Knowledge Mapping of the Literature on Fiber-Reinforced Geopolymers: A Scientometric Review

Abstract

:1. Introduction

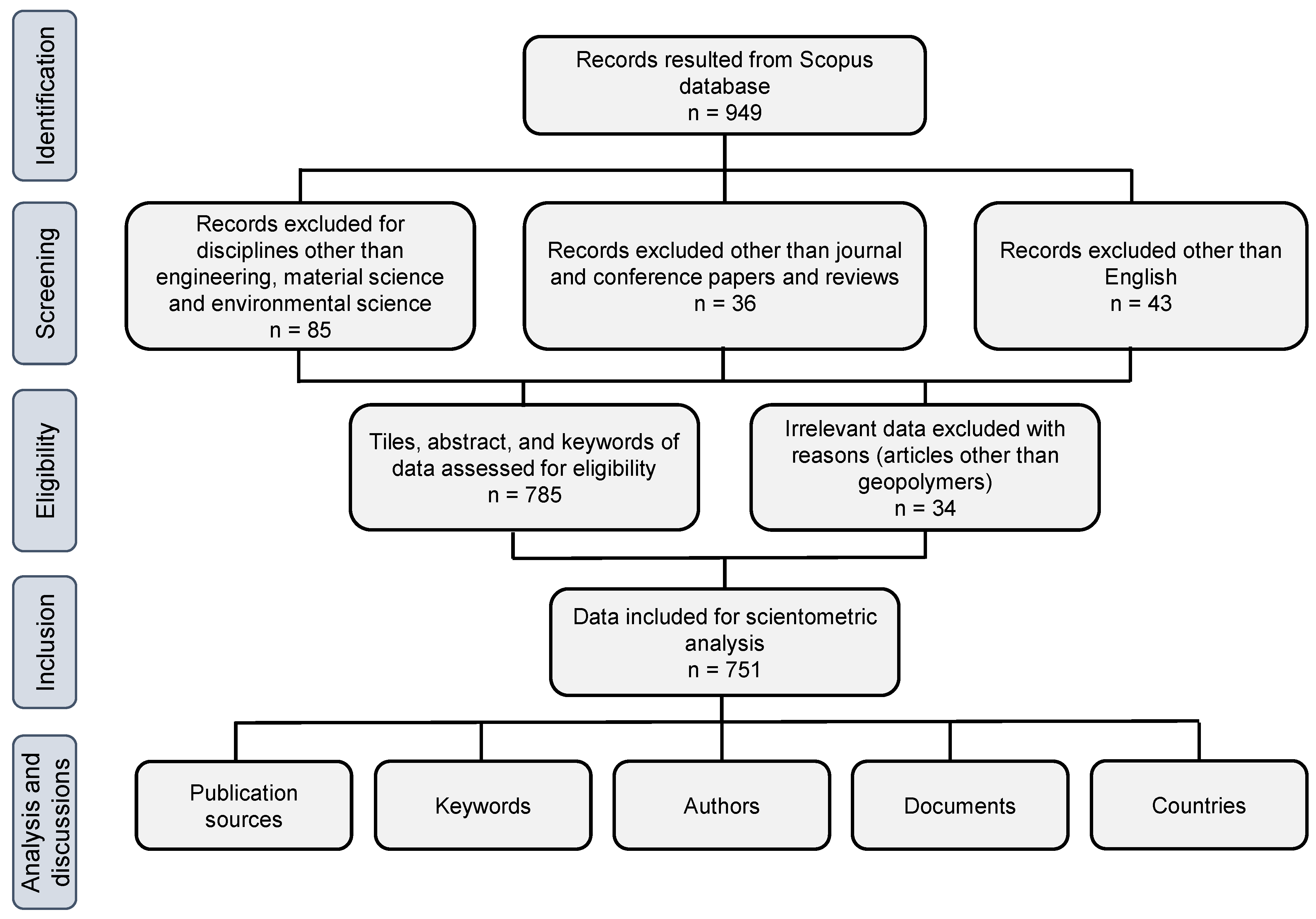

2. Review Strategy

3. Results and Discussion

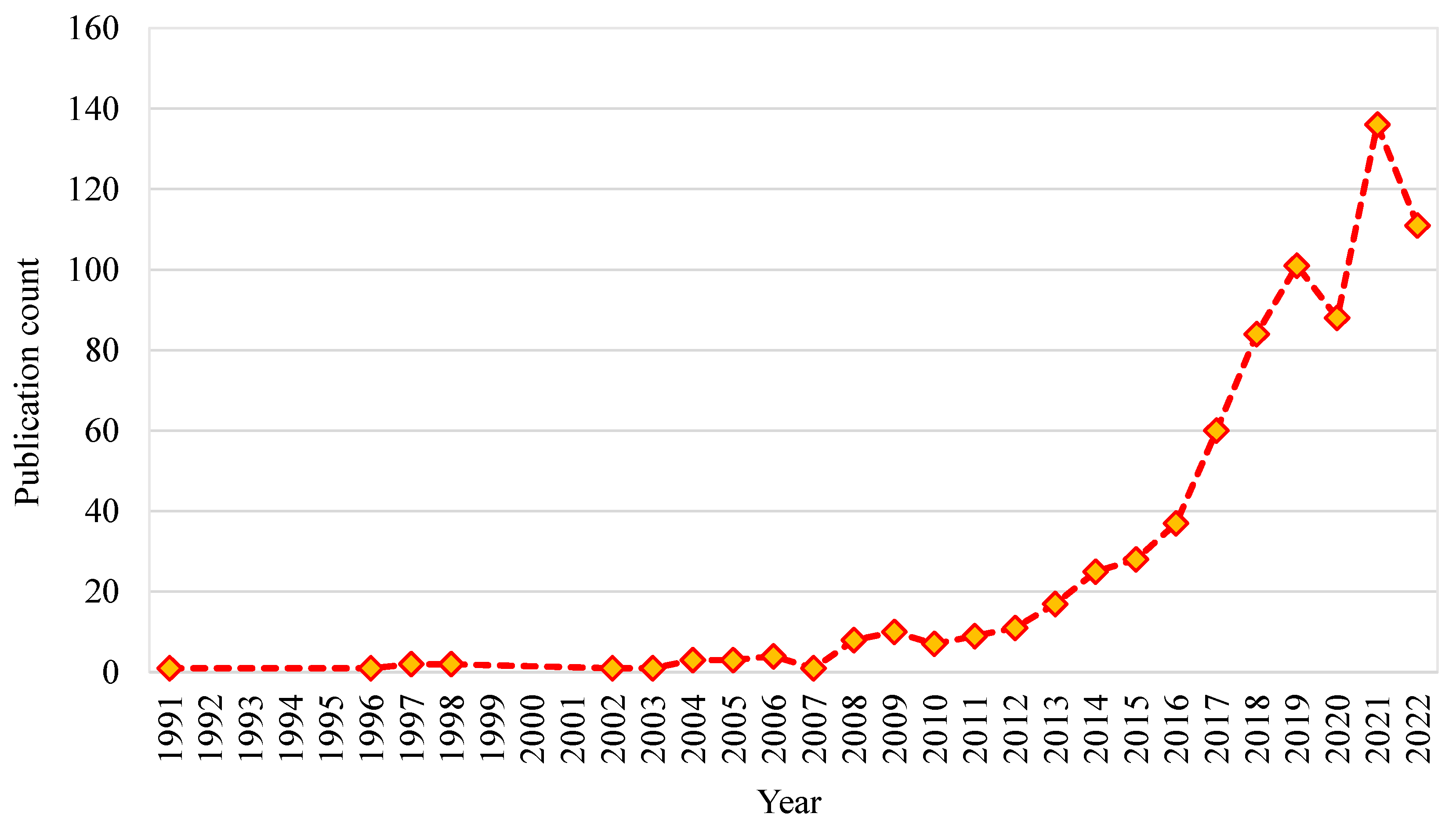

3.1. Progress on the Research of FRGP

3.2. Knowledge Visualization of Publishing Outlets

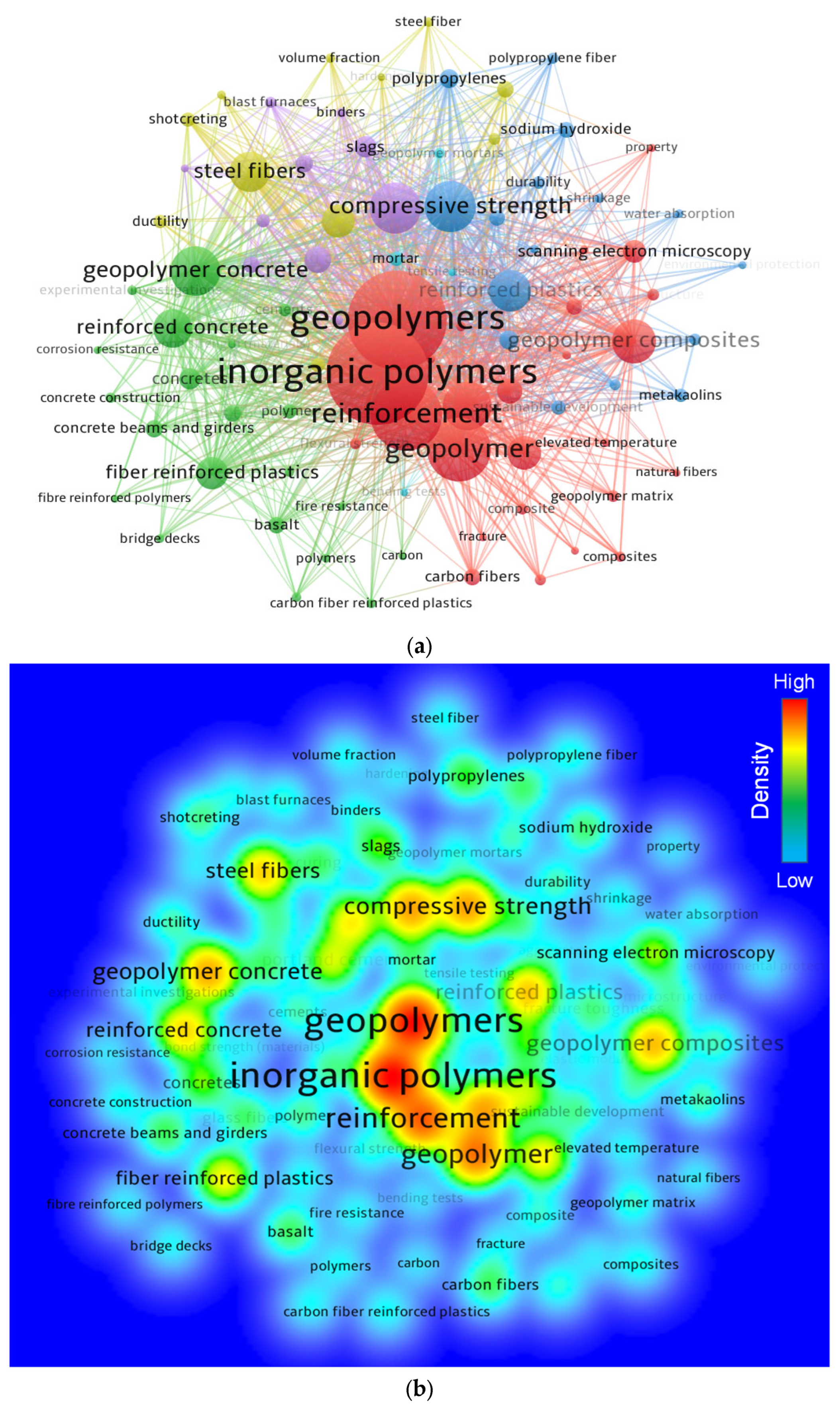

3.3. Knowledge Visualization of Keywords

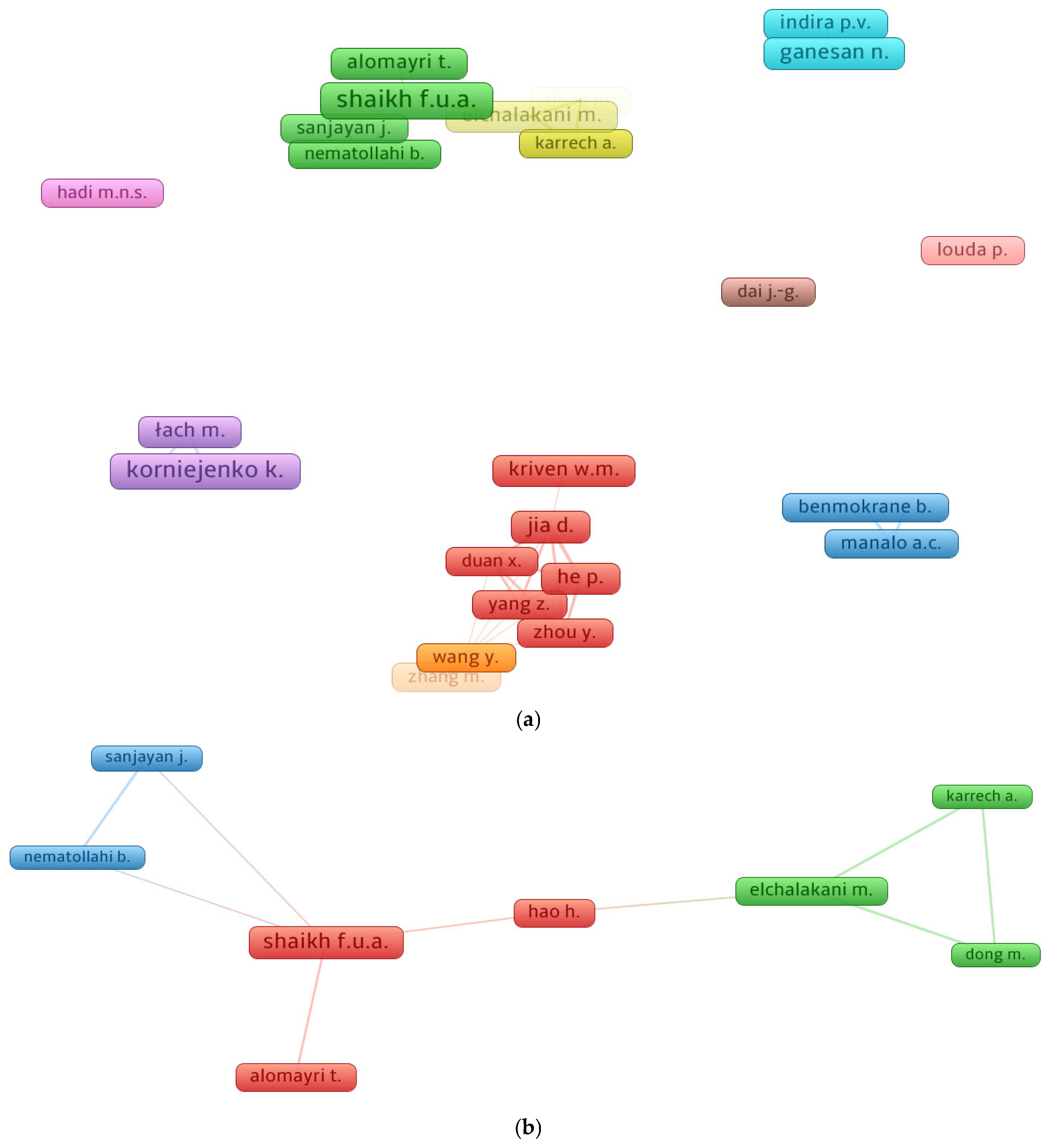

3.4. Knowledge Visualization of Researchers

3.5. Knowledge Visualization of Documents

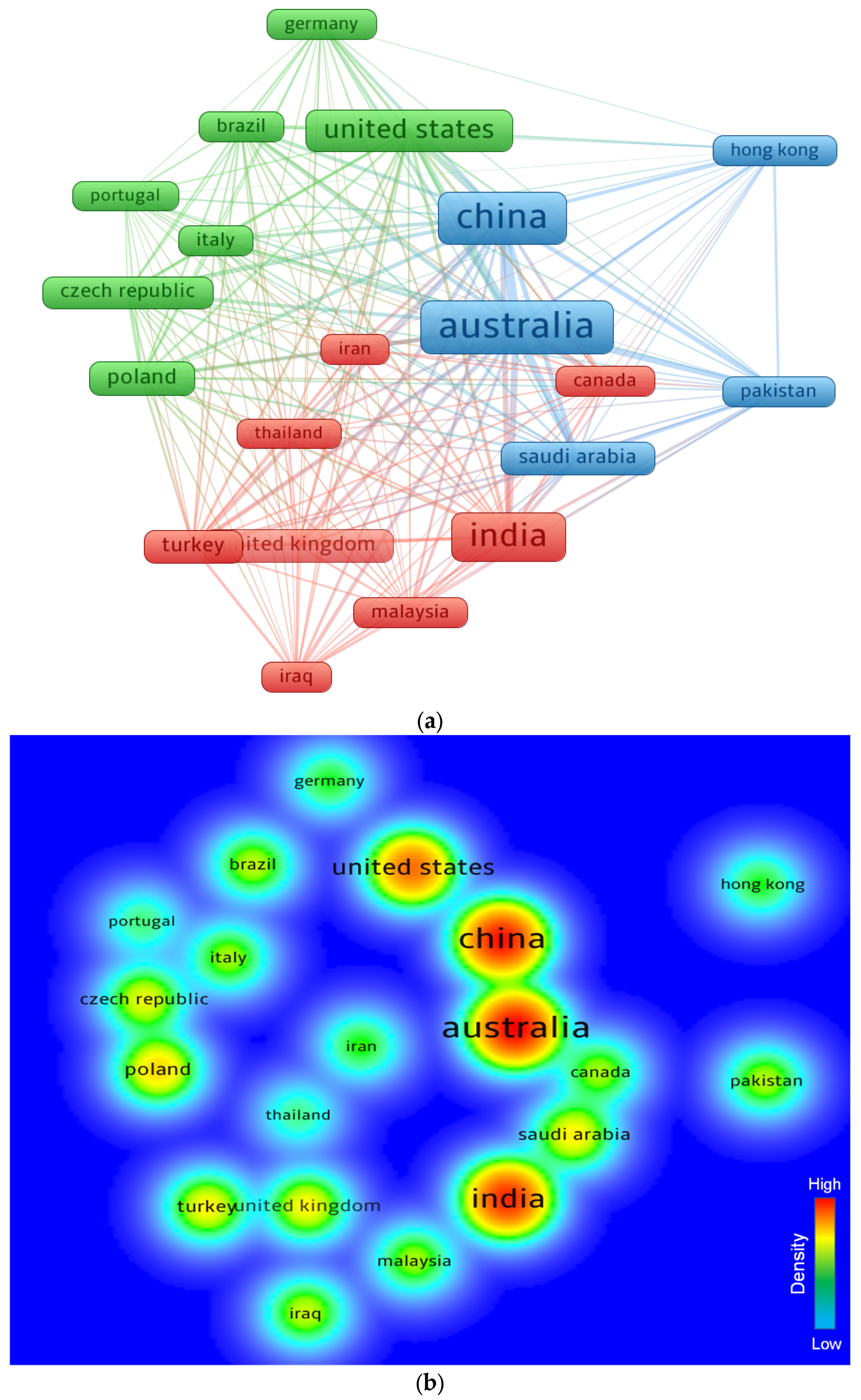

