Updated Perceptions on Polymer-Based Enhanced Oil Recovery toward High-Temperature High-Salinity Tolerance for Successful Field Applications in Carbonate Reservoirs

Abstract

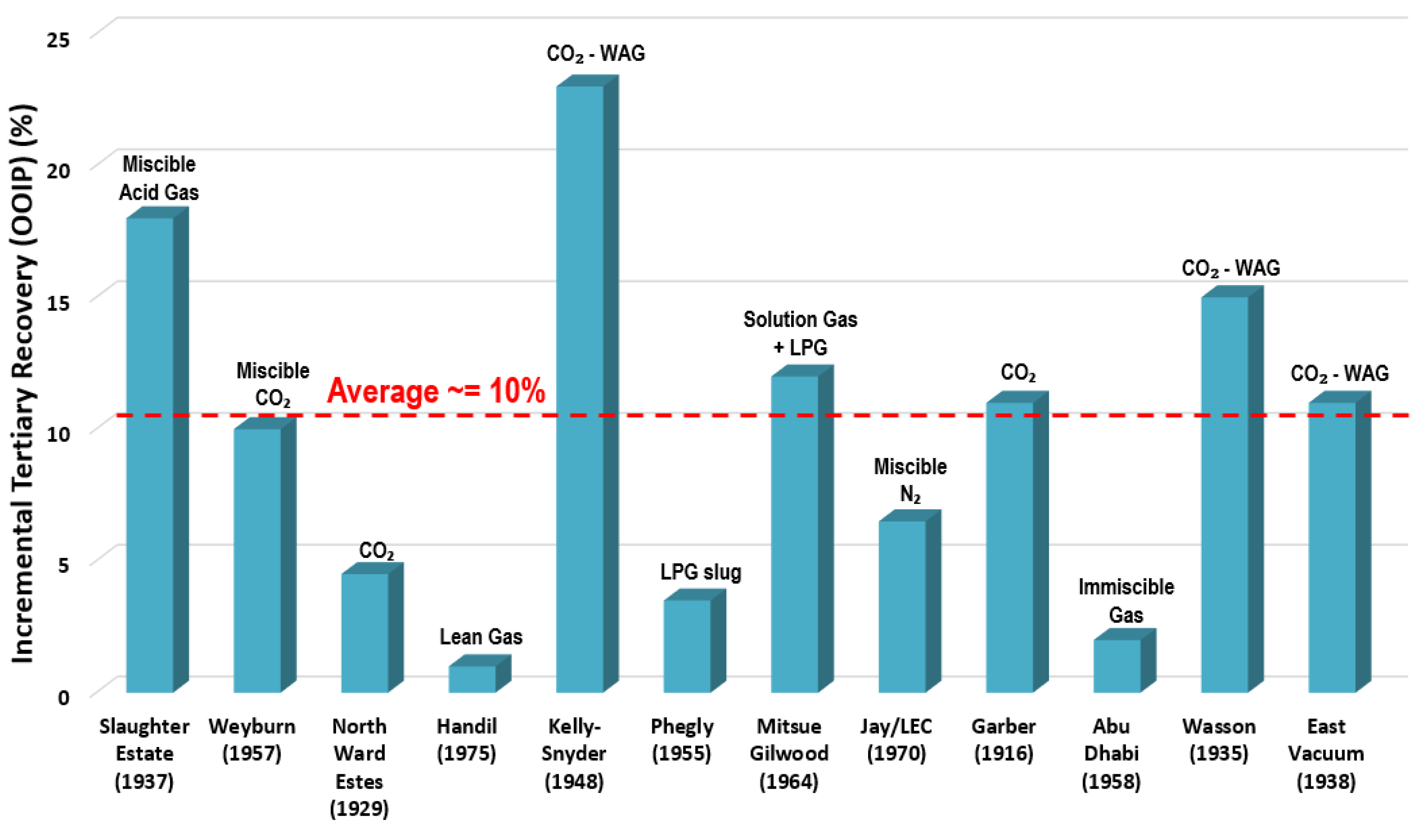

:1. Introduction

2. Challenges Associated with Polymer Flooding in Harsh Conditions

- Reservoir temperature of over 85 C;

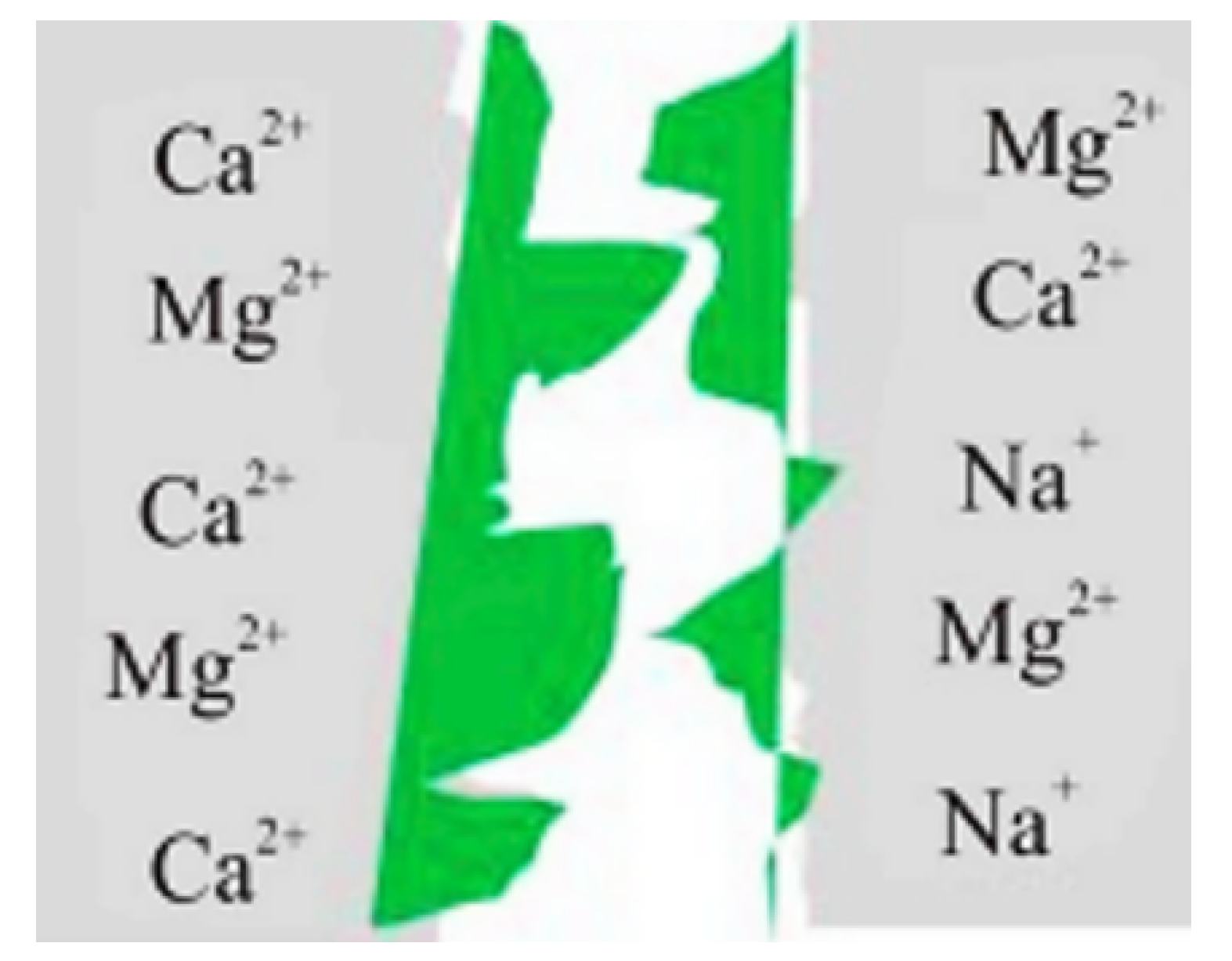

- Formation water salinity above 100,000 ppm (TDS);

- Concentration of divalent cations (hardness) above 1000 ppm;

- Permeability lower than 100 millidarcies (mD);

- Heterogeneity and complex structures of carbonates.

Instability and Degradation of Polymers under HTHS Conditions

3. Mechanisms of Polymer Flooding in Harsh Carbonate Reservoirs

4. Polymer Screening Criteria and Requirements for Polymer Flooding

4.1. Polymer Chemistry

4.2. Polymer Forms

4.3. Polymer Size

4.4. Rheology

4.5. Environmental Impact

4.6. Requirements of Polymer Flooding Agent

- High water solubility and injection performance;

- A required degree of thermal stability and ability to resist shear degradation;

- Suitability with brine salt and hardness;

- Satisfactory chemical and biological stability;

- Environmentally acceptable and non-polluting to oil reservoir;

- Must be reasonably priced and have logistical ease. Almost all the research is focused on acrylamide-based copolymers, hydrophobic polymers, and thermo-viscosifying polymers.

5. Potential Polymer Types Suitable for HTHS Carbonate Reservoirs

5.1. Synthetic Polymers

5.1.1. Hydrolyzed Polyacrylamide (HPAM)

5.1.2. Temperature- and Salt-Resistant Cross Linker and Polymer

5.1.3. Co-Polymers of Acrylamide

5.1.4. Comb Type Polymer

5.1.5. Co-Polymer of Acrylamide and Vinylpyrrolidone

5.1.6. Terpolymer

5.1.7. Cationic Polymer

5.1.8. Hydrophobically Modified Associating Polymers

5.1.9. Star Polymer

5.1.10. New Smart Thermoviscosifying Polymers (TVPs)

5.2. Biological Polymers

5.2.1. Xanthan Gum

5.2.2. Scleroglucan

5.2.3. Schizophyllan

5.2.4. Welan Gum

5.2.5. Hydroxyethylcellulose (HEC)

5.2.6. Starch–Graft-Poly (AM-co-AMPS)

5.3. Other Polymers

5.3.1. Co/Terpolymer and Polymer/Multiwalled Carbon Nanotubes (MWCNT) Hybrid

5.3.2. Hot-Melt Adhesive (HMA) Polymers

- The associative polymers with a single associating block;

- Telechelic group;

- Multisticker group;

- Combined HMA polymers group.

6. Experimental Laboratory Studies

6.1. Novel Polymers

6.1.1. Synthetic Polymers

- AMPS, ATBS- and NVP-Based Polymers

- The stability of hard brines increased as the ATBS concentrations in the polymer backbone chain increased, and a proportional increase in temperature tolerance along with the degree of heat was observed.

- After a year at 105 C temperatures, Superpusher SAV37 (containing more than 35 mol% ATBS and no NVP) maintained 60% of its viscosity in a hard brine (84,500 ppm TDS and 6000 ppm hardness). It could also only maintain 45% of its initial viscosity when held in a less saline but harder brine at the same temperature.

- Investigations into the capabilities of Superpusher SAV10 (which had significantly more than 35 mol% ATBS and no NVP) and Superpusher SAV333 (which was functionalized with ATBS and 30–45% NVP) in a hard brine (TDS of 84,500 ppm and 6000 ppm hardness) at a temperature of 140 C revealed that SAV10 could retain over 60% of its viscosity after a 6-month period, while SAV333 maintained over 90% of its viscosity. Dupuis et al. [169] made similar discoveries while studying these polymers.

- II.

- Hybrid HPAM/PAM Modifications

- III.

- Thermo-Viscosifying Polymers (TVPs)

- IV.

- Modified Acrylamide Co/Terpolymers and Multiwalled Carbon Nanotubes (MWCNTs)

- V.

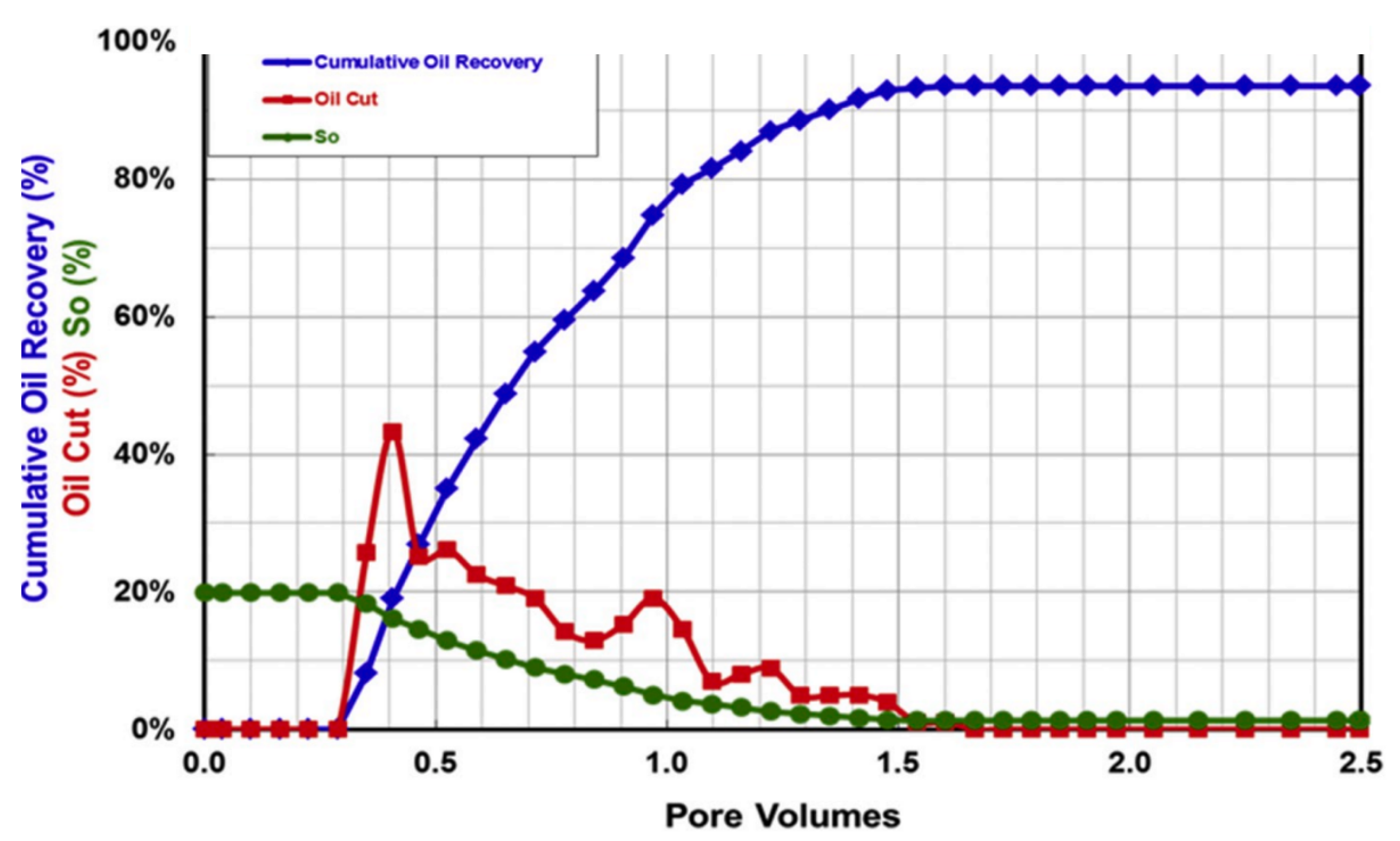

- Core Flooding Using Novel Polymers

- When exposed to HS (500 ppm) and/or oxygen at 150 ppb, the polymer SAV10 was found to be functional [176].

