In Vivo Modification of Microporous Structure in Bacterial Cellulose by Exposing Komagataeibacter xylinus Culture to Physical and Chemical Stimuli

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microorganism and Culture Medium

2.2. Inoculum Development

2.3. Biosynthesis of BC by K. xylinus under the Effect of Physical and Chemical Stimuli

2.4. Glucose, BC and Bacterial Biomass Quantification

2.5. BC Characterization

2.6. Determination of Rehydration Ratio

2.7. SEM Analysis

2.8. FTIR Analysis

3. Results and Discussion

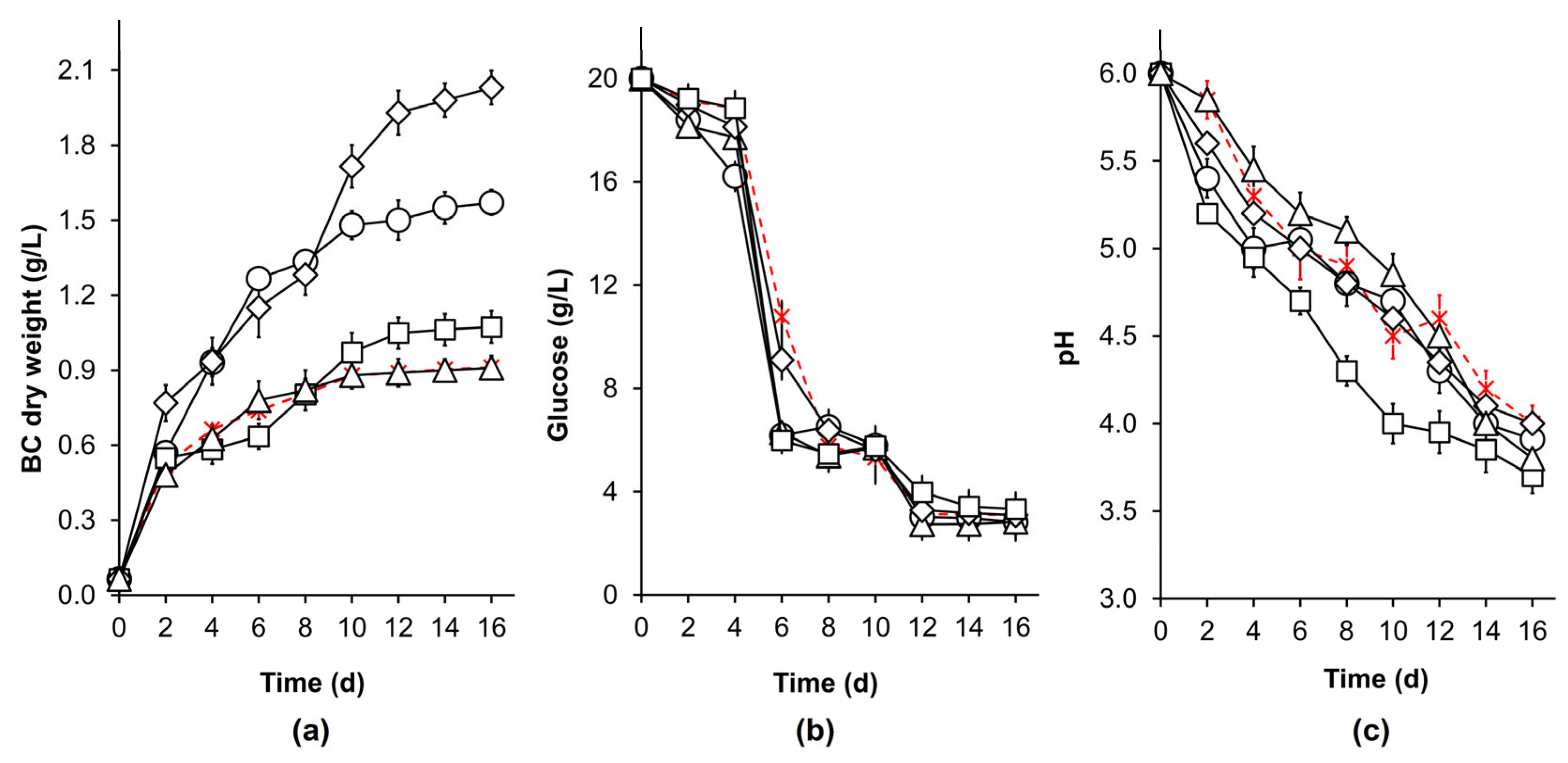

3.1. Effect of Physical and Chemical Stimuli on BC Biosynthesis by K. xylinus

3.2. Effect of Physical and Chemical Stimuli on BC Properties

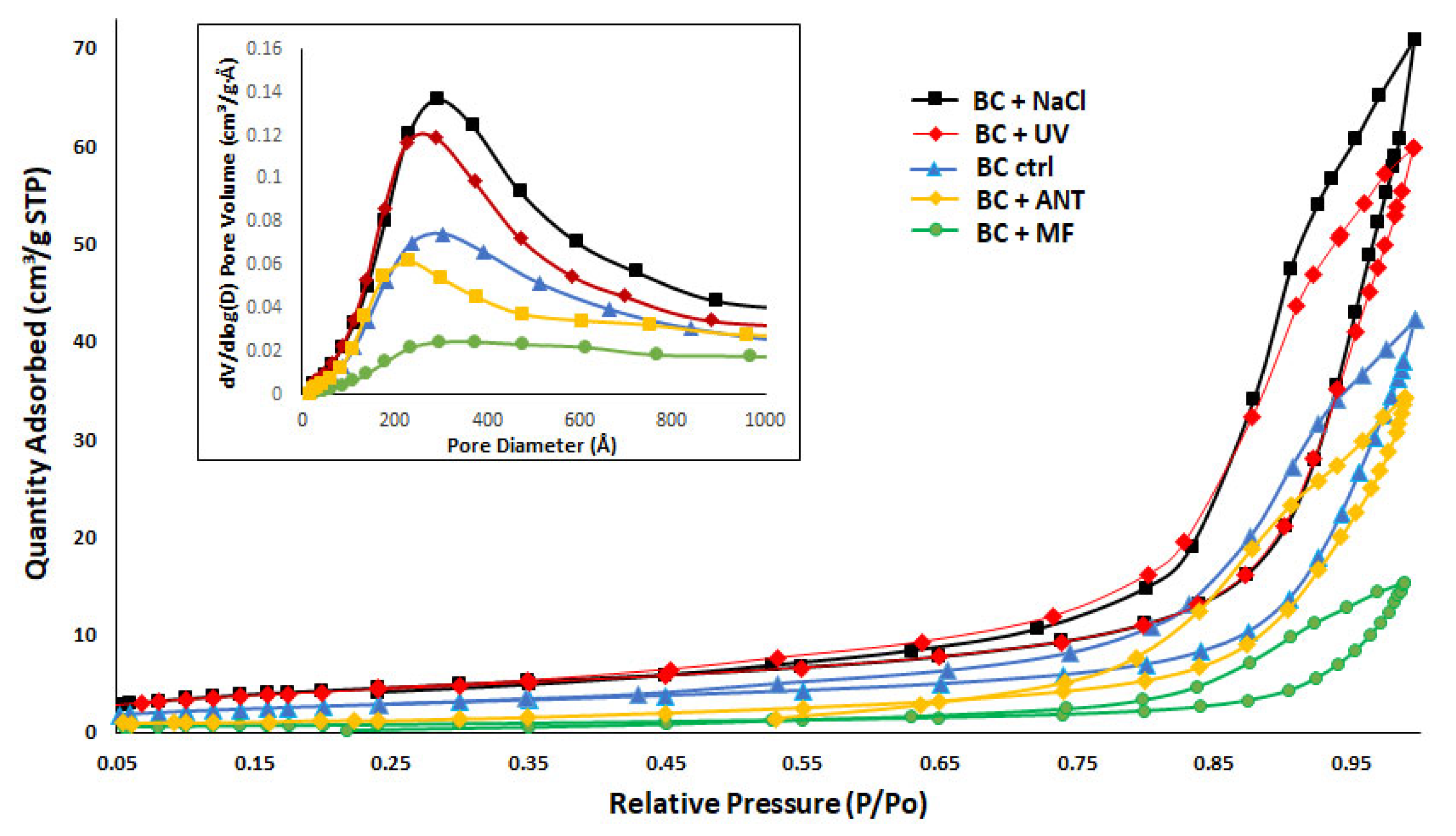

3.2.1. Specific Area and Pore Volume of BC

3.2.2. Rehydration Ratio and Crystallinity in BC Samples

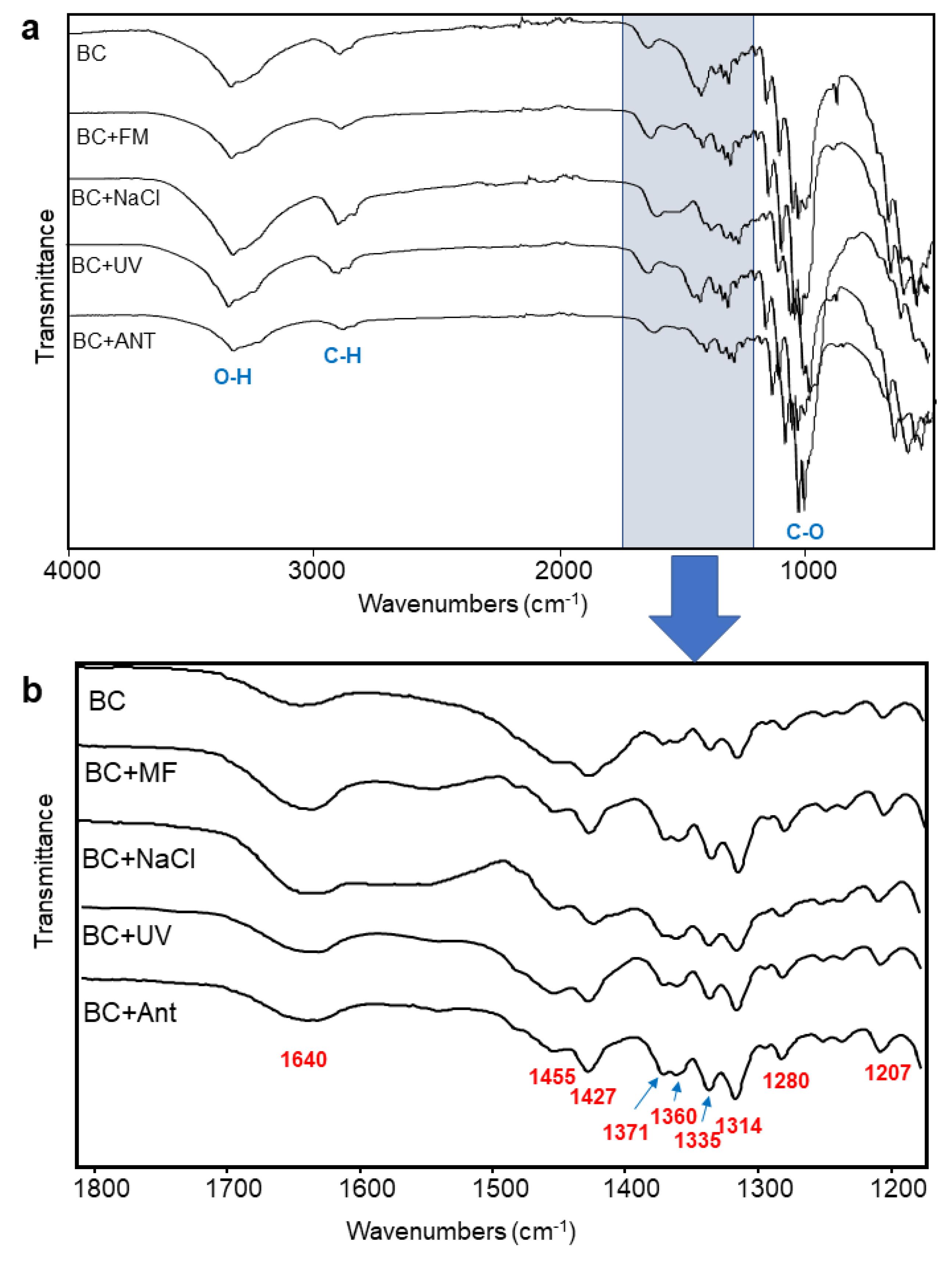

3.2.3. FTIR Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brown, R.M., Jr. Cellulose Structure and Biosynthesis: What Is in Store for the 21st Century? J. Polym. Sci. Part A Polym. Chem. 2004, 42, 487–495. [Google Scholar] [CrossRef]

- El-Saied, H.; Basta, A.H.; Gobran, R.H. Research Progress in Friendly Environmental Technology for the Production of Cellulose Products (Bacterial Cellulose and Its Application). Polym.-Plast. Technol. Eng. 2004, 43, 797–820. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Frone, A.N.; Chiulan, I. Nanostructured Biocomposites from Aliphatic Polyesters and Bacterial Cellulose. Ind. Crops Prod. 2016, 93, 251–266. [Google Scholar] [CrossRef]

