A Scientometric-Analysis-Based Review of the Research Development on Geopolymers

Abstract

:1. Introduction

2. Review Strategy

3. Results and Discussions

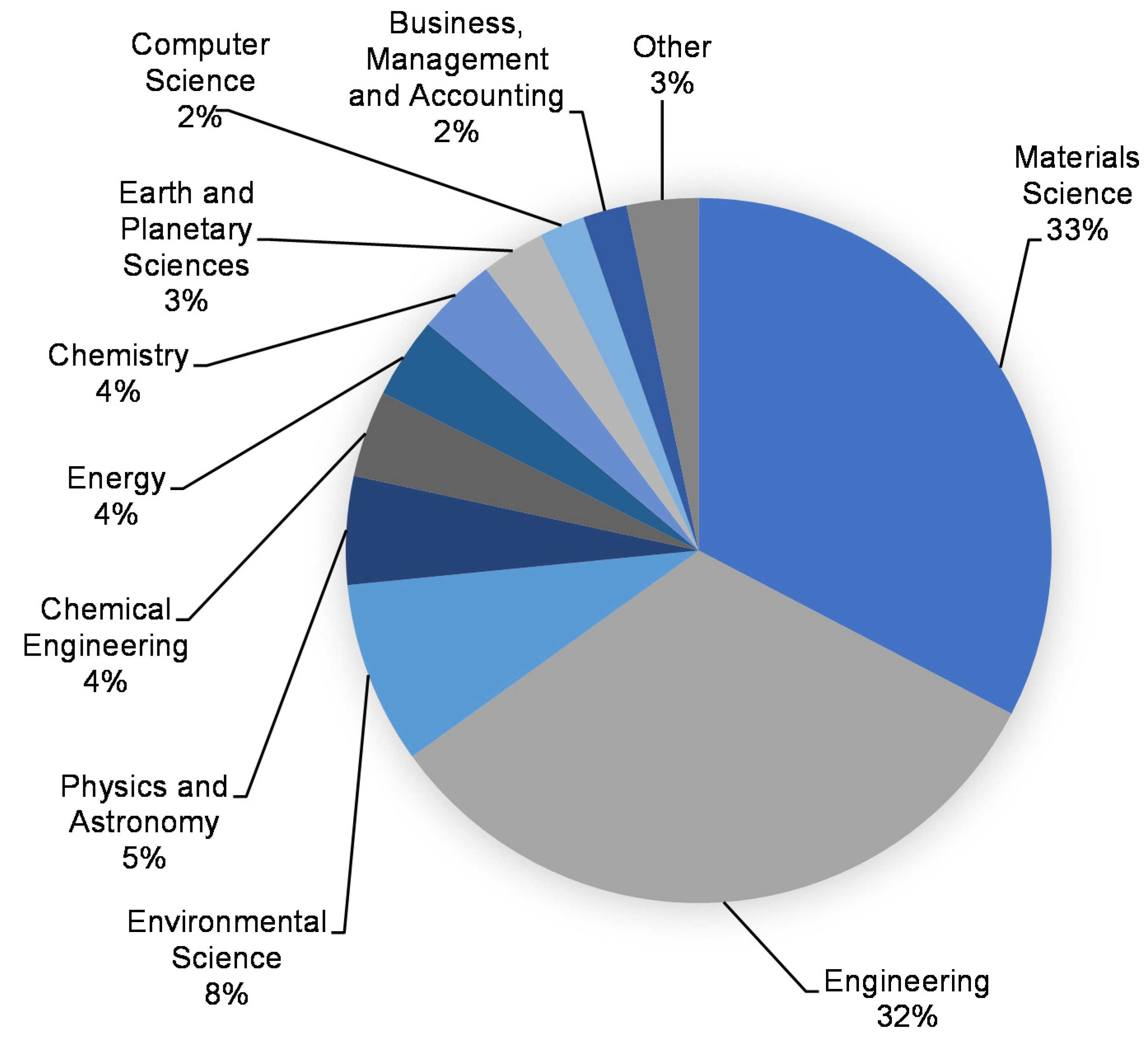

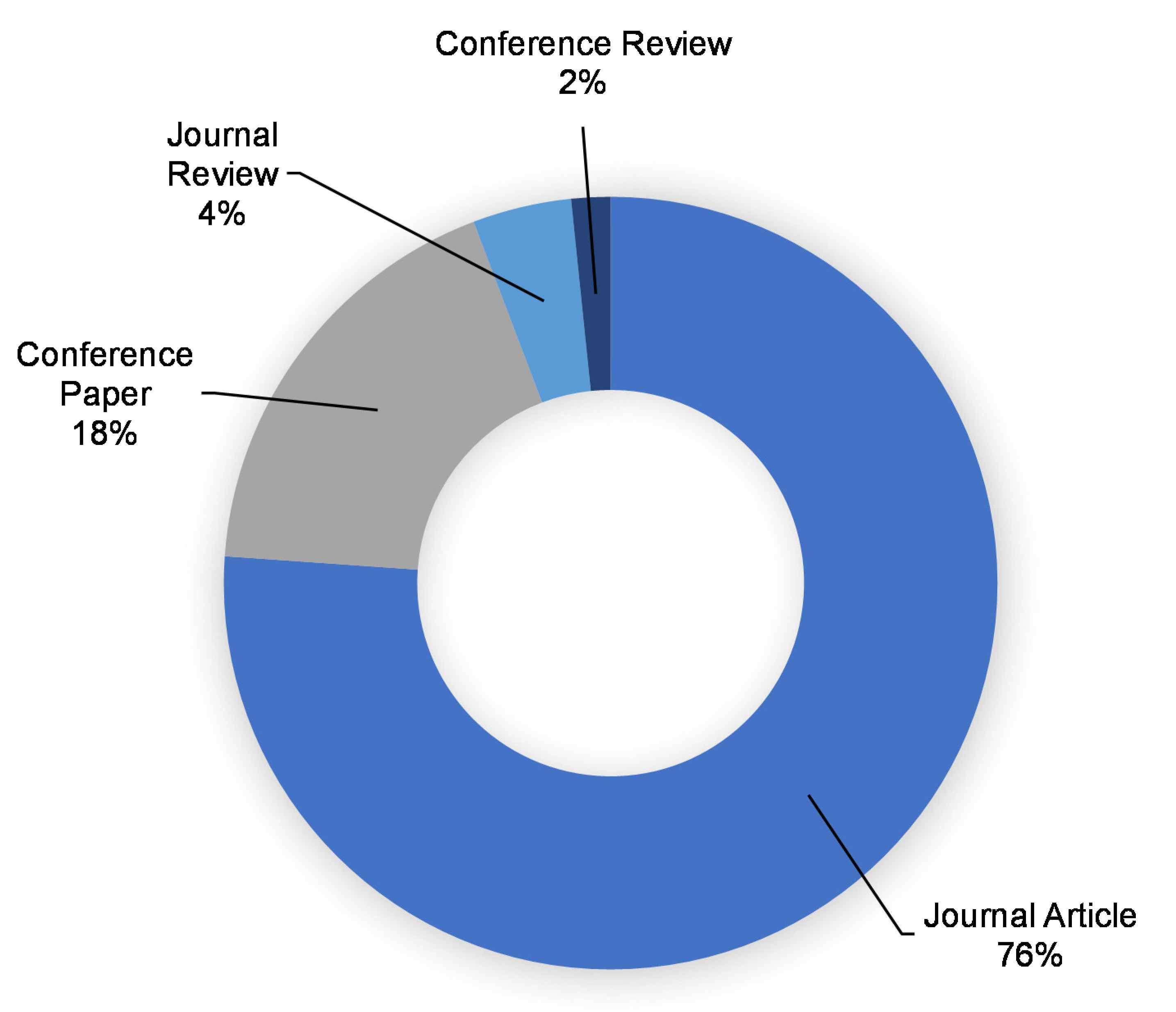

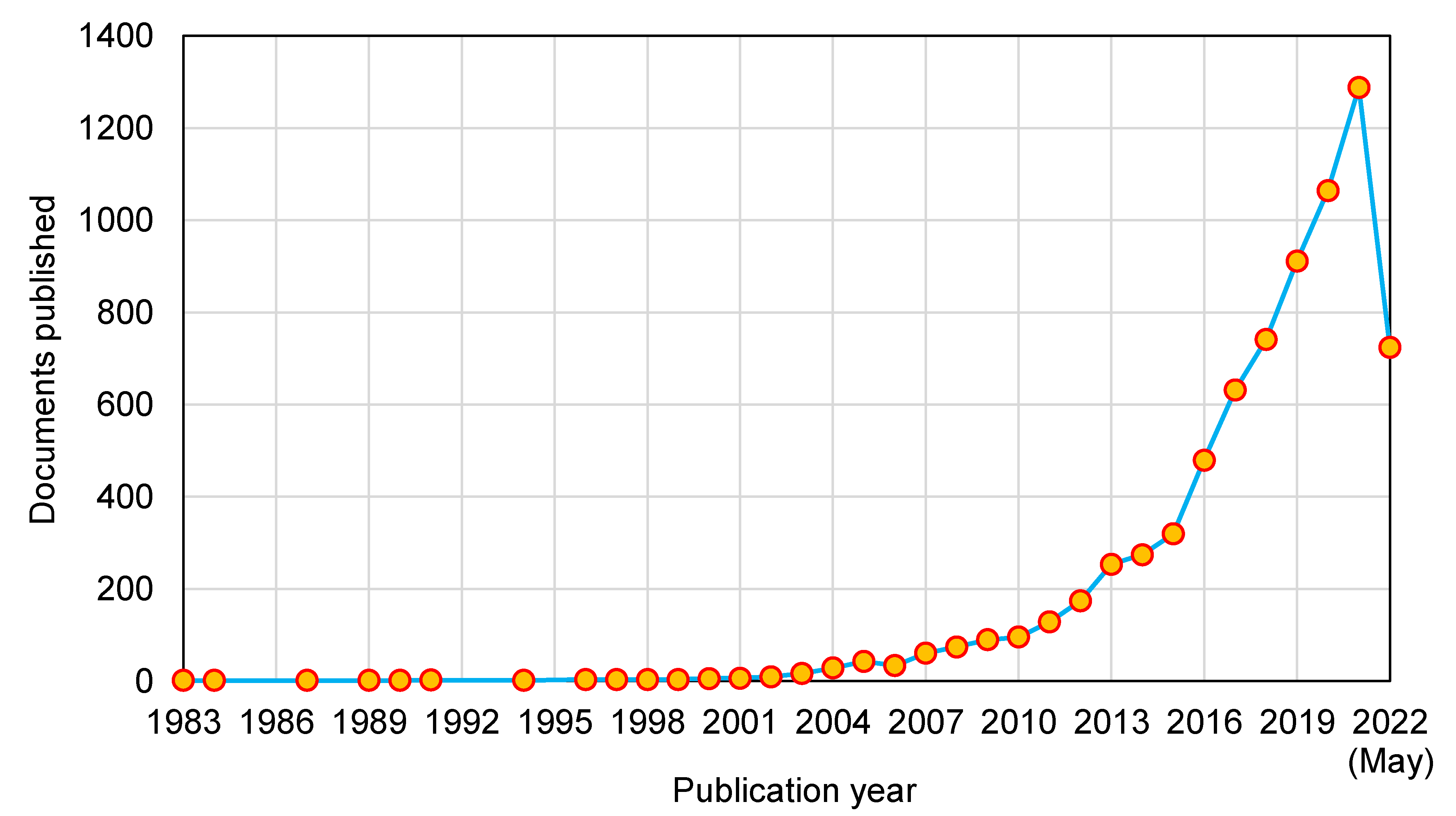

3.1. Subject Area and Yearly Publication of Documents

3.2. Bibliographic Coupling of Publication Sources

3.3. Co-Occurrence of Keywords

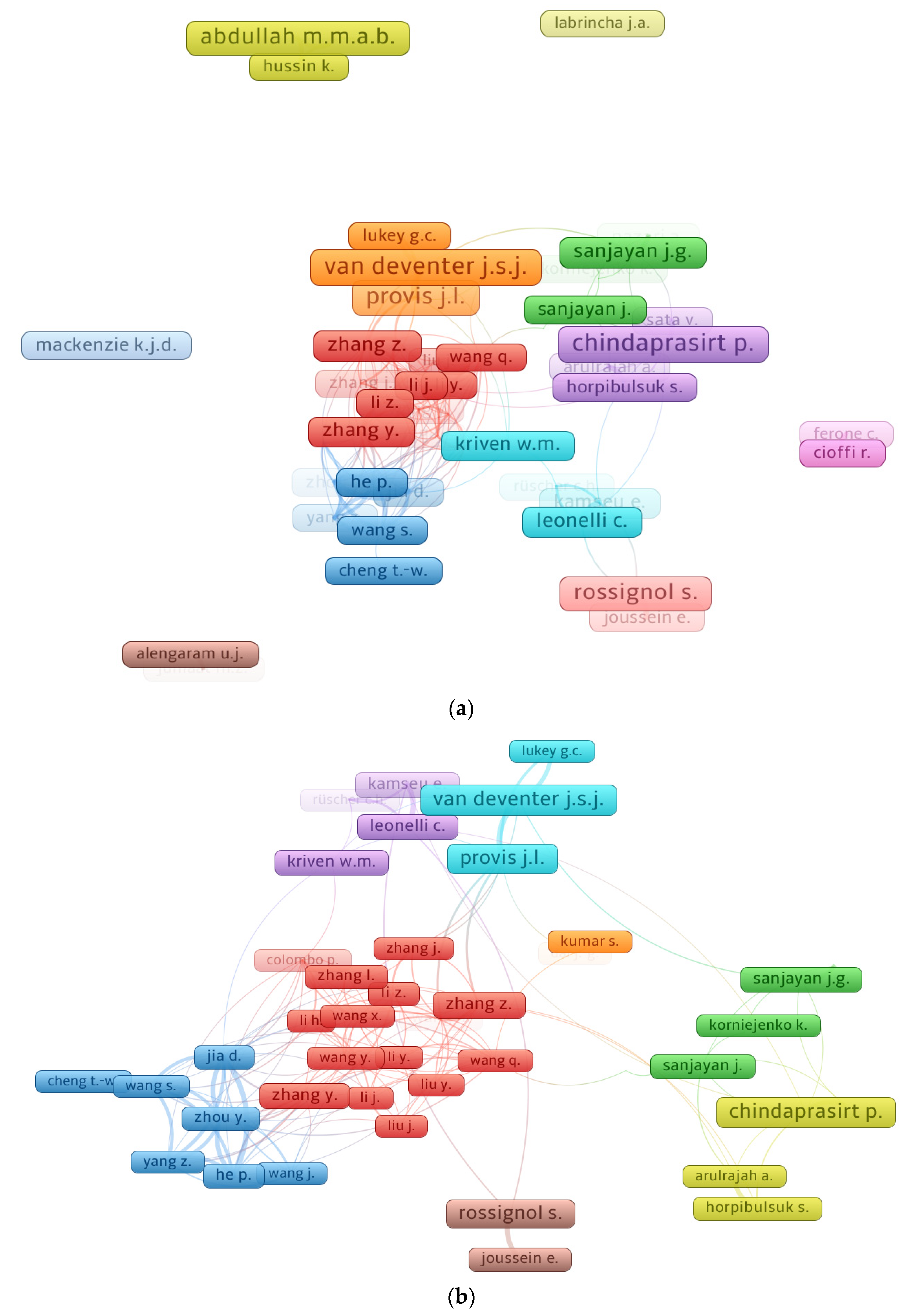

3.4. Authors’ Coauthorship

3.5. Bibliographic Coupling of Documents

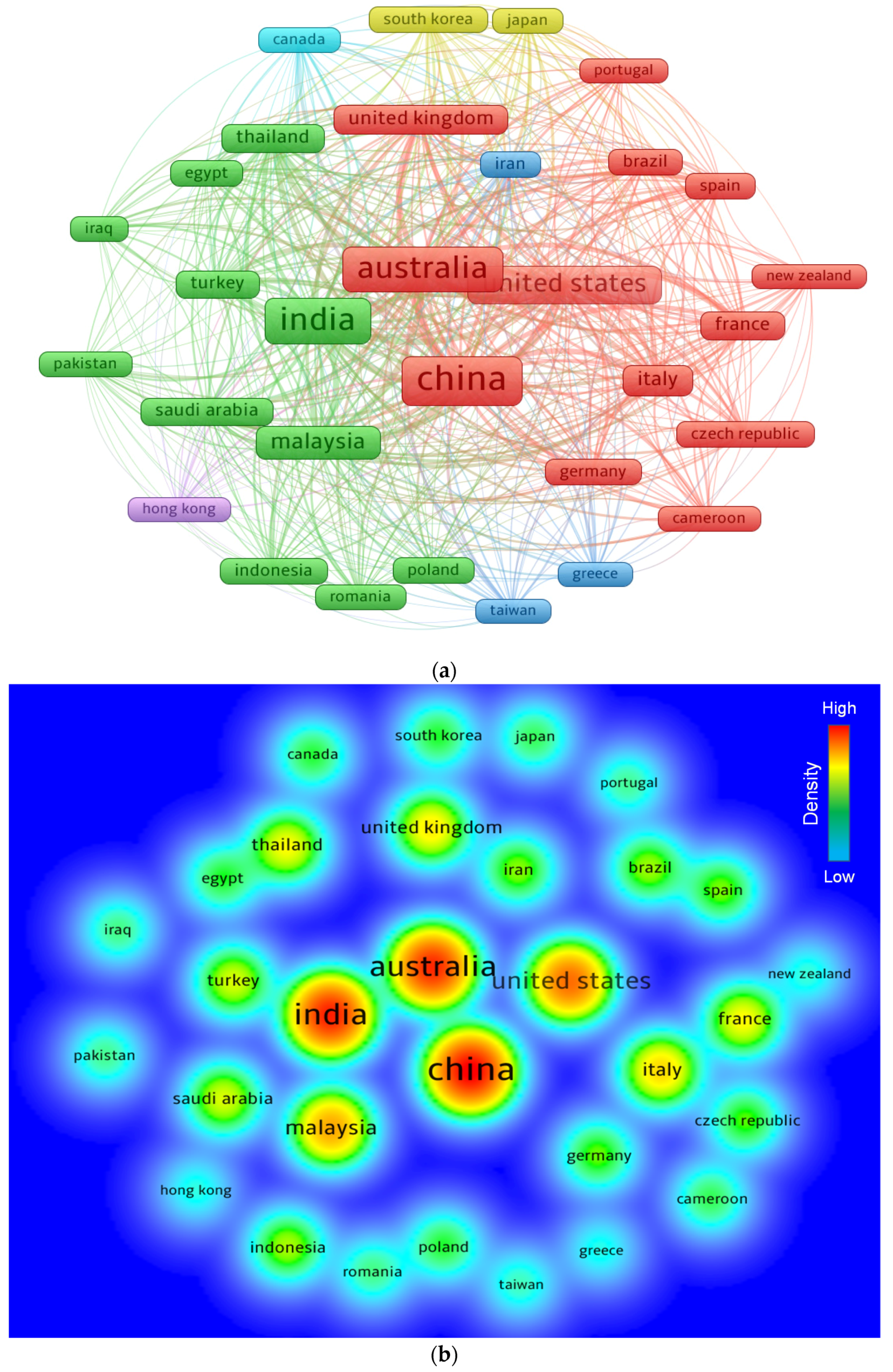

3.6. Bibliographic Coupling of Countries

4. Discussion

4.1. Applications of Geopolymer Concrete

4.2. Limitations and Potential Remedies

- Geopolymer composites need steam/heat curing for strength enhancement [96,97], which is challenging to apply to structural elements