Agglomerate Growth of Xanthan Gum Powder during Fluidized-Bed Agglomeration Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

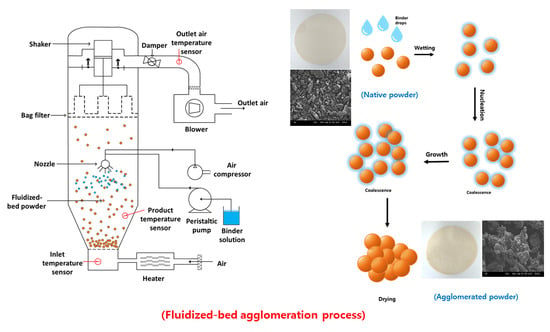

2.2. Fluidized-Bed Agglomeration

2.3. Particle Size Distribution (PSD)

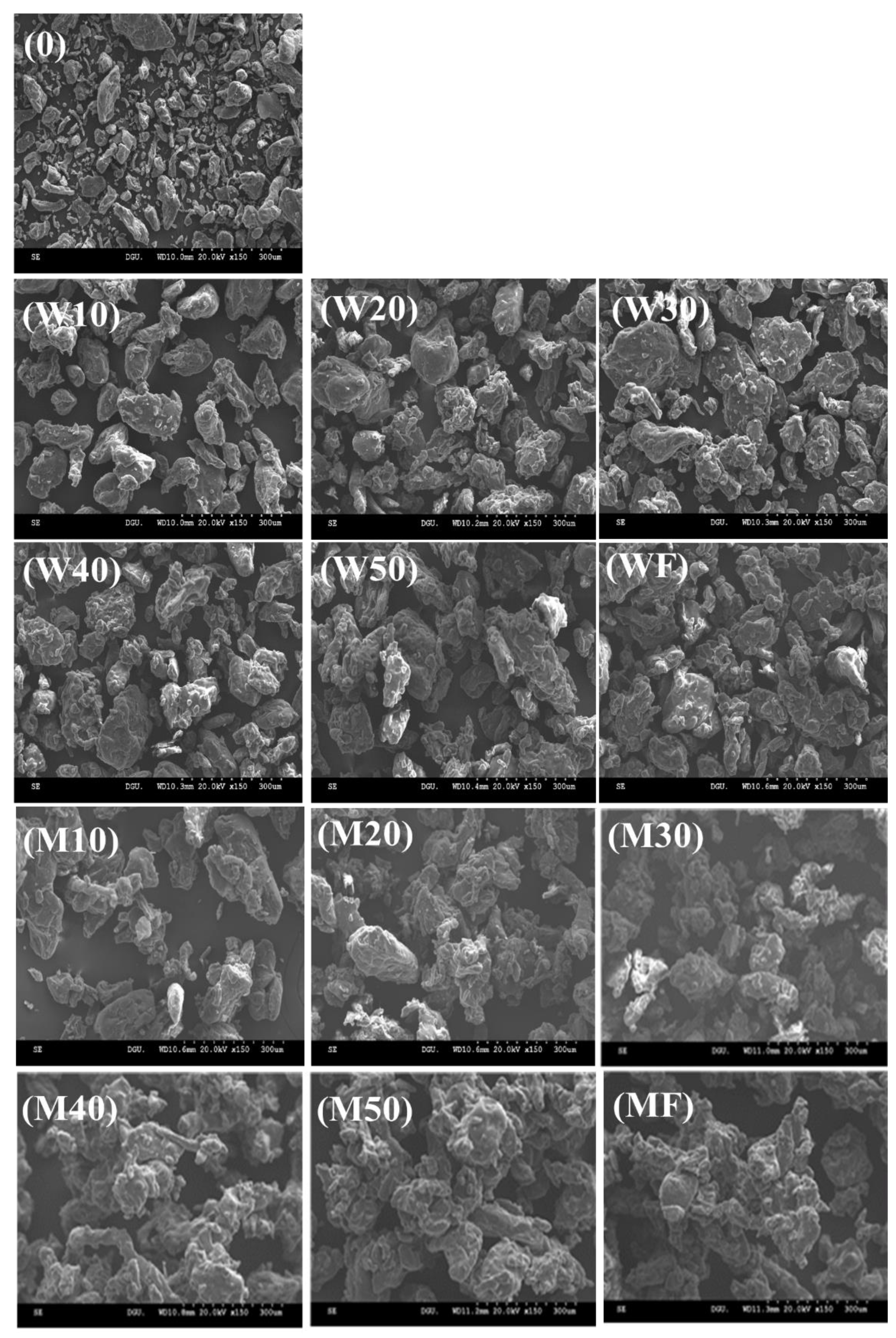

2.4. Particle Morphology (SEM)

2.5. Sample Preparation for Rheological Measurements

2.6. Rheology

2.7. Statistical Analysis

3. Results and Discussion

3.1. PSD and Particle Diameter

3.2. Particle Morphology

3.3. Dynamic Rheological Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, H.; Yoo, B. Agglomerated xanthan gum powder used as a food thickener: Effect of sugar binders on physical, microstructural, and rheological properties. Powder Technol. 2020, 362, 301–306. [Google Scholar] [CrossRef]

