Low Impact Velocity Modeling of 3D Printed Spatially Graded Elastomeric Lattices

Abstract

1. Introduction

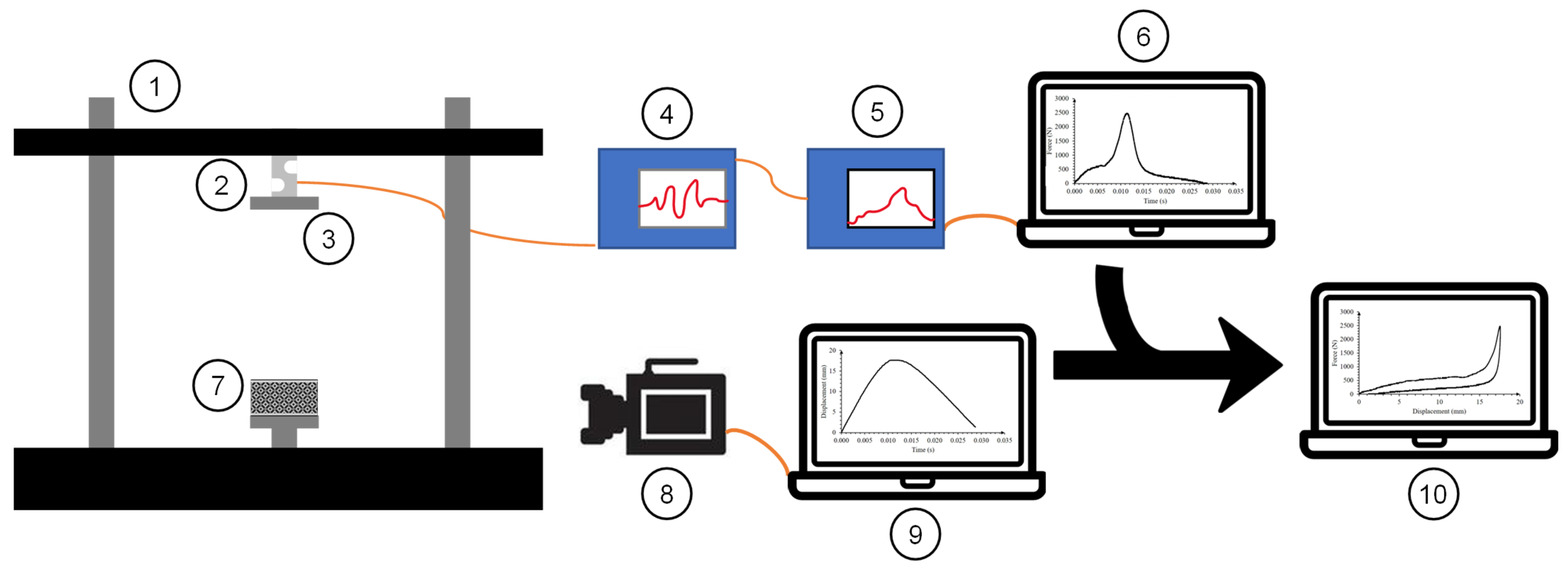

2. Materials and Methods

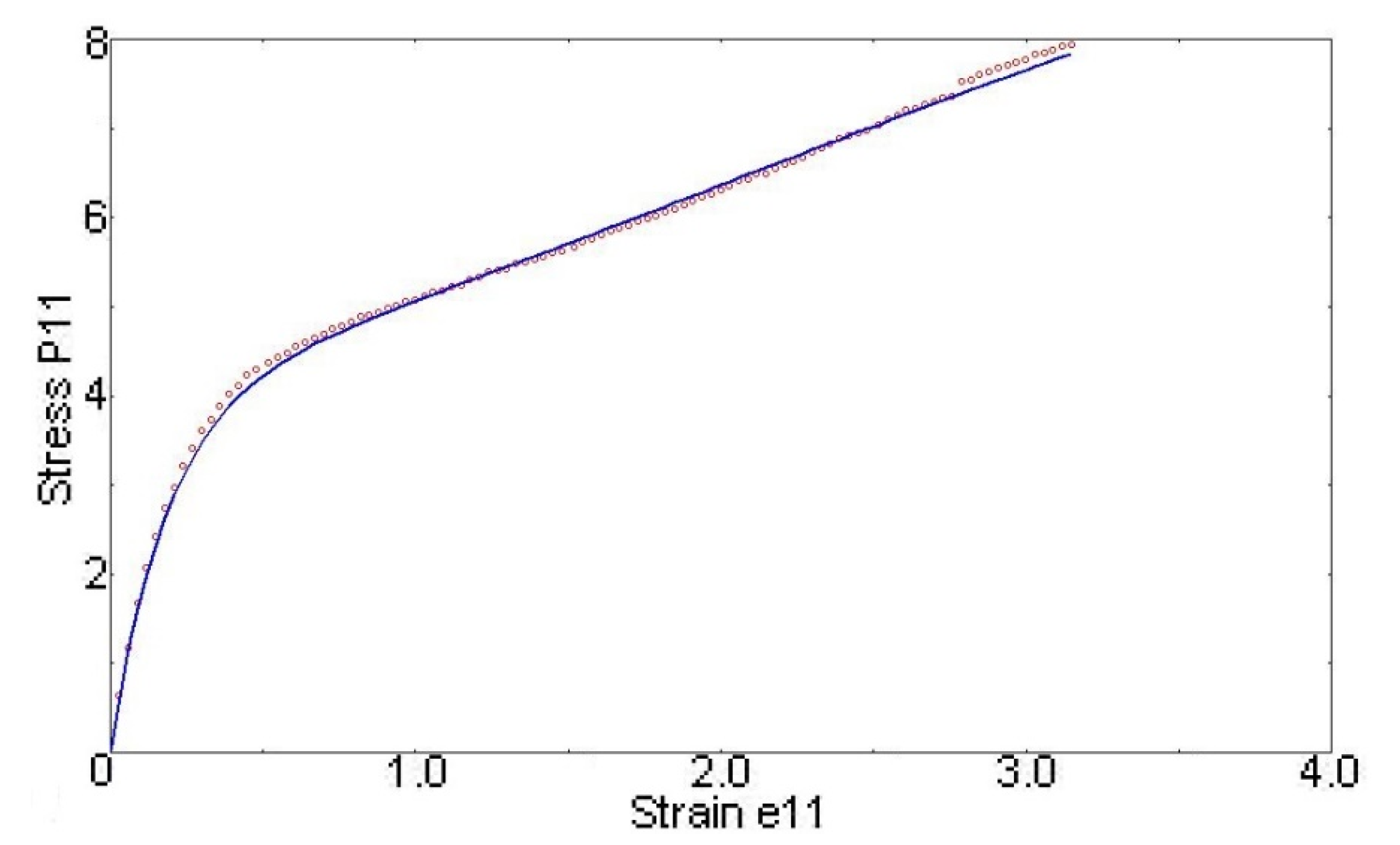