on-site. Nevertheless, enclosing the structural elements with films and creating a humid atmosphere might be an alternate curing method for geopolymer composites [98,99].

- Sodium-silicate deficiency is a further significant factor limiting geopolymer production. The environmental efficacy and financial advantage of geopolymers are highly dependent on the amount of alkali-activated material employed [23]. Geopolymer composites are also costly because of the high cost of activating solutions [100]. Utilizing rice husk ash as a silicon source in the production of sodium-silicate solution might reduce the requirement for sodium carbonate and quartz sand [101], both of which produce greenhouse gases during the production. Sodium silicate produced from rice husk ash and waste glass is an outstanding activator for the production of metakaolin-based geopolymers [102]. Utilizing glass-polishing waste as an activator may also be a cost-efficient option [103].

- Another factor that impacts the advancement of geopolymer composites is efflorescence. Salt growth in surface alkali-activated cement has been seen in several industrial applications and laboratory experiments, where it has been described as efflorescence. In silicon-rich settings, high concentrations of alkali activators can induce substantial efflorescence. The level of efflorescence decreased as the content of alumina increased [104]. The occurrence of geopolymer efflorescence decreases as silica concentration and grain size increase [105,106]. The use of nanosilica in geopolymer composites based on metakaolin is beneficial. Nanosilica decreased efflorescence by consuming alkali ions in excess from the pore solution, therefore forming an amorphous gel phase [107].

