New Insight into Rubber Composites Based on Graphene Nanoplatelets, Electrolyte Iron Particles, and Their Hybrid for Stretchable Magnetic Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Rubber Composites

2.3. Characterization Technique

3. Results and Discussion

3.1. Morphologies of Nanofillers

3.2. Filler Dispersion Analyzed through SEM Microscopy

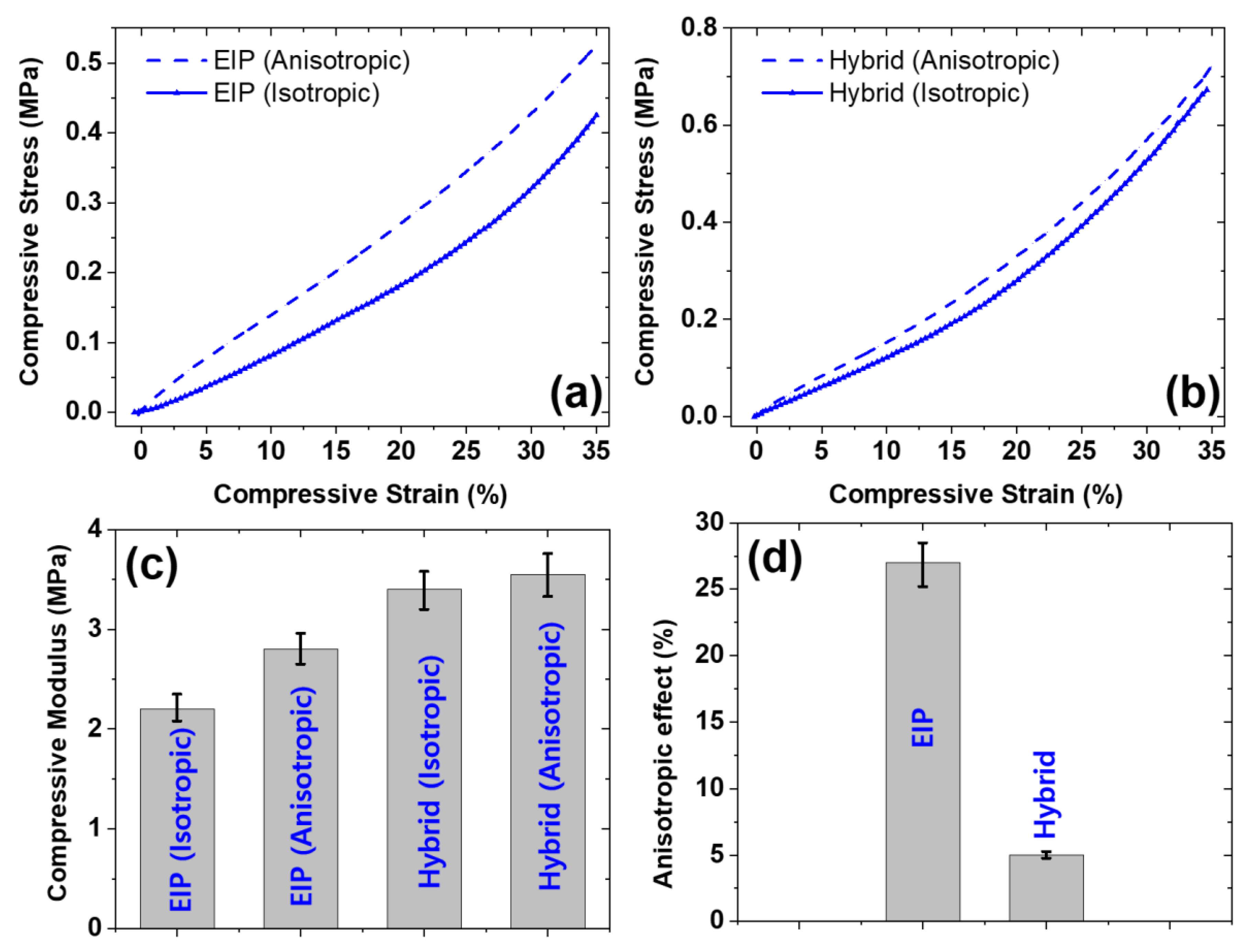

