Physical Properties of Starches Modified by Phosphorylation and High-Voltage Electrical Discharge (HVED)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Modification of Starch

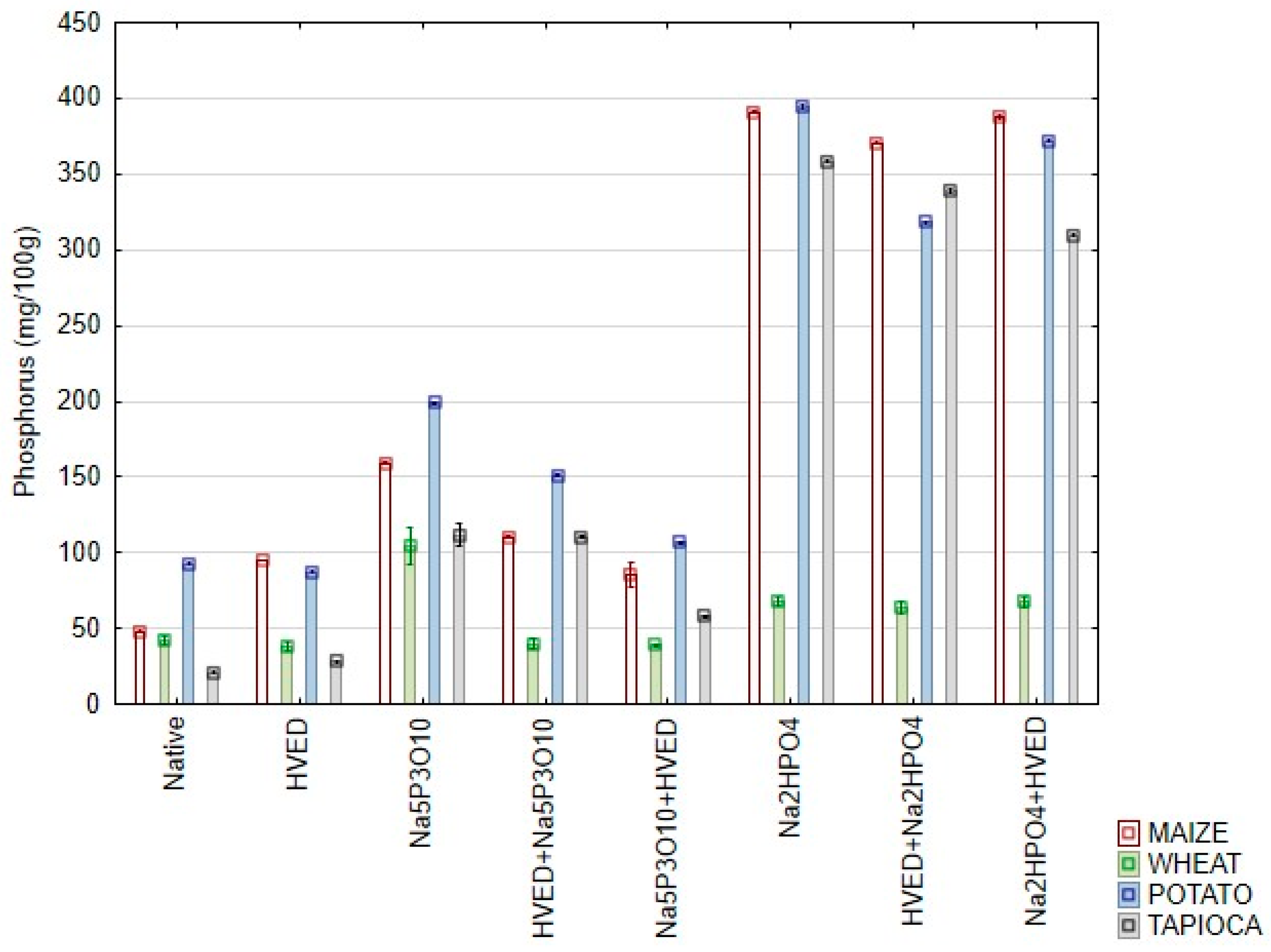

2.2. Phosphorus Content

2.3. Pasting Properties

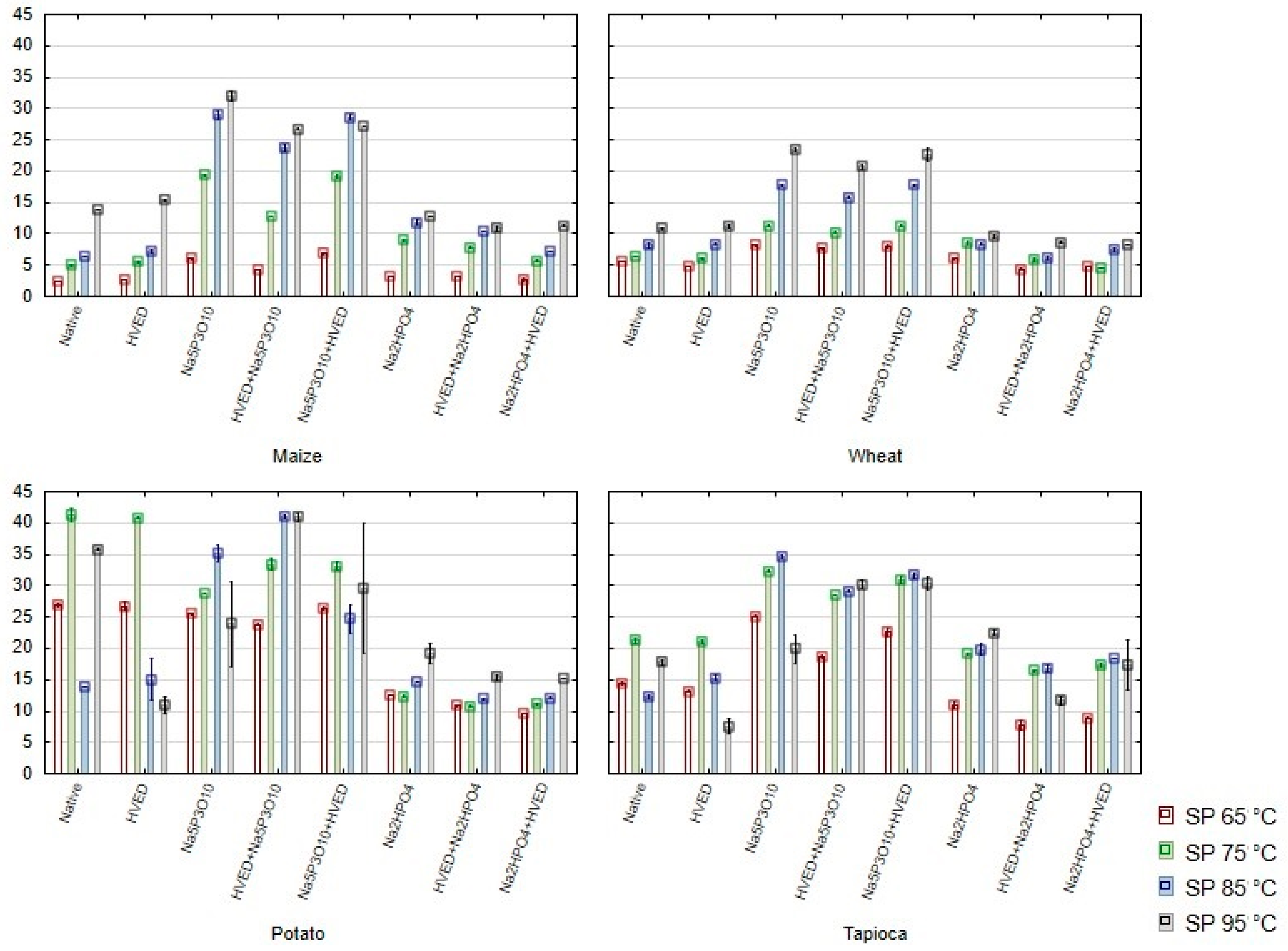

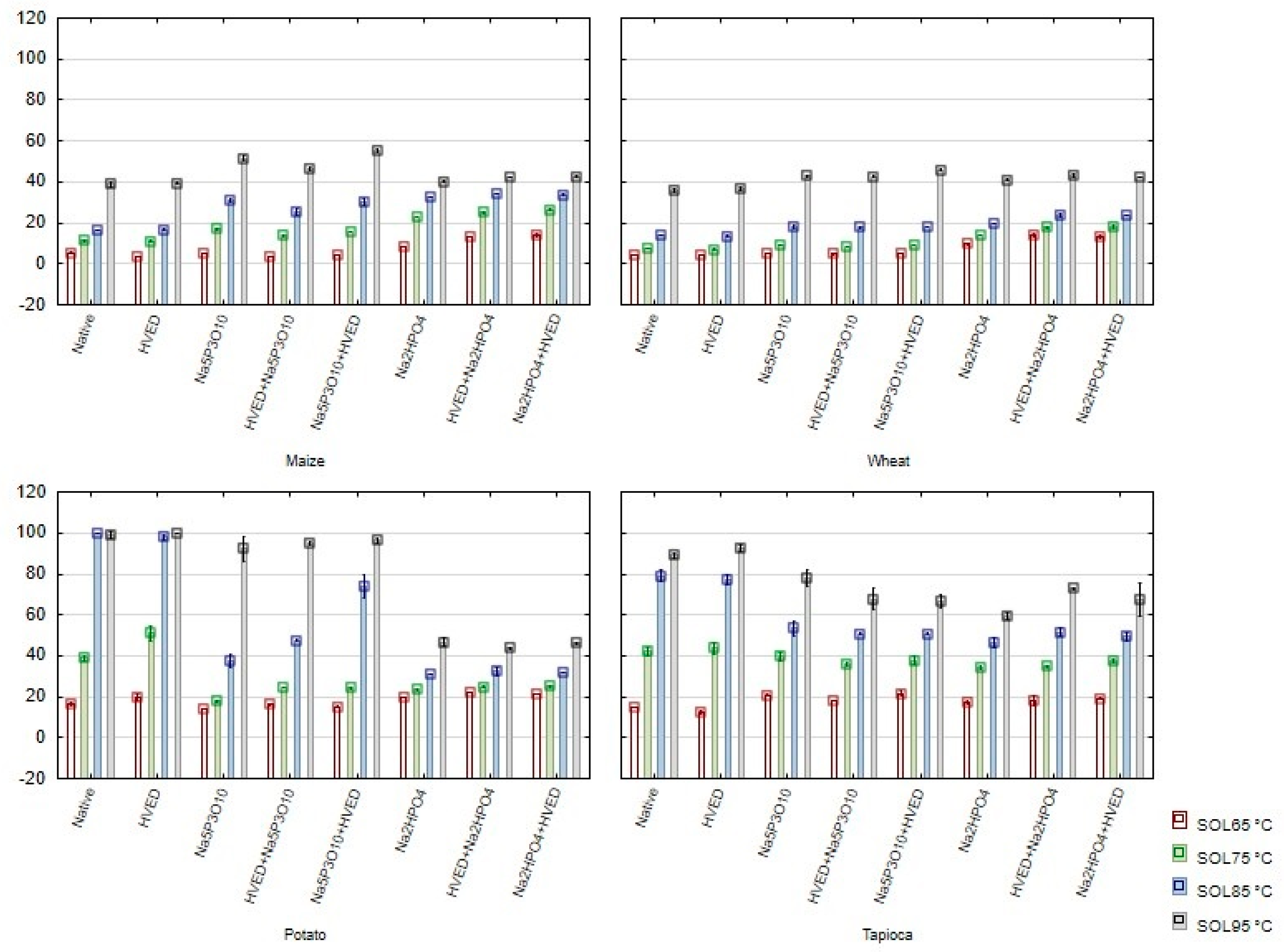

2.4. Swelling Power and Solubility

2.5. Texture Properties

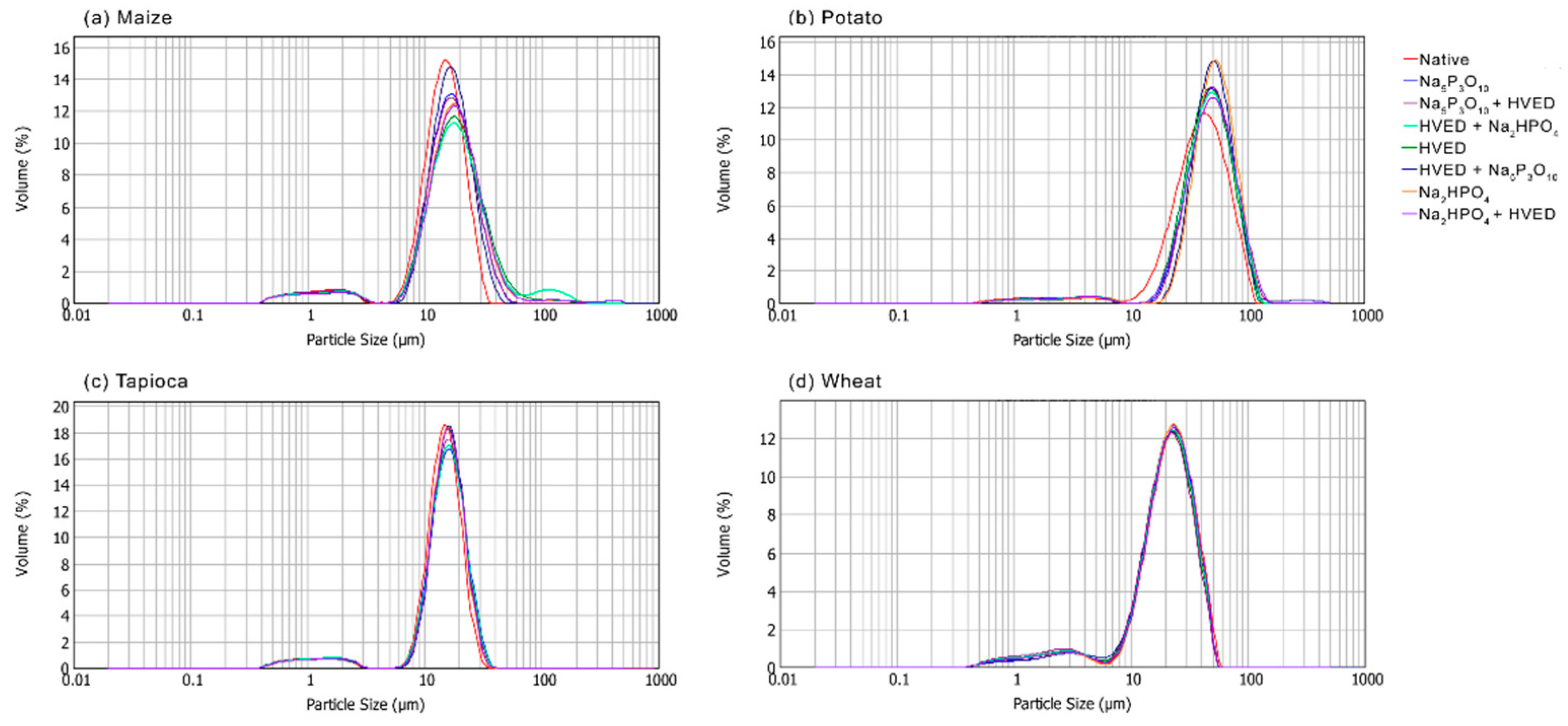

2.6. Particle Size

2.7. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, Y.; Picchioni, F. Modification of starch: A review on the application of “green” solvents and controlled functionalization. Carb. Polym. 2020, 241, 116350. [Google Scholar] [CrossRef] [PubMed]

- Jokić, S.; Pavlović, N.; Jozinović, A.; Ačkar, Đ.; Babić, J.; Šubarić, D. High-voltage electric discharge extraction of bioactive compounds from cocoa bean shell. Chem. Biochem. Eng. Q. 2019, 33, 271–280. [Google Scholar] [CrossRef]