- Yudianti, R.; Indrarti, L. Effect of Water Soluble Polymer on Structure and Mechanical Properties of Bacterial Cellulose Composites. J. Appl. Sci. 2007, 8, 177–180. [Google Scholar] [CrossRef] [Green Version]

- Vandamme, E.J.; De Baets, S.; Vanbaelen, A.; Joris, K.; De Wulf, P. Improved Production of Bacterial Cellulose and Its Application Potential. Polym. Degrad. Stab. 1998, 59, 93–99. [Google Scholar] [CrossRef]

- Czaja, W.K.; Young, D.J.; Kawecki, M.; Brown, R.M. The Future Prospects of Microbial Cellulose in Biomedical Applications. Biomacromolecules 2007, 8, 1–12. [Google Scholar] [CrossRef]

- Ashrafi, Z.; Lucia, L.; Krause, W. Bioengineering Tunable Porosity in Bacterial Nanocellulose Matrices. Soft Matter 2019, 15, 9359–9367. [Google Scholar] [CrossRef]

- Zhong, C. Industrial-Scale Production and Applications of Bacterial Cellulose. Front. Bioeng. Biotechnol. 2020, 8, 605374. [Google Scholar] [CrossRef]

- Pandit, A.; Kumar, R. A Review on Production, Characterization and Application of Bacterial Cellulose and Its Biocomposites. J. Polym. Environ. 2021, 29, 2738–2755. [Google Scholar] [CrossRef]

- Bäckdahl, H.; Esguerra, M.; Delbro, D.; Risberg, B.; Gatenholm, P. Engineering Microporosity in Bacterial Cellulose Scaffolds. J. Tissue Eng. Regen. Med. 2008, 2, 320–330. [Google Scholar] [CrossRef]

- Tang, W.; Jia, S.; Jia, Y.; Yang, H. The Influence of Fermentation Conditions and Post-Treatment Methods on Porosity of Bacterial Cellulose Membrane. World J. Microbiol. Biotechnol. 2009, 26, 125. [Google Scholar] [CrossRef]

- Al-Shamary, E.E.; Darwash, A.K.A. Influence of Fermentation Condition and Alkali Treatment on the Porosity and Thickness of Bacterial Cellulose Membranes. Tojsat 2013, 3, 10. [Google Scholar]

- Zhang, H.; Xu, X.; Chen, C.; Chen, X.; Huang, Y.; Sun, D. In Situ Controllable Fabrication of Porous Bacterial Cellulose. Mater. Lett. 2019, 249, 104–107. [Google Scholar] [CrossRef]

- Guo, J.; Catchmark, J.M. Surface Area and Porosity of Acid Hydrolyzed Cellulose Nanowhiskers and Cellulose Produced by Gluconacetobacter xylinus. Carbohydr. Polym. 2012, 87, 1026–1037. [Google Scholar] [CrossRef]

- Zhang, C.J.; Wang, L.; Zhao, J.C.; Zhu, P. Effect of Drying Methods on Structure and Mechanical Properties of Bacterial Cellulose Films. Adv. Mater. Res. 2011, 239–242, 2667–2670. [Google Scholar]

- Chang, W.-S.; Chen, H.-H. Physical Properties of Bacterial Cellulose Composites for Wound Dressings. Food Hydrocoll. 2016, 53, 75–83. [Google Scholar] [CrossRef]

- Chen, H.-H.; Chen, L.-C.; Huang, H.-C.; Lin, S.-B. In Situ Modification of Bacterial Cellulose Nanostructure by Adding CMC during the Growth of Gluconacetobacter xylinus. Cellulose 2011, 18, 1573–1583. [Google Scholar] [CrossRef]

- Chen, H.-H.; Lin, S.-B.; Hsu, C.-P.; Chen, L.-C. Modifying Bacterial Cellulose with Gelatin Peptides for Improved Rehydration. Cellulose 2013, 20, 1967–1977. [Google Scholar] [CrossRef]

- Meza-Contreras, J.C.; Manriquez-Gonzalez, R.; Gutiérrez-Ortega, J.A.; Gonzalez-Garcia, Y. XRD and Solid State 13C-NMR Evaluation of the Crystallinity Enhancement of 13C-Labeled Bacterial Cellulose Biosynthesized by Komagataeibacter xylinus under Different Stimuli: A Comparative Strategy of Analyses. Carbohydr. Res. 2018, 461, 51–59. [Google Scholar] [CrossRef]