3.3. Mechanical Properties under Compressive Strain

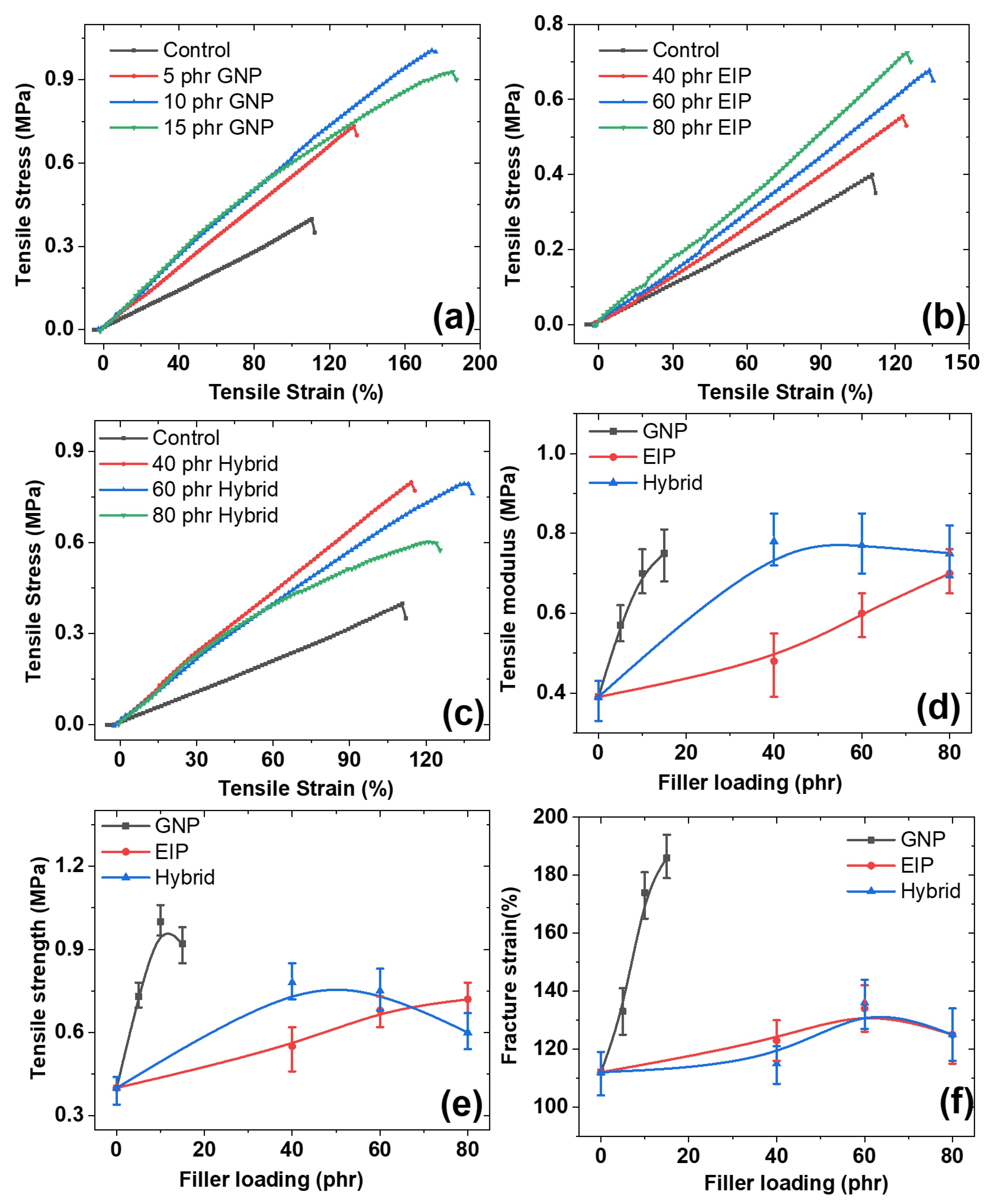

3.4. Mechanical Properties under Tensile Strain

3.5. Theoretical Models and Hardness of Composites

3.6. Reinforcement by Particulate Nanofillers

3.7. Anisotropic Magnetic Effect in Mechanical Properties

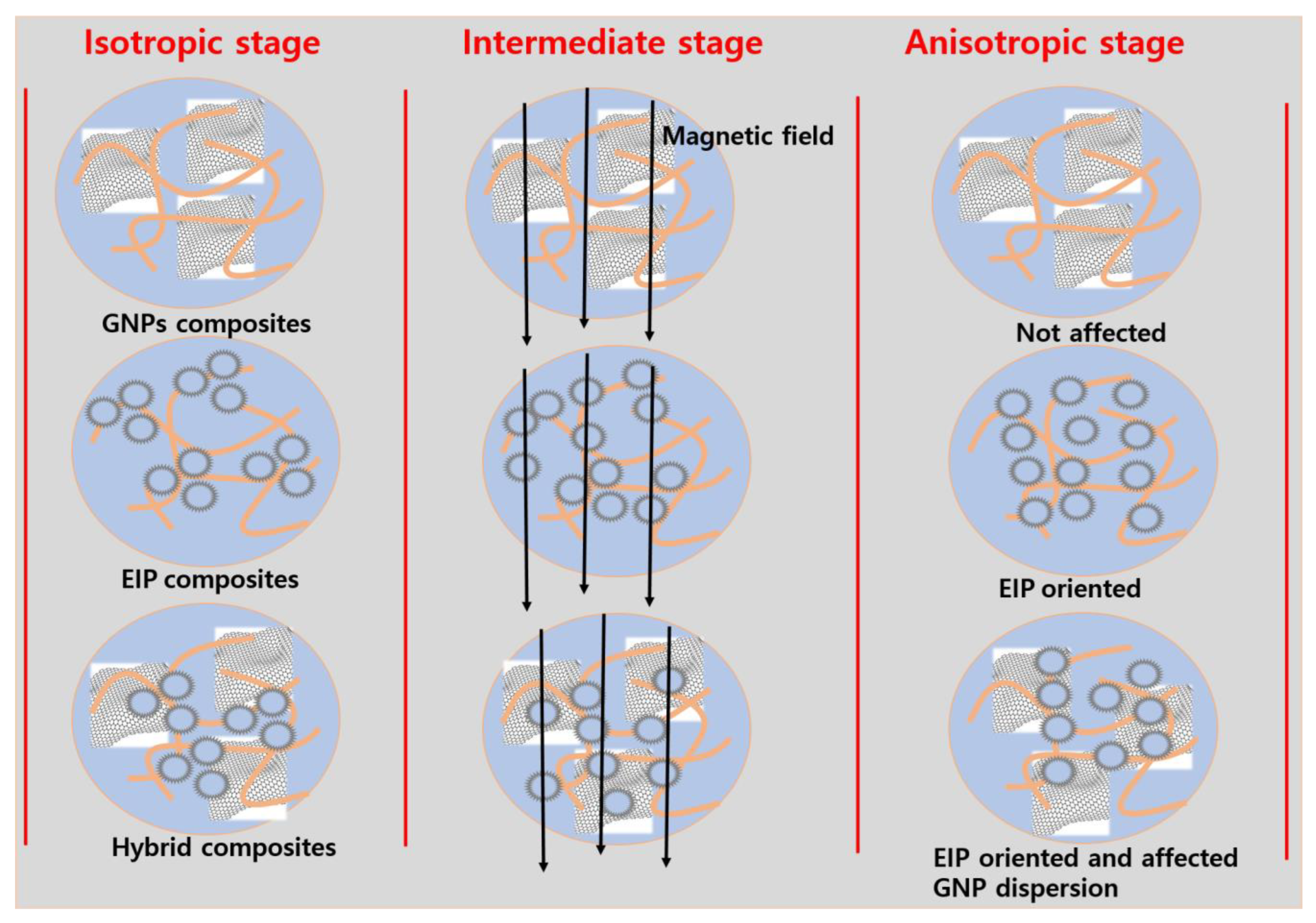

3.8. Mechanism of the Anisotropic Magnetic Effect

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Melzer, M.; Makarov, D.; Schmidt, O.G. A review on stretchable magnetic field sensorics. J. Phys. D Appl. Phys. 2019, 53, 083002. [Google Scholar] [CrossRef]

- Lazarus, N.; Bedair, S.S. Improved power transfer to wearable systems through stretchable magnetic composites. Appl. Phys. A 2016, 122, 1–7. [Google Scholar] [CrossRef]