3.6. Knowledge Mapping of Countries

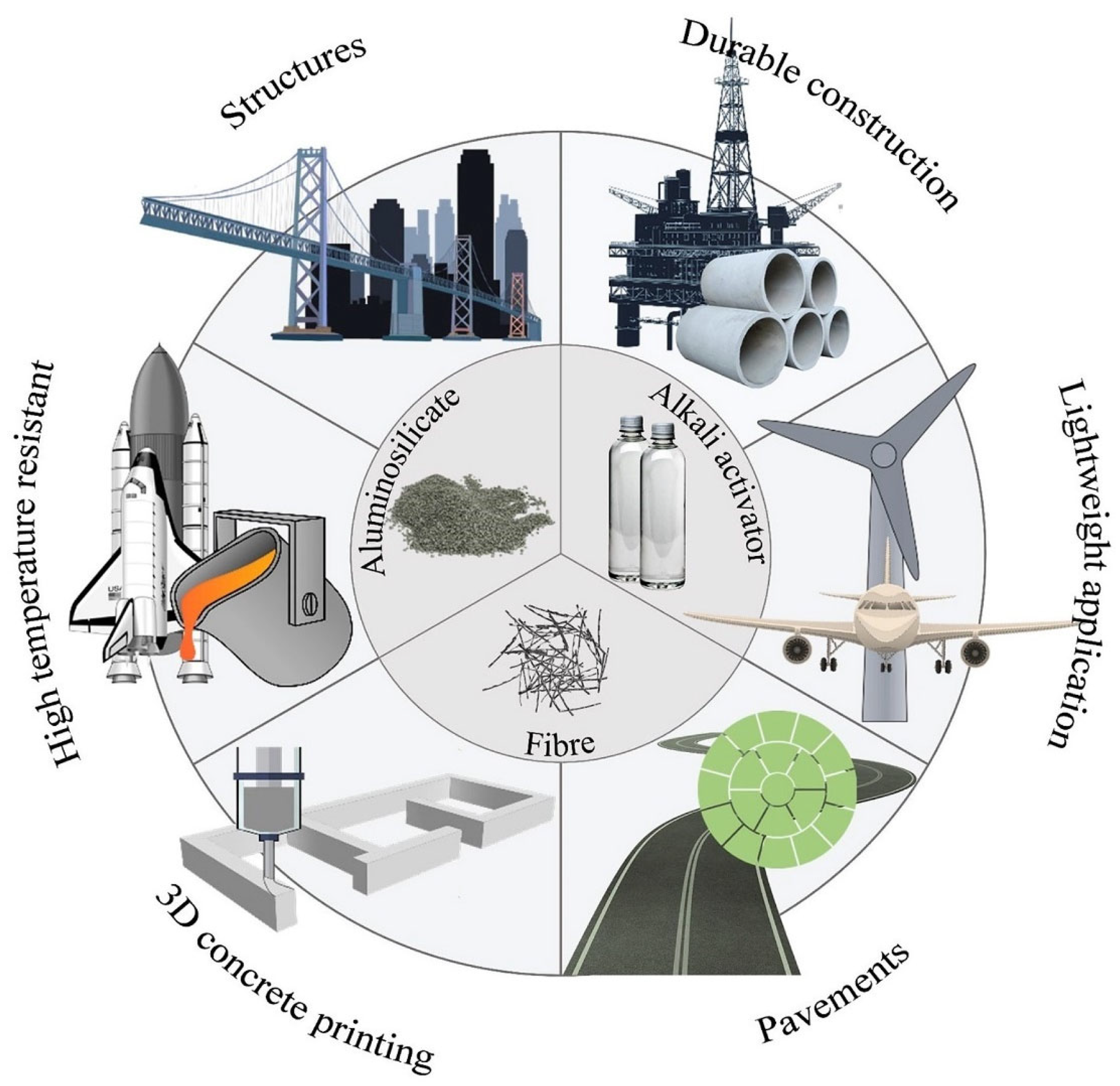

4. Discussion and Potential Applications

5. Conclusions

- The assessment of publication outlets presenting articles on FRGP studies showed that CBM, IOP Conference Series: Materials Science and Engineering, and Materials, are the top publishing outlets based on the number of publications with 95, 57, and 31 documents, respectively. In terms of total citations, the leading three publication outlets are CBM, with 3188; Composites Part B: Engineering, with 1615; and Ceramics International, with 690 citations.

- The assessment of keywords used in the research of FRGP discovered that inorganic polymers, geopolymers, reinforcement, geopolymer, and compressive strength are the five most commonly occurring terms. Additionally, based on the evaluation, it was disclosed that the FRGP has mainly been explored to increase mechanical performance and durability, mainly to reduce brittle behavior by bridging cracks.

- The evaluation of researchers showed that 27 writers had published at least 10 papers up to June 2022. In terms of the number of published documents, overall citations, and average citations, the top authors were considered. Shaikh F.U.A. was determined to be the most prolific author with the most publications (26) and total citations (1486). However, Nematollahi B. was placed at the top based on average citations (almost 62).

- The top countries were analyzed based on their participation in FRGP investigations, and it was found that only 20 countries published at least 10 articles. Australia, China, and India published 139, 129, and 116 articles, respectively. Additionally, Australia obtained 4153 citations, China obtained 3439 citations, and the United States obtained 1864 citations and were positioned as the leading three in terms of citations.