- Vanraes, P.; Nikiforov, A.Y.; Leys, C. Electrical discharge in water treatment technology for micropollutant decomposition. In Plasma Science and Technology; Mieno, T., Ed.; IntechOpen: London, UK, 2016; pp. 428–477. [Google Scholar] [CrossRef]

- Kiš, M.; Milošević, S.; Vučić, A.; Herceg, Z.; Vukušić, T.; Pleadin, J. Efficacy of low pressure DBD plasma in the reduction of T-2 and HT-2 toxin in oat flour. Food Chem. 2020, 316, 126372. [Google Scholar] [CrossRef] [PubMed]

- Grgić, I.; Ačkar, Đ.; Barišić, V.; Vlainić, M.; Knežević, N.; Medverec Knežević, Z. Nonthermal methods for starch modification-A review. J. Food Process. Preserv. 2019, 43, e14242. [Google Scholar] [CrossRef]

- Blennow, A.; Engelsen, S.B.; Nielsed, T.H.; Baunsgaard, L.; Mikkelsen, R. Starch phosphorylation: A new front line in starch research. Trends Plant Sci. 2002, 7, 445–450. [Google Scholar] [CrossRef]

- Ramadan, M.F.; Sitohy, M.Z. Phosphorylated starches: Preparation, properties, functionality, and techno-applications. Starch 2020, 72, 1900302. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Z.; Wu, J.; Xu, Z.; Liu, Z. Phosphrylation/caproylation of cornstarch to improve its adhesion to PLA and cotton fibers. RSC Adv. 2019, 9, 34880. [Google Scholar] [CrossRef]

- Grgić, I.; Grec, M.; Gryszkin, A.; Zieba, T.; Kopjar, M.; Ačkar, Đ.; Jozinović, A.; Miličević, B.; Zavadlav, S.; Babić, J. Starches modified by combination of phosphorylation and high-voltage electrical discharge (HVED) treatment. Pol. J. Food Nutr. Sci. 2021, 71, 79–88. [Google Scholar] [CrossRef]

- Ačkar, Đ.; Babić, J.; Šubarić, D.; Kopjar, M.; Miličević, B. Isolation of starch from two wheat varieties and their modification with epichlorohydrin. Carb. Polym. 2010, 81, 76–82. [Google Scholar] [CrossRef]