- The use of alkaline activators in greater concentrations may hasten ASR, hence restricting the usefulness of geopolymer composites. According to the researchers, ASR expansion was more easily generated in high-calcium and mixed systems than in low-calcium alkali-activated cement systems. Activators of varying kinds and dilutions can also induce ASR. Certain admixtures may lead to the development of ASR [108]. Therefore, further study on ASR is necessary to determine the crucial factors that influence its incidence.

5. Conclusions

- An evaluation of publication journals, including articles on geopolymers research, revealed that “CONBUILDMAT”, “Ceramics international”, and “Journal of cleaner production” are the top three sources, with 770, 221, and 151 publications, respectively. In terms of total citations, the top three publishing sources are “CONBULDMAT” with 34,289, “Cement and concrete research” with 12,256, and “Journal of materials science” with 9547 citations.

- Assessment of keywords on the topic research field reveals that geopolymer, fly ash, compressive strength, geopolymer concrete, and geopolymers are the five most often occurring terms. The keyword analysis found that geopolymer has mostly been researched to produce sustainable construction material and is mostly investigated to be produced from waste materials, such as fly ash, slag, silica fume, rice husk ash, etc.

- Analysis of researchers found that just 55 authors had published at least 25 articles on geopolymers research. According to their document count, overall citations, and average citations, the leading authors were categorized. Van Deventer J.S.J. and Chindaprasirt P. are the most prolific researchers with 93 publications each, followed by Provis J.L. with 86 and Abdullah M.M.A.B. with 79 publications. In terms of total citations, Van Deventer J.S.J. leads the field with 18,335, Provis J.L. is second with 15,257, and Lukey G.C. is third with 9891 overall citations in the present research domain. In addition, when the average number of citations is compared, the authors might be ranked as Lukey G.C. at the top with nearly 341 average citations, Van Deventer J.S.J. at second with about 197, and Provis J.L. in third with approximately 177 average citations.

- An assessment of published documents containing data on geopolymers revealed that Prasanna P. [53] ’s work “Geopolymer technology: The current state of the art” received 2573 citations. Davidovits J. [83] and Duxson P. [84] received 2507 and 1124 citations for their studies, respectively, and were among the top three. In addition, as of May 2022, just 28 papers had received more than 500 citations in the topic field.

- Based on their engagement in geopolymers research, the top countries were evaluated, and it was concluded that only 31 countries published at least 50 documents. The United States, China, and Indi China, India, and Australia presented 895, 776, and 743 documents, respectively. In addition, Australia received 54,555 citations, followed by China with 22,820 citations, and the United States received 15,649 citations.

- Since geopolymers require source materials with greater aluminosilicate concentrations, which are prevalent in various waste materials such as fly ash, slag, rice husk ash, etc., recycling these materials to create geopolymers would minimize environmental pollution.

- The large-scale applications of geopolymer concrete in the building sector are limited due to several restraints such as curing regime, deficiency and cost of activator solution, efflorescence, and ASR. Adopting potential remedies as discussed in this study might help increase the acceptance of geopolymer concrete in construction. However, further in-depth investigations are necessary on these solutions for the large-scale applicability of geopolymers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, M.; Cao, M.; Ai, H.; Hussain, A. Basalt Fibers in Modified Whisker Reinforced Cementitious Composites. Period. Polytech. Civ. Eng. 2022, 66, 344–354. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Chaopeng, X.; Ali, M. Experimental and analytical study of hybrid fiber reinforced concrete prepared with basalt fiber under high temperature. Fire Mater. 2022, 46, 205–226. [Google Scholar] [CrossRef]

- Khan, M.; Lao, J.; Dai, J.-G. Comparative study of advanced computational techniques for estimating the compressive strength of UHPC. Journal of Asian Concrete Federation 2022, 8, 51–68. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Ferrotto, M.F.; Asteris, P.G.; Borg, R.P.; Cavaleri, L. Strategies for Waste Recycling: The Mechanical Performance of Concrete Based on Limestone and Plastic Waste. Sustainability 2022, 14, 1706. [Google Scholar] [CrossRef]

- Li, G.; Zhou, C.; Ahmad, W.; Usanova, K.I.; Karelina, M.; Mohamed, A.M.; Khallaf, R. Fly Ash Application as Supplementary Cementitious Material: A Review. Materials 2022, 15, 2664. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Sayed, M.M. Mapping Research Knowledge on Rice Husk Ash Application in Concrete: A Scientometric Review. Materials 2022, 15, 3431. [Google Scholar] [CrossRef]

- Neupane, K.; Hadigheh, S.A. Sodium hydroxide-free geopolymer binder for prestressed concrete applications. Constr. Build. Mater. 2021, 293, 123397. [Google Scholar] [CrossRef]

- Niu, M.; Zhang, P.; Guo, J.; Wang, J. Effect of Municipal Solid Waste Incineration Fly Ash on the Mechanical Properties and Microstructure of Geopolymer Concrete. Gels 2022, 8, 341. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Liu, L.; Yang, W.; Liu, H.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A comprehensive overview of geopolymer composites: A bibliometric analysis and literature review. Case Stud. Constr. Mater. 2022, 16, e00830. [Google Scholar] [CrossRef]

- Ahmad, A.; Ahmad, W.; Aslam, F.; Joyklad, P. Compressive strength prediction of fly ash-based geopolymer concrete via advanced machine learning techniques. Case Stud. Constr. Mater. 2022, 16, e00840. [Google Scholar] [CrossRef]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P.; Zajdel, P. Sustainable approach of using sugarcane bagasse ash in cement-based composites: A systematic review. Case Stud. Constr. Mater. 2021, 15, e00698. [Google Scholar] [CrossRef]

- Min, J.; Zandi, Y.; Agdas, A.S.; Majdi, A.; Ali, H.E.; Jan, A.; Salameh, A.A.; Ebid, A.A. The Numerical Analysis of Replenishment of Hydrogel Void Space Concrete Using Hydrogels Containing Nano-Silica Particles through ELM-ANFIS. Gels 2022, 8, 299. [Google Scholar] [CrossRef]

- Wei, J.; Cen, K. Empirical assessing cement CO2 emissions based on China’s economic and social development during 2001–2030. Sci. Total Environ. 2019, 653, 200–211. [Google Scholar] [CrossRef]

- Hossain, M.U.; Cai, R.; Ng, S.T.; Xuan, D.; Ye, H. Sustainable natural pozzolana concrete—A comparative study on its environmental performance against concretes with other industrial by-products. Constr. Build. Mater. 2021, 270, 121429. [Google Scholar] [CrossRef]

- Abriyantoro, D.; Dong, J.; Hicks, C.; Singh, S.P. A stochastic optimisation model for biomass outsourcing in the cement manufacturing industry with production planning constraints. Energy 2019, 169, 515–526. [Google Scholar] [CrossRef]

- Carvalho, C.M.; Barbosa, N.P.; Bezerra, U.T.; Simas, T.B. Red ceramic industry residues: Used to produce Portland cement. Case Stud. Constr. Mater. 2020, 13, e00449. [Google Scholar] [CrossRef]

- Thwe, E.; Khatiwada, D.; Gasparatos, A. Life cycle assessment of a cement plant in Naypyitaw, Myanmar. Clean. Environ. Syst. 2021, 2, 100007. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Sousa, V.; Bogas, J.A. Comparison of energy consumption and carbon emissions from clinker and recycled cement production. J. Clean. Prod. 2021, 306, 127277. [Google Scholar] [CrossRef]