- The polymer met the injectivity criteria for a wide range of injection rates, from 1 ft/day to 120 ft/day, as well as a wide permeability range [176].

- There was a shear thickening characteristic in the polymer as the flow increased, but no evidence of mechanical degradation were found [176].

- The stability of the effluents’ viscosity was also detected [176].

6.1.2. Biopolymers

6.2. Conventional Polymers Mixed with Surfactants and Alkali Flooding

6.2.1. Polymer–Surfactant (PS) Flooding

6.2.2. Polymer–Surfactant–Alkali (ASP) Flooding

6.3. Polymer-Based Hybrid EOR

6.3.1. Low Salinity Polymer (LSP) Injection

6.3.2. Polymer Enhanced CO Foam Flooding

- AVS solution demonstrated higher viscosities than HPAM solution under harsh HTHS (high salinity and temperature) conditions.

- Surface tensions between AVS solution and CO were lowered, which was attributed to the addition of the surface activity group.

- The foaming factors of AOS/AVS were remarkable in brine salinities ranging from 1000 to 50,000 ppm and temperatures ranging from 25 C to 60 C.

- The CO foam blockage that was enhanced owing to AVS was promising and as required at a pressure of 2000 psi.

- When under identical conditions, the oil recoveries of the tertiary phase yielded by AVS/AOS were 5% to 7% higher than those of HPAM/AOS during the core flooding.

7. Numerical Studies and Field Applications

7.1. Novel Synthetic Polymers

7.1.1. Field Applications

- Wu et al. [104] reported the successful applicability of polymer-based cEOR in extreme temperature and salinity in one of the oilfields in China. They employed a SMG (soft micro gel) in this study, which was a new polymer known to be HTHS condition tolerant. The results obtained had an increased oil recovery factor from 44% to 66% [104].

- A polymer-based cEOR was undertaken in 1996 in Daqing oilfield in China. The incremental oil recovery factor from this field was observed to be 12% more than water flooding [203].

- Since, field application of HMA polymers can be challenging, therefore, based on the available literature, the reported applications of HMA polymers in the field are limited. However, extensive lab-scale investigations are underway to extend the findings to field applications. One pilot-scale test was conducted in Bohai Bay oil field in China using an HMA polymer, where 25,000 m of incremental oil was recovered and the water cut decreased from 95 to 54% [202].

- Two polymers 340 and 454 PAM were studied to ascertain their applicability in the Owasco Unit oil field in the United State (US). In this case, the reservoir lithology was sandstone with a temperature of 77 C [205]. The upshots from these projects was that emulsion-based synthetic polymer projects encountered greater issues of injectivity in contrast to the projects where the powder-type synthetic polymers were used. Furthermore, the rate of success for polymer-based projects that employed secondary mode injection was higher than those projects that implemented polymer injection in tertiary mode [78].

- Two polymer-based cEOR field pilots is commenced by in two reservoirs which are presently undergoing water-flooding. The targeted reservoirs cover multiple fields in Abu Dhabi [176,212]. The target reservoirs have high temperatures ranging from 100 C to 130 C, high-salinity formation brine of around 200,000 ppm, and high concentrations of divalent ions (Ca and Mg) of around 18,000 ppm, with a carbonate reservoir formation. Likewise, one of the targeted reservoirs presents a significant challenge for optimal recovery, as it has a high permeability contrast between the upper and lower zones. This is also a layered reservoir (i.e., the strata), which are a few feet in thickness, which can be correlated field wide, frequently beyond several kilometers [212]. Additionally, the cumulative permeability increases as the top of the reservoir approaches. This reservoir may be characterized at an elevated level as being made up of two main bodies, i.e., an upper zone (high permeable layers inter-bedded between low permeable layers) and a lower zone of low permeability layers of relatively uniform permeability distribution. The permeabilities in the upper part ranges from 10 to many 100 mD, and observations of underwater flooding exhibited good displacement of oil by water. The permeabilities in the lower part are on average much lower than in the upper part, varying between 1 and 10 mD. Thus, overall recovery from these low permeability zones is quite minimal, due to the fact that traditional injectants (i.e., water and gas) will propagate rapidly to the higher permeability regions of the upper reservoir, which overlies the lower reservoir, and a full pressure contact is experienced with it. Additionally, the recent study CO on Abu Dhabi reservoirs as mentioned above demonstrate that due to the high heterogeneity of the formation, where water flooding is the more feasible option than both continuous CO and CO WAG injection techniques [176,212]. Moreover, the specific properties of the Abu Dhabi reservoirs include light crude oil with API ranging from 35 to 40, which eliminates the EOR options that are thermal based. Thus, chemical cEOR alternatives are identified to have much greater potential in retrieving either remaining oil saturation or the bypassed oil in tight pores or low permeability reservoirs. Hence, for these reservoirs at Abu Dhabi, the deduced scheme is a combination of gas cEOR with mobility control options (such as polymer flooding). Even though cEOR methods may be highly challenging in the HTHS carbonate reservoirs in Abu Dhabi, the recently developed polymers have shown high tolerance to harsh carbonate reservoir conditions [67,130,169,172]. Therefore, ADNOC selected polymer-based cEOR as the foremost EOR option (ie.e, new field development plan), which comprises polymer injection, simultaneous injection of miscible gas and polymer (SIMGAP), simultaneous injection of water and polymer (SIWAP), and low-salinity polymer approaches [176,212]. For this field application plan, two polymer-based cEOR concepts were developed for these reservoirs [176,212]:

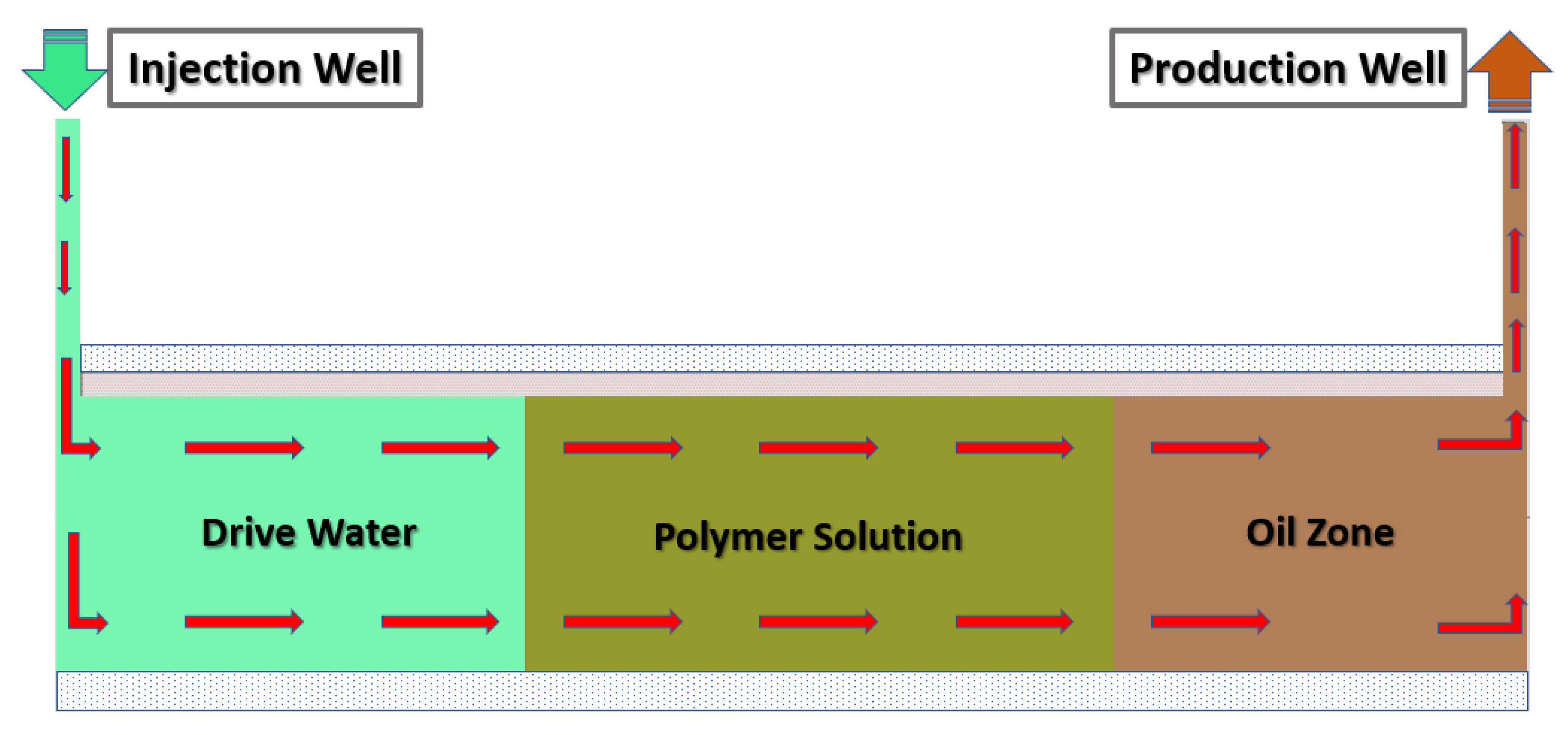

- Simultaneous injection of miscible gas and polymer (): The simultaneous injection of viscosified water (polymer solution) is for the upper highly permeable zone, and miscible gas (e.g., HS/CO) is for the low permeable lower zone. This creates a resultant lateral pressure gradient as a result, which is maintained in the upper zone, retaining gas confinement in the lower zone.

- Simultaneous injection of water and polymer (): The simultaneous injection of viscosified water (polymer solution) will be in the upper zone, and normal water will be for the lower zone. To create a variation of this concept, only viscosified water is injected in the reservoir which also culminates in an identical recovery factor as , but consumes a larger volume of polymer for injection.

- Although these novel processes have not yet been implemented in the field, the industry has decades of experience in water flooding, polymer-based cEOR, and miscible gas injection processes to rely on [176,212]. Therefore, these methods (SIMGAP and SIWAP) are a combination of two processes into a single practicable recovery mechanism [176,212]. Furthermore, the simulation results obtained show positive indications with both processes. Thus, these newly developed processes have the capacity to attain elevated recovery factors and evidently improve the sweep efficiency in reservoirs with highly heterogeneity. Consequently, the principal issue concerning these polymers-based EOR processes will be to derive a polymer which maintains its stability at HTHS (i.e., high temperature and high salinity) and has a desirable injectivity in carbonates [176,212].

- The data from the cited experiments [176,212] provided in this paper illustrate that an ATBS polymer was found to be a promising candidate due to the injectivity behavior, which can be adjusted for injection in accordance to the target reservoirs. Additionally, to be workable, both SIMGAP and SIWAP processes require a moderate rise in viscosity. Therefore, the results were found to be very encouraging and suggest successful progression toward possible field testing and piloting. Additionally, to limit the risk of these pilots, a polymer injectivity test was scheduled to commence in 2019. It was expected to begin once a desirable injectivity of the polymer was exhibited in the field; ADNOC will proceed with the initialization of the two polymer-based cEOR pilots to demonstrate the applicability of the two new polymer-based cEOR concepts. Thus, through the tests based on these novel concepts, it is anticipated that a sizable volume of ADNOC reservoirs, both onshore and offshore will become accessible for production [176,212].