2.1. Parent Material

2.2. Lattices

Compression Testing

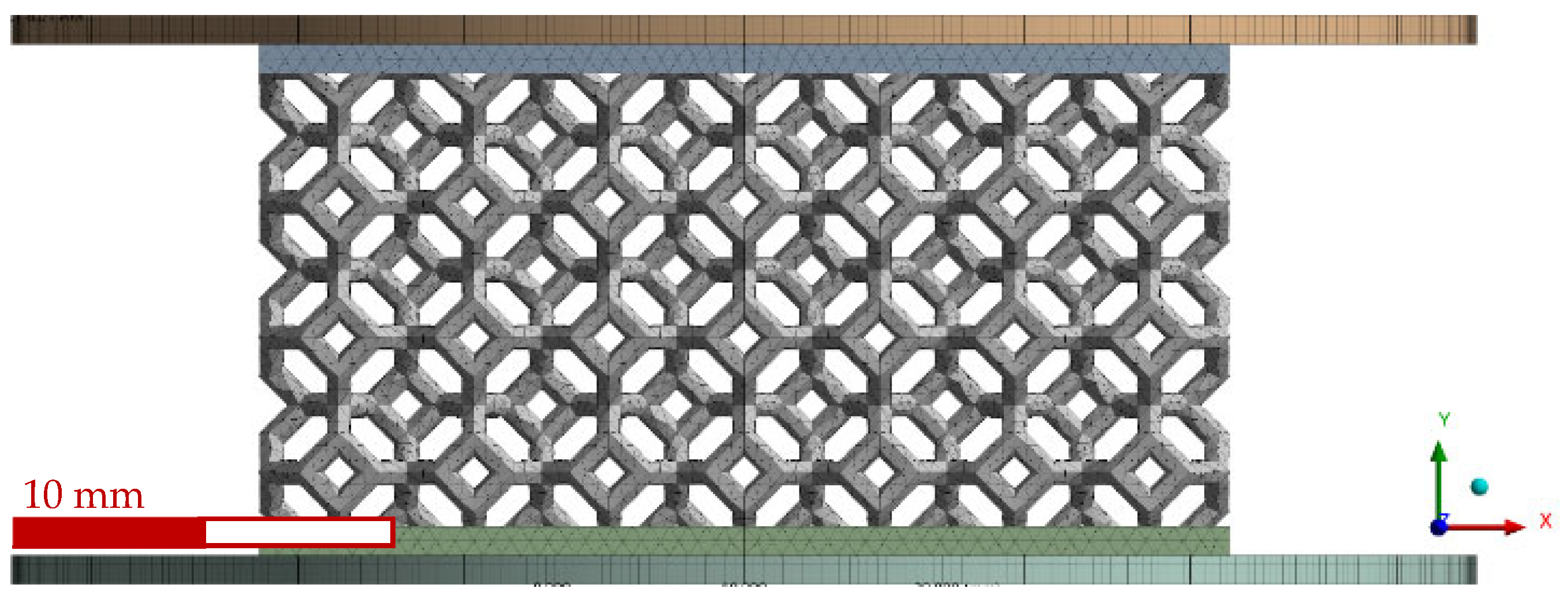

2.3. Finite Element Analysis

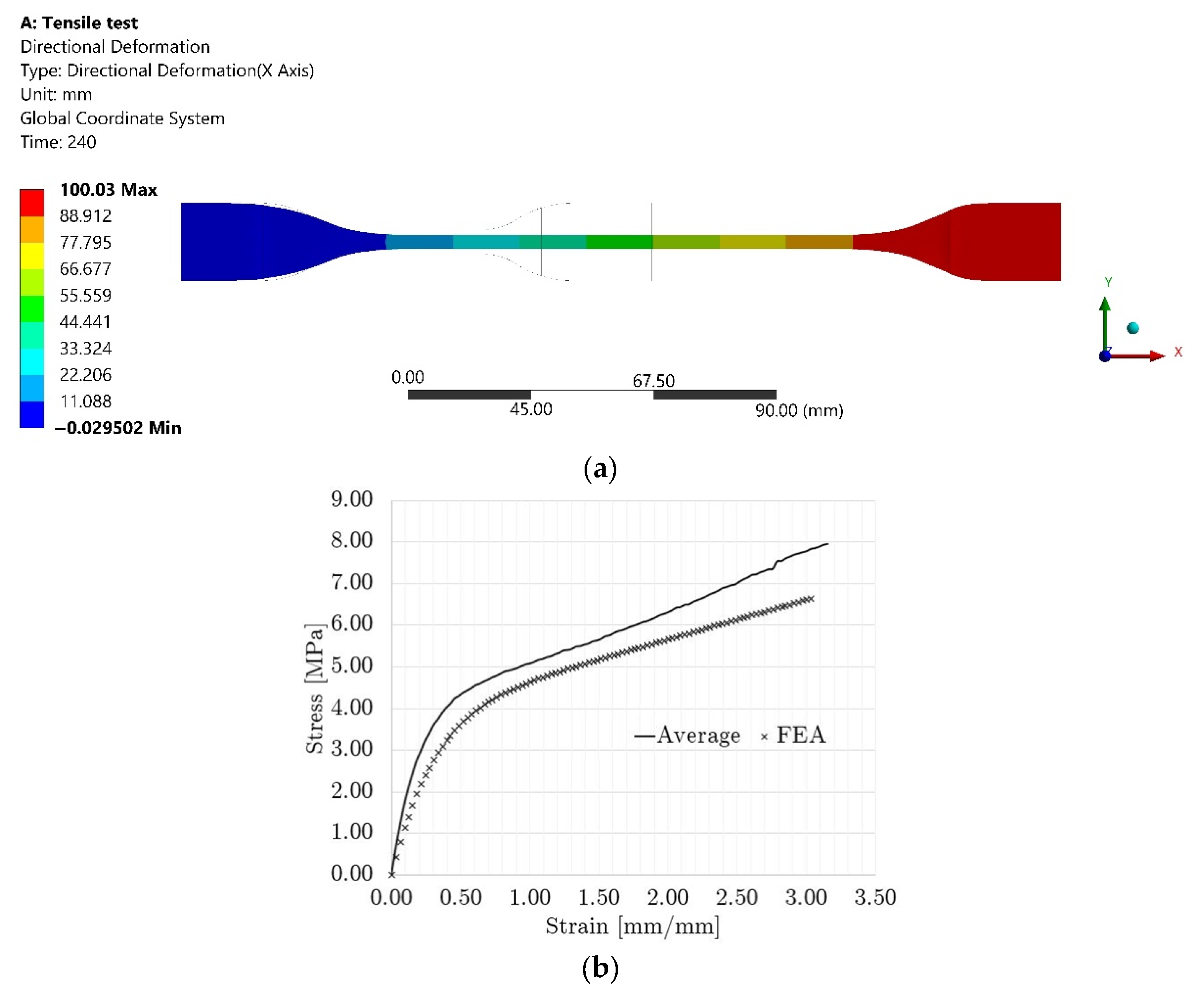

2.3.1. Tensile Test Modeling

2.3.2. Lattice Quasi-Static Compression