- Abramchuk, S.; Kramarenko, E.; Stepanov, G.; Nikitin, L.V.; Filipcsei, G.; Khokhlov, A.R.; Zrínyi, M. Novel highly elastic magnetic materials for dampers and seals: Part I. Preparation and characterization of the elastic materials. Polym. Adv. Technol. 2007, 18, 883–890. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Rubber-Tire Particles as Concrete Aggregate. J. Mater. Civ. Eng. 1993, 5, 478–496. [Google Scholar] [CrossRef]

- Li, T.; El-Aty, A.A.; Cheng, C.; Shen, Y.; Wu, C.; Yang, Q.; Hu, S.; Xu, Y.; Tao, J.; Guo, X. Investigate the Effect of the Magnetic Field on the Mechanical Properties of Silicone Rubber-Based Anisotropic Magnetorheological Elastomer during Curing Process. J. Renew. Mater. 2020, 8, 1411–1427. [Google Scholar] [CrossRef]

- Khimi, S.R.; Pickering, K. The effect of silane coupling agent on the dynamic mechanical properties of iron sand/natural rubber magnetorheological elastomers. Compos. Part B Eng. 2016, 90, 115–125. [Google Scholar] [CrossRef]

- Bica, I. The influence of the magnetic field on the elastic properties of anisotropic magnetorheological elastomers. J. Ind. Eng. Chem. 2012, 18, 1666–1669. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, N.; Park, S.S. Robust magneto-rheological elastomers performance for composites based on iron oxide and carbon black in silicone rubber. J. Polym. Res. 2022, 29, 1–11. [Google Scholar] [CrossRef]

- Aloui, S.; Klüppel, M. Magneto-rheological response of elastomer composites with hybrid-magnetic fillers. Smart Mater. Struct. 2014, 24, 025016. [Google Scholar] [CrossRef]

- Robertson, C.G.; Hardman, N.J. Nature of Carbon Black Reinforcement of Rubber: Perspective on the Original Polymer Nanocomposite. Polymers 2021, 13, 538. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’Ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Young, R.J.; Kinloch, I.A.; Gong, L.; Novoselov, K.S. The mechanics of graphene nanocomposites: A review. Compos. Sci. Technol. 2012, 72, 1459–1476. [Google Scholar] [CrossRef]

- Fan, Y.; Fowler, G.D.; Zhao, M. The past, present and future of carbon black as a rubber reinforcing filler—A review. J. Clean. Prod. 2020, 247, 119115. [Google Scholar] [CrossRef]

- Bokobza, L. Multiwall carbon nanotube elastomeric composites: A review. Polymer 2007, 48, 4907–4920. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, Z.; Zeng, H.; Yang, T.; Wang, X. Effects of graphene on various properties and applications of silicone rubber and silicone resin. Compos. Part A Appl. Sci. Manuf. 2020, 142, 106240. [Google Scholar] [CrossRef]

- Coran, A.Y. Chemistry of the vulcanization and protection of elastomers: A review of the achievements. J. Appl. Polym. Sci. 2002, 87, 24–30. [Google Scholar] [CrossRef]

- Wood, L.A. Synthetic Rubbers: A Review of Their Compositions, Properties, and Uses. Rubber Chem. Technol. 1940, 13, 861–885. [Google Scholar] [CrossRef]

- Bokobza, L. Natural Rubber Nanocomposites: A Review. Nanomaterials 2019, 9, 12. [Google Scholar] [CrossRef]

- Ranta, P.M.; Ownby, D.R. A Review of Natural-Rubber Latex Allergy in Health Care Workers. Clin. Infect. Dis. 2004, 38, 252–256. [Google Scholar] [CrossRef]

- Singha, N.K.; Bhattacharjee, S.; Sivaram, S.J.R.C. Hydrogenation of diene elastomers, their properties and applications: A critical review. Rubber Chem. Technol. 1997, 70, 309–367. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P. A review on silicone rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Lewis, F.M. The Science and Technology of Silicone Rubber. Rubber Chem. Technol. 1962, 35, 1222–1275. [Google Scholar] [CrossRef]

- El-Hag, A.; Jayaram, S.; Cherney, E. Fundamental and low frequency harmonic components of leakage current as a diagnostic tool to study aging of RTV and HTV silicone rubber in salt-fog. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 128–136. [Google Scholar] [CrossRef]