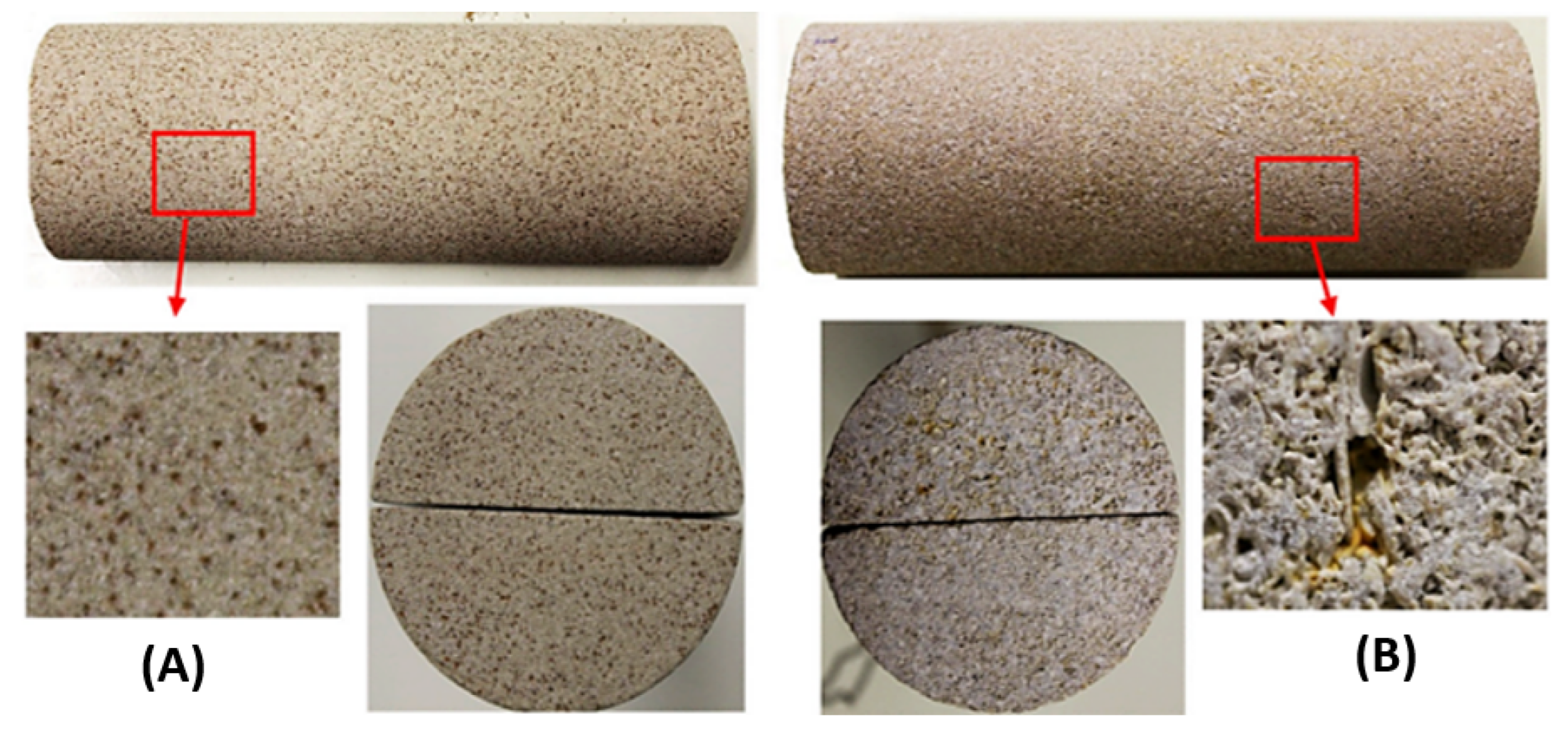

- In consistency with their plans, the very first of these injectivity pilot tests for carbonate with bypassed oil within the heterogeneous layers in Abu Dhabi reservoirs were completed successfully. A polymer-based cEOR technique was determined for retrieving the residual and remaining oil. With 10 years in its development, a polymer with high amounts of 2-acrylamido-tertiary-butyl sulfonic acid (ATBS) was used [169,176]. Through screening methods of thermal stability, bulk and in situ rheology, adsorption and injectivity for the harsh conditions of ADNOC reservoirs, their polymer was deemed suitable.Employing a de-risking strategy involved polymer injectivity test () followed by a multi-well pilot that was conducted before the final field implementation of polymer-based cEOR reservoir for several ADNOC reservoirs. The PIT took four months to be completed in February 2019 which was at a 250 temperature and salinity ppm conditions, with low HS content [206,213]. A total of barrels of viscous solution was expended for injection into the reservoir. The successfully attained the projected crucial performance indicators concerning, the quality of polymer solution, viscosity, concentration, injection rate and skid running time. The latter was confirmed via a dedicated surveillance and injection monitoring throughout the whole period. A new polymer with high (ATBS) content was identified, based on extensive laboratory studies, and an initial polymer injectivity test (PIT) that was conducted. Thus, this positive polymer injectivity test verified the new polymer’s efficacy for field application at HTHS carbonate reservoirs [206].

- Subsequently, ADNOC expanded on their designed polymer-based cEOR application to harsher field environment, which had a higher HS content. This second PIT was conceived for laying the groundwork for a multi-well pilot polymer flooding project, that dissipated the HS concentrations (20–40 ppm) to determine the injectivity at prototypical field conditions and in situ polymer functioning in HTHS reservoirs of Abu Dhabi. The PIT was initiated in February 2021 and completed in July 2021, spanning five months, after which chase water flood was run until December 2021. During this PIT, 108,392 barrels of polymer solution in total were injected successfully to acquire a large dataset through sustained monitoring, which was utilized in the assessment of injectivity and in-depth mobility reduction caused by the novel polymer. Initial results showed all of the key performance markers expected, including predictable viscosity yield and desired injectivity at target rates, which were coherent with the data from laboratory investigations. The PIT scheme was optimized with the use of down-hole shut-in tool (DHSIT) to obtain pressure fall-off (PFO) data that brought to light the behavior of the polymer in the near-wellbore area. Consequently, the polymer properties revealed through the PIT is to be used in enhancing field and sector models that will enable the assessment of polymer-based cEOR in myriad other giant, heterogeneous carbonate reservoirs. This is expected to contribute toward higher recovery in ADNOC and Middle Eastern carbonate oil fields [207].

- Another significant study was conducted by Jabbar et al. [204] on a viable sulfonated polymer (ATBS > 35 mol%) for possible employment in a super-giant carbonate field in the Middle East. In this study, polymer rheology and thermal stability were evaluated, and core flooding in a composite reservoir core with live-oil, as well as simulation in a representative sector of the field were performed. The features of the field are defined as highly heterogeneous with low permeability (5–10 mD) and streaks of (200 mD). Furthermore, the formation water has high salinity (i.e., TDS of 180,000 ppm and hardness of 16,000 ppm) and the reservoir temperature of 100 C increased the harshness of the environment. From the simulation, an incremental oil recovery of about 5% was shown when a pre-sheared polymer with a viscosity of 3 cP, concentration of 4000 ppm, and slug size of 0.25 PV was injected. They found the polymer flood effect to be much like that of infill drilling, except with a notable decrease in water production [204].

7.1.2. Novel Bio-Polymers

7.2. Conventional Polymers Mixed with Surfactants and Alkali

Field Applications

- For SP-based EOR, the pilot tests worldwide include the Russian Tpexozephoe Field, Hungarian H Field, Whittier Field in California, and North Gujarat Oil Field in India [37].

- For PSA-based EOR, large-scale field projects were successful and showed encouraging results. Etzikom in Alberta, Canada and Minas II oil field in Indonesia are two current field projects currently underway [37].

7.3. Polymer-Based Hybrid EOR

7.3.1. Low Salinity Polymer (LSP) Flooding

Numerical Studies

- Rivet [216] and Seright et al. [101] studied the combined effects of engineered water polymer flooding and highlighted the better polymer stability and yield, improved microscopic and macroscopic sweep efficiency, and reduction in chemical costs [101,216]. A seawater desalination process was developed for combined engineered water and polymer applications in an offshore field [217]. The hybrid engineered water polymer method can achieve up to 30% of OOIP incremental recovery [182].

- Alzayer and Sohrabi [218] conducted a numerical simulation study using a correlation between the residual oil saturation after water flooding (S) and the salinity of water [218], as developed by Webb et al. [219] utilizing the relevant published data in the literature [219]. The objective of the study was to improve the oil recovery from a heavy oil reservoir (80 cP and 20 API) using low salinity water (LSW) injection followed by polymer flooding (PF). A comparison of the different injection schemes showed that the combination of LSW and PF provided an additional 4% estimated ultimate recovery (EUR) of the original oil in place (OOIP) with significantly lower injection volumes required compared to both methods simulated separately.

- Using a combined MRST-IPhreeqc simulator, Al Shalabi et al. [12] developed a mechanistic model of hybrid low salinity polymer (LSP) flooding. In this study, a coupled numerical model was used to investigate the polymer–brine–rock geochemical interactions as well as the flow dynamics associated with LSP flooding. The geochemical software IPhreeqc, which is the interface module of PHREEQC, was combined with MATLAB Reservoir Simulation Toolbox (MRST). The impacts of polymer on polymer viscosity were captured using the Todd–Longstaff mixing model, inaccessible pore volume, permeability reduction, polymer adsorption, and salinity and shear rate effects [12]. The coupled simulator enables the real-time monitoring of the aqueous phase salinity and its impact on the polymer rheological characteristics, which is advantageous for LSP-based cEOR field applications.

Field Application

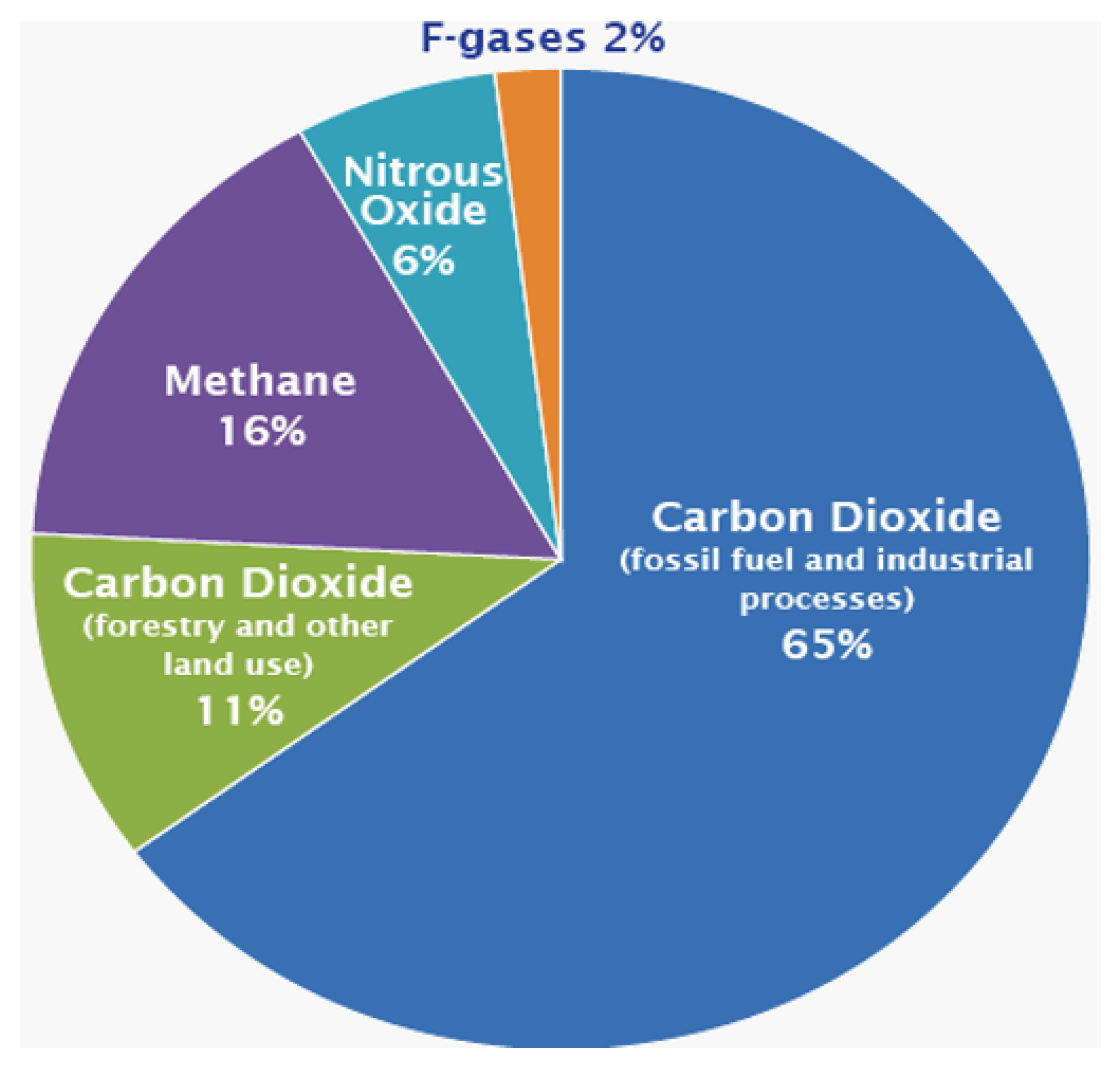

8. Environmental Impact of Polymer

- Satisfying global energy demand using polymer-based cEOR;

- Reduction in the CO intensity of produced oil (i.e., larger quantities of oil and cleaner oil).

9. Recommended Practices for Polymer Flooding in Harsh Conditions

- I.

- High Temperature

- II.

- High Salinity/Hardness

- III.

- Low Permeability

- IV.

