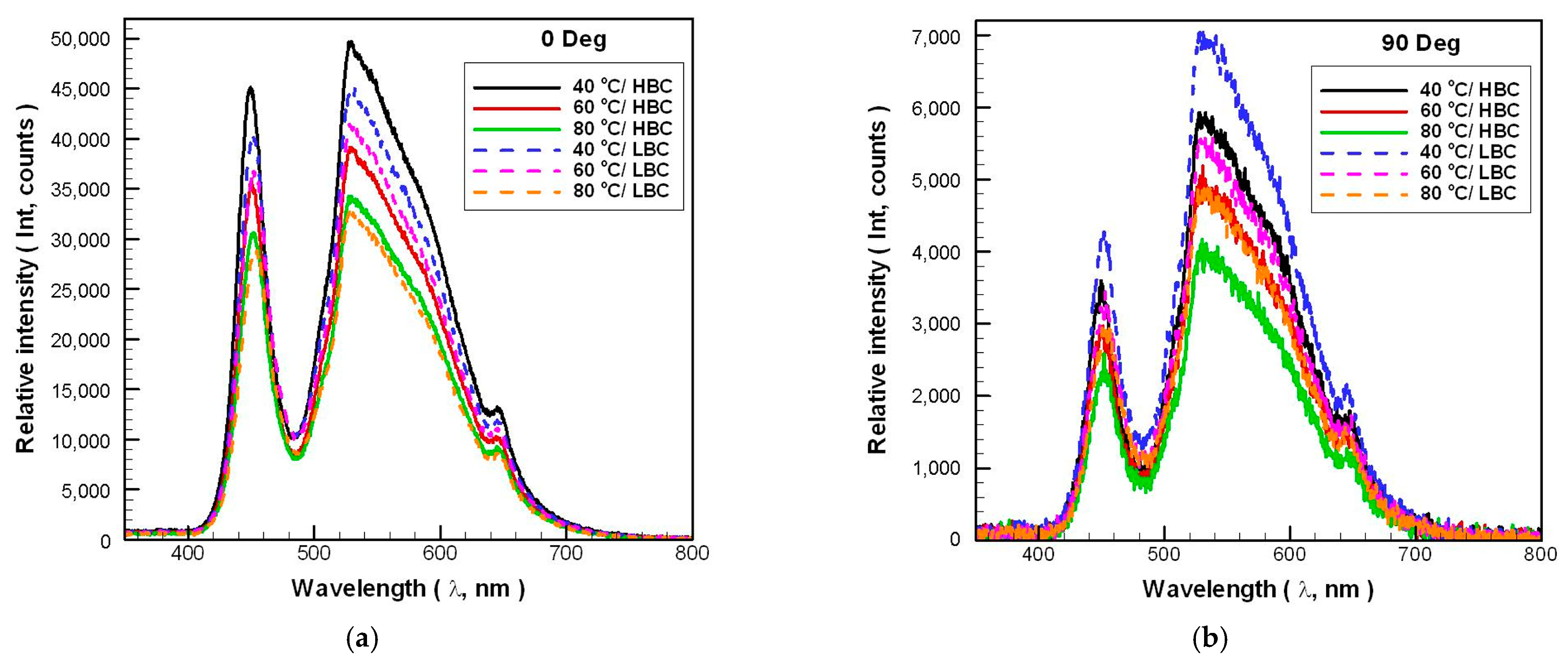

3. Experimental Design and Implementation

3.1. Description of the Experimental Subject

3.2. Thermal Resistance Analysis and Experimental Case Setting

- Case 0: The original automotive LED lamp without any GNHC (baseline).

- Case 1: Applying the GNHC on the junction gaps and surfaces of the substrate to the aluminum body and the aluminum body to the aluminum fin radiator (refer to the B and C position with yellow marks in Figure 3) by brush method. An 80 °C, 60 min duration heating process is performed for GNHC hardening.

- Case 2: Same as Case 1, plus a GNHC coating applied on the surface of the aluminum fin radiator (refer to D position in Figure 3) by brush method. An identical hardening procedure is performed as in Case 1.