- Barišić, V.; Jozinović, A.; Flanjak, I.; Šubarić, D.; Babić, J.; Miličević, B.; Doko, K.; Ačkar, Đ. Difficulties with use of cocoa bean shell in food production and high voltage electrical discharge as a possible solution. Sustainability 2020, 12, 3981. [Google Scholar] [CrossRef]

- Lim, S.; Seib, P.A. Preparation and Pasting Properties of Wheat and Corn Starch Phosphates. Cereal Chem. 1993, 70, 137–144. [Google Scholar]

- Choi, H.J.; Sung, J.H.; Park, D.P.; Park, B.J.; Jhon, M.S. Phosphorylation of potato starch and its electrorheological suspension. Biomacromolecules 2005, 6, 2182–2188. [Google Scholar] [CrossRef]

- Prasanthi, N.L.; Rama Rao, N. Starch Phosphate, A novel pharmaceutical excipient for tablet formulation. J. Pharm. Res. 2010, 3, 2919–2923. [Google Scholar]

- PN-EN ISO 3946:2000; Skrobia i Produkty Pochodne.Oznaczanie Calkowitej Zawartosci Fosforu. Metoda Spektrofotometryczna (Starches and Derived Products—Determination of Total Phosphorus Content—Spectrophotometric Method). Polski Komitet Normalizacyjny: Warszawa, Poland, 2000.