- Kumar, V.; Tang, X.-W.; Liu, S.-C.; Lee, D.-J. Studies on nanocomposites reinforced with CNTs in different types of dielectric rubber. Sensors Actuators A Phys. 2017, 267, 310–317. [Google Scholar] [CrossRef]

- Kumar, V.; Lee, G.; Singh, K.; Choi, J.; Lee, D.-J. Structure-property relationship in silicone rubber nanocomposites reinforced with carbon nanomaterials for sensors and actuators. Sens. Actuators A Phys. 2019, 303, 111712. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, N.; Manikkavel, A.; Song, M.; Lee, D.-J.; Park, S.-S. Silicone Rubber Composites Reinforced by Carbon Nanofillers and Their Hybrids for Various Applications: A Review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef]

- George, J.; Ishida, H. A review on the very high nanofiller-content nanocomposites: Their preparation methods and properties with high aspect ratio fillers. Prog. Polym. Sci. 2018, 86, 1–39. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Bhowmick, A.K. Synergy in carbon black-filled natural rubber nanocomposites. Part I: Mechanical, dynamic mechanical properties, and morphology. J. Mater. Sci. 2010, 45, 6126–6138. [Google Scholar] [CrossRef]

- Kozlov, G.V.; Dolbin, I.V. Transfer of Mechanical Stress from Polymer Matrix to Nanofiller in Dispersion-Filled Nanocomposites. Inorg. Mater. Appl. Res. 2019, 10, 226–230. [Google Scholar] [CrossRef]

- Samal, S.; Škodová, M.; Abate, L.; Blanco, I. Magneto-rheological elastomer composites. A review. Appl. Sci. 2020, 10, 4899. [Google Scholar] [CrossRef]

- Kim, Y.; Zhao, X. Magnetic Soft Materials and Robots. Chem. Rev. 2022, 122, 5317–5364. [Google Scholar] [CrossRef]

- Arumugam, A.B.; Subramani, M.; Dalakoti, M.; Jindal, P.; Selvaraj, R.; Khalife, E. Dynamic characteristics of laminated composite CNT reinforced MRE cylindrical sandwich shells using HSDT. Mech. Based Des. Struct. Mach. 2021, 1–17. [Google Scholar] [CrossRef]

- Li, R.; Wang, D.; Yang, P.A.; Tang, X.; Liu, J.; Li, X. Improved magneto-sensitive adhesion property of magnetorheological elastomers modified using graphene nanoplatelets. Ind. Eng. Chem. Res. 2020, 59, 9143–9151. [Google Scholar] [CrossRef]

- Selvaraj, R.; Ramamoorthy, M. Experimental and finite element vibration analysis of CNT reinforced MR elastomer sandwich beam. Mech. Based Des. Struct. Mach. 2020, 50, 2414–2426. [Google Scholar] [CrossRef]

- Arani, A.G.; Shahraki, M.E.; Haghparast, E. Instability analysis of axially moving sandwich plates with a magnetorheological elastomer core and GNP-reinforced face sheets. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 1–22. [Google Scholar] [CrossRef]

- Fan, L.; Wang, G.; Wang, W.; Lu, H.; Yang, F.; Rui, X. Size effect of carbon black on the structure and mechanical properties of magnetorheological elastomers. J. Mater. Sci. 2018, 54, 1326–1340. [Google Scholar] [CrossRef]

- Rahaman, M.; Chaki, T.K.; Khastgir, D. Development of high performance EMI shielding material from EVA, NBR, and their blends: Effect of carbon black structure. J. Mater. Sci. 2011, 46, 3989–3999. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, N.; Park, S.S. Soft Composites Filled with Iron Oxide and Graphite Nanoplatelets under Static and Cyclic Strain for Different Industrial Applications. Polymers 2022, 14, 2393. [Google Scholar] [CrossRef]

- Xie, L.; Zhu, Y. Tune the phase morphology to design conductive polymer composites: A review. Polym. Compos. 2017, 39, 2985–2996. [Google Scholar] [CrossRef]

- Cataldi, P.; Bayer, I.S.; Nanni, G.; Athanassiou, A.; Bonaccorso, F.; Pellegrini, V.; Castillo, A.E.D.R.; Ricciardella, F.; Artyukhin, S.; Tronche, M.-A.; et al. Effect of graphene nano-platelet morphology on the elastic modulus of soft and hard biopolymers. Carbon 2016, 109, 331–339. [Google Scholar] [CrossRef]