3.3. Experimental Procedure

3.4. Data Analysis and Relative Uncertainty

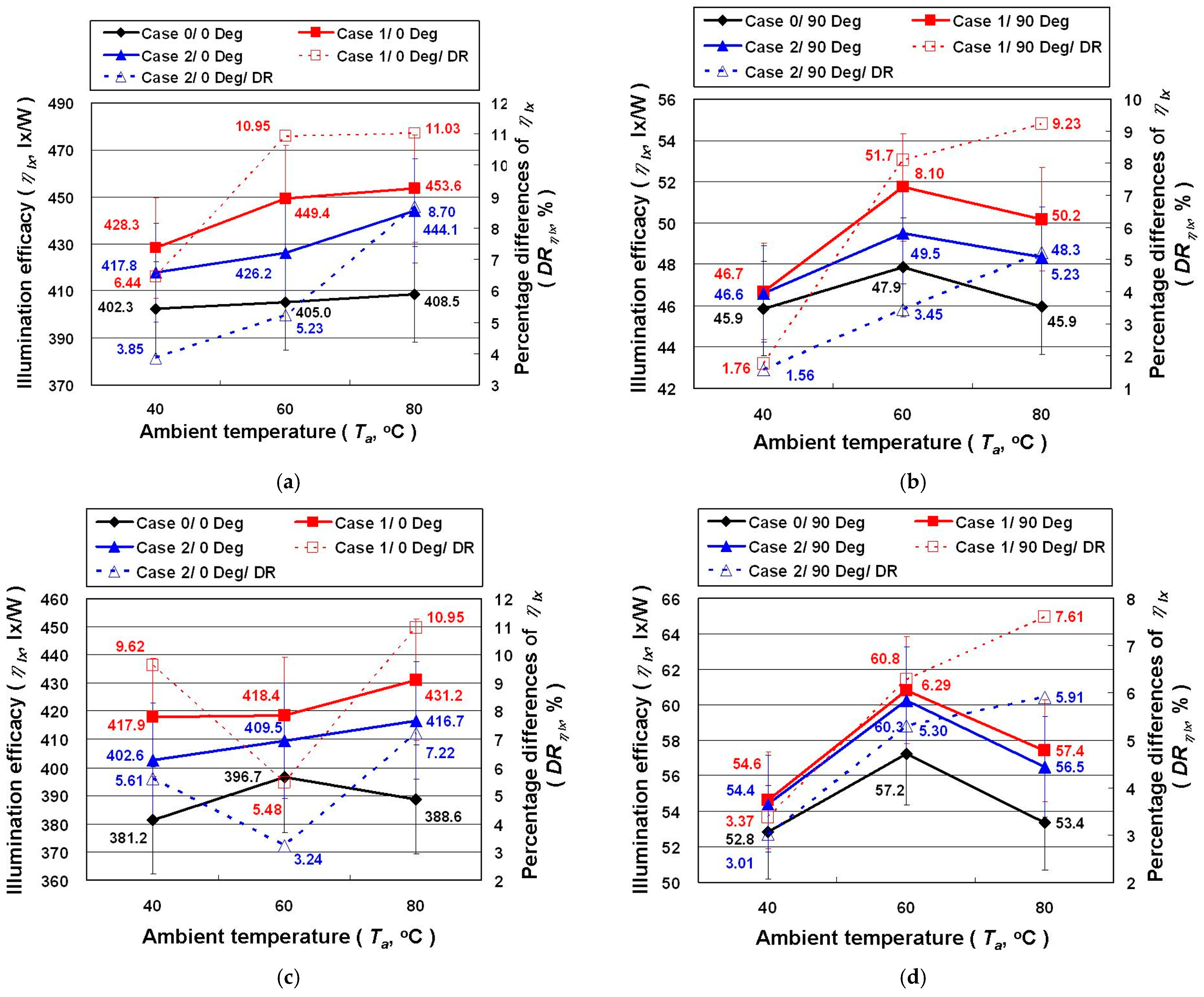

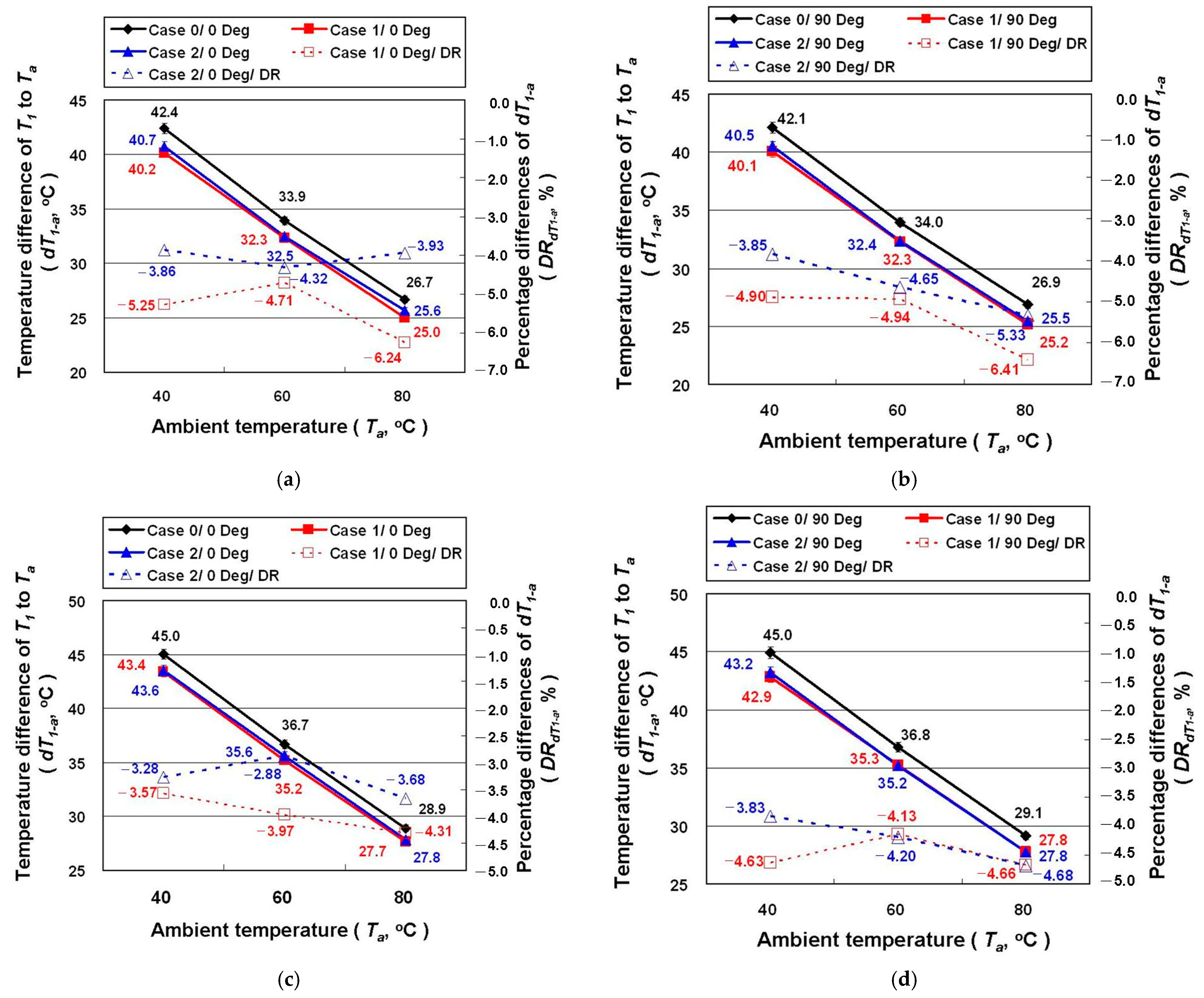

4. Results and Discussion

5. Conclusions

- Coating GNHC on the LED lamps can certainly reduce the RT and improve the heat dissipation performance of the automotive LED lamp.

- The GNHC performs better as a TIM than as a surface coating for the aluminum fin radiator of the studied automotive LED lamps.

- The illuminance and power consumption of automotive LED lamps are negatively correlated with the ambient temperature.

- The maximum ηlx of Case 1 and Case 2 with the high beam, irradiation angle of 0 degrees, and Ta at 80 °C, are 11.03% and 8.70% higher than Case 0, respectively.