2.3.3. Lattice Impact Loading

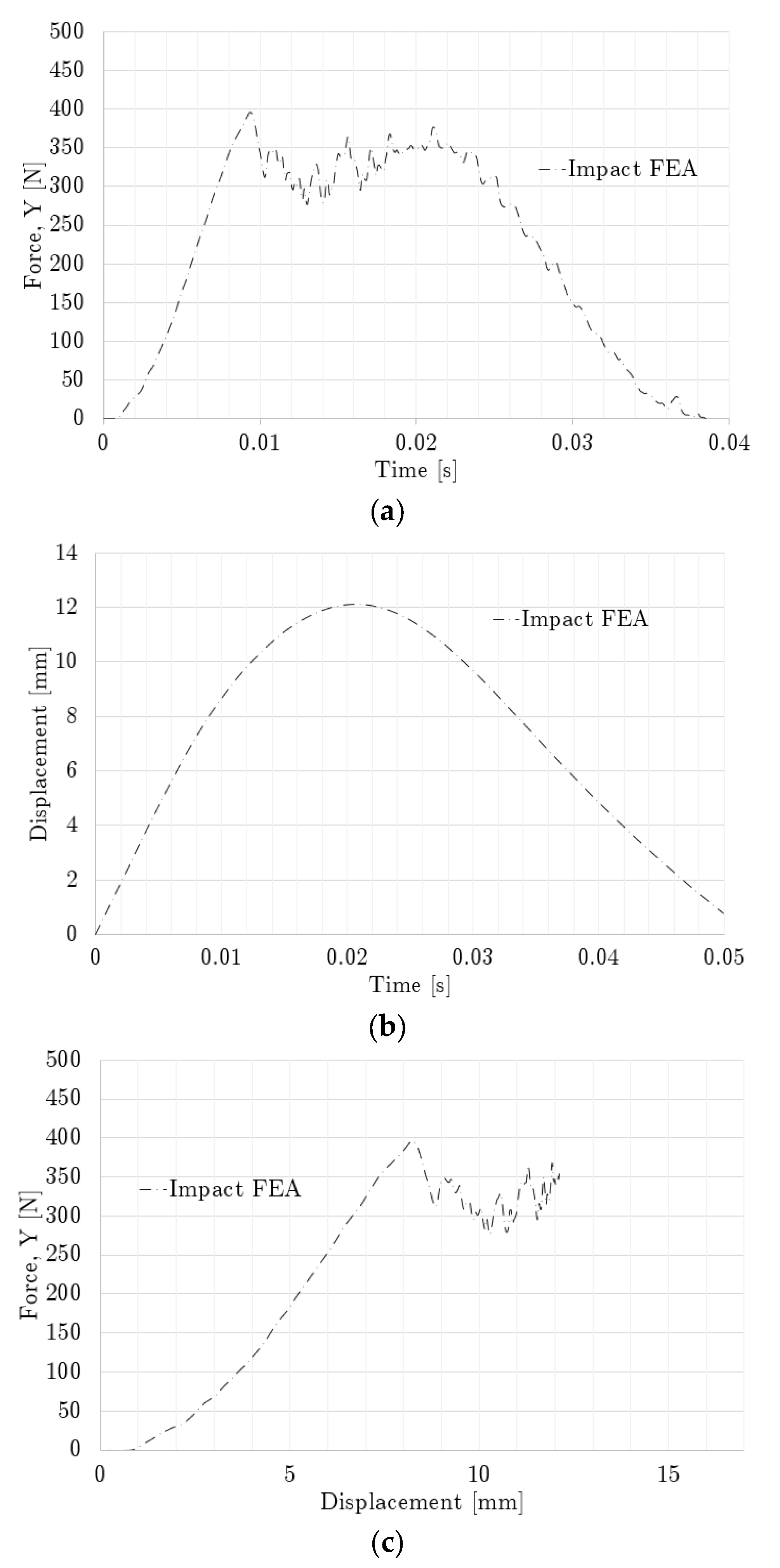

Side-Graded Lattice

Special Cases

Average Deceleration

3. Results and Discussion

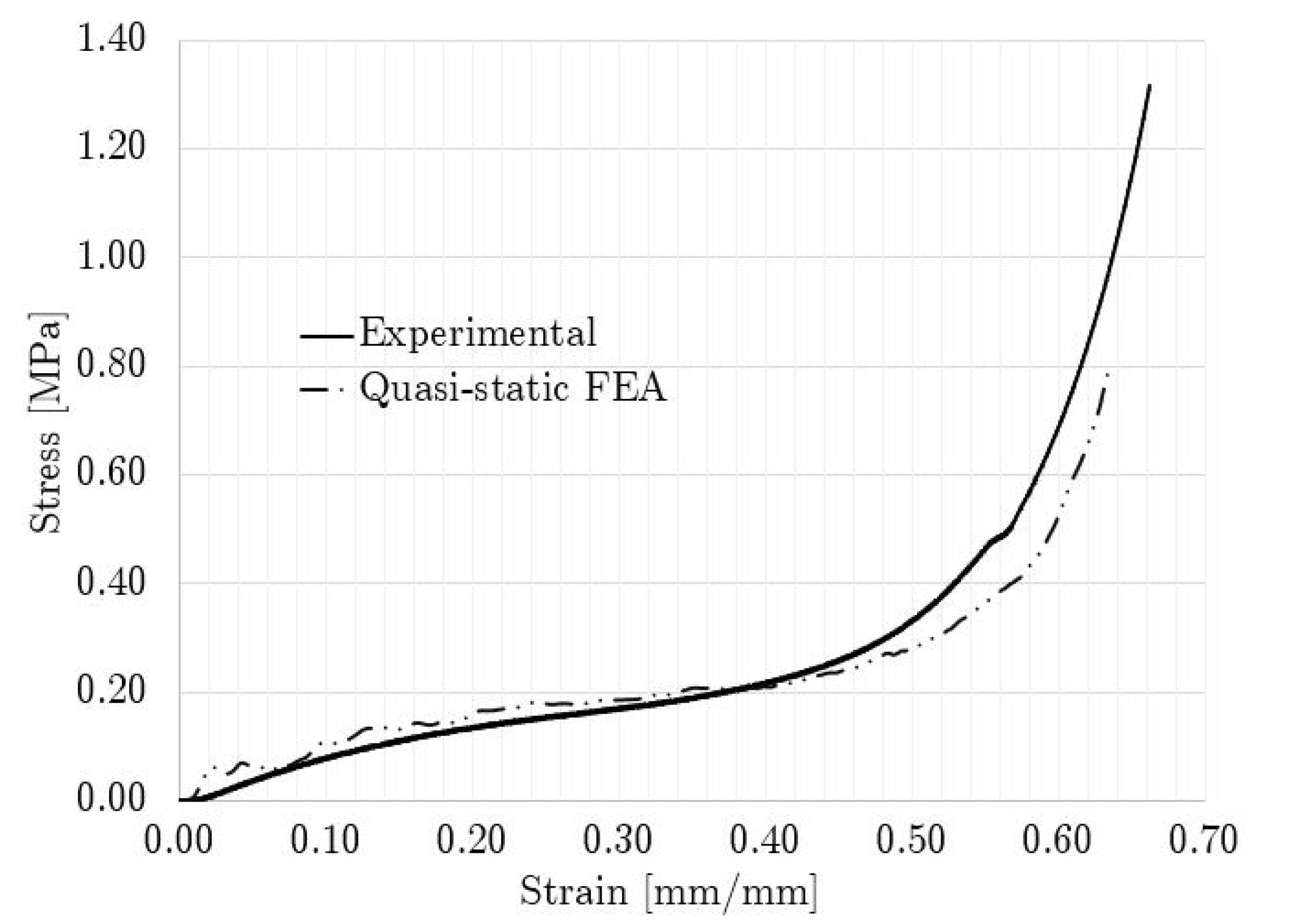

3.1. Parent Material