- Li, J.; Kim, J.-K. Percolation threshold of conducting polymer composites containing 3D randomly distributed graphite nanoplatelets. Compos. Sci. Technol. 2007, 67, 2114–2120. [Google Scholar] [CrossRef]

- Chong, H.M.; Hinder, S.J.; Taylor, A.C. Graphene nanoplatelet-modified epoxy: Effect of aspect ratio and surface functionality on mechanical properties and toughening mechanisms. J. Mater. Sci. 2016, 51, 8764–8790. [Google Scholar] [CrossRef]

- Safdari, M.; Al-Haik, M.S. Synergistic electrical and thermal transport properties of hybrid polymeric nanocomposites based on carbon nanotubes and graphite nanoplatelets. Carbon 2013, 64, 111–121. [Google Scholar] [CrossRef]

- Yu, L.-M.; Huang, H.-X. Temperature and shear dependence of rheological behavior for thermoplastic polyurethane nanocomposites with carbon nanofillers. Polymer 2022, 247, 124791. [Google Scholar] [CrossRef]

- Nasser, K.I.; del Río, J.M.L.; Mariño, F.; López, E.R.; Fernández, J. Double hybrid lubricant additives consisting of a phosphonium ionic liquid and graphene nanoplatelets/hexagonal boron nitride nanoparticles. Tribol. Int. 2021, 163, 107189. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Liu, M.; Gao, Y.; Hu, Z.; Nan, T.; Liang, X.; Chen, H.; Yang, J.; Cash, S.; et al. Highly Sensitive Flexible Magnetic Sensor Based on Anisotropic Magnetoresistance Effect. Adv. Mater. 2016, 28, 9370–9377. [Google Scholar] [CrossRef]

- Hussain, M.; Oku, Y.; Nakahira, A.; Niihara, K. Effects of wet ball-milling on particle dispersion and mechanical properties of particulate epoxy composites. Mater. Lett. 1996, 26, 177–184. [Google Scholar] [CrossRef]

- Tan, J.C.; Cheetham, A.K. Mechanical properties of hybrid inorganic–organic framework materials: Establishing fundamental structure–property relationships. Chem. Soc. Rev. 2011, 40, 1059–1080. [Google Scholar] [CrossRef]

- Zhao, F.; Bi, W.; Zhao, S. Influence of Crosslink Density on Mechanical Properties of Natural Rubber Vulcanizates. J. Macromol. Sci. Part B 2011, 50, 1460–1469. [Google Scholar] [CrossRef]

- McMillin, C.R. Biomedical Applications of Rubbers and Elastomers. Rubber Chem. Technol. 2006, 79, 500–519. [Google Scholar] [CrossRef]

- Budzien, J.; McCoy, J.D.; Adolf, D.B. Solute mobility and packing fraction: A new look at the Doolittle equation for the polymer glass transition. J. Chem. Phys. 2003, 119, 9269–9273. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, A.; Alam, N.; Park, S. Effect of graphite nanoplatelets surface area on mechanical properties of room-temperature vulcanized silicone rubber nanocomposites. J. Appl. Polym. Sci. 2022, 139, e52503. [Google Scholar] [CrossRef]

- Sagalianov, I.; Vovchenko, L.; Matzui, L.; Lazarenko, O. Synergistic Enhancement of the Percolation Threshold in Hybrid Polymeric Nanocomposites Based on Carbon Nanotubes and Graphite Nanoplatelets. Nanoscale Res. Lett. 2017, 12, 140. [Google Scholar] [CrossRef]

- Cilento, F.; Martone, A.; Carbone, M.G.P.; Galiotis, C.; Giordano, M. Nacre-like GNP/Epoxy composites: Reinforcement efficiency vis-a-vis graphene content. Compos. Sci. Technol. 2021, 211, 108873. [Google Scholar] [CrossRef]

- Wang, M.-J. Effect of polymer-filler and filler-filler interactions on dynamic properties of filled vulcanizates. Rubber Chem. Technol. 1998, 71, 520–589. [Google Scholar] [CrossRef]