- On average, the lamp power increases by 1.26% and 1.17% in Case 1 and Case 2 compared to Case 0, respectively. Meanwhile, the temperature difference between the aluminum fin radiator and ambient air on average increases by 3.25% and 6.35%, respectively, indicating that applying the GNHC on the radiator’s surface does not help reduce the thermal resistance.

- The minimum dT1-a of Case 1 and Case 2 with the high beam, irradiation angle of 90 degrees, and Ta at 80 °C, are 6.41% and 5.33% lower than Case 0, respectively.

- Increasing the GN concentration in GNHC, choosing lower viscosity epoxy resins, thinning the GNHC coatings, and improving coating technique are potential topics worth further investigation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, S.-H.; Lee, C.-H.; Yang, C.-H. Achromatic LED-based projection lens design for automobile headlamp. Optik 2019, 191, 89–99. [Google Scholar] [CrossRef]

- Zhu, Z.; Wei, S.; Liu, R.; Hong, Z.; Zheng, Z.; Fan, Z.; Ma, D. Freeform surface design for high-efficient LED low-beam headlamp lens. Opt. Commun. 2020, 477, 126269. [Google Scholar] [CrossRef]

- Nair, G.B.; Dhoble, S.J. A perspective perception on the applications of light-emitting diodes. Luminescence 2015, 30, 1167–1175. [Google Scholar] [CrossRef] [PubMed]

- OSRAM OSTAR Headlamp, Datasheet Version 1.2. Available online: https://media.digikey.com/pdf/Data%20Sheets/Osram%20PDFs/LE_UW_D1W3_01.pdf (accessed on 5 September 2021).

- Sökmen, K.F.; Yürüklü, E.; Yamankaradeniz, N. Computational thermal analysis of cylindrical fin design parameters and a new methodology for defining fin structure in LED automobile headlamp cooling applications. Appl. Therm. Eng. 2016, 94, 534–542. [Google Scholar] [CrossRef]

- Khandekar, S.; Sahu, G.; Muralidhar, K.; Gatapova, E.Y.; Kabov, O.A.; Hu, R.; Luo, X.; Zhao, L. Cooling of high-power LEDs by liquid sprays: Challenges and prospects. Appl. Therm. Eng. 2021, 184, 115640. [Google Scholar] [CrossRef]

- Luce, T. LED Headlamps: The Spiny Path to a Legal Headlamp. In In Proceedings of the SPIE 5663, Photonics in the Automobile, 16 February 2005; Available online: https://doi.org/10.1117/12.596878 (accessed on 8 September 2021).

- Senawiratne, J.; Chatterjee, A.; Detchprohm, T.; Zhao, W.; Li, Y.; Zhu, M.; Xia, Y.; Li, X.; Plawsky, J.; Wetzel, C. Junction temperature, spectral shift, and efficiency in GaInN-based blue and green light emitting diodes. Thin Solid Films 2010, 518, 1732–1736. [Google Scholar] [CrossRef]

- Jung, E.D.; Lee, Y.L. Development of a heat dissipating LED headlamp with silicone lens to replace halogen bulbs in used cars. Appl. Therm. Eng. 2015, 86, 143–150. [Google Scholar] [CrossRef]

- Singh, R.; Mochizuki, M.; Yamada, T.; Nguyen, T. Cooling of LED headlamp in automotive by heat pipes. Appl. Therm. Eng. 2020, 166, 114733. [Google Scholar] [CrossRef]

- Chen, S.; Chen, K.; Li, Z.; Tang, Y.; Zhuang, B.; Zhong, G.; Liang, G. Experimental investigation on the thermal performance of a light emitting diode headlamp with a flexible woven heat sink. Appl. Therm. Eng. 2017, 127, 1215–1222. [Google Scholar] [CrossRef]

- Lu, Z.; Bai, P.; Huang, B.; Henzen, A.; Coehoorn, R.; Liao, H.; Zhou, G. Experimental investigation on the thermal performance of three-dimensional vapor chamber for LED automotive headlamps. Appl. Therm. Eng. 2019, 157, 113478. [Google Scholar] [CrossRef]

- Razeeb, K.M.; Dalton, E.; Cross, G.L.W.; Robinson, A.J. Present and future thermal interface materials for electronic devices. Int. Mater. Rev. 2018, 63, 1–21. [Google Scholar] [CrossRef]