3.2. Lattice Quasi-Static Compression

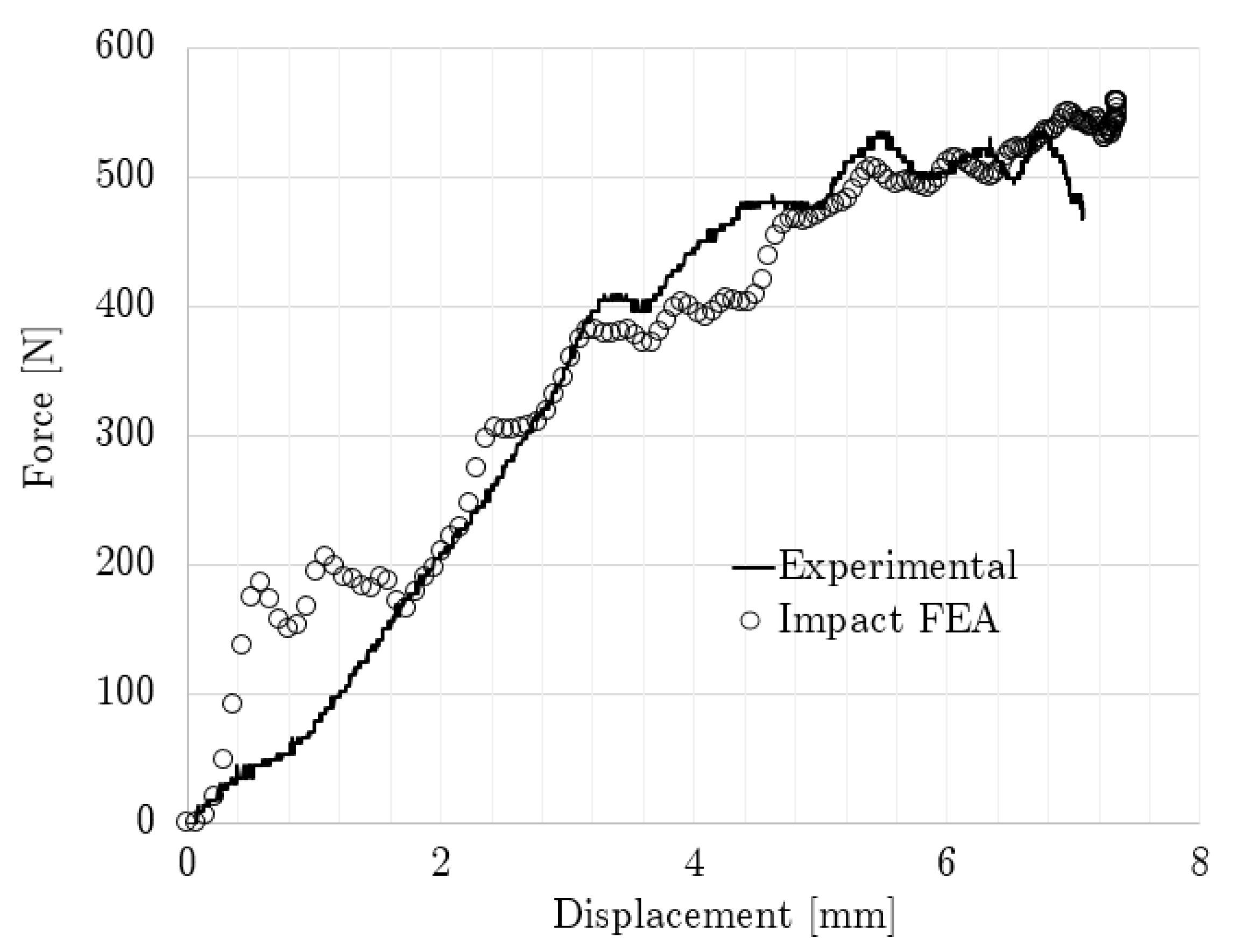

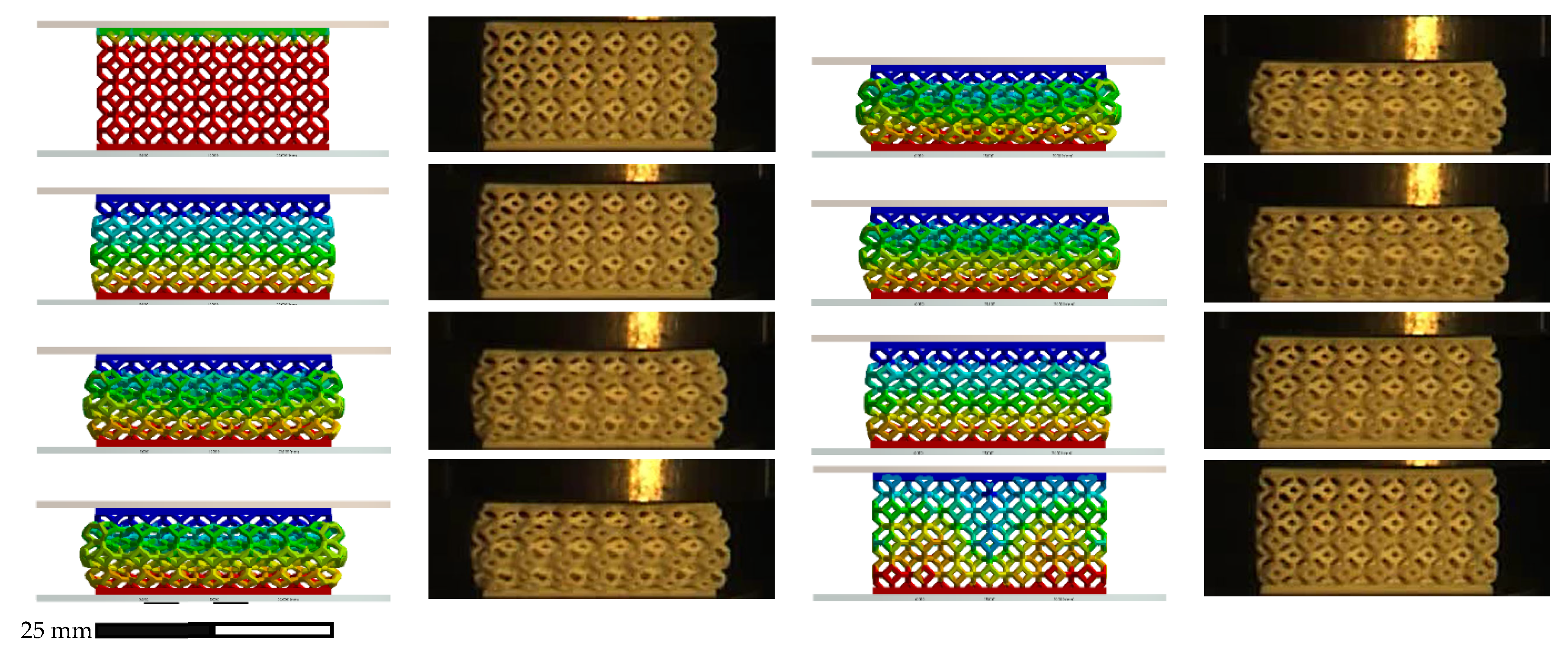

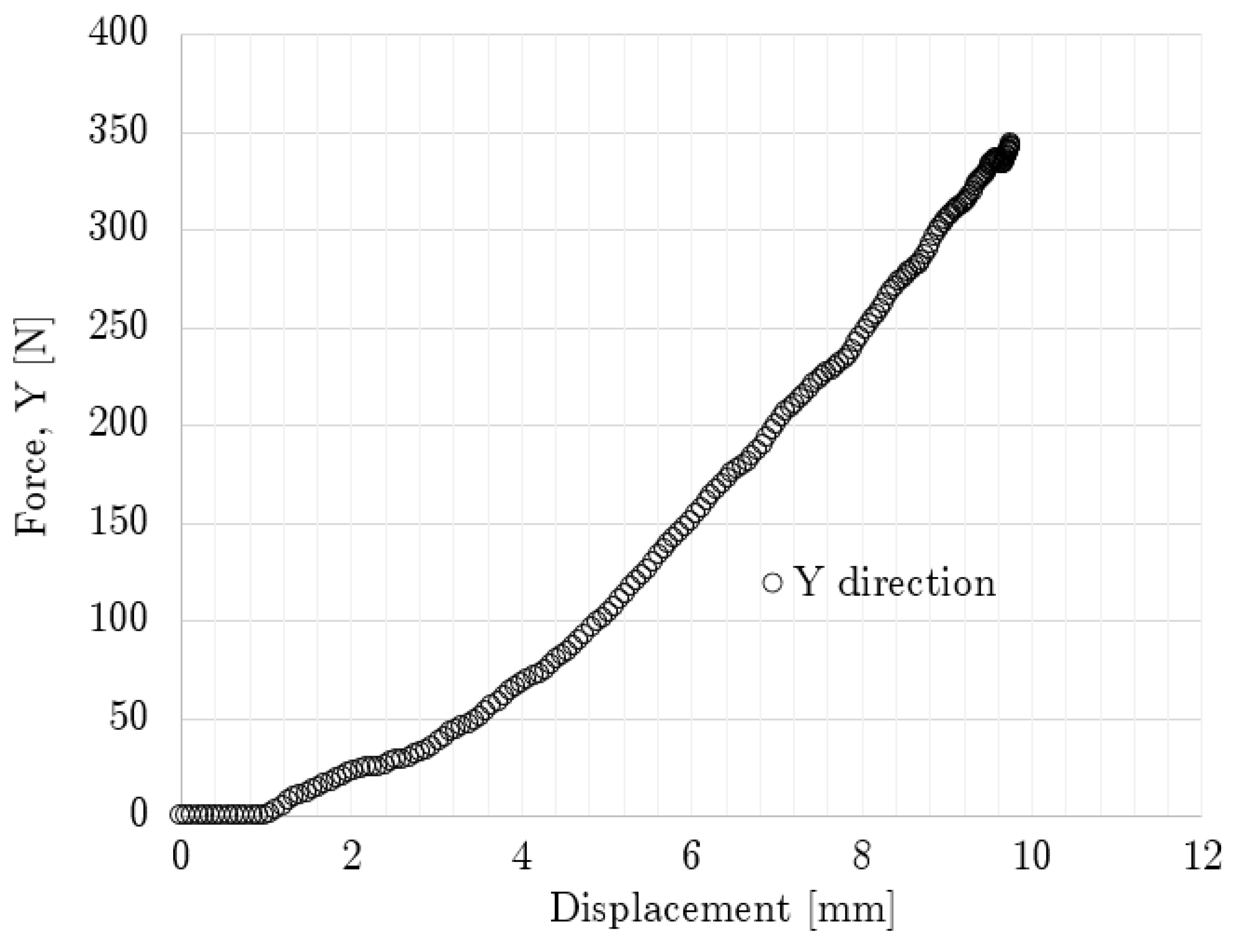

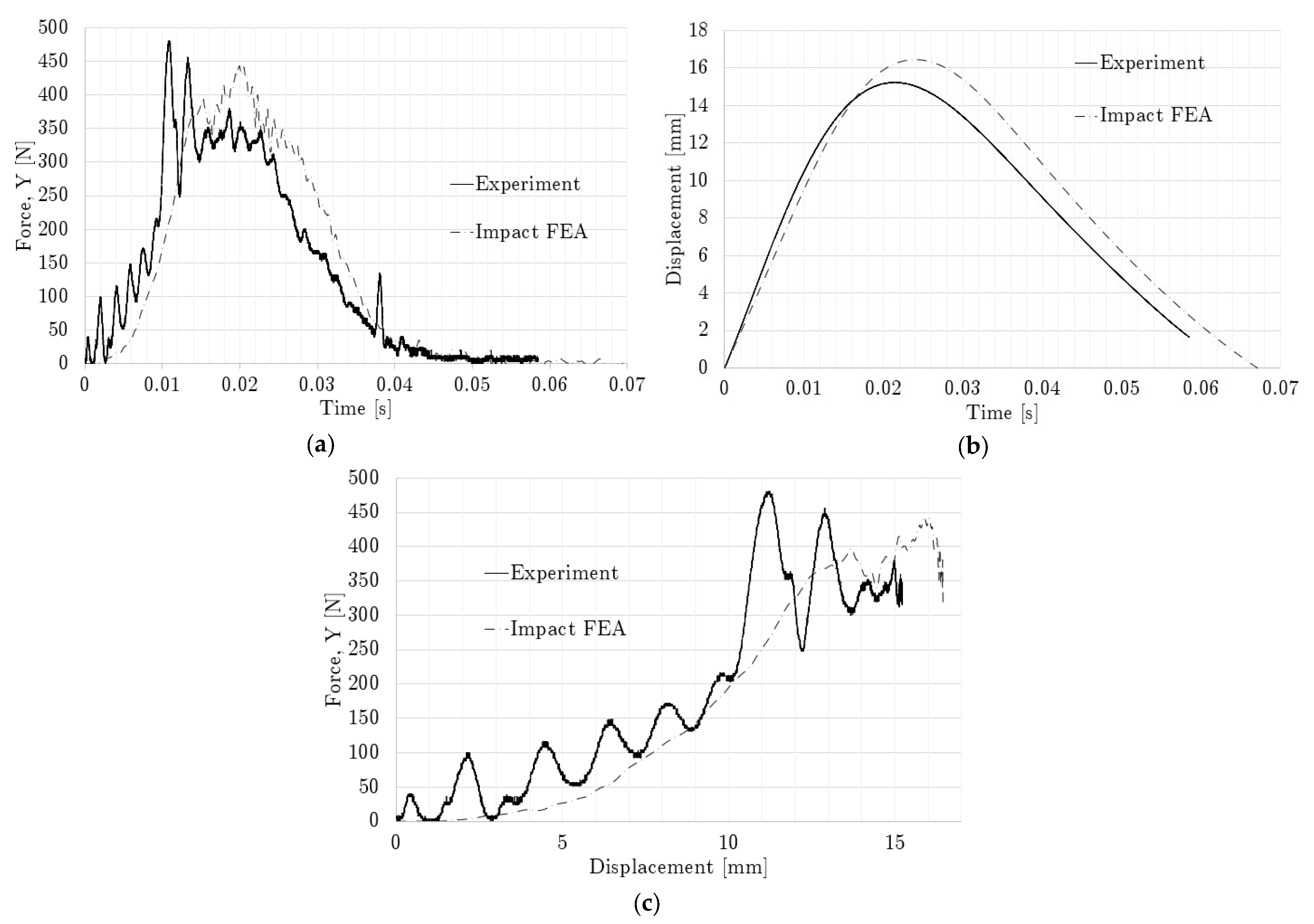