- Takeda, Y.; Shitaozono, T.; Hizukuri, S. Molecular Structure of Corn Starch. Starch. Stärke 1988, 40, 51–54. [Google Scholar] [CrossRef]

- Du, C.M.; Yan, J.H.; Li, X.D.; Cheron, B.G.; You, X.F.; Chi, Y.; Ni, M.J.; Cen, K.F. Simultaneous removal of polycyclic aromatic hydrocarbons and soot particles from flue gas by gliding arc discharge treatment. Plasma Chem. Plasma Process. 2006, 26, 517–525. [Google Scholar] [CrossRef]

- Grinevich, V.I.M.; Kvitkova, E.Y.; Plastinina, N.A.; Rybkin, V.V. Application of dielectric barrier discharge for waste water purification. Plasma Chem. Plasma Process. 2011, 31, 573–583. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Wei, Y.; Zhang, W.; Zhang, B. Thermal, pasting and gel textural properties of commercial starches from different botanical sources. J. Bioprocess. Biotech. 2014, 4, 161. [Google Scholar] [CrossRef]

- Pycia, K.; Gałkowska, D.; Juszczak, L.; Fortuna, T.; Witczak, T. Physicochemical, thermal and rheological properties of starches isolated from malting barley varieties. J. Food Sci. Technol. 2015, 52, 4797–4807. [Google Scholar] [CrossRef]

- Cui, S.W. Food Carbohydrates—Chemistry, Physical Properties, and Applications; CRC Press: Boca Raton, FL, USA, 2005; Chapters 7 and 8. [Google Scholar]

- Bie, P.; Pu, H.; Zhang, B.; Su, J.; Chen, L.; Li, X. Structural characteristics and rheological properties of plasma-treated starch. Innov. Food Sci. Emerg. Technol. 2015, 34, 196–204. [Google Scholar] [CrossRef]

- Khorram, S.; Zakerhamidi, M.S.; Karimzadeh, Z. Polarity functions’ characterization and the mechanism of starch modification by DC glow discharge plasma. Carbohydr. Polym. 2015, 127, 72–78. [Google Scholar] [CrossRef]

- Thirumdas, R.; Kothakota, A.; Annapure, U.; Siliveru, K.; Blundell, R.; Gatt, R.; Valdramidis, V.P. Plasma activated water (PAW): Chemistry, physico-chemical properties, applications in food and agriculture. Trends Food Sci. Technol. 2018, 77, 21–31. [Google Scholar] [CrossRef]

- Shujun, W.; Jinglin, Y.; Jiugao, Y.; Jiping, P.; Hongyan, L. Structure characterization of C-type starch granule by acid hydrolysis. Food Hydrocolloid. 2008, 22, 1283–1290. [Google Scholar] [CrossRef]

- BeMiller, J.; Whistler, R. Starch: Chemistry and Technology, 3rd ed.; Academic Press: Burlington, MA, USA, 2009; Chapter 8. [Google Scholar]

- Banura, S.; Thirumdas, R.; Kaur, A.; Deshmukh, R.R.; Annapure, U.S. Modification of starch using low pressure radio frequency air plasma. LWT Food Sci. Technol. 2018, 89, 719–724. [Google Scholar] [CrossRef]

- Wu, T.Y.; Sun, N.N.; Chau, C.F. Application of corona electrical discharge plasma on modifying the physicochemical properties of banana starch indigenous to Taiwan. J. Food Drug Anal. 2018, 26, 244–251. [Google Scholar] [CrossRef]

- Ascheri, D.P.R.; Pereira, L.D.; Bastos, S.M.C. Chemical, morphological, rheological and thermal properties of Solanum lycocarpum phosphorylated starches. Rev. Ceres 2014, 61, 458–466. [Google Scholar] [CrossRef]

- Nathania, I.; Sugih, A.K.; Muljana, H. Preliminary study on the synthesis of phosphorylated mung bean starch: The effect of pH on the physicochemical and functional properties. Indones. J. Chem. 2017, 17, 401–406. [Google Scholar] [CrossRef]

- Wongsagonsup, R.; Deeyai, P.; Chaiwat, W.; Horrungsiwat, S.; Leejariensuk, K.; Suphantharika, M.; Fuongfuchat, A.; Dangtip, S. Modification of tapioca starch by non-chemical route using jet atmospheric argon plasma. Carbohydr. Polym. 2014, 102, 790–798. [Google Scholar] [CrossRef]