- Otiaba, K.C.; Ekere, N.N.; Bhatti, R.S.; Mallik, S.; Alam, M.O.; Amalu, E.H. Thermal interface materials for automotive electronic control unit: Trends, technology and R&D challenges. Microelectron. Reliab. 2011, 51, 2031–2043. [Google Scholar]

- Ma, T.; Chakraborty, P.; Guo, X.; Cao, L.; Wang, Y. First-principles modeling of thermal transport in materials: Achievements, Opportunities, and Challenges. Int. J. Thermophys. 2020, 41, 9. [Google Scholar] [CrossRef]

- Han, W.; Chen, M.; Song, W.; Ge, C.; Zhang, X. Construction of hexagonal boron nitride@polystyrene nanocomposite with high thermal conductivity for thermal management application. Ceram. Int. 2020, 46, 7595–7601. [Google Scholar] [CrossRef]

- Yang, C.R.; Chen, C.D.; Cheng, C.; Shi, W.H.; Chen, P.H.; Teng, T.P. Thermal conductivity enhancement of AlN/PDMS composites using atmospheric plasma modification techniques. Int. J. Therm. Sci. 2020, 155, 106431. [Google Scholar] [CrossRef]

- Rybak, A.; Malinowski, L.; Adamus-Wlodarczyk, A.; Ulanski, P. Thermally conductive shape memory polymer composites filled with boron nitride for heat management in electrical insulation. Polymers 2021, 13, 2191. [Google Scholar] [CrossRef]

- Jang, S.; Choi, E.J.; Cheon, H.J.; Choi, W.I.; Shin, W.S.; Lim, J.-M. Fabrication of Al2O3/ZnO and Al2O3/Cu reinforced silicone rubber composite pads for thermal interface materials. Polymers 2021, 13, 3259. [Google Scholar] [CrossRef] [PubMed]

- Barako, M.T.; Isaacson, S.G.; Lian, F.; Pop, E.; Dauskardt, R.H.; Goodson, K.E.; Tice, J. Dense vertically aligned copper nanowire composites as high performance thermal interface materials. ACS Appl. Mater. Interfaces 2017, 9, 42067–42074. [Google Scholar] [CrossRef]

- Qiu, L.; Zou, H.; Wang, X.; Feng, Y.; Zhang, X.; Zhao, J.; Zhang, X.; Li, Q. Enhancing the interfacial interaction of carbon nanotubes fibers by Au nanoparticles with improved performance of the electrical and thermal conductivity. Carbon 2019, 141, 497–505. [Google Scholar] [CrossRef]

- Jeon, D.; Kim, S.H.; Choi, W.; Byon, C. An experimental study on the thermal performance of cellulose-graphene-based thermal interface materials. Int. J. Heat Mass Transf. 2019, 132, 944–951. [Google Scholar] [CrossRef]

- Feng, C.P.; Bai, L.; Bao, R.Y.; Wang, S.W.; Liu, Z.; Yang, M.B.; Chen, J.; Yang, W. Superior thermal interface materials for thermal management. Compos. Commun. 2019, 12, 80–85. [Google Scholar] [CrossRef]

- Mahadevan, B.K.; Naghibi, S.; Kargar, F.; Balandin, A.A. Non-curing thermal interface materials with graphene fillers for thermal management of concentrated photovoltaic solar cells. J. Carbon Res. 2020, 6, 2. [Google Scholar] [CrossRef] [Green Version]

- Wei, J.; Liao, M.; Ma, A.; Chen, Y.; Duan, Z.; Hou, X.; Li, M.; Jiang, N.; Yu, J. Enhanced thermal conductivity of polydimethylsiloxane composites with carbon fiber. Compos. Commun. 2020, 17, 141–146. [Google Scholar] [CrossRef]

- Bustero, I.; Gaztelumendi, I.; Obieta, I.; Mendizabal, M.A.; Zurutuza, A.; Ortega, A.; Alonso, B. Free-standing graphene films embedded in epoxy resin with enhanced thermal properties. Adv. Compos. Hybrid Mater. 2020, 3, 31–40. [Google Scholar] [CrossRef] [Green Version]