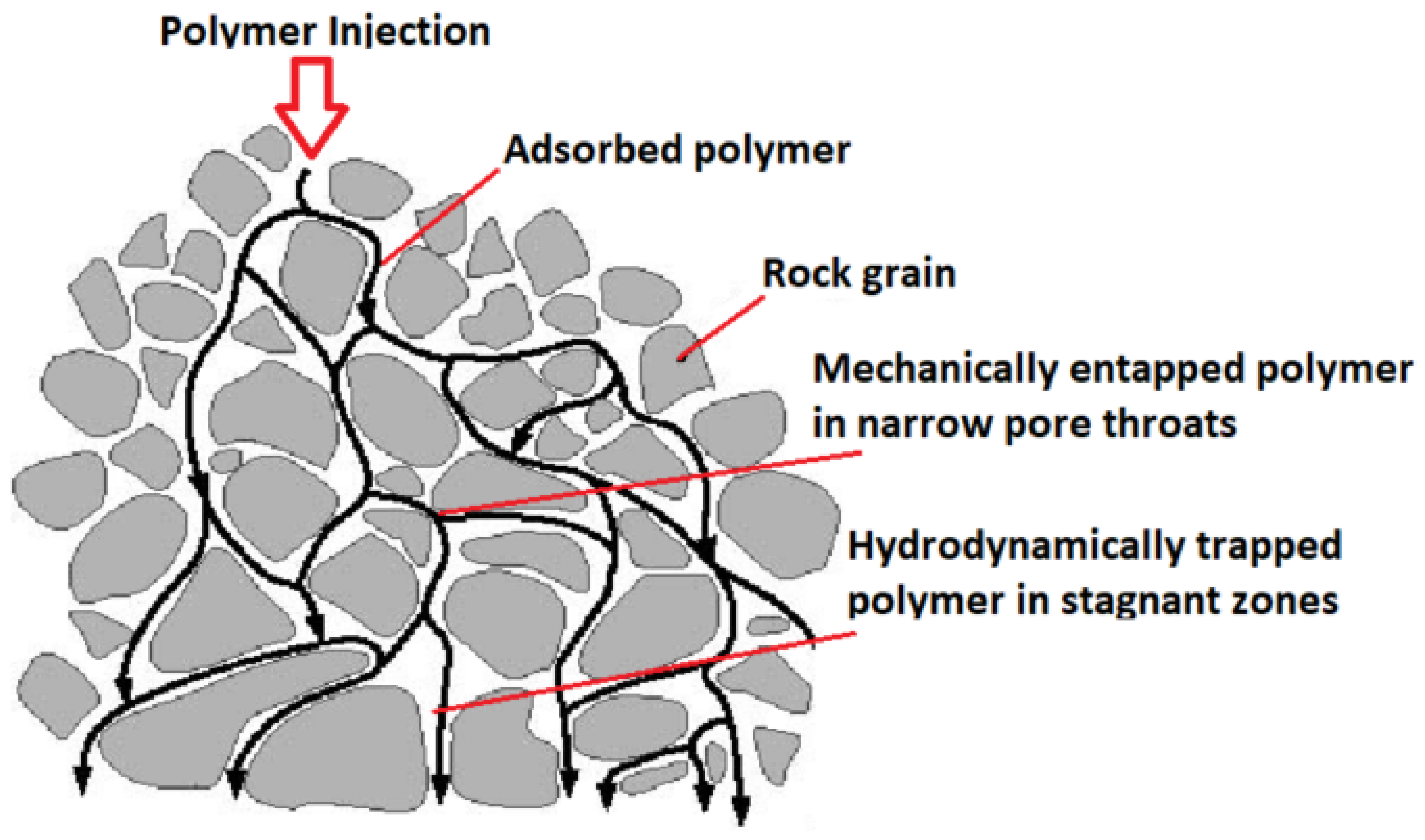

- Polymer Adsorption

- V.

- Polymerization

10. Final Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Symbols | |

| areal sweep efficiency | |

| displacement efficiency | |

| vertical sweep efficiency | |

| volumetric sweep efficiency | |

| k | absolute permeability |

| effective permeability of oil | |

| effective permeability of water | |

| M | mobility ratio |

| Deborah number | |

| n | shear-thinning index |

| water saturation | |

| Greek letters | |

| characteristic residence time | |

| relaxation time of the polymeric fluid | |

| phase mobility | |

| viscosity | |

| Subscripts/Superscripts | |

| i | initial |

| o | oil |

| w | water |

| Abbreviations | |

| AA | Acrylic Acid |

| AM | Acrylamide |

| AMPS | 2-Acrylamido-2-Methylpropane Sulfonic Acid |

| AN | (Sulfonated) Polyacrylamide |

| AOS | (Sodium) Alpha Olefin Sulfate |

| ATBS | Acrylamide Tertiary Butyl Sulfonic Acid |

| AVS | Amphiphilic Ter-polymer of AM, AMPS |

| BEM | Butylethyl Magnesium |

| CEOR | Chemical Enhanced Oil Recovery |

| CMG-STARS | Computer Modeling Group Ltd |

| CO | Carbon Dioxide |

| DOH | Degree of Hydrolysis |

| DTAB | Dodecyl-Trimethyl-Ammonium Bromide |

| EOR | Enhanced Oil Recovery |

| ERoEI | Exergy-Return on Exergy-Investment |

| WE | Engineered Water |

| EWF | Engineered Water Flooding |

| EWPF | Engineered Water Polymer Flooding |

| HAP | Hydrophobically Associating Polymers |

| HEC | Hydroxyethylcellulose |

| HMA | Hot-melt Adhesives |

| HMA | Hydrophobically Modified Associating |

| HMA-PAM | Hydrophobically Modified Associating Polymers-Polyacrylamide |

| HPAM | Hydrolyzed Polyacrylamide |

| HTHS | High Temperature High Salinity |

| IFT | Interfacial Tension |

| IOR | Improved Oil Recovery |

| IW | Injection Water |

| LCST | Lower Critical Solution Temperature |

| LSPF | Low-Salinity Polymer Flooding |

| LSW | Low-Salinity Water |

| LSWF | Low-Salinity Water Flooding |

| LSW-P | Low-Salinity Water Polymer |

| MW | Molecular Weight |

| MWCNT | Multi-Walled Carbon Nanotubes |

| NaCl | Sodium Chloride |

| NMR | Nuclear Magnetic Resonance |

| NVP | N-Vinylpyrrolidone |

| OOIP | Original Oil in place |

| PAM | Polyacrylamide |

| PEF | Polymer-Enhanced Foam |

| PF | Polymer Flooding |

| PS | Polymer–Surfactant |

| PSA | Polymer–Surfactant–Alkaline |

| PSF | Polymer–Surfactant Flooding |

| PV | Pore Volume |

| PZC | Point of Zero Charge |

| RE | Recovery Efficiency |

| SDBS | Sodium Dodecyl Benzene Sulfonate |

| SIMGAP | Simultaneous Injection of Miscible Gas and Polymer |

| SIWAP | Simultaneous Injection of Water and Polymer |

| SMG | Soft Micro Gel Polymers |

| SP | Surfactant–Polymer |

| STARPAM | Star-shaped Polymer of Polyacrylamide |

| TDS | Total Dissolved Solids |

| TVP | Thermo-Viscosifying Polymers |

| UTCHEM | University of Texas Chemical Simulator |

| VP | Vinylpyrrolidone |

References

- Bob, D. BP Energy Outlook; Report–BP Energy Economics; BP Energy Economics: London, UK, 2018. [Google Scholar]

- BP Energy Economics. BP Statistical Review of World Energy. Available online: https://www.imemo.ru/files/File/ru/events/2021/BP-2021.pdf (accessed on 10 February 2022).

- British Petroleum. BP Statistical Review of World Energy 2020: A Pivotal Moment. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf (accessed on 10 February 2022).

- Kokal, S.; Al-Kaabi, A. Enhanced Oil Recovery: Challenges & Opportunities; World Petroleum Council: Official Publication: London, UK, 2010; Volume 64, pp. 64–69. [Google Scholar]

- Roehl, P.O.; Choquette, P.W. Carbonate Petroleum Reservoirs; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Akbar, M.; Vissapragada, B.; Alghamdi, A.H.; Allen, D.; Herron, M.; Carnegie, A.; Dutta, D.; Olesen, J.R.; Chourasiya, R.; Logan, D.; et al. A snapshot of carbonate reservoir evaluation. Oilfield Rev. 2000, 12, 20–21. [Google Scholar]

- Cuiec, L. Rock/crude-oil interactions and wettability: An attempt to understand their interrelation. In SPE Annual Technical Conference and Exhibition; OnePetro: Richardson, TX, USA, 1984. [Google Scholar]

- Diab, W.N.; Al-Shalabi, E.W. Recent developments in polymer flooding for carbonate reservoirs under harsh conditions. In Offshore Technology Conference Brasil; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Lake, L.W. Enhanced Oil Recovery; U.S. Department of Energy: Washington, DC, USA, 1989.

- Stone, H.; Garder, A., Jr. Analysis of gas-cap or dissolved-gas drive reservoirs. Soc. Pet. Eng. J. 1961, 1, 92–104. [Google Scholar] [CrossRef]

- Taber, J.J.; Martin, F.D.; Seright, R. EOR screening criteria revisited-Part 1: Introduction to screening criteria and enhanced recovery field projects. SPE Reserv. Eng. 1997, 12, 189–198. [Google Scholar] [CrossRef] [Green Version]

- Al-Shalabi, E.W.; Alameri, W.; Hassan, A.M. Mechanistic modeling of hybrid low salinity polymer flooding: Role of geochemistry. J. Pet. Sci. Eng. 2022, 210, 110013. [Google Scholar] [CrossRef]

- Hassan, A.; Ayoub, M.; Eissa, M.; Bruining, H.; Al-Mansour, A.; Al-Guraishi, A. A Novel Hybrid Enhanced Oil Recovery Method by Smart Water-Injection and Foam-Flooding in Carbonate Reservoirs. In SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition; OnePetro: Richardson, TX, USA, 2020. [Google Scholar]

- Hassan, A.M.; Ayoub, M.; Eissa, M.; Bruining, H.; Zitha, P. Study of surface complexation modeling on a novel hybrid enhanced oil recovery (EOR) method; smart-water assisted foam-flooding. J. Pet. Sci. Eng. 2020, 195, 107563. [Google Scholar] [CrossRef]

- Hassan, A.; Ayoub, M.; Eissa, M.; Bruining, H.; Al-Mansour, A.; Al-Quraishi, A. A New Hybrid Improved and Enhanced Oil Recovery IOR/EOR Process Using Smart Water Assisted Foam SWAF Flooding in Carbonate Rocks; A Laboratory Study Approach. In International Petroleum Technology Conference; OnePetro: Richardson, TX, USA, 2021. [Google Scholar]

- Hassan, A.M.; Ayoub, M.; Eissa, M.; Al-Shalabi, E.W.; Almansour, A.; Alquraishi, A. Foamability and Foam Stability Screening for Smart Water Assisted Foam Flooding: A New Hybrid EOR Method. In International Petroleum Technology Conference; OnePetro: Richardson, TX, USA, 2022. [Google Scholar]

- Hassan, A.M.; Ayoub, M.A.; Mohyadinn, M.E.; Al-Shalabi, E.W.; Alakbari, F.S. A New Insight into Smart Water Assisted Foam SWAF Technology in Carbonate Rocks using Artificial Neural Networks ANNs. In Offshore Technology Conference Asia; OnePetro: Richardson, TX, USA, 2022. [Google Scholar]

- Hassan, A.M.; Ayoub, M.A.; Mohyadinn, M.E.; Al-Shalabi, E.W.; Al-Mansour, A.; Alquraishi, A. Increasing Reservoir Recovery Efficiency through Laboratory-Proven Hybrid Smart Water-Assisted Foam (SWAF) Flooding in Carbonate Reservoirs. Energies 2022, 15, 3058. [Google Scholar] [CrossRef]

- Babadagli, T. Development of mature oil fields—A review. J. Pet. Sci. Eng. 2007, 57, 221–246. [Google Scholar] [CrossRef]

- Turner, J.A. Sustainable hydrogen production. Science 2004, 305, 972–974. [Google Scholar] [CrossRef] [PubMed]

- Hassanpouryouzband, A.; Yang, J.; Tohidi, B.; Chuvilin, E.; Istomin, V.; Bukhanov, B.; Cheremisin, A. CO2 capture by injection of flue gas or CO2–N2 mixtures into hydrate reservoirs: Dependence of CO2 capture efficiency on gas hydrate reservoir conditions. Environ. Sci. Technol. 2018, 52, 4324–4330. [Google Scholar] [CrossRef]

- Lwisa, E. Chemical Enhanced Oil Recovery. Available online: https://www.researchgate.net/profile/Essa-Lwisa/publication/352241416_Chemical_Enhanced_Oil_Recovery/links/60d18fce92851ca3acbb2612/Chemical-Enhanced-Oil-Recovery.pdf (accessed on 14 February 2022).