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Meesala, C.R.; Verma, N.K.; Kumar, S. Critical review on fly-ash based geopolymer concrete. Struct. Concr. 2020, 21, 1013–1028. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Alanazi, H. Study of the Interfacial Transition Zone Characteristics of Geopolymer and Conventional Concretes. Gels 2022, 8, 105. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.D.; Vieira, C.M.F. Reaction mechanisms of alkali-activated materials. Rev. IBRACON Estrut. Mater. 2021, 14. [Google Scholar] [CrossRef]

- Marvila, M.T.; de Azevedo, A.R.G.; de Matos, P.R.; Monteiro, S.N.; Vieira, C.M.F. Materials for production of high and ultra-high performance concrete: Review and perspective of possible novel materials. Materials 2021, 14, 4304. [Google Scholar] [CrossRef]

- Farooq, F.; Jin, X.; Javed, M.F.; Akbar, A.; Shah, M.I.; Aslam, F.; Alyousef, R. Geopolymer concrete as sustainable material: A state of the art review. Constr. Build. Mater. 2021, 306, 124762. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Sibai, A. Geopolymers vs. Cement Matrix Materials: How Nanofiller Can Help a Sustainability Approach for Smart Construction Applications—A Review. Nanomaterials 2021, 11, 2007. [Google Scholar] [CrossRef]

- Rocha, T.d.S.; Dias, D.P.; França, F.C.C.; Guerra, R.R.d.S.; Marques, L.R.d.C.d.O. Metakaolin-based geopolymer mortars with different alkaline activators (Na+ and K+). Constr. Build. Mater. 2018, 178, 453–461. [Google Scholar] [CrossRef]

- Paiva, H.; Yliniemi, J.; Illikainen, M.; Rocha, F.; Ferreira, V.M. Mine tailings geopolymers as a waste management solution for a more sustainable habitat. Sustainability 2019, 11, 995. [Google Scholar] [CrossRef]

- Li, Z.; Fei, M.-E.; Huyan, C.; Shi, X. Nano-engineered, Fly Ash-Based Geopolymer Composites: An Overview. Resour. Conserv. Recycl. 2021, 168, 105334. [Google Scholar] [CrossRef]

- Pu, S.; Zhu, Z.; Song, W.; Wang, H.; Huo, W.; Zhang, J. A novel acidic phosphoric-based geopolymer binder for lead solidification/stabilization. J. Hazard. Mater. 2021, 415, 125659. [Google Scholar] [CrossRef]

- Oglat, A.A.; Shalbi, S.M. An Alternative Radiation Shielding Material Based on Barium-Sulphate (BaSO4)-Modified Fly Ash Geopolymers. Gels 2022, 8, 227. [Google Scholar] [CrossRef]

- Odeh, N.A.; Al-Rkaby, A.H.J. Strength, Durability, and Microstructures characterization of sustainable geopolymer improved clayey soil. Case Stud. Constr. Mater. 2022, 16, e00988. [Google Scholar] [CrossRef]

- Zinkaah, O.H.; Araba, A.; Alhawat, M. Performance of ACI code for predicting the flexural capacity and deflection of reinforced geopolymer concrete beams. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1090, 012067. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Neupane, K.; Chalmers, D.; Kidd, P. High-strength geopolymer concrete-properties, advantages and challenges. Adv. Mater. 2018, 7, 15–25. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Zhang, M.; Hu, W.; Bai, Y.; Huang, B. A laboratory investigation of steel to fly ash-based geopolymer paste bonding behavior after exposure to elevated temperatures. Constr. Build. Mater. 2020, 254, 119267. [Google Scholar] [CrossRef]

- Albitar, M.; Ali, M.S.M.; Visintin, P.; Drechsler, M. Durability evaluation of geopolymer and conventional concretes. Constr. Build. Mater. 2017, 136, 374–385. [Google Scholar] [CrossRef]

- Okoye, F.N.; Prakash, S.; Singh, N.B. Durability of fly ash based geopolymer concrete in the presence of silica fume. J. Clean. Prod. 2017, 149, 1062–1067. [Google Scholar] [CrossRef]

- Wong, L.S. Durability Performance of Geopolymer Concrete: A Review. Polymers 2022, 14, 868. [Google Scholar] [CrossRef] [PubMed]

- Youssf, O.; Elchalakani, M.; Hassanli, R.; Roychand, R.; Zhuge, Y.; Gravina, R.J.; Mills, J.E. Mechanical performance and durability of geopolymer lightweight rubber concrete. J. Build. Eng. 2022, 45, 103608. [Google Scholar] [CrossRef]

- Refaie, F.A.-Z.; Abbas, R.; Fouad, F.H. Sustainable construction system with Egyptian metakaolin based geopolymer concrete sandwich panels. Case Stud. Constr. Mater. 2020, 13, e00436. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment–A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Billong, N.; Oti, J.; Kinuthia, J. Using silica fume based activator in sustainable geopolymer binder for building application. Constr. Build. Mater. 2021, 275, 122177. [Google Scholar] [CrossRef]

- Zakka, W.P.; Lim, N.H.A.S.; Khun, M.C. A scientometric review of geopolymer concrete. J. Clean. Prod. 2021, 280, 124353. [Google Scholar] [CrossRef]

- Wen, N.; Zhao, Y.; Yu, Z.; Liu, M. A sludge and modified rice husk ash-based geopolymer: Synthesis and characterization analysis. J. Clean. Prod. 2019, 226, 805–814. [Google Scholar] [CrossRef]

- Podolsky, Z.; Liu, J.; Dinh, H.; Doh, J.H.; Guerrieri, M.; Fragomeni, S. State of the Art on the Application of Waste Materials in Geopolymer Concrete. Case Stud. Constr. Mater. 2021, 15, e00637. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Kljajević, L.; Nenadović, M.; Ivanović, M.; Bučevac, D.; Mirković, M.; Mladenović Nikolić, N.; Nenadović, S. Heat Treatment of Geopolymer Samples Obtained by Varying Concentration of Sodium Hydroxide as Constituent of Alkali Activator. Gels 2022, 8, 333. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Ahmad, W.; Chaiyasarn, K.; Ostrowski, K.A.; Aslam, F.; Zajdel, P.; Joyklad, P. Prediction of Geopolymer Concrete Compressive Strength Using Novel Machine Learning Algorithms. Polymers 2021, 13, 3389. [Google Scholar] [CrossRef]

- Reddy, M.S.; Dinakar, P.; Rao, B.H. Mix design development of fly ash and ground granulated blast furnace slag based geopolymer concrete. J. Build. Eng. 2018, 20, 712–722. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Lin, C. Microstructure Analysis and Effects of Single and Mixed Activators on Setting Time and Strength of Coal Gangue-Based Geopolymers. Gels 2022, 8, 195. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Lin, C. Compressive and Flexural Properties of Ultra-Fine Coal Gangue-Based Geopolymer Gels and Microscopic Mechanism Analysis. Gels 2022, 8, 145. [Google Scholar] [CrossRef]