- Ačkar, Đ.; Šubarić, D.; Babić, J.; Miličević, B.; Jozinović, A. Modification of wheat starch with succinic acid/acetanhydride and azelaic acid/acetanhydride mixtures II. Chemical and physical properties. J. Food Sci. Technol. 2014, 51, 1463–1472. [Google Scholar] [CrossRef]

- Babić, J.; Šubarić, D.; Ačkar, Đ.; Kovačević, D.; Piližota, V.; Kopjar, M. Preparation and characterization of acetylated tapioca starches. Dtsch Lebensmitt Rundsch 2007, 103, 580–585. [Google Scholar]

- Svihus, B.; Uhlen, A.K.; Harstad, O.M. Effect of starch granule structure, associated components and processing on nutritive value of cereal starch: A review. Anim. Feed Sci. Technol. 2005, 122, 303–320. [Google Scholar] [CrossRef]

- Singh, N.; Singh, J.; Sodhi, N.S. Morphological, thermal, rheological and noodle-making properties of potato and corn starch. J. Sci. Food Agric. 2002, 82, 1376–1383. [Google Scholar] [CrossRef]

- Okyere, A.Y.; Rajendran, S.; Annor, G.A. Cold plasma technologies: Their effect on starch properties and industrial scale-up for starch modification. Curr. Res. Food Sci. 2022, 5, 451–463. [Google Scholar] [CrossRef] [PubMed]

| Starch | Treatment | Pasting Temperature (°C) | Maximum Viscosity (BU) | Gelatinisation Maximum (°C) | Viscosity at 92 °C (BU) | Viscosity after 15 min at 92 °C (BU) | Viscosity at 50 °C (BU) | Viscosity after 15 min at 50 °C (BU) | Breakdown | Setback |

|---|---|---|---|---|---|---|---|---|---|---|

| Maize | Native | 73.35 ± 0.07 d | 258.50 ± 3.54 a | 88.40 ± 0.14 f | 247.00 ± 2.83 a | 167.00 ± 1.41 a | 327.50 ± 4.95 a.b | 300.50 ± 3.54 c | 91.50 ± 2.12 a | 160.50 ± 0.54 b |

| HVED | 72.00 ± 0.14 c | 317.00 ± 9.90 b | 83.50 ± 0.42 e | 295.50 ± 7.78 b | 183.00 ± 5.66 a.b | 387.50 ± 0.71 b | 349.50 ± 9.19 e | 134.00 ± 4.24 b | 204.50 ± 4.95 c | |

| Na5P3O10 | 68.25 ± 0.21 a | 562.00 ± 1.41 e | 71.05 ± 0.49 a | 429.00 ± 1.41 d.e | 263.50 ± 0.71 c | 525.50 ± 0.71 c | 448.50 ± 3.54 f | 298.50 ± 0.71 e | 262.00 ± 1.41 d | |

| HVED + Na5P3O10 | 70.10 ± 0.00 b | 507.00 ± 1.41 d | 78.10 ± 0.00 c | 410.50 ± 2.12 d | 252.00 ± 1.41 b.c | 514.50 ± 0.71 c | 441.00 ± 2.83 f | 254.00 ± 2.83 d | 262.50 ± 2.12 d | |

| Na5P3O10 + HVED | 68.65 ± 0.07 a | 559.50 ± 0.71 e | 74.45 ± 0.07 b | 445.00 ± 11.31 e | 270.00 ± 1.41 a | 539.00 ± 4.24 c | 459.50 ± 2.12 f | 289.50 ± 0.71 e | 269.00 ± 2.83 d | |

| Na2HPO4 | 72.30 ± 0.14 c | 389.00 ± 7.07 c | 80.30 ± 0.99 d | 329.00 ± 11.31 c | 172.00 ± 1.41 a | 504.00 ± 212.13 c | 326.50 ± 4.95 d | 217.00 ± 8.49 c | 182.00 ± 1.41 b | |

| HVED + Na2HPO4 | 73.50 ± 0.14 d | 323.50 ± 3.54 b | 83.30 ± 0.57 e | 277.00 ± 4.24 b | 132.00 ± 7.07 a | 250.50 ± 4.95 a | 237.50 ± 4.95 a | 191.50 ± 10.61 c | 118.50 ± 2.12 a | |

| Na2HPO4 + HVED | 73.30 ± 0.42 d | 330.00 ± 7.07 b | 83.65 ± 0.35 e | 291.50 ± 0.71 b | 143.50 ± 7.78 a | 280.00 ± 9.90 a | 264.00 ± 8.49 b | 186.00 ± 14.14 c | 136.50 ± 2.12 a | |

| Wheat | Native | 67.55 ± 0.49 B | 328.00 ± 2.83 B | 93.30 ± 0.85 A | 324.00 ± 1.41 C | 234.50 ± 2.12 B | 541.50 ± 6.36 C | 428.00 ± 7.07 C | 93.50 ± 0.71 A | 307.00 ± 4.24 c |