- Reiter, P.K. A Water-Sensitive Sandstone Flood Using Low Salinity Water. Master’s Thesis, University of Oklahoma, Norman, OK, USA, 1961. [Google Scholar]

- Bernard, G.G. Effect of floodwater salinity on recovery of oil from cores containing clays. In SPE California Regional Meeting; OnePetro: Richardson, TX, USA, 1967. [Google Scholar]

- Hallenbeck, L.; Sylte, J.; Ebbs, D.; Thomas, L. Implementation of the Ekofisk field waterflood. SPE Form. Eval. 1991, 6, 284–290. [Google Scholar] [CrossRef]

- Romanuka, J.; Hofman, J.; Ligthelm, D.J.; Suijkerbuijk, B.; Marcelis, A.; Oedai, S.; Brussee, N.; van der Linde, A.; Aksulu, H.; Austad, T. Low salinity EOR in carbonates. In SPE Improved Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2012. [Google Scholar]

- Shariatpanahi, S.F.; Strand, S.; Austad, T. Initial wetting properties of carbonate oil reservoirs: Effect of the temperature and presence of sulfate in formation water. Energy Fuels 2011, 25, 3021–3028. [Google Scholar] [CrossRef]

- Aghaeifar, Z.; Strand, S.; Austad, T.; Puntervold, T.; Aksulu, H.; Navratil, K.; Storas, S.; Hamsø, D. Influence of formation water salinity/composition on the low-salinity enhanced oil recovery effect in high-temperature sandstone reservoirs. Energy Fuels 2015, 29, 4747–4754. [Google Scholar] [CrossRef]

- Morrow, N.; Buckley, J. Improved oil recovery by low-salinity waterflooding. J. Pet. Technol. 2011, 63, 106–112. [Google Scholar] [CrossRef]

- Jadhunandan, P.P. Effects of Brine Composition, Crude Oil, and Aging Conditions on Wettability and Oil Recovery. Ph.D. Thesis, Department of Petroleum Engineering, New Mexico Institute of Mining & Technology, Socorro, NM, USA, 1990. [Google Scholar]

- Nasralla, R.A.; Alotaibi, M.B.; Nasr-El-Din, H.A. Efficiency of oil recovery by low salinity water flooding in sandstone reservoirs. In SPE Western North American Region Meeting; OnePetro: Richardson, TX, USA, 2011. [Google Scholar]

- Firozjaii, A.M.; Saghafi, H.R. Review on chemical enhanced oil recovery using polymer flooding: Fundamentals, experimental and numerical simulation. Petroleum 2020, 6, 115–122. [Google Scholar] [CrossRef]

- Green, D.W.; Willhite, G.P. Enhanced Oil Recovery; Henry L. Doherty Memorial Fund of AIME, Society of Petroleum Engineers: Richardson, TX, USA, 1998; Volume 6. [Google Scholar]

- Lake, L.W.; Johns, R.; Rossen, B.; Pope, G.A. Fundamentals of Enhanced Oil Recovery; Society of Petroleum Engineers Richardson: Richardson, TX, USA, 2014; Volume 1. [Google Scholar]

- Brownell, L.E.; Katz, D.L. Flow of fluids through porous media. 1. Single homogeneous fluids. Chem. Eng. Prog. 1947, 43, 537–548. [Google Scholar]

- Rellegadla, S.; Prajapat, G.; Agrawal, A. Polymers for enhanced oil recovery: Fundamentals and selection criteria. Appl. Microbiol. Biotechnol. 2017, 101, 4387–4402. [Google Scholar] [CrossRef]

- Ragab, A.; Mansour, E.M. Enhanced Oil Recovery: Chemical Flooding. In Geophysics and Ocean Waves Studies; IntechOpen: London UK, 2021. [Google Scholar]

- Shakeel, M.; Pourafshary, P.; Rehan Hashmet, M. Hybrid Engineered Water–Polymer Flooding in Carbonates: A Review of Mechanisms and Case Studies. Appl. Sci. 2020, 10, 6087. [Google Scholar] [CrossRef]

- Chieng, Z.; Mohyaldinn, M.E.; Hassan, A.; Bruining, H. Experimental investigation and performance evaluation of modified viscoelastic surfactant (VES) as a new thickening fracturing fluid. Polymers 2020, 12, 1470. [Google Scholar] [CrossRef]

- Li, X.; Zhang, F.; Liu, G. Review on polymer flooding technology. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 675, p. 012199. [Google Scholar]

- Karimov, D.; Hashmet, M.R.; Pourafshary, P. A laboratory study to optimize ion composition for the hybrid low salinity water/polymer flooding. In Offshore Technology Conference Asia; OnePetro: Richardson, TX, USA, 2020. [Google Scholar]

- Musa, T.A.; Ibrahim, A.F.; Nasr-El-Din, H.A.; Hassan, A. New insights into guar gum as environmentally friendly polymer for enhanced oil recovery in high-salinity and high-temperature sandstone reservoirs. J. Pet. Explor. Prod. 2021, 11, 1905–1913. [Google Scholar] [CrossRef]

- Kamal, M.S.; Sultan, A.S.; Al-Mubaiyedh, U.A.; Hussein, I.A. Review on polymer flooding: Rheology, adsorption, stability, and field applications of various polymer systems. Polym. Rev. 2015, 55, 491–530. [Google Scholar] [CrossRef]

- Jouenne, S. Polymer flooding in high temperature, high salinity conditions: Selection of polymer type and polymer chemistry, thermal stability. J. Pet. Sci. Eng. 2020, 195, 107545. [Google Scholar] [CrossRef]

- Li, J.; Liu, W.; Sun, L.; Cong, S.; Jia, R.; Zhang, J.; Yang, Y. Effect of Emulsification on Surfactant Partitioning in Surfactant-Polymer Flooding. J. Surfactants Deterg. 2019, 22, 1387–1394. [Google Scholar] [CrossRef]

- Guilyardi, E.; Lescarmontier, L.; Matthews, R.; Point, S.P.; Rumjaun, A.B.; Schlüpmann, J.; Wilgenbus, D. IPCC Special Report “Global Warming of 1.5 ∘C”: Summary for Teachers; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Wu, D.; Hao, J.; Wang, W.; Yu, Y.; Fu, X.Z.; Luo, J.L. Energy-saving H2 Generation Coupled with Oxidative Alcohol Refining over Bimetallic Phosphide Ni2P- CoP Junction Bifunctional Electrocatalysts. ChemSusChem 2021, 14, 5450–5459. [Google Scholar] [CrossRef] [PubMed]

- Abe, J.O.; Popoola, A.; Ajenifuja, E.; Popoola, O. Hydrogen energy, economy and storage: Review and recommendation. Int. J. Hydrog. Energy 2019, 44, 15072–15086. [Google Scholar] [CrossRef]

- Mouli-Castillo, J.; Wilkinson, M.; Mignard, D.; McDermott, C.; Haszeldine, R.S.; Shipton, Z.K. Inter-seasonal compressed-air energy storage using saline aquifers. Nat. Energy 2019, 4, 131–139. [Google Scholar] [CrossRef]

- Scafidi, J.; Wilkinson, M.; Gilfillan, S.M.; Heinemann, N.; Haszeldine, R.S. A quantitative assessment of the hydrogen storage capacity of the UK continental shelf. Int. J. Hydrogen Energy 2021, 46, 8629–8639. [Google Scholar] [CrossRef]

- Heinemann, N.; Alcalde, J.; Miocic, J.M.; Hangx, S.J.; Kallmeyer, J.; Ostertag-Henning, C.; Hassanpouryouzband, A.; Thaysen, E.M.; Strobel, G.J.; Schmidt-Hattenberger, C.; et al. Enabling large-scale hydrogen storage in porous media—The scientific challenges. Energy Environ. Sci. 2021, 14, 853–864. [Google Scholar] [CrossRef]

- Silva, I.G.; de Melo, M.A.; Luvizotto, J.M.; Lucas, E.F. Polymer flooding: A sustainable enhanced oil recovery in the current scenario. In Latin American & Caribbean Petroleum Engineering Conference; OnePetro: Richardson, TX, USA, 2007. [Google Scholar]

- Algharaib, M.; Alajmi, A.; Gharbi, R. Improving polymer flood performance in high salinity reservoirs. J. Pet. Sci. Eng. 2014, 115, 17–23. [Google Scholar] [CrossRef]

- Klimenko, A.; Molinier, V.; Dubos, F.; Joly, M.; Saint-Loubert, M.; Jouenne, S.; Passade-Boupat, N.; Bourrel, M. Surfactant–Polymer Flooding at High Temperature and High Salinity: Promising Lab Scale Experiments in Challenging Conditions. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2020. [Google Scholar]

- Telmadarreie, A.; Trivedi, J.J. Static and dynamic performance of wet foam and polymer-enhanced foam in the presence of heavy oil. Colloids Interfaces 2018, 2, 38. [Google Scholar] [CrossRef] [Green Version]

- Sheng, J.J. Status of surfactant EOR technology. Petroleum 2015, 1, 97–105. [Google Scholar] [CrossRef] [Green Version]

- Samanta, A.; Bera, A.; Ojha, K.; Mandal, A. Effects of alkali, salts, and surfactant on rheological behavior of partially hydrolyzed polyacrylamide solutions. J. Chem. Eng. Data 2010, 55, 4315–4322. [Google Scholar] [CrossRef]

- Sorbie, K.S. Polymer-Improved Oil Recovery; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Xu, X.; Saeedi, A.; Rezaee, R.a.; Liu, K. Investigation on a novel polymer with surface activity for polymer enhanced CO2 foam flooding. In SPE International Symposium on Oilfield Chemistry; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Seright, R.S.; Fan, T.; Wavrik, K.; de Carvalho Balaban, R. New insights into polymer rheology in porous media. SPE J. 2011, 16, 35–42. [Google Scholar] [CrossRef]

- Zaitoun, A.; Makakou, P.; Blin, N.; Al-Maamari, R.S.; Al-Hashmi, A.; Abdel-Goad, M.; Al-Sharji, H.H. Shear stability of EOR polymers. SPE J. 2012, 17, 335–339. [Google Scholar] [CrossRef]

- Hashmet, M.R.; Qaiser, Y.; Mathew, E.S.; AlAmeri, W.; AlSumaiti, A.M. Injection of polymer for improved sweep efficiency in high temperature high salinity carbonate reservoirs: Linear X-ray aided flood front monitoring. In SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition; OnePetro: Richardson, TX, USA, 2017. [Google Scholar]

- Unsal, E.; Ten Berge, A.; Wever, D. Low salinity polymer flooding: Lower polymer retention and improved injectivity. J. Pet. Sci. Eng. 2018, 163, 671–682. [Google Scholar] [CrossRef]

- Han, M.; Zhou, X.; Alhasan, F.B.; Zahrani, B.; AlSofi, A.M. Laboratory investigation of the injectivity of sulfonated polymer solutions into carbonate reservoir rocks. In SPE EOR Conference at Oil and Gas West Asia; OnePetro: Richardson, TX, USA, 2012. [Google Scholar]

- Alfazazi, U.; AlAmeri, W.; Hashmet, M.R. Experimental investigation of polymer flooding with low-salinity preconditioning of high temperature–high-salinity carbonate reservoir. J. Pet. Explor. Prod. Technol. 2019, 9, 1517–1530. [Google Scholar] [CrossRef] [Green Version]

- Levitt, D.; Pope, G.A. Selection and screening of polymers for enhanced-oil recovery. In SPE Symposium on Improved oil Recovery; OnePetro: Richardson, TX, USA, 2008. [Google Scholar]

- Gaillard, N.; Giovannetti, B.; Favero, C.; Caritey, J.P.; Dupuis, G.; Zaitoun, A. New water soluble anionic NVP acrylamide terpolymers for use in harsh EOR conditions. In SPE Improved Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2014. [Google Scholar]

- Sorbie, K. Polymer-Improved Oil Recovery, 115 Glasgow; Blackie & Son: Scotland, UK, 1991; pp. 126–163. [Google Scholar]

- Thomas, R.; Morgenthaler, L. Introduction to matrix treatments. In Reservoir Stimulation; Elsevier B.V.: Amsterdam, The Netherlands, 1999; pp. 1–38. [Google Scholar]

- Alfazazi, U.; AlAmeri, W.; Hashmet, M.R. Screening of new HPaM base polymers for applications in high temperature and high salinity carbonate reservoirs. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Gaillard, N.; Giovannetti, B.; Leblanc, T.; Thomas, A.; Braun, O.; Favero, C. Selection of customized polymers to enhance oil recovery from high temperature reservoirs. In SPE Latin American and Caribbean Petroleum Engineering Conference; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Sheng, J.J. Modern Chemical Enhanced Oil Recovery: Theory and Practice; Gulf Professional Publishing: London, UK, 2010. [Google Scholar]

- Taber, J.J. Technical screening guides for the enhanced recovery of oil. In SPE Annual Technical Conference and Exhibition; OnePetro: Richardson, TX, USA, 1983. [Google Scholar]

- Goodlett, G.; Honarpour, M.; Chung, F.; Sarathi, P. The role of screening and laboratory flow studies in EOR process evaluation. In SPE Rocky Mountain Regional Meeting; OnePetro: Richardson, TX, USA, 1986. [Google Scholar]

- Gao, C.H. Scientific research and field applications of polymer flooding in heavy oil recovery. J. Pet. Explor. Prod. Technol. 2011, 1, 65–70. [Google Scholar] [CrossRef] [Green Version]

- Kang, P.S.; Lim, J.S.; Huh, C. Screening criteria for application of EOR processes in offshore fields. In Proceedings of the Twenty-Fourth International Ocean and Polar Engineering Conference, Busan, Korea, 15–20 June 2014; OnePetro: Richardson, TX, USA, 2014. [Google Scholar]

- Saleh, L.D.; Wei, M.; Bai, B. Data analysis and updated screening criteria for polymer flooding based on oilfield data. SPE Reserv. Eval. Eng. 2014, 17, 15–25. [Google Scholar] [CrossRef]

- Standnes, D.C.; Skjevrak, I. Literature review of implemented polymer field projects. J. Pet. Sci. Eng. 2014, 122, 761–775. [Google Scholar] [CrossRef]

- Saboorian-Jooybari, H.; Dejam, M.; Chen, Z. Half-century of heavy oil polymer flooding from laboratory core floods to pilot tests and field applications. In SPE Canada Heavy Oil Technical Conference; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Zhang, Y.; Wei, M.; Bai, B.; Yang, H.; Kang, W. Survey and data analysis of the pilot and field polymer flooding projects in China. In SPE Improved Oil Recovery Conference; OnePetro: Richardson, TX, USA, 2016. [Google Scholar]

- Rivas, C.; Gathier, F. C-EOR projects–offshore challenges. In Proceedings of the Twenty-Third International Offshore and Polar Engineering Conference, Anchorage, AK, USA, 30 June–5 July 2013; OnePetro: Richardson, TX, USA, 2013. [Google Scholar]

- Chapman, E.; Mercer, D.; Jerauld, G.; Shields, R.; Sorbie, K.; Mogford, D.; Cable, A. Polymer flooding for EOR in the Schiehallion Field-porous flow rheological studies of high molecular weight polymers. In Proceedings of the IOR 2015—18th European Symposium on Improved Oil Recovery, Dresden, Germany, 16 April 2015; European Association of Geoscientists & Engineers: Dubai, United Arab Emirates, 2015; p. cp-445. [Google Scholar]