- The potential applications of FRGP composites include elevated temperature resistance, 3D printing, lightweight structures, bridges, and pavements. However, in-depth research, techniques, and guidelines are required for large-scale practical uses of FRGP.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ahmad, W.; Ahmad, A.; Aslam, F.; Mohamed, A.; Vatin, N.I. Application of Soft Computing Techniques to Predict the Strength of Geopolymer Composites. Polymers 2022, 14, 1074. [Google Scholar] [CrossRef] [PubMed]

- Raza, A.; Azab, M.; Baki, Z.A.; El Hachem, C.; El Ouni, M.H.; Kahla, N.B. Experimental study on mechanical, toughness and microstructural characteristics of micro-carbon fibre-reinforced geopolymer having nano TiO2. Alex. Eng. J. 2022; in press. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Lin, C. Microstructure Analysis and Effects of Single and Mixed Activators on Setting Time and Strength of Coal Gangue-Based Geopolymers. Gels 2022, 8, 195. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zhang, Y.; Lin, C. Compressive and Flexural Properties of Ultra-Fine Coal Gangue-Based Geopolymer Gels and Microscopic Mechanism Analysis. Gels 2022, 8, 145. [Google Scholar] [CrossRef]

- Zou, Y.; Zheng, C.; Alzahrani, A.M.; Ahmad, W.; Ahmad, A.; Mohamed, A.M.; Khallaf, R.; Elattar, S. Evaluation of Artificial Intelligence Methods to Estimate the Compressive Strength of Geopolymers. Gels 2022, 8, 271. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Xu, Y.; Guo, P.; Akono, A.-T. Novel Wet Electrospinning Inside a Reactive Pre-Ceramic Gel to Yield Advanced Nanofiber-Reinforced Geopolymer Composites. Polymers 2022, 14, 3943. [Google Scholar] [CrossRef]

- Han, R.; Guo, X.; Guan, J.; Yao, X.; Hao, Y. Activation Mechanism of Coal Gangue and Its Impact on the Properties of Geopolymers: A Review. Polymers 2022, 14, 3861. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Sibai, A. Geopolymers vs. Cement Matrix Materials: How Nanofiller Can Help a Sustainability Approach for Smart Construction Applications—A Review. Nanomaterials 2021, 11, 2007. [Google Scholar] [CrossRef]

- Lan, T.; Meng, Y.; Ju, T.; Chen, Z.; Du, Y.; Deng, Y.; Song, M.; Han, S.; Jiang, J. Synthesis and application of geopolymers from municipal waste incineration fly ash (MSWI FA) as raw ingredient—A review. Resour. Conserv. Recycl. 2022, 182, 106308. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Abdalla, A.A.; Mohammed, A.S.; Mohammed, A.A.; Mosavi, A. Statistical Methods for Modeling the Compressive Strength of Geopolymer Mortar. Materials 2022, 15, 1868. [Google Scholar] [CrossRef]

- Amin, M.N.; Khan, K.; Javed, M.F.; Aslam, F.; Qadir, M.G.; Faraz, M.I. Prediction of Mechanical Properties of Fly-Ash/Slag-Based Geopolymer Concrete Using Ensemble and Non-Ensemble Machine-Learning Techniques. Materials 2022, 15, 3478. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Lee, W.-H.; Cheng, T.-W.; Chen, W.; Li, Y.-F. The Length Change Ratio of Ground Granulated Blast Furnace Slag-Based Geopolymer Blended with Magnesium Oxide Cured in Various Environments. Polymers 2022, 14, 3386. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Yang, H.; Liu, L.; Yang, W.; Liu, H.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A comprehensive overview of geopolymer composites: A bibliometric analysis and literature review. Case Stud. Constr. Mater. 2022, 16, e00830. [Google Scholar] [CrossRef]

- Davidovits, J.; Cordi, S.A. Synthesis of new high temperature geo-polymers for reinforced plastics/composites. Spe. Pactec. 1979, 79, 151–154. [Google Scholar]

- Meesala, C.R.; Verma, N.K.; Kumar, S. Critical review on fly-ash based geopolymer concrete. Struct. Concr. 2020, 21, 1013–1028. [Google Scholar] [CrossRef]

- Lo, K.-W.; Lin, W.-T.; Lin, Y.-W.; Cheng, T.-W.; Lin, K.-L. Synthesis Metakaolin-Based Geopolymer Incorporated with SiC Sludge Using Design of Experiment Method. Polymers 2022, 14, 3395. [Google Scholar] [CrossRef]

- Farooq, F.; Jin, X.; Javed, M.F.; Akbar, A.; Shah, M.I.; Aslam, F.; Alyousef, R. Geopolymer concrete as sustainable material: A state of the art review. Constr. Build. Mater. 2021, 306, 124762. [Google Scholar] [CrossRef]

- Ahmad, A.; Ahmad, W.; Chaiyasarn, K.; Ostrowski, K.A.; Aslam, F.; Zajdel, P.; Joyklad, P. Prediction of Geopolymer Concrete Compressive Strength Using Novel Machine Learning Algorithms. Polymers 2021, 13, 3389. [Google Scholar] [CrossRef] [PubMed]

- Hay, R.; Celik, K. Hydration, carbonation, strength development and corrosion resistance of reactive MgO cement-based composites. Cem. Concr. Res. 2020, 128, 105941. [Google Scholar] [CrossRef]

- Han, S.; Zhong, J.; Ding, W.; Ou, J. Strength, hydration, and microstructure of seawater sea-sand concrete using high-ferrite Portland cement. Constr. Build. Mater. 2021, 295, 123703. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M. Assessment of geopolymer composites durability at one year age. J. Build. Eng. 2020, 32, 101453. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Nazar, S. A Scientometric-Analysis-Based Review of the Research Development on Geopolymers. Polymers 2022, 14, 3676. [Google Scholar] [CrossRef]

- Lyu, B.-C.; Ding, C.; Guo, L.-P.; Chen, B.; Wang, A.-G. Basic performances and potential research problems of strain hardening geopolymer composites: A critical review. Constr. Build. Mater. 2021, 287, 123030. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Li, W.; Shumuye, E.D.; Shiying, T.; Wang, Z.; Zerfu, K. Eco-friendly fibre reinforced geopolymer concrete: A critical review on the microstructure and long-term durability properties. Case Stud. Constr. Mater. 2022, 16, e00894. [Google Scholar] [CrossRef]

- Zhang, M.; Na, M.; Yang, Z.; Shi, Y.; Guerrieri, M.; Pan, Z. Study on mechanical properties and solidification mechanism of stabilized dredged materials with recycled GFRP fibre reinforced geopolymer. Case Stud. Constr. Mater. 2022, 17, e01187. [Google Scholar] [CrossRef]