- Tian, Z.; Tang, X.; Xiu, Z.; Zhou, H.; Xue, Z. The mechanical properties improvement of environmentally friendly fly ash-based geopolymer mortar using bio-mineralization. J. Clean. Prod. 2022, 332, 130020. [Google Scholar] [CrossRef]

- Jindal, B.B. Investigations on the properties of geopolymer mortar and concrete with mineral admixtures: A review. Constr. Build. Mater. 2019, 227, 116644. [Google Scholar] [CrossRef]

- Lan, T.; Meng, Y.; Ju, T.; Chen, Z.; Du, Y.; Deng, Y.; Song, M.; Han, S.; Jiang, J. Synthesis and application of geopolymers from municipal waste incineration fly ash (MSWI FA) as raw ingredient—A review. Resour. Conserv. Recycl. 2022, 182, 106308. [Google Scholar] [CrossRef]

- Sandanayake, M.; Law, D.; Sargent, P. A new framework for assessing the environmental impacts of circular economy friendly soil waste-based geopolymer cements. Build. Environ. 2022, 210, 108702. [Google Scholar] [CrossRef]

- Ilcan, H.; Sahin, O.; Kul, A.; Yildirim, G.; Sahmaran, M. Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-Printing. Constr. Build. Mater. 2022, 328, 127114. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Alengaram, U.J.; Yap, S.P. Mechanical strength and permeation properties of high calcium fly ash-based geopolymer containing recycled brick powder. J. Build. Eng. 2020, 32, 101655. [Google Scholar] [CrossRef]

- John, S.K.; Nadir, Y.; Girija, K. Effect of source materials, additives on the mechanical properties and durability of fly ash and fly ash-slag geopolymer mortar: A review. Constr. Build. Mater. 2021, 280, 122443. [Google Scholar] [CrossRef]

- Pilehvar, S.; Cao, V.D.; Szczotok, A.M.; Carmona, M.; Valentini, L.; Lanzón, M.; Pamies, R.; Kjøniksen, A.-L. Physical and mechanical properties of fly ash and slag geopolymer concrete containing different types of micro-encapsulated phase change materials. Constr. Build. Mater. 2018, 173, 28–39. [Google Scholar] [CrossRef]

- Zou, Y.; Zheng, C.; Alzahrani, A.M.; Ahmad, W.; Ahmad, A.; Mohamed, A.M.; Khallaf, R.; Elattar, S. Evaluation of Artificial Intelligence Methods to Estimate the Compressive Strength of Geopolymers. Gels 2022, 8, 271. [Google Scholar] [CrossRef]

- Xu, Y.; Zeng, J.; Chen, W.; Jin, R.; Li, B.; Pan, Z. A holistic review of cement composites reinforced with graphene oxide. Constr. Build. Mater. 2018, 171, 291–302. [Google Scholar] [CrossRef]

- Xiao, X.; Skitmore, M.; Li, H.; Xia, B. Mapping knowledge in the economic areas of green building using scientometric analysis. Energies 2019, 12, 3011. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.; Huo, X.; Owusu-Manu, D.-G. A scientometric analysis and visualization of global green building research. Build. Environ. 2019, 149, 501–511. [Google Scholar] [CrossRef]

- Markoulli, M.P.; Lee, C.I.; Byington, E.; Felps, W.A. Mapping Human Resource Management: Reviewing the field and charting future directions. Hum. Resour. Manag. Rev. 2017, 27, 367–396. [Google Scholar] [CrossRef]

- Afgan, S.; Bing, C. Scientometric review of international research trends on thermal energy storage cement based composites via integration of phase change materials from 1993 to 2020. Constr. Build. Mater. 2021, 278, 122344. [Google Scholar] [CrossRef]

- Huang, S.; Wang, H.; Ahmad, W.; Ahmad, A.; Ivanovich Vatin, N.; Mohamed, A.M.; Deifalla, A.F.; Mehmood, I. Plastic Waste Management Strategies and Their Environmental Aspects: A Scientometric Analysis and Comprehensive Review. Int. J. Environ. Res. Public Health 2022, 19, 4556. [Google Scholar] [CrossRef] [PubMed]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Park, J.Y.; Nagy, Z. Comprehensive analysis of the relationship between thermal comfort and building control research-A data-driven literature review. Renew. Sustain. Energy Rev. 2018, 82, 2664–2679. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Papadonikolaki, E.; Palliyaguru, R.; Arashpour, M. Collaboration in BIM-based construction networks: A bibliometric-qualitative literature review. Int. J. Proj. Manag. 2017, 35, 1288–1301. [Google Scholar] [CrossRef]

- Zuo, J.; Zhao, Z.-Y. Green building research–current status and future agenda: A review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

- Darko, A.; Zhang, C.; Chan, A.P. Drivers for green building: A review of empirical studies. Habitat Int. 2017, 60, 34–49. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, M.; Smarzewski, P. Effect of Short Fiber Reinforcements on Fracture Performance of Cement-Based Materials: A Systematic Review Approach. Materials 2021, 14, 1745. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Osei-Kyei, R. Scientometric review of global research trends on green buildings in construction journals from 1992 to 2018. Energy Build. 2019, 190, 69–85. [Google Scholar] [CrossRef]

- Song, H.; Liu, J.; He, K.; Ahmad, W. A comprehensive overview of jute fiber reinforced cementitious composites. Case Stud. Constr. Mater. 2021, 15, e00724. [Google Scholar] [CrossRef]

- Yu, F.; Hayes, B.E. Applying data analytics and visualization to assessing the research impact of the Cancer Cell Biology (CCB) Program at the University of North Carolina at Chapel Hill. J. E Sci. Librariansh. 2018, 7, 4. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Roviello, G.; Asprone, D.; Menna, C.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Application-oriented chemical optimization of a metakaolin based geopolymer. Materials 2013, 6, 1920–1939. [Google Scholar] [CrossRef] [PubMed]

- Provis, J.L.; Bernal, S.A. Geopolymers and related alkali-activated materials. Annu. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Aldred, J.; Day, J. Is geopolymer concrete a suitable alternative to traditional concrete. In Proceedings of the 37th Conference on Our World in Concrete & Structures, Singapore, 29–31 August 2012; pp. 1–14. [Google Scholar]

- Provis, J.L.; Arbi, K.; Bernal, S.A.; Bondar, D.; Buchwald, A.; Castel, A.; Chithiraputhiran, S.; Cyr, M.; Dehghan, A.; Dombrowski-Daube, K. RILEM TC 247-DTA round robin test: Mix design and reproducibility of compressive strength of alkali-activated concretes. Mater. Struct. 2019, 52, 1–13. [Google Scholar] [CrossRef]