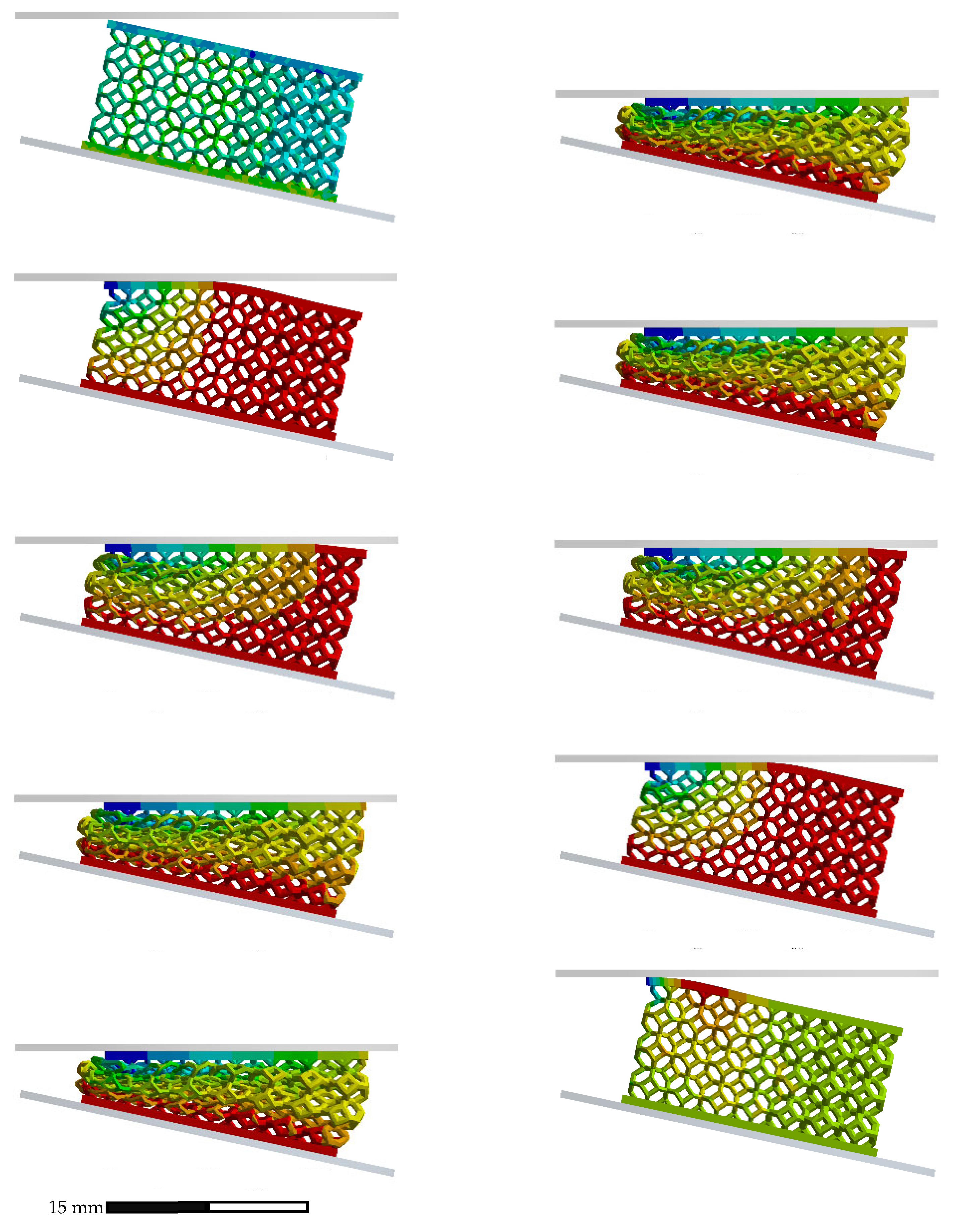

3.3. Lattice Impact Loading

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Babu, S.S.; Goodridge, R. Additive Manufacturing. Mater. Sci. Technol. 2015, 31, 881–883. [Google Scholar] [CrossRef]