- Samal, S.; Blanco, I. An Application Review of Fiber-Reinforced Geopolymer Composite. Fibers 2021, 9, 23. [Google Scholar] [CrossRef]

- Abbas, A.-G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A state-of-the-art review on fibre-reinforced geopolymer composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Wang, K. Numerical modeling of rebar-matrix bond behaviors of nano-SiO2 and PVA fiber reinforced geopolymer composites. Ceram. Int. 2021, 47, 11727–11737. [Google Scholar] [CrossRef]

- Raza, A.; Alashker, Y.; Azab, M.; Khan, Q.u.Z.; Abdallah, M.; Barakat, O.; Elhadi, K.M. Development of eco-friendly alkali-activated nanocomposites comprising micro-fibers at ambient curing conditions. Case Stud. Constr. Mater. 2022, 17, e01540. [Google Scholar] [CrossRef]

- Lingyu, T.; Dongpo, H.; Jianing, Z.; Hongguang, W. Durability of geopolymers and geopolymer concretes: A review. Rev. Adv. Mater. Sci. 2021, 60, 1–14. [Google Scholar] [CrossRef]

- de Oliveira, L.B.; de Azevedo, A.R.G.; Marvila, M.T.; Pereira, E.C.; Fediuk, R.; Vieira, C.M.F. Durability of geopolymers with industrial waste. Case Stud. Constr. Mater. 2022, 16, e00839. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, P.; Guo, J.; Gao, Z. Single and synergistic enhancement on durability of geopolymer mortar by polyvinyl alcohol fiber and nano-SiO2. J. Mater. Res. Technol. 2021, 15, 1801–1814. [Google Scholar] [CrossRef]

- Chen, K.; Wu, D.; Xia, L.; Cai, Q.; Zhang, Z. Geopolymer concrete durability subjected to aggressive environments—A review of influence factors and comparison with ordinary Portland cement. Constr. Build. Mater. 2021, 279, 122496. [Google Scholar] [CrossRef]

- Łach, M.; Kluska, B.; Janus, D.; Kabat, D.; Pławecka, K.; Korniejenko, K.; Guigou, M.D.; Choińska, M. Effect of Fiber Reinforcement on the Compression and Flexural Strength of Fiber-Reinforced Geopolymers. Appl. Sci. 2021, 11, 10443. [Google Scholar] [CrossRef]

- Ganesh, A.C.; Muthukannan, M. Development of high performance sustainable optimized fiber reinforced geopolymer concrete and prediction of compressive strength. J. Clean. Prod. 2021, 282, 124543. [Google Scholar] [CrossRef]

- Natali Murri, A.; Medri, V.; Landi, E. Production and thermomechanical characterization of wool–geopolymer composites. J. Am. Ceram. Soc. 2017, 100, 2822–2831. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Kozub, B.; Bazan, P.; Mierzwiński, D.; Korniejenko, K. Fly-Ash-Based Geopolymers Reinforced by Melamine Fibers. Materials 2021, 14, 400. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F.; Ma, G. Effect of Carbon Fibres on Electromagnetic-Interference-Shielding Properties of Geopolymer Composites. Polymers 2022, 14, 3750. [Google Scholar] [CrossRef]

- Farooq, M.; Bhutta, A.; Banthia, N. Tensile performance of eco-friendly ductile geopolymer composites (EDGC) incorporating different micro-fibers. Cem. Concr. Compos. 2019, 103, 183–192. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Zakka, W.P.; Lim, N.H.A.S.; Khun, M.C. A scientometric review of geopolymer concrete. J. Clean. Prod. 2021, 280, 124353. [Google Scholar] [CrossRef]

- Udomsap, A.D.; Hallinger, P. A bibliometric review of research on sustainable construction, 1994–2018. J. Clean. Prod. 2020, 254, 120073. [Google Scholar] [CrossRef]

- Markoulli, M.P.; Lee, C.I.; Byington, E.; Felps, W.A. Mapping Human Resource Management: Reviewing the field and charting future directions. Hum. Resour. Manag. Rev. 2017, 27, 367–396. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Sayed, M.M. Mapping Research Knowledge on Rice Husk Ash Application in Concrete: A Scientometric Review. Materials 2022, 15, 3431. [Google Scholar] [CrossRef] [PubMed]

- Aghaei Chadegani, A.; Salehi, H.; Yunus, M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ale Ebrahim, N. A comparison between two main academic literature collections: Web of Science and Scopus databases. Asian Soc. Sci. 2013, 9, 18–26. [Google Scholar] [CrossRef]

- Afgan, S.; Bing, C. Scientometric review of international research trends on thermal energy storage cement based composites via integration of phase change materials from 1993 to 2020. Constr. Build. Mater. 2021, 278, 122344. [Google Scholar] [CrossRef]

- Bergman, E.M.L. Finding citations to social work literature: The relative benefits of using Web of Science, Scopus, or Google Scholar. J. Acad. Librariansh. 2012, 38, 370–379. [Google Scholar] [CrossRef] [Green Version]

- Meho, L.I. Using Scopus’s CiteScore for assessing the quality of computer science conferences. J. Informetr. 2019, 13, 419–433. [Google Scholar] [CrossRef]

- Mei, J.; Xu, G.; Ahmad, W.; Khan, K.; Amin, M.N.; Aslam, F.; Alaskar, A. Promoting sustainable materials using recycled rubber in concrete: A review. J. Clean. Prod. 2022, 373, 133927. [Google Scholar] [CrossRef]

- Huang, S.; Wang, H.; Ahmad, W.; Ahmad, A.; Ivanovich Vatin, N.; Mohamed, A.M.; Deifalla, A.F.; Mehmood, I. Plastic Waste Management Strategies and Their Environmental Aspects: A Scientometric Analysis and Comprehensive Review. Int. J. Environ. Res. Public Health 2022, 19, 4556. [Google Scholar] [CrossRef]

- Zhang, B.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A scientometric analysis approach to analyze the present research on recycled aggregate concrete. J. Build. Eng. 2022, 46, 103679. [Google Scholar] [CrossRef]

- Zuo, J.; Zhao, Z.-Y. Green building research–current status and future agenda: A review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