| HVED | 68.25 ± 0.07 B | 321.00 ± 4.24 B | 92.05 ± 0.78 A | 320.00 ± 2.83 C | 236.50 ± 2.12 B | 549.00 ± 1.41 C | 447.00 ± 12.73 C | 84.50 ± 6.36 A | 312.50 ± 3.54 c.d | |

| Na5P3O10 | 63.45 ± 0.49 A | 523.50 ± 2.12 C | 92.60 ± 0.42 A | 500.00 ± 21.21 D | 344.50 ± 10.61 C | 655.00 ± 18.38 D | 524.50 ± 13.44 D | 178.50 ± 7.78 B | 310.50 ± 7.78 c | |

| HVED + Na5P3O10 | 62.50 ± 0.71 A | 521.00 ± 2.83 C | 92.75 ± 0.49 B | 510.00 ± 5.66 D.E | 348.00 ± 2.83 C | 680.50 ± 3.54 D | 553.50 ± 0.71 E | 173.00 ± 0.00 B | 332.50 ± 0.71 d | |

| Na5P3O10 + HVED | 62.80 ± 0.57A | 540.50 ± 3.54 C | 93.10 ± 0.14 A | 527.50 ± 6.36 E | 352.50 ± 7.78 C | 669.00 ± 8.49 D | 540.00 ± 5.66 D.E | 186.50 ± 12.02 B | 316.50 ± 0.71 c.d | |

| Na2HPO4 | 68.05 ± 0.35 B | 240.00 ± 12.73 A | 94.25 ± 1.48 A | 236.00 ± 7.07 B | 168.50 ± 4.95 A.B | 319.00 ± 7.07 B | 306.50 ± 9.19 B | 70.50 ± 7.78 A | 150.50 ± 2.12 b | |

| HVED + Na2HPO4 | 70.80 ± 0.99 C | 209.50 ± 2.12 A | 93.35 ± 0.07 A | 194.00 ± 1.41 A | 125.00 ± 1.41 A | 229.50 ± 4.95 A | 220.50 ± 4.95 A | 85.00 ± 0.00 A | 104.50 ± 3.54 a | |

| Na2HPO4 + HVED | 70.65 ± 0.07 C | 219.00 ± 2.83 A | 93.15 ± 0.07 A | 205.50 ± 4.95 A | 142.00 ± 1.41 A | 251.00 ± 4.24 A.B | 240.00 ± 2.83 A | 76.50 ± 3.54 A | 109.00 ± 5.66 a | |

| Potato | Native | 58.55 ± 0.21 b.c.d | 1640.00 ± 73.54 e | 65.05 ± 0.35 b | 698.50 ± 10.61 c | 514.50 ± 2.12 b | 1143.50 ± 10.61 c | 1011.00 ± 7.07 d | 1125.00 ± 76.37 d | 629.00 ± 8.49 e |

| HVED | 60.40 ± 0.00 e | 1677.00 ± 29.70 f | 63.65 ± 1.34 b | 688.00 ± 7.07 c | 525.00 ± 1.41 b | 1149.00 ± 7.07 c | 1000.00 ± 15.56 d | 1151.50 ± 27.58 d | 624.00 ± 5.66 e | |

| Na5P3O10 | 56.25 ± 0.21 a | 1509.00 ± 32.53 d | 67.35 ± 0.78 c | 862.50 ± 3.54 e | 496.00 ± 5.66 b | 885.50 ± 38.89 b | 731.50 ± 30.41 c | 1012.50 ± 26.16 c | 389.50 ± 33.23 d | |

| HVED + Na5P3O10 | 58.50 ± 0.99 b.c | 1893.00 ± 11.31 h | 61.00 ± 0.00 a | 860.00 ± 43.84 e | 480.00 ± 19.80 b | 835.00 ± 15.56 b | 728.00 ± 16.97 c | 1413.00 ± 8.49 f | 355.00 ± 35.36 c | |

| Na5P3O10 + HVED | 55.90 ± 0.57 a | 1755.00 ± 26.87 g | 60.80 ± 0.28 a | 824.00 ± 0.00 d | 490.50 ± 0.71 b | 855.00 ± 22.63 b | 716.50 ± 17.68 c | 1262.00 ± 25.46 e | 364.50 ± 21.92 c | |

| Na2HPO4 | 57.65 ± 0.35 b | 705.00 ± 16.97 c | 72.25 ± 2.62 d | 567.50 ± 12.02 b | 278.50 ± 4.95 a | 529.00 ± 7.07 a | 409.00 ± 4.24 b | 426.50 ± 12.02 b | 250.50 ± 2.12 b | |

| HVED + Na2HPO4 | 58.90 ± 0.14 c.d | 579.00 ± 1.41 a | 74.90 ± 2.26 e | 513.50 ± 7.78 b | 243.00 ± 11.31 a | 454.00 ± 22.63 a | 371.50 ± 20.51 a | 335.00 ± 9.90 a | 211.00 ± 11.31 a | |