- Rosen, D. Design for Additive Manufacturing: Past, Present, and Future Directions. J. Mech. Des. 2014, 136, 8–9. [Google Scholar] [CrossRef]

- Pan, C.; Han, Y.; Lu, J. Design and Optimization of Lattice Structures: A Review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Helou, M.; Kara, S. Design, Analysis and Manufacturing of Lattice Structures: An Overview. Int. J. Comput. Integr. Manuf. 2018, 31, 243–261. [Google Scholar] [CrossRef]

- ISO/ASTM 52900; Additive Manufacturing—General Principles—Terminology. International Organization for Standardization: Geneva, Switzerland, 2015; pp. 1–19.

- Mahmoud, D.; Elbestawi, M.A. Lattice Structures and Functionally Graded Materials Applications in Additive Manufacturing of Orthopedic Implants: A Review. J. Manuf. Mater. Process. 2017, 1, 13. [Google Scholar] [CrossRef]

- Paul, S. Finite Element Analysis in Fused Deposition Modeling Research: A Literature Review. Measurement 2021, 178, 109320. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Xu, Y.; Zhang, W.; Zhu, J. Compressive Behavior and Energy Absorption of Polymeric Lattice Structures Made by Additive Manufacturing. Front. Mech. Eng. 2020, 15, 319–327. [Google Scholar] [CrossRef]

- Kummert, C.; Schmid, H.J.; Risse, L.; Kullmer, G. Mechanical Characterization and Numerical Modeling of Laser-Sintered TPE Lattice Structures. J. Mater. Res. 2021, 36, 3182–3193. [Google Scholar] [CrossRef]

- Zhang, P.; To, A.C. Transversely Isotropic Hyperelastic-Viscoplastic Model for Glassy Polymers with Application to Additive Manufactured Photopolymers. Int. J. Plast. 2016, 80, 56–74. [Google Scholar] [CrossRef]

- Sun, B.; Kulinsky, L. Fabrication of Regular Polystyrene Foam Structures with Selective Laser Sintering. Mater. Today Commun. 2017, 13, 346–353. [Google Scholar] [CrossRef]

- Habib, F.N.; Iovenitti, P.; Masood, S.H.; Nikzad, M. Fabrication of Polymeric Lattice Structures for Optimum Energy Absorption Using Multi Jet Fusion Technology. Mater. Des. 2018, 155, 86–98. [Google Scholar] [CrossRef]

- Maskery, I.; Sturm, L.; Aremu, A.O.; Panesar, A.; Williams, C.B.; Tuck, C.J.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Insights into the Mechanical Properties of Several Triply Periodic Minimal Surface Lattice Structures Made by Polymer Additive Manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Parry, L.; Wildman, R.D.; Tuck, C.J.; Ashcroft, I.A. Effective Design and Simulation of Surface-Based Lattice Structures Featuring Volume Fraction and Cell Type Grading. Mater. Des. 2018, 155, 220–232. [Google Scholar] [CrossRef]

- Habib, F.; Iovenitti, P.; Masood, S.; Nikzad, M.; Ruan, D. Design and Evaluation of 3D Printed Polymeric Cellular Materials for Dynamic Energy Absorption. Int. J. Adv. Manuf. Technol. 2019, 103, 2347–2361. [Google Scholar] [CrossRef]

- Li, Z.-H.; Nie, Y.-F.; Liu, B.; Kuai, Z.-Z.; Zhao, M.; Liu, F. Mechanical Properties of AlSi10Mg Lattice Structures Fabricated by Selective Laser Melting. Mater. Des. 2020, 192, 108709. [Google Scholar] [CrossRef]

- Fadeel, A.; Abdulhadi, H.; Srinivasan, R.; Mian, A. A Computational Approach in Understanding the Low-Velocity Impact Behavior and Damage of 3D-Printed Polymer Lattice Structures. J. Mater. Eng. Perform. 2021, 30, 6511–6521. [Google Scholar] [CrossRef]

- León-Becerra, J.; González-Estrada, O.A.; Quiroga, J. Effect of Relative Density in In-Plane Mechanical Properties of Common 3D-Printed Polylactic Acid Lattice Structures. ACS Omega 2021, 6, 29830–29838. [Google Scholar] [CrossRef]

- Li, W.; Fan, H.; Bian, Y.; Yang, F. Plastic Deformation and Energy Absorption of Polycrystalline-like Lattice Structures. Mater. Des. 2021, 198, 109321. [Google Scholar] [CrossRef]

- Kankanamge, U.M.H.U.; Mohamed, O.A.; Xu, W. Superelastic Behavior of Additively Manufactured Nylon-12 Lattice Structures. J. Mater. Eng. Perform. 2021, 30, 9352–9358. [Google Scholar] [CrossRef]

- Montgomery, S.M.; Hilborn, H.; Hamel, C.M.; Kuang, X.; Long, K.N.; Qi, H.J. The 3D Printing and Modeling of Functionally Graded Kelvin Foams for Controlling Crushing Performance. Extreme Mech. Lett. 2021, 46, 101323. [Google Scholar] [CrossRef]

- Jhou, S.Y.; Hsu, C.C.; Yeh, J.C. The Dynamic Impact Response of 3d-Printed Polymeric Sandwich Structures with Lattice Cores: Numerical and Experimental Investigation. Polymers 2021, 13, 4032. [Google Scholar] [CrossRef] [PubMed]

- Fadeel, A.; Abdulhadi, H.; Newaz, G.; Srinivasan, R.; Mian, A. Computational Investigation of the Post-Yielding Behavior of 3D-Printed Polymer Lattice Structures. J. Comput. Des. Eng. 2022, 9, 263–277. [Google Scholar] [CrossRef]

- Eren, O.; Sezer, H.K.; Yalçın, N. Effect of Lattice Design on Mechanical Response of PolyJet Additively Manufactured Cellular Structures. J. Manuf. Process. 2022, 75, 1175–1188. [Google Scholar] [CrossRef]

- Verma, S.; Yang, C.K.; Lin, C.H.; Jeng, J.Y. Additive Manufacturing of Lattice Structures for High Strength Mechanical Interlocking of Metal and Resin during Injection Molding. Addit. Manuf. 2022, 49, 102463. [Google Scholar] [CrossRef]

- Dar, U.A.; Mian, H.H.; Abid, M.; Nutkani, M.B.; Jamil, A.; Sheikh, M.Z. Quasi-Static Compression and Deformation Behavior of Additively Manufactured Flexible Polymeric Lattice Structure. J. Mater. Eng. Perform. 2022, 31, 3107–3119. [Google Scholar] [CrossRef]

- Graziosi, S.; Ballo, F.M. 3D Printing of Bending-Dominated Soft Lattices: Numerical and Experimental Assessment. Rapid Prototyp. J. 2022, 11, 51–64. [Google Scholar] [CrossRef]

- Shen, F.; Yuan, S.; Guo, Y.; Zhao, B.; Bai, J.; Qwamizadeh, M.; Chua, C.K.; Wei, J.; Zhou, K. Energy Absorption of Thermoplastic Polyurethane Lattice Structures via 3D Printing: Modeling and Prediction. Int. J. Appl. Mech. 2016, 8, 1640006. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Mechanical and FEA-Assisted Characterization of Fused Filament Fabricated Triply Periodic Minimal Surface Structures. J. Compos. Sci. 2021, 5, 58. [Google Scholar] [CrossRef]