- Pourrameza, G.Z.; Roayaei, A.M.; Qezelbash, Q.R. Optimization of Culture Conditions for Bacterial Cellulose Production by Acetobacter sp. 4B-2. Biotechnology 2008, 8, 150–154. [Google Scholar] [CrossRef] [Green Version]

- Kowalski, W. (Ed.) Mathematical modeling of UV disinfection. In Ultraviolet Germicidal Irradiation Handbook: UVGI for Air and Surface Disinfection; Springer: Berlin/Heidelberg, Germany, 2009; pp. 51–72. ISBN 978-3-642-01999-9. [Google Scholar]

- Mu, Y.; Yu, H.-Q.; Wang, G. A Kinetic Approach to Anaerobic Hydrogen-Producing Process. Water Res. 2007, 41, 1152–1160. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- García-Sánchez, M.E.; Robledo-Ortiz, J.R.; Jiménez-Palomar, I.; González-Reynoso, O.; González-García, Y. Production of Bacterial Cellulose by Komagataeibacter xylinus Using Mango Waste as Alternative Culture Medium. Rev. Mex. Ing. Quím. 2020, 19, 851–865. [Google Scholar] [CrossRef] [Green Version]

- Lin, S.-B.; Hsu, C.-P.; Chen, L.-C.; Chen, H.-H. Adding Enzymatically Modified Gelatin to Enhance the Rehydration Abilities and Mechanical Properties of Bacterial Cellulose. Food Hydrocoll. 2009, 23, 2195–2203. [Google Scholar] [CrossRef]

- Zeng, X.; Small, D.P.; Wan, W. Statistical Optimization of Culture Conditions for Bacterial Cellulose Production by Acetobacter xylinum BPR 2001 from Maple Syrup. Carbohydr. Polym. 2011, 85, 506–513. [Google Scholar] [CrossRef]

- Keshk, S.M.A.S.; Sameshima, K. Evaluation of Different Carbon Sources for Bacterial Cellulose Production. Afr. J. Biotechnol. 2005, 4, 478–482. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, Y.; Chi, Y.; Xu, N.; Yao, W.; Sun, B. Effects of Alcohols on Bacterial Cellulose Production by Acetobacter xylinum 186. World J. Microbiol. Biotechnol. 2011, 27, 2281–2285. [Google Scholar] [CrossRef]

- Pereira, R.V.; Bicalho, M.L.; Machado, V.S.; Lima, S.; Teixeira, A.G.; Warnick, L.D.; Bicalho, R.C. Evaluation of the Effects of Ultraviolet Light on Bacterial Contaminants Inoculated into Whole Milk and Colostrum, and on Colostrum Immunoglobulin G. J. Dairy Sci. 2014, 97, 2866–2875. [Google Scholar] [CrossRef] [Green Version]

- Williams, W.S.; Cannon, R.E. Alternative Environmental Roles for Cellulose Produced by Acetobacter xylinum. Appl. Environ. Microbiol. 1989, 55, 2448–2452. [Google Scholar] [CrossRef] [Green Version]

- Ren, Z.; Leng, X.; Liu, Q. Effect of a Static Magnetic Field on the Microscopic Characteristics of Highly Efficient Oil-Removing Bacteria. Water Sci. Technol. 2018, 77, 296–303. [Google Scholar] [CrossRef]

- Albuquerque, W.W.C.; Costa, R.M.P.B.; de Salazar e Fernandes, T.; Porto, A.L.F. Evidences of the Static Magnetic Field Influence on Cellular Systems. Prog. Biophys. Mol. Biol. 2016, 121, 16–28. [Google Scholar] [CrossRef] [PubMed]

- Quan, V.M.; Li, B.; Sukyai, P. Bacterial Cellulose Modification Using Static Magnetic Field. Cellulose 2020, 27, 5581–5596. [Google Scholar] [CrossRef]

- Fijałkowski, K.; Rakoczy, R.; Żywicka, A.; Drozd, R.; Zielińska, B.; Wenelska, K.; Cendrowski, K.; Peitler, D.; Kordas, M.; Konopacki, M.; et al. Time Dependent Influence of Rotating Magnetic Field on Bacterial Cellulose. Int. J. Polym. Sci. 2016, 2016, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Singhal, K.K.; Mukim, M.D.; Dubey, C.K.; Nagar, J.C. An Updated Review on Pharmacology and Toxicities Related to Chloramphenicol. Asian J. Pharm. Res. Dev. 2020, 8, 104–109. [Google Scholar] [CrossRef]

