Mechanical Properties of High Temperature Vulcanized Silicone Rubber Aged in the Natural Environment

Abstract

1. Introduction

2. Samples and Test Methods

2.1. Test Samples

2.2. Mechanical Property Testing and Analysis

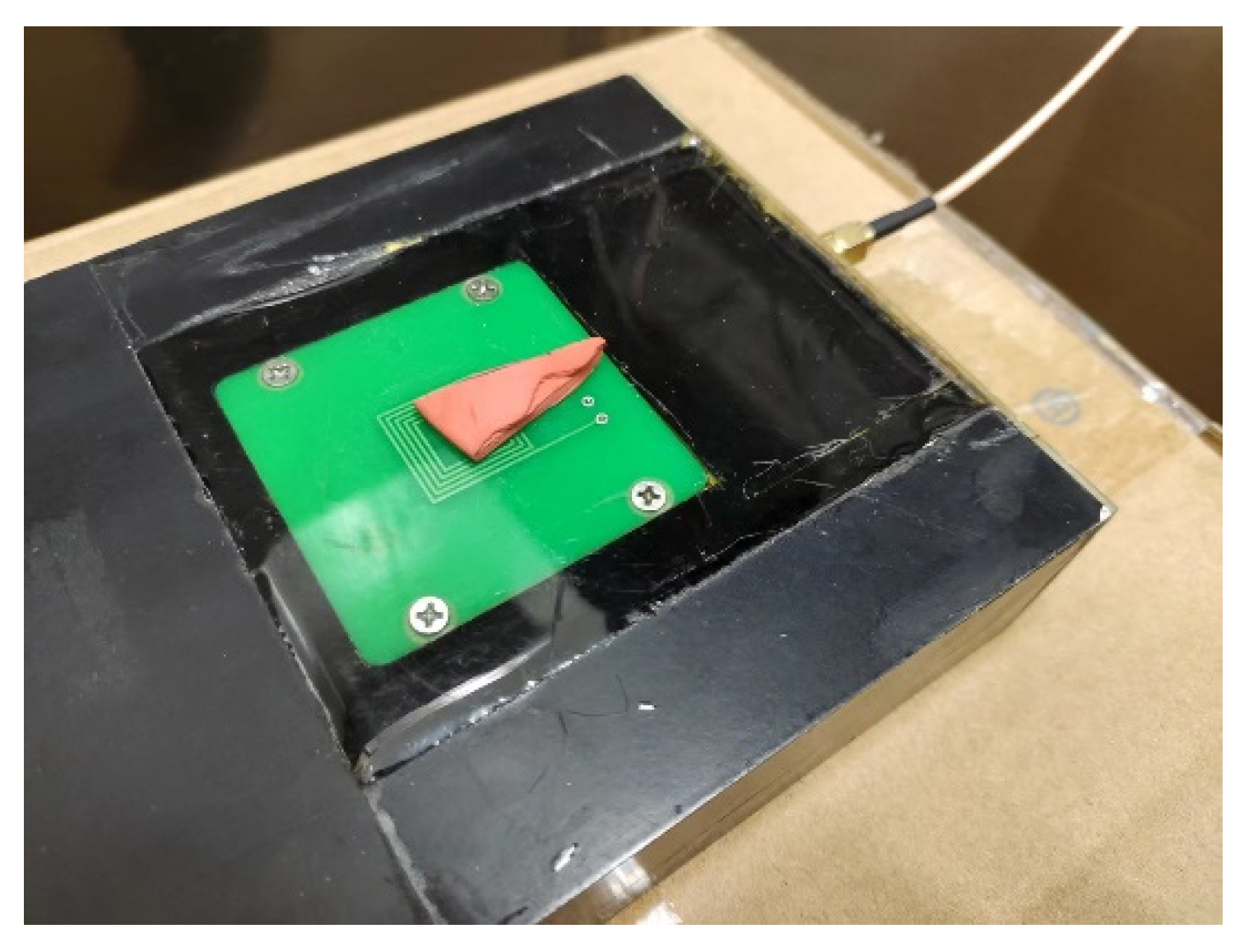

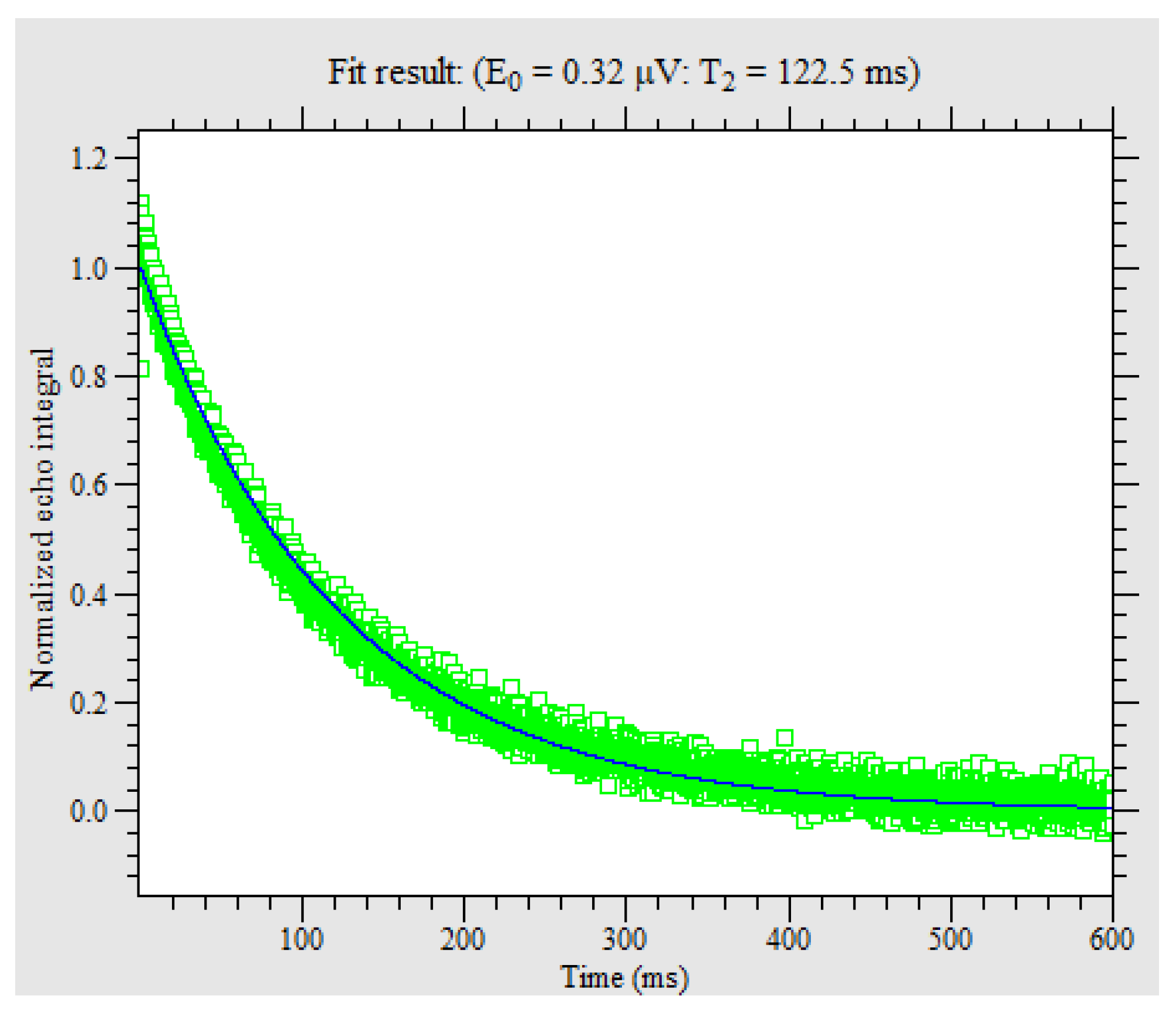

2.2.1. NMR Test

2.2.2. Hardness Test

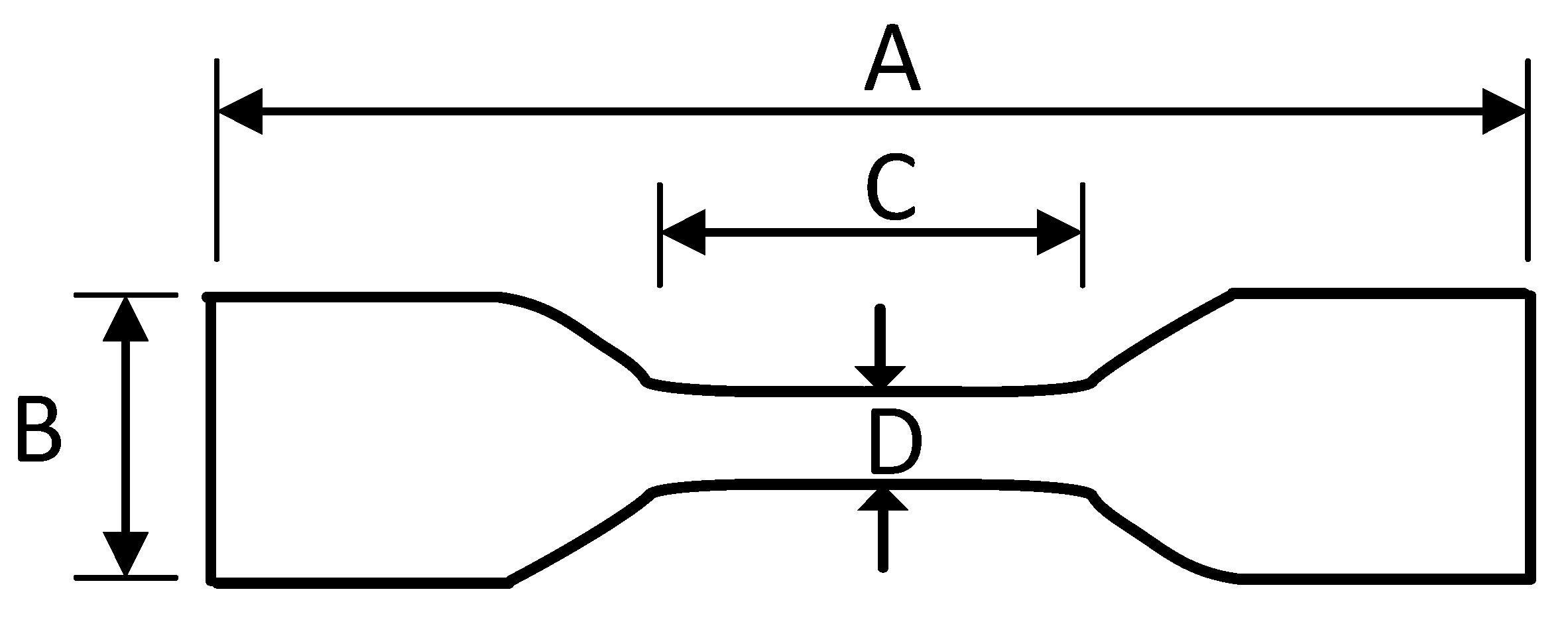

2.2.3. Mechanical Property Test

2.2.4. TGA Analysis

2.2.5. Surface Microscopic Topography Test

3. Results and Discussion

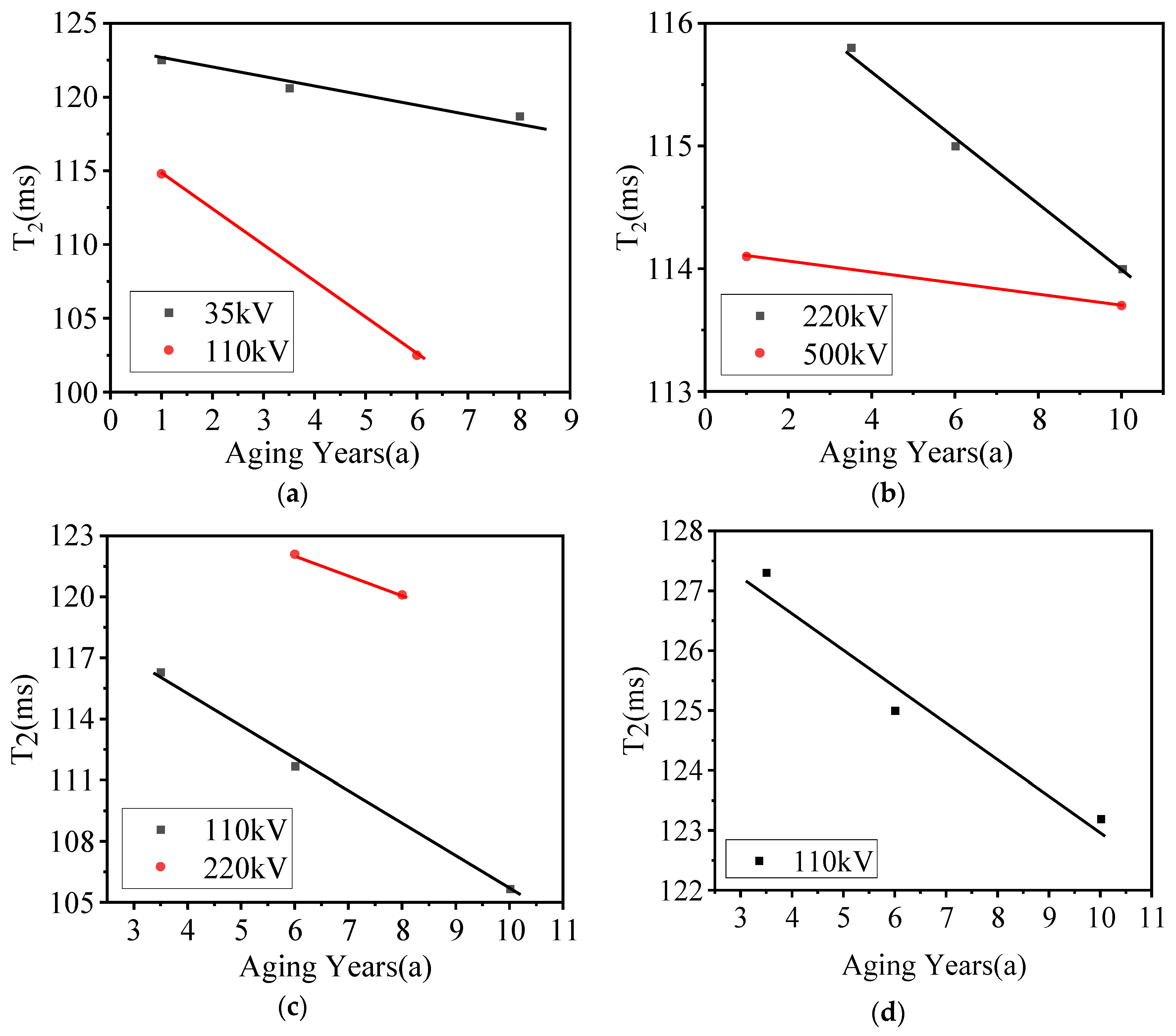

3.1. NMR Test Results

- (1)

- With the increase in years of aging, the T2 values of the composite insulator sheds decreased, and the two showed certain linearity. For example, the 35 kV sheds from factory A had aging periods of 1, 3.5, and 8 years, and their T2 values were 122.5 ms, 120.6 ms, and 118.7 ms, respectively, indicating a gradual decrease.

- (2)

- The sheds’ T2 values were different at different voltage grades with the same aging periods from the same manufacturer. For example, factory A produced 35 kV and 110 kV sheds and with aging periods of 1 year their T2 values were 122.5 ms and 114.8 ms, respectively. The 110 kV and 220 kV sheds from factory C with aging periods of 6 years had T2 values of 111.7 ms and 122.1 ms, respectively.

- (3)

- Sheds with the same aging period and the same voltage level from different factories had different T2 values. For example, factories B and C both produced 220 kV sheds which had an aging period of 6 years, with T2 values of 115.0 ms and 122.1 ms, respectively. Factories A, C, and D all made 110 kV sheds with aging periods of 6 years, and the T2 values of the three were 102.5 ms, 116.3 ms, and 125.0 ms, respectively.