- Darko, A.; Zhang, C.; Chan, A.P. Drivers for green building: A review of empirical studies. Habitat Int. 2017, 60, 34–49. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, M.; Smarzewski, P. Effect of Short Fiber Reinforcements on Fracture Performance of Cement-Based Materials: A Systematic Review Approach. Materials 2021, 14, 1745. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Osei-Kyei, R. Scientometric review of global research trends on green buildings in construction journals from 1992 to 2018. Energy Build. 2019, 190, 69–85. [Google Scholar] [CrossRef]

- Su, H.-N.; Lee, P.-C. Mapping knowledge structure by keyword co-occurrence: A first look at journal papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- Yu, F.; Hayes, B.E. Applying data analytics and visualization to assessing the research impact of the Cancer Cell Biology (CCB) Program at the University of North Carolina at Chapel Hill. J. E-Sci. Librariansh. 2018, 7, 4. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Lyon, R.E.; Balaguru, P.N.; Foden, A.; Sorathia, U.; Davidovits, J.; Davidovics, M. Fire-resistant aluminosilicate composites. Fire Mater. 1997, 21, 67–73. [Google Scholar] [CrossRef]

- Panda, B.; Chandra Paul, S.; Jen Tan, M. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Li, W.; Xu, J. Mechanical properties of basalt fiber reinforced geopolymeric concrete under impact loading. Mater. Sci. Eng. A 2009, 505, 178–186. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Mehrali, M.; Alengaram, U.J.; Jumaat, M.Z. High tensile strength fly ash based geopolymer composite using copper coated micro steel fiber. Constr. Build. Mater. 2016, 112, 629–638. [Google Scholar] [CrossRef] [Green Version]

- Mundra, S.; Bernal Lopez, S.; Criado, M.; Hlaváček, P.; Ebell, G.; Reinemann, S.; Gluth, G.; Provis, J. Steel corrosion in reinforced alkali-activated materials. RILEM Tech. Lett. 2017, 2, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Monticelli, C.; Natali, M.E.; Balbo, A.; Chiavari, C.; Zanotto, F.; Manzi, S.; Bignozzi, M.C. Corrosion behavior of steel in alkali-activated fly ash mortars in the light of their microstructural, mechanical and chemical characterization. Cem. Concr. Res. 2016, 80, 60–68. [Google Scholar] [CrossRef]

- Nematollahi, B.; Qiu, J.; Yang, E.-H.; Sanjayan, J. Micromechanics constitutive modelling and optimization of strain hardening geopolymer composite. Ceram. Int. 2017, 43, 5999–6007. [Google Scholar] [CrossRef]

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Cornelis Metselaar, H.S.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Javadi Pordsari, A.; Mehrali, M.; Alengaram, U.J.; Jumaat, M.Z. A comprehensive study of the polypropylene fiber reinforced fly ash based geopolymer. PLoS ONE 2016, 11, e0147546. [Google Scholar] [CrossRef] [Green Version]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Naidu Nerella, V.; Mechtcherine, V. Effect of Polypropylene Fibre Addition on Properties of Geopolymers Made by 3D Printing for Digital Construction. Materials 2018, 11, 2352. [Google Scholar] [CrossRef] [Green Version]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Hammell, J.A.; Balaguru, P.N.; Lyon, R.E. Strength retention of fire resistant aluminosilicate–carbon composites under wet–dry conditions. Compos. Part B Eng. 2000, 31, 107–111. [Google Scholar] [CrossRef]

- Saafi, M.; Andrew, K.; Tang, P.L.; McGhon, D.; Taylor, S.; Rahman, M.; Yang, S.; Zhou, X. Multifunctional properties of carbon nanotube/fly ash geopolymeric nanocomposites. Constr. Build. Mater. 2013, 49, 46–55. [Google Scholar] [CrossRef]

- Bi, S.; Liu, M.; Shen, J.; Hu, X.M.; Zhang, L. Ultrahigh self-sensing performance of geopolymer nanocomposites via unique interface engineering. ACS Appl. Mater. Interfaces 2017, 9, 12851–12858. [Google Scholar] [CrossRef]

- Davidovits, J. Reinforced geopolymer composites: A critical review. Mater. Today 2016, 31. [Google Scholar]

- Masi, G.; Rickard, W.D.A.; Bignozzi, M.C.; van Riessen, A. The effect of organic and inorganic fibres on the mechanical and thermal properties of aluminate activated geopolymers. Compos. Part B Eng. 2015, 76, 218–228. [Google Scholar] [CrossRef]

- Mills-Brown, J.; Potter, K.; Foster, S.; Batho, T. The development of a high temperature tensile testing rig for composite laminates. Compos. Part A Appl. Sci. Manuf. 2013, 52, 99–105. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Synthesis and mechanical properties of cotton fabric reinforced geopolymer composites. Compos. Part B Eng. 2014, 60, 36–42. [Google Scholar] [CrossRef]