- Nguyen, P.-T.; Nguyen, T.-T.; Bui, D.-C.; Hong, P.-T.; Hoang, Q.-K.; Nguyen, H.-T. Exopolysaccharide Production by Lactic Acid Bacteria: The Manipulation of Environmental Stresses for Industrial Applications. AIMS Microbiol. 2020, 6, 451–469. [Google Scholar] [CrossRef]

- Neysens, P.; Messens, W.; De Vuyst, L. Effect of Sodium Chloride on Growth and Bacteriocin Production by Lactobacillus Amylovorus DCE 471. Int. J. Food Microbiol. 2003, 88, 29–39. [Google Scholar] [CrossRef]

- Zhang, X.; Nakaura, Y.; Zhu, J.; Zhang, Z.; Yamamoto, K. Effect of Hyperosmotic Salt Concentration and Temperature on Viability of Escherichia Coli during Cold Storage. Biocontrol. Sci. 2020, 25, 55–62. [Google Scholar] [CrossRef]

- Embuscado, M.E.; Marks, J.S.; BeMiller, J.N. Bacterial Cellulose. I. Factors Affecting the Production of Cellulose by Acetobacter xylinum. Food Hydrocoll. 1994, 8, 407–418. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, C.; Yang, J.; Nie, Y.; Chen, C.; Sun, D. Recent Advances in Bacterial Cellulose. Cellulose 2014, 21, 1–30. [Google Scholar] [CrossRef]

- Jaramillo, R.; Perna, O.; Revollo, A.B.; Arrieta, C.; Escamilla, E. Efecto de Diferentes Concentraciones de Fructosa Sobre la Producción de Celulosa Bacteriana en Cultivo Estático. Rev. Colomb. Cienc. Anim. 2013, 5, 116. [Google Scholar] [CrossRef]

- Cromie, S.; Doelle, H.W. Nutritional Effects on the Kinetics of Ethanol Production from Glucose by Zymomonas Mobilis. Eur. J. Appl. Microbiol. Biotechnol. 1981, 11, 116–119. [Google Scholar] [CrossRef]

- Olz, R.; Larsson, K.; Adler, L.; Gustafsson, L. Energy Flux and Osmoregulation of Saccharomyces Cerevisiae Grown in Chemostats under NaCl Stress. J. Bacteriol. 1993, 175, 2205–2213. [Google Scholar] [CrossRef] [PubMed]

- Nascimento, L.F.C.; Botura, G.; Mota, R.P. Glucose Consume and Growth of E. Coli under Electromagnetic Field. Rev. Inst. Med. Trop. Sao Paulo 2003, 45, 65–67. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodriguez Justo, O.; Haber Pérez, V.; Chacon Alvarez, D.; Monte Alegre, R. Growth of Escherichia Coli under Extremely Low-Frequency Electromagnetic Fields. Appl. Biochem. Biotechnol. 2006, 134, 155–163. [Google Scholar] [CrossRef]

- Filipič, J.; Kraigher, B.; Tepuš, B.; Kokol, V.; Mandic-Mulec, I. Effects of Low-Density Static Magnetic Fields on the Growth and Activities of Wastewater Bacteria Escherichia Coli and Pseudomonas Putida. Bioresour. Technol. 2012, 120, 225–232. [Google Scholar] [CrossRef] [PubMed]

- Rani, M.U.; Udayasankar, K.; Appaiah, K.A.A. Properties of Bacterial Cellulose Produced in Grape Medium by Native Isolate Gluconacetobacter sp. J. Appl. Polym. Sci. 2011, 120, 2835–2841. [Google Scholar] [CrossRef]

- Yoruk, H.M.; Sayar, N.A. Topological Analysis of Carbon Flux during Multi-Stress Adaptation in Halomonas sp. AAD12. Electron. J. Biotechnol. 2015, 18, 480–485. [Google Scholar] [CrossRef] [Green Version]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of Gases, with Special Reference to the Evaluation of Surface Area and Pore Size Distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Particle Technology Series; Springer: Dordrecht, The Netherlands, 2004; Volume 16, ISBN 978-90-481-6633-6. [Google Scholar]

- Gromovykh, T.I.; Pigaleva, M.A.; Gallyamov, M.O.; Ivanenko, I.P.; Ozerova, K.E.; Kharitonova, E.P.; Bahman, M.; Feldman, N.B.; Lutsenko, S.V.; Kiselyova, O.I. Structural Organization of Bacterial Cellulose: The Origin of Anisotropy and Layered Structures. Carbohydr. Polym. 2020, 237, 116140. [Google Scholar] [CrossRef]