- (4)

- The aging speeds of sheds with the same voltage levels from different factories were different, as reflected in the linear fitting line showing different slopes. For example, the slopes of the fitting lines of the 110 kV sheds from factories A and C were 2.46 and 1.63, respectively. The greater the slope, the faster the T2 value decreased with the aging period, i.e., the faster the aging speed.

- (5)

- There were also differences in the overall T2 values of sheds from different factories. The T2 value of sheds from factory D maintained a high level during the aging period, and the T2 of the sample aged for 10 years was 123.2 ms. The maximum value of T2 of the aged samples from factory B was 115.8 ms, and the aging period was 3.5 years. For factory C that value was 122.1 ms, and the aging period was 6 years.

3.2. Hardness Test Results

- (1)

- With the increase in years of aging, the hardness of composite insulator sheds generally showed an increasing trend. For example, the aging periods of the 35 kV sheds from factory A were 1, 3.5, and 8 years, and the hardness was 68.8, 70.8, and 78, respectively. The 110 kV samples from factory D showed an upward trend in general from 3.5 years to 10 years, and the hardness increased by 2.61%. The hardness of the samples from factory D with an aging period from 3.5 years to 6 years and the hardness of the 220 kV sheds from factory C decreased slightly. Combined with the high overall value of T2, the overall chemical structure did not change dramatically, and the actual degree of aging was not high. It can be speculated that the drop point may have been caused by different onsite sampling locations, according to the sheds’ leeward aspect, exposure of inner and outer positions to ultraviolet rays, etc. The severity of natural aging factors differed, resulting in diverse test results for the same sheds taken from different sampling positions.

- (2)

- Sheds with the same years of aging and voltage levels from different factories had different hardness values. For example, factories A, C, and D all produced samples with voltage of 110 kV and an aging period of 6 years, with hardness 75.2, 83, and 76.5, respectively.

- (3)

- There were also differences in the overall hardness of the sheds from different factories. The hardness variation range of the sheds from factories B and D during the aging period was 2, and the ranges for A and C were 9.8 and 6, respectively. The effect of ultraviolet aging on the hardness of samples from factories A and C was more obvious.

3.3. Mechanical Properties Test Results

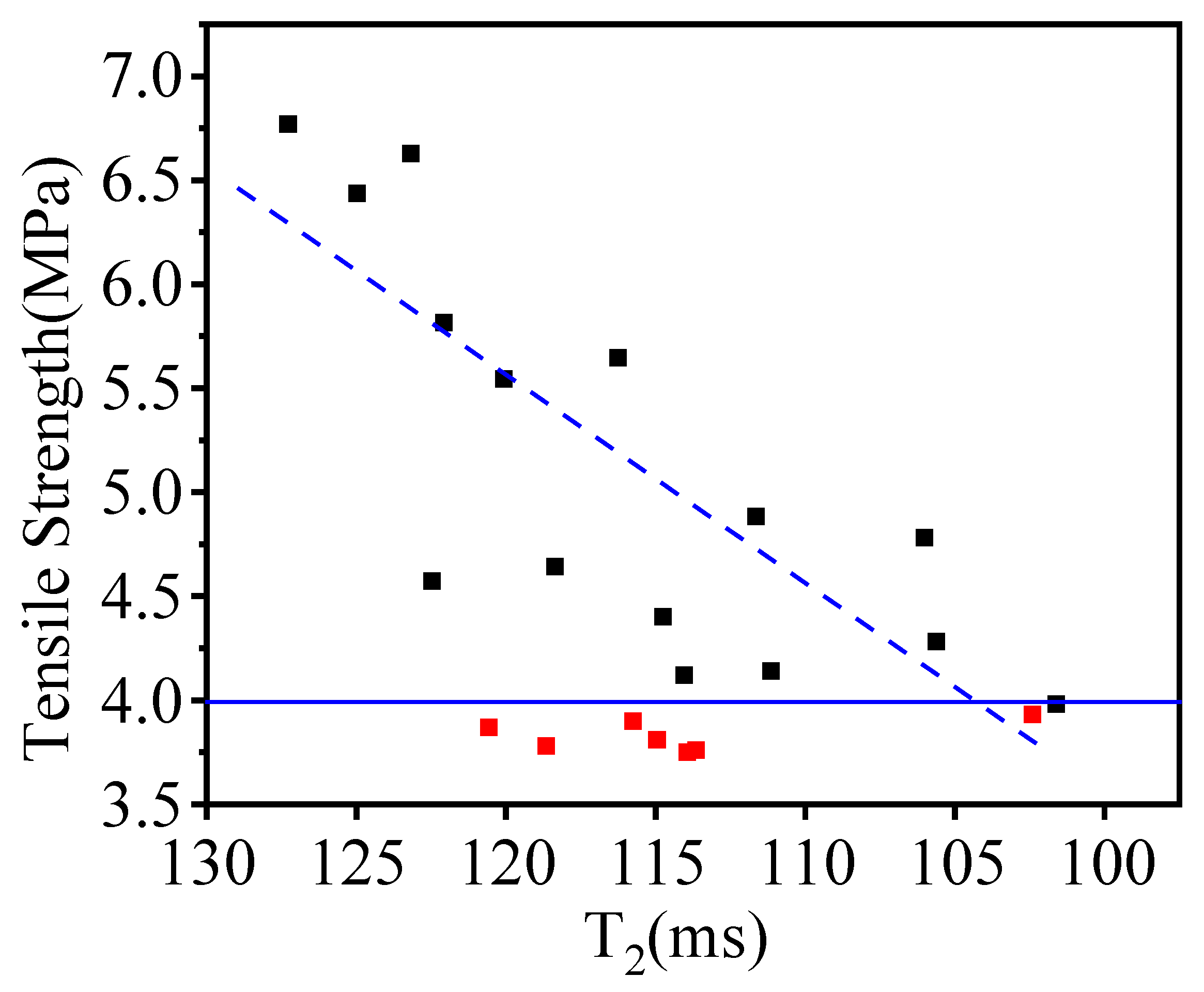

- (1)