- Cipriani, C.E.; Ha, T.; Martinez Defilló, O.B.; Myneni, M.; Wang, Y.; Benjamin, C.C.; Wang, J.; Pentzer, E.B.; Wei, P. Structure-Processing-Property Relationships of 3D Printed Porous Polymeric Materials. ACS Mater. Au 2021, 1, 69–80. [Google Scholar] [CrossRef]

- Nazir, A.; Gohar, A.; Lin, S.; Jeng, J. Flexural Properties of Periodic Lattice Structured Lightweight Cantilever Beams Fabricated Using Additive Manufacturing: Experimental and Finite Element Methods. 3D Print. Addit. Manuf. 2022, Ahead of Print. [Google Scholar] [CrossRef]

- Yang, L.; Harrysson, O.; West, H.; Cormier, D. Modeling of Uniaxial Compression in a 3D Periodic Re-Entrant Lattice Structure. J. Mater. Sci. 2013, 48, 1413–1422. [Google Scholar] [CrossRef]

- Li, C.; Lei, H.; Liu, Y.; Zhang, X.; Xiong, J.; Zhou, H.; Fang, D. Crushing Behavior of Multi-Layer Metal Lattice Panel Fabricated by Selective Laser Melting. Int. J. Mech. Sci. 2018, 145, 389–399. [Google Scholar] [CrossRef]

- Ling, C.; Cernicchi, A.; Gilchrist, M.D.; Cardiff, P. Mechanical Behaviour of Additively-Manufactured Polymeric Octet-Truss Lattice Structures under Quasi-Static and Dynamic Compressive Loading. Mater. Des. 2019, 162, 106–118. [Google Scholar] [CrossRef]

- Geng, L.; Wu, W.; Sun, L.; Fang, D. Damage Characterizations and Simulation of Selective Laser Melting Fabricated 3D Re-Entrant Lattices Based on in-Situ CT Testing and Geometric Reconstruction. Int. J. Mech. Sci. 2019, 157–158, 231–242. [Google Scholar] [CrossRef]

- Lei, H.; Li, C.; Meng, J.; Zhou, H.; Liu, Y.; Zhang, X.; Wang, P.; Fang, D. Evaluation of Compressive Properties of SLM-Fabricated Multi-Layer Lattice Structures by Experimental Test and μ-CT-Based Finite Element Analysis. Mater. Des. 2019, 169, 107685. [Google Scholar] [CrossRef]

- Santiago, C.C.; Yelamanchi, B.; Diosdado De la Peña, J.A.; Lamb, J.; Roguski, K.; Turzyński, F.; Faruqui, R.; Choo, K.; du Plessis, A.; Sillani, F.; et al. Thermoplastic Extrusion Additive Manufacturing of High-Performance Carbon Fiber PEEK Lattices. Crystals 2021, 11, 1453. [Google Scholar] [CrossRef]

- Gorguluarslan, R.M.; Gungor, O.U.; Yıldız, S.; Erem, E. Energy Absorption Behavior of Stiffness Optimized Graded Lattice Structures Fabricated by Material Extrusion. Meccanica 2021, 56, 2825–2841. [Google Scholar] [CrossRef]

- Goel, A.; Anand, S. Design of Functionally Graded Lattice Structures Using B-Splines for Additive Manufacturing. Procedia Manuf. 2019, 34, 655–665. [Google Scholar] [CrossRef]

- Altamimi, S.; Lee, D.W.; Barsoum, I.; Rowshan, R.; Jasiuk, I.M.; Abu Al-Rub, R.K. On Stiffness, Strength, Anisotropy, and Buckling of 30 Strut-Based Lattices with Cubic Crystal Structures. Adv. Eng. Mater. 2021, 24, 2101379. [Google Scholar] [CrossRef]

- Clough, E.C.; Plaisted, T.A.; Eckel, Z.C.; Cante, K.; Hundley, J.M.; Schaedler, T.A. Elastomeric Microlattice Impact Attenuators. Matter 2019, 1, 1519–1531. [Google Scholar] [CrossRef]

- Ashby, M.F. The Properties of Foams and Lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P. Ti–6Al–4V Triply Periodic Minimal Surface Structures for Bone Implants Fabricated via Selective Laser Melting. J. Mech. Behav. Biomed. Mater. 2015, 51, 61–73. [Google Scholar] [CrossRef]

- Soe, S.P.; Martindale, N.; Constantinou, C.; Robinson, M. Mechanical Characterisation of Duraform® Flex for FEA Hyperelastic Material Modelling. Polym. Test. 2014, 34, 103–112. [Google Scholar] [CrossRef]

- Srinivas, R.P.; Alomarah, A.; Masood, S.H.; Nikzad, M.; Habib, F.N.; Riza, S.H. Mechanical Response of a Compressed Novel 3D Tetrachiral Structure Processed by MJF 3D Printing Process. Mater Today Proc 2021, 46, 4776–4781. [Google Scholar] [CrossRef]

- Al Rifaie, M.; Mian, A.; Katiyar, P.; Majumdar, P.; Srinivasan, R. Drop-Weight Impact Behavior of Three-Dimensional Printed Polymer Lattice Structures with Spatially Distributed Vertical Struts. J. Dyn. Behav. Mater. 2019, 5, 387–395. [Google Scholar] [CrossRef]

- ALM. TPE 300 Material Data Sheet. Available online: http://alm-llc.com/wp-content/uploads/2021/05/TPE-300-Data-Sheet-2021.pdf (accessed on 1 August 2021).

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2010; pp. 1–17. [CrossRef]

- Ge, C.; Priyadarshini, L.; Cormier, D.; Pan, L.; Tuber, J. A Preliminary Study of Cushion Properties of a 3D Printed Thermoplastic Polyurethane Kelvin Foam. Packag. Technol. Sci. 2018, 31, 361–368. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, Q. Highly-Stretchable 3D-Architected Mechanical Metamaterials. Sci. Rep. 2016, 6, 34147. [Google Scholar] [CrossRef]

- ASTM D1621-16; Standard Test Method for Compressive Properties of Rigid Cellular Plastics. ASTM International: West Conshohocken, PA, USA, 2016.

- Biocore. Helmet Test Protocol; Biocore: Charlottesville, VA, USA, 2019; pp. 1–46. [Google Scholar]

- Brown, D.; Christian, W.; Hanson, R.M. Tracker Video Analysis and Modelling Tool. Available online: https://physlets.org/tracker/ (accessed on 18 August 2022).

- Sasso, M.; Palmieri, G.; Chiappini, G.; Amodio, D. Characterization of Hyperelastic Rubber-like Materials by Biaxial and Uniaxial Stretching Tests Based on Optical Methods. Polym. Test. 2008, 27, 995–1004. [Google Scholar] [CrossRef]

- Pearson, I.; Pickering, M. The Determination of a Highly Elastic Adhesive’s Material Properties and Their Representation in Finite Element Analysis. Finite Elem. Anal. Des. 2001, 37, 221–232. [Google Scholar] [CrossRef]

- Bradley, G.L.; Chang, P.C.; McKenna, G.B. Rubber Modeling Using Uniaxial Test Data. J. Appl. Polym. Sci. 2001, 81, 837–848. [Google Scholar] [CrossRef]

- Shahzad, M.; Kamran, A.; Siddiqui, M.Z.; Farhan, M. Mechanical Characterization and FE Modelling of a Hyperelastic Material. Mater. Res. 2015, 18, 918–924. [Google Scholar] [CrossRef]

- Keerthiwansa, R.; Javorik, J.; Kledrowetz, J.; Nekoksa, P. Elastomer Testing: The Risk of Using Only Uniaxial Data for Fitting the Mooney-Rivlin Hyperelastic-Material Model. Mater. Tehnol. 2018, 52, 3–8. [Google Scholar] [CrossRef]

- Rahman, H.; Yarali, E.; Zolfagharian, A.; Serjouei, A.; Bodaghi, M. Energy Absorption and Mechanical Performance of Functionally Graded Soft–Hard Lattice Structures. Materials 2021, 14, 1366. [Google Scholar] [CrossRef]