- Han, B.; Chen, H.; Hu, T.; Ye, H.; Xu, L. High electrical conductivity in polydimethylsiloxane composite with tailored graphene foam architecture. J. Mol. Struct. 2020, 1203, 127416. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhuang, X.; Wu, F.; Liu, F. High-performance thermal management nanocomposites: Silver functionalized graphene nanosheets and multiwalled carbon nanotube. Crystals 2018, 8, 398. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Sun, J.; Zeng, X.; Sun, R.; Xu, J.B.; Wong, C.P. Construction of 3D skeleton for polymer composites achieving a high thermal conductivity. Small 2018, 14, 1704044. [Google Scholar] [CrossRef]

- Ren, F.; Song, D.; Li, Z.; Jia, L.; Zhao, Y.; Yan, D.; Ren, P. Synergistic effect of graphene nanosheets and carbonyl iron–nickel alloy hybrid filler on electromagnetic interference shielding and thermal conductivity of cyanate ester composites. J. Mater. Chem. C 2018, 6, 1476–1486. [Google Scholar] [CrossRef]

- Lee, S.; Suh, D.; Kim, W.; Xu, C.; Kim, T.; Song, C.; Yoo, C.; Kim, Y.; Kim, J.; Baik, S. Carbon nanotube covalent bonding mediates extraordinary electron and phonon transports in soft epoxy matrix interface materials. Carbon 2020, 157, 12–21. [Google Scholar] [CrossRef]

- Enternal Materials Co., Ltd. Available online: https://www.eternal-group.com/Product/Detail/1989?level2=48&lang=en&level1=81 (accessed on 5 October 2021).

- Golden Innovation Business Co., Ltd. Available online: https://www.gibusiness.com/products.asp (accessed on 5 October 2021).

- Wu, J.-B.; Lin, M.-L.; Cong, X.; Liu, H.-N.; Tan, P.-H. Raman spectroscopy of graphene-based materials and its applications in related devices. Chem. Soc. Rev. 2018, 47, 1822–1873. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silva, D.L.; Campos, J.L.E.; Fernandes, T.F.D.; Rocha, J.N.; Machado, L.R.P.; Soares, E.M.; Miquita, H.; Miranda, H.; Rebalo, C.; Neto, P.O.; et al. Raman spectroscopy analysis of number of layers in mass-produced graphene flakes. Carbon 2020, 161, 181–189. [Google Scholar] [CrossRef]

- Ibrahim, A.; Klopocinska, A.; Horvat, K.; Hamid, Z.A. Graphene-based nanocomposites: Synthesis, mechanical properties, and characterizations. Polymers 2021, 13, 2869. [Google Scholar] [CrossRef] [PubMed]

| Irradiation Angle (Deg) | Ta (°C) | Case No. | High Beam | Low Beam | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| P (W) | DRP (%) | IL (lx) | DRIL(%) | P (W) | DRP(%) | IL (lx) | DRIL(%) | |||