- With the increase in years of aging, the tensile strength of composite insulator sheds generally showed a downward trend. For example, the years of aging of the 35 kV sheds from factory A were 1, 3.5, and 8 years, and the tensile strengths were 4.58 MPa, 3.88 MPa, and 3.79 MPa, respectively. For sheds from factory D, the tensile strength dropped from 6.77 MPa to 6.63 MPa with increased aging from 3.5 to 10 years.

- (2)

- The tensile strength was different in sheds of different voltage levels but from the same factory with the same aging period. For example, the 35 kV and 110 kV sheds aged for one year in factory A had tensile strength values of 4.58 MPa and 4.41 MPa, respectively. The 220 kV and 110 kV sheds aged 6 years from factory C had tensile strength values of 5.82 MPa and 4.89 MPa, respectively.

- (3)

- Sheds with the same aging period and voltage level from different factories had different tensile strengths. For example, the factories A, C, and D all produced samples with a voltage level of 110 kV and an aging period of 6 years, and their tensile strengths were 3.94 MPa, 4.89 MPa, and 6.44 MPa, respectively.

- (4)

- Sheds from different factories showed the same phenomenon of rapid performance decline in the early stages of aging. The tensile strength of the 35 kV sheds from factory A decreased by 15.2% and 2.3%, respectively, in the aging period of 1 year to 3.5 years and of 3.5 years to 8 years. The tensile strength of the sheds decreased faster when initially aged by natural factors. This phenomenon is reflected by the changing slope of the straight line in the figure. This phenomenon was also apparent in the 110 kV factory C and 220 kV factory B samples.

- (5)

- There were similarities and differences in the overall tensile strengths of sheds from different factories. For example, the measured minimum tensile strength of the sheds from factory D after aging is 6.44 MPa, which was much higher than the other three factories. The tensile strength of the sheds from each of the four factories showed the same phenomenon, generally higher at high voltage levels than at low voltage levels.