- Poulsen, A.; Shook, G.M.; Jackson, A.; Ruby, N.; Charvin, K.; Dwarakanath, V.; Thach, S.; Ellis, M. Results of the UK Captain Field interwell EOR pilot. In SPE Improved Oil Recovery Conference; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Wang, W.; Lu, X. Property evaluation of EOR technology by means of expansive granular crosslinked polymer. In SPE Production and Operations Symposium; OnePetro: Richardson, TX, USA, 2009. [Google Scholar]

- Jouenne, S.; Chakibi, H.; Levitt, D. Polymer stability after successive mechanical-degradation events. SPE J. 2018, 23, 18–33. [Google Scholar] [CrossRef]

- Seright, R.S. The effects of mechanical degradation and viscoelastic behavior on injectivity of polyacrylamide solutions. Soc. Pet. Eng. J. 1983, 23, 475–485. [Google Scholar] [CrossRef]

- Kaminsky, R.D.; Wattenbarger, R.C.; Szafranski, R.C.; Coutee, A. Guidelines for polymer flooding evaluation and development. In IPTC 2007: International Petroleum Technology Conference; European Association of Geoscientists & Engineers: Dubai, United Arab Emirates, 2007; p. cp-147. [Google Scholar]

- Hassan, A.M.; Ayoub, M.; Eissa, M.; Musa, T.; Bruining, H.; Farajzadeh, R. Exergy return on exergy investment analysis of natural-polymer (Guar-Arabic gum) enhanced oil recovery process. Energy 2019, 181, 162–172. [Google Scholar] [CrossRef] [Green Version]

- Farajzadeh, R.; Kahrobaei, S.; De Zwart, A.; Boersma, D. Life-cycle production optimization of hydrocarbon fields: Thermoeconomics perspective. Sustain. Energy Fuels 2019, 3, 3050–3060. [Google Scholar] [CrossRef] [Green Version]

- Thomas, A. Polymer Flooding. In Chemical Enhanced Oil Recovery (cEOR)—A Practical Overview; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Han, M.; AlSofi, A.; Fuseni, A.; Zhou, X.; Hassan, S. Development of chemical EOR formulations for a high temperature and high salinity carbonate reservoir. In IPTC 2013: International Petroleum Technology Conference; European Association of Geoscientists & Engineers: Dubai, United Arab Emirates, 2013; p. cp-350. [Google Scholar]

- Wever, D.; Picchioni, F.; Broekhuis, A. Polymers for enhanced oil recovery: A paradigm for structure—Property relationship in aqueous solution. Prog. Polym. Sci. 2011, 36, 1558–1628. [Google Scholar] [CrossRef]

- Lee, V.B. The Development and Evaluation of Polymers for Enhanced Oil Recovery. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2015. [Google Scholar]

- Pu, W.; Shen, C.; Wei, B.; Yang, Y.; Li, Y. A comprehensive review of polysaccharide biopolymers for enhanced oil recovery (EOR) from flask to field. J. Ind. Eng. Chem. 2018, 61, 1–11. [Google Scholar] [CrossRef]

- Delamaide, E. Polymers and their limits in temperature, salinity and hardness: Theory and practice. In SPE Asia Pacific Oil and Gas Conference and Exhibition; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Scott, A.J.; Romero-Zerón, L.; Penlidis, A. Evaluation of polymeric materials for chemical enhanced oil recovery. Processes 2020, 8, 361. [Google Scholar] [CrossRef] [Green Version]

- Fu, M.L.; Zhou, J.C.; Xiong, F.; YE, C.; WANG, R.H. A Study on Formation Plugging Mechanism of Cross linked Polymer Flooding in Henan Oilfield. Oilfield Chem. 2010, 2, 188–191. [Google Scholar]

- Chang, H.; Zhang, Z.; Wang, Q.; Xu, Z.; Guo, Z.; Sun, H.; Cao, X.; Qiao, Q. Advances in polymer flooding and alkaline/surfactant/polymer processes as developed and applied in the People’s Republic of China. J. Pet. Technol. 2006, 58, 84–89. [Google Scholar] [CrossRef]

- Levitt, D.; Klimenko, A.; Jouenne, S.; Chamerois, M.; Bourrel, M. Overcoming design challenges of chemical EOR in high-temperature, high salinity carbonates. In SPE Middle East Oil and Gas Show and Conference; OnePetro: Richardson, TX, USA, 2013. [Google Scholar]

- Moradi-Araghi, A.; Cleveland, D.; Westerman, I. Development and evaluation of eor polymers suitable for hostile environments: II-Copolymers of acrylamide and sodium AMPS. In SPE International Symposium on Oilfield Chemistry; OnePetro: Richardson, TX, USA, 1987. [Google Scholar]

- Seright, R.S.; Campbell, A.; Mozley, P.; Han, P. Stability of partially hydrolyzed polyacrylamides at elevated temperatures in the absence of divalent cations. SPE J. 2010, 15, 341–348. [Google Scholar] [CrossRef]

- Zaitoun, A.; Potie, B. Limiting conditions for the use of hydrolyzed polyacrylamides in brines containing divalent ions. In SPE Oilfield and Geothermal Chemistry Symposium; OnePetro: Richardson, TX, USA, 1983. [Google Scholar]

- Wang, G.; Yi, X.; Feng, X.; Jing, B.; Ouyang, J. Synthesis and study of a new copolymer for polymer flooding in high-temperature, high-salinity reservoirs. Chem. Technol. Fuels Oils 2012, 48, 112–119. [Google Scholar] [CrossRef]

- Wu, X.; Yang, Z.; Xu, H.; Zhang, L.; Xiong, C.; Yang, H.; Shao, L.; Kang, B.; Fu, Y.; Tian, X.; et al. Success and lessons learned from polymerflooding a ultra high temperature and ultra high salinity oil reservoir-A case study from west China. In SPE Improved Oil Recovery Conference; OnePetro: Richardson, TX, USA, 2016. [Google Scholar]

- Firozjaii, A.M.; Moradi, S. Sensitivity analysis and optimization of the effective parameters on ASP flooding compared to polymer flooding using CMG-STARS. J. Pet. Environ. Biotechnol. 2018, 9, 2. [Google Scholar] [CrossRef]

- Khune, G.; Donaruma, L.; Hatch, M.; Kilmer, N.; Shepitka, J.; Martin, F. Modified acrylamide polymers for enhanced oil recovery. J. Appl. Polym. Sci. 1985, 30, 875–885. [Google Scholar] [CrossRef]

- Sabhapondit, A.; Borthakur, A.; Haque, I. Characterization of acrylamide polymers for enhanced oil recovery. J. Appl. Polym. Sci. 2003, 87, 1869–1878. [Google Scholar] [CrossRef]

- Dimitrov, I.; Trzebicka, B.; Müller, A.H.; Dworak, A.; Tsvetanov, C.B. Thermosensitive water-soluble copolymers with doubly responsive reversibly interacting entities. Prog. Polym. Sci. 2007, 32, 1275–1343. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Z.Y.; Han, Y.G.; Feng, Y.J.; Tang, C.L. A novel thermoviscosifying water-soluble polymer for enhancing oil recovery from high-temperature and high-salinity oil reservoirs. In Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2011; Volume 306, pp. 654–657. [Google Scholar]

- Wu, Y.; Liu, X.; Wang, Y.; Guo, Z.; Feng, Y. Synthesis and Aggregation Behaviors of Well-Defined Thermoresponsive Pentablock Terpolymers with Tunable LCST. Macromol. Chem. Phys. 2012, 213, 1489–1498. [Google Scholar] [CrossRef]

- Shepitka, J.; Case, C.; Donaruma, L.; Hatch, M.; Kilmer, N.; Khune, G.; Martin, F.; Ward, J.; Wilson, K. Partially imidized, water-soluble polymeric amides. I. Partially imidized polyacrylamide and polymethacrylamide. J. Appl. Polym. Sci. 1983, 28, 3611–3617. [Google Scholar] [CrossRef]

- Liu, J.F.; Feng, J.Y.; Yang, S.Z.; Gang, H.Z.; Mu, B.Z. The recovery of viscosity of HPAM solution in presence of high concentration sulfide ions. J. Pet. Sci. Eng. 2020, 195, 107605. [Google Scholar] [CrossRef]

- Davison, P.; Mentzer, E. Polymer flooding in North Sea reservoirs. Soc. Pet. Eng. J. 1982, 22, 353–362. [Google Scholar] [CrossRef]

- Moradi-Araghi, A.; Doe, P.H. Hydrolysis and precipitation of polyacrylamides in hard brines at elevated temperatures. SPE Reserv. Eng. 1987, 2, 189–198. [Google Scholar] [CrossRef]

- Maitin, B. Performance analysis of several polyacrylamide floods in North German oil fields. In SPE/DOE Enhanced Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 1992. [Google Scholar]

- Berge, A.; Lenchenkov, N.; Wever, D.; Farajzadeh, R.; Al-Mjeni, R.; Glasbergen, G. The role of synthetic polymer on rock-fluid interactions and the resulting change in ionic composition and viscosity of the polymer slug for a ceor flood in the sultanate of oman. In SPE EOR Conference at Oil and Gas West Asia; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Pope, G.; Nelson, R. A chemical flooding compositional simulator. Soc. Pet. Eng. J. 1978, 18, 339–354. [Google Scholar] [CrossRef]

- Ghannam, M.T.; Esmail, M.N. Rheological properties of aqueous polyacrylamide solutions. J. Appl. Polym. Sci. 1998, 69, 1587–1597. [Google Scholar] [CrossRef]

- Quadri, S.M.; Jiran, L.; Shoaib, M.; Hashmet, M.R.; AlSumaiti, A.M.; Alhassan, S.M. Application of biopolymer to improve oil recovery in high temperature high salinity carbonate reservoirs. In Abu Dhabi International Petroleum Exhibition and Conference; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Quadri, S.M.R.; Shoaib, M.; AlSumaiti, A.M.; Alhassan, S.M. Screening of polymers for EOR in high temperature, high salinity and carbonate reservoir conditions. In International Petroleum Technology Conference; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Liu, Y.; Jessop, P.G.; Cunningham, M.; Eckert, C.A.; Liotta, C.L. Switchable surfactants. Science 2006, 313, 958–960. [Google Scholar] [CrossRef] [PubMed]

- Sarsenbekuly, B.; Kang, W.; Fan, H.; Yang, H.; Dai, C.; Zhao, B.; Aidarova, S.B. Study of salt tolerance and temperature resistance of a hydrophobically modified polyacrylamide based novel functional polymer for EOR. Colloids Surfaces A Physicochem. Eng. Asp. 2017, 514, 91–97. [Google Scholar] [CrossRef]

- Xu, Y.; Gao, P.; Yang, M.; Huang, G.; Wang, B. Synthesis and aqueous solution properties of a novel nonionic, amphiphilic comb-type polyacrylamide. J. Macromol. Sci. Part B 2011, 50, 1691–1704. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, J.; Xu, X.; Liu, W.; Zhang, J.; Fan, M.; Wang, J. Synthesis and characterization of a series of modified polyacrylamide. Colloid Polym. Sci. 2009, 287, 237–241. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Z.; Wu, K.; Hou, Q.; Long, H. Enhanced oil recovery by chemical flooding from the biostromal carbonate reservoir. In SPE Enhanced Oil Recovery Conference; OnePetro: Richardson, TX, USA, 2013. [Google Scholar]

- Doe, P.H.; Moradi-Araghi, A.; Shaw, J.E.; Stahl, G.A. Development and evaluation of EOR polymers suitable for hostile environments part 1: Copolymers of vinylpyrrolidone and acrylamide. SPE Reserv. Eng. 1987, 2, 461–467. [Google Scholar] [CrossRef]

- Bridgewater, J.; Pace, S.; Gardner, G.; Schulz, D. Enhanced Oil Recovery with Hydrophobically Associating Polymers Containing N-Vinyl-Pyrrolidone Functionality; Technical Report; U.S. Department of Energy: Washington, DC, USA, 1987. [Google Scholar]

- Gaillard, N.; Giovannetti, B.; Favero, C. Improved oil recovery using thermally and chemically protected compositions based on co-and ter-polymers containing acrylamide. In SPE Improved Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2010. [Google Scholar]

- Kulawardana, E.U.; Koh, H.; Kim, D.H.; Liyanage, P.J.; Upamali, K.A.; Huh, C.; Weerasooriya, U.; Pope, G.A. Rheology and transport of improved EOR polymers under harsh reservoir conditions. In SPE Improved Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2012. [Google Scholar]

- Vermolen, E.; Van Haasterecht, M.; Masalmeh, S.K.; Faber, M.J.; Boersma, D.M.; Gruenenfelder, M. Pushing the envelope for polymer flooding towards high-temperature and high-salinity reservoirs with polyacrylamide based ter-polymers. In SPE Middle East Oil and Gas Show and Conference; OnePetro: Richardson, TX, USA, 2011. [Google Scholar]

- Uhl, J.; Ching, T.; Bae, J. A laboratory study of new, surfactant-containing polymers for high-salinity reservoirs. SPE Adv. Technol. Ser. 1995, 3, 113–119. [Google Scholar] [CrossRef]

- Kathmann, E.E.; McCormick, C.L. Water-soluble polymers. 71. pH responsive behavior of terpolymers of sodium acrylate, acrylamide, and the zwitterionic monomer 4-(2-acrylamido-2-methylpropanedimethylammonio) butanoate. J. Polym. Sci. Part A: Polym. Chem. 1997, 35, 231–242. [Google Scholar] [CrossRef]

- Fernandez, I. Evaluation of cationic water-soluble polymers with improved thermal stability. In SPE International Symposium on Oilfield Chemistry; OnePetro: Richardson, TX, USA, 2005. [Google Scholar]