- Cuq, B.; Mandato, S.; Jeantet, R.; Saleh, K.; Ruiz, T. Agglomeration/granulation in food powder production. In Handbook of Food Powders; Elsevier: Amsterdam, The Netherlands, 2013; pp. 150–177. [Google Scholar]

- Lee, H.; Yoo, B. Agglomeration of galactomannan gum powders: Physical, rheological, and structural characterizations. Carbohyd. Polym. 2021, 256, 117599. [Google Scholar] [CrossRef] [PubMed]

- Seo, A.; Holm, P.; Schæfer, T. Effects of droplet size and type of binder on the agglomerate growth mechanisms by melt agglomeration in a fluidised bed. Eur. J. Pharm Sci. 2002, 16, 95–105. [Google Scholar] [CrossRef]

- Bellocq, B.; Cuq, B.; Ruiz, T.; Duri, A.; Cronin, K.; Ring, D. Impact of fluidized bed granulation on structure and functional properties of the agglomerates based on the durum wheat semolina. Innov. Food Sci. Emerg. 2018, 45, 73–83. [Google Scholar] [CrossRef]

- Szulc, K.; Lenart, A. Surface modification of dairy powders: Effects of fluid-bed agglomeration and coating. Int. Dairy. J. 2013, 33, 55–61. [Google Scholar] [CrossRef]

- Ji, J.F.; Cronin, K.; Fitzpatrick, J.; Fenelon, M.; Miao, S. Effects of fluid bed agglomeration on the structure modification and reconstitution behaviour of milk protein isolate powders. J. Food Eng. 2015, 167, 175–182. [Google Scholar] [CrossRef]

- Ji, J.F.; Fitzpatrick, J.; Cronin, K.; Fenelon, M.A.; Miao, S. The effects of fluidised bed and high shear mixer granulation processes on water adsorption and flow properties of milk protein isolate powder. J. Food Eng. 2017, 192, 19–27. [Google Scholar] [CrossRef]

- Atalar, I.; Yazici, F. Influence of top spray fluidized bed agglomeration conditions on the reconstitution property and structure modification of skim yoghurt powder. J. Food Process Pres. 2018, 42, 13414. [Google Scholar] [CrossRef]

- Rayo, L.M.; e Carvalho, L.C.; Sardá, F.A.; Dacanal, G.C.; Menezes, E.W.; Tadini, C.C. Production of instant green banana flour (Musa cavendischii, var. Nanicao) by a pulsed-fluidized bed agglomeration. Lwt-Food Sci Technol. 2015, 63, 461–469. [Google Scholar] [CrossRef]

- Haas, K.; Dohnal, T.; Andreu, P.; Zehetner, E.; Kiesslich, A.; Volkert, M.; Fryer, P.; Jaeger, H. Particle engineering for improved stability and handling properties of carrot concentrate powders using fluidized bed granulation and agglomeration. Powder Technol. 2020, 370, 104–115. [Google Scholar] [CrossRef]

- Chemache, L.; Lecoq, O.; Namoune, H.; Oulahna, D. Agglomeration properties of gluten-free flours under water addition and shearing conditions. Lwt-Food Sci. Technol. 2019, 110, 40–47. [Google Scholar] [CrossRef]

- Jinapong, N.; Suphantharika, M.; Jamnong, P. Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. J. Food Eng. 2008, 84, 194–205. [Google Scholar] [CrossRef]

- Sakhare, S.D.; Inamdar, A.A.; Soumya, C.; Indrani, D.; Rao, G.V. Effect of flour particle size on microstructural, rheological and physico-sensory characteristics of bread and south Indian parotta. J. Food Sci. Technol. Mys. 2014, 51, 4108–4113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Doublier, J.L.; Cuvelier, G. Gums and hydrocolloids: Functional aspects. In Carbohydrates in Food; Marcel Deckker Inc.: New York, NY, USA, 2006; pp. 283–318. [Google Scholar]

| Binder Type | Agglomeration Time (min) | D10 (μm) | D50 (μm) | D90 (μm) | Span (−) |

|---|---|---|---|---|---|

| Water | 0 (Native) | 15.5 ± 0.04 g | 72.7 ± 0.09 g | 167 ± 0.13 f | 2.09 ± 0.00 a |

| 10 | 62.7 ± 1.37 f (304) | 142 ± 0.92 f (95.4) | 335 ± 4.12 e (100) | 1.91 ± 0.04 c | |