- Fröhlich, J.; Niedermeier, W.; Luginsland, H.D. The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos. Part A Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Scotti, R.; Wahba, L.; Crippa, M.; D’Arienzo, M.; Donetti, R.; Santo, N.; Morazzoni, F. Rubber–silica nanocomposites obtained by in situ sol–gel method: Particle shape influence on the filler–filler and filler–rubber interactions. Soft Matter 2012, 8, 2131–2143. [Google Scholar] [CrossRef]

- Kim, D.B.; Lee, J.W.; Cho, Y.S. Anisotropic In Situ Strain-Engineered Halide Perovskites for High Mechanical Flexibility. Adv. Funct. Mater. 2021, 31, 2007131. [Google Scholar] [CrossRef]

- Galimberti, M.; Kumar, V.; Coombs, M.; Cipolletti, V.; Agnelli, S.; Pandini, S.; Conzatti, L. Filler networking of a nanographite with a high shape anisotropy and synergism with carbon black in poly (1, 4-cis-isoprene)–based nanocomposites. Rubber Chem. Technol. 2014, 87, 197–218. [Google Scholar] [CrossRef]

- Srivyas, P.D.; Charoo, M. Tribological behavior of hybrid aluminum self-lubricating composites under dry sliding conditions at elevated temperature. Tribol. Mater. Surfaces Interfaces 2021, 16, 1–15. [Google Scholar] [CrossRef]

- Rohm, K.; Solouki Bonab, V.; Manas-Zloczower, I. In situ TPU/graphene nanocomposites: Correlation between filler aspect ratio and phase morphology. Polym. Eng. Sci. 2021, 61, 1018–1027. [Google Scholar] [CrossRef]

- Rahman, O.A.; Sribalaji, M.; Mukherjee, B.; Laha, T.; Keshri, A.K. Synergistic effect of hybrid carbon nanotube and graphene nanoplatelets reinforcement on processing, microstructure, interfacial stress and mechanical properties of Al2O3 nanocomposites. Ceram. Int. 2018, 44, 2109–2122. [Google Scholar] [CrossRef]

- Yu, J.; Kil Choi, H.; Kim, H.S.; Kim, S.Y. Synergistic effect of hybrid graphene nanoplatelet and multi-walled carbon nanotube fillers on the thermal conductivity of polymer composites and theoretical modeling of the synergistic effect. Compos. Part A Appl. Sci. Manuf. 2016, 88, 79–85. [Google Scholar] [CrossRef]

- Fukahori, Y.; Hon, A.A.; Jha, V.; Busfield, J.J.C. Modified guth–gold equation for carbon black–filled rubbers. Rubber Chem. Technol. 2013, 86, 218–232. [Google Scholar] [CrossRef]

- Wolff, S.; Donnet, J.-B. Characterization of Fillers in Vulcanizates According to the Einstein-Guth-Gold Equation. Rubber Chem. Technol. 1990, 63, 32–45. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Kumar, V.; Tang, X.-W.; Lee, D.-J. Mechanical and electrical behavior of rubber nanocomposites under static and cyclic strain. Compos. Sci. Technol. 2017, 142, 1–9. [Google Scholar] [CrossRef]

- Domurath, J.; Saphiannikova, M.; Heinrich, G. The concept of hydrodynamic amplification infilled elastomers. Kautsch. Gummi Kunstst. 2017, 70, 40. [Google Scholar]

- Wang, Y.-X.; Wu, Y.-P.; Li, W.-J.; Zhang, L.-Q. Influence of filler type on wet skid resistance of SSBR/BR composites: Effects from roughness and micro-hardness of rubber surface. Appl. Surf. Sci. 2010, 257, 2058–2065. [Google Scholar] [CrossRef]

- Whitesides, G.M. Soft robotics. Angew. Chem. Int. Ed. 2018, 57, 4258–4273. [Google Scholar] [CrossRef]

- Das, C.; Bansod, N.D.; Kapgate, B.P.; Reuter, U.; Heinrich, G.; Das, A. Development of highly reinforced acrylonitrile butadiene rubber composites via controlled loading of sol-gel titania. Polymer 2017, 109, 25–37. [Google Scholar] [CrossRef]

- Sharma, A.; Morisada, Y.; Fujii, H. Bending induced mechanical exfoliation of graphene interlayers in a through thickness Al-GNP functionally graded composite fabricated via novel single-step FSP approach. Carbon 2022, 186, 475–491. [Google Scholar] [CrossRef]