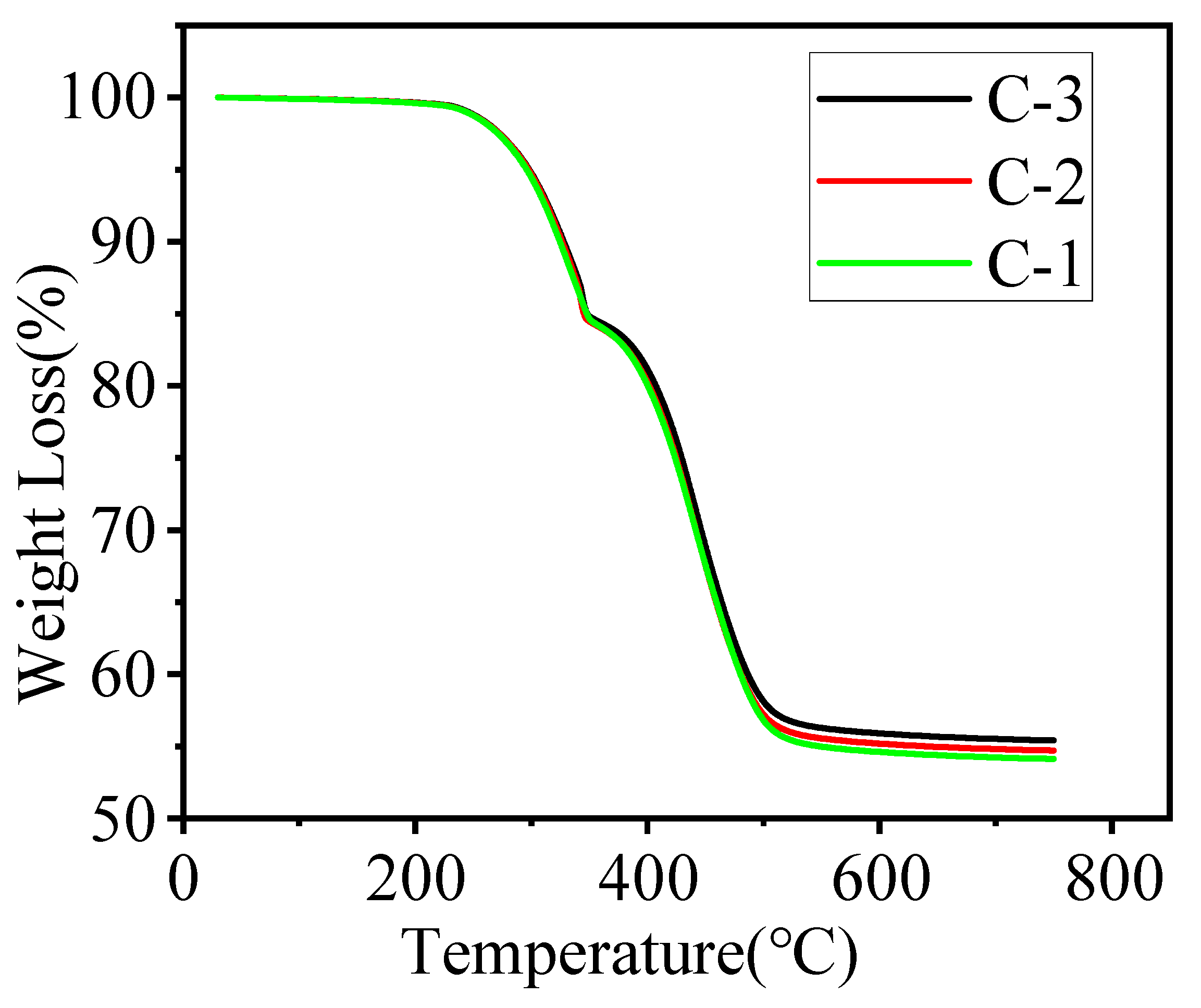

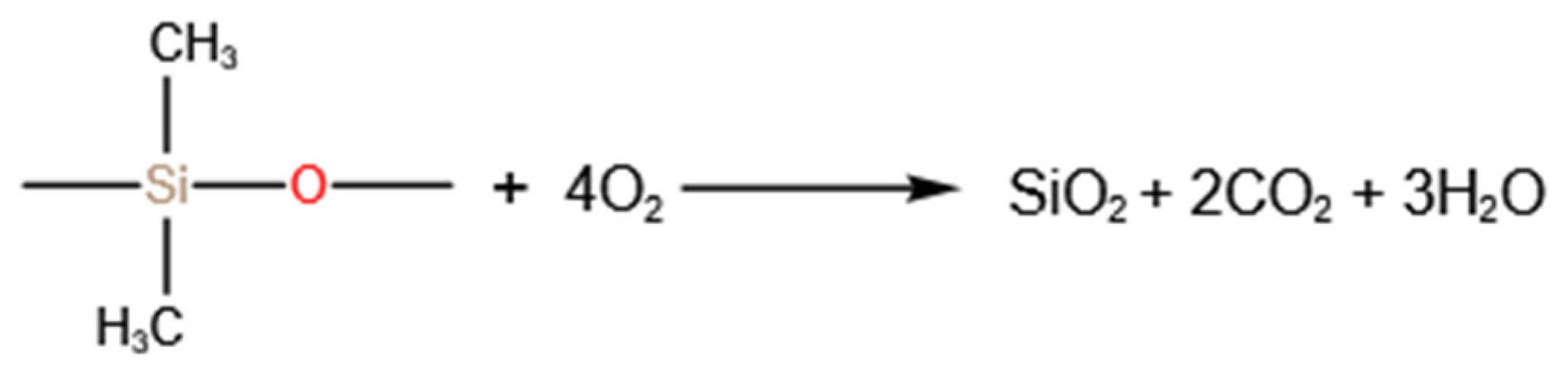

3.4. Thermogravimetric (TGA) Analysis Results

3.5. SEM Test Results

4. Conclusions

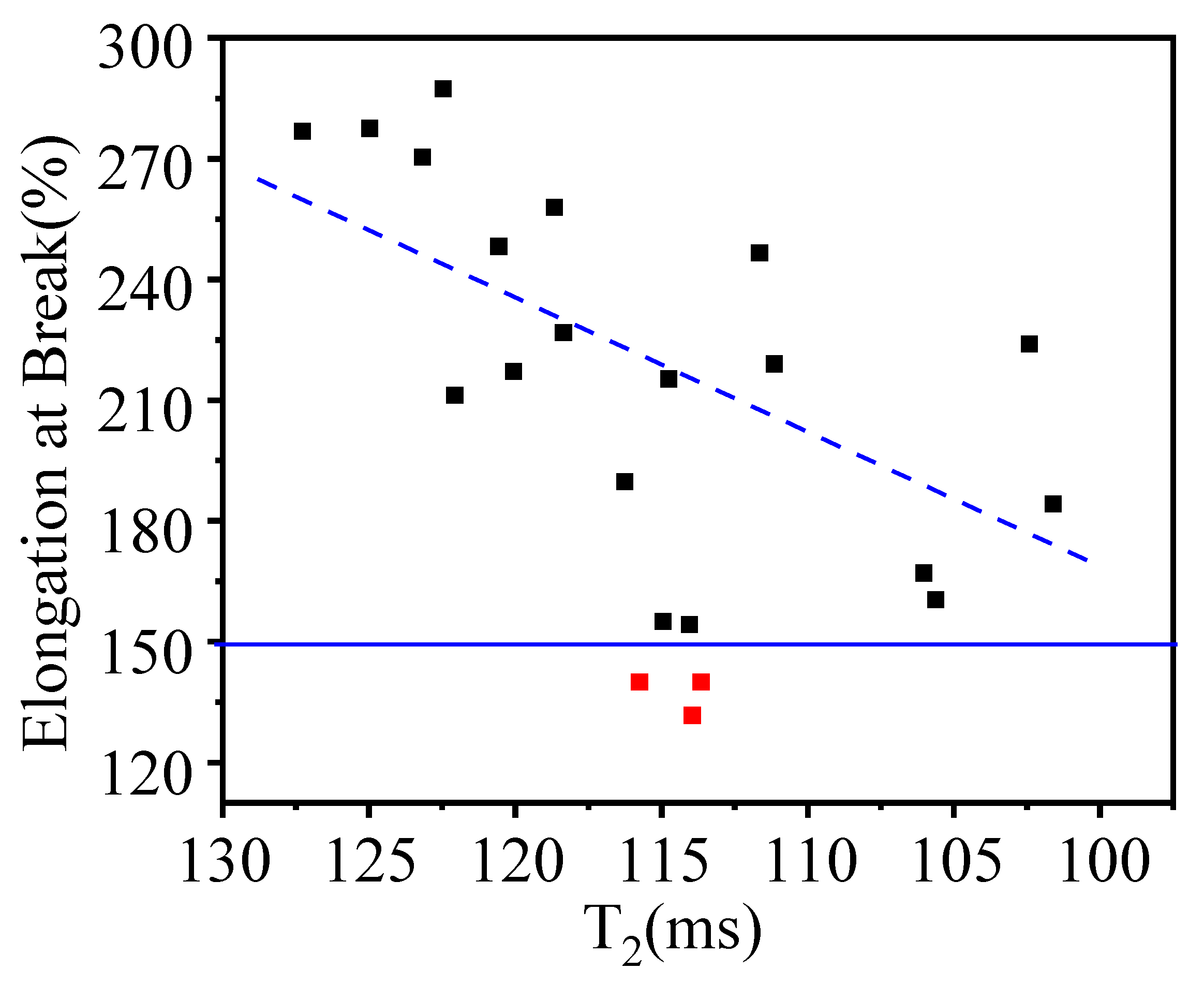

- Natural aging reduces the mechanical properties of silicone rubber insulator sheds. The main effect is that with the increase in years of aging, the surface of the material becomes harder, and the tensile strength decreases. The elongation at break value fluctuates, but generally shows a decreasing trend.

- There was a certain linearity between the transverse relaxation time T2 of the sheds, measured by NMR testing, and the recorded years of aging, showing that the longer the aging period, the smaller was the T2. There was consistency in measuring the mechanical properties of sheds with years of aging and T2 as characteristic values.

- Natural aging is mainly caused by environmental factors. The samples in this paper were mainly affected by snow, fog, and ultraviolet rays, from which ultraviolet energy damages the chemical bonds of the silicone rubber sheds. Microscopically, this process is a dynamic confrontation between chemical bond breaking and cross-linking. Macroscopically, the surface morphology of the sheds and the content of inorganic fillers are changed, thereby affecting the mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cherne, E.A. 50 years in the development of polymer suspension-type insulators. IEEE Electr. Insul. Mag. 2013, 29, 18–26. [Google Scholar] [CrossRef]

- Liang, X.D.; Wang, S.W.; Fan, J.; Guan, Z.C. Development of composite insulators in China. IEEE Trans. Dielectr. Electr. Insul. 1999, 6, 586–594. [Google Scholar] [CrossRef]

- Mavrikakis, N.C.; Mikropoulos, P.N.; Siderakis, K. Evaluation of field-ageing effects on insulating materials of composite suspension insulators. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 490–498. [Google Scholar] [CrossRef]

- Chakraborty, R.; Reddy, B.S. Studies on high temperature vulcanized silicone rubber insulators under arid climatic aging. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1751–1760. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Jiang, X.; Liang, T.; Zhang, D. Research on Lifespan Prediction of Composite Insulators in a High Altitude Area Experimental Station. Appl. Sci. 2019, 9, 3364. [Google Scholar] [CrossRef]