- Gluth, G.J.G.; Arbi, K.; Bernal, S.A.; Bondar, D.; Castel, A.; Chithiraputhiran, S.; Dehghan, A.; Dombrowski-Daube, K.; Dubey, A.; Ducman, V. RILEM TC 247-DTA round robin test: Carbonation and chloride penetration testing of alkali-activated concretes. Mater. Struct. 2020, 53, 21. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Van Deventer, J.S.J. Progress in the Adoption of Geopolymer Cement. In Handbook of Low Carbon Concrete; Butterworth-Heinemann: Woburn, MA, USA, 2016; pp. 217–262. [Google Scholar]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.; Delaqua, G.C.G.; Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F. Performance of geopolymer tiles in high temperature and saturation conditions. Constr. Build. Mater. 2021, 286, 122994. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Teixeira Marvila, M.; Barbosa de Oliveira, L.; Macario Ferreira, W.; Colorado, H.; Rainho Teixeira, S.; Mauricio Fontes Vieira, C. Circular economy and durability in geopolymers ceramics pieces obtained from glass polishing waste. Int. J. Appl. Ceram. Technol. 2021, 18, 1891–1900. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Marvila, M.T.; Rocha, H.A.; Cruz, L.R.; Vieira, C.M.F. Use of glass polishing waste in the development of ecological ceramic roof tiles by the geopolymerization process. Int. J. Appl. Ceram. Technol. 2020, 17, 2649–2658. [Google Scholar] [CrossRef]

- Ojha, A.; Aggarwal, P.; Gupta, L. Curing Regimes Effect on the Strength Parameters of Geopolymer Concrete: A Short Review. In Advances in Sustainable Construction Materials; Springer: Berlin/Heidelberg, Germany, 2021; pp. 651–657. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Assessment of important parameters involved in the synthesis of geopolymer composites: A review. Constr. Build. Mater. 2020, 264, 120276. [Google Scholar] [CrossRef]

- Ganesh, A.C.; Devi, R.K.; Srikar, P.; Prasad, S.; Kumar, M.M.; Sarath, R.P. Pervious Geopolymer Concrete under Ambient Curing. Mater. Today Proc. 2021, 46, 2737–2741. [Google Scholar] [CrossRef]

- Paul, E. Performance assessment of geopolymer concrete using various industrial wastes. Mater. Today Proc. 2021, 45, 5149–5152. [Google Scholar] [CrossRef]

- à Moungam, L.M.B.; Mohamed, H.; Kamseu, E.; Billong, N.; Melo, U.C. Properties of geopolymers made from fired clay bricks wastes and rice husk ash (RHA)-sodium hydroxide (NaOH) activator. Mater. Sci. Appl. 2017, 8, 537–552. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Kamseu, E.; Leonelli, C. Geopolymer binders from metakaolin using sodium waterglass from waste glass and rice husk ash as alternative activators: A comparative study. Constr. Build. Mater. 2016, 114, 276–289. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Ranjbar, N. Synthesis of sodium waterglass from white rice husk ash as an activator to produce metakaolin-based geopolymer cements. J. Build. Eng. 2016, 6, 252–261. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Marvila, M.T.; Ali, M.; Khan, M.I.; Masood, F.; Vieira, C.M.F. Effect of the addition and processing of glass polishing waste on the durability of geopolymeric mortars. Case Stud. Constr. Mater. 2021, 15, e00662. [Google Scholar] [CrossRef]

- Xiao, R.; Ma, Y.; Jiang, X.; Zhang, M.; Zhang, Y.; Wang, Y.; Huang, B.; He, Q. Strength, microstructure, efflorescence behavior and environmental impacts of waste glass geopolymers cured at ambient temperature. J. Clean. Prod. 2020, 252, 119610. [Google Scholar] [CrossRef]

- Wang, J.; Li, F.; Zhou, Z.; Du, P.; Xu, D.; Xie, N.; Cheng, X.; Liu, Y. Effect of zeolite on waste based alkali-activated inorganic binder efflorescence. Constr. Build. Mater. 2018, 158, 683–690. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, T.; Xu, D.; Zhou, Z.; Du, P.; Xie, N.; Cheng, X.; Liu, Y. Effect of nano-silica on the efflorescence of waste based alkali-activated inorganic binder. Constr. Build. Mater. 2018, 167, 381–390. [Google Scholar] [CrossRef]

- Sun, K.; Peng, X.; Wang, S.; Zeng, L.; Ran, P.; Ji, G. Effect of nano-SiO2 on the efflorescence of an alkali-activated metakaolin mortar. Constr. Build. Mater. 2020, 253, 118952. [Google Scholar] [CrossRef]

- Wang, W.; Noguchi, T. Alkali-silica reaction (ASR) in the alkali-activated cement (AAC) system: A state-of-the-art review. Constr. Build. Mater. 2020, 252, 119105. [Google Scholar] [CrossRef]

| S/N | Source of Publication | Publication Count | Total Citations Received |

|---|---|---|---|

| 1 | Construction and building materials | 770 | 34,289 |

| 2 | Ceramics international | 221 | 7430 |

| 3 | Journal of cleaner production | 151 | 7772 |

| 4 | Materials | 148 | 1807 |

| 5 | IOP conference series: Materials science and engineering | 135 | 633 |

| 6 | Cement and concrete composites | 124 | 8314 |

| 7 | Journal of materials in civil engineering | 114 | 3083 |

| 8 | Ceramic engineering and science proceedings | 100 | 742 |

| 9 | MATEC web of conferences | 99 | 591 |

| 10 | Journal of building engineering | 98 | 1048 |

| 11 | Materials today: Proceedings | 94 | 374 |

| 12 | Cement and concrete research | 81 | 12,256 |

| 13 | International journal of civil engineering and technology | 73 | 352 |

| 14 | Journal of materials science | 72 | 9547 |

| 15 | Materials letters | 70 | 2537 |

| 16 | Case studies in construction materials | 70 | 532 |

| 17 | Journal of the American ceramic society | 68 | 3387 |

| 18 | Journal of hazardous materials | 61 | 5762 |

| 19 | IOP conference series: earth and environmental science | 53 | 54 |

| 20 | Materials and design | 52 | 4834 |

| 21 | Procedia engineering | 51 | 1713 |

| 22 | Polymers | 46 | 176 |

| 23 | Materials and structures/materiaux et constructions | 43 | 2327 |

| 24 | Sustainability (Switzerland) | 41 | 279 |

| 25 | Journal of noncrystalline solids | 39 | 1978 |

| 26 | Composites part b: Engineering | 38 | 2680 |

| 27 | Silicon | 36 | 113 |

| 28 | Ceramics-Silikaty | 34 | 1161 |

| S/N | Keyword | Occurrences |

|---|---|---|

| 1 | Geopolymer | 2064 |

| 2 | Fly ash | 953 |

| 3 | Compressive strength | 692 |

| 4 | Geopolymer concrete | 484 |

| 5 | Geopolymers | 401 |

| 6 | Microstructure | 395 |

| 7 | Metakaolin | 348 |

| 8 | Mechanical properties | 311 |

| 9 | Durability | 209 |

| 10 | Strength | 142 |

| 11 | Slag | 132 |

| 12 | Sustainability | 106 |

| 13 | Alkali activation | 97 |

| 14 | Porosity | 93 |

| 15 | Concrete | 91 |

| 16 | Workability | 83 |

| 17 | Flexural strength | 81 |

| 18 | GGBS | 77 |

| 19 | Geopolymer mortar | 76 |

| 20 | Red mud | 75 |

| 21 | Rice husk ash | 75 |

| 22 | Sodium silicate | 75 |

| 23 | Sodium hydroxide | 66 |

| 24 | Silica fume | 65 |

| 25 | Ground granulated blast furnace slag | 64 |

| 26 | Geopolymerization | 62 |

| 27 | Rheology | 61 |

| 28 | Ambient curing | 58 |

| 29 | Thermal conductivity | 57 |

| 30 | SEM | 54 |

| S/N | Author Name | Articles Published | Total Citations Received | Average Citation Count |