- Sanchavanakit, N.; Sangrungraungroj, W.; Kaomongkolgit, R.; Banaprasert, T.; Pavasant, P.; Phisalaphong, M. Growth of Human Keratinocytes and Fibroblasts on Bacterial Cellulose Film. Biotechnol. Prog. 2006, 22, 1194–1199. [Google Scholar] [CrossRef]

- Sano, M.B.; Rojas, A.D.; Gatenholm, P.; Davalos, R.V. Electromagnetically Controlled Biological Assembly of Aligned Bacterial Cellulose Nanofibers. Ann. Biomed. Eng. 2010, 38, 2475–2484. [Google Scholar] [CrossRef] [PubMed]

- Park, M.; Park, S.; Hyun, J. Use of Magnetic Nanoparticles to Manipulate the Metabolic Environment of Bacteria for Controlled Biopolymer Synthesis. ACS Appl. Mater. Interfaces 2012, 4, 5114–5117. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.-H.; Liu, Q.-J.; Sun, X.-W.; Li, X.-J.; Liu, M.; Jia, S.-R.; Xie, Y.-Y.; Zhong, C. Tailoring Bacterial Cellulose Structure through CRISPR Interference-Mediated Downregulation of GalU in Komagataeibacter xylinus CGMCC 2955. Biotechnol. Bioeng. 2020, 117, 2165–2176. [Google Scholar] [CrossRef] [PubMed]

- Sya’di, Y.K.; Wahyuni, E.T.; Rahayu, E.S.; Cahyanto, M.N. Effect of Culture Conditions on the Properties of Bacterial Cellulose Produced by Gluconacetobacter xylinus BTCC B796. Int. J. Sci. Technol. 2017, 5. [Google Scholar]

- Gomes, R.J.; de Sousa Faria-Tischer, P.C.; Tischer, C.A.; Constantino, L.V.; de Freitas Rosa, M.; Chideroli, R.T.; de Pádua Pereira, U.; Spinosa, W.A. Komagataeibacter Intermedius V-05: An Acetic Acid Bacterium Isolated from Vinegar Industry, with High Capacity for Bacterial Cellulose Production in Soybean Molasses Medium. Food Technol. Biotechnol. 2021, 59, 432–442. [Google Scholar] [CrossRef]

- Huang, H.-C.; Chen, L.-C.; Lin, S.-B.; Hsu, C.-P.; Chen, H.-H. In Situ Modification of Bacterial Cellulose Network Structure by Adding Interfering Substances during Fermentation. Bioresour. Technol. 2010, 101, 6084–6091. [Google Scholar] [CrossRef]

- Zografi, G.; Kontny, M.J.; Yang, A.Y.S.; Brenner, G.S. Surface Area and Water Vapor Sorption of Microcrystalline Cellulose. Int. J. Pharm. 1984, 18, 99–116. [Google Scholar] [CrossRef]

- Stanisławskaa, A.; Staroszczykb, H.; Szkodoa, M. The effect of dehydration/rehydration of bacterial nanocellulose on its tensile strength and physicochemical properties. Carbohydr. Polym. 2020, 236, 116023. [Google Scholar] [CrossRef]

- Fuller, M.E.; Andaya, C.; McClay, K. Evaluation of ATR-FTIR for Analysis of Bacterial Cellulose Impurities. J. Microbiol. Methods 2018, 144, 145–151. [Google Scholar] [CrossRef]

- Gea, S.; Reynolds, C.T.; Roohpour, N.; Wirjosentono, B.; Soykeabkaew, N.; Bilotti, E.; Peijs, T. Investigation into the Structural, Morphological, Mechanical and Thermal Behaviour of Bacterial Cellulose after a Two-Step Purification Process. Bioresour. Technol. 2011, 102, 9105–9110. [Google Scholar] [CrossRef]

- Atykyan, N.; Revin, V.; Shutova, V. Raman and FT-IR Spectroscopy Investigation the Cellulose Structural Differences from Bacteria Gluconacetobacter Sucrofermentans during the Different Regimes of Cultivation on a Molasses Media. AMB Express 2020, 10, 84. [Google Scholar] [CrossRef] [PubMed]

| Chemical/Physical Stimuli | Exposition Level | BC (g/L) a | Bacterial Biomass (g/L) a | Glucose Consumption (%) b | Final pH c |