| 0 | 40 | Case 0 | 12.97 | / | 5217 | / | 12.50 | / | 4765 | / |

| Case 1 | 13.16 | 1.51 | 5637 | 8.05 | 12.60 | 0.76 | 5263 | 10.46 | ||

| Case 2 | 13.29 | 2.53 | 5555 | 6.49 | 12.58 | 0.68 | 5067 | 6.33 | ||

| 60 | Case 0 | 11.12 | / | 4503 | / | 10.65 | / | 4225 | / | |

| Case 1 | 11.23 | 1.04 | 5048 | 12.10 | 10.81 | 1.54 | 4525 | 7.10 | ||

| Case 2 | 11.31 | 1.71 | 4820 | 7.03 | 10.83 | 1.68 | 4435 | 4.97 | ||

| 80 | Case 0 | 9.24 | / | 3777 | / | 8.93 | / | 3472 | / | |

| Case 1 | 9.41 | 1.79 | 4268 | 13.02 | 9.06 | 1.42 | 3907 | 12.53 | ||

| Case 2 | 9.37 | 1.37 | 4162 | 10.19 | 9.06 | 1.37 | 3773 | 8.69 | ||

| 90 | 40 | Case 0 | 13.21 | / | 606 | / | 12.69 | / | 670 | / |

| Case 1 | 13.38 | 1.29 | 625 | 3.08 | 12.82 | 1.04 | 700 | 4.45 | ||

| Case 2 | 13.28 | 0.52 | 619 | 2.09 | 12.71 | 0.19 | 692 | 3.21 | ||

| 60 | Case 0 | 11.21 | / | 536 | / | 10.82 | / | 619 | / | |

| Case 1 | 11.33 | 1.07 | 586 | 9.26 | 10.92 | 0.92 | 664 | 7.27 | ||

| Case 2 | 11.33 | 1.11 | 561 | 4.60 | 10.87 | 0.49 | 655 | 5.82 | ||

| 80 | Case 0 | 9.29 | / | 427 | / | 8.97 | / | 478 | / | |

| Case 1 | 9.42 | 1.38 | 473 | 10.73 | 9.09 | 1.41 | 522 | 9.13 | ||

| Case 2 | 9.42 | 1.34 | 455 | 6.64 | 9.06 | 1.06 | 512 | 7.04 | ||

| Irradiation Angle (Deg) | Ta (°C) (Set) | Case No. | T1 (°C) | T2 (°C) | T3 (°C) | Ta (°C) | dT1-2 (°C) | dT2-3 (°C) | dT3-a (°C) | DRdT1-2 (%) | DRdT2-3 (%) | DRdT3-a (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (a) | ||||||||||||

| 0 | 40 | Case 0 | 82.8 | 71.2 | 65.3 | 40.5 | 11.6 | 5.9 | 24.8 | / | / | / |

| Case 1 | 80.5 | 70.9 | 65.7 | 40.3 | 9.6 | 5.1 | 25.4 | −17.30 | −13.53 | 2.35 | ||

| Case 2 | 81.0 | 71.4 | 66.7 | 40.3 | 9.6 | 4.7 | 26.4 | −16.92 | −20.49 | 6.21 | ||

| 60 | Case 0 | 94.0 | 84.4 | 79.6 | 60.1 | 9.5 | 4.9 | 19.5 | / | / | / | |

| Case 1 | 92.6 | 84.5 | 80.3 | 60.3 | 8.1 | 4.2 | 20.0 | −14.87 | −14.50 | 2.72 | ||

| Case 2 | 92.7 | 84.5 | 80.8 | 60.3 | 8.2 | 3.8 | 20.5 | −14.34 | −22.36 | 5.11 | ||

| 80 | Case 0 | 106.1 | 98.4 | 94.5 | 79.4 | 7.7 | 3.9 | 15.0 | / | / | / | |

| Case 1 | 105.0 | 98.3 | 95.0 | 80.0 | 6.7 | 3.3 | 15.0 | −13.13 | −16.25 | −0.10 | ||

| Case 2 | 105.2 | 98.5 | 95.5 | 79.6 | 6.8 | 3.0 | 15.9 | −12.36 | −23.22 | 5.42 | ||

| 90 | 40 | Case 0 | 82.5 | 71.0 | 64.2 | 40.3 | 11.5 | 6.7 | 23.9 | / | / | / |

| Case 1 | 80.5 | 70.5 | 65.4 | 40.4 | 9.9 | 5.2 | 25.0 | −13.61 | −23.22 | 4.44 | ||

| Case 2 | 81.1 | 71.1 | 66.5 | 40.5 | 10.0 | 4.6 | 25.9 | −13.27 | −31.65 | 8.52 | ||

| 60 | Case 0 | 93.9 | 84.4 | 79.0 | 59.9 | 9.6 | 5.4 | 19.0 | / | / | / | |

| Case 1 | 92.6 | 84.3 | 80.1 | 60.3 | 8.3 | 4.2 | 19.7 | −12.72 | −21.78 | 3.75 | ||

| Case 2 | 92.7 | 84.3 | 80.5 | 60.3 | 8.4 | 3.8 | 20.2 | −12.17 | −29.69 | 6.25 | ||

| 80 | Case 0 | 106.6 | 98.7 | 94.3 | 79.7 | 7.9 | 4.4 | 14.6 | / | / | / | |

| Case 1 | 105.1 | 98.3 | 94.9 | 79.9 | 6.8 | 3.3 | 15.0 | −12.90 | −25.14 | 2.80 | ||