|---|---|---|---|---|

| 1 | Van Deventer J.S.J. | 93 | 18,335 | 197 |

| 2 | Chindaprasirt P. | 93 | 7598 | 82 |

| 3 | Provis J.L. | 86 | 15,257 | 177 |

| 4 | Abdullah M.M.A.B. | 79 | 857 | 11 |

| 5 | Rossignol S. | 78 | 1790 | 23 |

| 6 | Zhang Z. | 61 | 2760 | 45 |

| 7 | Sanjayan J.G. | 56 | 3577 | 64 |

| 8 | Leonelli C. | 56 | 1688 | 30 |

| 9 | Kriven W.M. | 52 | 1439 | 28 |

| 10 | Zhang Y. | 52 | 885 | 17 |

| 11 | Kamseu E. | 51 | 1296 | 25 |

| 12 | Sanjayan J. | 47 | 2231 | 47 |

| 13 | He P. | 46 | 1391 | 30 |

| 14 | Wang H. | 44 | 2668 | 61 |

| 15 | Jia D. | 43 | 1392 | 32 |

| 16 | Mackenzie K.J.D. | 42 | 2725 | 65 |

| 17 | Nazari A. | 41 | 1523 | 37 |

| 18 | Zhang L. | 39 | 1546 | 40 |

| 19 | Sandu A.V. | 39 | 503 | 13 |

| 20 | Zhou Y. | 38 | 1134 | 30 |

| 21 | Li Z. | 38 | 852 | 22 |

| 22 | Horpibulsuk S. | 37 | 2293 | 62 |

| 23 | Joussein E. | 37 | 994 | 27 |

| 24 | Shaikh F.U.A. | 36 | 2162 | 60 |

| 25 | Arulrajah A. | 36 | 1856 | 52 |

| 26 | Wang S. | 36 | 911 | 25 |

| 27 | Li J. | 35 | 262 | 7 |

| 28 | Kumar S. | 33 | 1838 | 56 |

| 29 | Wang Y. | 33 | 398 | 12 |

| 30 | Hussin K. | 32 | 515 | 16 |

| 31 | Korniejenko K. | 32 | 318 | 10 |

| 32 | Van Riessen A. | 31 | 3829 | 124 |

| 33 | Sata V. | 31 | 2670 | 86 |

| 34 | Zhang J. | 31 | 1487 | 48 |

| 35 | Yang Z. | 31 | 517 | 17 |

| 36 | Li Y. | 30 | 431 | 14 |

| 37 | Lukey G.C. | 29 | 9891 | 341 |

| 38 | Kamarudin H. | 29 | 1518 | 52 |

| 39 | Cioffi R. | 29 | 1500 | 52 |

| 40 | Wang Q. | 29 | 227 | 8 |

| 41 | Sarker P.K. | 28 | 2774 | 99 |

| 42 | Cheng T.-W. | 28 | 591 | 21 |

| 43 | Liu Y. | 28 | 348 | 12 |

| 44 | Alengaram U.J. | 27 | 1928 | 71 |

| 45 | Castel A. | 27 | 1197 | 44 |

| 46 | Ferone C. | 27 | 1132 | 42 |

| 47 | Colombo P. | 27 | 986 | 37 |

| 48 | Wang J. | 27 | 263 | 10 |

| 49 | Labrincha J.A. | 26 | 1222 | 47 |

| 50 | Rüscher C.H. | 26 | 444 | 17 |

| 51 | Dai J.-G. | 26 | 422 | 16 |

| 52 | Wang X. | 26 | 199 | 8 |

| 53 | Liu J. | 26 | 130 | 5 |

| 54 | Jumaat M.Z. | 25 | 2055 | 82 |

| 55 | Li H. | 25 | 369 | 15 |

| S/N | Article | Title | Citations Received |

|---|---|---|---|

| 1 | Duxson P. [53] | Geopolymer technology: The current state of the art | 2573 |

| 2 | Davidovits J. [83] | Geopolymers-Inorganic polymeric new materials | 2507 |

| 3 | Duxson P. [84] | The role of inorganic polymer technology in the development of ‘green concrete’ | 1124 |

| 4 | Mclellan B.C. [52] | Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement | 870 |

| 5 | Turner L.K. [51] | Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete | 862 |

| S/N | Country | Documents Published | Overall Citations |

|---|---|---|---|

| 1 | China | 895 | 22,820 |

| 2 | India | 776 | 12,041 |

| 3 | Australia | 743 | 54,555 |

| 4 | United States | 516 | 15,649 |

| 5 | Malaysia | 364 | 10,334 |

| 6 | Italy | 265 | 7953 |

| 7 | United Kingdom | 231 | 10,077 |

| 8 | France | 209 | 8825 |

| 9 | Thailand | 205 | 10,254 |

| 10 | Saudi Arabia | 179 | 3391 |

| 11 | Turkey | 178 | 3011 |

| 12 | Indonesia | 150 | 1355 |

| 13 | Brazil | 144 | 2718 |

| 14 | Iran | 136 | 3529 |

| 15 | Spain | 130 | 7315 |

| 16 | Germany | 125 | 3405 |

| 17 | Czech Republic | 120 | 3108 |

| 18 | Egypt | 107 | 2421 |

| 19 | South Korea | 106 | 2497 |

| 20 | Poland | 105 | 1012 |

| 21 | Canada | 104 | 2101 |

| 22 | Cameroon | 96 | 2893 |

| 23 | Japan | 94 | 3038 |

| 24 | Iraq | 81 | 1078 |

| 25 | Romania | 80 | 1121 |

| 26 | Pakistan | 77 | 903 |

| 27 | Portugal | 75 | 2460 |

| 28 | Taiwan | 64 | 1630 |

| 29 | New Zealand | 56 | 3042 |

| 30 | Hong Kong | 54 | 1466 |

| 31 | Greece | 52 | 2748 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, K.; Ahmad, W.; Amin, M.N.; Nazar, S. A Scientometric-Analysis-Based Review of the Research Development on Geopolymers. Polymers 2022, 14, 3676. https://doi.org/10.3390/polym14173676

Khan K, Ahmad W, Amin MN, Nazar S. A Scientometric-Analysis-Based Review of the Research Development on Geopolymers. Polymers. 2022; 14(17):3676. https://doi.org/10.3390/polym14173676

Chicago/Turabian StyleKhan, Kaffayatullah, Waqas Ahmad, Muhammad Nasir Amin, and Sohaib Nazar. 2022. "A Scientometric-Analysis-Based Review of the Research Development on Geopolymers" Polymers 14, no. 17: 3676. https://doi.org/10.3390/polym14173676

APA StyleKhan, K., Ahmad, W., Amin, M. N., & Nazar, S. (2022). A Scientometric-Analysis-Based Review of the Research Development on Geopolymers. Polymers, 14(17), 3676. https://doi.org/10.3390/polym14173676