| 20 | 74.8 ± 1.40 e (382) | 169 ± 3.66 e (133) | 411 ± 3.94 c (129) | 1.99 ± 0.03 b | |

| 30 | 82.4 ± 0.61 d (431) | 181 ± 1.88 d (149) | 416 ± 8.96 c (149) | 1.84 ± 0.03 d | |

| 40 | 96.7 ± 0.60 b (523) | 209 ± 2.47 b (188) | 471 ± 1.74 b (188) | 1.79 ± 0.02 d | |

| 50 | 105 ± 1.20 a (578) | 227 ± 3.83 a (212) | 496 ± 0.72 a (212) | 1.72 ± 0.04 e | |

| Final product | 92.0 ± 0.93 c (493) | 189 ± 1.91 c (160) | 396 ± 2.30 d (160) | 1.61 ± 0.01 f | |

| 0 (Native) | 15.5 ± 0.04 g | 72.7 ± 0.09 f | 167 ± 0.13 f | 2.09 ± 0.00 a | |

| MD | 10 | 67.4 ± 0.57 f (334) | 153 ± 1.63 e (110) | 334 ± 3.21 e (99.5) | 1.75 ± 0.01 b |

| 20 | 79.9 ± 0.45 e (415) | 176 ± 1.01 d (142) | 357 ± 2.74 d (113) | 1.58 ± 0.03 c | |

| 30 | 86.9 ± 0.11 d (460) | 186 ± 1.92 c (156) | 368 ± 4.38 d (120) | 1.51 ± 0.01 d | |

| 40 | 99.9 ± 1.27 c (544) | 211 ± 5.10 b (189) | 412 ± 14.3 b (146) | 1.48 ± 0.03 c | |

| 50 | 107 ± 0.86 a (591) | 221 ± 2.55 a (204) | 430 ± 5.35 a (157) | 1.46 ± 0.00 c | |

| Final product | 106 ± 0.78 b (580) | 209 ± 1.65 b (188) | 390 ± 3.50 c (133) | 1.36 ± 0.01 f |

| Binder Type | Agglomeration Time (min) | G′ (Pa) | G″ (Pa) | Tan δ |

|---|---|---|---|---|

| Water | 0 (Native) | 21.7 ± 0.02 c | 7.10 ± 0.01 c | 0.33 ± 0.00 b |

| 10 | 21.3 ± 0.01 e | 7.22 ± 0.02 b | 0.34 ± 0.00 a | |

| 20 | 21.5 ± 0.03 d | 7.24 ± 0.01 b | 0.34 ± 0.00 a | |

| 30 | 21.8 ± 0.08 c | 7.34 ± 0.01 a | 0.34 ± 0.00 a | |

| 40 | 21.9 ± 0.06 c | 7.34 ± 0.01 a | 0.34 ± 0.00 a | |

| 50 | 22.3 ± 0.05 b | 7.35 ± 0.03 a | 0.33 ± 0.00 b | |

| Final product | 22.4 ± 0.01 a | 7.33 ± 0.01 a | 0.33 ± 0.00 b | |

| 0 (Native) | 21.7 ± 0.02 a | 7.10 ± 0.01 a | 0.33 ± 0.00 b | |

| MD | 10 | 20.0 ± 0.04 e | 6.85 ± 0.01 c | 0.34 ± 0.00 a |

| 20 | 21.0 ± 0.03 b | 6.92 ± 0.02 b | 0.33 ± 0.01 b | |

| 30 | 21.0 ± 0.02 b | 6.92 ± 0.03 b | 0.33 ± 0.00 b | |

| 40 | 20.3 ± 0.04 c | 6.75 ± 0.03 d | 0.33 ± 0.00 b | |

| 50 | 20.3 ± 0.01 c | 6.73 ± 0.04 d | 0.33 ± 0.00 b | |

| Final product | 20.2 ± 0.01 d | 6.92 ± 0.01 b | 0.34 ± 0.00 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Yoo, B. Agglomerate Growth of Xanthan Gum Powder during Fluidized-Bed Agglomeration Process. Polymers 2022, 14, 4018. https://doi.org/10.3390/polym14194018

Lee D, Yoo B. Agglomerate Growth of Xanthan Gum Powder during Fluidized-Bed Agglomeration Process. Polymers. 2022; 14(19):4018. https://doi.org/10.3390/polym14194018

Chicago/Turabian StyleLee, Donghyeon, and Byoungseung Yoo. 2022. "Agglomerate Growth of Xanthan Gum Powder during Fluidized-Bed Agglomeration Process" Polymers 14, no. 19: 4018. https://doi.org/10.3390/polym14194018

APA StyleLee, D., & Yoo, B. (2022). Agglomerate Growth of Xanthan Gum Powder during Fluidized-Bed Agglomeration Process. Polymers, 14(19), 4018. https://doi.org/10.3390/polym14194018