|---|---|---|---|---|---|

| Control | 0.81 + 0.12 | 2.76 + 0.3 | 84.35 + 2.14 | 4 + 0.1 | |

| UV light (nm) | 254 | 1.09 + 0.28 | 2.72 + 0.4 | 88.77 + 1.35 | 3.5 + 0.2 |

| 366 | 1.85 + 0.13 | 3.01 + 0.5 | 84.01 + 4.24 | 4.1 + 0.4 | |

| Static magnetic field c | 1 | 0.81 + 0.18 | 2.79 + 0.4 | 83.23 + 3.11 | 3.8 + 0.3 |

| 2 | 0.79 + 0.11 | 3.37 + 0.4 | 79.89 + 2.77 | 4.1 + 0.4 | |

| NaCl (g/L) | 5 | 0.95 + 0.12 | 0.0 + 0.0 | 85.56 + 0.33 | 3.7 + 0.3 |

| 20 | 0.05 + 0.0 | 2.31 + 0.2 | 23.64 + 0.63 | 5.1 + 0.2 | |

| Chloramphenicol (mM) | 0.10 | 0.87 + 0.11 | 2.34 + 0.5 | 80.61 + 0.92 | 4.1 + 0.1 |

| 0.25 | 1.39 + 0.23 | 2.48 + 0.4 | 85.73 + 2.91 | 3.9 + 0.2 |

| Physical/Chemical Stimuli | BC (g/L) | BC Production Rate (g/L/d) | Sugar Consumption Rate (g/L/d) | YP/S (mg/g) |

|---|---|---|---|---|

| BC | 0.90 ± 0.04 | 0.234 ± 0.01 | 4.1 ± 0.16 | 56.71 ± 1.89 |

| BC + UV (366 nm) | 1.96 ± 0.10 | 0.141 ± 0.01 | 4.1 ± 0.20 | 124.11 ± 2.46 |

| BC + MF (1 T magnet) | 0.91 ± 0.01 | 0.162 ± 0.00 | 8.9 ± 0.06 | 58.14 ± 0.56 |

| BC + NaCl (5 g/L) | 1.06 ± 0.11 | 0.092 ± 0.01 | 6.7 ± 0.53 | 65.79 ± 4.18 |

| BC + ANT (0.25 mM) a | 1.48 ± 0.13 | 0.138 ± 0.01 | 5.4 ± 0.47 | 91.64 ± 7.20 |

| Sample | BET Surface Area (m2 g−1) | Average Pore Diameter (nm) | Pore Volume (cm3 g−1) | Rehydration Ratio (%) | Crystallinity (%) a |

|---|---|---|---|---|---|

| BC ctrl | 9.81 | 23.6 | 0.066 | 7.85 | 76.5 |

| BC + UV (366 nm) | 15.05 | 21.37 | 0.093 | 7.83 | 83.2 |

| BC + MF (1 T magnet) | 2.55 | 25.73 | 0.024 | 22.43 | 81.5 |

| BC + NaCl (5 g/L) | 15.72 | 25.44 | 0.11 | 15.75 | 86.1 |

| BC + ANT (0.25 mM) b | 4.08 | 21.42 | 0.053 | 17.95 | 83.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-García, Y.; Meza-Contreras, J.C.; Gutiérrez-Ortega, J.A.; Manríquez-González, R. In Vivo Modification of Microporous Structure in Bacterial Cellulose by Exposing Komagataeibacter xylinus Culture to Physical and Chemical Stimuli. Polymers 2022, 14, 4388. https://doi.org/10.3390/polym14204388

González-García Y, Meza-Contreras JC, Gutiérrez-Ortega JA, Manríquez-González R. In Vivo Modification of Microporous Structure in Bacterial Cellulose by Exposing Komagataeibacter xylinus Culture to Physical and Chemical Stimuli. Polymers. 2022; 14(20):4388. https://doi.org/10.3390/polym14204388

Chicago/Turabian StyleGonzález-García, Yolanda, Juan C. Meza-Contreras, José A. Gutiérrez-Ortega, and Ricardo Manríquez-González. 2022. "In Vivo Modification of Microporous Structure in Bacterial Cellulose by Exposing Komagataeibacter xylinus Culture to Physical and Chemical Stimuli" Polymers 14, no. 20: 4388. https://doi.org/10.3390/polym14204388

APA StyleGonzález-García, Y., Meza-Contreras, J. C., Gutiérrez-Ortega, J. A., & Manríquez-González, R. (2022). In Vivo Modification of Microporous Structure in Bacterial Cellulose by Exposing Komagataeibacter xylinus Culture to Physical and Chemical Stimuli. Polymers, 14(20), 4388. https://doi.org/10.3390/polym14204388