- Shepherd, T.; Winwood, K.; Venkatraman, P.; Alderson, A.; Allen, T. Validation of a Finite Element Modeling Process for Auxetic Structures under Impact. Phys. Status Solidi B Basic Res. 2020, 257, 1900197. [Google Scholar] [CrossRef]

- Reppel, T.; Weinberg, K. Experimental Determination of Elastic and Rupture Properties of Printed Ninjaflex. Tech. Mech. 2018, 38, 104–112. [Google Scholar] [CrossRef]

- Heiml, E.; Kalteis, A.; Major, Z. Experimental Investigation and Simulation of 3D-Printed Lattice Structures. Acta Polytech. CTU Proc. 2019, 25, 52–57. [Google Scholar] [CrossRef]

- Rohan, P.Y.; Lobos, C.; Nazari, M.A.; Perrier, P.; Payan, Y. Finite Element Models of the Human Tongue: A Mixed-Element Mesh Approach. Comput. Methods Biomech. Biomed. Eng. Imaging Vis. 2016, 5, 390–400. [Google Scholar] [CrossRef][Green Version]

- Pinedo, B.; Hadfield, M.; Tzanakis, I.; Conte, M.; Anand, M. Thermal Analysis and Tribological Investigation on TPU and NBR Elastomers Applied to Sealing Applications. Tribol. Int. 2018, 127, 24–36. [Google Scholar] [CrossRef]

- Chou, C.C.; Nyquist, G.W. Analytical Studies of the Head Injury Criterion (HIC). SAE Tech. Pap. 1974, 83, 398–410. [Google Scholar] [CrossRef]

- Bartolomé, L.; Aginagalde, A.; Martínez, A.B.; Urchegui, M.A.; Tato, W. Experimental Characterization and Modelling Large-Strain Viscoelastic Behavior of a Thermoplastic Polyurethane Elastomer. Rubber Chem. Technol. 2013, 86, 146–164. [Google Scholar] [CrossRef]

- Nie, Y. Cyclic Tensile Response of a Polyurethane Material. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2016. [Google Scholar]

- Yi, J.; Boyce, M.; Lee, G.; Balizer, E. Large Deformation Rate-Dependent Stress–Strain Behavior of Polyurea and Polyurethanes. Polymer 2006, 47, 319–329. [Google Scholar] [CrossRef]

- Cho, H.; Mayer, S.; Pöselt, E.; Susoff, M.; Veld, P.J.; Rutledge, G.C.; Boyce, M.C. Deformation Mechanisms of Thermoplastic Elastomers: Stress-Strain Behavior and Constitutive Modeling. Polymer 2017, 128, 87–99. [Google Scholar] [CrossRef]

- Wang, M.; Shan, D.; Liao, Y.; Xia, L. Investigation of Inelastic Behavior of Elastomeric Composites during Loading–Unloading Cycles. Polym. Bull. 2018, 75, 561–568. [Google Scholar] [CrossRef]

- Schemmer, B.; Kronenbitter, C.; Mecking, S. Thermoplastic Polyurethane Elastomers with Aliphatic Hard Segments Based on Plant-Oil-Derived Long-Chain Diisocyanates. Macromol. Mater. Eng. 2018, 303, 1700416. [Google Scholar] [CrossRef]

- Miao, Y.; He, H.; Li, Z. Strain Hardening Behaviors and Mechanisms of Polyurethane under Various Strain Rate Loading. Polym. Eng. Sci. 2020, 60, 1083–1092. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Pötschke, P.; Ameli, A. Bidirectional and Stretchable Piezoresistive Sensors Enabled by Multimaterial 3D Printing of Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. Polymers 2018, 11, 11. [Google Scholar] [CrossRef]

- Bera, M.; Prabhakar, A.; Maji, P.K. Nanotailoring of Thermoplastic Polyurethane by Amine Functionalized Graphene Oxide: Effect of Different Amine Modifier on Final Properties. Compos. B Eng. 2020, 195, 108075. [Google Scholar] [CrossRef]

- Sarva, S.S.; Deschanel, S.; Boyce, M.C.; Chen, W. Stress-Strain Behavior of a Polyurea and a Polyurethane from Low to High Strain Rates. Polymer 2007, 48, 2208–2213. [Google Scholar] [CrossRef]

- Fan, J.; Chen, A. Studying a Flexible Polyurethane Elastomer with Improved Impact-Resistant Performance. Polymers 2019, 11, 467. [Google Scholar] [CrossRef]

- Smith, L.V.; Duris, J.G. Progress and Challenges in Numerically Modelling Solid Sports Balls with Application to Softballs. J. Sports Sci. 2009, 27, 353–360. [Google Scholar] [CrossRef]

- Andena, L.; Briatico-Vangosa, F.; Cazzoni, E.; Ciancio, A.; Mariani, S.; Pavan, A. Modeling of Shock Absorption in Athletics Track Surfaces. Sports Eng. 2015, 18, 1–10. [Google Scholar] [CrossRef][Green Version]

- Ledesma-Orozco, E.R.; Diosdado-De La Peña, J.A.; Pérez-Soto, G.I.; Salazar-Garibay, A.; Reveles-Arredondo, J.F.; Villalobos-Llamas, G.; Durán-Reséndiz, P. Non-Linear Analysis of Energy Absorption Systems under Impact Loads through FEM. In Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition, IMECE 2011, Denver, CO, USA, 11–17 November 2011; Volume 3. [Google Scholar]

- Płatek, P.; Rajkowski, K.; Cieplak, K.; Sarzyński, M.; Małachowski, J.; Woźniak, R.; Janiszewski, J. Deformation Process of 3D Printed Structures Made from Flexible Material with Different Values of Relative Density. Polymers 2020, 12, 2120. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| λ1 | 2.502 | MPa |

| α1 | −0.463 | - |

| λ2 | −14.542 | MPa |

| α2 | −2.237 | - |

| λ3 | −158.713 | MPa |

| α3 | 0.103 | - |

| Parameter | Quasi-Static Loading | Impact Loading | Unit |

|---|---|---|---|

| Value | Value | ||

| λ1 | 1.904 | 3.929 | MPa |

| α1 | −0.151 | 0.113 | - |

| λ2 | −12.342 | −11.520 | MPa |

| α2 | −2.060 | −2.236 | - |

| λ3 | 189.499 | −101.145 | MPa |

| α3 | −0.080 | 0.144 | - |

| Case | Average Deceleration [×1000 m/s2] |

|---|---|

| Non-graded simple impact | 82.7 |

| Non-graded oblique impact | 74.1 |

| Side-graded | 28.0 |

| Inversed side-graded | 35.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diosdado-De la Peña, J.A.; Dwyer, C.M.; Krzeminski, D.; MacDonald, E.; Saldaña-Robles, A.; Cortes, P.; Choo, K. Low Impact Velocity Modeling of 3D Printed Spatially Graded Elastomeric Lattices. Polymers 2022, 14, 4780. https://doi.org/10.3390/polym14214780

Diosdado-De la Peña JA, Dwyer CM, Krzeminski D, MacDonald E, Saldaña-Robles A, Cortes P, Choo K. Low Impact Velocity Modeling of 3D Printed Spatially Graded Elastomeric Lattices. Polymers. 2022; 14(21):4780. https://doi.org/10.3390/polym14214780

Chicago/Turabian StyleDiosdado-De la Peña, Jose Angel, Charles M. Dwyer, David Krzeminski, Eric MacDonald, Alberto Saldaña-Robles, Pedro Cortes, and Kyosung Choo. 2022. "Low Impact Velocity Modeling of 3D Printed Spatially Graded Elastomeric Lattices" Polymers 14, no. 21: 4780. https://doi.org/10.3390/polym14214780

APA StyleDiosdado-De la Peña, J. A., Dwyer, C. M., Krzeminski, D., MacDonald, E., Saldaña-Robles, A., Cortes, P., & Choo, K. (2022). Low Impact Velocity Modeling of 3D Printed Spatially Graded Elastomeric Lattices. Polymers, 14(21), 4780. https://doi.org/10.3390/polym14214780