- Zou, C.; Zhao, P.; Ge, J.; Lei, Y.; Luo, P. β-Cyclodextrin modified anionic and cationic acrylamide polymers for enhancing oil recovery. Carbohydr. Polym. 2012, 87, 607–613. [Google Scholar] [CrossRef]

- Argillier, J.F.; Audibert, A.; Lecourtier, J.; Moan, M.; Rousseau, L. Solution and adsorption properties of hydrophobically associating water-soluble polyacrylamides. Colloids Surfaces A Physicochem. Eng. Asp. 1996, 113, 247–257. [Google Scholar] [CrossRef]

- Lijian, D.; Biao, W. Hydrophobically associating terpolymer and its complex with a stabilizer in brine for enhanced oil recovery. In SPE International Symposium on Oilfield Chemistry; OnePetro: Richardson, TX, USA, 1995. [Google Scholar]

- Jiang, W.; Kang, X.; Xie, K.; Lu, X. Degree of the association of hydrophobically associating polymer and its adaptability to the oil reservoir. Pet. Geol. Oilfield Dev. Daqing 2013, 32, 103–107. [Google Scholar]

- Jiang, J.; Rui, Z.; Hazlett, R.; Lu, J. An integrated technical-economic model for evaluating CO2 enhanced oil recovery development. Appl. Energy 2019, 247, 190–211. [Google Scholar] [CrossRef]

- Feng, Y.; Billon, L.; Grassl, B.; Bastiat, G.; Borisov, O.; François, J. Hydrophobically associating polyacrylamides and their partially hydrolyzed derivatives prepared by post-modification. 2. Properties of non-hydrolyzed polymers in pure water and brine. Polymer 2005, 46, 9283–9295. [Google Scholar] [CrossRef]

- Feng, Y.; Billon, L.; Grassl, B.; Khoukh, A.; François, J. Hydrophobically associating polyacrylamides and their partially hydrolyzed derivatives prepared by post-modification. 1. Synthesis and characterization. Polymer 2002, 43, 2055–2064. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Zheng, X.; CHEN, H.l.; MING, H. Sealing characteristics of compound system of cross-link polymer microspheres and association polymer. Mod. Chem. Ind. 2013, 33, 86–89. [Google Scholar]

- Blencowe, A.; Tan, J.F.; Goh, T.K.; Qiao, G.G. Core cross-linked star polymers via controlled radical polymerisation. Polymer 2009, 50, 5–32. [Google Scholar] [CrossRef] [Green Version]

- Iwashita, J.; Hirayama, T.; Takagi, I.; Matsuzawa, K.; Suzuki, K.; Yoshizawa, S.; Konno, K.; Yahagi, M.; Sato, K.; Tagawa, S.; et al. Characteristics of main chain decomposable STAR polymer for EUV resist. In Advances in Resist Materials and Processing Technology XXVIII; International Society for Optics and Photonics: Bellingham, WA, USA, 2011; Volume 7972, p. 79720L. [Google Scholar]

- Wenli, L.; Dong, H.; Li, W.; Qingxia, L.; Jian, F. Synthesis and property evaluation of a salt-and alkali-resistant star-polymer. Pet. Explor. Dev. 2010, 37, 477–482. [Google Scholar] [CrossRef]

- Li, X.; Yin, H.Y.; Zhang, R.S.; Cui, J.; Wu, J.W.; Feng, Y.J. A salt-induced viscosifying smart polymer for fracturing inter-salt shale oil reservoirs. Pet. Sci. 2019, 16, 816–829. [Google Scholar] [CrossRef] [Green Version]

- Nasr, S.; Soudi, M.R.; Haghighi, M. Xanthan production by a native strain of X. campestris and evaluation of application in EOR. Pak. J. Biol. Sci. PJBS 2007, 10, 3010–3013. [Google Scholar] [CrossRef]

- Seright, R.S.; Wavrik, K.E.; Zhang, G.; AlSofi, A.M. Stability and behavior in carbonate cores for new enhanced-oil-recovery polymers at elevated temperatures in hard saline brines. SPE Reserv. Eval. Eng. 2021, 24, 1–18. [Google Scholar] [CrossRef]

- Alquraishi, A.A.; Alsewailem, F.D. Xanthan and guar polymer solutions for water shut off in high salinity reservoirs. Carbohydr. Polym. 2012, 88, 859–863. [Google Scholar] [CrossRef]

- Rivenq, R.; Donche, A.; Nolk, C. Improved scleroglucan for polymer flooding under harsh reservoir conditions. SPE Reserv. Eng. 1992, 7, 15–20. [Google Scholar] [CrossRef]

- Kalpakci, B.; Jeans, Y.; Magri, N.; Padolewski, J. Thermal stability of scleroglucan at realistic reservoir conditions. In SPE/DOE Enhanced Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 1990. [Google Scholar]

- Zohuriaan, M.; Shokrolahi, F. Thermal studies on natural and modified gums. Polym. Test. 2004, 23, 575–579. [Google Scholar] [CrossRef]

- Xu, L.; Xu, G.; Liu, T.; Chen, Y.; Gong, H. The comparison of rheological properties of aqueous welan gum and xanthan gum solutions. Carbohydr. Polym. 2013, 92, 516–522. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Zhang, S.F.; Ma, X.C.; Wang, D.Z.; Yang, J.Z. Synthesis and application of starch-graft-poly (AM-co-AMPS) by using a complex initiation system of CS-APS. Carbohydr. Polym. 2007, 69, 189–195. [Google Scholar] [CrossRef]

- Sen, R. Biotechnology in petroleum recovery: The microbial EOR. Prog. Energy Combust. Sci. 2008, 34, 714–724. [Google Scholar] [CrossRef]

- Haruna, M.A.; Nourafkan, E.; Hu, Z.; Wen, D. Improved polymer flooding in harsh environments by free-radical polymerization and the use of nanomaterials. Energy Fuels 2019, 33, 1637–1648. [Google Scholar] [CrossRef]

- Volpert, E.; Selb, J.; Candau, F.; Green, N.; Argillier, J.; Audibert, A. Adsorption of hydrophobically associating polyacrylamides on clay. Langmuir 1998, 14, 1870–1879. [Google Scholar] [CrossRef]

- Chassenieux, C.; Nicolai, T.; Benyahia, L. Rheology of associative polymer solutions. Curr. Opin. Colloid Interface Sci. 2011, 16, 18–26. [Google Scholar] [CrossRef]

- Perttamo, E.K. Characterization of Associating Polymer (AP) Solutions. Influences on Flow Behavior by the Degree of Hydrophobicity and Salinity. Master’s Thesis, The University of Bergen, Bergen, Norway, 2013. [Google Scholar]

- Niu, Y.; Jian, O.; Zhu, Z.; Wang, G.; Sun, G.; Shi, L. Research on hydrophobically associating water-soluble polymer used for EOR. In SPE International Symposium on Oilfield Chemistry; OnePetro: Richardson, TX, USA, 2001. [Google Scholar]

- Huang, Y.; Santore, M.M. Dynamics in adsorbed layers of associative polymers in the limit of strong backbone- surface attractions. Langmuir 2002, 18, 2158–2165. [Google Scholar] [CrossRef]

- Tanaka, R.; Williams, P.; Meadows, J.; Phillips, G. The adsorption of hydroxyethyl cellulose and hydrophobically modified hydroxyethyl cellulose onto polystyrene latex. Colloids Surfaces 1992, 66, 63–72. [Google Scholar] [CrossRef]

- Zhu, Y.; Lei, M.; Zhu, Z. Development and performance of salt-resistant polymers for chemical flooding. In SPE Middle East Oil & Gas Show and Conference; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Leblanc, T.; Braun, O.; Thomas, A.; Divers, T.; Gaillard, N.; Favero, C. Rheological properties of stimuli-responsive polymers in solution to improve the salinity and temperature performances of polymer-based chemical enhanced oil recovery technologies. In SPE Asia Pacific Enhanced Oil Recovery Conference; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Kamal, M.S.; Sultan, A. Thermosensitive water soluble polymers: A solution to high temperature and high salinity reservoirs. In SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition; OnePetro: Richardson, TX, USA, 2017. [Google Scholar]

- Levitt, D.B.; Dufour, S.; Pope, G.; Morel, D.; Gauer, P. Design of an ASP flood in a high-temperature, high-salinity, low-permeability carbonate. In IPTC 2012: International Petroleum Technology Conference; European Association of Geoscientists & Engineers: Dubai, United Arab Emirates, 2012; p. cp-280. [Google Scholar]

- Jensen, T.; Kadhum, M.; Kozlowicz, B.; Sumner, E.; Malsam, J.; Muhammed, F.; Ravikiran, R. Chemical EOR under harsh conditions: Scleroglucan as a viable commercial solution. In SPE Improved Oil Recovery Conference; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Ouellette, R.; Rawn, J. 15-Synthetic Polymers. In Principles of Organic Chemistry; Ouellette, R.J., Rawn, J.D., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 397–419. [Google Scholar]

- Svec, F.; Tennikova, T.B.; Deyl, Z. Monolithic Materials: Preparation, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Dupuis, G.; Antignard, S.; Giovannetti, B.; Gaillard, N.; Jouenne, S.; Bourdarot, G.; Morel, D.; Zaitoun, A. A New Thermally Stable Synthetic Polymer for Harsh Conditions of Middle East Reservoirs. Part I. Thermal Stability and Injection in Carbonate Cores. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2017. [Google Scholar]

- Alfazazi, U.; Thomas, N.C.; Alameri, W.; Al-Shalabi, E.W. Experimental investigation of polymer injectivity and retention under harsh carbonate reservoir conditions. J. Pet. Sci. Eng. 2020, 192, 107262. [Google Scholar] [CrossRef]

- Sandengen, K.; Meldahl, M.; Gjersvold, B.; Molesworth, P.; Gaillard, N.; Braun, O.; Antignard, S. Long term stability of ATBS type polymers for enhanced oil recovery. J. Pet. Sci. Eng. 2018, 169, 532–545. [Google Scholar] [CrossRef]

- Rodriguez, L.; Antignard, S.; Giovannetti, B.; Dupuis, G.; Gaillard, N.; Jouenne, S.; Bourdarot, G.; Morel, D.; Zaitoun, A.; Grassl, B. A new thermally stable synthetic polymer for harsh conditions of middle east reservoirs: Part II. Nmr and size exclusion chromatography to assess chemical and structural changes during thermal stability tests. In SPE Improved Oil Recovery Conference; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Driver, J.W.; Britton, C.; Hernandez, R.; Glushko, D.; Pope, G.A.; Delshad, M. Conditioning Polymer Solutions for Injection into Tight Reservoir Rocks. In SPE Improved Oil Recovery Conference; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Zhu, D.; Wei, L.; Wang, B.; Feng, Y. Aqueous hybrids of silica nanoparticles and hydrophobically associating hydrolyzed polyacrylamide used for EOR in high-temperature and high-salinity reservoirs. Energies 2014, 7, 3858–3871. [Google Scholar] [CrossRef] [Green Version]

- Bennetzen, M.V.; Gilani, S.F.; Mogensen, K.; Ghozali, M.; Bounoua, N. Successful polymer flooding of low-permeability, oil-wet, carbonate reservoir cores. In Abu Dhabi International Petroleum Exhibition and Conference; OnePetro: Richardson, TX, USA, 2014. [Google Scholar]

- Masalmeh, S.; AlSumaiti, A.; Gaillard, N.; Daguerre, F.; Skauge, T.; Skuage, A. Extending polymer flooding towards high-temperature and high-salinity carbonate reservoirs. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Jouenne, S.; Chakibi, H.; Levitt, D. Polymer Stability Following Successive Mechanical Degradation Events. In Proceedings of the IOR 2015—18th European Symposium on Improved Oil Recovery, Dresden, Germany, 14–16 April 2015; European Association of Geoscientists & Engineers: Dubai, United Arab Emirates, 2015; p. cp-445. [Google Scholar]

- Sheng, J.J. Critical review of low-salinity waterflooding. J. Pet. Sci. Eng. 2014, 120, 216–224. [Google Scholar] [CrossRef]

- Wang, J.; Han, M.; Fuseni, A.B.; Cao, D. Surfactant adsorption in surfactant-polymer flooding for carbonate reservoirs. In SPE Middle East Oil & Gas Show and Conference; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Wang, L.; Mohanty, K. Enhanced oil recovery in gasflooded carbonate reservoirs by wettability-altering surfactants. SPE J. 2015, 20, 60–69. [Google Scholar] [CrossRef]

- Abalkhail, N.; Liyanage, P.J.; Upamali, K.A.; Pope, G.A.; Mohanty, K.K. Alkaline-surfactant-polymer formulation development for a HTHS carbonate reservoir. J. Pet. Sci. Eng. 2020, 191, 107236. [Google Scholar] [CrossRef]

- Pourafshary, P.; Moradpour, N. Hybrid EOR methods utilizing low-salinity water. Enhanc. Oil Recov. Process. New Technol 2019, 8, 25. [Google Scholar]

- Dong, X.; Liu, H.; Chen, Z. Introduction to hybrid enhanced oil recovery processes. In Developments in Petroleum Science; Elsevier: Amsterdam, The Netherlands, 2021; Volume 73, pp. 1–46. [Google Scholar]

- Al-Murayri, M.T.; Kamal, D.S.; Al-Sabah, H.M.; AbdulSalam, T.; Al-Shamali, A.; Quttainah, R.; Glushko, D.; Britton, C.; Delshad, M.; Liyanage, J.; et al. Low-Salinity Polymer Flooding in a High-Temperature Low-Permeability Carbonate Reservoir in West Kuwait. In SPE Kuwait Oil & Gas Show and Conference; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Lee, Y.; Lee, W.; Jang, Y.; Sung, W. Oil recovery by low-salinity polymer flooding in carbonate oil reservoirs. J. Pet. Sci. Eng. 2019, 181, 106211. [Google Scholar] [CrossRef]