| Na2HPO4 + HVED | 59.50 ± 0.28 d.e | 617.00 ± 16.97 b | 81.05 ± 0.64 f | 555.00 ± 5.66 a | 274.00 ± 0.00 a | 517.00 ± 12.73 a | 419.50 ± 0.71 b | 342.00 ± 16.97 a | 243.00 ± 12.73 b | |

| Tapioca | Native | 66.30 ± 0.57 B | 644.00 ± 0.00 C | 74.65 ± 0.92 B.C | 382.00 ± 2.83 B | 205.50 ± 0.71 A | 444.50 ± 6.36 C | 411.50 ± 3.54 C | 438.50 ± 0.71 C | 239.00 ± 5.66 c |

| HVED | 66.10 ± 0.14 B | 648.00 ± 15.56 C | 74.45 ± 0.21 B.C | 387.50 ± 2.12 B | 205.00 ± 7.07 A | 422.50 ± 6.36 B.C | 409.50 ± 2.12 C | 442.50 ± 9.19 C | 217.50 ± 0.71 c | |

| Na5P3O10 | 64.15 ± 0.07 A | 882.00 ± 1.41 D | 73.65 ± 0.07 A.B | 546.00 ± 7.07 D | 343.00 ± 0.00 B | 568.50 ± 9.19 D | 507.00 ± 2.83 E | 537.00 ± 1.41 E | 225.50 ± 9.19 c | |

| HVED + Na5P3O10 | 65.05 ± 1.06 A | 805.50 ± 10.61 E | 73.60 ± 1.27 A.B | 482.00 ± 5.66 C | 317.50 ± 2.12 B | 584.50 ± 6.36 D | 481.50 ± 4.95 D | 488.00 ± 9.90 D | 267.00 ± 4.24 d | |

| Na5P3O10 + HVED | 64.40 ± 0.85 A | 920.50 ± 7.78 F | 72.45 ± 0.21 A | 556.00 ± 4.24 D | 492.50 ± 195.87 C | 619.00 ± 4.24 D | 527.50 ± 12.02 E | 562.00 ± 12.73 E | 261.50 ± 0.71 d | |

| Na2HPO4 | 67.85 ± 0.64 C | 525.00 ± 2.83 B | 76.70 ± 0.28 D | 378.50 ± 4.95 B | 188.00 ± 1.41 A | 361.00 ± 1.41 A.B | 296.00 ± 4.24 B | 337.50 ± 0.71 B | 173.00 ± 0.00 b | |

| HVED + Na2HPO4 | 69.35 ± 0.21 D | 428.00 ± 1.41 A | 76.95 ± 0.21 D | 314.50 ± 0.71 A | 151.50 ± 2.12 A | 295.50 ± 4.95 A | 238.50 ± 4.95 A | 275.50 ± 0.71 A | 144.00 ± 2.83 a | |

| Na2HPO4 + HVED | 69.25 ± 0.07 D | 445.00 ± 5.66 A | 76.15 ± 1.20 C.D | 325.50 ± 2.12 A | 157.00 ± 1.41 A | 308.50 ± 4.95 A | 250.00 ± 1.41 A | 288.50 ± 6.36 A | 151.50 ± 3.54 a.b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ačkar, Đ.; Grec, M.; Grgić, I.; Gryszkin, A.; Styczyńska, M.; Jozinović, A.; Miličević, B.; Šubarić, D.; Babić, J. Physical Properties of Starches Modified by Phosphorylation and High-Voltage Electrical Discharge (HVED). Polymers 2022, 14, 3359. https://doi.org/10.3390/polym14163359

Ačkar Đ, Grec M, Grgić I, Gryszkin A, Styczyńska M, Jozinović A, Miličević B, Šubarić D, Babić J. Physical Properties of Starches Modified by Phosphorylation and High-Voltage Electrical Discharge (HVED). Polymers. 2022; 14(16):3359. https://doi.org/10.3390/polym14163359

Chicago/Turabian StyleAčkar, Đurđica, Marijana Grec, Ivanka Grgić, Artur Gryszkin, Marzena Styczyńska, Antun Jozinović, Borislav Miličević, Drago Šubarić, and Jurislav Babić. 2022. "Physical Properties of Starches Modified by Phosphorylation and High-Voltage Electrical Discharge (HVED)" Polymers 14, no. 16: 3359. https://doi.org/10.3390/polym14163359

APA StyleAčkar, Đ., Grec, M., Grgić, I., Gryszkin, A., Styczyńska, M., Jozinović, A., Miličević, B., Šubarić, D., & Babić, J. (2022). Physical Properties of Starches Modified by Phosphorylation and High-Voltage Electrical Discharge (HVED). Polymers, 14(16), 3359. https://doi.org/10.3390/polym14163359