- Zhu, Y.; Ma, B.; Liu, X.; Song, B.; Zhang, X. Aging performance of silicone rubber exposed to UV and sandstorm. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Shenzhen, China, 20–23 October 2013. [Google Scholar]

- Ullah, I.; Ullah, R.; Amin, M.; Rahman, R.A.; Khan, A.; Ullah, N.; Alotaibi, S. Lifetime Estimation and Orientation Effect Based on Long-Term Degradation Analysis of Thermoset and Thermoplastic Insulators. Polymers 2022, 14, 3927. [Google Scholar] [CrossRef]

- Zhang, Z.; Pang, G.; Lu, M.; Gao, C.; Jiang, X. Research on Silicone Rubber Sheds of Decay-Like Fractured Composite Insulators Based on Hardness, Hydrophobicity, NMR, and FTIR. Polymers 2022, 14, 3424. [Google Scholar] [CrossRef]

- Khan, H.; Mahmood, A.; Ullah, I.; Amin, M.; Nazir, M.T. Hydrophobic, dielectric and water immersion performance of 9000 h multi-stresses aged silicone rubber composites for high voltage outdoor insulation. Eng. Fail. Anal. 2021, 122, 105223. [Google Scholar] [CrossRef]

- Xie, S.Y.; Zhou, M.; Chen, L.K.; Huang, H.; Song, S.N.; Wang, J.G. Mechanical properties and damage characteristics of composite insulator sheds for island operation. High Volt. Eng. 2021, 47, 1824–1830. [Google Scholar]

- Zhang, Z.; Pang, G.; MA, X.; Liang, T.; Jiang, X. Mechanical Properties of High-Temperature Vulcanized Silicone Rubber Under Acid-Fog With AC Energized. IEEE Access 2022, 10, 95553–95564. [Google Scholar] [CrossRef]

- Ito, S.; Hirai, N.; Ohki, Y. Changes in mechanical and dielectric properties of silicone rubber induced by severe aging. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 722–730. [Google Scholar] [CrossRef]

- Coser, E.; Ferreira, C.A.; Giacomini Angelini, J.M.; Aragão, B.; Perez, I.A. Mechanical analysis of silicone rubber used on the cover of polymeric insulators. IEEE Lat. Am. Trans. 2010, 8, 653–657. [Google Scholar] [CrossRef]

- Guo, L.M.; Lv, Y.N.; Deng, Z.F.; Wang, Y.; Zan, X. Tension testing of silicone rubber at high strain rates. Polym. Test. 2016, 50, 270–275. [Google Scholar] [CrossRef]