| Case 2 | 104.9 | 98.0 | 95.0 | 79.4 | 6.9 | 3.1 | 15.5 | −12.42 | −31.18 | 6.37 | ||

| (b) | ||||||||||||

| 0 | 40 | Case 0 | 85.5 | 73.4 | 67.0 | 40.4 | 12.1 | 6.4 | 26.5 | / | / | / |

| Case 1 | 84.0 | 73.8 | 68.3 | 40.6 | 10.2 | 5.6 | 27.7 | −15.76 | −13.13 | 4.28 | ||

| Case 2 | 84.1 | 73.9 | 68.9 | 40.6 | 10.2 | 5.0 | 28.3 | −15.51 | −21.26 | 6.62 | ||

| 60 | Case 0 | 96.6 | 86.5 | 81.2 | 59.9 | 10.1 | 5.3 | 21.3 | / | / | / | |

| Case 1 | 95.4 | 86.7 | 82.2 | 60.2 | 8.7 | 4.5 | 22.0 | −13.67 | −14.70 | 3.28 | ||

| Case 2 | 95.6 | 86.9 | 82.7 | 60.0 | 8.8 | 4.1 | 22.7 | −12.95 | −22.11 | 6.68 | ||

| 80 | Case 0 | 108.4 | 100.2 | 95.9 | 79.5 | 8.2 | 4.3 | 16.4 | / | / | / | |

| Case 1 | 107.4 | 100.2 | 96.5 | 79.7 | 7.2 | 3.6 | 16.8 | −11.79 | −15.58 | 2.37 | ||

| Case 2 | 107.4 | 100.1 | 96.8 | 79.6 | 7.3 | 3.3 | 17.2 | −10.79 | −21.96 | 4.65 | ||

| 90 | 40 | Case 0 | 85.3 | 73.3 | 66.0 | 40.3 | 12.0 | 7.3 | 25.7 | / | / | / |

| Case 1 | 83.5 | 72.9 | 67.4 | 40.7 | 10.6 | 5.6 | 26.7 | −11.52 | −23.19 | 3.80 | ||

| Case 2 | 84.1 | 73.4 | 68.4 | 40.8 | 10.6 | 5.0 | 27.6 | −11.20 | −30.88 | 7.22 | ||

| 60 | Case 0 | 96.9 | 86.8 | 80.8 | 60.1 | 10.1 | 6.0 | 20.7 | / | / | / | |

| Case 1 | 95.3 | 86.4 | 81.7 | 60.0 | 8.9 | 4.6 | 21.7 | −11.49 | −22.49 | 4.74 | ||

| Case 2 | 95.5 | 86.5 | 82.4 | 60.3 | 9.0 | 4.2 | 22.1 | −10.91 | −30.29 | 6.58 | ||

| 90 | Case 0 | 108.8 | 100.5 | 95.7 | 79.7 | 8.3 | 4.8 | 16.0 | / | / | / | |

| Case 1 | 107.5 | 100.1 | 96.4 | 79.7 | 7.4 | 3.7 | 16.7 | −11.02 | −24.25 | 4.58 | ||

| Case 2 | 107.5 | 100.1 | 96.8 | 79.7 | 7.4 | 3.4 | 17.0 | −11.06 | −30.77 | 6.55 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, T.-P.; Chen, W.-J.; Chang, C.-H. Enhanced Heat Dissipation Performance of Automotive LED Lamps Using Graphene Coatings. Polymers 2022, 14, 50. https://doi.org/10.3390/polym14010050

Teng T-P, Chen W-J, Chang C-H. Enhanced Heat Dissipation Performance of Automotive LED Lamps Using Graphene Coatings. Polymers. 2022; 14(1):50. https://doi.org/10.3390/polym14010050

Chicago/Turabian StyleTeng, Tun-Ping, Wei-Jen Chen, and Chun-Hsin Chang. 2022. "Enhanced Heat Dissipation Performance of Automotive LED Lamps Using Graphene Coatings" Polymers 14, no. 1: 50. https://doi.org/10.3390/polym14010050

APA StyleTeng, T.-P., Chen, W.-J., & Chang, C.-H. (2022). Enhanced Heat Dissipation Performance of Automotive LED Lamps Using Graphene Coatings. Polymers, 14(1), 50. https://doi.org/10.3390/polym14010050