| S/N | Publication Outlet | Documents | Citations | Average Citations |

|---|---|---|---|---|

| 1 | Construction and Building Materials | 95 | 3188 | 34 |

| 2 | IOP Conference Series: Materials Science and Engineering | 57 | 198 | 3 |

| 3 | Materials | 31 | 498 | 16 |

| 4 | Ceramics International | 27 | 690 | 26 |

| 5 | Composites Part B: Engineering | 21 | 1615 | 77 |

| 6 | Ceramic Engineering and Science Proceedings | 21 | 195 | 9 |

| 7 | Structures | 20 | 263 | 13 |

| 8 | Materials Today: Proceedings | 20 | 55 | 3 |

| 9 | Cement and Concrete Composites | 16 | 598 | 37 |

| 10 | Composite Structures | 15 | 325 | 22 |

| 11 | Journal of Materials in Civil Engineering | 12 | 415 | 35 |

| 12 | Engineering Structures | 12 | 374 | 31 |

| 13 | Polymers | 12 | 85 | 7 |

| 14 | Journal of Building Engineering | 11 | 105 | 10 |

| 15 | Case Studies in Construction Materials | 11 | 41 | 4 |

| 16 | International Journal of Civil Engineering and Technology | 10 | 32 | 3 |

| 17 | MATEC Web of Conferences | 10 | 31 | 3 |

| S/N | Keyword | Occurrences |

|---|---|---|

| 1 | Inorganic polymers | 514 |

| 2 | Geopolymers | 496 |

| 3 | Reinforcement | 326 |

| 4 | Geopolymer | 285 |

| 5 | Compressive strength | 216 |

| 6 | Fly ash | 214 |

| 7 | Geopolymer concrete | 205 |

| 8 | Fibers | 204 |

| 9 | Geopolymer composites | 180 |

| 10 | Reinforced plastics | 167 |

| 11 | Steel fibers | 158 |

| 12 | Reinforced concrete | 152 |

| 13 | Mechanical properties | 127 |

| 14 | Tensile strength | 126 |

| 15 | Fiber reinforced plastics | 120 |

| 16 | Portland cement | 97 |

| 17 | Bending strength | 90 |

| 18 | Scanning electron microscopy | 79 |

| 19 | Concretes | 72 |

| 20 | Slags | 71 |

| 21 | Polypropylenes | 63 |

| 22 | Fiber reinforced materials | 62 |

| 23 | Concrete beams and girders | 55 |

| 24 | Curing | 54 |

| 25 | Basalt | 53 |

| 26 | Carbon fibers | 53 |

| 27 | Glass fibers | 52 |

| 28 | Fiber-reinforced | 51 |

| 29 | Ordinary Portland cement | 51 |

| 30 | Silicates | 50 |

| S/N | Researcher | Publication Count | Total Citations | Average Citations |

|---|---|---|---|---|

| 1 | Shaikh F.U.A. | 26 | 1486 | 57 |

| 2 | Korniejenko K. | 25 | 274 | 11 |

| 3 | Ganesan N. | 18 | 220 | 12 |

| 4 | Jia D. | 17 | 638 | 38 |

| 5 | Hao H. | 17 | 323 | 19 |

| 6 | Alomayri T. | 16 | 714 | 45 |

| 7 | He P. | 16 | 638 | 40 |

| 8 | Kriven W.M. | 16 | 341 | 21 |

| 9 | Elchalakani M. | 16 | 186 | 12 |

| 10 | Łach M. | 15 | 87 | 6 |

| 11 | Indira P.V. | 13 | 69 | 5 |

| 12 | Zhou Y. | 12 | 382 | 32 |

| 13 | Sanjayan J. | 11 | 634 | 58 |

| 14 | Benmokrane B. | 11 | 409 | 37 |

| 15 | Manalo A.C. | 11 | 377 | 34 |

| 16 | Yang Z. | 11 | 195 | 18 |

| 17 | Wang Y. | 11 | 138 | 13 |

| 18 | Louda P. | 11 | 126 | 11 |

| 19 | Nematollahi B. | 10 | 621 | 62 |

| 20 | Maranan G.B. | 10 | 360 | 36 |

| 21 | Zhang M. | 10 | 273 | 27 |

| 22 | Duan X. | 10 | 193 | 19 |

| 23 | Dong M. | 10 | 149 | 15 |

| 24 | Karrech A. | 10 | 140 | 14 |

| 25 | Hadi M.N.S. | 10 | 97 | 10 |

| 26 | Dai J.-G. | 10 | 94 | 9 |

| 27 | Mikuła J. | 10 | 90 | 9 |

| S/N | Article | Title | Citations |

|---|---|---|---|

| 1 | Davidovits J. [64] | Geopolymers—Inorganic Polymeric New Materials | 2553 |

| 2 | Yan L. [65] | A Review of Recent Research on the use of Cellulosic Fibres, their Fibre Fabric Reinforced Cementitious, Geo-polymer and Polymer Composites in Civil Engineering | 310 |

| 3 | Lyon R.E. [66] | Fire-Resistant Aluminosilicate Composites | 291 |

| 4 | Panda B. [67] | Anisotropic Mechanical Performance of 3D Printed Fiber Reinforced Sustainable Construction Material | 265 |

| 5 | Li W. [68] | Mechanical Properties of Basalt Fiber Reinforced Geopolymeric Concrete under Impact Loading | 258 |

| S/N | Country | Publications | Citations |

|---|---|---|---|

| 1 | Australia | 139 | 4153 |

| 2 | China | 129 | 3493 |

| 3 | India | 116 | 853 |

| 4 | United States | 79 | 1864 |

| 5 | Poland | 41 | 530 |

| 6 | Saudi Arabia | 34 | 699 |

| 7 | United Kingdom | 33 | 802 |

| 8 | Turkey | 33 | 557 |

| 9 | Czech Republic | 30 | 313 |

| 10 | Iraq | 26 | 331 |

| 11 | Brazil | 25 | 545 |

| 12 | Pakistan | 24 | 320 |

| 13 | Italy | 23 | 820 |

| 14 | Canada | 23 | 689 |

| 15 | Malaysia | 23 | 491 |

| 16 | Iran | 18 | 438 |

| 17 | Germany | 17 | 599 |

| 18 | Hong Kong | 17 | 521 |

| 19 | Portugal | 13 | 396 |

| 20 | Thailand | 12 | 332 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkadhim, H.A.; Amin, M.N.; Ahmad, W.; Khan, K.; Al-Hashem, M.N.; Houda, S.; Azab, M.; Baki, Z.A. Knowledge Mapping of the Literature on Fiber-Reinforced Geopolymers: A Scientometric Review. Polymers 2022, 14, 5008. https://doi.org/10.3390/polym14225008

Alkadhim HA, Amin MN, Ahmad W, Khan K, Al-Hashem MN, Houda S, Azab M, Baki ZA. Knowledge Mapping of the Literature on Fiber-Reinforced Geopolymers: A Scientometric Review. Polymers. 2022; 14(22):5008. https://doi.org/10.3390/polym14225008

Chicago/Turabian StyleAlkadhim, Hassan Ali, Muhammad Nasir Amin, Waqas Ahmad, Kaffayatullah Khan, Mohammed Najeeb Al-Hashem, Sara Houda, Marc Azab, and Zaher Abdel Baki. 2022. "Knowledge Mapping of the Literature on Fiber-Reinforced Geopolymers: A Scientometric Review" Polymers 14, no. 22: 5008. https://doi.org/10.3390/polym14225008

APA StyleAlkadhim, H. A., Amin, M. N., Ahmad, W., Khan, K., Al-Hashem, M. N., Houda, S., Azab, M., & Baki, Z. A. (2022). Knowledge Mapping of the Literature on Fiber-Reinforced Geopolymers: A Scientometric Review. Polymers, 14(22), 5008. https://doi.org/10.3390/polym14225008

_Chen.png)