- Périgo, E.A.; Weidenfeller, B.; Kollár, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Filipcsei, G.; Csetneki, I.; Szilágyi, A.; Zrínyi, M. Magnetic Field-Responsive Smart Polymer Composites. In Oligomers—Polymer Composites Molecular Imprinting; Springer: Berlin/Heidelberg, Germany, 2007; pp. 137–189. [Google Scholar] [CrossRef]

- Erb, R.M.; Libanori, R.; Rothfuchs, N.; Studart, A.R. Composites Reinforced in Three Dimensions by Using Low Magnetic Fields. Science 2012, 335, 199–204. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.-J.; Dang, C.-Y.; Tang, B.-L.; Yang, X.-H.; Nie, H.-J.; Lu, J.-J.; Zhang, T.-T.; Friedrich, K. The reinforcing effect of oriented graphene on the interlaminar shear strength of carbon fabric/epoxy composites. Mater. Des. 2020, 185, 108257. [Google Scholar] [CrossRef]

- Nielsen, L.E. Models for the Permeability of Filled Polymer Systems. J. Macromol. Sci. Part A Chem. 1967, 1, 929–942. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, R.; Hu, N.; Chai, J.; Cheng, Y.; Zhang, L.; Wei, H.; Kong, E.S.-W.; Zhang, Y. The Prospective Two-Dimensional Graphene Nanosheets: Preparation, Functionalization and Applications. Nano-Micro Lett. 2012, 4, 1–9. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Zhou, X.; Kara, U.I.; Mamtani, R.S.; Lv, H.; Zhang, M.; Yang, Z.; Li, Y.; Wang, C.; et al. An angle-insensitive electromagnetic absorber enabling a wideband absorption. J. Mater. Sci. Technol. 2022, 113, 33–39. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Sun, W.; Liu, J.; Yan, H.; Han, H.; Bian, H.; Li, Y. Regulating lignin content to obtain excellent bamboo-derived electromagnetic wave absorber with thermal stability. Chem. Eng. J. 2022, 430, 133178. [Google Scholar] [CrossRef]

- Lou, Z.; Han, X.; Liu, J.; Ma, Q.; Yan, H.; Yuan, C.; Yang, L.; Han, H.; Weng, F.; Li, Y. Nano-Fe3O4/bamboo bundles/phenolic resin oriented recombination ternary composite with enhanced multiple functions. Compos. Part B Eng. 2021, 226, 109335. [Google Scholar] [CrossRef]

| Formulation | RTV-SR (phr) | GNP (phr) | EIP (phr) | Vulcanizing Solution (phr) |

|---|---|---|---|---|

| Control | 100 | - | - | 2 |

| RTV-SR/GNP | 100 | 5, 10, 15 | - | 2 |

| RTV-SR/EIP | 100 | 40, 60, 80 | 2 | |

| RTV-SR/Hybrid | 100 | 5, 10, 15 | 35, 50, 65 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, V.; Alam, M.N.; Park, S.-S.; Lee, D.-J. New Insight into Rubber Composites Based on Graphene Nanoplatelets, Electrolyte Iron Particles, and Their Hybrid for Stretchable Magnetic Materials. Polymers 2022, 14, 4826. https://doi.org/10.3390/polym14224826

Kumar V, Alam MN, Park S-S, Lee D-J. New Insight into Rubber Composites Based on Graphene Nanoplatelets, Electrolyte Iron Particles, and Their Hybrid for Stretchable Magnetic Materials. Polymers. 2022; 14(22):4826. https://doi.org/10.3390/polym14224826

Chicago/Turabian StyleKumar, Vineet, Md Najib Alam, Sang-Shin Park, and Dong-Joo Lee. 2022. "New Insight into Rubber Composites Based on Graphene Nanoplatelets, Electrolyte Iron Particles, and Their Hybrid for Stretchable Magnetic Materials" Polymers 14, no. 22: 4826. https://doi.org/10.3390/polym14224826

APA StyleKumar, V., Alam, M. N., Park, S.-S., & Lee, D.-J. (2022). New Insight into Rubber Composites Based on Graphene Nanoplatelets, Electrolyte Iron Particles, and Their Hybrid for Stretchable Magnetic Materials. Polymers, 14(22), 4826. https://doi.org/10.3390/polym14224826