- Khan, H.; Amin, M.; Ahmad, A. Performance evaluation of alumina trihydrate and silica-filled silicone rubber composites for outdoor high-voltage insulation. Turk. J. Electr. Eng. Comput. Sci. 2018, 26, 2688–2700. [Google Scholar] [CrossRef]

- Rashid, A.; Saleem, J.; Amin, M.; Ali, M. Long-term aging characteristics of co-filled nano-silica and micro-ATH in HTV silicone rubber composite insulators. Polym. Polym. Compos. 2020, 20, 1–17. [Google Scholar] [CrossRef]

- Wang, S.; Hou, M.; Ma, K.; Li, Z.; Geng, H.; Zhang, W.; Li, N. Research on the Influence of Extremely Cold Environment on the Performance of Silicone Rubber and Fluorinated Silicone Rubber. Polymers 2022, 14, 1898. [Google Scholar] [CrossRef]

- Liu, B.; Zhan, L.; Lu, H.; Zhang, J. Advances in Characterizing Gas Hydrate Formation in Sediments with NMR Transverse Relaxation Time. Water 2022, 14, 330. [Google Scholar] [CrossRef]

- Xu, Z.; Cui, X.J.; Meng, K.K.; Xia, Y.F. Novel Unilateral NMR Sensor for Assessing the Aging Status of Silicone Rubber Insulator. IEEE Sens. J. 2016, 16, 1168–1175. [Google Scholar]

- ISO 48-4; Rubber, Vulcanized or Thermoplastic—Determination of Hardness—Part 4: Indentation Hardness by Durometer Method (Shore Hardness). International Organisation for Standardization (ISO): Geneva, Switzerland, 2018.

- ISO 37; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organisation for Standardization (ISO): Geneva, Switzerland, 2018.

- Cheng, L.; Mei, H.W.; Wang, L.M.; Guan, Z.C.; Zhang, F.Z. Research on aging evaluation and remaining lifespan prediction of composite insulators in high temperature and humidity regions. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2850–2857. [Google Scholar] [CrossRef]

- DL/T 376-2010; General Technical Conditions for Silicone Rubber Insulating Materials for Composite Insulators. DL/T: Beijing, China, 2010.

- Song, W.; Shen, W.W.; Zhang, G.J.; Song, B.P.; Lang, Y.; Su, G.Q.; Mu, H.B.; Deng, J.B. Aging characterization of high temperature vulcanized silicone rubber housing material used for outdoor insulation. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 961–969. [Google Scholar] [CrossRef]

- Moghadam, M.K.; Taheri, M.; Gharazi, S.; Keramati, M.; Bahrami, M.; Riahi, N. A study of composite insulator aging using the tracking wheel test. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1805–1811. [Google Scholar] [CrossRef]

- Cardoso, R.; Balestro, A.C.; Dellallibera, A.; Costa, E.C.M.; Angelini, J.M.G.; Mei, L.H.I. Silicone insulators of power transmission lines with a variable inorganic load concentration: Electrical and physiochemical analyses. Measurement 2014, 50, 63–73. [Google Scholar] [CrossRef]

- Fan, S.C.; Zhang, X.; Lu, Y.; Gao, Y.F. Characterization of HTV silicone rubber with different content of ATH filler by mechanical measurements, FTIR and XPS analyzes. In Proceedings of the 2018 12th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Xi’an, China, 20–24 May 2018. [Google Scholar]

| CPMG Parameters | Numerical Value |

|---|---|

| Pulse width/μs | 11 |

| Echo time/μs | 120 |

| Echo number/piece | 200 |

| Repeat time/ms | 2000 |

| Repetitions/time | 168 |

| Sampling time interval/μs | 1 |

| Sample Number | Voltage Class/kV | Aging Years/a | T2/ms |

|---|---|---|---|

| C-1 | 110 | 3.5 | 116.3 |

| C-2 | 110 | 6 | 111.7 |

| C-3 | 110 | 10 | 105.7 |

| Sample Number | First Stage Weight Loss/% | Second Stage Weight Loss/% | Residual Mass/% |

|---|---|---|---|

| C-1 | 15.72 | 29.54 | 54.50 |

| C-2 | 15.69 | 29.04 | 55.13 |

| C-3 | 15.41 | 28.64 | 55.82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zhao, J.; Wan, X.; Jiang, X.; Hu, J. Mechanical Properties of High Temperature Vulcanized Silicone Rubber Aged in the Natural Environment. Polymers 2022, 14, 4439. https://doi.org/10.3390/polym14204439

Zhang Z, Zhao J, Wan X, Jiang X, Hu J. Mechanical Properties of High Temperature Vulcanized Silicone Rubber Aged in the Natural Environment. Polymers. 2022; 14(20):4439. https://doi.org/10.3390/polym14204439

Chicago/Turabian StyleZhang, Zhijin, Jianjie Zhao, Xiaodong Wan, Xingliang Jiang, and Jianlin Hu. 2022. "Mechanical Properties of High Temperature Vulcanized Silicone Rubber Aged in the Natural Environment" Polymers 14, no. 20: 4439. https://doi.org/10.3390/polym14204439

APA StyleZhang, Z., Zhao, J., Wan, X., Jiang, X., & Hu, J. (2022). Mechanical Properties of High Temperature Vulcanized Silicone Rubber Aged in the Natural Environment. Polymers, 14(20), 4439. https://doi.org/10.3390/polym14204439