- Zhao, Y.; Yin, S.; Seright, R.S.; Ning, S.; Zhang, Y.; Bai, B. Enhancing heavy-oil-recovery efficiency by combining low-salinity-water and polymer flooding. SPE J. 2021, 26, 1535–1551. [Google Scholar] [CrossRef]

- Yan, W.; Miller, C.A.; Hirasaki, G.J. Foam sweep in fractures for enhanced oil recovery. Colloids Surfaces A Physicochem. Eng. Asp. 2006, 282, 348–359. [Google Scholar] [CrossRef]

- Heller, J.; Dandge, D.; Card, R.; Donaruma, L. Direct thickeners for mobility control of CO2 floods. Soc. Pet. Eng. J. 1985, 25, 679–686. [Google Scholar] [CrossRef]

- Horgue, P.; Soulaine, C.; Franc, J.; Guibert, R.; Debenest, G. An open-source toolbox for multiphase flow in porous media. Comput. Phys. Commun. 2015, 187, 217–226. [Google Scholar] [CrossRef] [Green Version]

- Chakravarthy, D.; Muralidharan, V.; Putra, E.; Hidayati, D.; Schechter, D.S. Mitigating oil bypassed in fractured cores during CO2 flooding using WAG and polymer gel injections. In SPE/DOE Symposium on Improved oil Recovery; OnePetro: Richardson, TX, USA, 2006. [Google Scholar]

- Li, W.; Dong, Z.; Sun, J.; Schechter, D.S. Polymer-alternating-gas simulation—A case study. In SPE EOR Conference at Oil and Gas West Asia; OnePetro: Richardson, TX, USA, 2014. [Google Scholar]

- Smith, D.H. Surfactant-Based Mobility Control; Technical Report; American Chemical Society: Washington, DC, USA, 1988. [Google Scholar]

- Hiraski, G.J. The steam-foam process. J. Pet. Technol. 1989, 41, 449–456. [Google Scholar] [CrossRef]

- Zhang, Y.; Yue, X.; Dong, J.; Yu, L. New and effective foam flooding to recover oil in heterogeneous reservoir. In SPE/DOE Improved Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2000. [Google Scholar]

- Ransohoff, T.; Radke, C. Mechanisms of foam generation in glass-bead packs. SPE Reserv. Eng. 1988, 3, 573–585. [Google Scholar] [CrossRef] [Green Version]

- Rossen, W.; Gauglitz, P. Percolation theory of creation and mobilization of foams in porous media. AIChE J. 1990, 36, 1176–1188. [Google Scholar] [CrossRef]

- Gauglitz, P.A.; Friedmann, F.; Kam, S.I.; Rossen, W. Foam generation in porous media. In SPE/DOE Improved Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2002. [Google Scholar]

- Dicksen, T.; Hirasaki, G.J.; Miller, C.A. Conditions for foam generation in homogeneous porous media. In SPE/DOE Improved oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2002. [Google Scholar]

- Donaldson, E.C.; Chilingarian, G.V.; Yen, T.F. Enhanced Oil Recovery, II: Processes and Operations; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Heller, J.P. CO2 Foams in Enhanced Oil Recovery; Advances in Chemistry; American Chemical Society: Washington, DC, USA, 1994; Volume 242. [Google Scholar] [CrossRef]

- Lal, R.; Negassa, W.; Lorenz, K. Carbon sequestration in soil. Curr. Opin. Environ. Sustain. 2015, 15, 79–86. [Google Scholar] [CrossRef]

- Wei, Z.; Jian, Z.; Ming, H.; Wentao, X.; Guozhi, F.; Wei, J.; Fujie, S.; Shouwei, Z.; Yongjun, G.; Zhongbin, Y. Application of hydrophobically associating water-soluble polymer for polymer flooding in China offshore heavy oilfield. In IPTC 2007: International Petroleum Technology Conference; European Association of Geoscientists & Engineers: Dubai, United Arab Emirates, 2007; p. cp-147. [Google Scholar]

- Jiran, L. Experimental Investigation and Simulation of Polymer Flooding in High Temperature High Salinity Carbonate Reservoirs. Ph.D. Thesis, The Petroleum Institute (United Arab Emirates), Abu Dhabi, United Arab Emirates, 2015. [Google Scholar]

- Jabbar, M.; Xiao, R.; Teletzke, G.F.; Willingham, T.; Al Obeidli, A.; Al Sowaidi, A.; Britton, C.; Delshad, M.; Li, Z. Polymer EOR Assessment through Integrated Laboratory and Simulation Evaluation for an Offshore Middle East Carbonate Reservoir. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Mohsenatabar Firozjaii, A.; Akbari, M.; Zargar, G. Sensitivity analysis and optimization on effective parameters during chemical enhanced oil recovery (CEOR) using experimental design and numerical simulation. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 41, 1847–1861. [Google Scholar] [CrossRef]

- Rachapudi, R.; Alshehhi, S.; BinAmro, A.A.; Masalmeh, S.; Dey, A.; Al Nuimi, S.; Kenawy, M.; Fabbri, C.; Romero, C.; Xu, S.; et al. World First Polymer Injectivity Test in High Salinity and High Temperature Carbonate Reservoir, Case Study from a Giant Reservoir in UAE. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2020. [Google Scholar]

- Baloch, S.; Leon, J.; Masalmeh, S.; Chappell, D.; Brodie, J.; Romero, C.; Al Mazrouei, S.; Al Tenaiji, A.; Al Balooshi, M.; Igogo, A.; et al. Expanding Polymer Injectivity Tests on a Second Giant Carbonate UAE Oil Reservoir at High Salinity & High Temperature Conditions. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2021. [Google Scholar]

- Manrique, E.; Thomas, C.; Ravikiran, R.; Izadi, M.; Lantz, M.; Romero, J.; Alvarado, V. EOR: Current status and opportunities. In SPE Improved oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2010. [Google Scholar]

- Ghosh, P.; Sharma, H.; Mohanty, K.K. Chemical Flooding in Low Permeability Carbonate Rocks. In SPE Annual Technical Conference and Exhibition; OnePetro: Richardson, TX, USA, 2017. [Google Scholar]

- Moore, J.K. Reservoir barrier and polymer waterflood, Northeast Hallsville Crane unit. J. Pet. Technol. 1969, 21, 1130–1136. [Google Scholar] [CrossRef]

- Tiwari, D.; Marathe, R.V.; Patel, N.K.; Ramachandran, K.; Maurya, C.R.; Tewari, P. Performance of polymer flood in Sanand field, India-A case study. In SPE Asia Pacific Oil and Gas Conference and Exhibition; OnePetro: Richardson, TX, USA, 2008. [Google Scholar]

- Masalmeh, S.; Wei, L.; Hillgartner, H.; Al-Mjeni, R.; Blom, C. Developing high resolution static and dynamic models for waterflood history matching and EOR evaluation of a Middle Eastern carbonate reservoir. In Abu Dhabi International Petroleum Conference and Exhibition; OnePetro: Richardson, TX, USA, 2012. [Google Scholar]

- Leon, J.M.; Masalmeh, S.K.; Xu, S.; AlSumaiti, A.M.; BinAmro, A.A.; Baslaib, M.A. Analysis of the World’s First Polymer Injectivity Test in a Carbonate Reservoir Under Extreme Harsh Conditions in ADNOC’s Reservoirs. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2021. [Google Scholar]

- Al-Shalabi, E.W. Numerical modeling of biopolymer flooding in high-temperature high-salinity carbonate cores. In Offshore Technology Conference Asia; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Rai, S.K.; Bera, A.; Mandal, A. Modeling of surfactant and surfactant–polymer flooding for enhanced oil recovery using STARS (CMG) software. J. Pet. Explor. Prod. Technol. 2015, 5, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Rivet, S.M. Coreflooding Oil Displacements with Low Salinity Brine. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2009. [Google Scholar]

- Ayirala, S.; Uehara-Nagamine, E.; Matzakos, A.; Chin, R.; Doe, P.; van Den Hoek, P. A designer water process for offshore low salinity and polymer flooding applications. In SPE Improved Oil Recovery Symposium; OnePetro: Richardson, TX, USA, 2010. [Google Scholar]

- Alzayer, H.; Sohrabi, M. Numerical simulation of improved heavy oil recovery by low-salinity water injection and polymer flooding. In SPE Saudi Arabia Section Technical Symposium and Exhibition; OnePetro: Richardson, TX, USA, 2013. [Google Scholar]

- Webb, K.; Lager, A.; Black, C. Comparison of high/low salinity water/oil relative permeability. In Proceedings of the International Symposium of the Society of Core Analysts, Abu Dhabi, United Arab Emirates, 29 October–2 November 2008; Volume 29. [Google Scholar]

- Hirasaki, G.; Pope, G. Analysis of factors influencing mobility and adsorption in the flow of polymer solution through porous media. Soc. Pet. Eng. J. 1974, 14, 337–346. [Google Scholar] [CrossRef]

- Han, B.; Lee, J. Sensitivity analysis on the design parameters of enhanced oil recovery by polymer flooding with low salinity waterflooding. In The Twenty-Fourth International Ocean and Polar Engineering Conference; OnePetro: Richardson, TX, USA, 2014. [Google Scholar]

- Khamees, T.K.; Flori, R.E.; Alsubaih, A.A.; Alhuraishawy, A.K. Modeling the effects of salinity, polymer rheology, temperature, and reservoir wettability on the performance of in-depth gel treatment coupled with surfactant and polymer flooding. In Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Richardson, TX, USA, 2014. [Google Scholar]

- Ning, S.; Barnes, J.; Edwards, R.; Dunford, K.; Eastham, K.; Dandekar, A.; Zhang, Y.; Cercone, D.; Ciferno, J. First Ever Polymer Flood Field Pilot to Enhance the Recovery of Heavy Oils on Alaska’s North Slope—Polymer Injection Performance. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 22–24 July 2019; Society of Exploration Geophysicists: Houston, TX, USA, 2019; pp. 1671–1688. [Google Scholar]

- Zhao, Y.; Yin, S.; Seright, R.S.; Ning, S.; Zhang, Y.; Bai, B. Performance of Low Salinity Polymer Flood in Enhancing Heavy Oil Recovery on the Alaska North Slope. In Proceedings of the Unconventional Resources Technology Conference, Austin, TX, USA, 20–22 July 2020; Society of Exploration Geophysicists: Houston, TX, USA, 2020; pp. 1929–1943. [Google Scholar]

- Wang, D.; Li, C.; Seright, R.S. Laboratory Evaluation of Polymer Retention in a Heavy Oil Sand for a Polymer Flooding Application on Alaska’s North Slope. SPE J. 2020, 25, 1842–1856. [Google Scholar] [CrossRef]

- Sun, X.F.; Song, Z.Y.; Cai, L.F.; Zhang, Y.Y.; Li, P. Phase behavior of heavy oil–solvent mixture systems under reservoir conditions. Pet. Sci. 2020, 17, 1683–1698. [Google Scholar] [CrossRef]

- Kargozarfard, Z.; Riazi, M.; Ayatollahi, S. Viscous fingering and its effect on areal sweep efficiency during waterflooding: An experimental study. Pet. Sci. 2019, 16, 105–116. [Google Scholar] [CrossRef] [Green Version]

- Saboorian-Jooybari, H.; Dejam, M.; Chen, Z. Heavy oil polymer flooding from laboratory core floods to pilot tests and field applications: Half-century studies. J. Pet. Sci. Eng. 2016, 142, 85–100. [Google Scholar] [CrossRef]

- Dandekar, A.; Bai, B.; Barnes, J.; Cercone, D.; Ciferno, J.; Ning, S.; Seright, R.; Sheets, B.; Wang, D.; Zhang, Y. First Ever Polymer Flood Field Pilot-A Game Changer to Enhance the Recovery of Heavy Oils on Alaska’s North Slope. In SPE Western Regional Meeting; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Dandekar, A.; Bai, B.; Barnes, J.; Cercone, D.; Ciferno, J.; Edwards, R.; Ning, S.; Schulpen, W.; Seright, R.; Sheets, B.; et al. First ever polymer flood field pilot to enhance the recovery of heavy oils on Alaska’s North Slope Pushing Ahead One Year Later. In SPE Western Regional Meeting; OnePetro: Richardson, TX, USA, 2021. [Google Scholar]

- Al Shalabi, E.W.; Sepehrnoori, K. Low Salinity and Engineered Water Injection for Sandstone and Carbonate Reservoirs; Gulf Professional Publishing: London, UK, 2017. [Google Scholar]

- Al-Shalabi, E.W.; Sepehrnoori, K.; Pope, G. Numerical modeling of combined low salinity water and carbon dioxide in carbonate cores. J. Pet. Sci. Eng. 2016, 137, 157–171. [Google Scholar] [CrossRef]

- Al-Shalabi, E.W.; Sepehrnoori, K.; Delshad, M.; Pope, G. A Novel Method to Model Low Salinity Water Injection in Carbonate Oil Reservoirs. In SPE EOR Conference at Oil and Gas West Asia; OnePetro: Richardson, TX, USA, 2014. [Google Scholar]

- Al-Shalabi, E.W.; Sepehrnoori, K.; Pope, G. New mobility ratio definition for estimating volumetric sweep efficiency of low salinity water injection. Fuel 2015, 158, 664–671. [Google Scholar] [CrossRef]

- Al-Shalabi, E.W.; Sepehrnoori, K. A comprehensive review of low salinity/engineered water injections and their applications in sandstone and carbonate rocks. J. Pet. Sci. Eng. 2016, 139, 137–161. [Google Scholar] [CrossRef]